Polyolefin rotomolding composition, its preparation method and application

A composition and polyolefin technology, applied in the field of polyolefin compositions, can solve problems such as growing moss, water pollution, etc., and achieve the effects of improving smoothness, enhancing dispersion, and good sanitation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

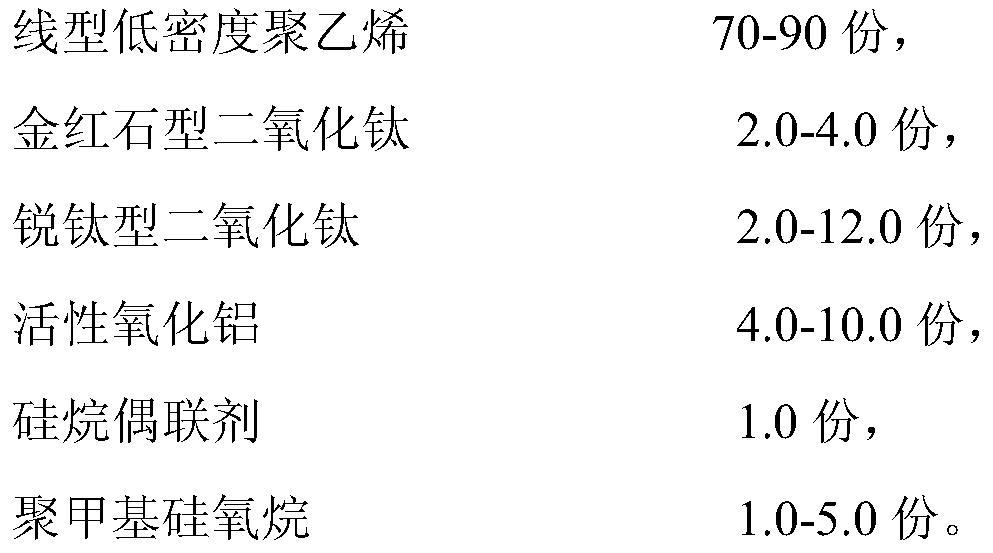

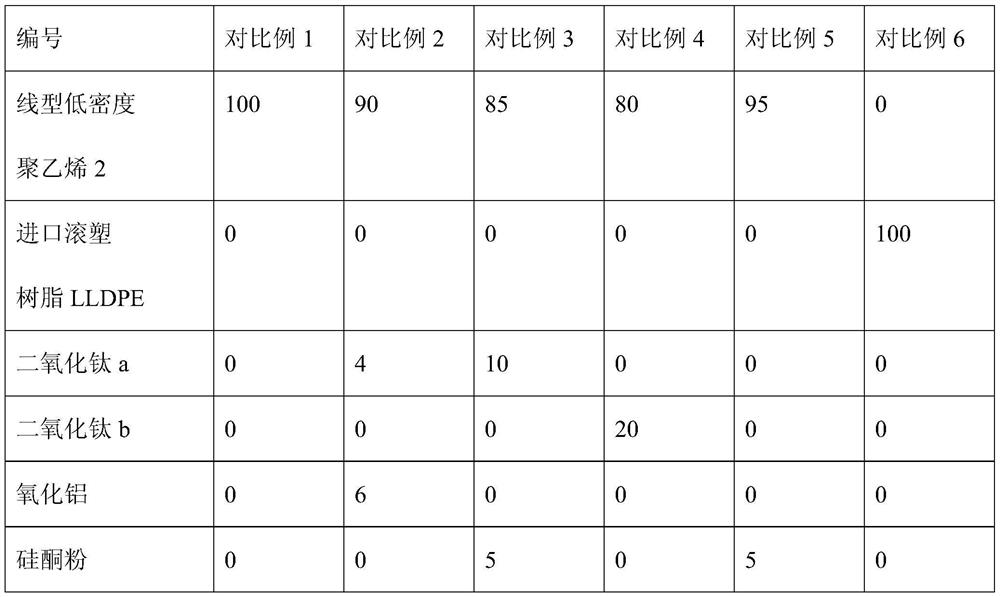

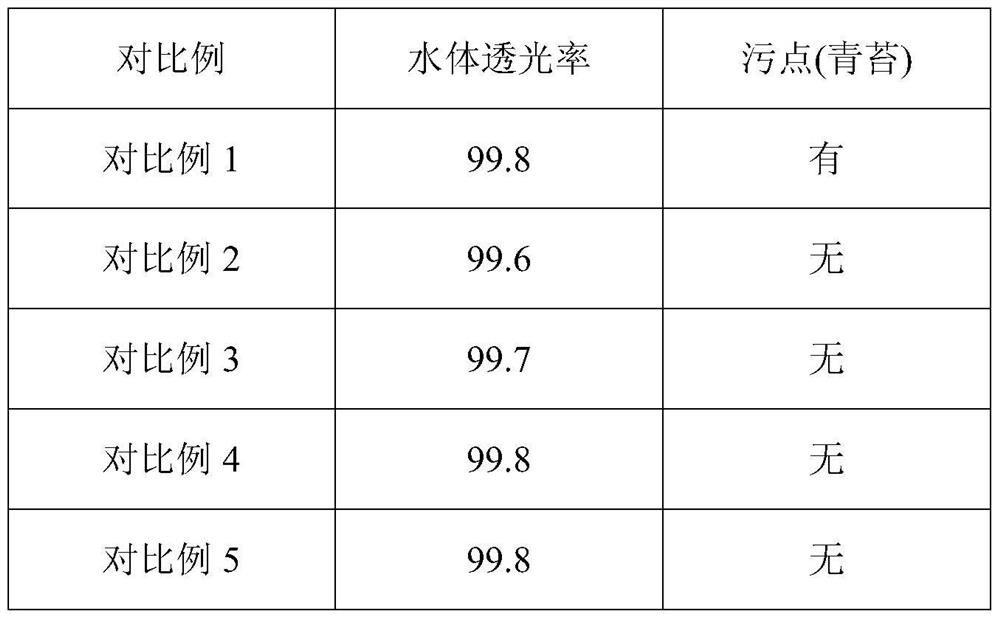

Method used

Image

Examples

Embodiment 1

[0038] (1) Mix rutile-type titanium dioxide and anatase-type titanium dioxide, add activated alumina, and then add 1 part of silane coupling agent KH-570, put it in a mixer, mix in a high-speed mixer, and mix at a temperature of 60°C. The speed is 1200 rpm, mixed for 10 minutes, and the material is discharged for later use;

[0039] (2) Mix linear low-density polyethylene, polymethylsiloxane, and the components obtained in step (1), the rotating speed is 1200 rpm, and the mixing time is 10 minutes; Granules, the temperature is 180°C, the screw speed is 120 rpm, the feeding material is 60 rpm, the particle length is 1.5mm, and it is ground into 25 mesh powder after drying;

[0040] (3) Grinding LLDPE 1 into 35 mesh powder;

[0041] (4) Add the powder of step (2) and step (3) into the test mold at a ratio of 2:3 (wt%) to form a 100-liter hollow box with a thickness of 6 cm and a rotational molding temperature of 230°C , The rotational molding time is 30 minutes.

[0042] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com