Patents

Literature

56results about How to "Solve fouling and clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

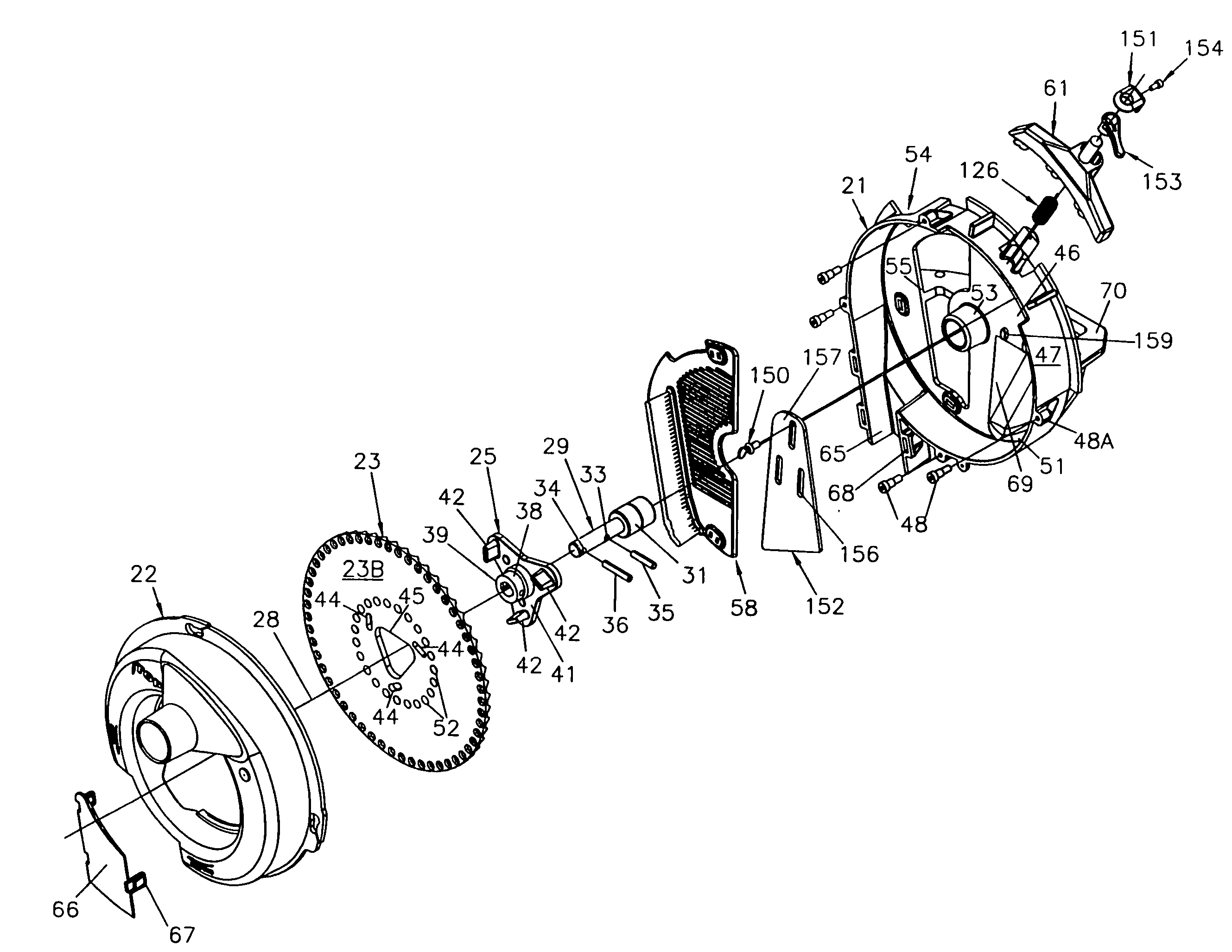

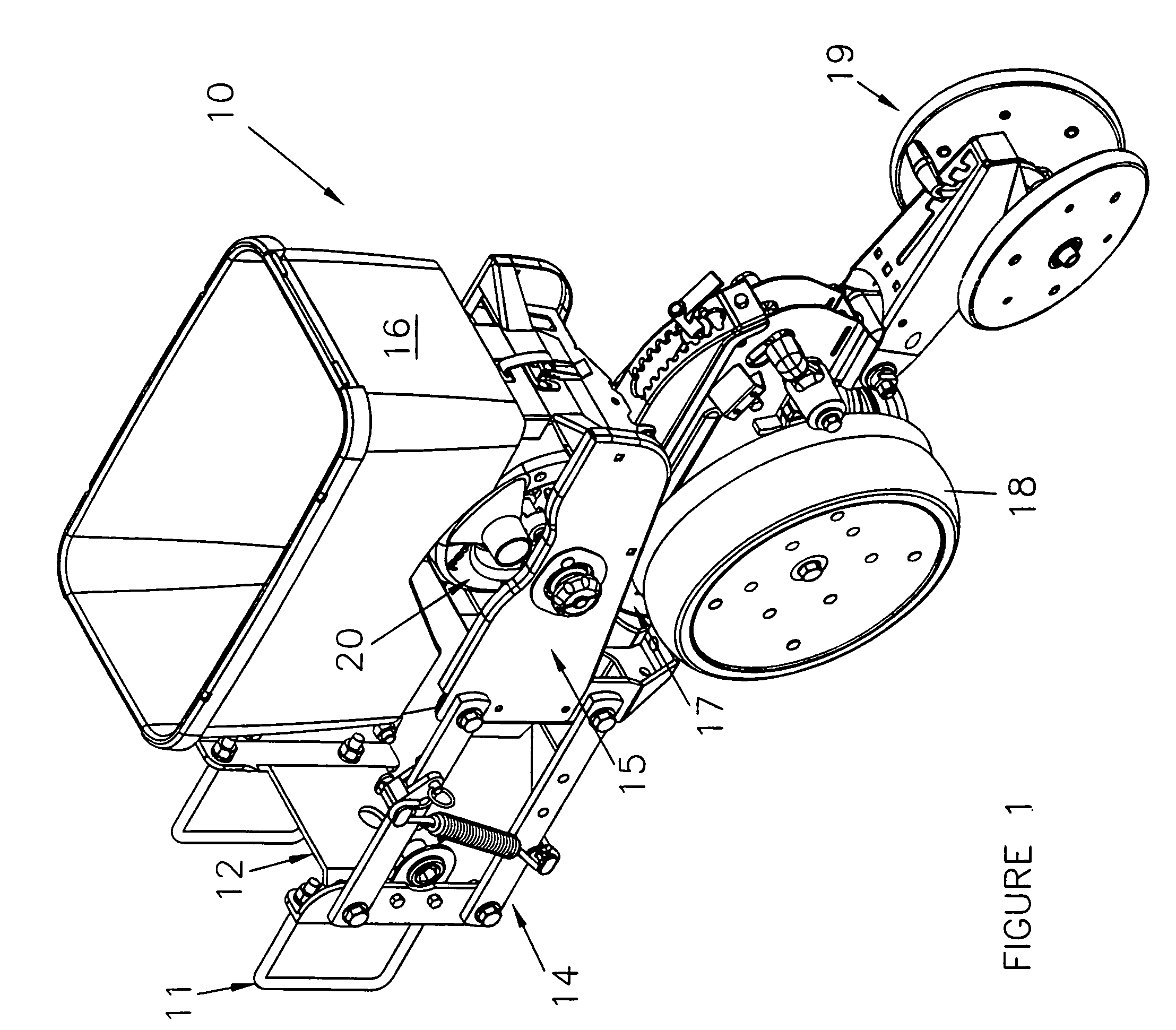

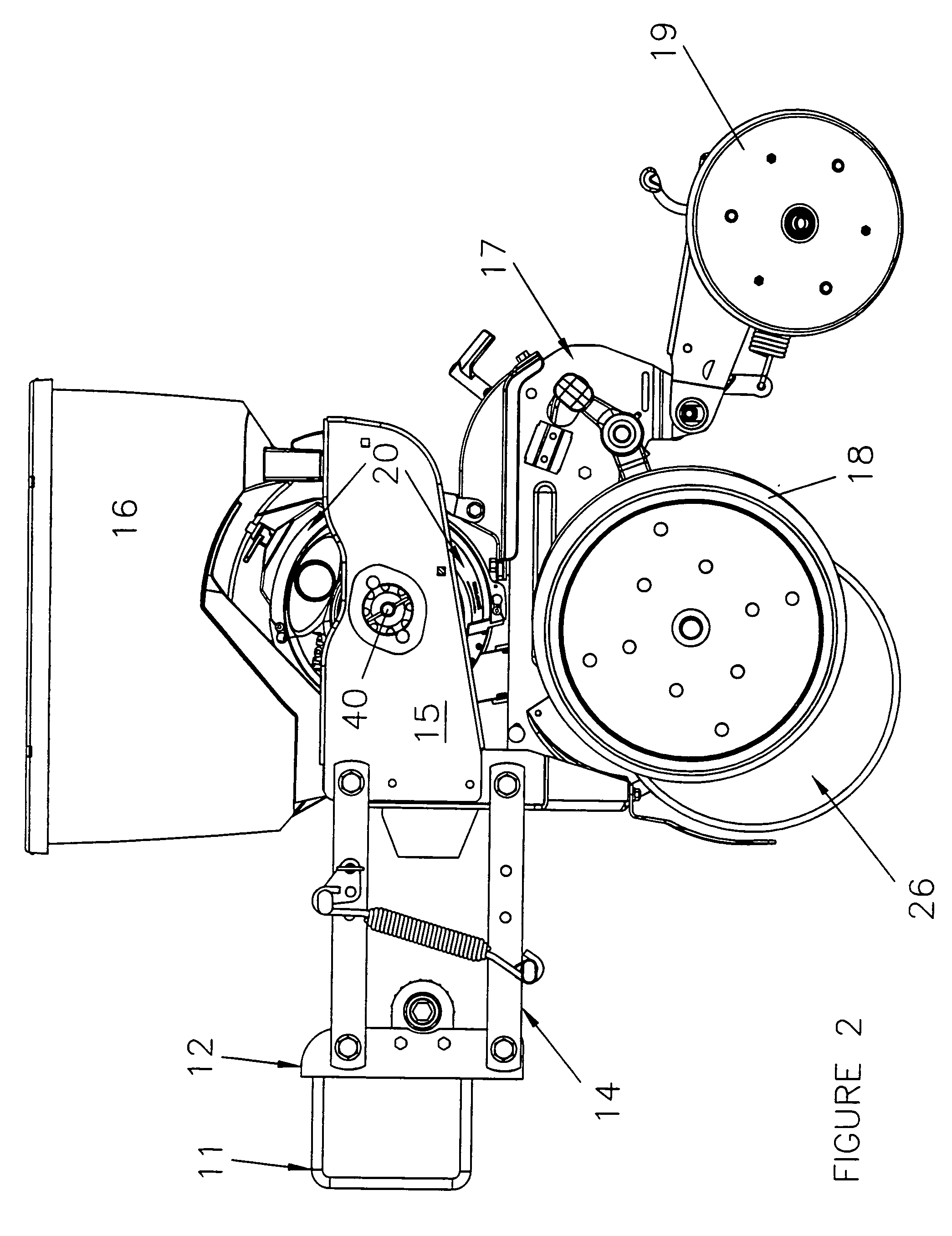

Air seed meter

InactiveUS20050204972A1Increase the sectionSolve fouling and cloggingPotato plantersFurrow making/coveringCircular discVisual inspection

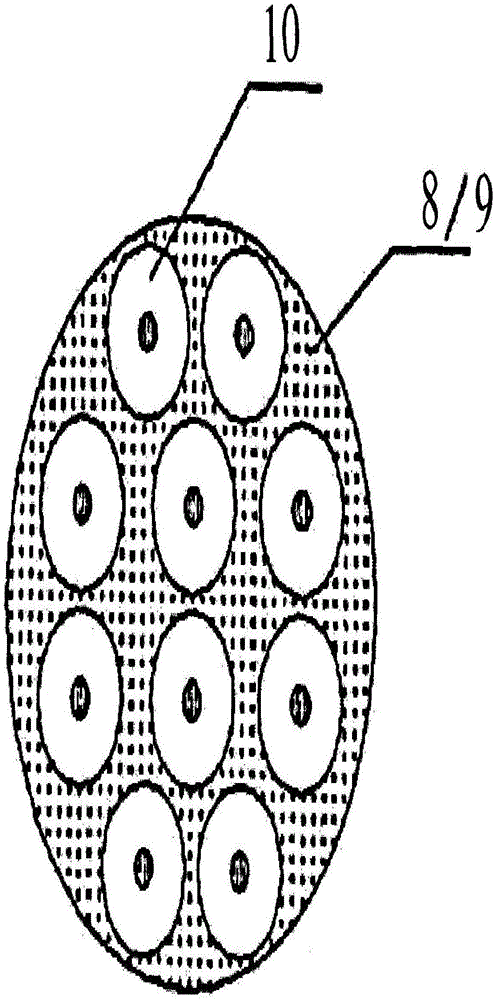

An air seed meter for an agricultural planter includes a vacuum cover which has a central opening which exposes the central portion of the seed disc to the exterior. The central opening of the vacuum cover is centered on a location offset from the axis of rotation of the seed disc. This reduces disc wear at the disc-vacuum cover interface, and renders the disc more accessible for self-cleaning, visual inspection and verification of the proper disc. Openings in the central, open portion of the disc, the back wall of the seed housing and the side wall of the seed housing cooperate to equalize the air pressure in the seed reservoir to atmospheric pressure and reduce or eliminate reverse air currents in the discharge chute. An adjustable brush with three separate stations cooperates with an edge-release, beveled disc to apply a progressively more forceful singulation force to eliminate duplicate seeds.

Owner:KINZE MFG INC

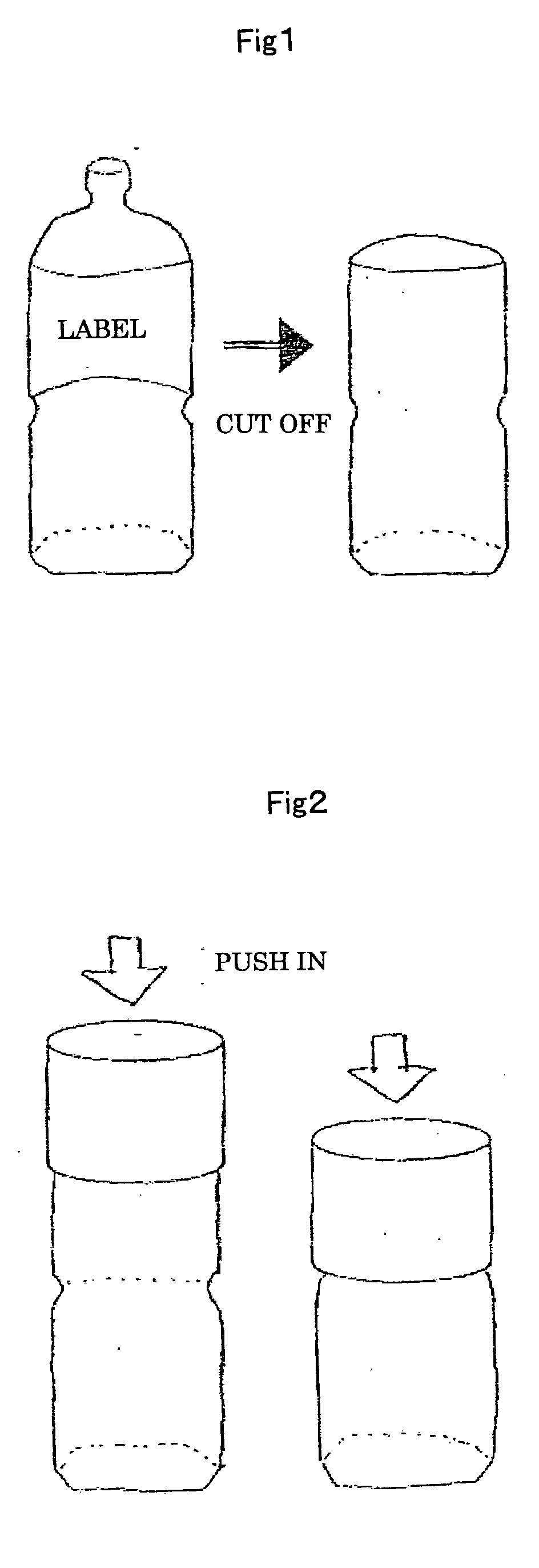

Heat shrinking polyester film

InactiveUS20060063008A1Good printabilityHigh transparencySynthetic resin layered productsFlat articlesPolyesterEngineering

A heat-shrinkable polyester type film has a dynamic friction coefficient of at least one face with one face of another film of μd≦0.27 and range R≦0.05 and a weight loss of less than 0.24 g / m2 after 10 reciprocation times with 400 g load using a color fastness rubbing tester comprising a friction element bearing a sand paper with #1000 particle diameter.

