Application of sugar-mill lime sludge in wet flue gas desulfurization

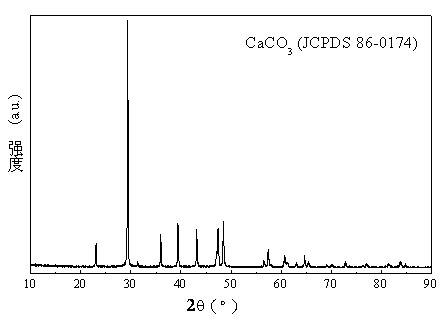

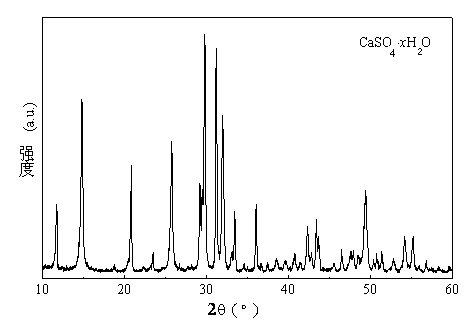

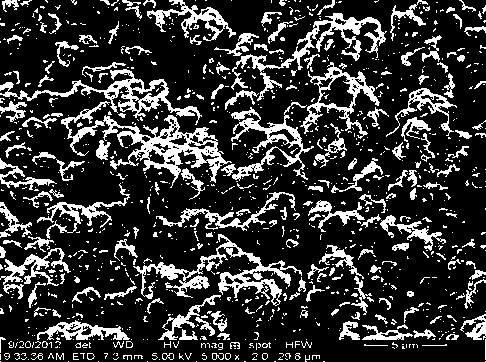

A technology for filtering mud and wet desulfurization in a sugar factory is applied in the field of solid waste resource utilization, which can solve the problems of low economic benefit and complicated process, and achieve the effects of high economic and social benefits, high purity and strong adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Desulfurize the flue gas produced by two 75 t / h circulating fluidized bed coal-fired boilers in a thermal power plant. The flue gas temperature is 135°C and the flow rate is 189,000 m 3 / h, SO 2 The concentration is 3000 mg / Nm 3 .

[0029] 1. Preparation of slurry: Mix the wet filter mud discharged from the sugar factory with 10 mass times of water and stir to make a slurry.

[0030] 2. After preparing the slurry, desulfurize the flue gas according to the conventional steps of the limestone-gypsum desulfurization process. The difference is that the desulfurization agent (that is, the absorbent) used is the slurry prepared in the above step 1, and the calcium-sulfur ratio is controlled during desulfurization. for 1-1.1.

[0031] After desulfurization treatment, SO in the flue gas 2 The concentration is 90 mg / Nm 3 , calculate the desulfurization rate: desulfurization rate = (3000?90) / 3000 × 100% = 97%.

Embodiment 2

[0033] Desulfurize the flue gas produced by two 75 t / h circulating fluidized bed coal-fired boilers in a thermal power plant. The flue gas temperature is 135°C and the flow rate is 189,000 m 3 / h, SO 2 The concentration is 5750 mg / Nm 3 .

[0034] 1. Preparation of slurry: Mix the wet filter mud discharged from the sugar factory with 12 mass times of water and stir to make a slurry.

[0035] 2. After preparing the slurry, desulfurize the flue gas according to the conventional steps of the limestone-gypsum desulfurization process. The difference is that the desulfurization agent (that is, the absorbent) used is the slurry prepared in the above step 1, and the calcium-sulfur ratio is controlled during desulfurization. for 1-1.1.

[0036] After desulfurization treatment, SO in the flue gas 2 The concentration is 200 mg / Nm 3 , calculate the desulfurization rate: desulfurization rate = (5750? 200 / 5750) × 100% = 96.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com