Patents

Literature

138 results about "Sugar mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite microbial inoculum organic multielement compound fertilizer and production method thereof

ActiveCN102690151AImprove physicsGood biological propertiesFertilizer mixturesThiobacillus ferrooxidansBran

The invention discloses a composite microbial inoculum organic multielement compound fertilizer which is prepared from microbial inoculum, organic component and inorganic fertilizer. The microbial inoculum is a composite microbial inoculum which comprises the following three types of microbial inocula: resource type microbial inoculum, which contains Bacillus megaterium, thiobacillus thiooxidans, Bacillus mucilaginosus and Bacillus circulans; environment-friendly microbial inoculum, which contains Arthrobacter and Alcaligenes; and antibiotic microbial inoculum, which contains Streptomycs micuoflavus and Streptomyces jingyangensis. The organic component is one or more of cereal crop straw, subsidiary agricultural product dreg, sugar mill bagasse, bran coat, municipal and rural domestic waste, and livestock and poultry dung. The inorganic fertilizer is one or more of nitrogen fertilizer, phosphate fertilizer, potash fertilizer and medium / micro-nutrient element fertilizer. The weight proportion of microbial inoculum to organic constituent to inorganic fertilizer is (5-25):(18-28):(47-77).

Owner:赵大伟

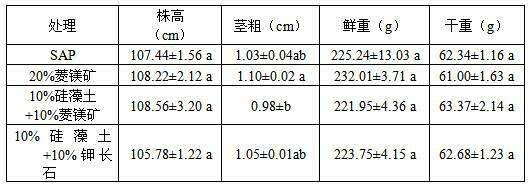

Superabsorbent composite and preparation method thereof

InactiveCN102321486AImprove water absorptionImprove water retentionOrganic fertilisersSoil conditioning compositionsSludgePolyacrylamide

The invention discloses a superabsorbent composite and a preparation method thereof. The superabsorbent composite disclosed by the invention comprises a conventional polyacrylamide or polyacrylate water-retaining agent or a mixture of a water absorbent (SAP) and an auxiliary material; the auxiliary material is an organic and / or inorganic auxiliary material; the organic auxiliary material is one or the mixture of restaurant sludge, municipal sludge, beer filtered mud, sugar mill mud, paper mud and plant residues; and preferably, the inorganic auxiliary material is one or the mixture of bentonite, zeolite, potassium feldspar, kieselguhr, magnesite and carbamide. In the invention, the superabsorbent composite is prepared by using a simple mixing and synthesis processing method through adding the cheap auxiliary material with a better cooperation effect with the SAP; the superabsorbent composite has the advantages of good water absorption and water retaining effects and low cost; and the method disclosed by the invention is simple and practical and has significant meanings in actual promotion and application.

Owner:SOUTH CHINA AGRI UNIV

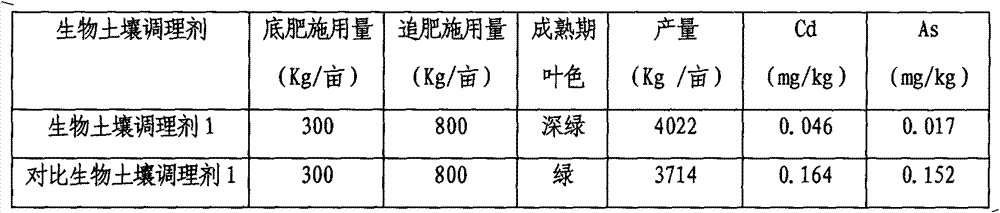

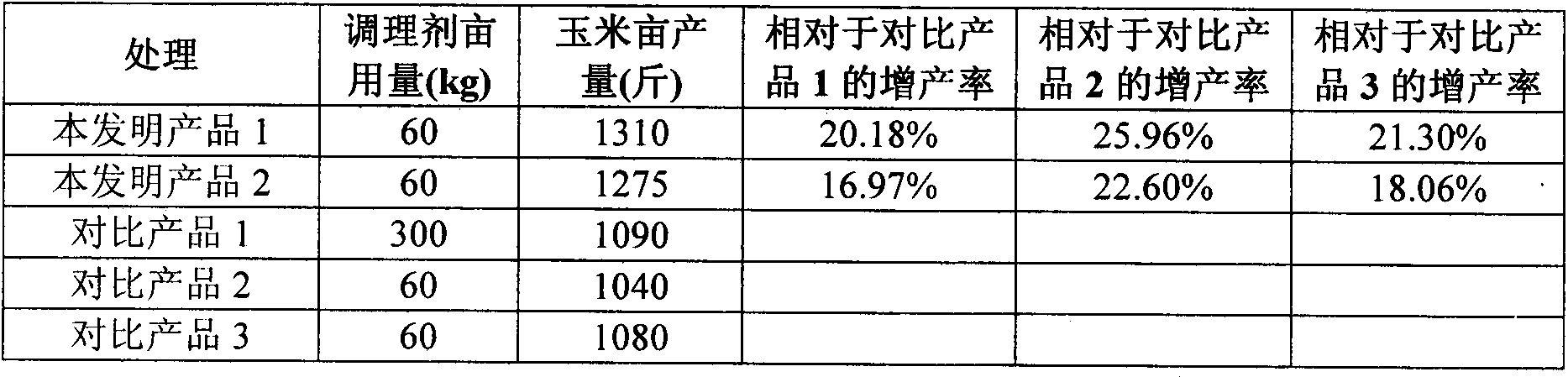

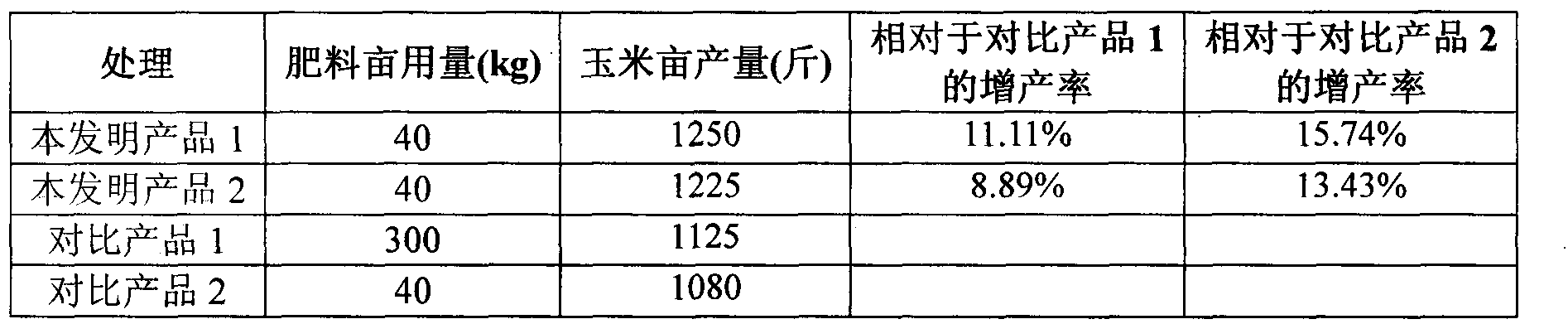

Biological soil conditioning agent containing sugar mill alcohol waste liquid, filter residue or peat

ActiveCN103113170AOptimal Structural BalanceIncrease productionClimate change adaptationBioloigcal waste fertilisersLiquid wasteMicroorganism

The invention relates to a biological soil conditioning agent containing sugar mill alcohol waste liquid, filter residue or peat. The biological soil conditioning agent is characterized by being prepared from sugar mill alcohol waste liquid treated by acid and alkali treatment, peat and sugar mill filter residue obtained from microorganism fermentation, wherein the ratio of the sugar mill alcohol waste liquid treated by the acid and alkali treatment, the peat and the sugar mill filter residue obtained from the microorganism fermentation is (2000-5000): (100-300): (500-800) in parts by weight. The biological soil conditioning agent disclosed by the invention can provide balanced influence on the crops and can optimize structural balance of the soil, and can maintain sufficient soil nutrition for a long period and improve crop yield. And furthermore, the biological soil conditioning agent disclosed by the invention can additionally reduce heavy metal content in the crops.