Owner:TOYOBO CO LTD

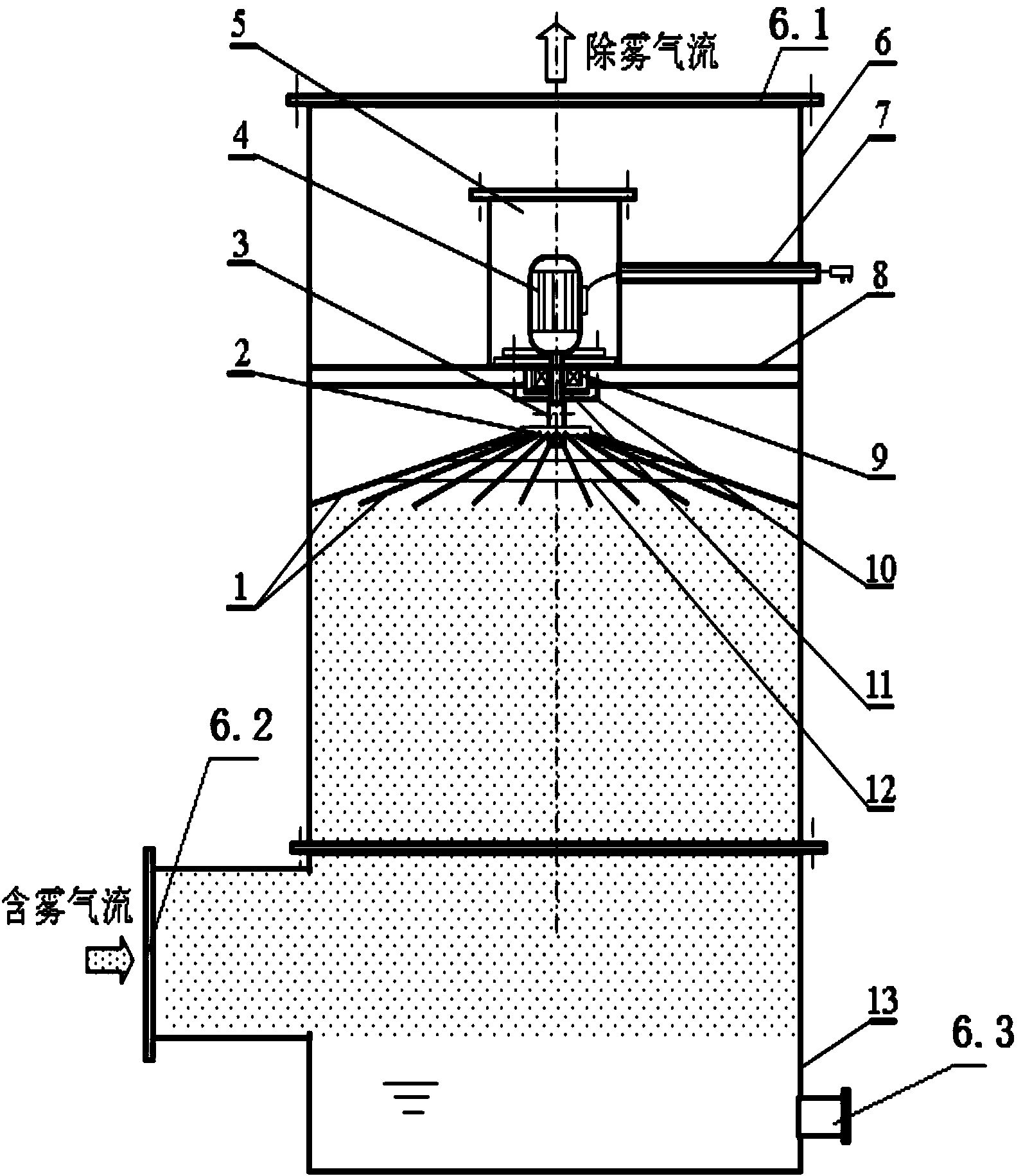

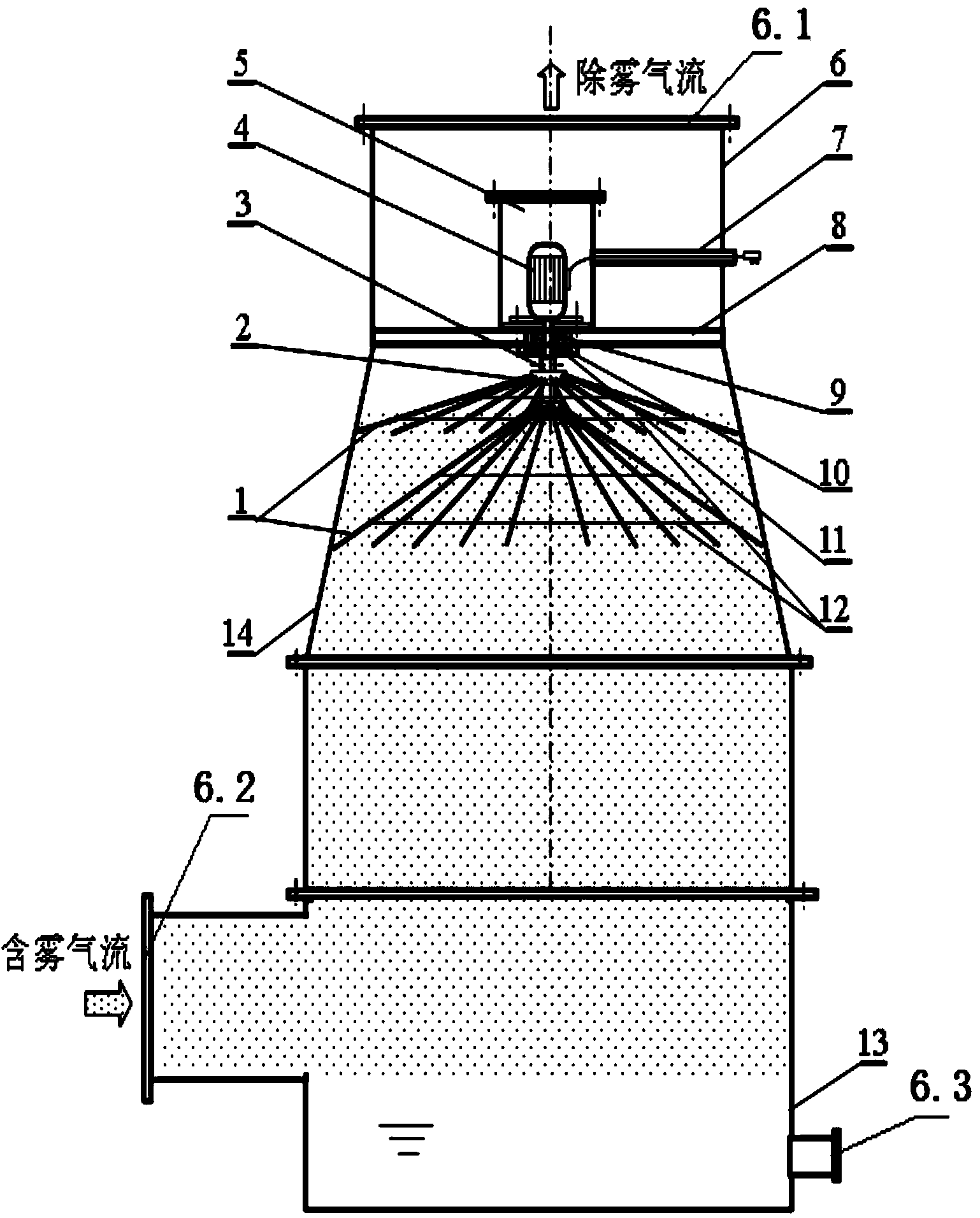

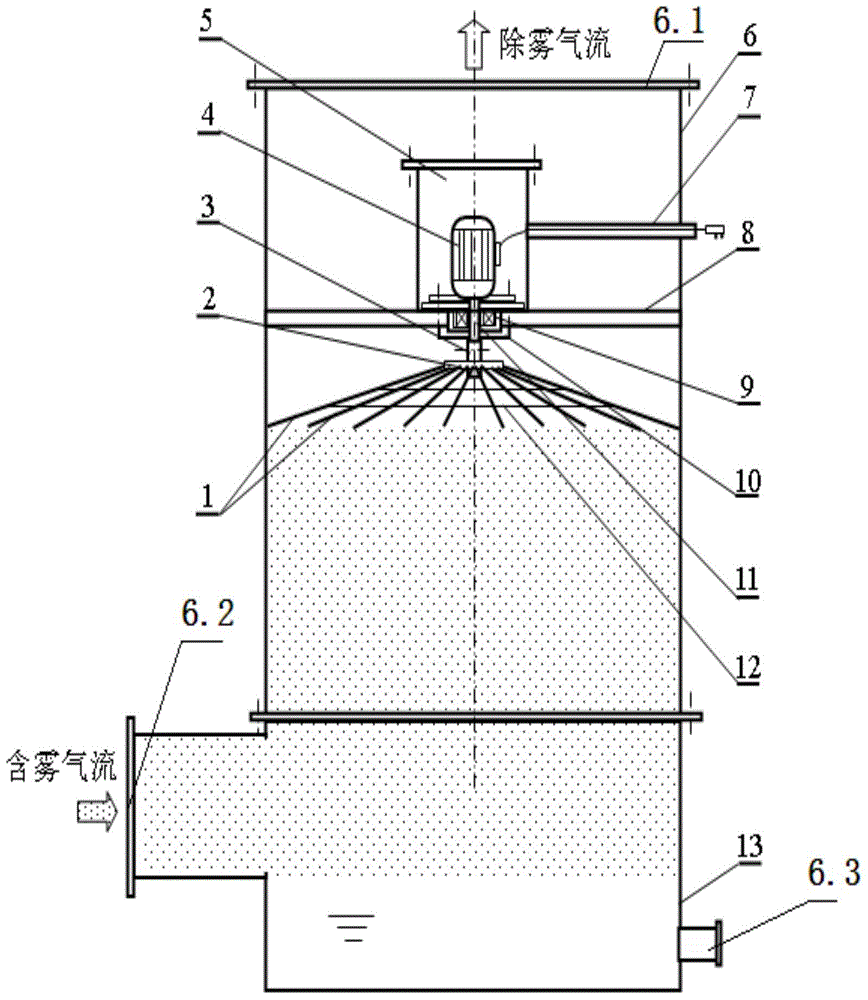

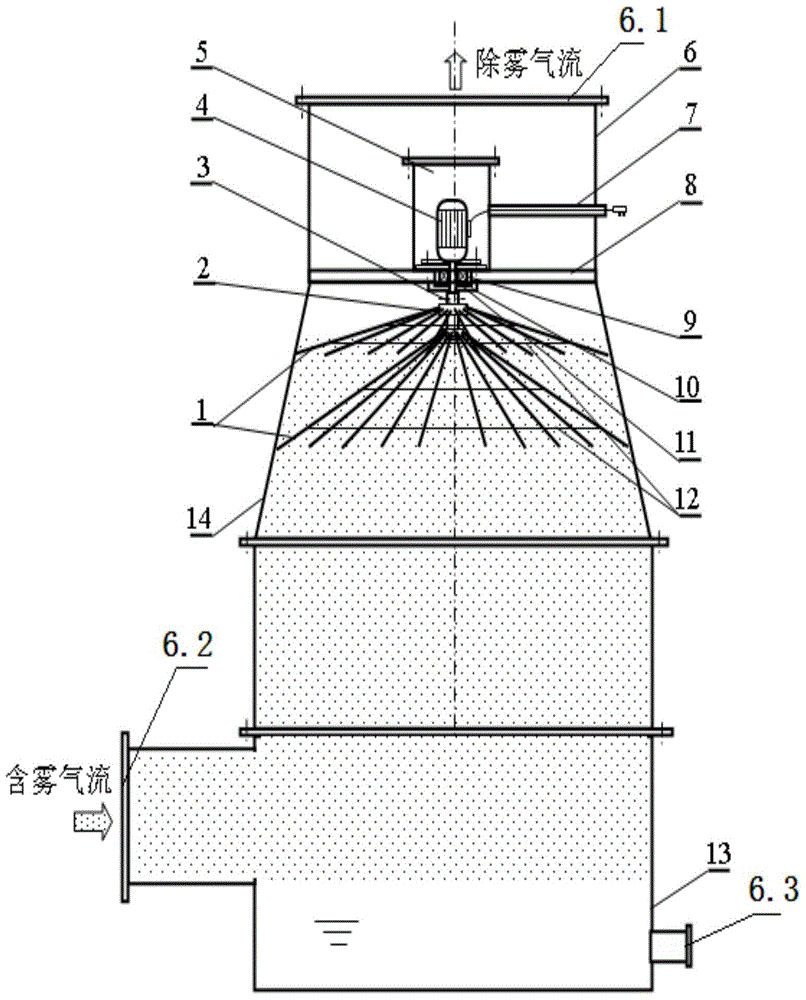

Flexible fiber spiral line demisting device

InactiveCN103657266AAvoid the problem of secondary sheddingStrong turbulent diffusion effectDispersed particle separationFlue gasEngineering

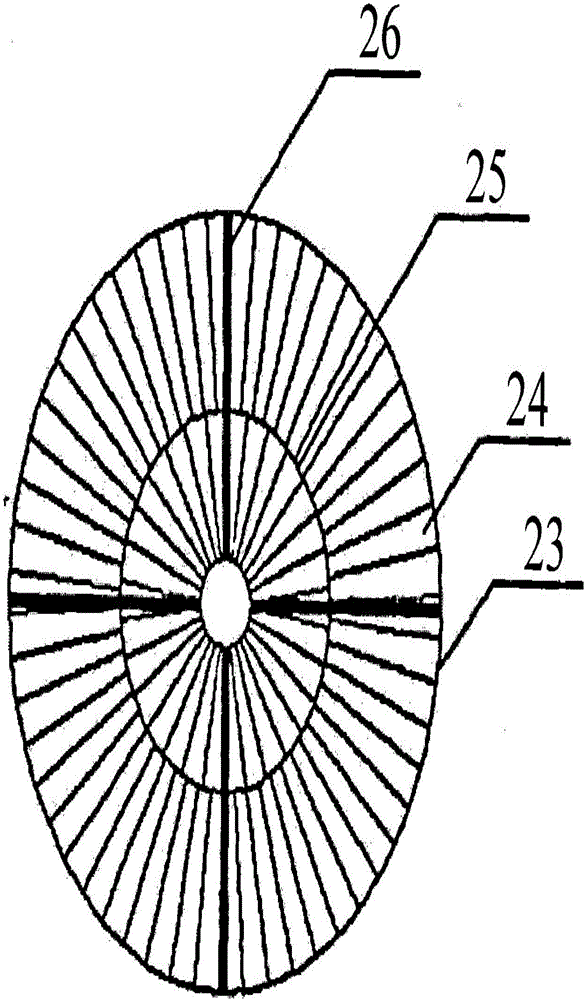

The invention relates to a flexible fiber spiral line demisting device, which solves the problems that the existing demising device has low demisting efficiency, the filter type demister is easy to block and the static demister is high in cost and large in occupied area and is corroded and scaled. According to the technical scheme, the flexible fiber spiral line demisting device comprises a gas inlet, a gas outlet and an exhaust cylinder of a liquid discharge pipe, wherein a motor is arranged on the vertical center line of the upper section of the exhaust cylinder; a rotating shaft of the motor is sleeved with a shaft sleeve; at least one layer of disc is arranged in the axis direction of the shaft sleeve; flexible fiber spiral lines are arranged on the disc; the flexible fiber spiral lines comprise a plurality of warps; one end of each warp is connected to the disc uniformly and the other end of each warp is a free end. The flexible fiber spiral line demisting device has the advantages of low resistance, high efficiency, no occupied area, no corrosion, no scaling and blockage, large flue gas treatment quantity, simple structure, light weight, low energy consumption and low cost.

Owner:JIANGHAN UNIVERSITY +2

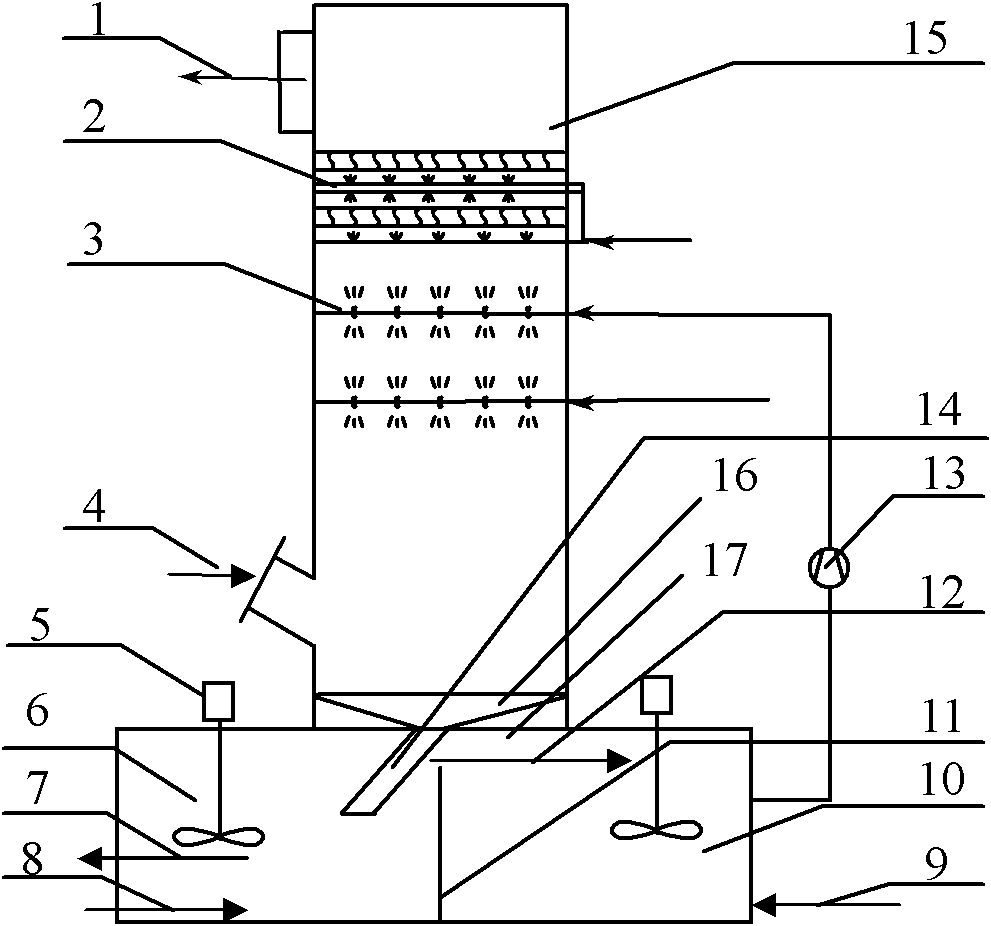

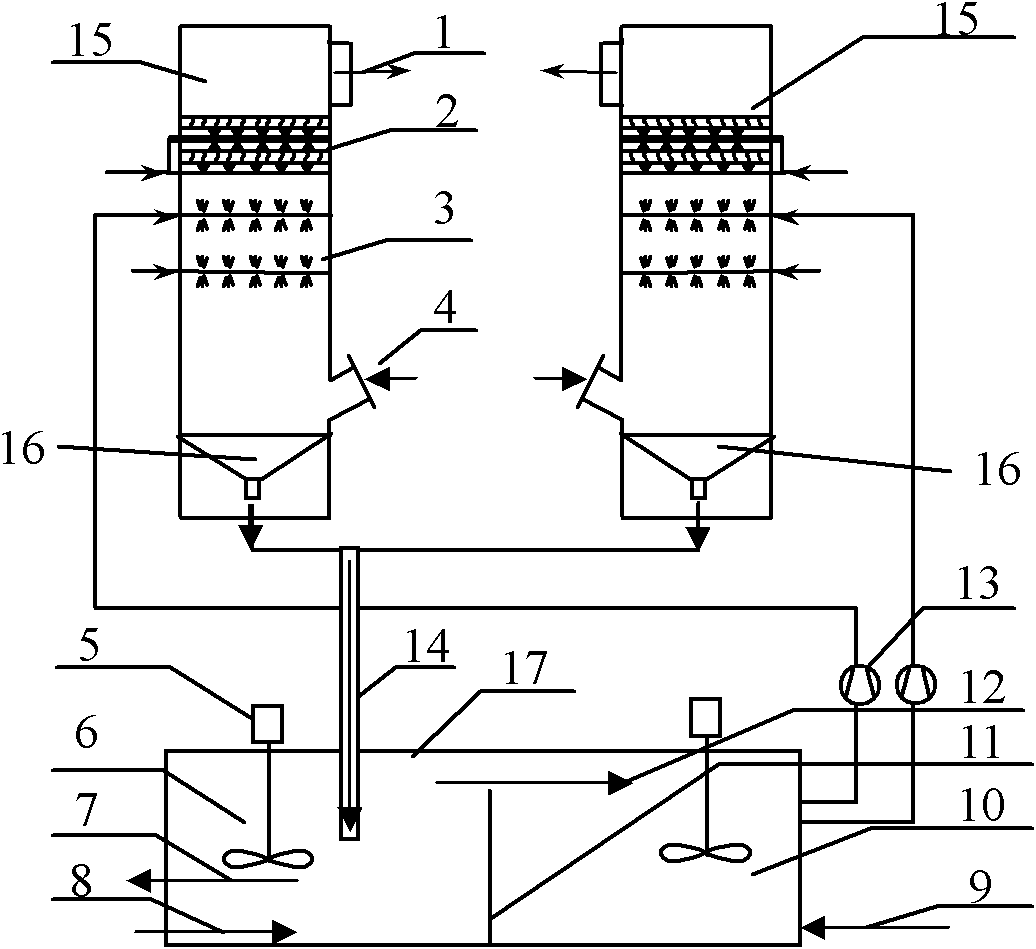

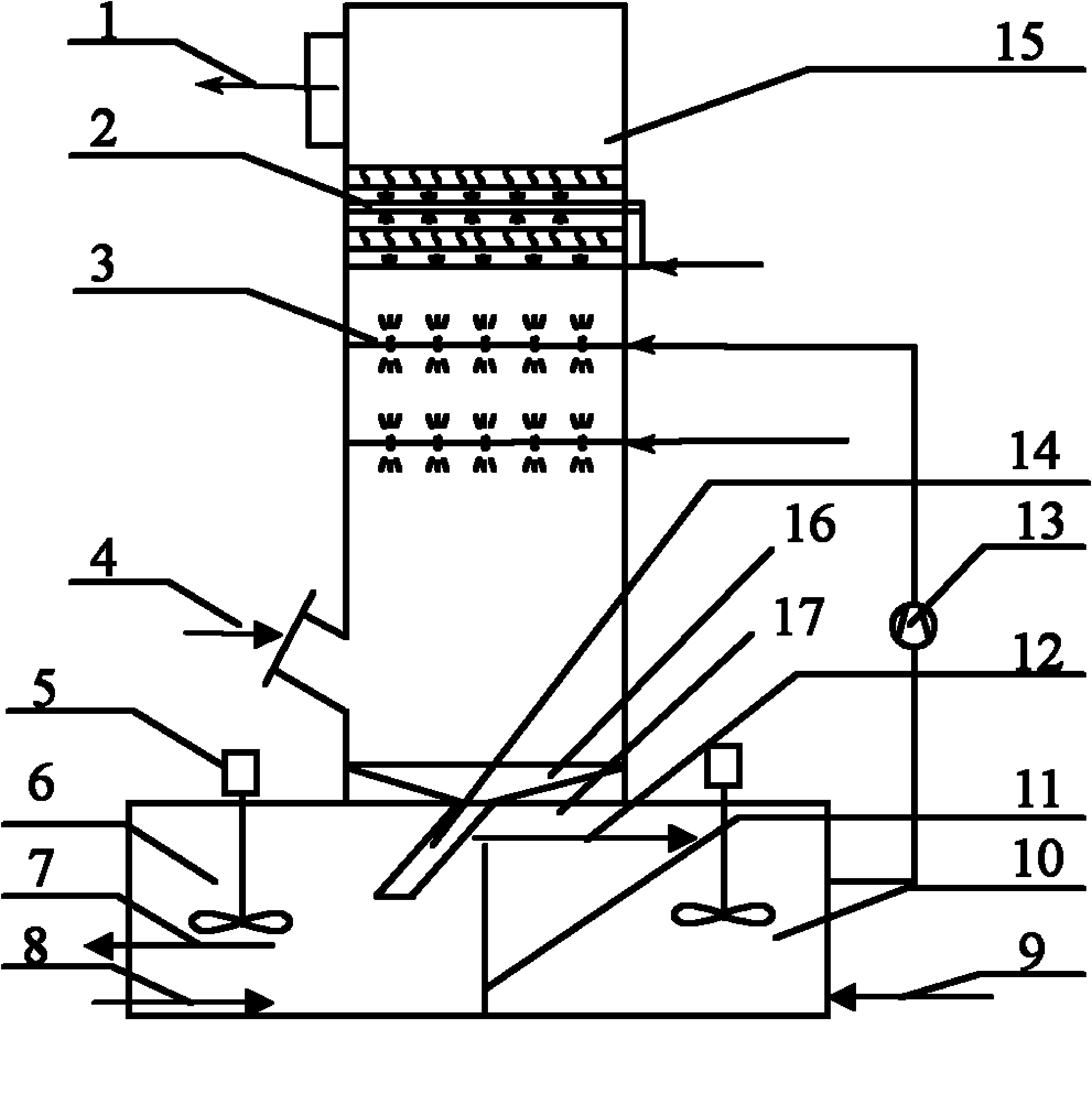

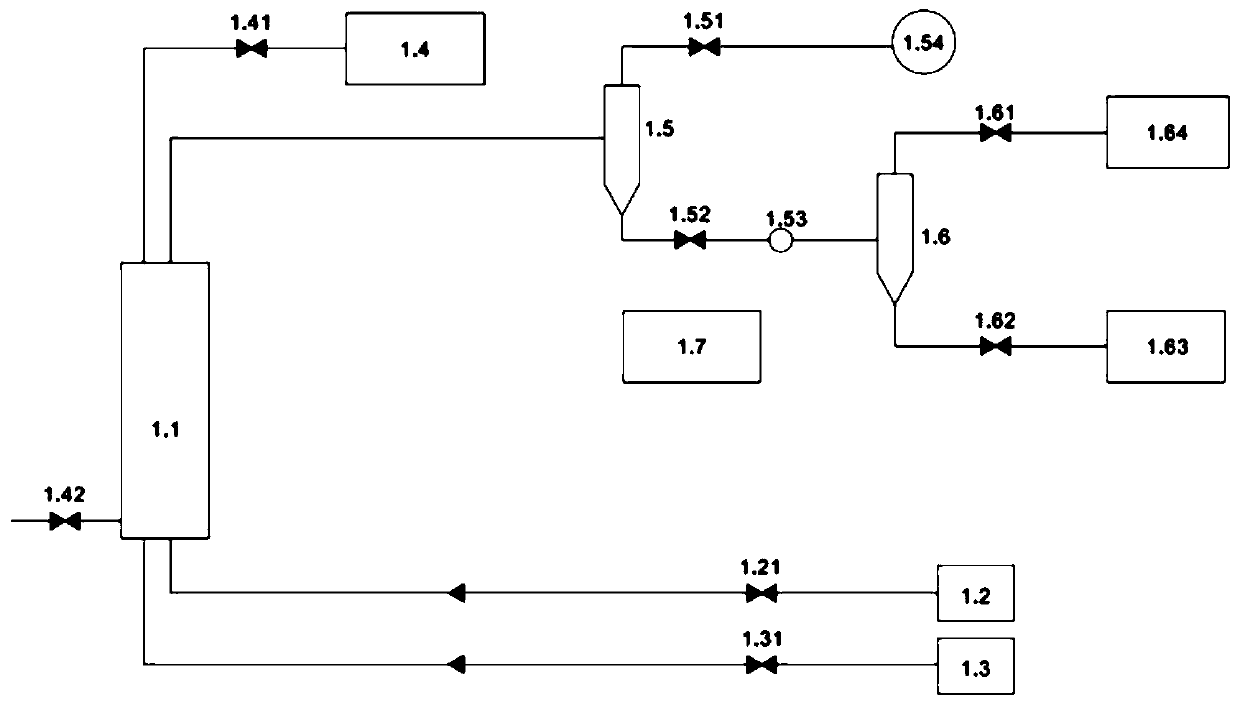

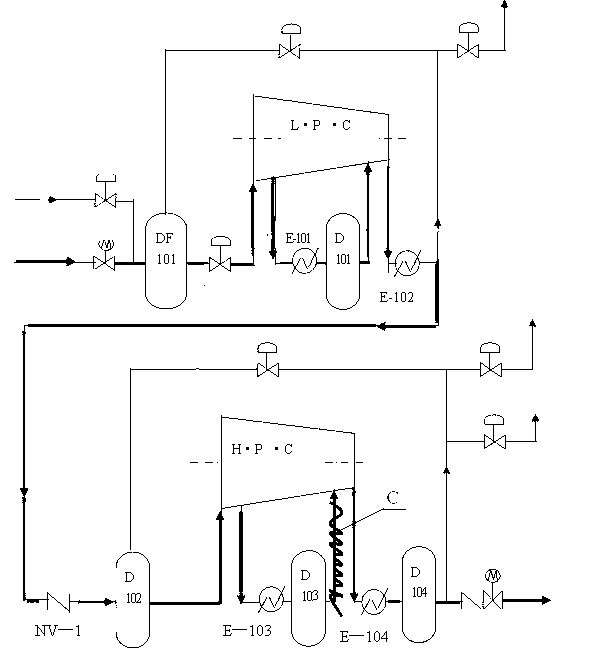

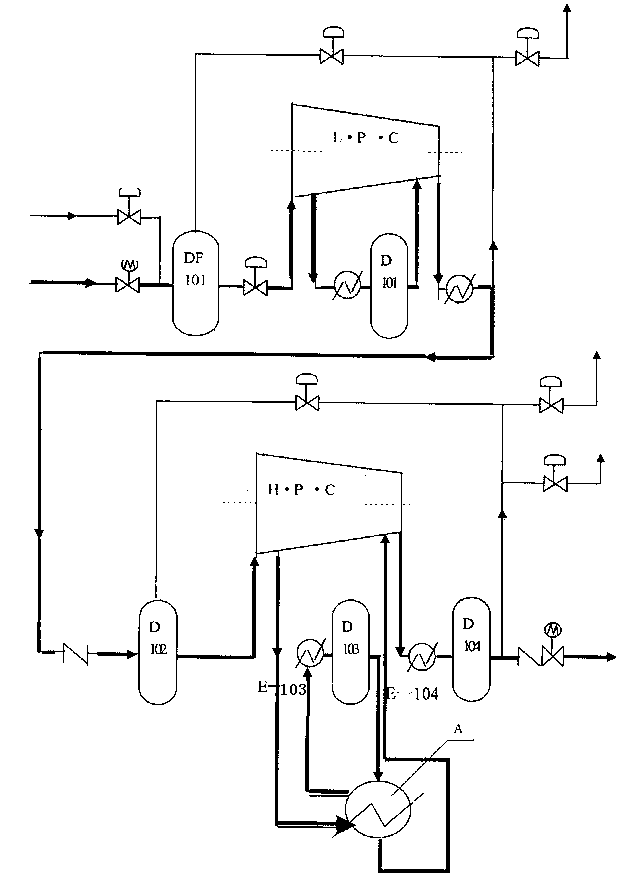

Double-groove wet-process flue gas desulfuration device and method operating on basis of two pH values

InactiveCN102091519AAvoid badSolve the problem of operation safety and stabilityDispersed particle separationSulfurCalcium sulfite

The invention discloses a double-groove wet-process flue gas desulfuration device and a double-groove wet-process flue gas desulfuration method operating on the basis of two pH values, which relate to a flue gas desulfuration device and a flue gas desulfuration method. The aim of the invention is to remove SO2 from the flue gas under a high pH value condition by using desulfurating spray slurry and to dissolve limestone and oxidize calcium sulfite under a low pH value condition so as to improve desulfuration efficiency and quality of gypsum and reduce limestone consumption, investment and operation cost. In the invention, a circulating oxidization tank at the bottom of an absorption tower is divided into two parts, an oxidation pond receives desulfurizating slurry flowing out from a desulfurization tower, the oxidation pond operates in a pH range from 4.0 to 5.5, and in the oxidation pond, sulfite ions are oxidized, and byproduct of desulfuration is led out from the oxidation pond; and fresh limestone slurry is added into a circulating pond, the circulating pond operates in a pH range from 6 to 6.5, and slurry is led from the circulating pound into the absorption tower to be sprayed for deselfuration. The device and the method contribute to improving quality of gypsum, desulfuration efficiency, reducing limestone consumption and lowering investment and operation cost, and are suitable for flue gas desulfuration when sulfur coal is burnt or different kinds of fire coal are burnt.

