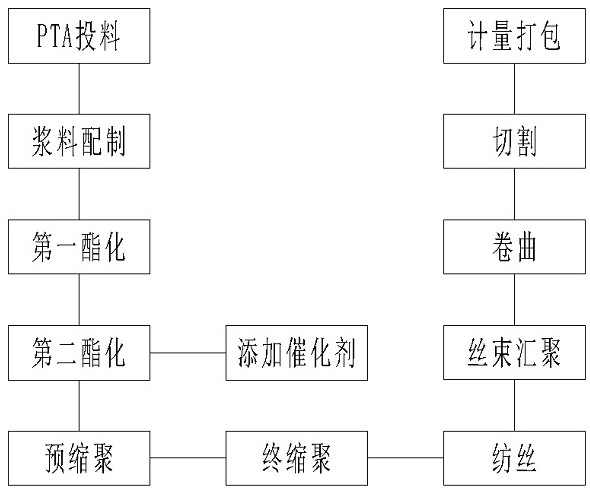

Production process of short fibers special for high-cleanness spunlace non-woven fabric

A production process and clean water technology, applied in the field of polyester staple fiber production, can solve problems such as inability to apply various raw material transportation methods, fuzzing, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

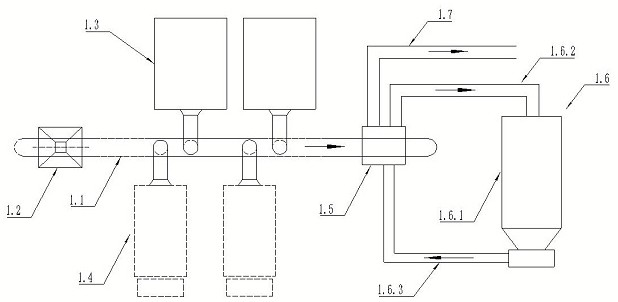

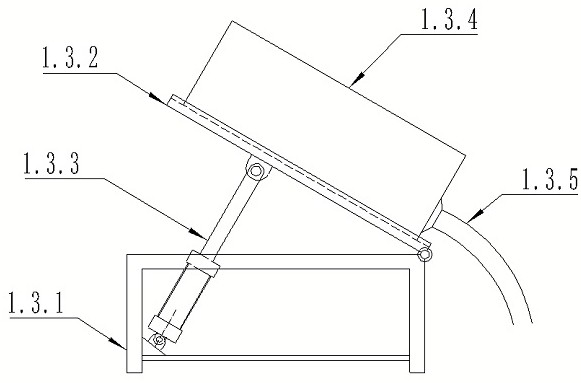

[0077] see Figure 1~22 , the present invention relates to a special short fiber production process for high-clean spunlace non-woven fabrics. The high-clean spunlace non-woven short fiber production line includes a feeding system 1, a slurry preparation tank 2, an esterification reactor 3, a catalyst addition system 4, a polycondensation reactor 5, a filter 6, and a filter element cleaning device 7 , process wastewater pretreatment system 8, spinning machine 9, oiling ring 10, wire storage box 11, wire guide frame 12, tail wire alarm device 13, crimping machine 14, tow amplitude modulation device 15, spinning cutting machine 16 and Packing machine 17; the feeding system 1, slurry preparation kettle 2, esterification reaction kettle 3, polycondensation reaction kettle 5, spinning machine 9, oiling ring 10, wire storage box 11, wire guide frame 12, crimping machine 14 1. Spinning and cutting machine 16 and baler 17 are arranged sequentially;

[0078] The feeding system 1 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com