Owner:叶长东

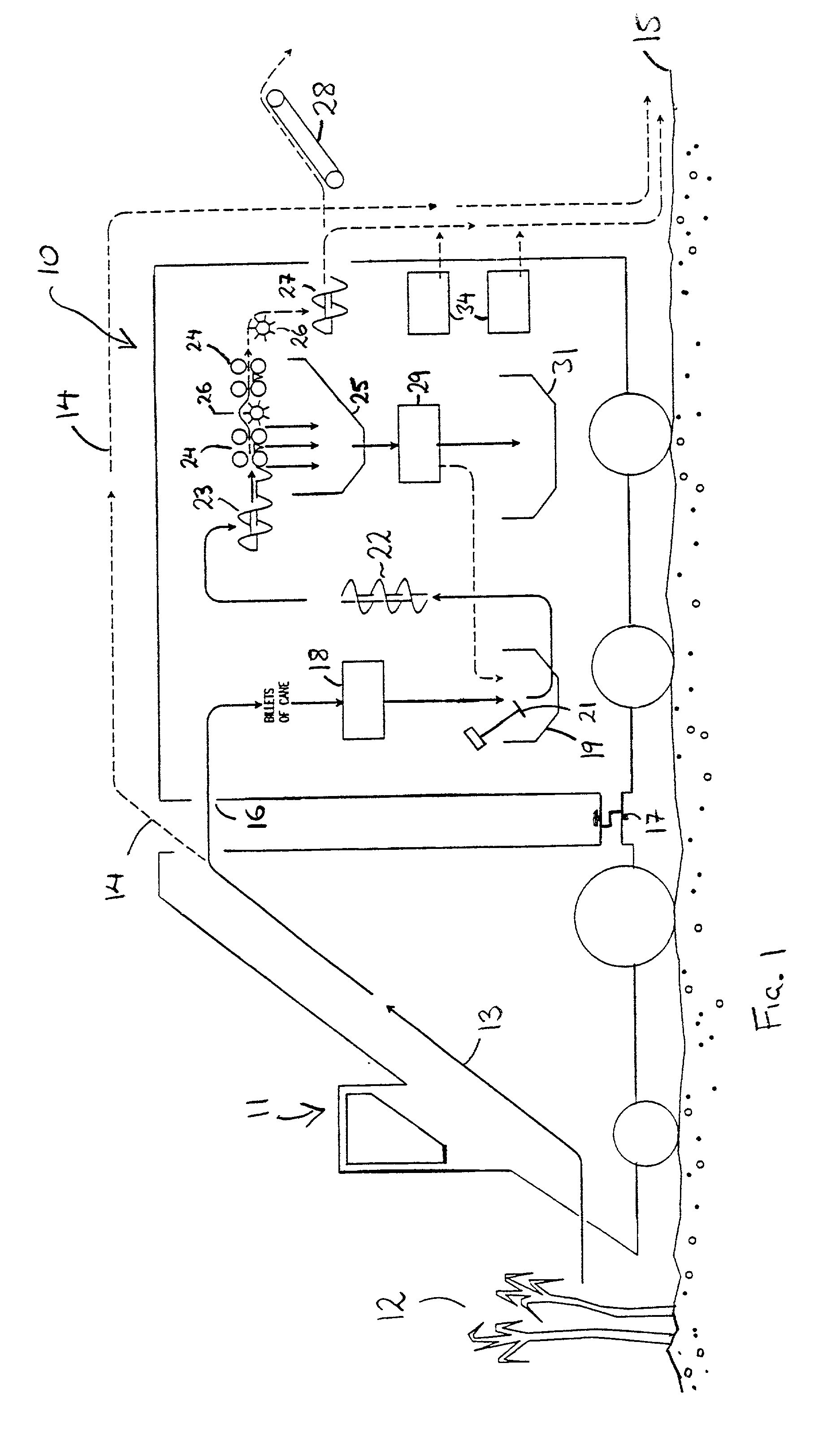

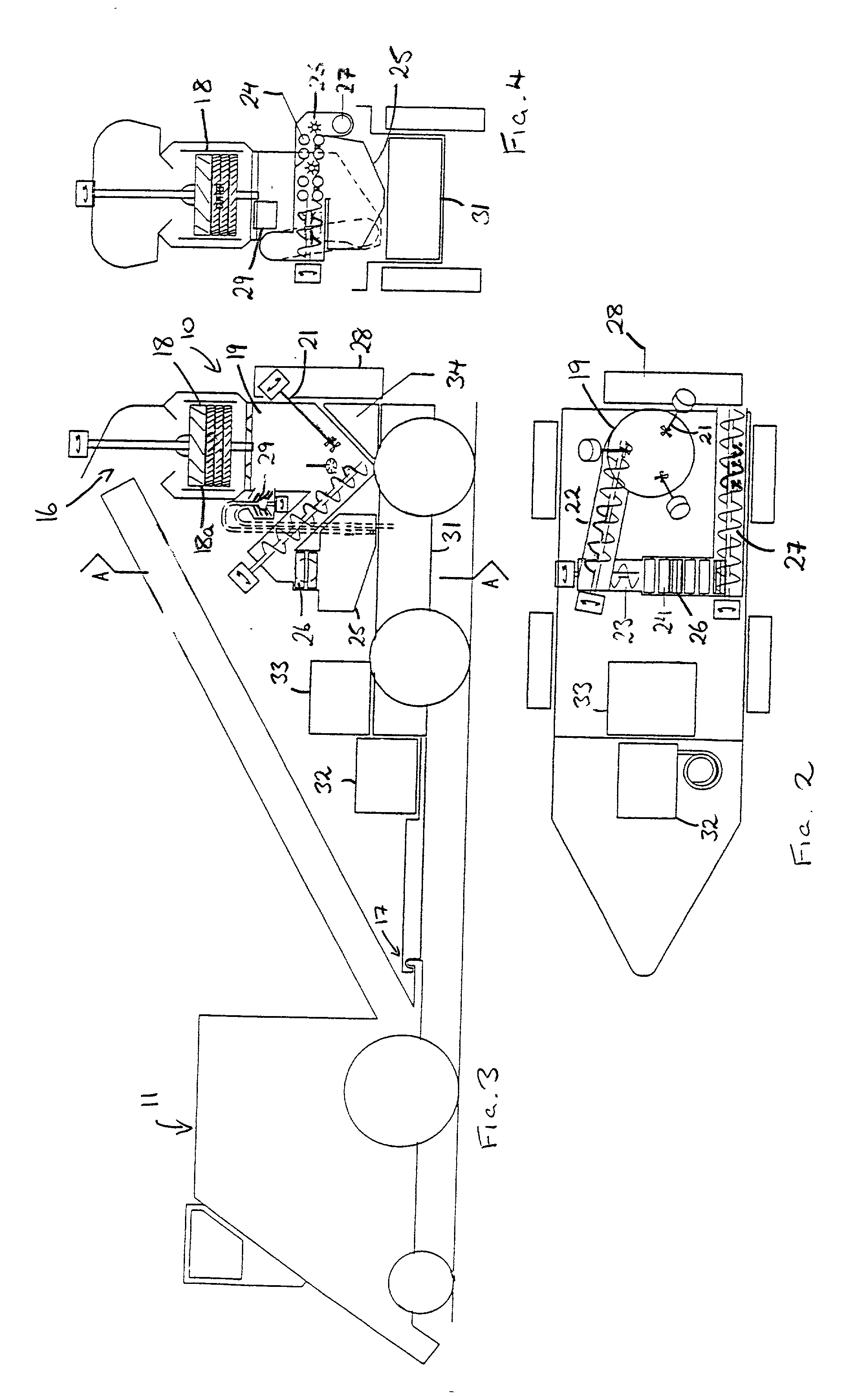

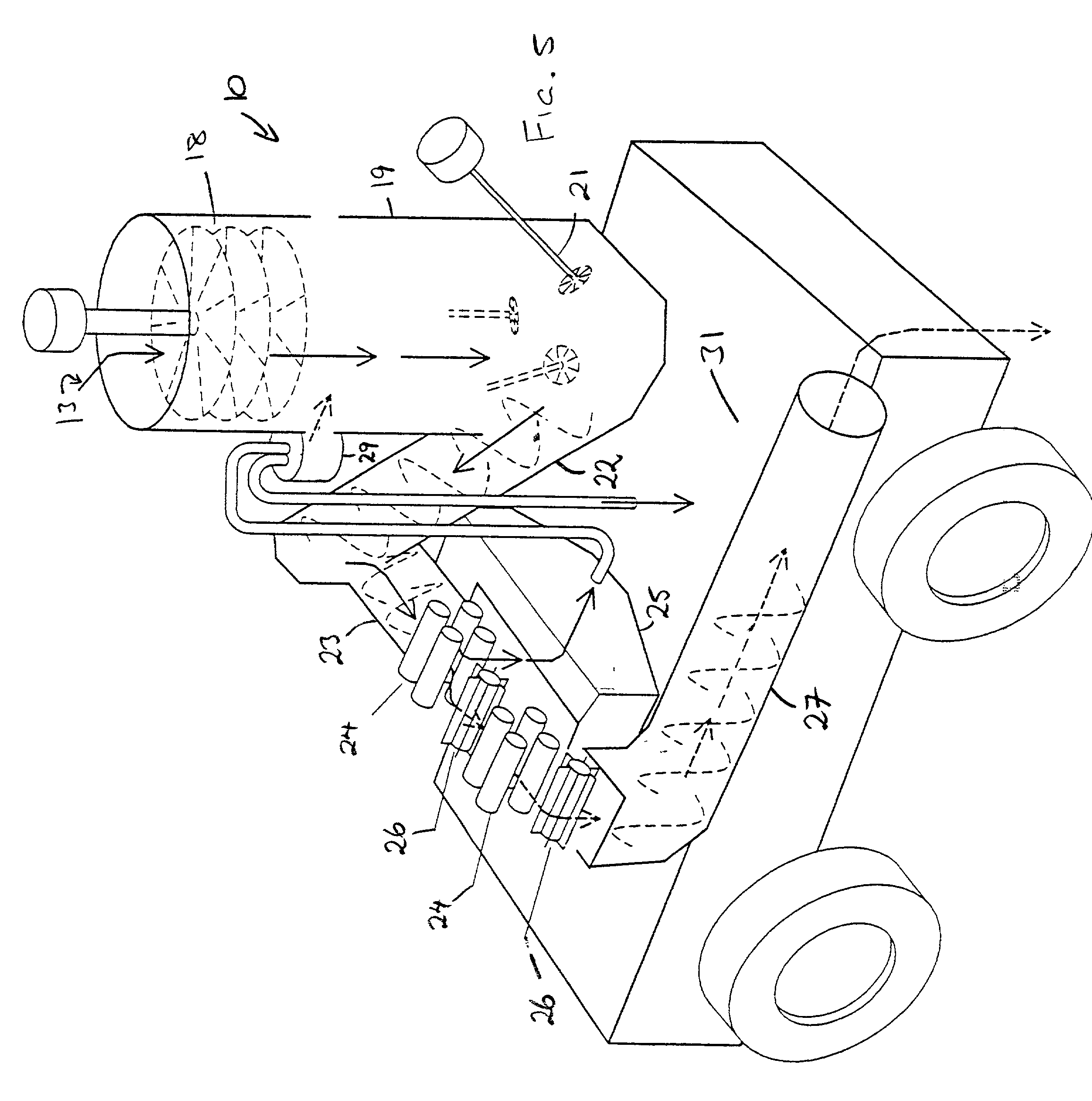

In-field sugar cane processor

An apparatus and method for extracting sugar-containing juice from sugar-containing plant matter, such as sugar cane. The apparatus is adapted to be installed in or near the field in which the plant matter is to be harvested. The apparatus comprises an inlet means for receiving the plant matter, a comminuting means for finely comminuting the received plant matter, and a separating means for separating the sugar-containing juice from the finely comminuted plant matter. Use of the apparatus at or near the site of harvest reduces the quantity of fibrous material transported to the sugar mill. It also allows return to the field of much of the fibrous matter that is at present lost in the harvesting process.

Owner:BIOMASS TECH PTY LTD

Special organic/inorganic compound fertilizer for sugarcane produced by use of filter mud from sugar factory

InactiveCN103288522AIncrease profitImprove fertilizer efficiencyFertilizer mixturesAgricultural engineeringSugar mill

The invention discloses a special organic / inorganic compound fertilizer for sugarcane produced by use of the filter mud from a sugar factory. The special organic / inorganic compound fertilizer is prepared from the following raw materials in percentage by weight: 4.17-42.87% of urea, 11.52-60.87% of calcium superphosphate or calcium magnesium phosphate, 3.33-16.66% of potassium chloride and 25.0-37.5% of dry filter mud. The special organic / inorganic compound fertilizer is prepared by the following steps of: (1) stacking the filter mud for natural fermentation; rotting the stacked filter mud for ripening from top to bottom; spreading the rotten filter mud; drying in the sunlight until the water content is 15-25%, and grinding the filter mud by a grinder; adding nitrogen, phosphorus and potash fertilizer into the filter mud after fermentation and grinding according to the proportion of the raw materials; mixing and then grinding, granulating, drying, cooling and screening; and packaging to obtain a finished product. The special organic / inorganic compound fertilizer disclosed by the invention has the advantages of long fertilizer efficiency, soil improvement, soil fertility improvement, avoidance of soil hardening and the like, can effectively improve the yield per unit by 0.5-1.0 ton of sugarcane and the sugar content of the sugarcane by 0.5-1.0%, and also can improve the utilization rate of the chemical fertilizer by 3-5%.

Owner:云南中蔗农业科技有限责任公司 +1

Fertilizer special for guava and production method of fertilizer

InactiveCN104829399AImprove qualityProportion content is reasonableFertilizer mixturesRoot growthPhosphate

The invention discloses fertilizer special for guava and a production method of the fertilizer. The fertilizer comprises, by weight, 30-50 parts of decomposed organic fertilizer, 15-20 parts of potassium dihydrogen phosphate, 2-8 parts of urea, 12-18 parts of plant ash, 10-15 parts of lime and 1-3 parts of trace element fertilizer, wherein the decomposed organic fertilizer is the product obtained by adding strains into sisal hemp residues, sugar factory alcohol waste liquid, sugarcane filtered mud and bagasse pith to perform fermentation; the trace element fertilizer includes iron, zinc and boron. The fertilizer special for guava has the advantages that the fertilizer is reasonable in nitrogen, phosphorus and potassium proportion and contains the trace element fertilizer; when the fertilizer is applied, shoot robustness can be achieved, flowering and fruiting can be promoted, soil can be improved, root growth can be promoted, guava quality can be increased at the same time, and guava tree yield can be increased.

Owner:杨芳

Method for producing microbial agent by using filter mud of sugar mills through fermentation

InactiveCN102924133ASimple processLow costBio-organic fraction processingOrganic fertilisersBiosphereMicrobial agent

The invention provides a method for producing a microbial agent by using filter mud of sugar mills through fermentation, belonging to the field of the production technology of the microbial agents. The method can produce the high quality microbial agent and treat the pollutions caused by the industrial waste filter mud of the sugar mills at the same time, and also can achieve the circulating economic benefits for the sugar industries. The method comprises the steps of mixing the filter mud of the sugar mills, weathered coal of the humic acid or grass carbon and dried straw to obtain a mixture, controlling the water content of the mixture to 33%-70%, adding the microbial agent into the mixture at a mass ratio of 2% of the microbial agent to the mixture, rapidly stirring to form a homogeneous mixture, loading into a sealing bag, and carrying out anaerobic fermentation for 10 days at a room temperature of the south of China to obtain the microbial agent with an effective living bacteria number being greater than or equal to 300 million / g (higher than the national standard of 200 million / g). According to the invention, the method has the advantages of low cost, simple operation and high product quality, achieves the effective resource utilization through converting the filter mud of the sugar mill into a treasure, solves the problem of the environmental pollution and saves high environmental protection cost for the sugar industries, and brings good economic benefits at the same time, which can form a closed biosphere of the sugar production; and the biosphere creates circulating economic benefits, and brings rich rewards to the sugar industries and the sugarcane farmers.

Owner:王天喜 +1

Method for preparing active humic acid liquor by utilizing alcohol slops of sugar house, its product and application

InactiveCN1535936AReduce stimulationReduce consumptionClimate change adaptationBioloigcal waste fertilisersLiquid wasteAccelerant

The present invention relates to a method for preparing active humic acid liquor by utilizing alcohol slops of sugar mill, its product and application. The method includes the following steps: clearing alcohol slops of sugar mill, making calcium salt and other non-soluble substances in the slops be precipitated to obtain supernatant fluid, evaporating said supernatant fluid at lowest temp. to obtain concentrated liquor, adding halogen oxide into the concentrated liquor and stirring them in the reactor at room temperature and making activation to obtain the active humic acid liquor. Said invented active humic acid liquor can be directly used as accelerator for accelerating seed germination and rootage, also can be made into various fertilizes for vegetables and fruit tree.

Owner:越百年创新肥业(海南)有限公司

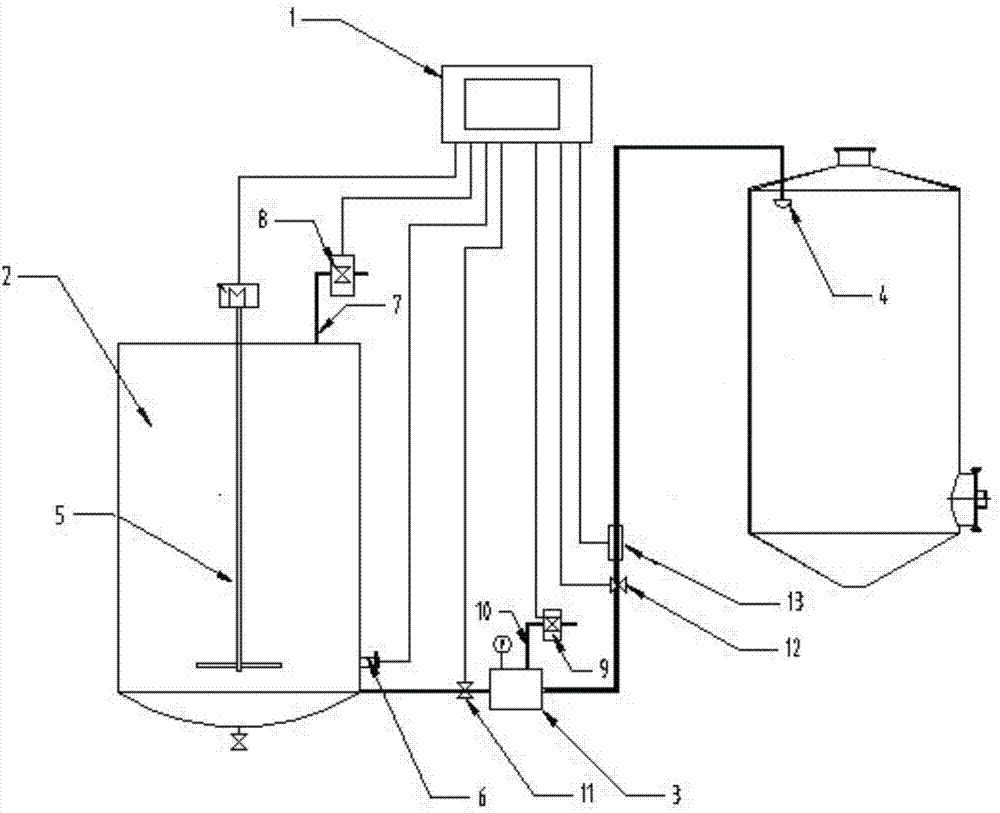

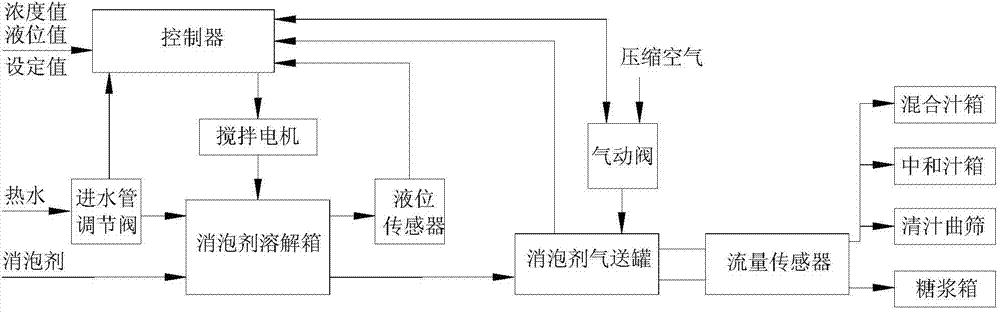

Automatic defoaming control system of sugar mill and operating method of automatic defoaming control system

InactiveCN104707367ASolve wasteSolve the situation of high sensitivity insensitivityRotary stirring mixersMixer accessoriesControl systemPneumatic valve

The invention provides an automatic defoaming control system of a sugar mill and an operating method of the automatic defoaming control system. The automatic defoaming control system comprises a defoaming agent dissolution tank, a pneumatic defoaming agent conveying device, a water inlet pipe regulating valve, a first pneumatic valve, a second pneumatic valve, a spraying device, a liquid level sensor, an air inlet regulating valve, a flow sensor and a controller. The addition of hot water is controlled by the water inlet pipe regulating valve according to the amount of a defoaming agent to accomplish proportional dilution; a cycle program is set in the controller to open the air inlet regulating valve at a fixed time; the dissolved defoaming agent is sprayed to a defoaming area via the spraying device; the pneumatic defoaming agent conveying device conveys the defoaming agent by a compressed air manner to lower the maintenance cost; the conveying amount of the defoaming agent is measured by controlling the opening time of the second pneumatic valve to achieve effects of automatic proportional dilution, timing and quantitative spraying of the defoaming agent; foam is eliminated timely to avoid sugar loss or influence on product quality due to tank boil-overs, sugar leakage and the like; the labor and consumption of the defoaming agent are reduced; and the production cost is lowered.