Owner:HARBIN INST OF TECH

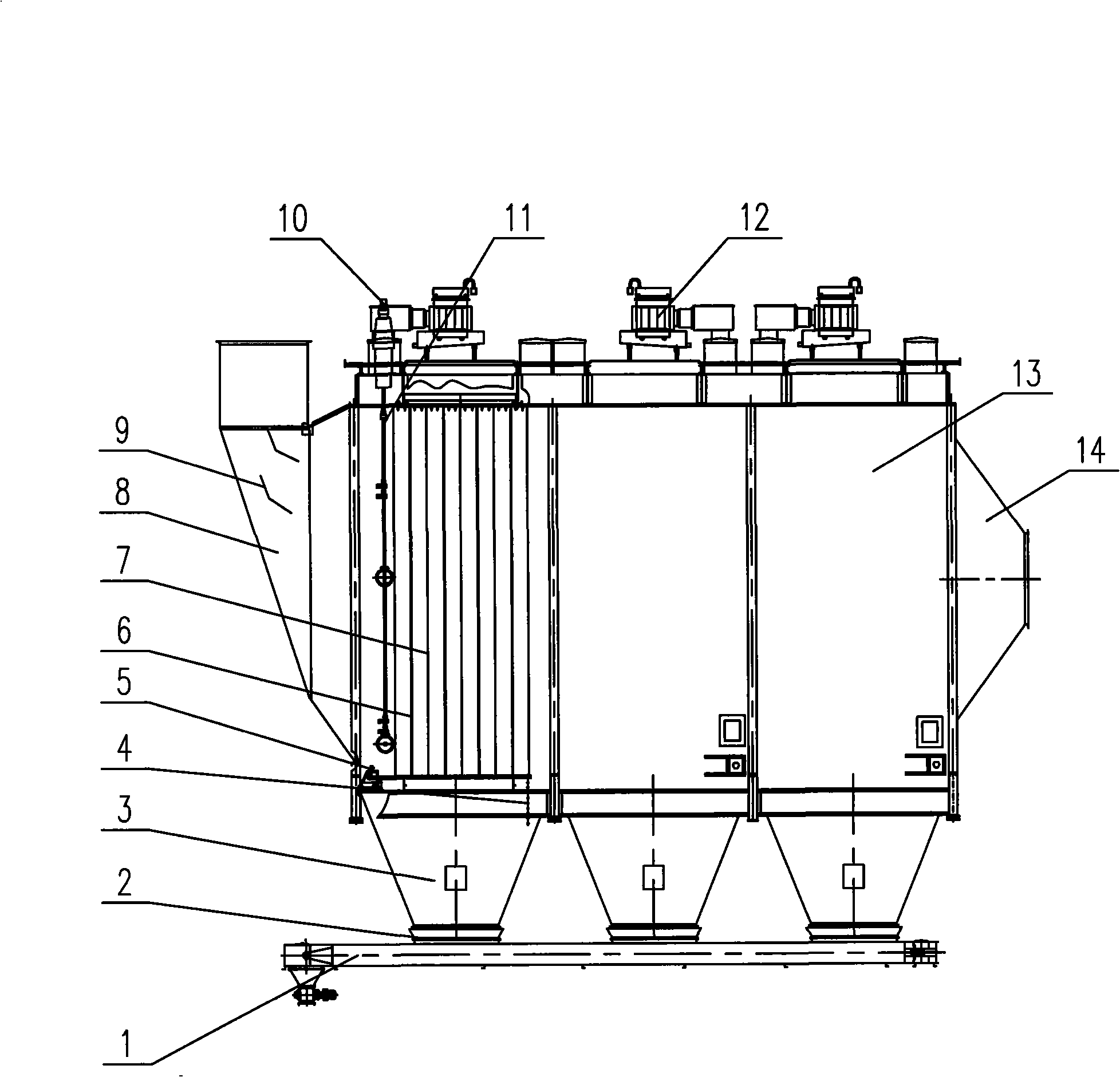

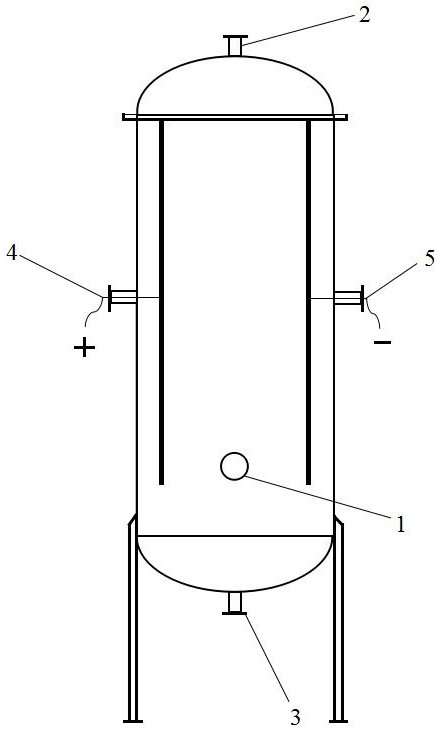

Horizontal type electric dust collector

ActiveCN101347760AAvoid contactAvoid corrosionExternal electric electrostatic seperatorElectrodes cleaningEngineeringVibration transmission

The invention provides a horizontal electric dust remover. A sealing head and an outlet sealing head are respectively arranged at the front and the back ends of a shell body, a dust hopper is connected at the lower end, a discharge outlet at the lower end of the dust hopper is connected with a dust discharge device by an expansion buffer device of the discharge outlet which is difficult to be blocked; a high voltage power supply is connected with a cathode system, an anode system and the cathode system are suspended in the shell body to form an electric field, the anode system carries out the dust removal by an anode vibration device, the cathode system carries out the dust removal by a cathode vibration device; a front air baffle, a back air baffle and a discharge lever are arranged in the dust hopper to constitute an air running and purifying device of the dust hopper. A heater is arranged in a cover shell of the cathode vibration transmission device, and an air suction pipe which is communicated with interior and exterior is arranged on the cover shell. The horizontal electric dust remover can overcome the shortcoming of the air running in a bypass of the dust hopper of the existing electric dust remover, avoid the problems of easy dewing and dust accumulation creepage of an electromagnetic rotary shaft in the cathode transmission device, prevent the occurrence of the phenomenon of dust accumulation blockage, effectively ensure the dust removing effect of the electric dust remover and ensure the emission to achieve the standards.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

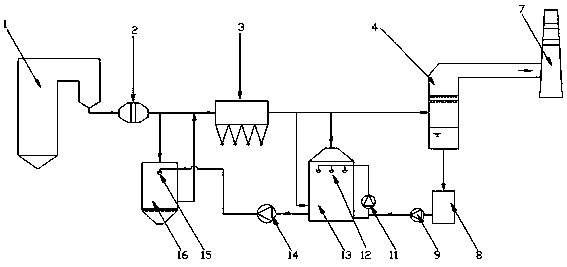

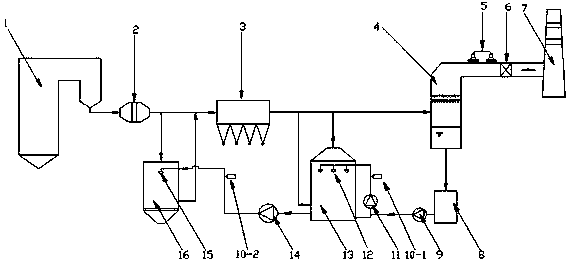

Device and method realizing synergic effects of waste heat utilization, desulfurization wastewater zero-emission and smoke plume removal

PendingCN108285188ASimple processUniversalAuxillary pretreatmentWaste water treatment from gaseous effluentsSmoke plumeZero emission

The invention discloses a device and a method realizing synergic effects of waste heat utilization, desulfurization wastewater zero-emission and smoke plume removal, the device comprises a boiler, anair preheater, a dust remover, a desulfurization tower and a chimney which are sequentially connected through a pipeline, a wastewater sedimentation tank, a wastewater concentration tower and a wastewater flashing tower simultaneously are connected to corresponding equipment in the device, a high-temperature gas required in the working process of the wastewater flashing tower and the wastewater concentration tower is taken from high-temperature flue gas during the operation of the device; and generated gases are sent into the dust remover for dust removal circulation. An acoustic wave agglomeration device and a demister are disposed in a connecting pipe between the desulfurization tower and the chimney. The method comprises the steps of concentrating and flashing the high temperature fluegas in the process of operation of the desulfurization wastewater utilization device, and finally feeding the concentrated and flashed gas to the device for circulation, thereby achieving zero emission, discharged smoke plume can be reduced by use of synergic effects of the reduced flue gas temperature, the acoustic wave agglomeration device and the demister, and the goal of energy saving and environmental protection, wastewater zero-emission and exhaust emission reduction can be comprehensively realized.

Owner:NANJING CHANGRONG ACOUSTIC INC +2

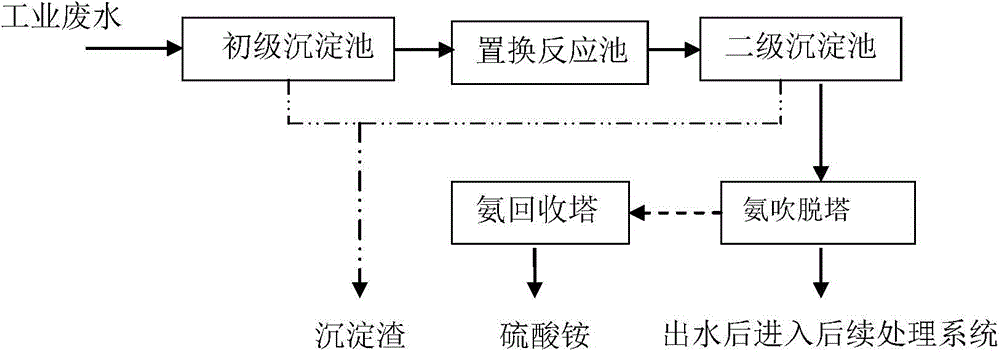

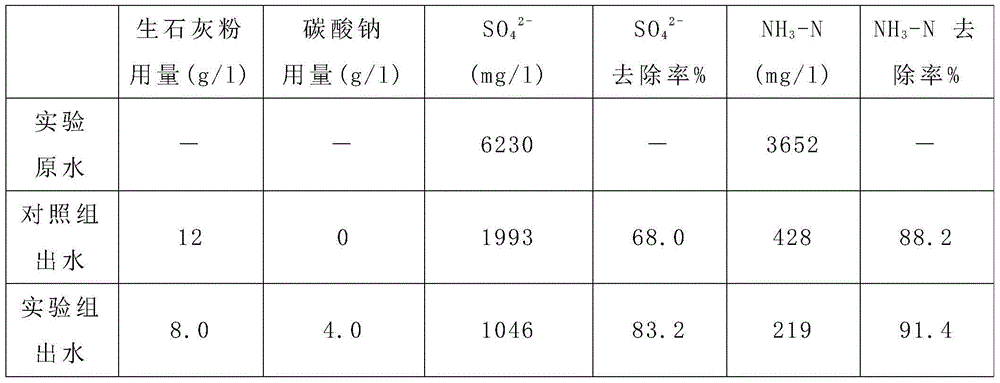

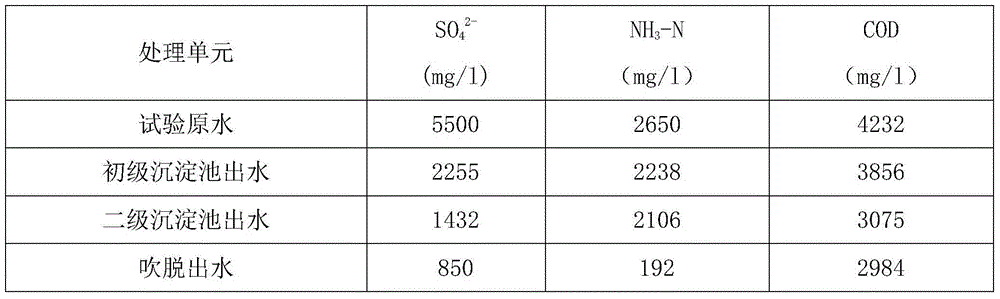

Treatment method for industrial wastewater

ActiveCN104591435AReduce the concentration of ammonia nitrogenReduce dosageMultistage water/sewage treatmentAmmonia compoundsHigh concentrationSulfate radicals

The invention belongs to the field of sewage treatment, and relates to a treatment method for industrial wastewater. The method comprises steps of primary precipitation, replacement reaction, secondary precipitation, ammonia stripping and ammonia recycling; removal rate to sulfate radicals in industrial wastewater is up to 80%, removal rate to ammonia nitrogen is up to 90%; the method is particularly applicable to treatment of high-concentration ammonium sulfate wastewater, meanwhile, solves the difficult problem that calcium sulphate scaling blocks equipment and pipelines and increases operation load in the conventional precipitation methods.

Owner:北京潮白环保科技股份有限公司

Heat-shrinkable polyester-type film

InactiveUS7960028B2Good printabilityHigh transparencySynthetic resin layered productsPretreated surfacesPolyesterEngineering

A heat-shrinkable polyester type film has a dynamic friction coefficient of at least one face with one face of another film of μd≦0.27 and range R≦0.05 and a weight loss of less than 0.24 g / m2 after 10 reciprocation times with 400 g load using a color fastness rubbing tester comprising a friction element bearing a sand paper with #1000 particle diameter.

Owner:TOYOBO CO LTD

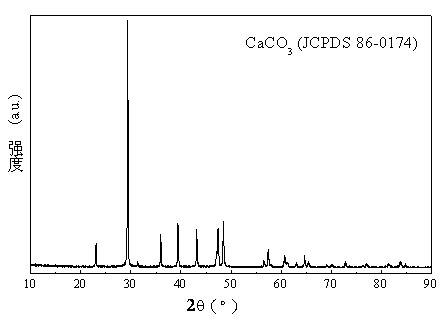

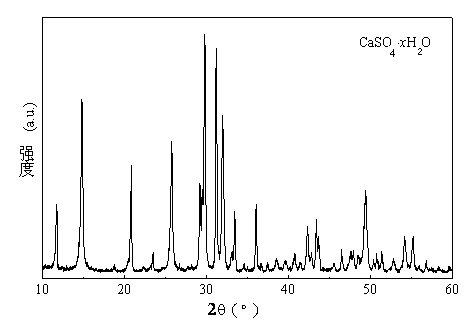

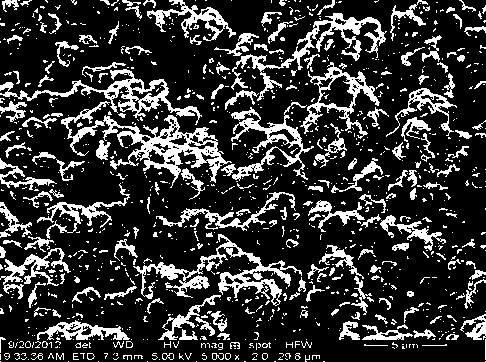

Application of sugar-mill lime sludge in wet flue gas desulfurization

The invention discloses the application of sugar-mill lime sludge in wet flue gas desulfurization. The application of the sugar-mill lime sludge is characterized in that the sugar-mill wet lime sludge is directly mixed with water to prepare slurry liquid, and the slurry liquid serves as an absorbing agent in a limestone-gypsum wet desulfurization method; the desulfurization absorbing agent is the waste lime sludge (namely filter residue or yellow mud) generated by the sugar prepared by a carbonic acid method in a sugar mill, mixed with water to form the slurry liquid with the proportion of 1:10-1:12, and used for absorbing sulfur dioxide (SO2) discharged by a coal burning boiler; and when the calcium-sulfur ratio is 1-1.1, the removal ratio of SO2 is up to more than 95 percent, the national desulfurization standard is met. The application of the sugar-mill lime sludge in the wet flue gas desulfurization adopts the waste residue of enterprises as the desulfuration absorbing agent, so as to be convenient and economic for material taking, simple in processing, and universal with the limestone-gypsum wet desulfurization method in requirements for equipment. The method not only saves the cost of purchasing an desulfurization agent, but also finds a way out for safe disposal of the lime sludge, so as to realize the purposes of treatment of wastes by other wastes, energy conservation and emission reduction, and have larger social environment benefits and economic benefits.

Owner:UNIV OF JINAN

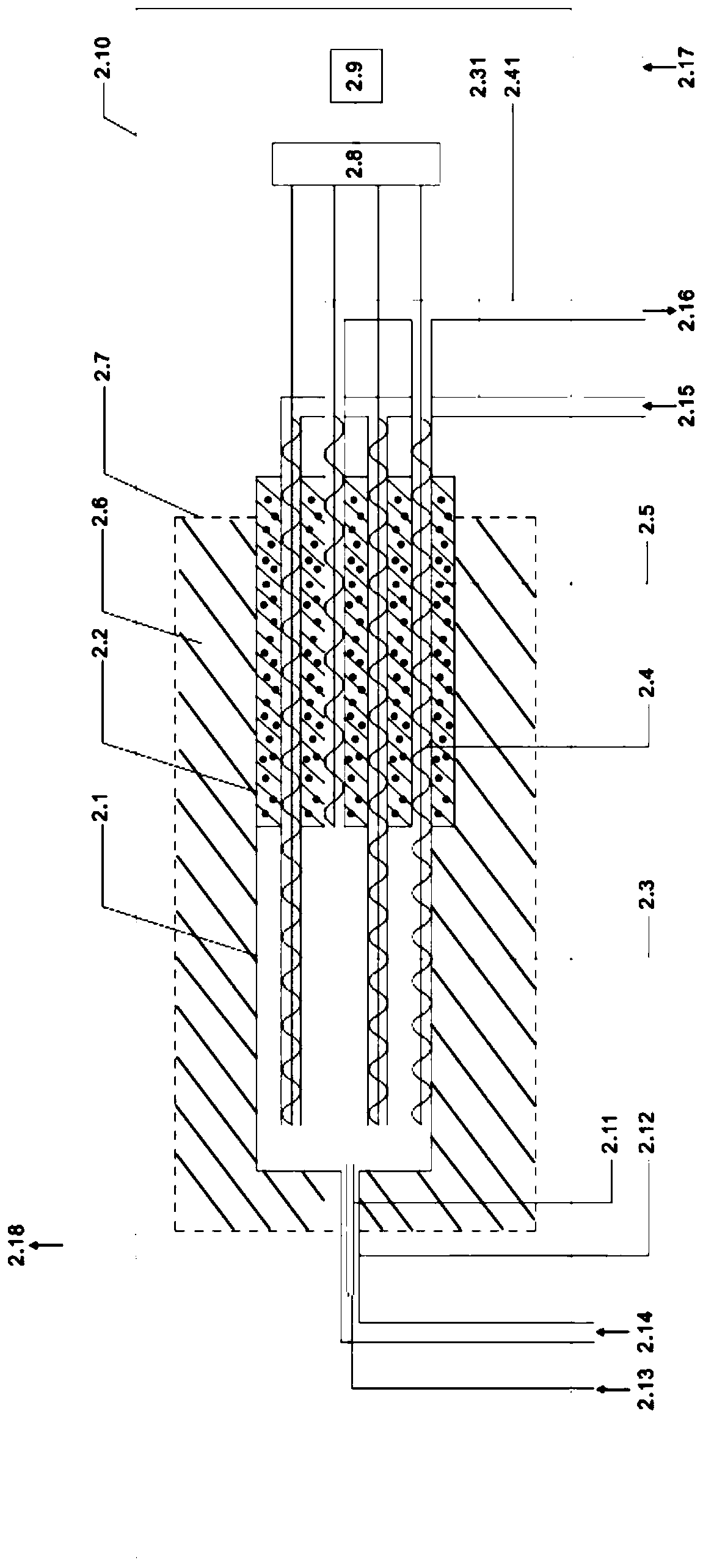

Supercritical water oxidation process and catalytic wet oxidation process combined reactor

ActiveCN106745660AGreat operating flexibilityGood structural strengthWater contaminantsWater/sewage treatment by oxidationSalting outReaction tube

The invention discloses a supercritical water oxidation process and catalytic wet oxidation process combined reactor. A main reaction tube is vertically arranged in a casing and is fixed by a cover plate flange at an opening of the casing; an upper opening is closed; a frame type sieve plate is circularly arranged between the casing and the main reaction tube inside the casing and is fixed; a catalyst is stored in the frame type sieve plate; a wastewater inlet and an oxygen inlet are formed in the upper part of the main reaction tube; a clear water outlet and a clear water inlet which are respectively formed in the upper side and the lower side of the frame type sieve plate are formed in the wall surface of the casing; the clear water outlet is sequentially connected into a heat exchanger and a circulating pump towards a direction of the clear water inlet; a saline water outlet is formed in the bottom of the casing. According to the reactor disclosed by the invention, a supercritical water oxidation process and a catalytic wet oxidation process are respectively used or are simultaneously and jointly used; supercritical oxidation is performed in the main reaction tube; catalytic wet oxidation is performed outside the main reaction tube; the reactor has relatively-high operation elasticity, provides optimization selection possibility for wastewater treatment with different fields, different concentrations and different treatment requirements and has the advantages of good structural strength, low manufacturing cost and convenience in arrangement; the problem of scale blockage of a supercritical water oxidation reactor due to high-temperature corrosion and salting out is effectively solved.

Owner:JIANGSU KUNZHONG MACHINERY

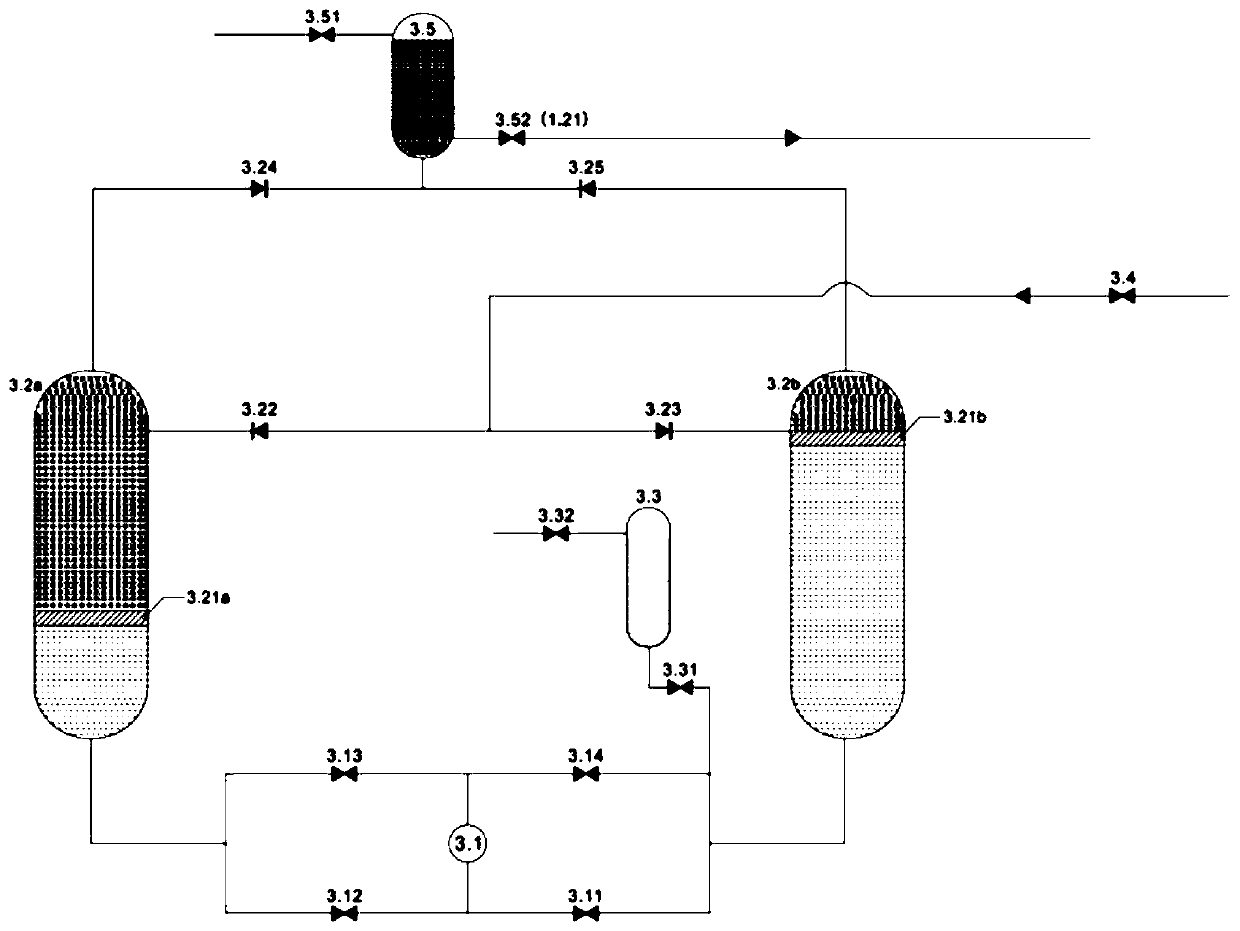

System for recycling fluorine and silicon resources from wet-process phosphoric acid tail gas and recovery method thereof

InactiveCN104906920ALow costIncrease added valueSilicaDispersed particle separationRecovery methodHigh concentration

The invention relates to the field of the tail gas treatment technology and in particular relates to a system for recycling fluorine and silicon resources from wet-process phosphoric acid tail gas and a recovery method of the system. Fluorosilicic acid solution is circularly treated in the system, the scale blockage phenomenon of the system can be avoided, fluorosilicic acid can flow out in a solution mode in a cooling process of the tail gas, then fluorosilicic acid is further treated so that the fluorine and silicon resources can be recycled; a small amount of water is adopted for absorption treatment in a tail gas absorption process, then the acquired fluorosilicic acid solution is used for washing tail gas circularly; thus, fluorosilicic acid solution from a fluorine washing tower I has high concentration, the fluorine washing tower I and a fluorine washing tower II are combined to ensure that the fluorine-containing substances during the tail gas empting treatment is low, the recovery rate of the fluorine and silicon resources is improved and the environment pollution rate is reduced.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

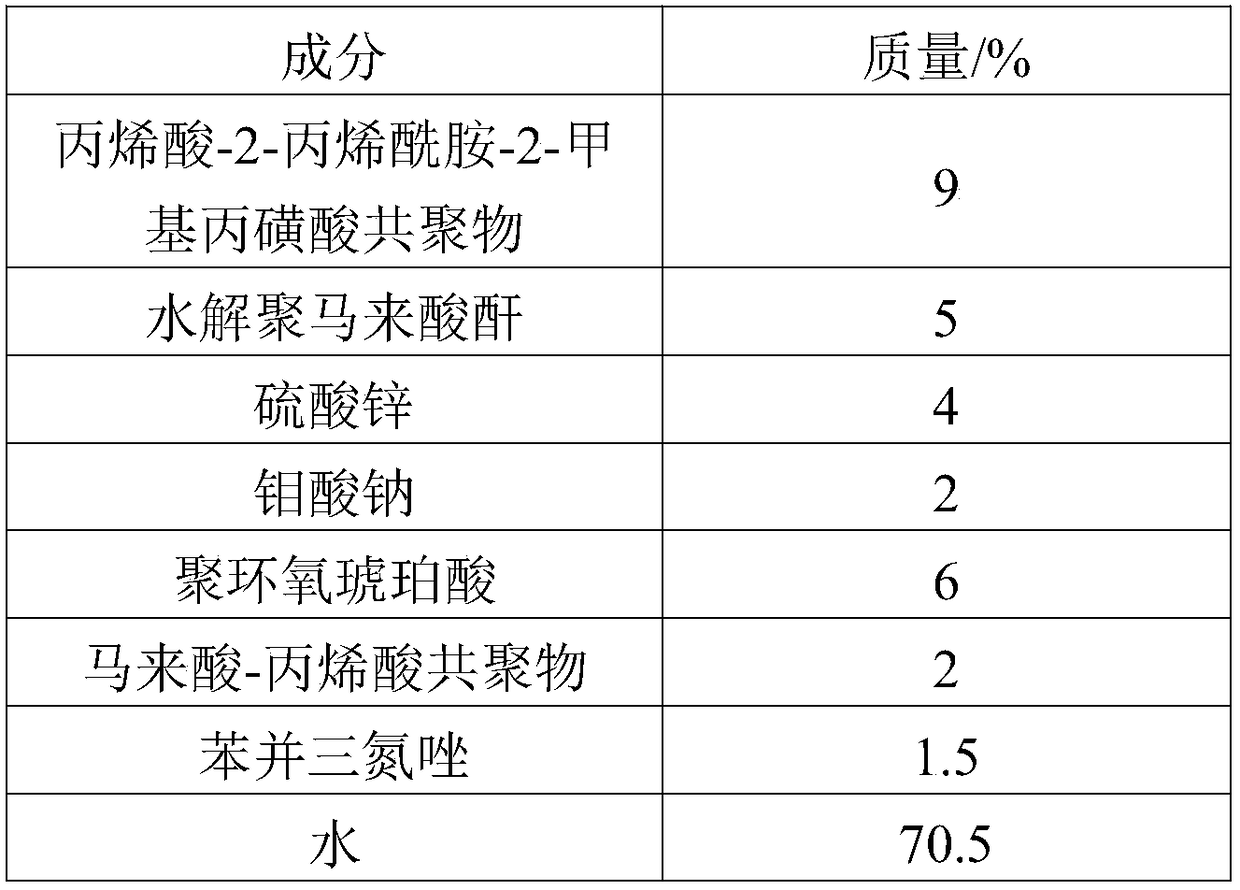

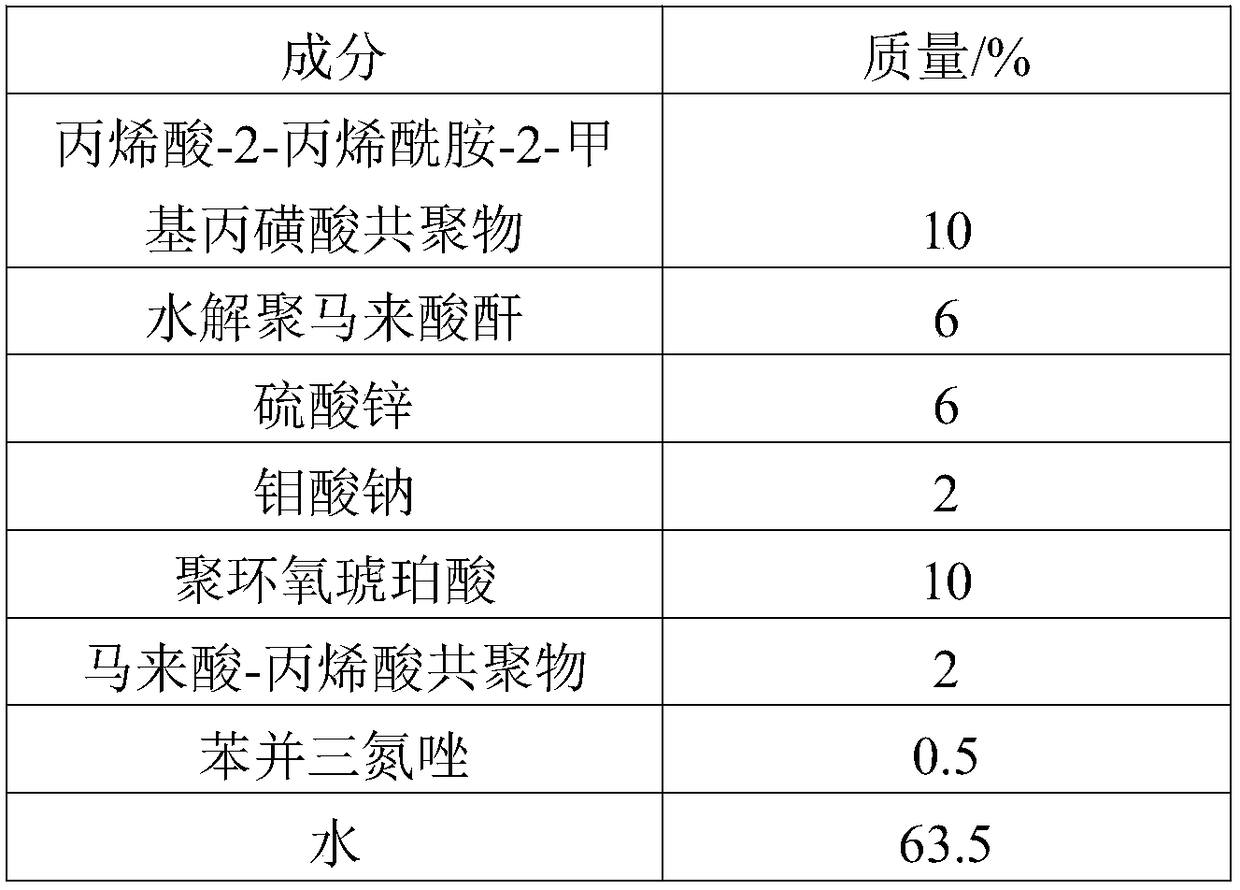

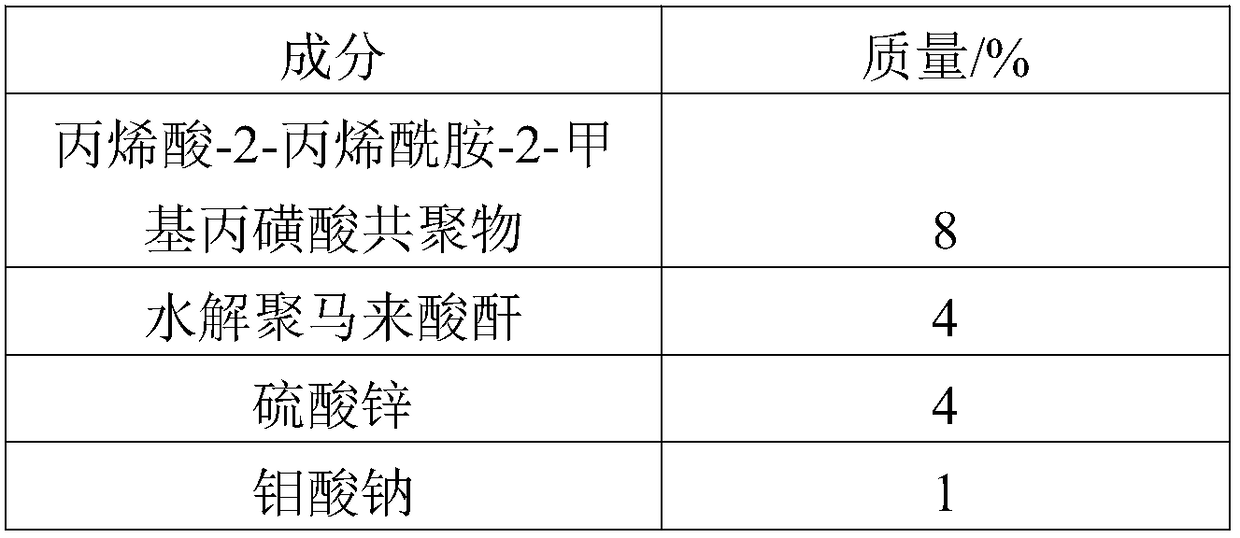

Composite phosphorus-free corrosion-scale inhibitor and preparation method thereof

ActiveCN109264878AStrong targetingLow costSpecific water treatment objectivesScale removal and water softeningMaterials scienceCorrosion

The invention relates to a composite phosphorus-free corrosion-scale inhibitor and a preparation method thereof and belongs to the field of preparation of corrosion-scale inhibitors. The technical problem to be solved herein is to provide a composite phosphorus-free corrosion-scale inhibitor for industrial circulating water systems in order to solve the nozzle blocking and scale coating problems of an industrial circulating water system. The composite phosphorus-free corrosion-scale inhibitor provided herein comprises, by weight, 5-10 parts of acrylic acid-2-acrylamido-2-methylpropane sulfonicacid copolymer, 2-6 parts of hydrolyzed maleic anhydride, 4-6 parts of zinc sulfate, 1-3 parts of sodium molybdate, 5-10 parts of polyepoxysuccinic acid, 1-3 parts of maleic acid-acrylic acid copolymer, and 0.5-2 parts of benzotriazole. Compared with like corrosion-scale inhibitors, the composite phosphorus-free corrosion-scale inhibitor herein has the advantages of good specificity, low cost, good operational convenience, good convenience and high speed, good environmental friendliness, good safety, high efficiency and the like.

Owner:RUITIAN SECURITY & ENVIRONMENTAL PROTECTION CO LTD PANZHIHUA GANGCHENG GRP

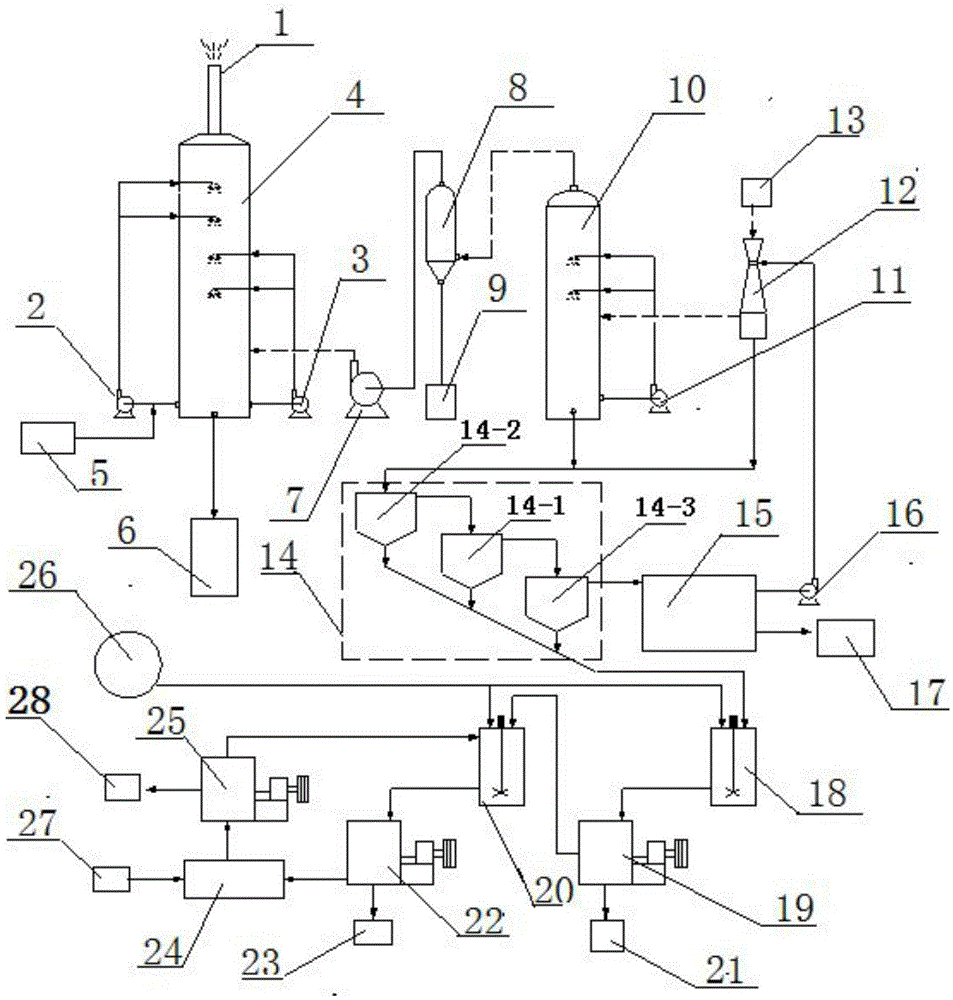

Ultra-critical gasification device and method

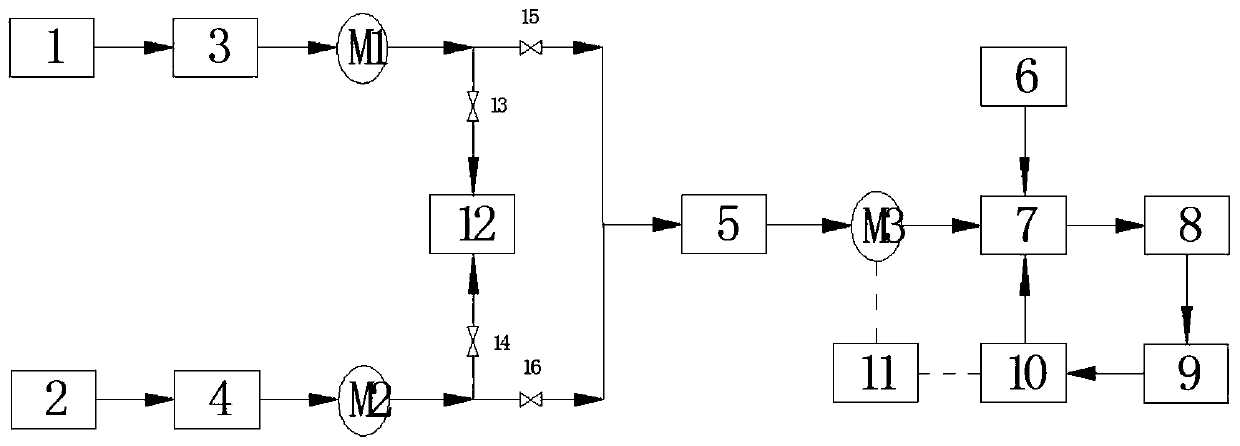

PendingCN109810728ASolve fouling and cloggingEffective heat transferBulk chemical productionGranular/pulverulent flues gasificationHearthProcess engineering

The invention relates to an ultra-critical gasification device, which comprises an ultra-critical gasification furnace, an ultra-critical gasification furnace heat exchanging device and a hearth usedfor gasifying materials. The heat exchanging device and the hearth are communicated, the heat exchanging device is provided with a material inlet and a material outlet, the material inlet is used to feed the materials before gasification, the material outlet is used to discharge the materials after gasification, the material inlet of the heat exchanging device is communicated with the material outlet through the hearth, the material inlet and the material outlet are both exposed from the ultra-critical gasification furnace, the hearth is provided with an oxygen spraying pipe used to input an oxidant and a gas spraying pipe used to input combustible gas, and an igniting device used to ignite is arranged between an end of the oxygen spraying pipe and an end of the gas spraying pipe in the hearth. The invention also relates to an ultra-critical gasification method, so that a preheating system, an ultra-critical water medium heating system and the gasification system are integrated, effective insulation measures are taken to save energy, conditions for realizing ultra-critical gasification are achieved to the most.

Owner:楼龙春

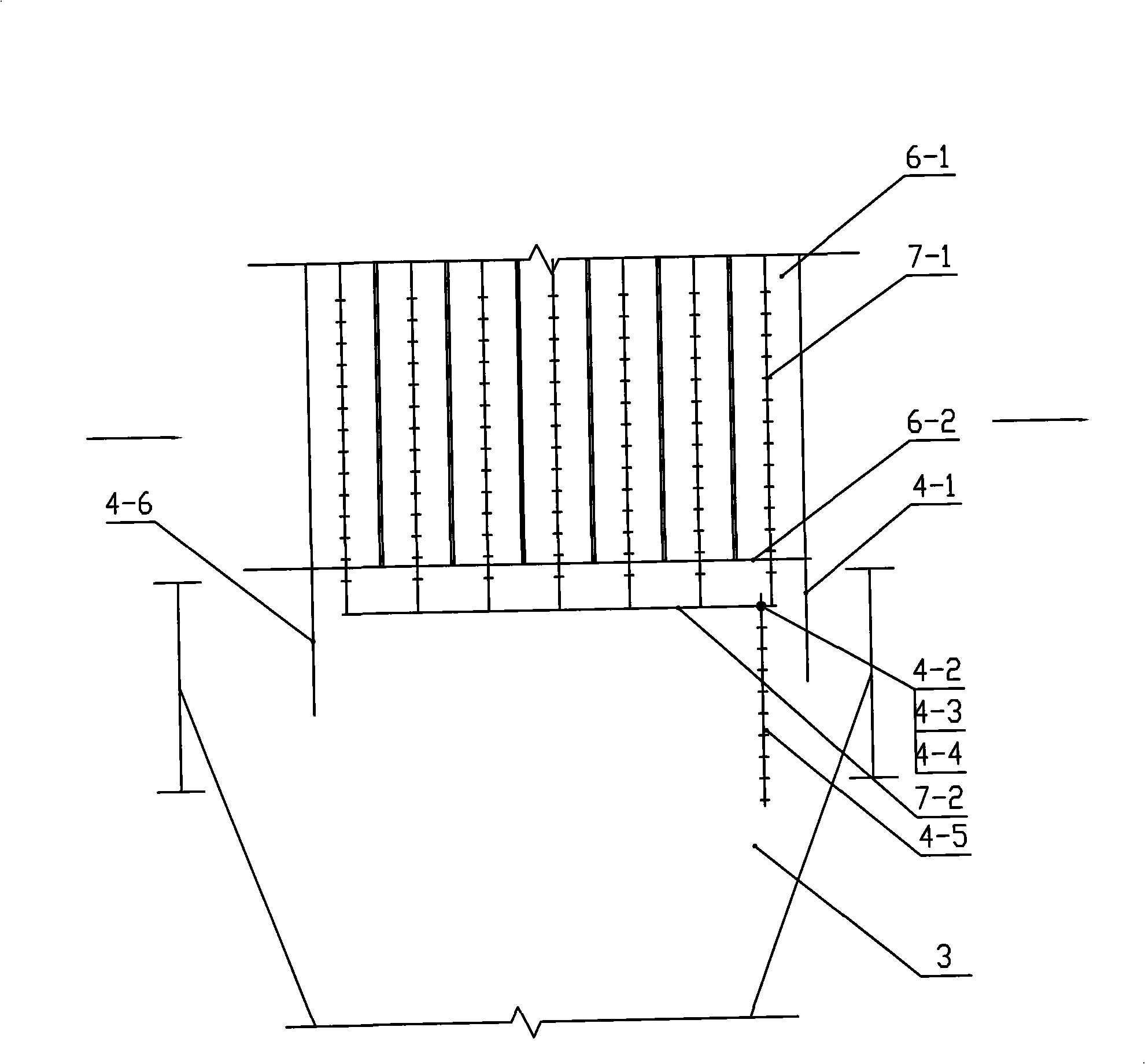

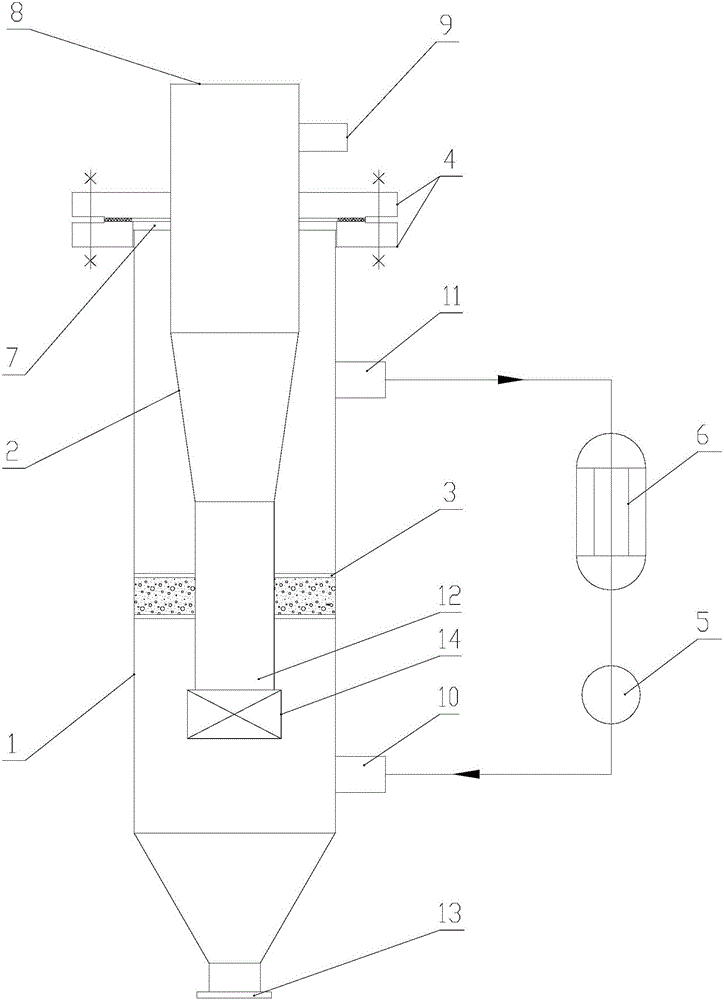

Pneumatic packed rotating tower realizing self-distribution parallel flow

InactiveCN106178768AUniform self-distributing airflowConfiguration parameter reductionUsing liquid separation agentFlue gasEngineering

The invention provides a pneumatic packed rotating tower realizing self-distribution parallel flow. The pneumatic packing rotating tower comprises a desulphurization and dust removal absorption tower body, a rotary demister arranged at the internal upper part of the tower, a self-distribution parallel flow separating plate arranged in the tower, a liquid distributing device arranged on an upper separating plate, annular pneumatic rotational flow devices arranged in holes in the upper separating plate and a lower separating plate, annular packing supporting plates arranged in holes located in the upper separating plate and the lower separating plate, packing press plates and packing, wherein concentric inner and outer cylinders arranged in the holes in the upper separating plate and the lower separating plate are welded with the upper separating plate and the lower separating plate, each inner cylinder adopts a hollow structure with sealed end and is equipped with a gas flow adjusting plate located on the upper separating plate and on the periphery of an outer cylinder of the corresponding hole. By means of the pneumatic packing rotating tower, self-distribution parallel flow of gas in the tower can be realized, the amplification effect of a packed tower is solved, and scaling and blockage in a packing region are avoided due to the internal circulation flow of the packing. The invention aims to provide a packing absorption device with simple structure, high mass transfer efficiency, low investment, low operation and maintenance cost and wide flue gas load application range.