Owner:南宁苏格尔科技有限公司

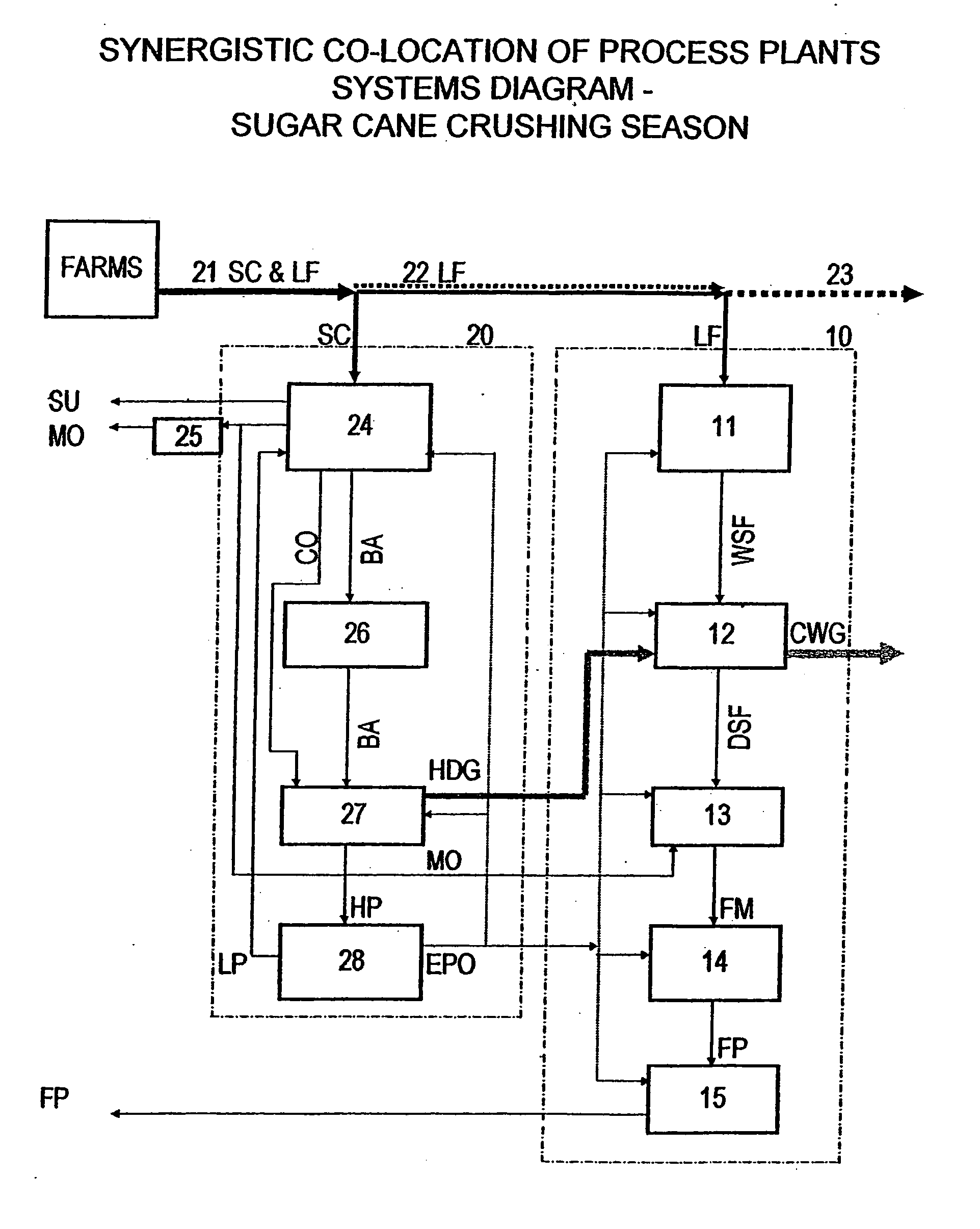

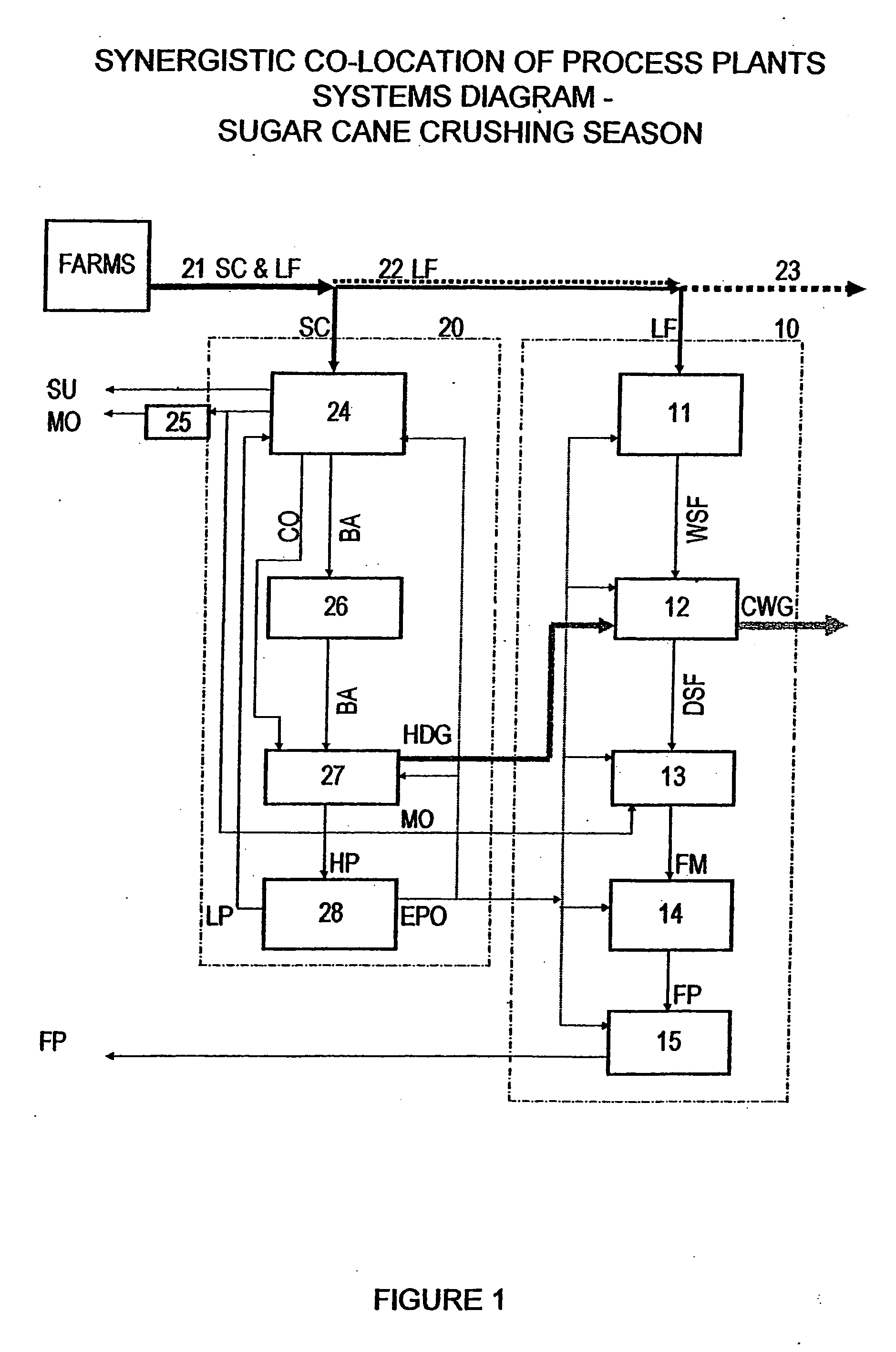

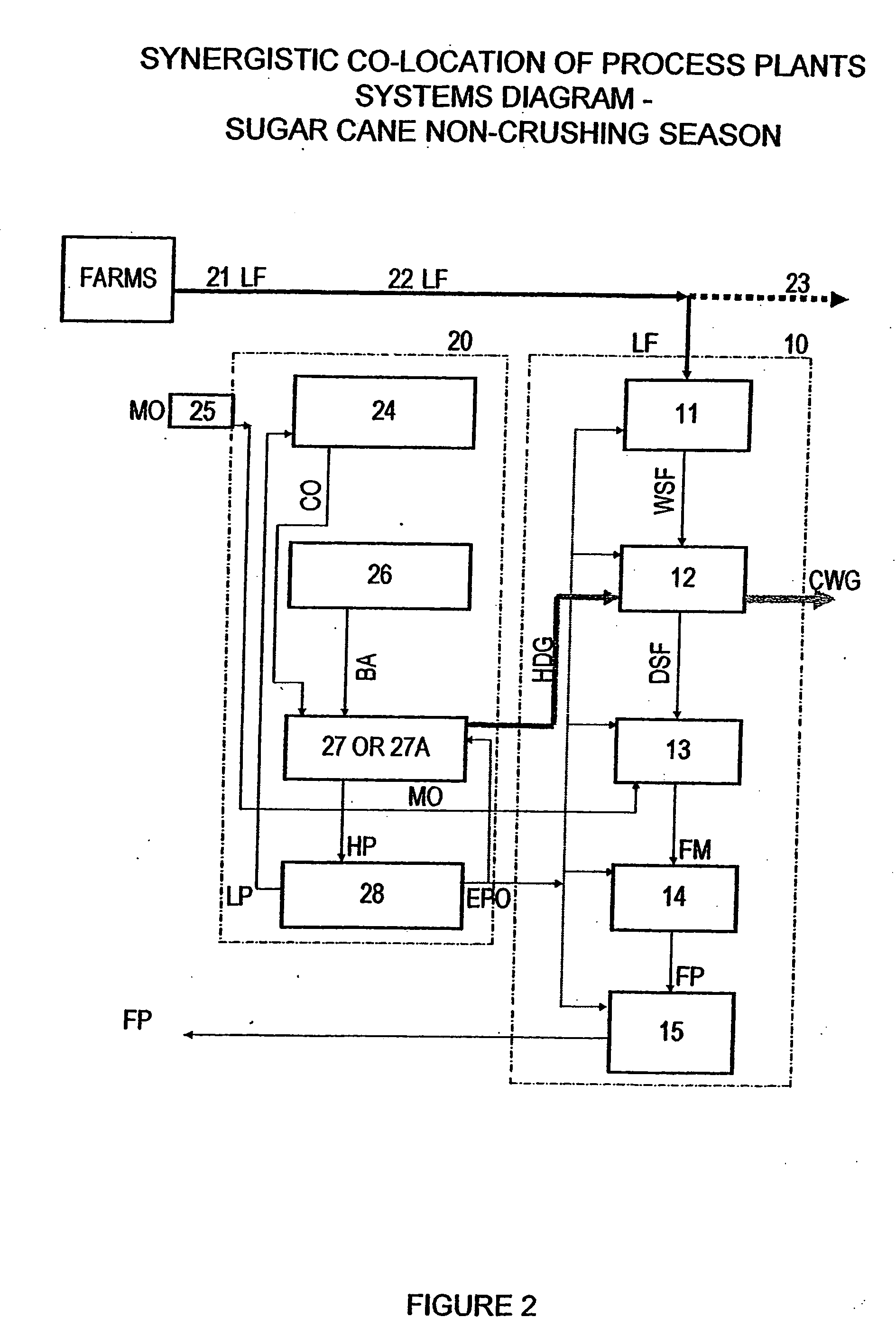

Synergistic co-location of process plants

InactiveUS20060003064A1High nutritional valueValue maximizationFeeding-stuffFood processingSugar caneSugar mill

Legume fodder crops, grown as soil-enhancing fallow crops for sugar cane, are processed in feed mills co-located with existing cane sugar mills to produce animal feed products, such as hay, with a positive economic value. The process uses some of the sugar mills' excess fibre by-product (bagasse) as the energy source for the dehydration of the fodder.

Owner:AGROTEKNIK

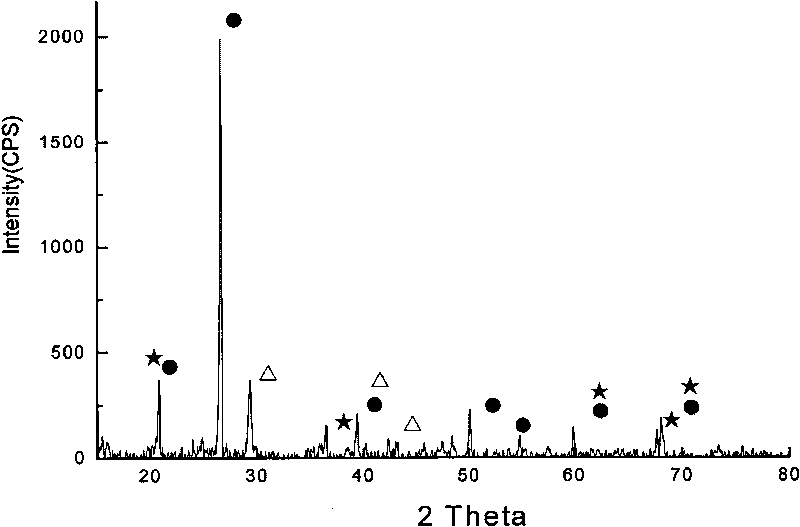

Biological filter material by utilizing sugar mill mud and method

InactiveCN101746882AHigh strengthImprove adsorption capacityEnergy based wastewater treatmentSustainable biological treatmentFiberPorosity

The invention relates to a biological filter material by utilizing sugar mill mud and a method; solid waste sugar mill mud and waste ceramics are used as main raw materials, binder clay and pore-forming agents and the like are added to prepare the biological filter material; the raw materials forms finished products by crushing, batching, ball-milling, sieving, forming, drying, sintering and cooling and other procedures; sawdust, leaves, fiber and the like can be used as the pore-forming agents for preparing the biological filter material; after the pore-forming agents and the powdery raw materials are mixed and formed, the pore-forming agents are distributed in a blank body disorderly, so as to form holes which are run-through in a three-dimensional space after being sintered. The porous biological filter material produced by the invention has high intensity, large porosity, large specific surface area and good chemical stability and can be used for sewage treatment.