Owner:天津深蓝宇节能减排技术有限公司

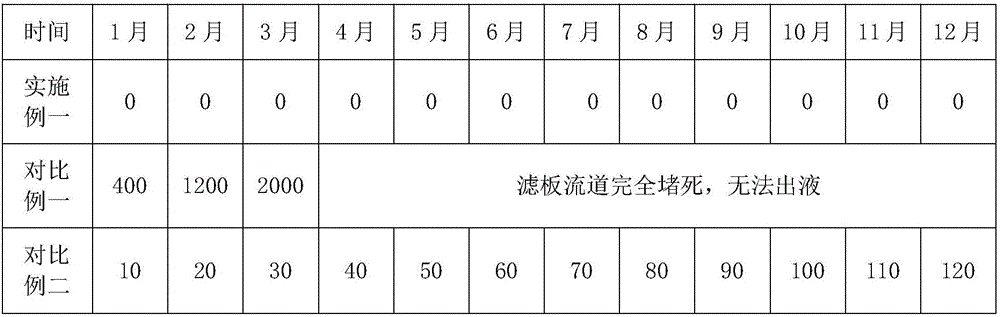

Method for preventing scaling of controlled filtration equipment in titanium dioxide production process

InactiveCN106629838ASolve fouling and cloggingIncrease productivityTitanium dioxideIron sulfateFiltration

The invention relates to a method for controlled filtration in titanium dioxide production via sulfuric acid method, in particular to a method for preventing scaling of controlled filtration equipment in titanium dioxide production process; the method comprises the steps of (1) preheating post-crystallization filtrate, obtained by removing iron sulfate heptahydrate crystal via crystallization, to a temperature above extracting temperature of solid matter to be extracted to obtain pre-heated filtrate, wherein the solid matter to be extracted is obtained by acidolysis of ilmenite; (2) performing controlled filtration on the preheated filtrate. The method has the advantages that the problem that a filter plate is blocked due to scaling during controlled filtration can be thoroughly solve; production efficiency of the whole titanium dioxide production process is improved; the method is simple and is easy to popularize.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

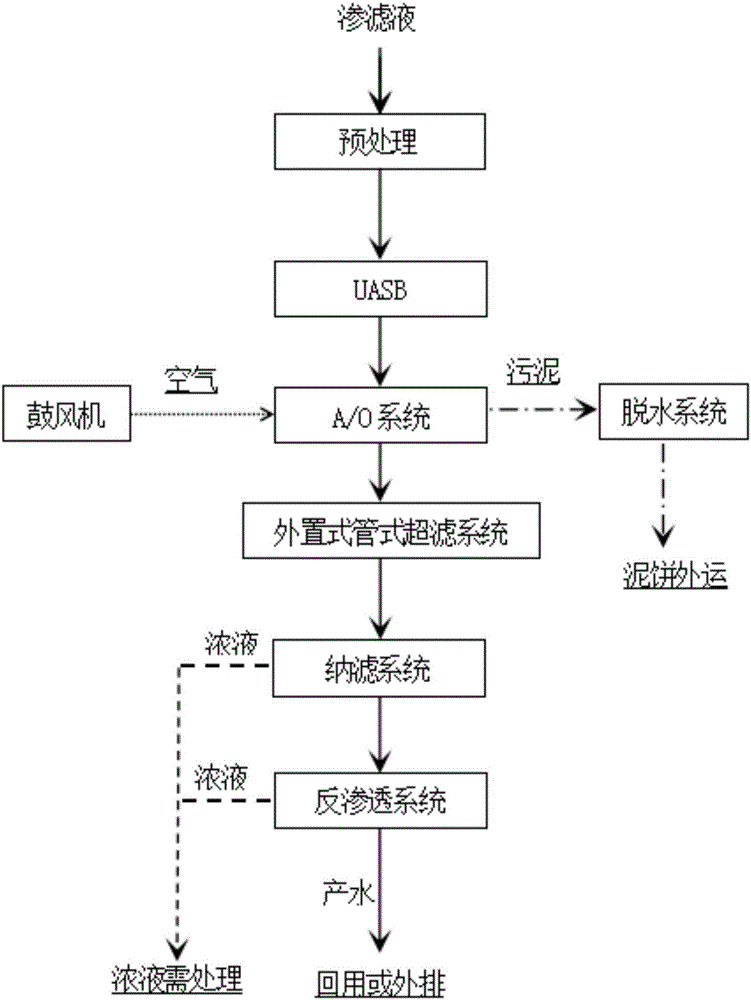

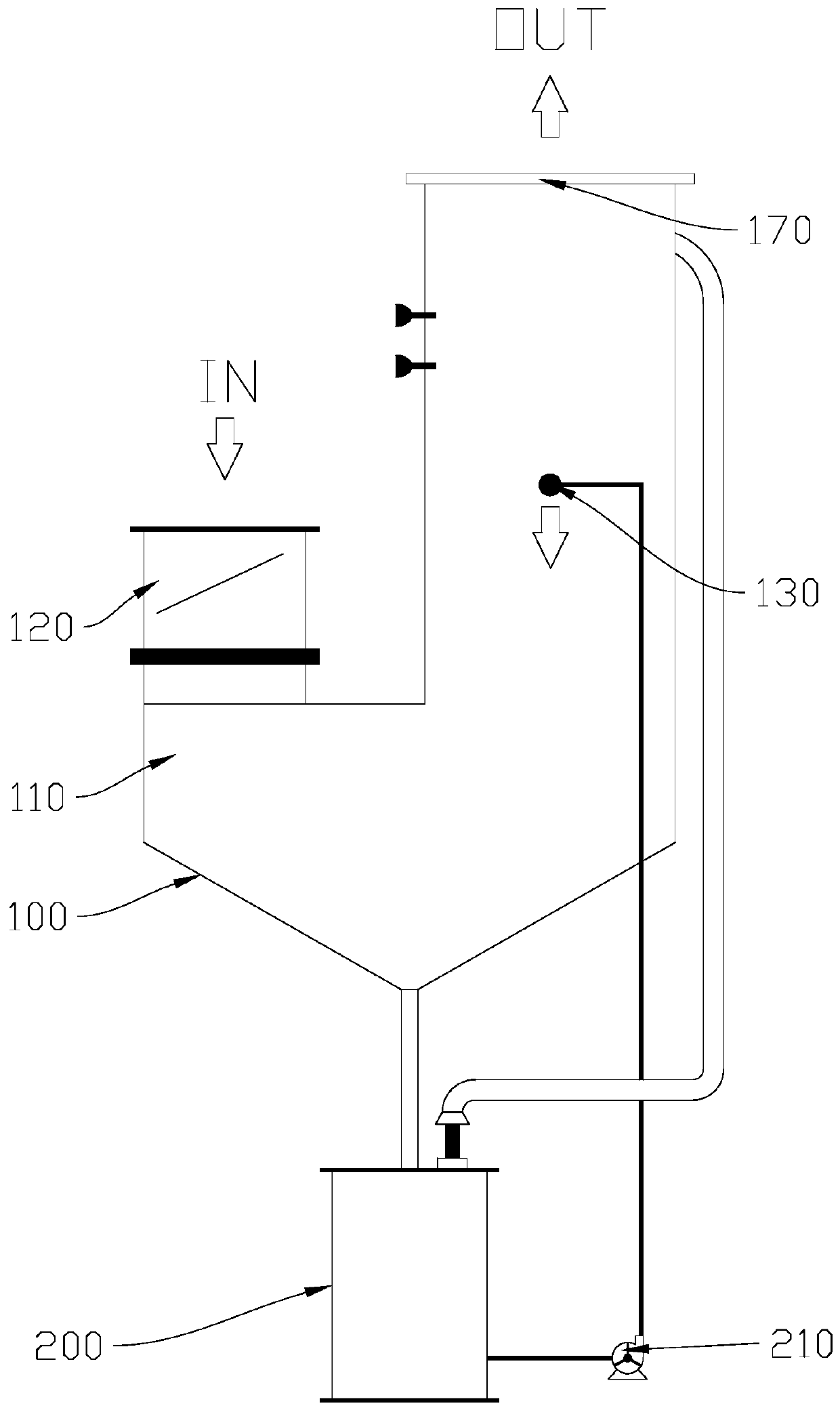

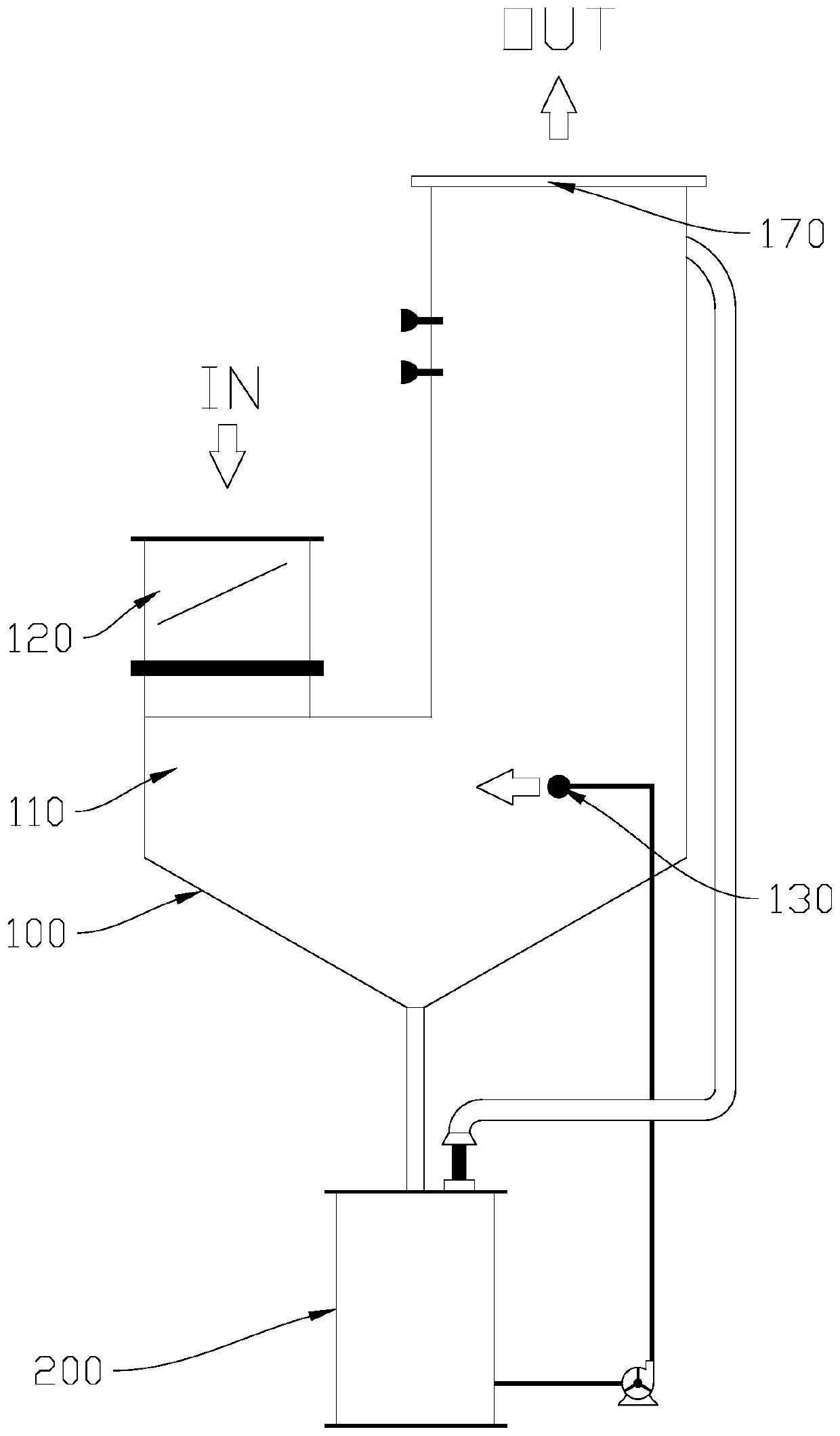

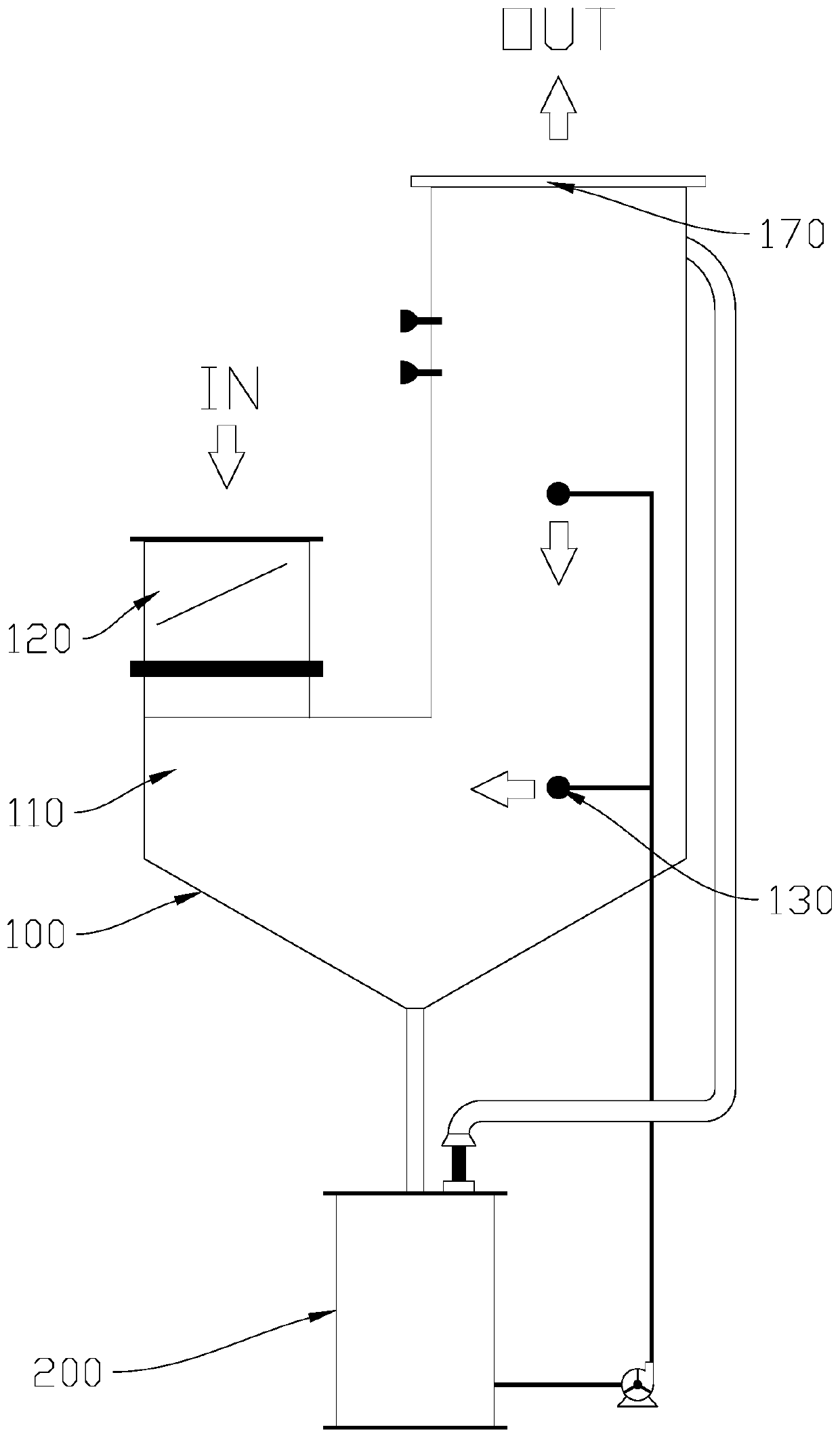

Wastewater treatment system and wastewater treatment method

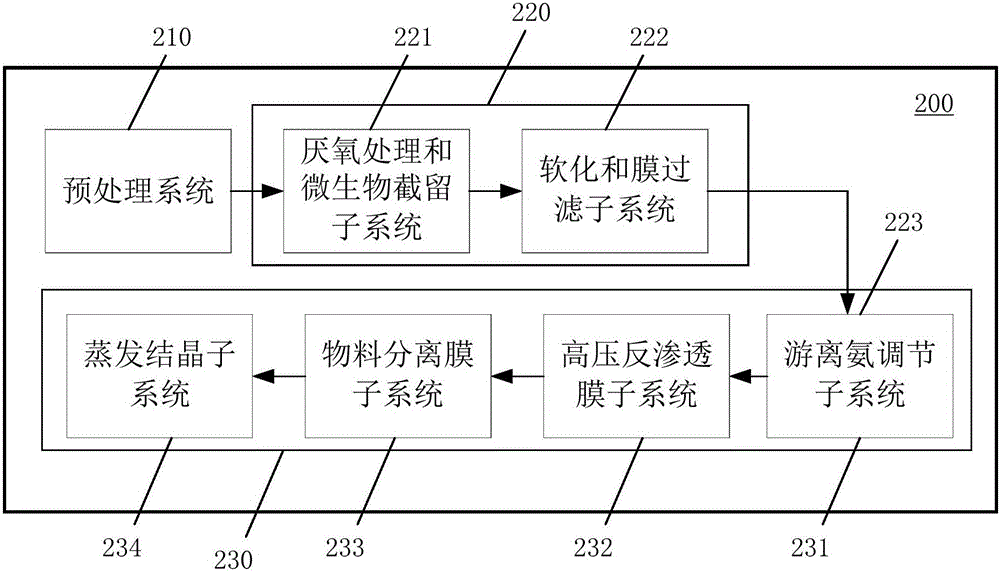

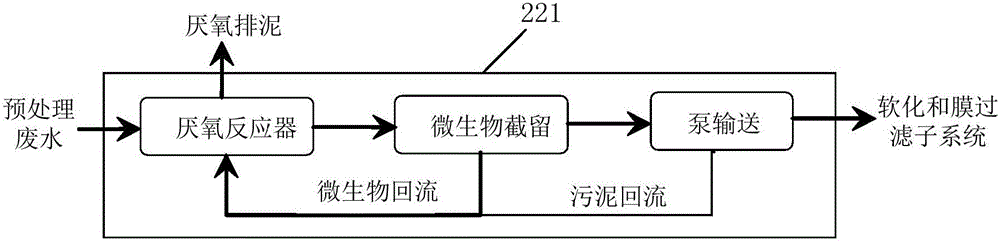

ActiveCN107522350ASolve the problem of running out of water and mudSolve efficiency problemsWater softeningMultistage water/sewage treatmentFiltrationReverse osmosis

The invention discloses a wastewater treatment system and a wastewater treatment method. The wastewater treatment system comprises a pretreatment system which is used for regulating and precipitating wastewater to obtain pretreated wastewater, a first treatment system which is used for performing anaerobic treatment and microbial retention on the pretreated wastewater and performing softening and membrane filtration on the microbial retained wastewater to obtain softened membrane-filtered effluent, and a second treatment system which is used for transforming free ammonia in the softened membrane-filtered effluent into ion ammonia to obtain transformed effluent and performing high-pressure reverse osmosis treatment, material separation treatment and evaporative crystallization treatment on the transformed effluent. According to the wastewater treatment system, specific pollutants can be relatively completely removed in each treatment unit on the technical process, and an advantageous treatment condition is created for the subsequent unit to form an innovative complete combination process, so that the treatment task of subsequent units becomes simpler, the treatment difficulty becomes lower, and the treatment effect becomes better.

Owner:北京众力清源环保科技有限公司

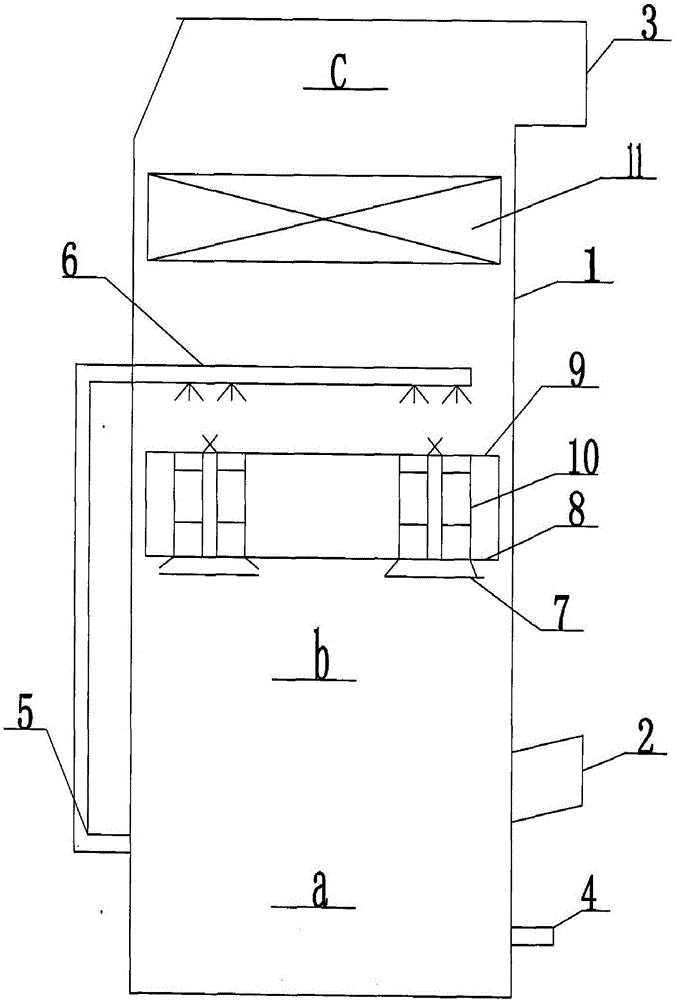

Quick cleaning device for furnace body induction coil

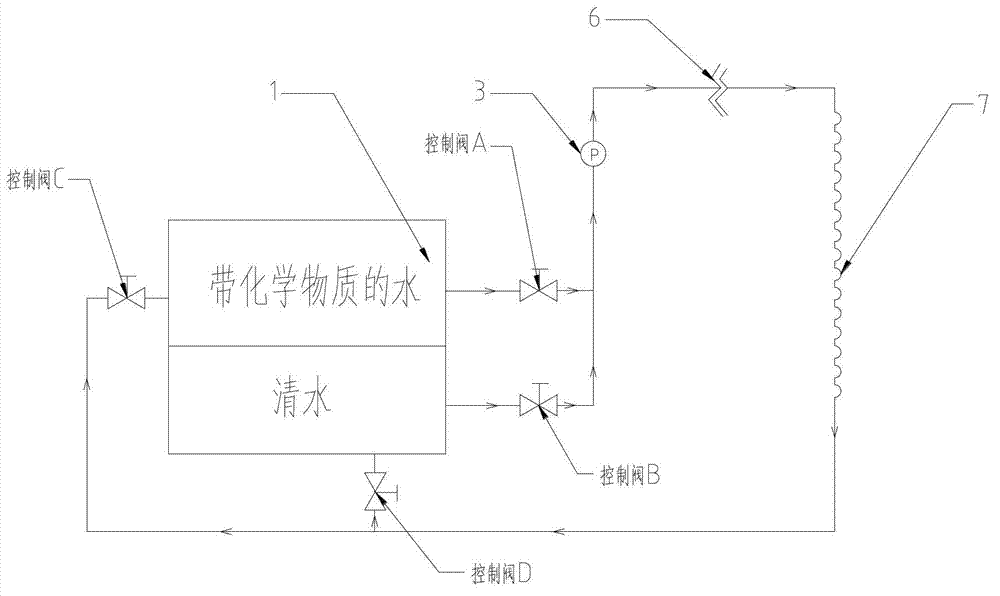

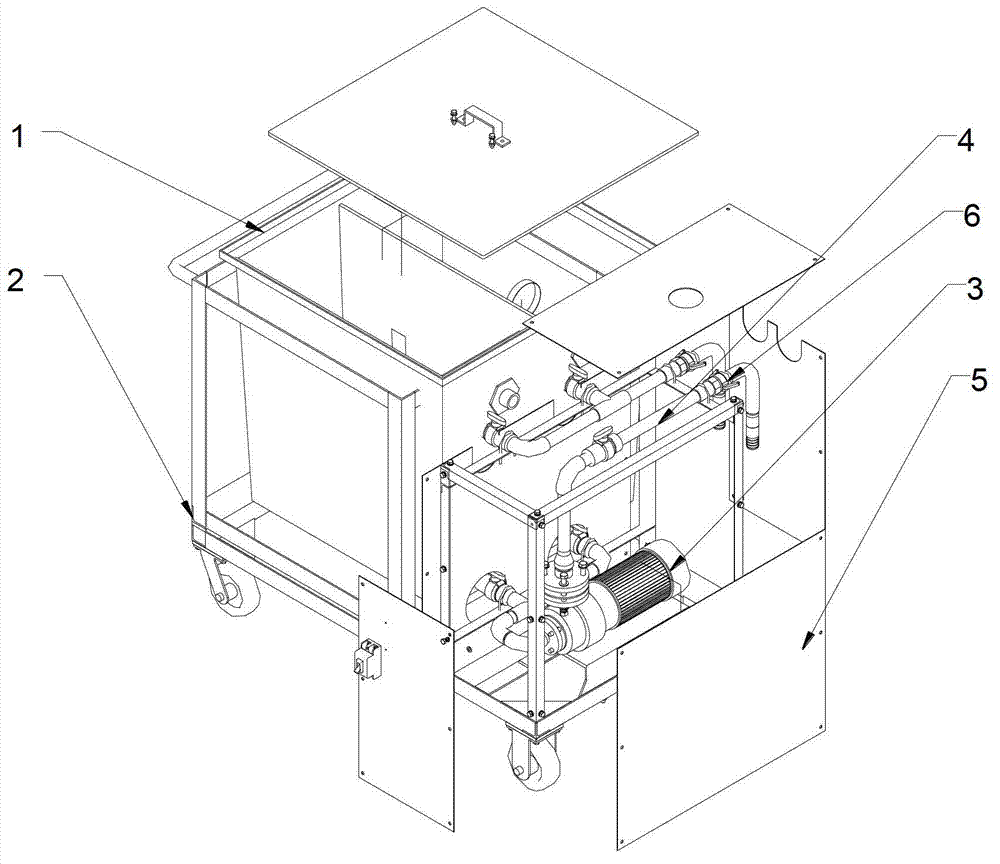

InactiveCN103114295ASolve fouling and cloggingEasy to cleanCleaning using liquidsClean waterChemical substance

The invention discloses a quick cleaning device for a furnace body induction coil. The quick cleaning device comprises a barrel. The quick cleaning device is characterized by further comprising a centrifugal pump, wherein the inside of the barrel is separated into two cavity bodies, wherein one cavity body contains water with chemical substances, the other cavity body contains clean water, the two cavity bodies of the barrel are respectively connected with the centrifugal pump through pipelines, and the centrifugal pump is connected with a connection end of a cleaning head for cleaning the furnace body induction coil through the pipeline. The device can be used for solving the problems that scales are easily formed on a heat exchange surface of an induction coil of the prior art due to high temperature in a circulation process of circulating water, the temperature of the induction coil is quickly raised when the scales reach a certain thickness, a shut-down phenomenon is caused by abnormal operation of the induction coil, and production is influenced. The quick cleaning device for the furnace body induction coil is low in cost, simple in structure and complete in function and can effectively remove the scales of the induction coil.

Owner:FIVE POWER ELECTRICAL TECHKUNSHAN

Anti-scaling system and method for wet deslagging system of thermal power plant

PendingCN110921962AAvoid formingAvoid formation of CaCO

<sub>3</sub>

dirtWaste water treatment from gaseous effluentsMultistage water/sewage treatmentPH meterBoiler slag

The invention discloses an anti-scaling system and method for a wet deslagging system of a thermal power plant. The anti-scaling system comprises a controller, a fine treatment regeneration system, afirst online pH meter, a fine treatment regeneration acidic wastewater delivery valve, a fine treatment regeneration alkaline wastewater delivery valve, a chemical regeneration system, a second onlinepH meter, a chemical regeneration acidic wastewater delivery valve, a chemical regeneration alkaline wastewater delivery valve, a desulfurization system, a slag removal system water replenishing tank, a slag removal system water replenishing tank delivery pump, a slag conveyor, a boiler, a slag overflow tank, a concentration tank, a clean water tank and a third online pH meter, According to the system and the method, the scaling problem of pipelines and equipment of the wet deslagging system can be prevented and the disposal problem of regenerated wastewater of the whole plant can be solved and the cost is low.

Owner:XIAN THERMAL POWER RES INST CO LTD

Surface treatment method for self-cleaning anti-jamming demister blade

ActiveCN105199127ASolve fouling and cloggingImprove bindingLiquid surface applicatorsPolyurea/polyurethane coatingsAnti jammingChlorinated polyvinyl chloride

The invention relates to a surface treatment method for a self-cleaning anti-jamming demister blade. The demister blade is prepared from a PP material. The method comprises the following steps: 1) spraying a solution containing chlorinated polyvinyl chloride on the surface of the demister blade and carrying out drying and curing at room temperature so as to obtain a chlorinated polyvinyl chloride resin layer on the surface of the demister blade; and 2) coating the surface of the chlorinated polyvinyl chloride resin layer with a UV light-cured paint, then spraying a super-hydrophobic coating and curing the demister blade under a UV lamp after drying and curing of the super-hydrophobic coating. With the surface treatment method for demister blade, the phenomena of fouling and obstruction of the demister blade can be fundamentally avoided, and descaling cost is reduced; the coated coating has excellent bonding force with the base material (i.e., the demister blade), and adhesion reaches more than grade 2 in testing according to the Standard GB / T9286-1998; and the demister blade can working for a long time in a high temperature wet environment and has high economic and environmental benefits.

Owner:武汉珈合实业投资管理有限公司

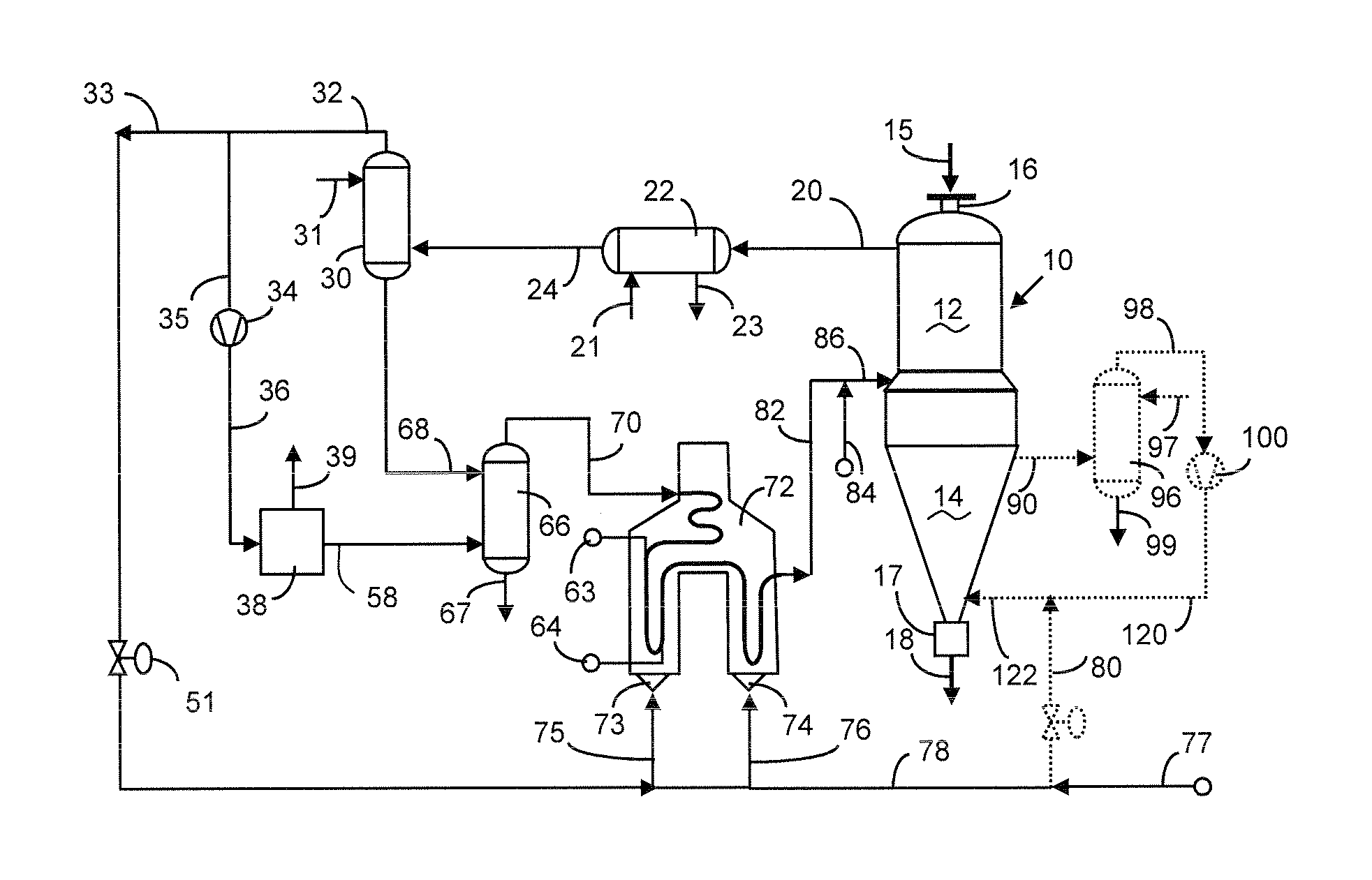

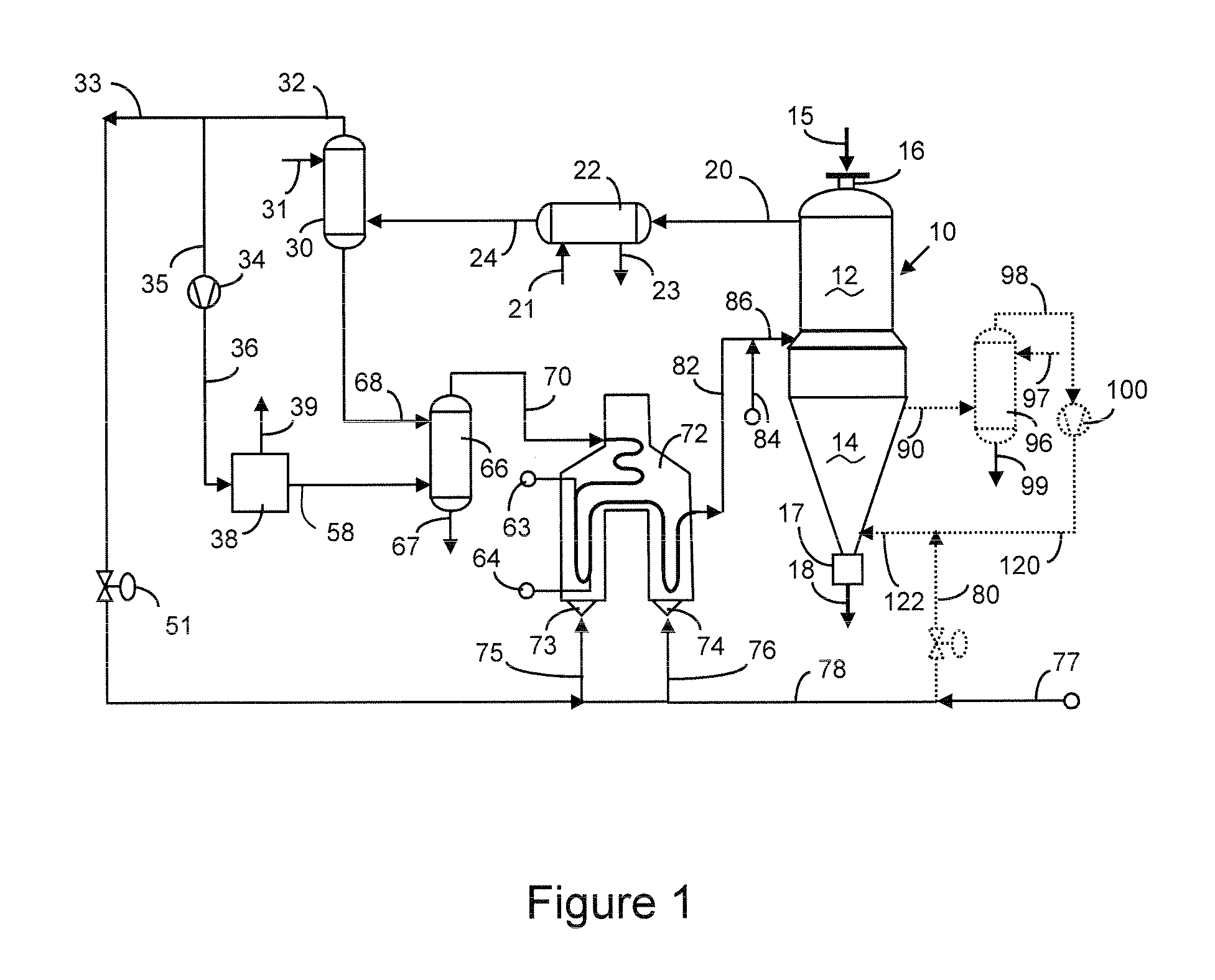

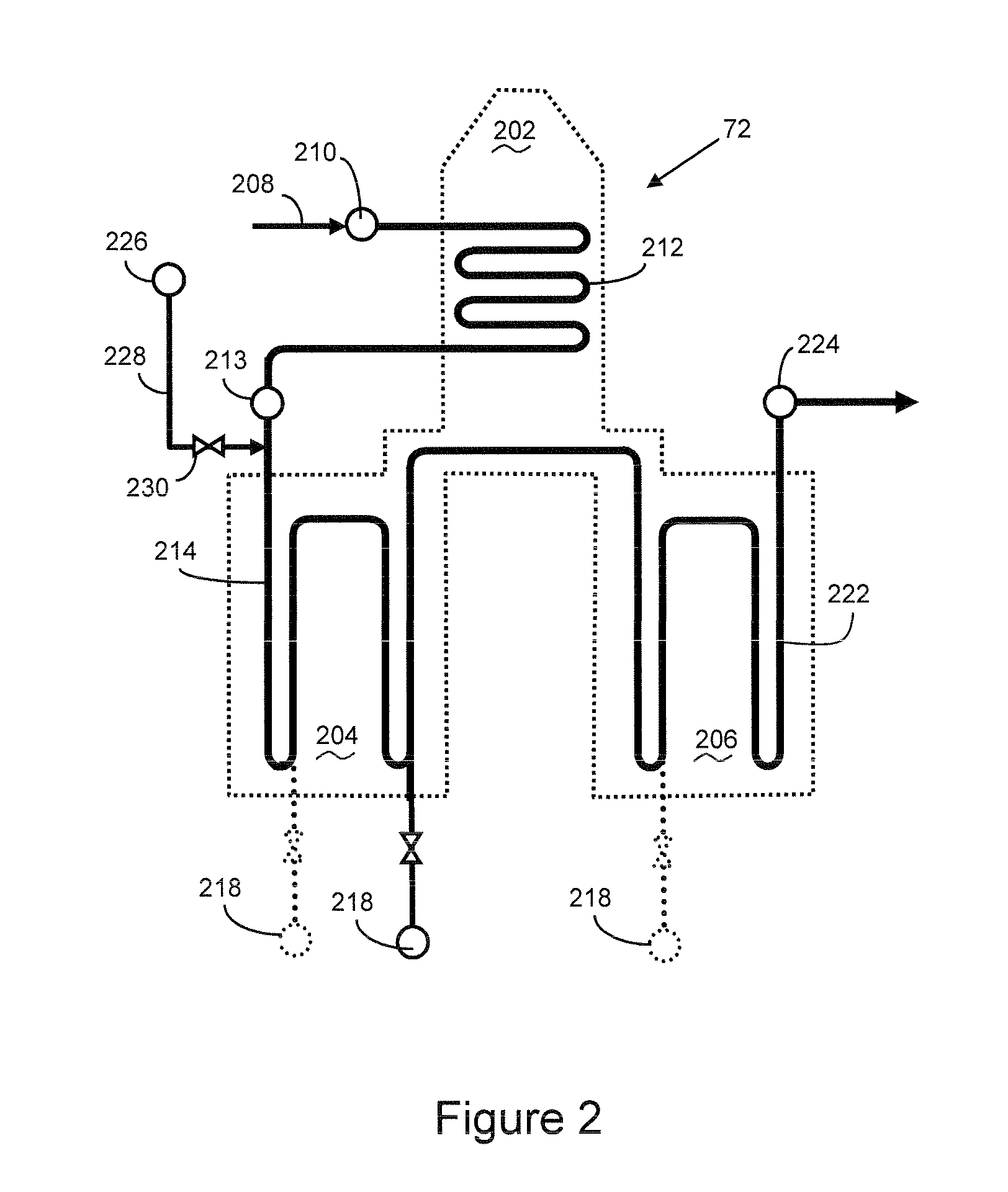

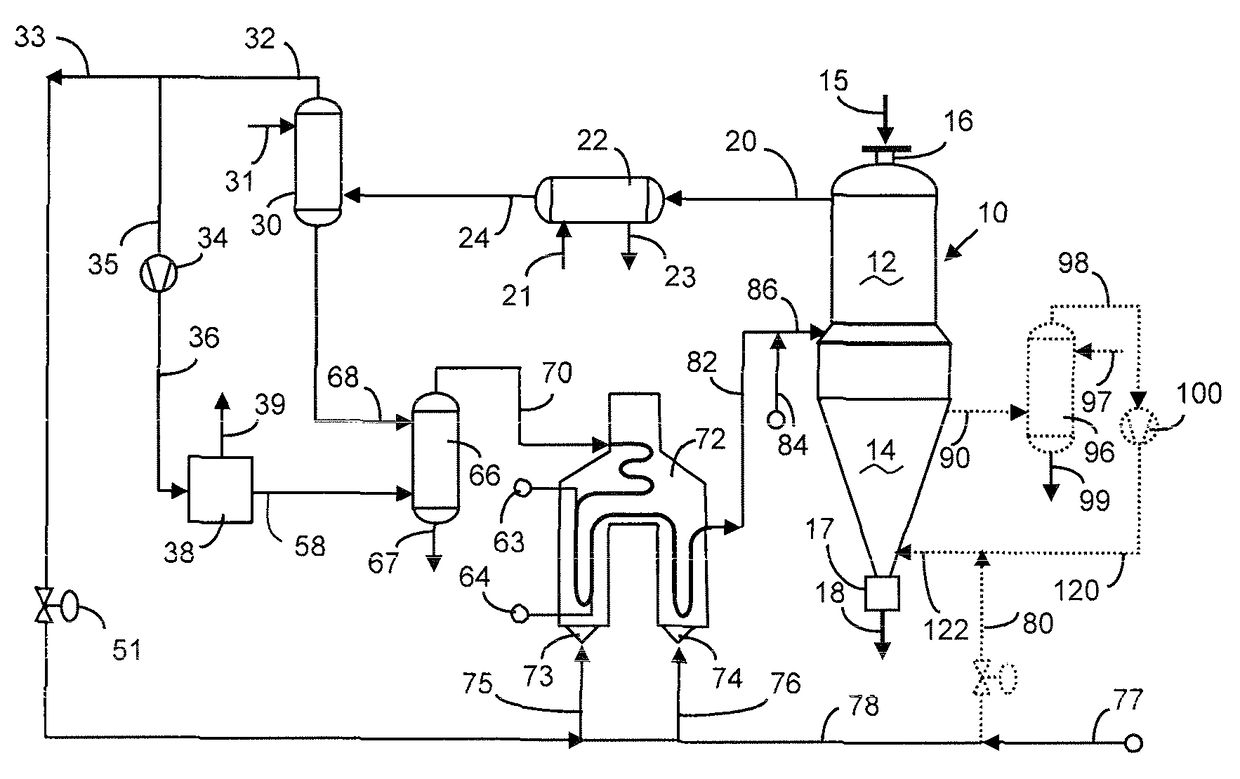

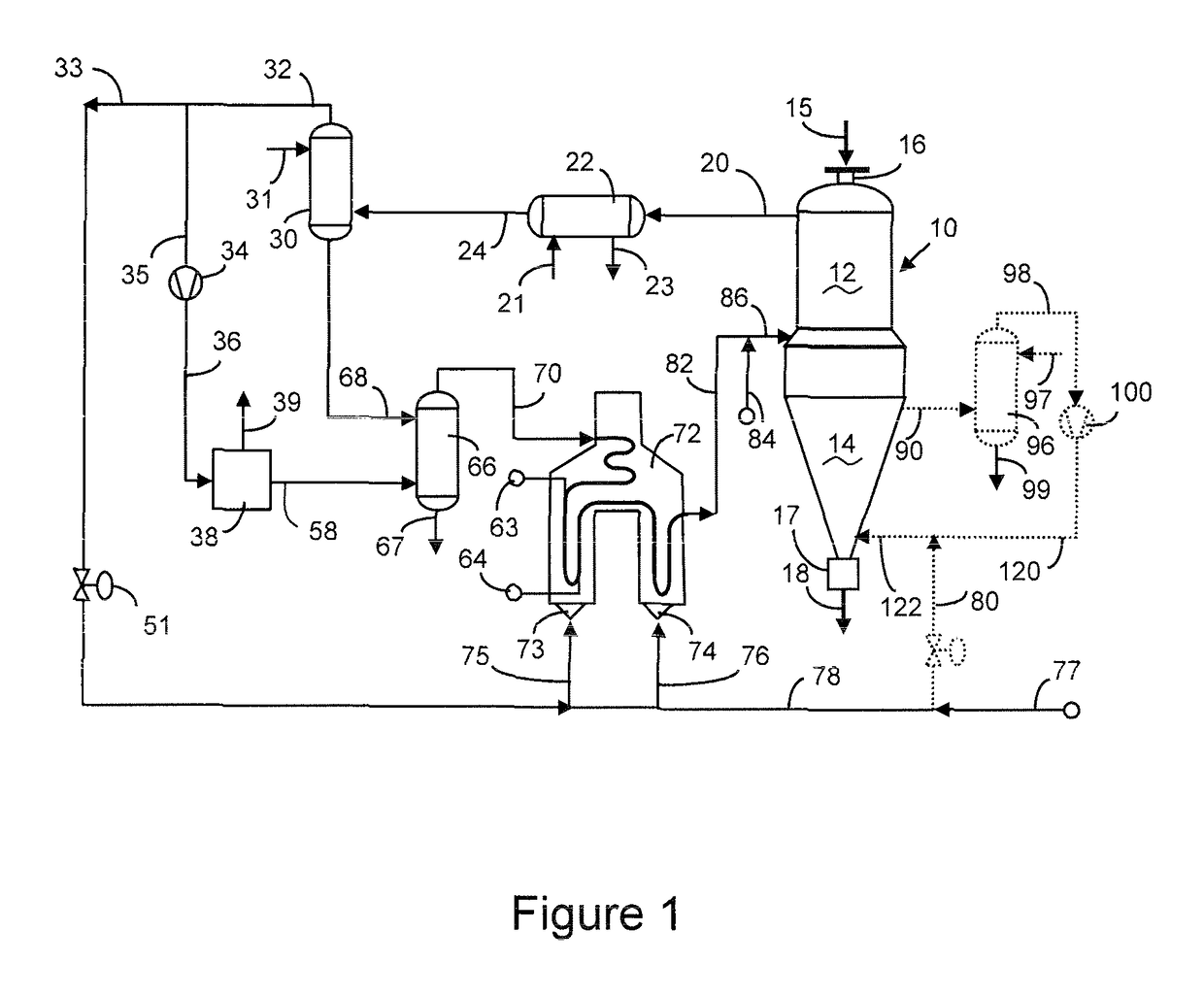

Method and apparatus for production of direct reduced iron (DRI) utilizing coke oven gas

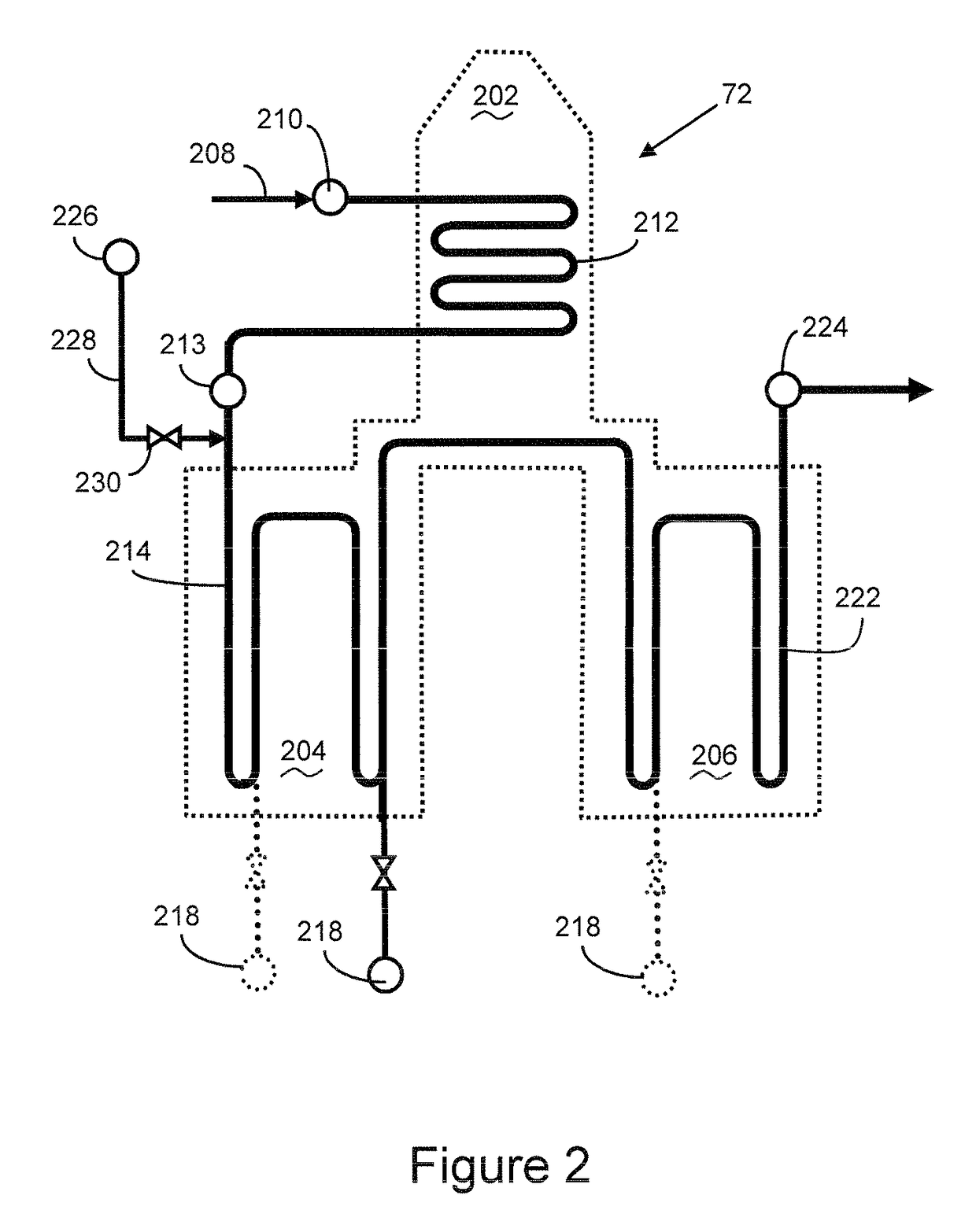

ActiveUS20150184264A1Minimize carbon depositionSolve fouling and cloggingThermal non-catalytic crackingBlast furnace detailsGas heaterOxygen

Direct reduction process and plant for producing DRI comprising a reduction reactor and at least one reducing gas heater typically comprising a convective heating section and a radiant heating section for raising the reducing gas temperature to a level adequate for iron oxides reduction to metallic iron, typically above 850° C., wherein the reducing gas fed to the reduction reactor comprises a stream of reducing gas recycled from the reduction reactor and a make-up stream of coke oven gas containing carbon compounds which may form carbon deposits in the heating path of said heater, namely BTX and other complex carbon compounds. The heater is provided with means for feeding oxidizing agents, for example steam, steam and air and / or oxygen at predetermined heating tubes successively for eliminating the carbon deposits which may form inside the heating tubes of said heater without interrupting the operation of the plant. The make-up stream of cold COG can be combined with the recycled gas at a point in the gas heating path of the heater where the tubes have a skin wall temperature of at least 700° C., or when the mixture of recycled gas and COG is at a temperature above 700° C. for minimizing clogging or fouling of heating equipment.