Owner:HAINAN UNIVERSITY +1

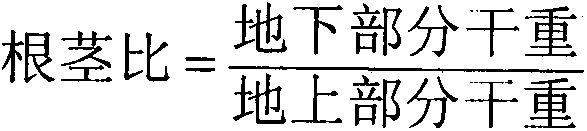

Humic acid type organic-inorganic soil conditioner prepared from wastes of sugar mills and alcohol plants

ActiveCN103626593AIncrease productionIncrease root to shoot ratioClimate change adaptationBioloigcal waste fertilisersAlcoholSoil conditioner

The invention relates to a humic acid type organic-inorganic soil conditioner prepared from wastes of sugar mills and alcohol plants. The soil conditioner contains active humic acid, an organic soil conditioner, an inorganic soil conditioner and a bactericide. The invention also relates to a preparation method of the composition and applications to the aspects of promoting crops to take root and increasing production.

Owner:广西湾贝海洋生物科技有限公司

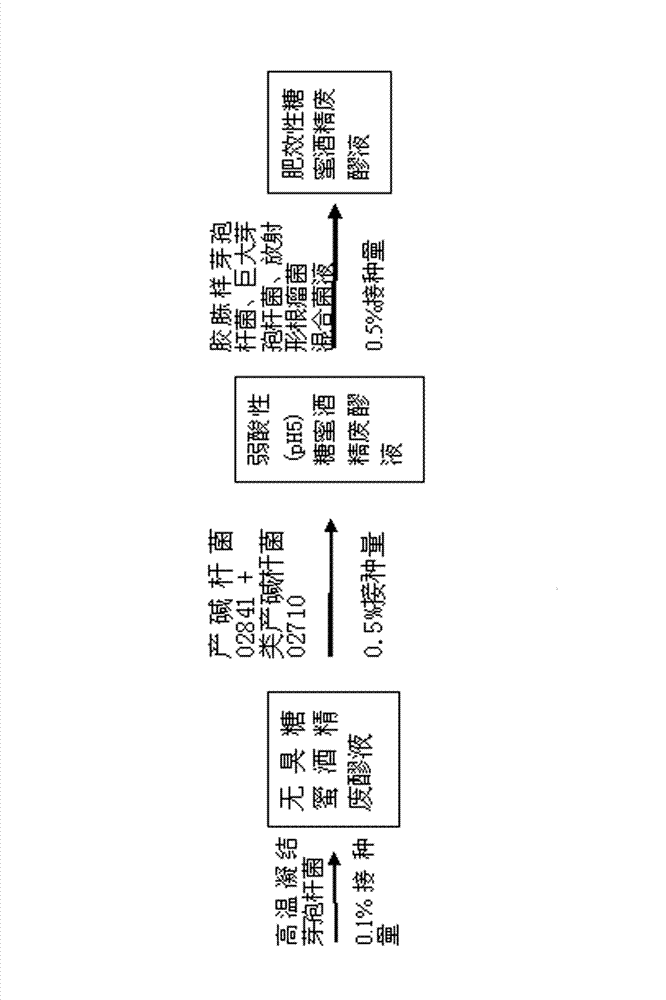

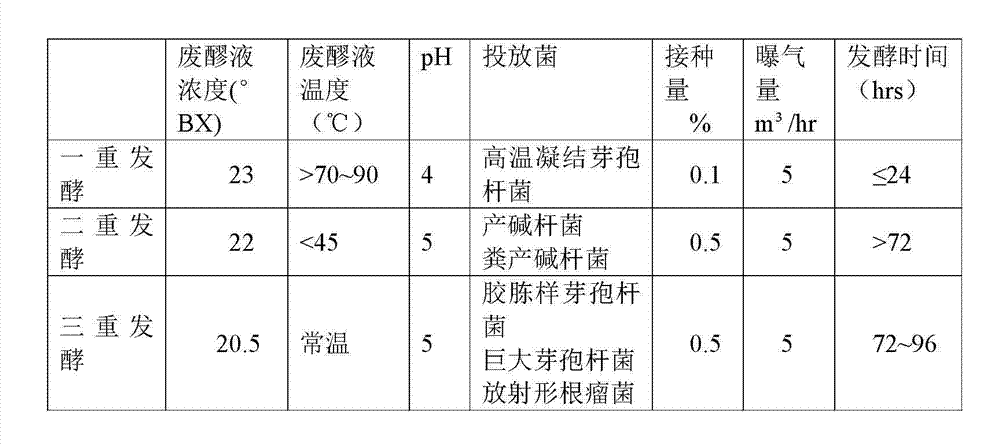

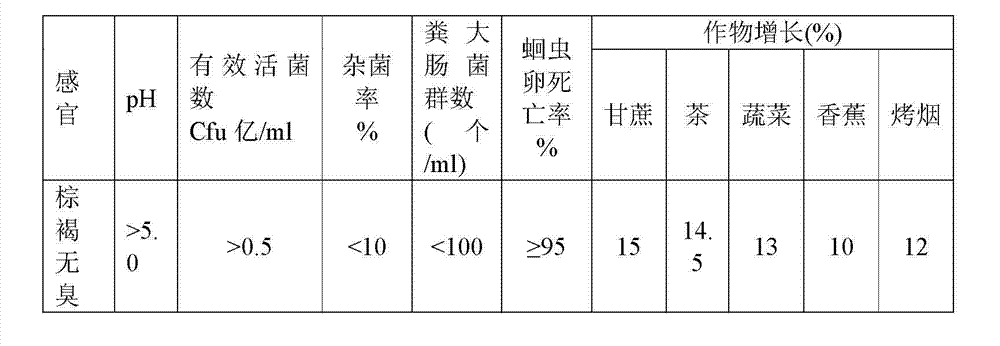

Method for preparing fertilizer effect type molasses alcohol waste mash bacterial liquid through triple fermentation

InactiveCN103193521AImprove fertilizer efficiencyIncrease productionClimate change adaptationBioloigcal waste fertilisersLiquid wasteInsect pest

The invention discloses a method for preparing a fertilizer effect type molasses alcohol waste mash bacterial liquid through triple fermentation. The method comprises steps of: inoculating high-temperature bacillus thermocoagulans Sp.nov. into a high-tempreature (90 DEG C) molasses alcohol waste mash which is just discharged to be fermented preferentially so as to prevent the waste mash from getting smelly in a cooling process due to putrefying bacteria contamination; cooling the waste mash to be below 45 DEG C, and then inoculating strains of Alicaligenes ACCC 02841 and strains of Alicaligenes faecalis ACCC 01720 for secondary fermentation so as to improve the pH of the waste mash; and finally, adding Bacillus macilaginosus, BacillusmegateriumGMCC 1.270 and Rhizobiumradiobacter for the third fermentation, thus preparing the organic waste mash bacterial liquid which is safe and odor-free and has a lasting fertilizer effect. The waste mash bacterial liquid after triple fermentation can be fully used as an agricultural liquid fertilizer, is safe and odor-free, realizes zero emission of the waste mash and is an organic bacterial liquid fertilizer which is popular with most peasants. Applications of a plurality of sugar mills prove that the bacterial liquid can replace at least more than half of the application amount of a chemical fertilizer; and by utilizing the bacterial liquid, soil is improved, the rhizosphere active fertility is increased, and plant diseases and insect pests are reduced.

Owner:YUNNAN KANGTAI ENVIRONMENT SCI & TECH

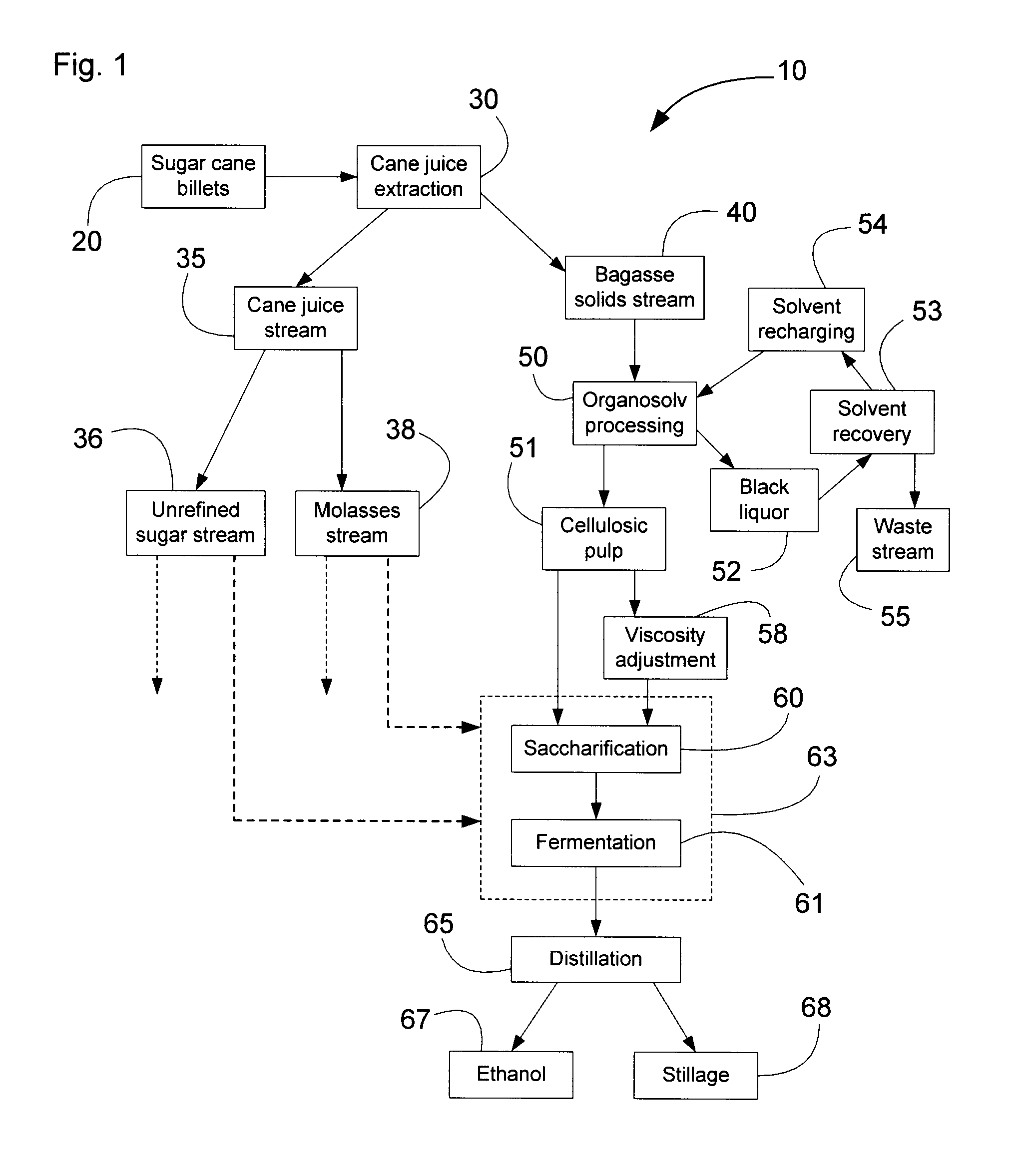

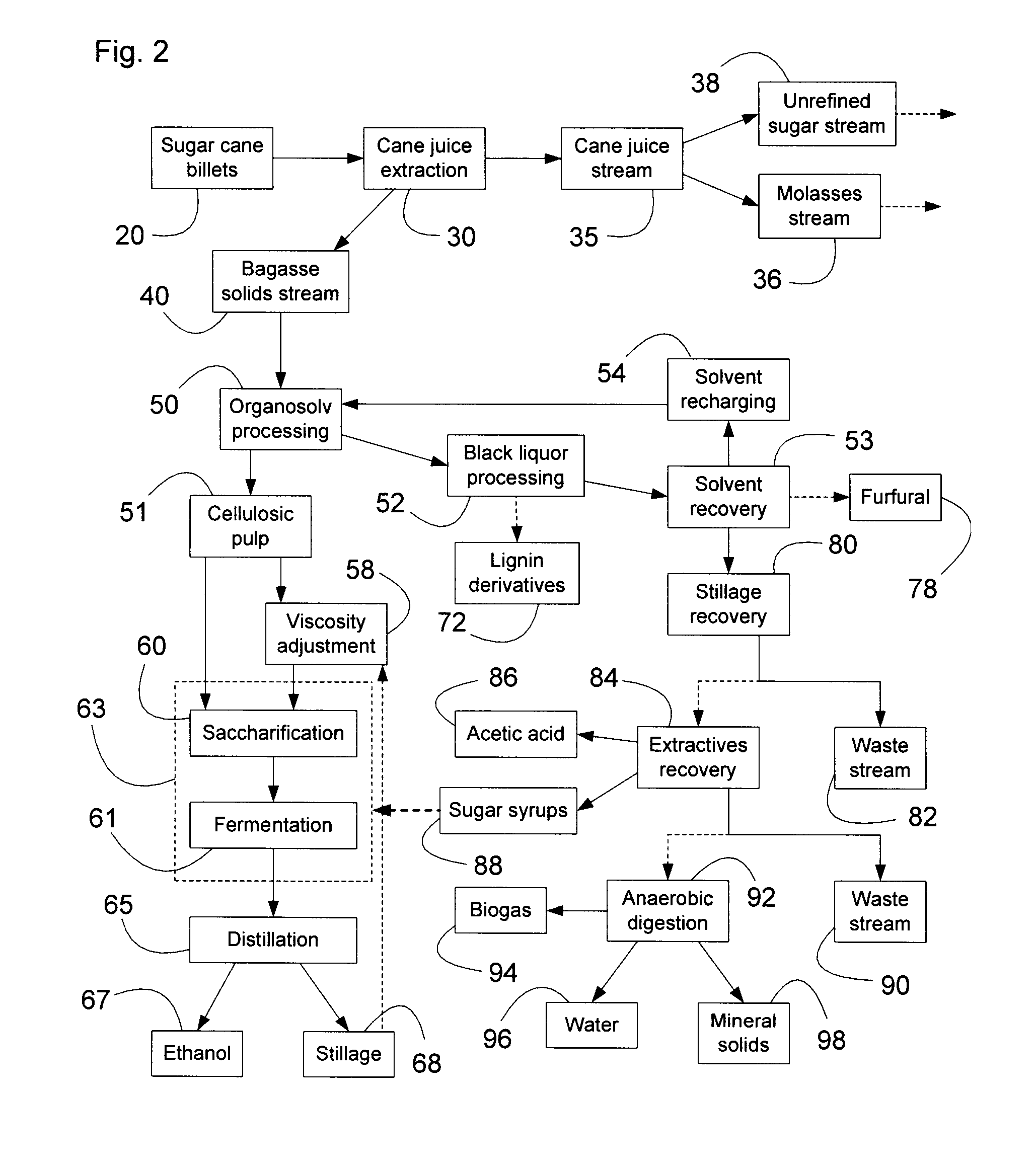

Organosolv biorefining of whole sugar cane

InactiveUS20120094348A1Reduce accumulationBioreactor/fermenter combinationsPressurized chemical processOrganosolvCellulose pulp

An apparatus for processing sugar cane to concurrently produce sugar from cane juice, and ethanol and other co-products from bagasse. The apparatus comprises equipment for separating a cane juice stream and a fibrous bagasse from a sugar cane feed-stock, equipment for refining the cane juice, equipment for processing the fibrous bagasse for recovery therefrom of a cellulosic pulp and a liquor stream, equipment for saccharification and fermentation of the cellulosic pulp to produce a fermentation beer therefrom, and equipment for recovery of an ethanol stream from the fermentation beer. Legacy sugar mills may be retrofitted with a bagasse biorefining apparatus to concurrently produce ethanol and co-products, with existing cane juice extraction and processing operations.

Owner:LIGNOL INNOVATIONS

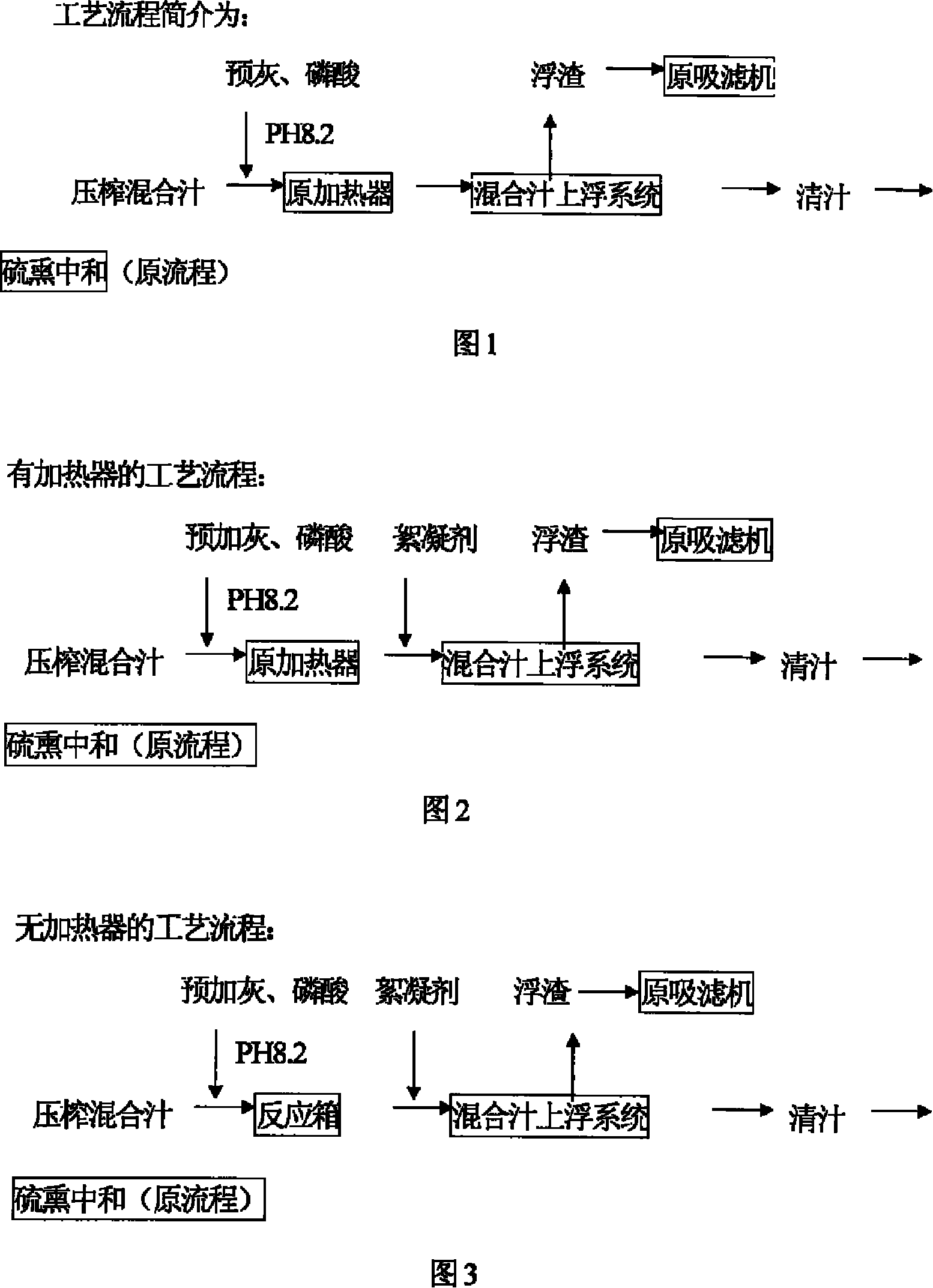

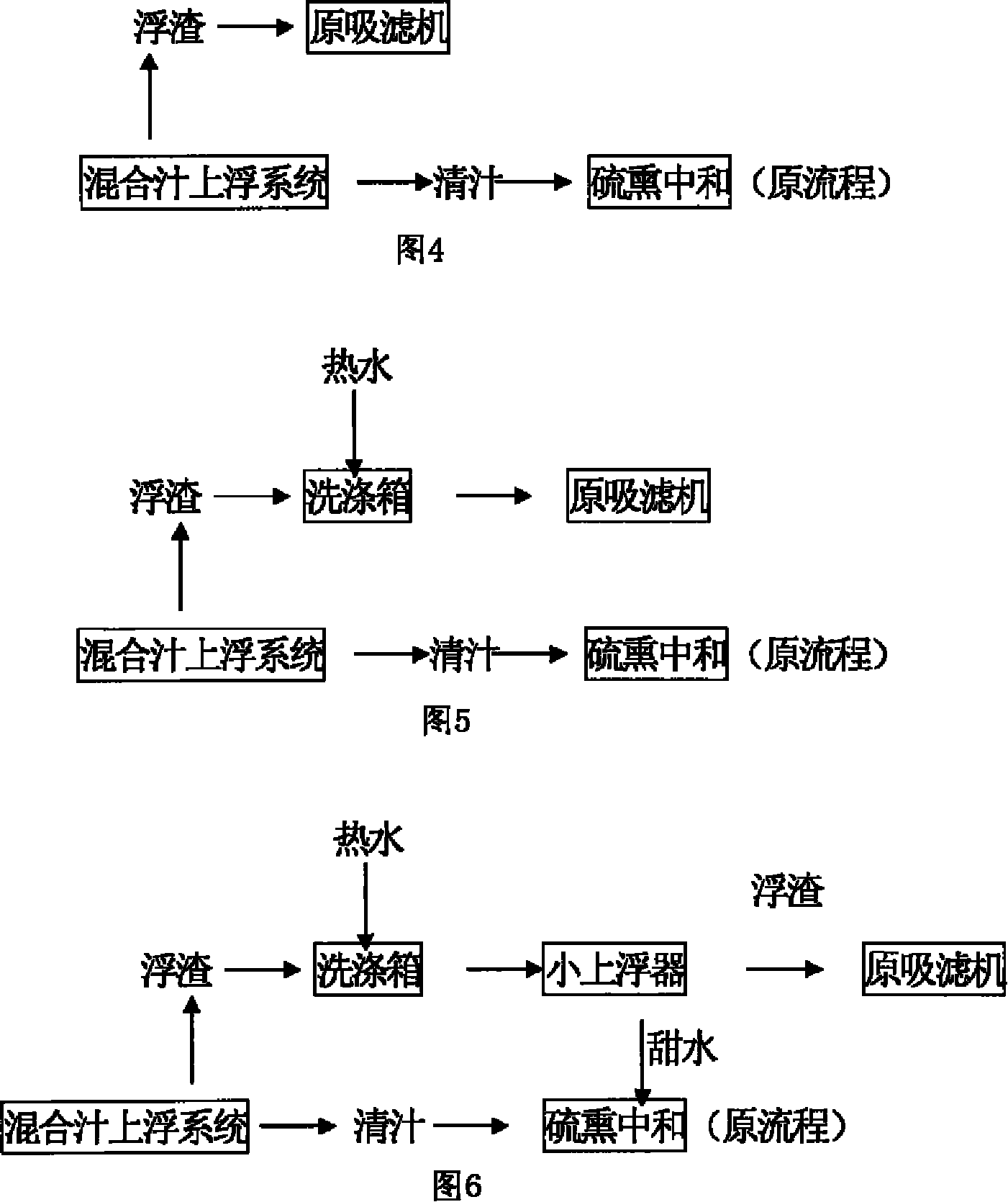

Low temperature processing technique for sugar mill mixing liquor by sulfurous acid method

InactiveCN101144109AQuality improvementReduce turbidityPurification by oxidation/reductionFlocculationProduct gas

The present invention relates to a mixing low-temperature treatment process used in a sulfitation sugar mill where sugar cane juice is treated. The present invention is characterized in that 2 to 10 baume degrees of lime cream watery solution is added into the pressed combination juice manufactured according to the traditional process, 5 to 1000 ppm of clarificant used by a G409 aluminum raw massecuite, 50 to 1000 ppm of chitosan exclusively used for the flocculation and the purification, one or more of CO 2 can be added to be matched and used, to lead the solution to be prepared into the solution of pH value (6-12) after the solution is mixed; the clarificant with 0.01-0.2 percent of concentration and 1 to 4 ppm of mass is mixed; the mixed solution is sent into a float-up device. The present invention has the advantage that the stoving intensity can be decreased by 35 percent to 45 percent. Thus the loss of the sugar share is decreased, and the quantity of the raw material is saved. The reduction of the depositional area is greatly helpful to improve the juicing amount and the withdrawal, thereby decreasing the investment; the product quality and the withdrawal are improved; the production cost is low, the material which is harmful to the food is not required to be added, and only the usual drug in the sugar manufacturing process of the sugar mill is required to be added.

Owner:黄桂忠

Chinaure-containing high-efficiency slow-release compound fertilizer

InactiveCN104058846AWide variety of sourcesImprove adsorption capacityFertilizer mixturesEthylenediamineSludge

The invention relates to the field of compound fertilizers, particularly a chinaure-containing high-efficiency slow-release compound fertilizer. The fertilizer is prepared from the following raw materials in parts by weight: 10-15 parts of 1250-2000-mesh kieselguhr, 12-15 parts of calcium superphosphate, 20-22 parts of urea, 12-14 parts of plant ash, 15-18 parts of sugar mill lime sludge, 8-10 parts of rotten vegetable leaf, 4-6 parts of glycerophosphate sodium, 5-8 parts of xylanase, 20-22 parts of oil tea cake powder, 28-30 parts of poultry manure, 4-6 parts of sodium isoascorbate, 10-12 parts of glycidol ether epoxy resin, 3-5 parts of butyl glycidyl ether, 1-2 parts of polyethyleneglycol, 1-2 parts of ethylenediamine, 5-7 parts of pine needle powder, 2-4 parts of chinaure, 4-5 parts of borax, 2-3 parts of sodium tripolyphosphate, 1-3 parts of potassium permanganate, 2-4 parts of zinc gluconate, 6-8 parts of table vinegar and 4-5 parts of assistant. The compound fertilizer has multiple nutrients; the kieselguhr and coating agent are utilized to implement dual slow-release coatings; and the coating agent contains the chinaure, and can prevent the insects and ants from biting. The fertilizer has the advantages of low tendency to nutrient loss, long fertilizer efficiency, no toxicity or harm to soil and favorable crop root environment, has the functions of sterilization and corrosion resistance, and enhances the yield and quality.

Owner:安徽省巨星肥业有限公司

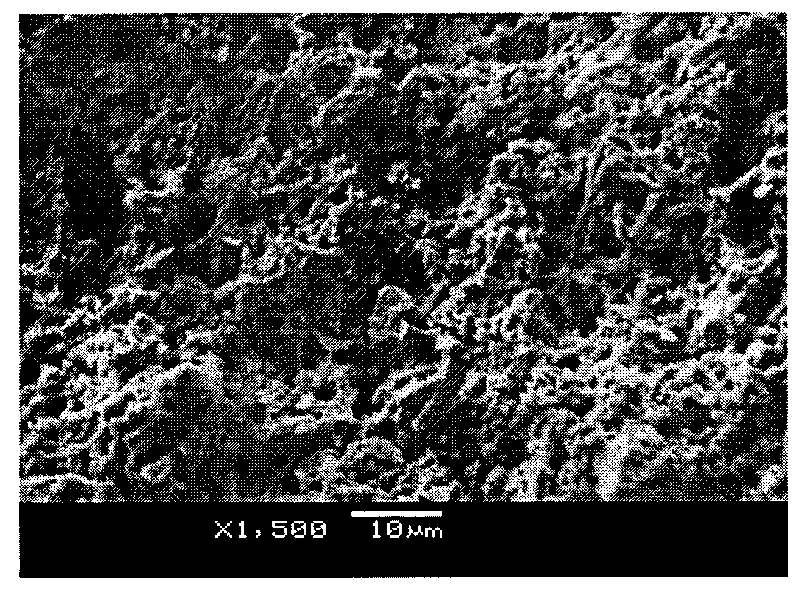

Bagasse composite soil conditioner preparation method

InactiveCN104388096AImprove utilizationThe preparation process route is reasonableOrganic fertilisersSoil conditioning compositionsCelluloseEnvironmental resistance

The present invention discloses a bagasse composite soil conditioner preparation method, wherein the main byproduct bagasse of sugar production from sugarcane is adopted as a raw material, and is combined with starch and kaolin through a graft copolymerization method so as to prepare the soil conditioner having high heavy metal adsorption capacity, wherein the bagasse contains a lot of cellulose, such that the application of the bagasse to prepare the soil repair agent has economic values and significant environmental significance. According to the present invention, the main byproduct bagasse of the sugar production industry and the natural products such as starch and kaolin are adopted as the raw materials, the characteristics of reasonable process route and reliable product performance are provided, the prepared composite material has the high heavy metal adsorption and the high soil repair capability, the method has advantages of increase of the comprehensive utilization of the sugar mill byproduct, no secondary pollution and the like, and the soil repair agent prepared by using the method can effectively absorb heavy metals in the soil, wherein the cadmium adsorption rate achieves more than 45%, and the copper adsorption rate achieves more than 52%.