Owner:DANIELI & C OFF MEC SPA +1

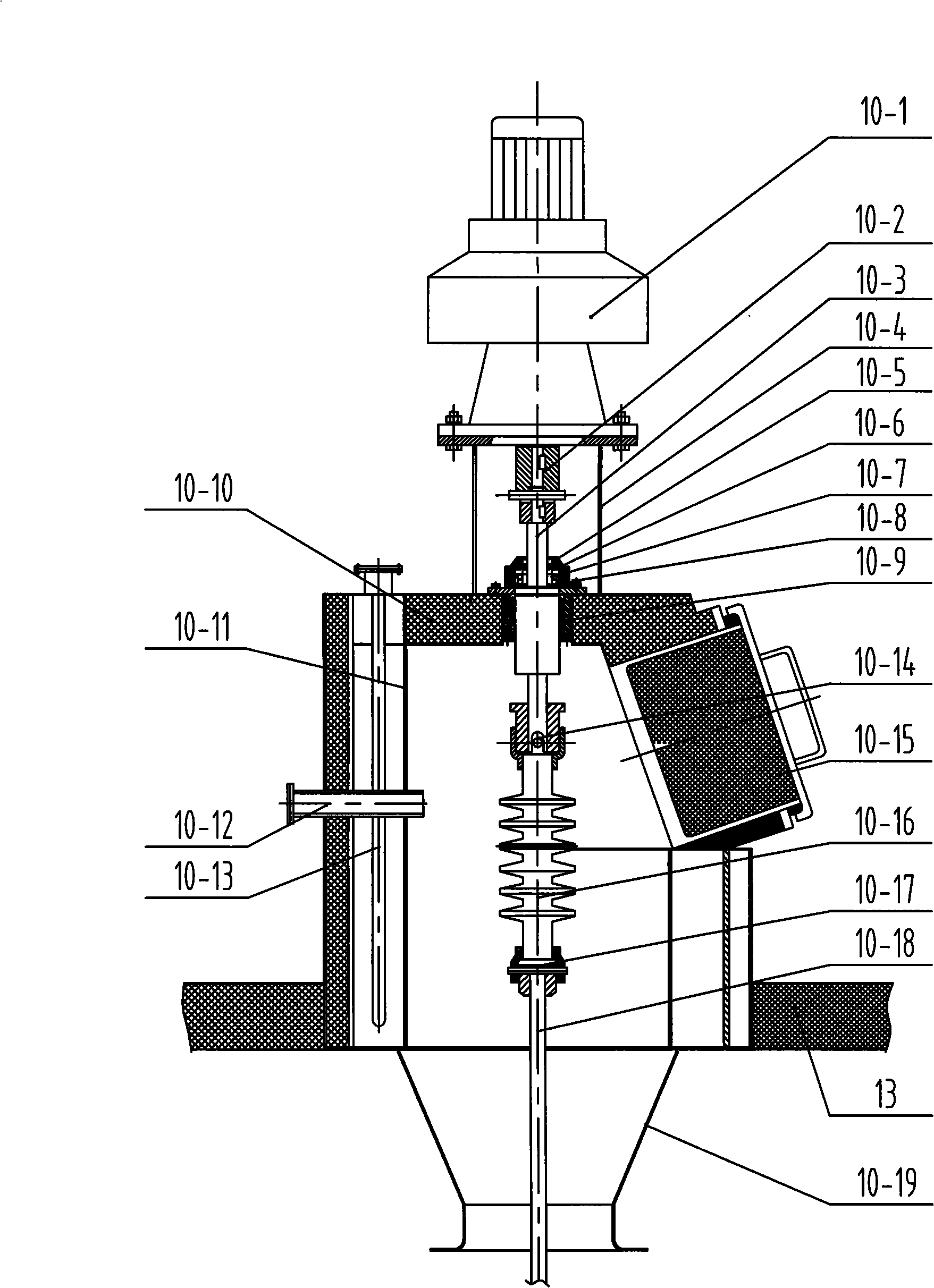

Flexible fiber spinning demisting device

InactiveCN103657266BImprove defogging efficiencySimple structureDispersed particle separationFlue gasEngineering

The invention relates to a flexible fiber spiral line demisting device, which solves the problems that the existing demising device has low demisting efficiency, the filter type demister is easy to block and the static demister is high in cost and large in occupied area and is corroded and scaled. According to the technical scheme, the flexible fiber spiral line demisting device comprises a gas inlet, a gas outlet and an exhaust cylinder of a liquid discharge pipe, wherein a motor is arranged on the vertical center line of the upper section of the exhaust cylinder; a rotating shaft of the motor is sleeved with a shaft sleeve; at least one layer of disc is arranged in the axis direction of the shaft sleeve; flexible fiber spiral lines are arranged on the disc; the flexible fiber spiral lines comprise a plurality of warps; one end of each warp is connected to the disc uniformly and the other end of each warp is a free end. The flexible fiber spiral line demisting device has the advantages of low resistance, high efficiency, no occupied area, no corrosion, no scaling and blockage, large flue gas treatment quantity, simple structure, light weight, low energy consumption and low cost.

Owner:JIANGHAN UNIVERSITY +2

Method and apparatus for production of direct reduced iron (DRI) utilizing coke oven gas

ActiveUS9725778B2Solve fouling and cloggingMinimizes the carbon depositsThermal non-catalytic crackingExhaust gas handlingGas heaterOxygen

Direct reduction process and plant for producing DRI comprising a reduction reactor and at least one reducing gas heater typically comprising a convective heating section and a radiant heating section for raising the reducing gas temperature to a level adequate for iron oxides reduction to metallic iron, typically above 850° C., wherein the reducing gas fed to the reduction reactor comprises a stream of reducing gas recycled from the reduction reactor and a make-up stream of coke oven gas containing carbon compounds which may form carbon deposits in the heating path of said heater, namely BTX and other complex carbon compounds. The heater is provided with means for feeding oxidizing agents, for example steam, steam and air and / or oxygen at predetermined heating tubes successively for eliminating the carbon deposits which may form inside the heating tubes of said heater without interrupting the operation of the plant. The make-up stream of cold COG can be combined with the recycled gas at a point in the gas heating path of the heater where the tubes have a skin wall temperature of at least 700° C., or when the mixture of recycled gas and COG is at a temperature above 700° C. for minimizing clogging or fouling of heating equipment.

Owner:DANIELI & C OFF MEC SPA +1

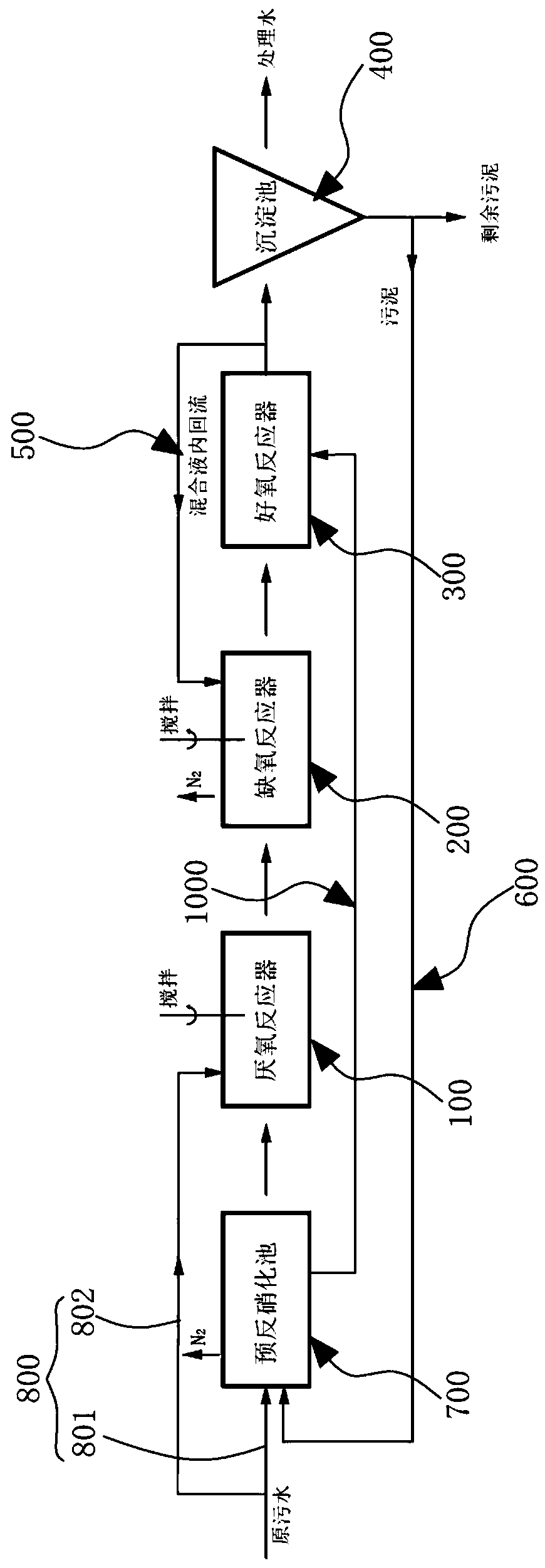

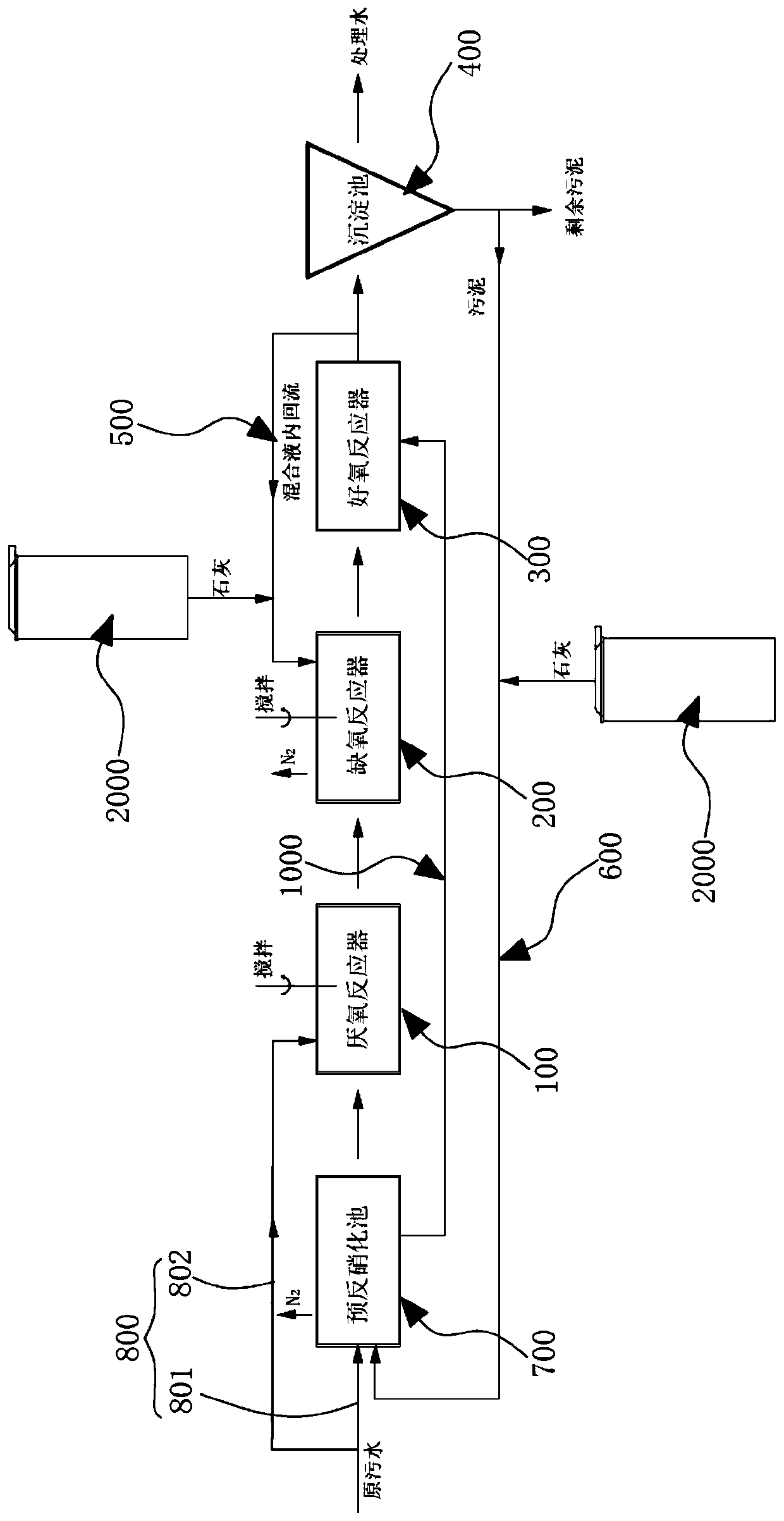

Improved AAO water treatment system and sewage processing method thereof

PendingCN110143726AImprove impactExquisite designWater treatment parameter controlTransportation and packagingWater treatment systemNitrate nitrogen

The invention discloses an improved AAO water treatment system and a sewage processing method thereof. The improved AAO water treatment system comprises an anaerobic reactor, an anoxic reactor, an aerobic reactor, and a settling tank, which are connected in sequence. The aerobic reactor is connected to the anoxic reactor through an inner backflow pipeline. The settling tank is connected to a pre-de-nitrification tank through a sludge outer backflow pipeline. The pre-de-nitrification tank is connected to the anaerobic reactor. The fluid inlet end of the pre-de-nitrification tank is connected toa first branch of a raw sewage inlet pipe, and a second branch of the raw sewage inlet pipe is connected to the anaerobic reactor. Compared with a conventional A2O method, a pre-de-nitrification tankis arranged before an anaerobic tank; the backflow sludge and raw sewage of a settling tank are introduced into the pre-de-nitrification tank; organic substances in the raw sewage are utilized by microbes as a carbon source to carry out de-nitrification; the performance of a conventional AAO system on reducing the influence of backflow nitrate is improved; the bad influence of nitrate nitrogen onanaerobic phosphorus release is eliminated; the phosphorus removing effect is ensured; and the nitrogen removing effect is guaranteed at the same time.

Owner:苏州新工环境工程技术有限公司

Organic waste liquid gasification furnace and waste gas treatment process

PendingCN110469858AIncrease in sizeIncrease contact areaEvaporator accessoriesIncinerator apparatusIndustrial wasteCorrosion

The invention discloses an organic waste liquid gasification furnace and a waste gas treatment process, belongs to the field of industrial waste gas treatment, avoids the situations of scaling and blockage of a nozzle during incineration, and solves the problem of corrosion of waste liquid to equipment. The organic waste liquid gasification furnace comprises a furnace body and a gasification chamber in the furnace body, wherein an air inlet channel and an air outlet channel which communicate with the gasification chamber are arranged in the furnace body; a waste liquid storage tank for storingthe waste liquid is arranged on the outer side of the furnace body and communicates with a waste liquid outlet at the bottom of the gasification chamber; an atomizing nozzle is arranged in the furnace body and used for atomizing the waste liquid in the waste liquid storage tank and then spraying the atomized waste liquid into the furnace body; and hot air is introduced into the air inlet channelto evaporate organic volatiles in the waste liquid mist, then the hot air is blown out of the air outlet channel along with the organic volatiles, and the incompletely gasified waste liquid flows backinto the waste liquid storage tank. The organic waste liquid gasification furnace and the waste gas treatment process can be applied to products of waste liquid treatment devices and the like.

Owner:杭州三祐环境科技有限公司

Brine pipeline scale inhibitor, and use and application method thereof

InactiveCN102795713BSolve fouling and cloggingReduce spawn rateScale removal and water softeningLower limitPolyaspartic acid

The invention relates to a brine pipeline scale inhibitor, composed of hydroxyethylidene-1,1-diphosphonic acid, an acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, polyaspartic acid (sodium) and polyacrylic acid. The brine pipeline scale inhibitor is capable of reducing the scaling tendency of salts such as calcium sulfate and calcium carbonate, forming stable complexes, promoting dissolving reaction and gradually dissolving the previous scale layer under excellent chelating, low limit inhibition and lattice distortion actions of organic phosphine and by means of excellent dispersing performance of the polymer to scales; and the brine pipeline scale inhibitor has scale inhibition and descaling functions and thereby is a good scale inhibitor for a brine delivery system.

Owner:明增安

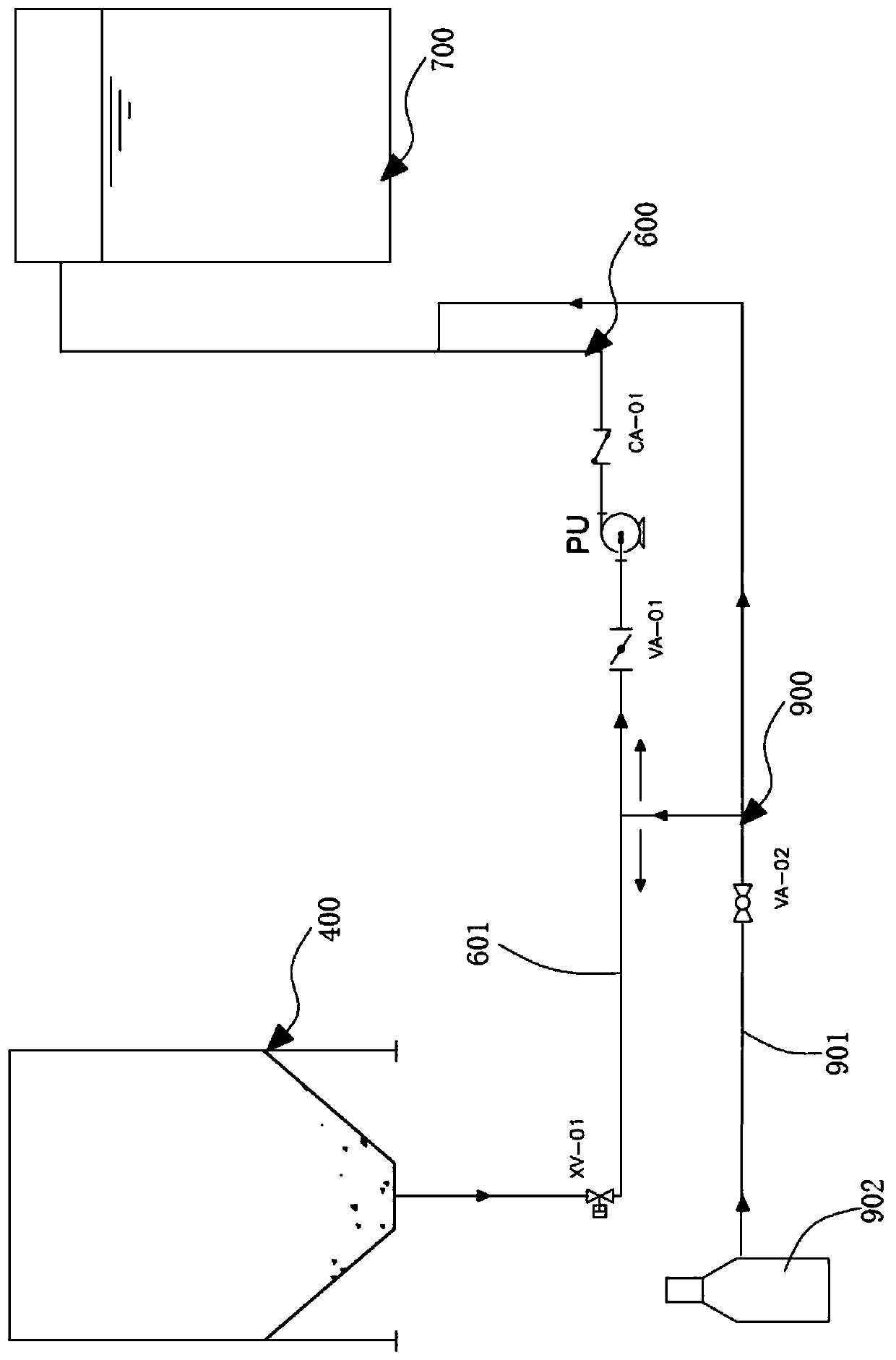

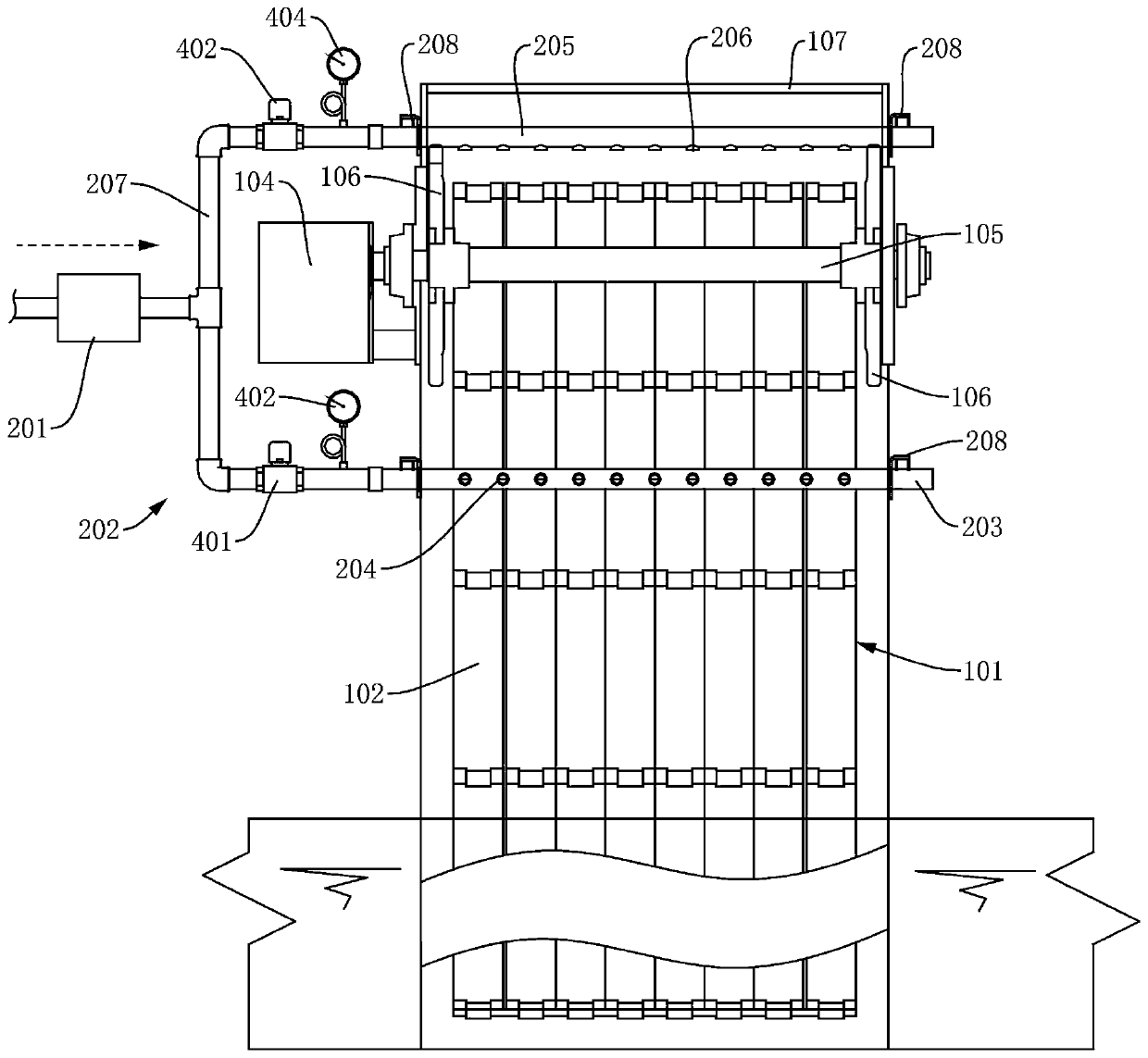

Flushing system, sewage treatment system and method for flushing screen plate

ActiveCN111495010AEasy to cleanSolve the blockageStationary filtering element filtersWater treatment systemRinse water