Owner:GUANGXI UNIV

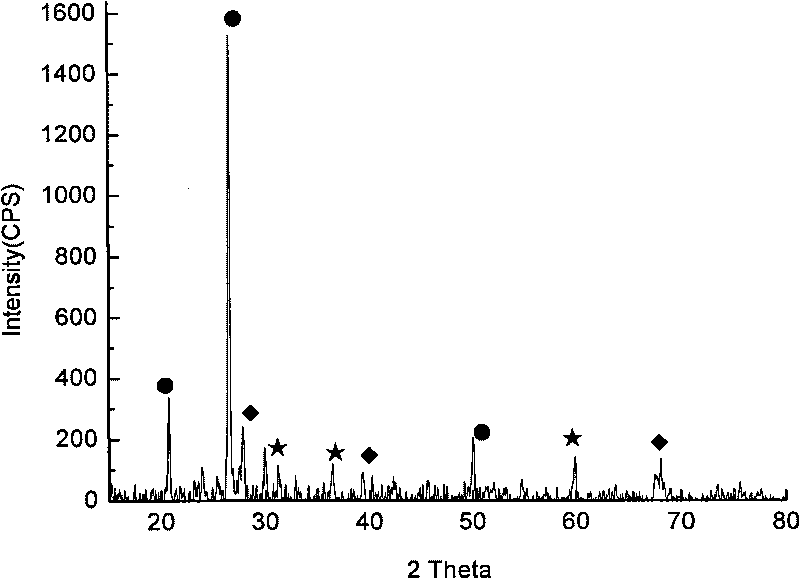

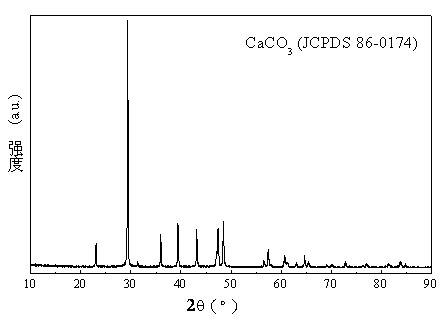

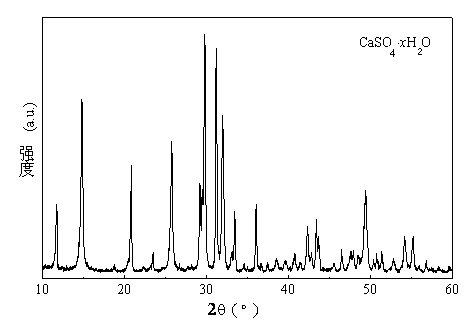

Application of sugar-mill lime sludge in wet flue gas desulfurization

The invention discloses the application of sugar-mill lime sludge in wet flue gas desulfurization. The application of the sugar-mill lime sludge is characterized in that the sugar-mill wet lime sludge is directly mixed with water to prepare slurry liquid, and the slurry liquid serves as an absorbing agent in a limestone-gypsum wet desulfurization method; the desulfurization absorbing agent is the waste lime sludge (namely filter residue or yellow mud) generated by the sugar prepared by a carbonic acid method in a sugar mill, mixed with water to form the slurry liquid with the proportion of 1:10-1:12, and used for absorbing sulfur dioxide (SO2) discharged by a coal burning boiler; and when the calcium-sulfur ratio is 1-1.1, the removal ratio of SO2 is up to more than 95 percent, the national desulfurization standard is met. The application of the sugar-mill lime sludge in the wet flue gas desulfurization adopts the waste residue of enterprises as the desulfuration absorbing agent, so as to be convenient and economic for material taking, simple in processing, and universal with the limestone-gypsum wet desulfurization method in requirements for equipment. The method not only saves the cost of purchasing an desulfurization agent, but also finds a way out for safe disposal of the lime sludge, so as to realize the purposes of treatment of wastes by other wastes, energy conservation and emission reduction, and have larger social environment benefits and economic benefits.