The invention relates to a flushing system, a sewage treatment system and a method for flushing a screen plate. The flushing system comprises a flushing pump and a flushing device body used for flushing the screen plate; a suction inlet of the flushing pump is used for being communicated with flushing water, a discharge outlet of the flushing pump is communicated with the flushing device body, andthe flushing device body is provided with a plurality of first nozzles used for flushing the inner side face of the screen plate and a plurality of second nozzles used for flushing the outer side face of the screen plate. The flushing system is compact in structure, the mode of combining inner side flushing and outer side flushing is adopted, the defect that only outer side back flushing is usedcan be overcome, and thus the cleaning effect of the screen plate is effectively improved; in a scene that water contains a viscous agent, the problem of blockage of filtering holes in the screen plate can be effectively solved, particularly the problems that in the prior art, the filtering holes of a conical structure are prone to blockage when only outer side flushing is adopted, and duct blockage is further compacted through outer side flushing water pressure can be effectively solved, and the flushing system is particularly suitable for occasions where the conical filtering holes are formed.

Owner:SCIMEE TECH & SCI CO LTD

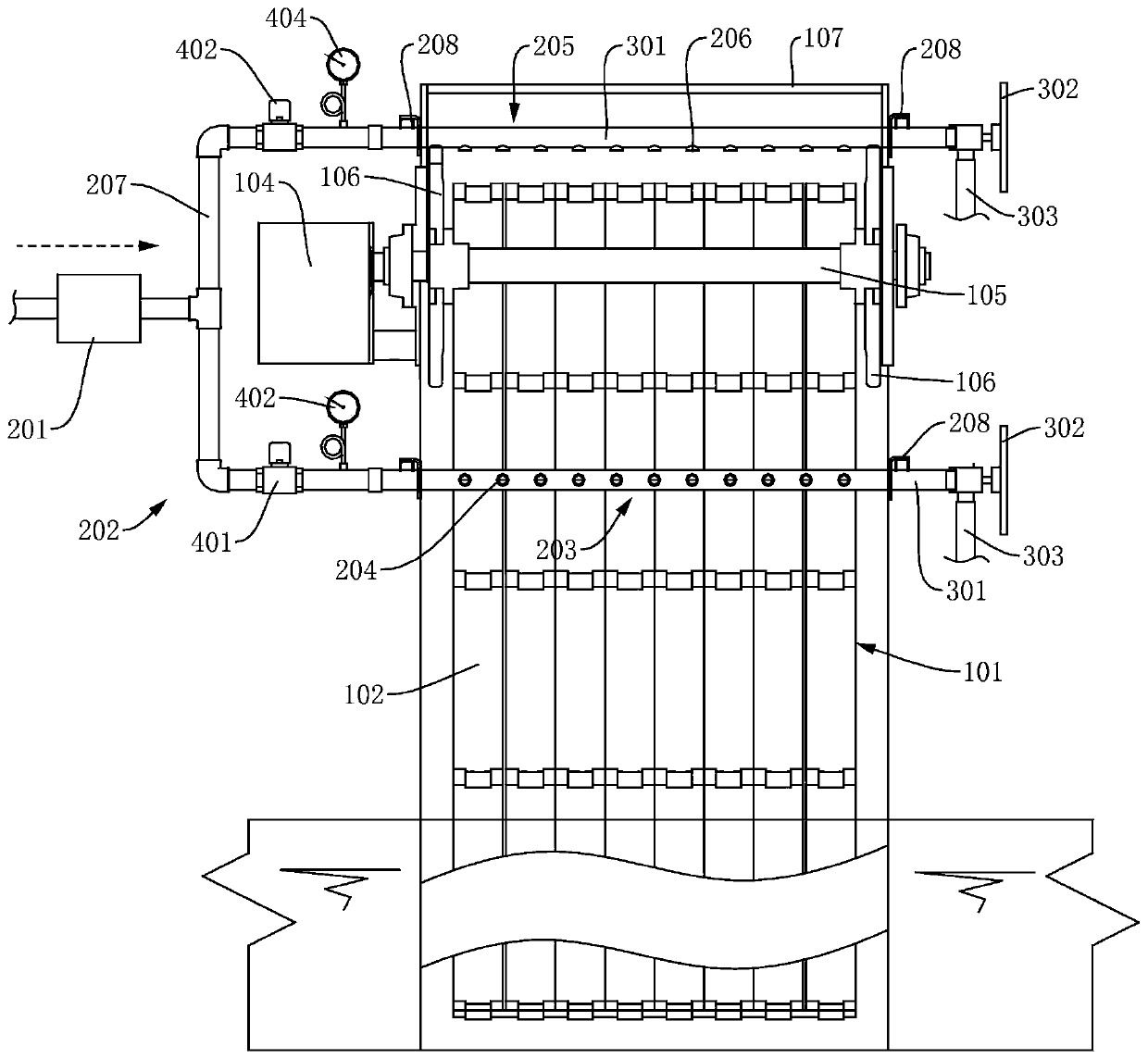

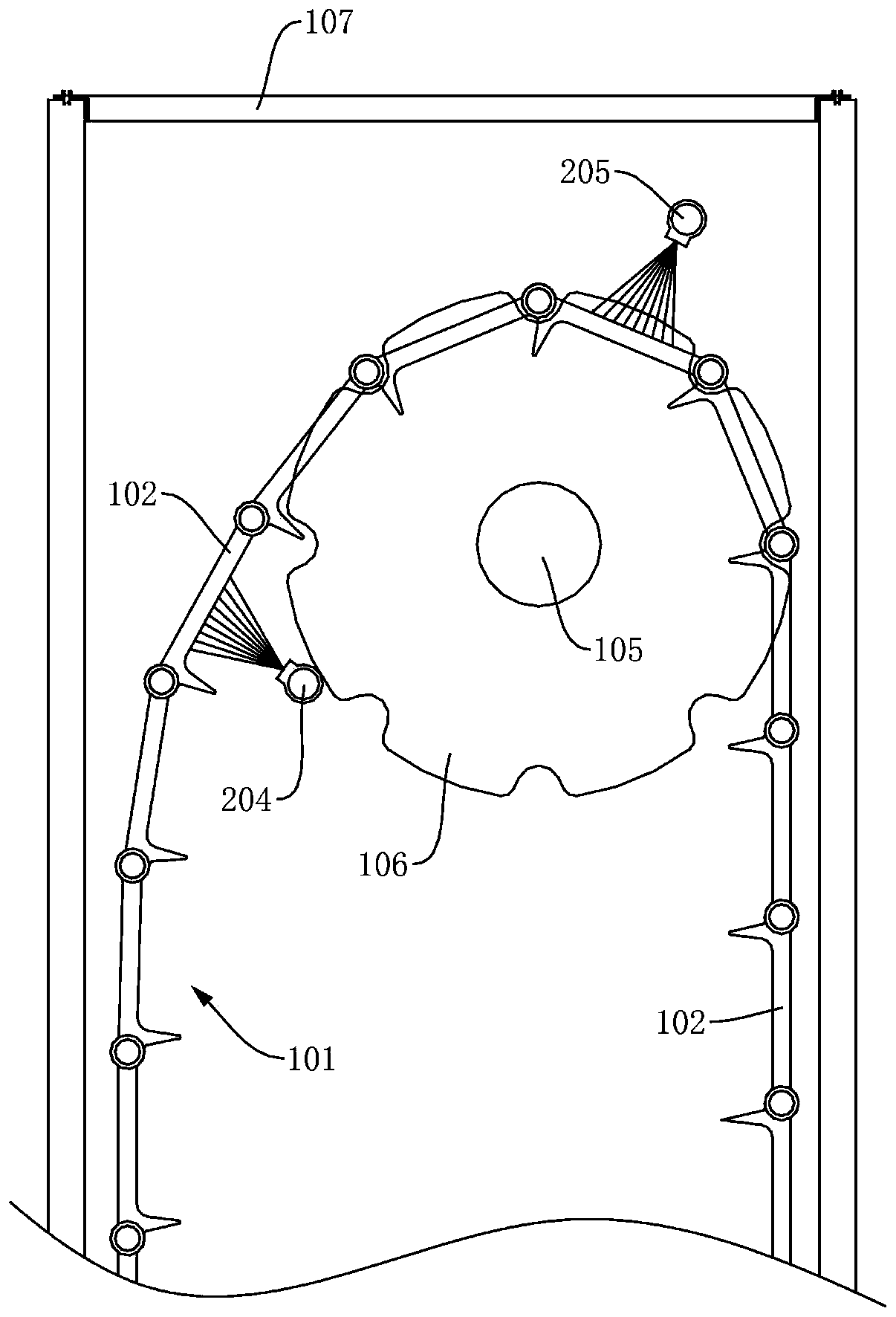

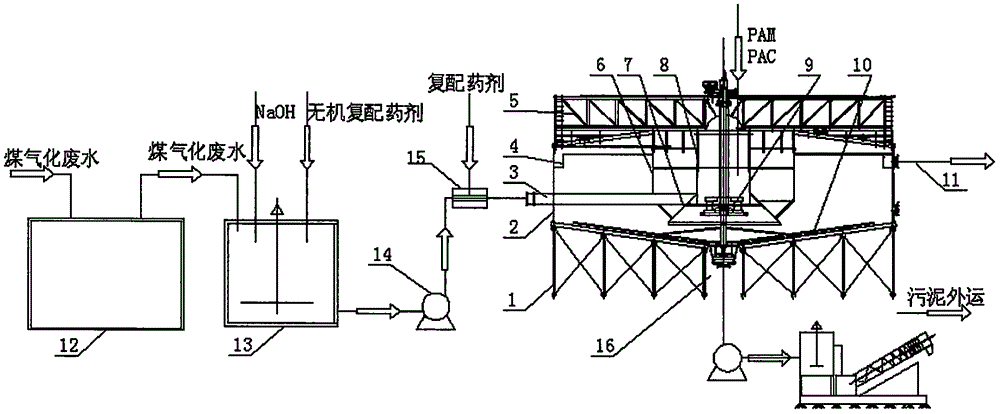

Synchronous calcium-magnesium-silicon removal pretreatment device of coal chemical industry wastewater and application method

InactiveCN105884080ASynchronous and efficient silicon removalSynchronous and efficient hardeningWater contaminantsWater softeningSocial benefitsWastewater

The invention discloses a synchronous calcium-magnesium-silicon removal pretreatment device of coal chemical industry wastewater and an application method. The device comprises a wastewater collection pool, a first-level reaction tank and an integrated clarifier, wherein the wastewater collection pool receives the coal chemical industry wastewater and is communicated with the first-level reaction tank through a pipeline; and after being treated in the first-level reaction tank, the coal chemical industry wastewater is input into a second-level reaction chamber in the integrated clarifier through a pump and a liquid medicine mixer for mixing reaction and settling separation. The synchronous calcium-magnesium-silicon removal pretreatment combined device of coal chemical industry wastewater is simple and stable in structure; and given the needs of vigorous development of the national coal chemical industry, the device disclosed by the invention has a broad market prospect, and good economic and social benefits are to be brought for sure.

Owner:宜兴市荣盛达环保有限公司 +2

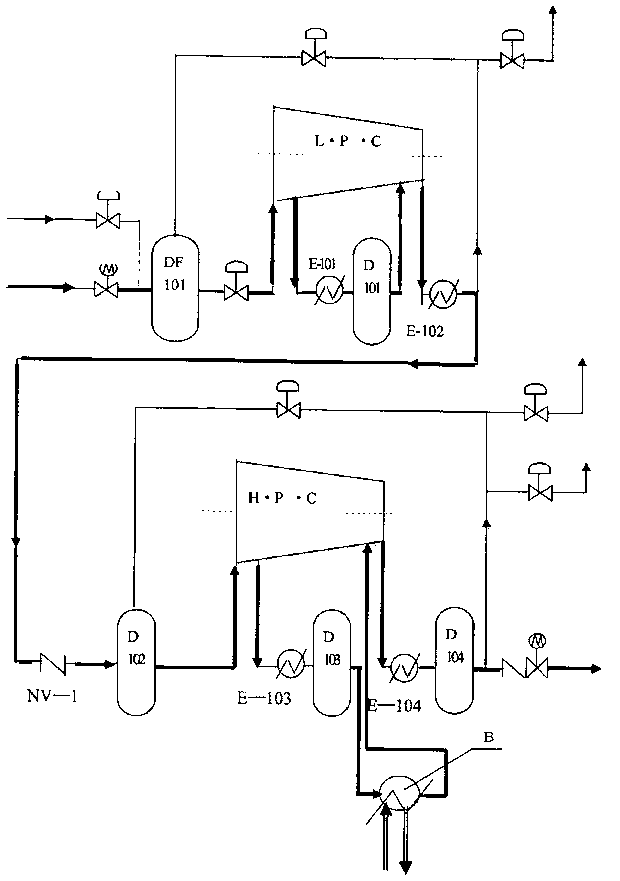

Inter-section scale inhibition method for centrifugal natural gas compressor set

InactiveCN102996489AOvercome congenital deficienciesSolve fouling and cloggingPump componentsPumpsImpellerHydrocarbon dew point

An inter-section scale inhibition method for a centrifugal natural gas compressor set includes a method a, a method b or a method c. A heat exchanger is additionally arranged at the position between an inter-section separator outlet to a next section first stage impeller inlet, an outlet pipeline at the back of a scaling section of the centrifugal natural gas compressor set is connected with an inlet of the additionally arranged heat exchanger, an outlet of the additionally arranged heat exchanger is connected with an inlet of a cooler through a pipeline, an outlet of the cooler is connected with an inlet of a separator, an outlet of the separator is connected with an inlet of a heat exchange coil pipe arranged in the heat exchanger, and an outlet of the heat exchange coil pipe is connected with an inlet of a scaling section first stage impeller. High-temperature natural gases at an outlet behind the scaling section and low-temperature natural gases emitted from the separator are exchanged, and temperature at the separator outlet after heat exchange compensates external temperature loss and is higher than the critical temperature for generating the water dew point and the hydrocarbon dew point.

Owner:CHINA PETROLEUM & CHEM CORP +1

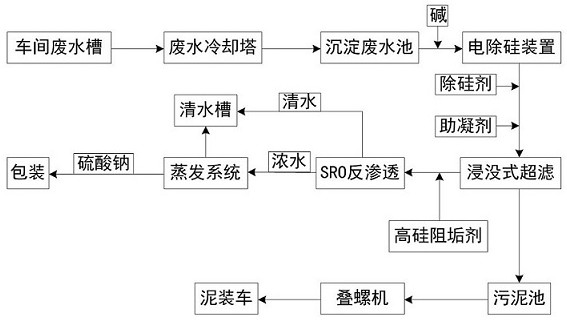

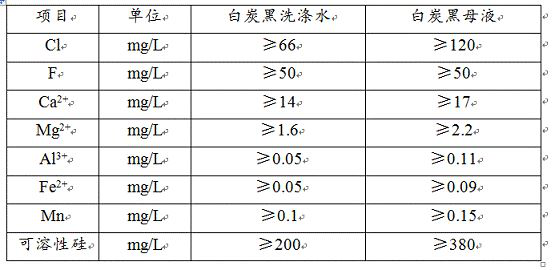

Process method for treating precipitated white carbon black wastewater

ActiveCN111807596AAchieving "zero" emissionsExtended use timeSludge treatmentWater contaminantsReverse osmosisWastewater

The invention discloses a process method for treating precipitated white carbon black wastewater. The method comprises the following steps of: carrying out electrolytic silicon removal treatment on pretreated precipitated white carbon black wastewater through an electrolytic silicon removal device; performing ultrafiltration treatment on the wastewater subjected to electrolytic silicon removal through an immersed ultrafiltration membrane assembly to obtain ultrafiltered water; performing reverse osmosis treatment on the ultrafiltered water through an SRO reverse osmosis system to obtain clearwater and concentrated water; and sending the concentrated water to an evaporation system for evaporation treatment to obtain anhydrous sodium sulfate. Experiments prove that compared with the prior art, the process method has the advantages that soluble silicon in the precipitated white carbon black wastewater can be effectively removed, the problems of scaling and blockage of an ultrafiltrationmembrane and a reverse osmosis membrane are well solved, the service life of the membranes is greatly prolonged, the treatment cost is reduced, and zero emission of the precipitated white carbon blackwastewater is realized.

Owner:JIANGXI BLACK CAT CARBON BLACK CO LTD

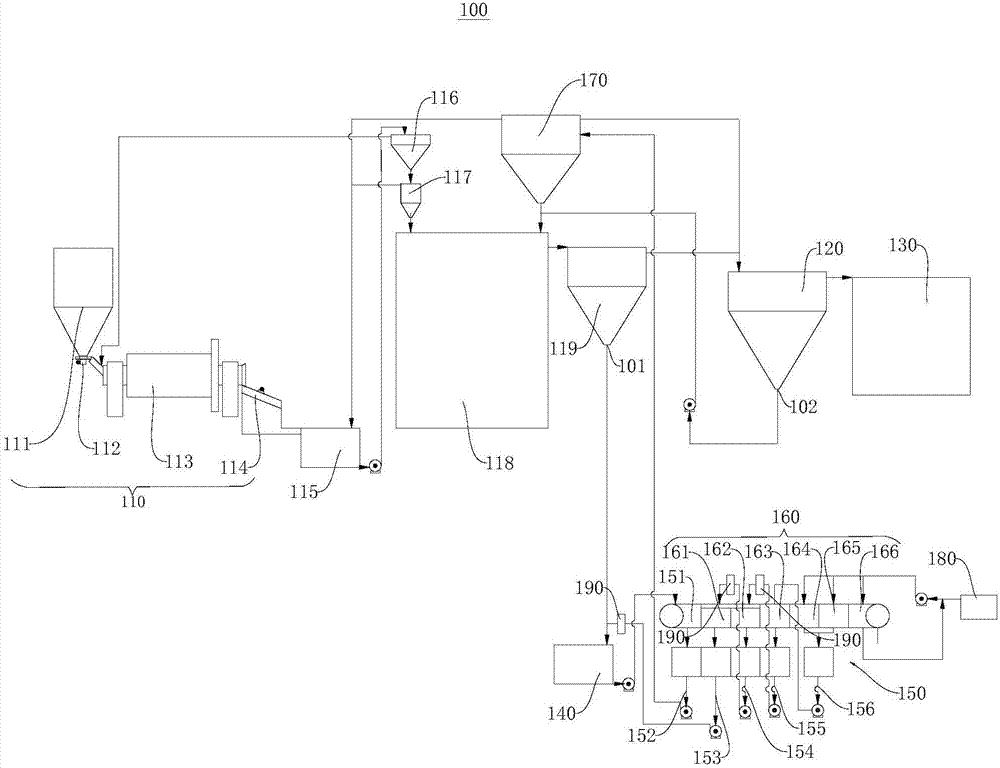

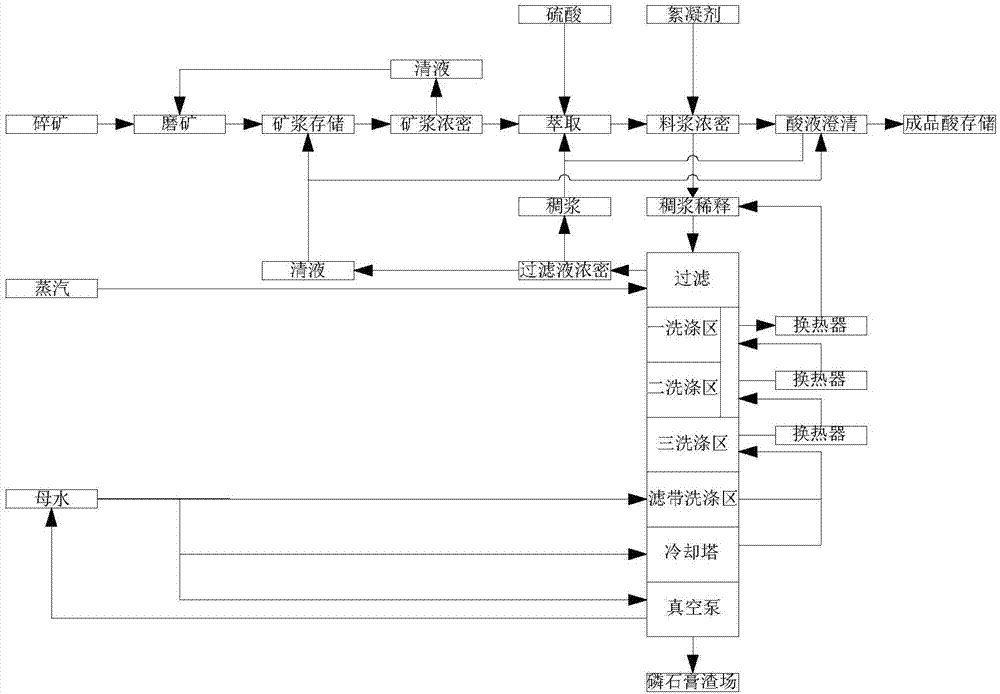

Wet phosphoric acid production system and wet phosphoric acid production method

ActiveCN106882776ASolve fouling and cloggingReduce damage ratePhosphoric acidProcess optimizationPhosphoric acid

The invention relates to the field of chemical engineering, and particularly discloses a wet phosphoric acid production system and a wet phosphoric acid production method. The wet phosphoric acid production system comprises mineral aggregate conveying equipment, an ore pulp storage tank, an ore pulp thickening tank, an ore pulp overhead tank, an extraction tank, a slurry thickening tank, a phosphoric acid clarification tank and a phosphoric acid storage tank. A thick slurry outlet of the slurry thickening tank is communicated to a material inlet of a thick slurry diluting tank, so that filtering and cleaning equipment does not participate in filtering of phosphoric acid stock solution, and only filters diluted slurry separated through a slurry thickener. The problems of scaling and blockage of a filter and relevant pipelines are effectively solved. By process optimization, the production efficiency is greatly improved, and the equipment utilization rate is increased; the production unit production of a product can be reduced. The wet phosphoric acid production method makes use of the wet phosphoric acid production system, so that during wet phosphoric acid production, the production efficiency is high.

Owner:胡士清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com