Owner:UNIV OF JINAN

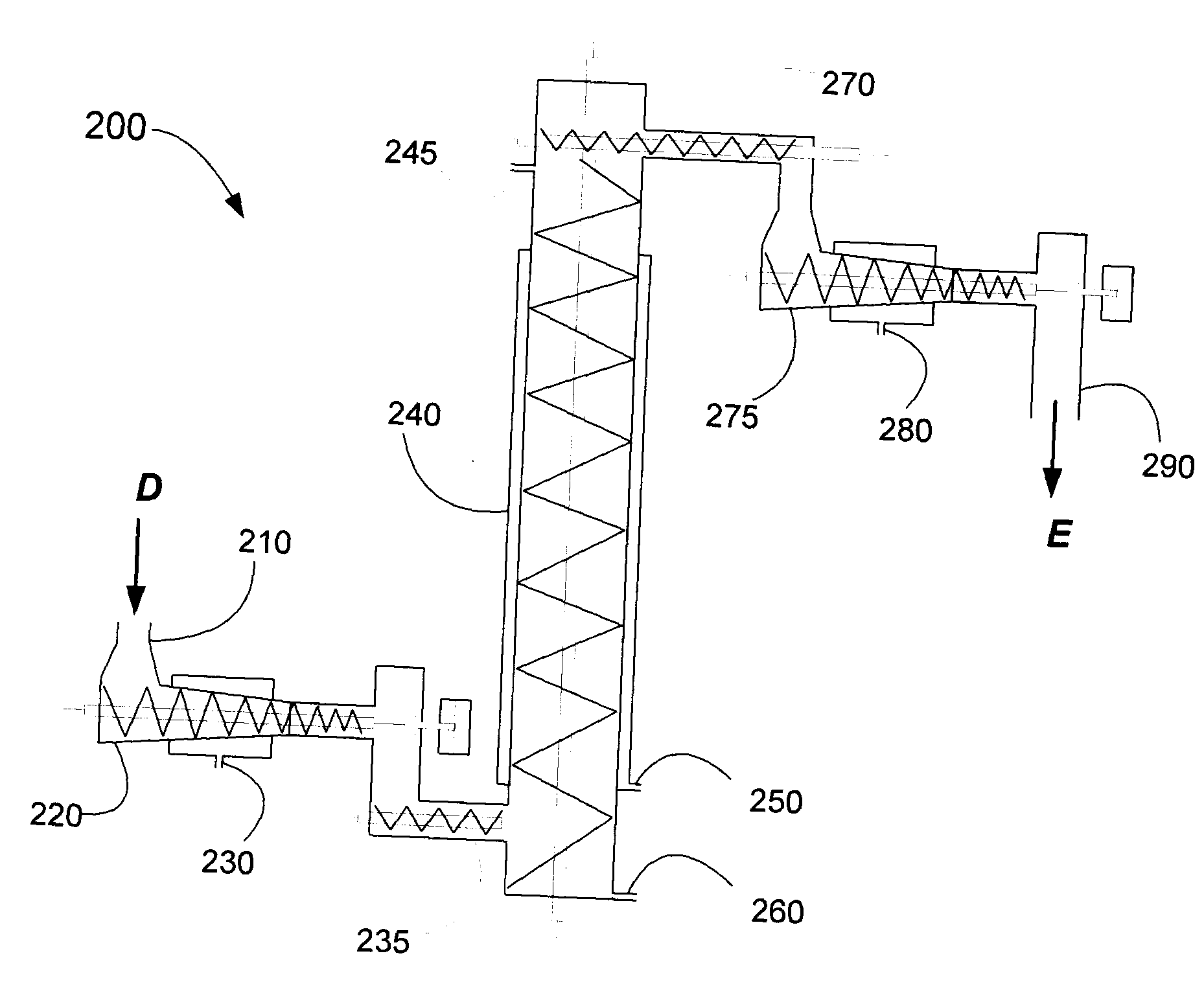

Portable sugar mill

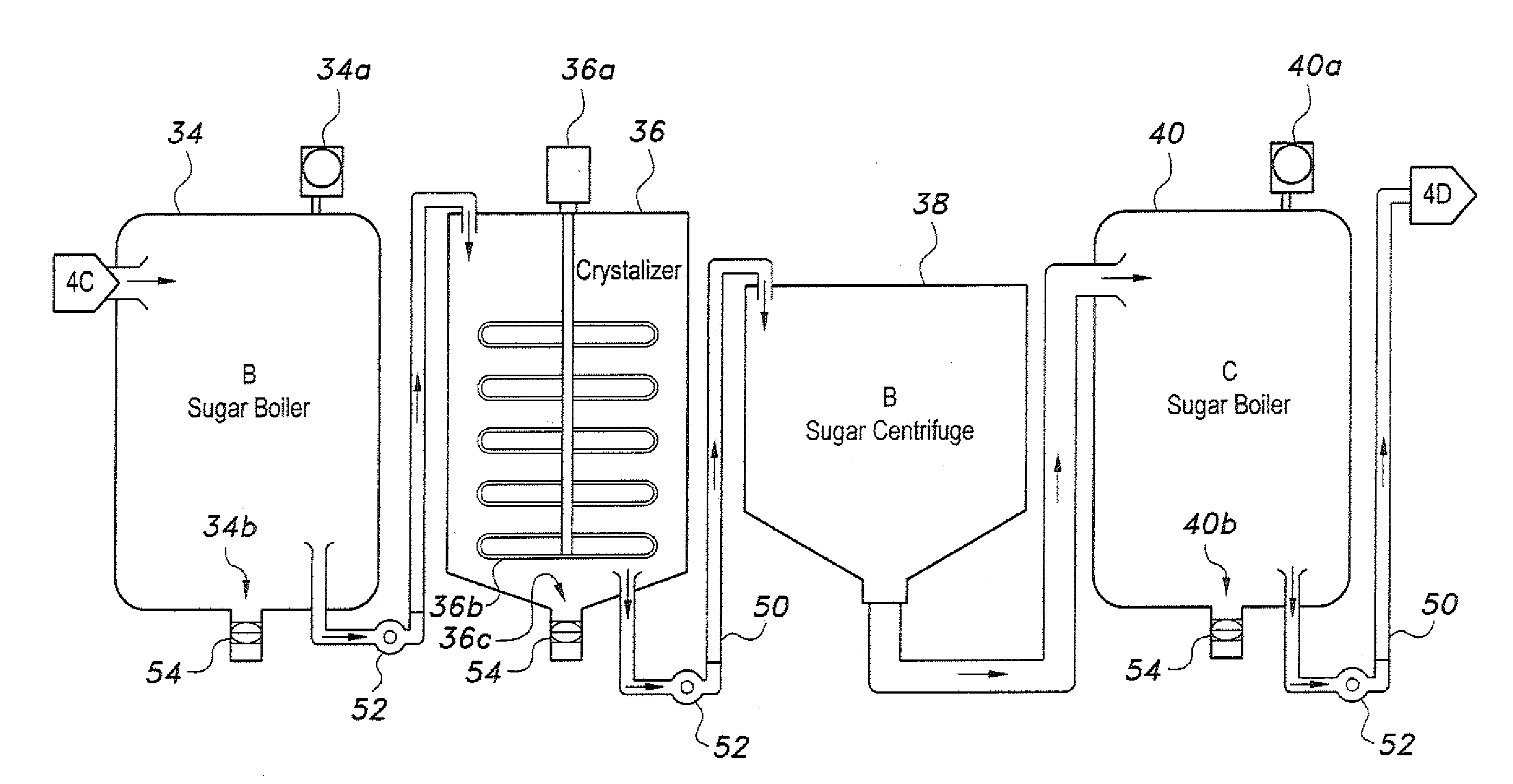

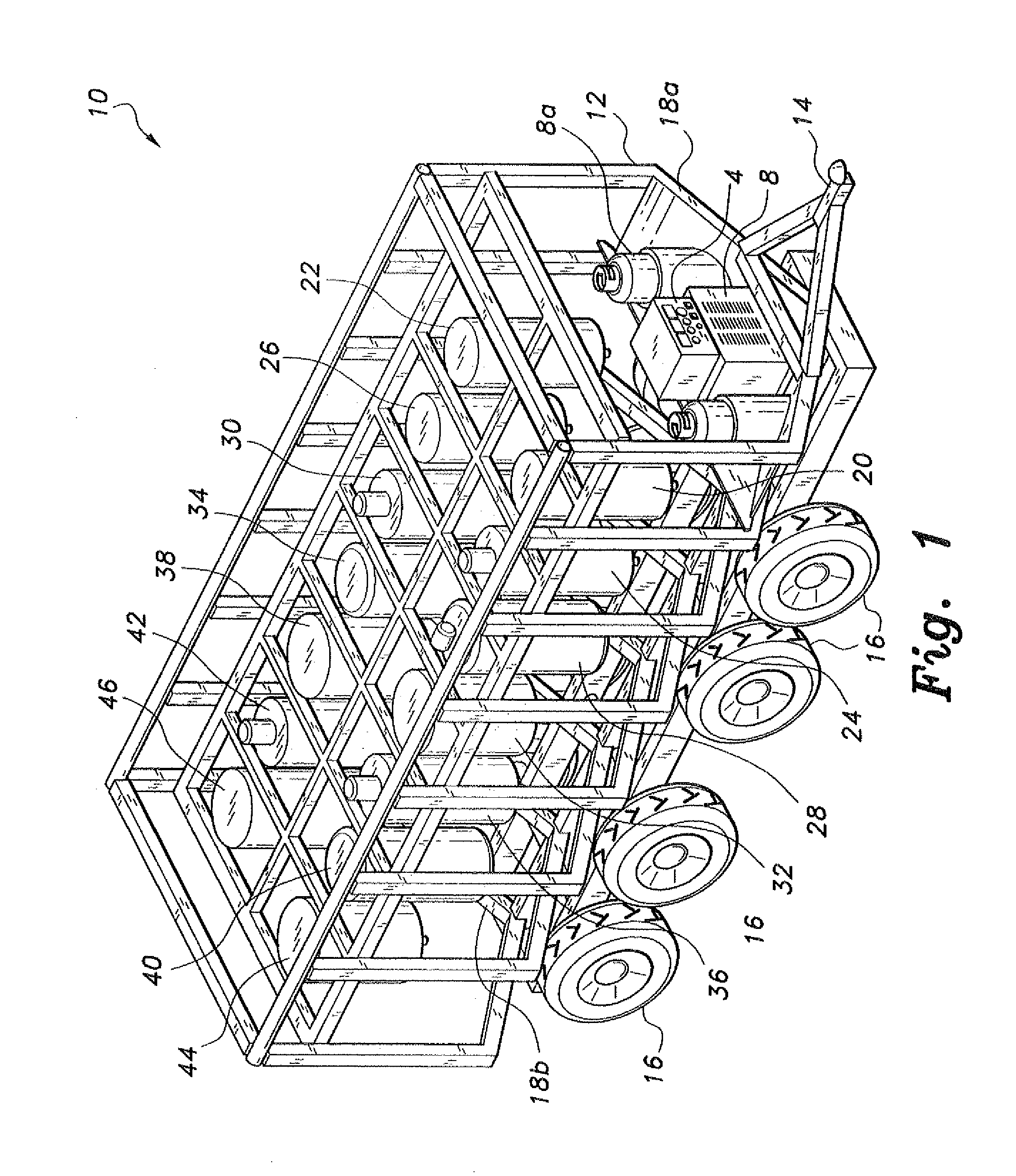

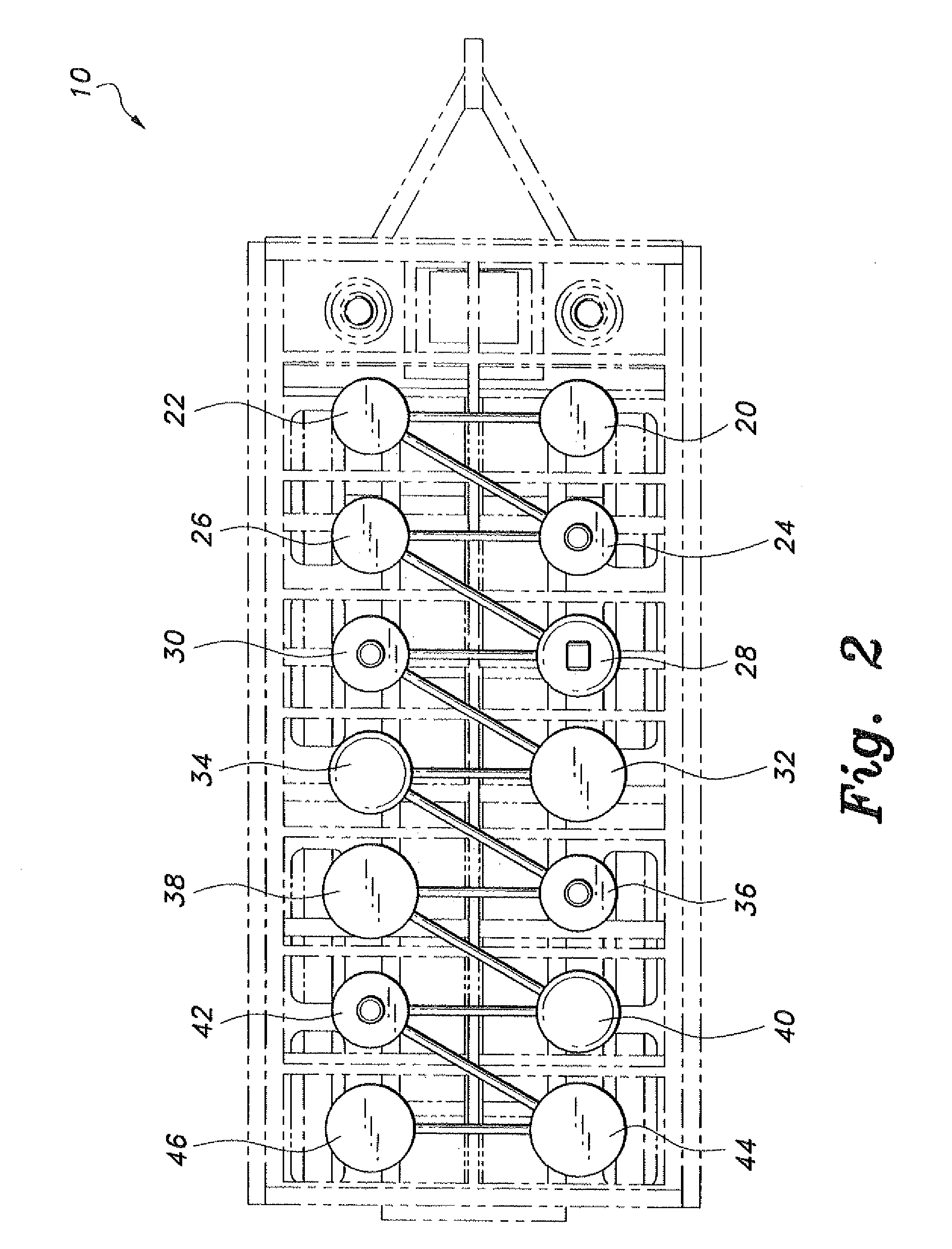

InactiveUS20130042858A1Readily apparentSugar crystal separationCentrifugal force sediment separationFruit juiceSaccharum

The portable sugar mill is established on a mobile platform for transport to the harvesting field, so that the juice of the harvested sugar cane may be processed and refined in the field. The portable sugar mill converts the juice, which contains sucrose, into raw sugar crystals (brown sugar) and molasses. The portable sugar mill includes a separator tank, a pre-heating tank, a clarifier, and three successive stages of evaporative crystallization and separation of crystals from syrup. The portable sugar mill has a programmable logic controller and a plurality of sensors, control relays, pumps, motors, heaters, and valves that operate automatically under direction of the programmable logic controller.

Owner:JEDWIN MARKETING

Method for preparing organic fertilizer from sugar mill mud

ActiveCN104496570AImprove breathabilityGood aerobic fermentation stateClimate change adaptationSewage/sludge fertilisersAgricultural engineeringOrganic manure

The invention provides a method for preparing an organic fertilizer from sugar mill mud. The method comprises the following steps: blending a certain proportion by weight of sugar mill mud having the moisture content of 60%-80% and a certain proportion by weight of adjusting material having the moisture content of 10%-70% to obtain a mud fermentation material having the moisture content of 50%-75%; next, putting the mud fermentation material on a three-dimensional fermentation apparatus composed of 2-40 layers and 2-40 groups of belt conveyors in the horizontal direction for dynamic aerobic fermentation, and after the mud fermentation material is converted into a decomposed organic material, directly applying the mud fermentation material as an organic fertilizer or an organic raw material for producing organic fertilizer products. According to the method, the sugar mill mud and bagasse can be effectively utilized, the fermentation effect is good, the floor area is small, and meanwhile, secondary pollution generated by stink can be avoided and the purposes of high efficiency and environmental friendliness are achieved.

Owner:广西田东力源宝科技有限公司

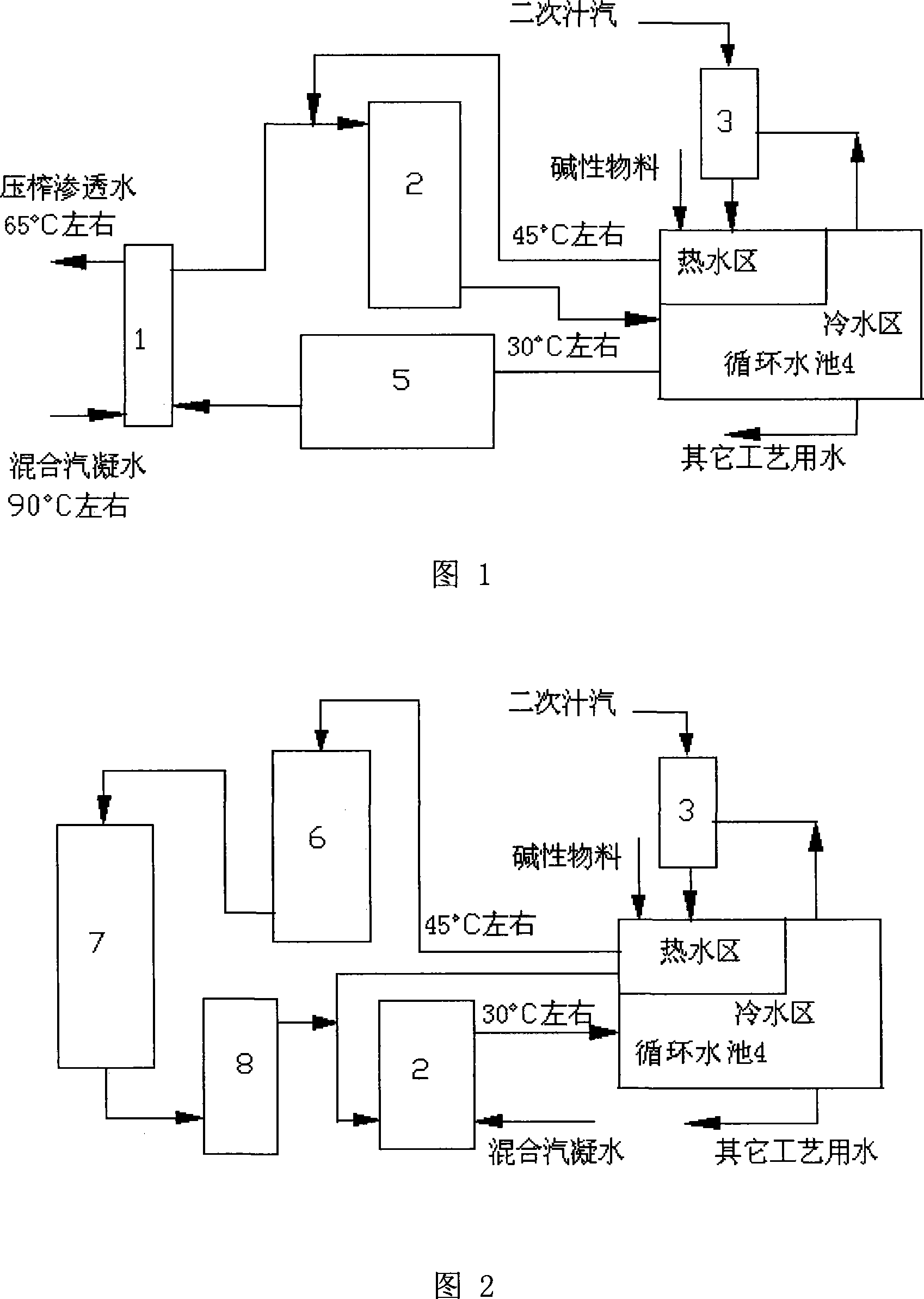

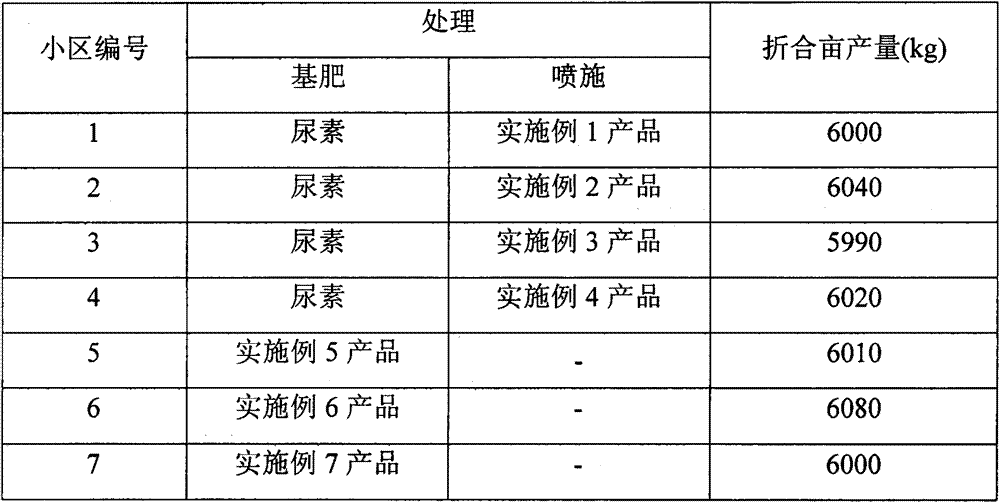

Novel technique for quality-preservation treatment of sugar plant circulation cooling water

InactiveCN101182088AHighlight substantive featuresSignificant progressWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFiltration membraneCooling tower

The invention relates to a treatment technology and equipment of circulating cooling water of a sugar factory juice steam condensing system. The technology process includes steps as follows: firstly, pH value of the circulating cooling water is regulated to be neutralized through alkaline materials; secondly, circulating water in a circulating a circulating water tank is rotated; the third step is to cool mixed steam condensing water after fetching a part of heat and supplement the circulating water in the circulating water tank; and fourthly, a part of the cooling water which has circulated for many times is heated to be at the temperature of about 65 degree Celsius after being filtered through an ultra-filtration membrane system and is sent to the press to be used as pressing infiltration water, or a part of the cooling water which has circulated for many times is sent to a boiler to be used as ash water, and the circulating water is recharged again through the settlement and the filtration. The equipment includes the circulating water tank, a cooling tower, a condenser, the ultra-filtration system, a heat exchanger, a boiler water membrane dust removing and ash sluicing system and a sediment pool. The invention can ensure the circulating cooling water to be not metamorphic and stink. The mixed steam condensing water and the part of the cooling water which has circulated for many times are ensured to be utilized reasonably. A large quantity of production water is saved for sugar manufacturing factories. No sewage is discharged. The investment is saved. And the invention has the advantages of low operating cost and stable operation.

Owner:广西工院糖业科技有限责任公司 +1

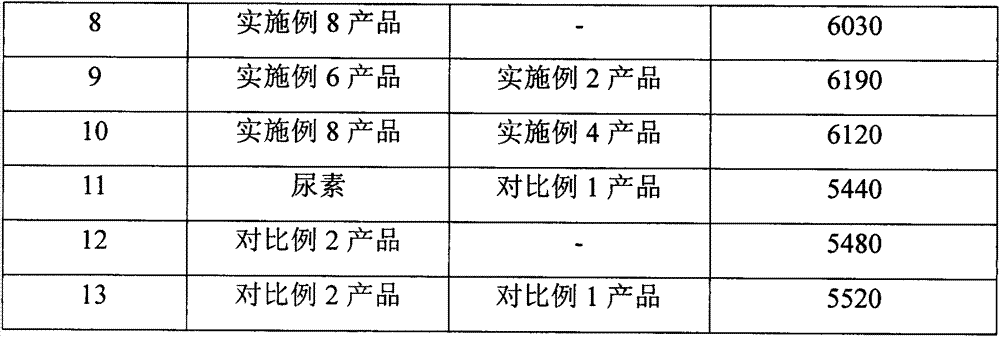

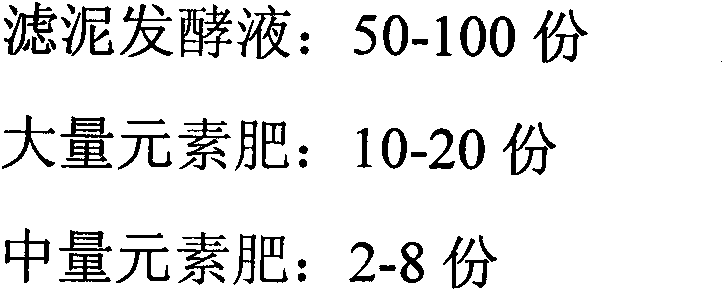

Humic acid type fluid or solid organic fertilizer composition utilizing wastes from sugar mills, alcohol plants, gourmet powder factories and yeast plants

ActiveCN103896659ATake advantage ofIncrease chlorophyll contentFertilising methodsFertilizer mixturesMinor elementYeast

The invention relates to a humic acid type fluid or solid organic fertilizer composition utilizing wastes from sugar mills, alcohol plants, gourmet powder factories and yeast plants and containing lime sludge and secondary and minor elements, which contains an organic fertilizer, a secondary element fertilizer, a minor element fertilizer and the like, wherein the organic fertilizer comprises lime sludge leavening, and the lime sludge is from sugar mills, alcohol plants, gourmet powder factories or yeast plants. Preferably, the organic fertilizer composition also contains appropriate bactericide such as fenhexamid. The organic fertilizer composition can effectively increase the chlorophyll content of cucumber leaves, and can also increase the yield of cucumbers.

Owner:广西勤德科技股份有限公司

Material and heat equilibrium automatic control system in refining process in sugar mill

InactiveCN106094776AThermal balance optimizationThermodynamic balance automatic control optimizationEnergy industryTotal factory controlAutomatic controlMathematical model

The invention provides a material and heat equilibrium automatic control system in the refining process in a sugar mill. The system comprises a material and heat coordinated management system and a refining section material and heat equilibrium automatic control optimization system. The material and heat equilibrium coordinated management system adopts the Internet-of-things technology and the cloud computing technology to realize mutual coordination of material and heat equilibrium and automatic control in each section of refining. The refining section material and heat equilibrium automatic control optimization system collects and analyzes automatic control system process data and cross-region material, equipment and heat data in each section of refining through the Internet and the cloud, builds corresponding mathematical models and a series of control strategies, and realizes full-automatic control of production in clarification, evaporation and sugar boiling sections in the refining process. Through cross-region equipment, material and heat coordination, material and heat equilibrium is realized, the control system is optimized, high efficiency and energy saving are achieved, the quality of finished sugar is improved, and environmental pollution and energy consumption in the production process of sugar products are reduced.

Owner:广西宏智科技有限公司

Method of producing lime by microwave heating calcined filter mud of sugar factory

InactiveCN102285675AReduce pollutionNo secondary pollutionCarbon compoundsSludge treatment by pyrolysisMicrowaveFree cooling

The invention discloses a method for producing lime by using microwave calcining carbonation method sugar factory filter mud. Mix the carbonation sugar factory filter sludge directly or with a certain amount of coke and other carbon source fuels, put it into an alumina crucible and place it in a microwave reactor, heat the filter sludge to 500-1200°C with microwaves, and keep it warm at this temperature After 1-30 minutes, turn off the microwave heating switch, cool naturally to room temperature, and obtain a lime product mainly containing calcium oxide. Its advantage is that the waste filter mud of carbonic acid sugar factory is used as raw material and calcined at high temperature to obtain lime and kiln gas containing carbon dioxide, which can be reused in sugar production and turn waste into treasure.

Owner:周少基

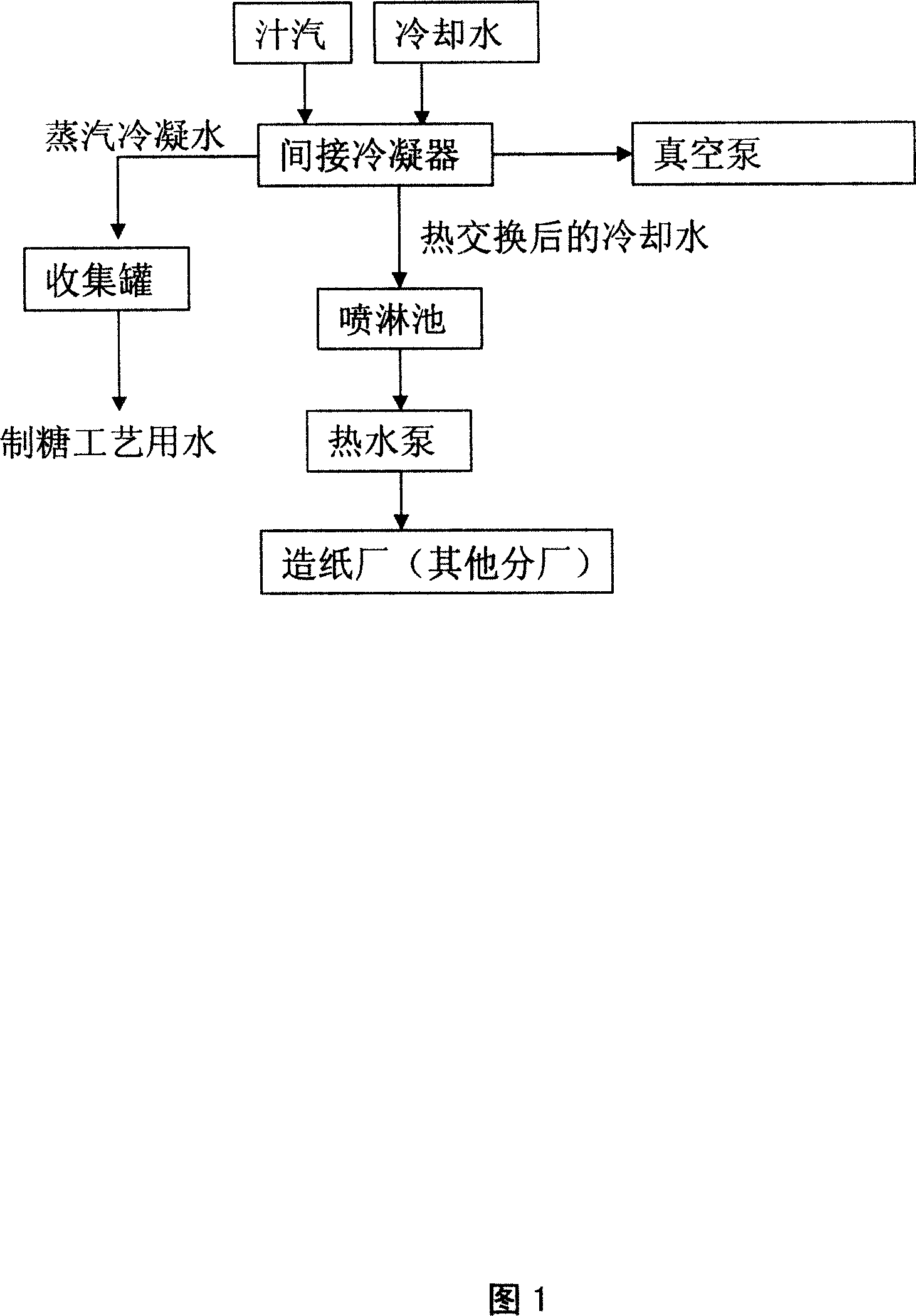

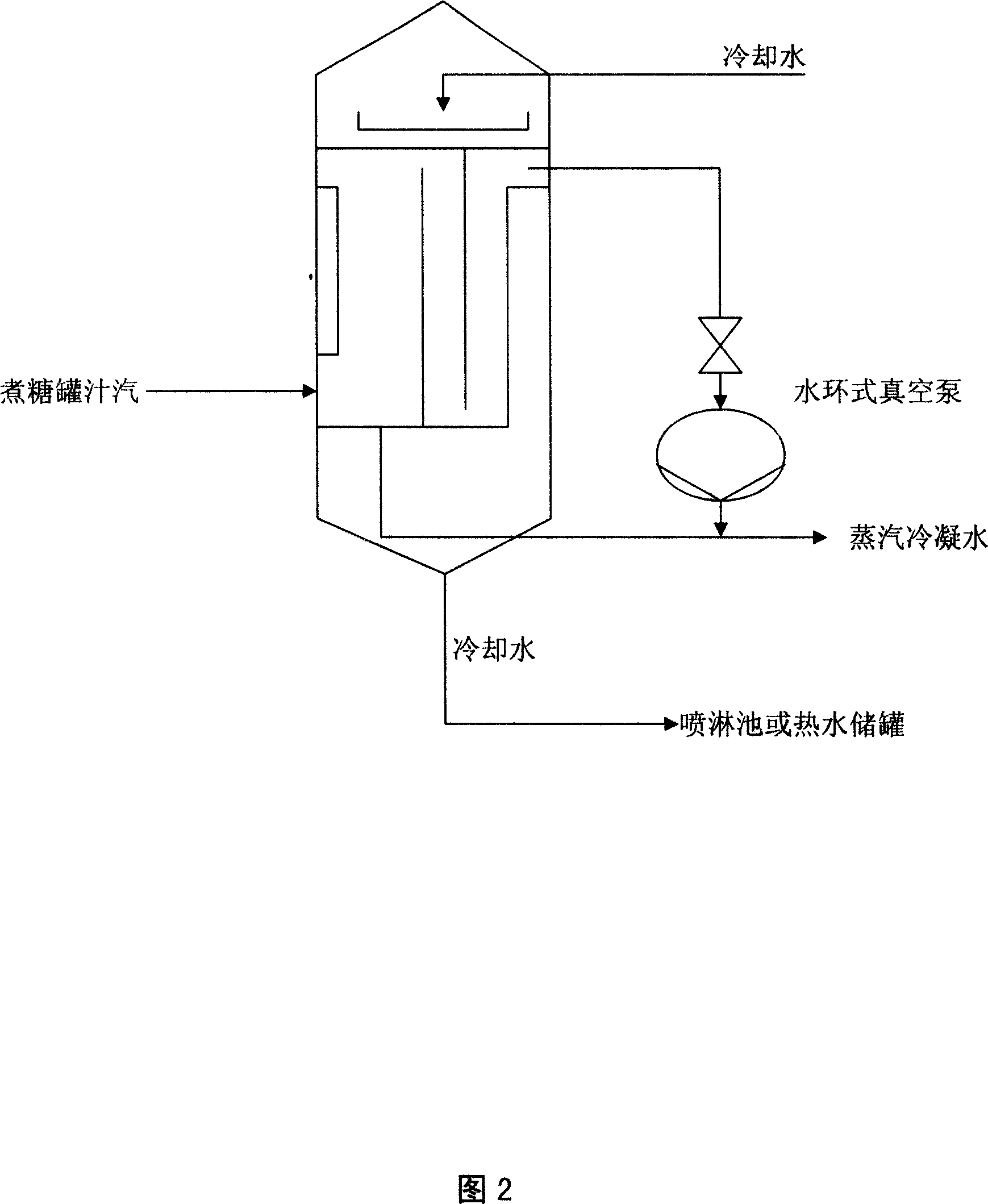

Method and device for comprehensively utilizing water from boiling sugar production

InactiveCN1987320AHarm reductionAvoid mutual pollution and the disadvantages that cannot be reusedSteam/vapor condensersSugar juice boiling/evaporationEngineeringSewage

The method introduces both juice and gas at exit above bowl of boiling sugar, and cooling water to indirect condenser at same time. In the indirect condenser, juice-gas, cooling water pass through different channels. Being connected to condenser, vacuum pump forms vacuum on the exit above bowl of boiling sugar. Condensed juice-gas in the indirect condenser going to collection bowl is as process water recycled by sugar mill. After passing through the exit of the indirect condenser, cooling water going to spray pond or hot water storage tank is as hot water for production or living water. The invention saves process water, and reduces discharge of sewage.

Owner:GUANGXI YUEGUI GUANGYE HOLDINGS CO LTD

Humic acid type water-retaining slow-release controlled-release organic fertilizer prepared from wastes of sugar mills and alcohol plants

ActiveCN103626594AIncrease productionPromote rootingClimate change adaptationBioloigcal waste fertilisersControl releaseAlcohol

The invention relates to a humic acid type water-retaining slow-release controlled-release organic fertilizer prepared from wastes of sugar mills and alcohol plants. The fertilizer contains active humic acid, a water-retaining agent, an organic fertilizer and a bactericide. The water-retaining slow-release controlled-release organic fertilizer can effectively promote crops to take root and increase production.

Owner:广西湾贝海洋生物科技有限公司

Method for production of cattle and sheep complete feed by twice fermentation of bagasse as raw material

ActiveCN106234755AImprove fermentation effectIncrease profitFood processingAnimal feeding stuffFermentationPasture

The invention discloses a method for production of cattle and sheep complete feed by twice fermentation of bagasse as the raw material. The cattle and sheep complete feed is prepared from the following raw materials by weight: 50-85 parts of bagasse, 10-15 parts of a plant material, 8-10 parts of corn flour, 5-8 parts of bean dregs, 5-8 parts of rice bran, 0.1-1 part of fermentation strain, and 0.1-0.3 part of trace elements. The plant material includes one of sugarcane tail end, cassava stem leaves, fresh pasture, wheat straw, rice straw, corn stalk, paper mulberry, peanut vine and weed or is a mixture of more than one of the substances. The method provided by the invention takes the sugar factory by-product bagasse for fermentation to prepare the cattle and sheep feed, belongs to a leftover recycle project and turns "waste" into wealth, does not discharge waste residue, and is green and environment-friendly. The making method is simple and low in cost. The cattle and sheep feed obtained by fermentation has comprehensive nutrition and fragrant and sweet taste, and improves the appetite of cattle and sheep, so that cattle and sheep can like eating and grow quickly.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI +1

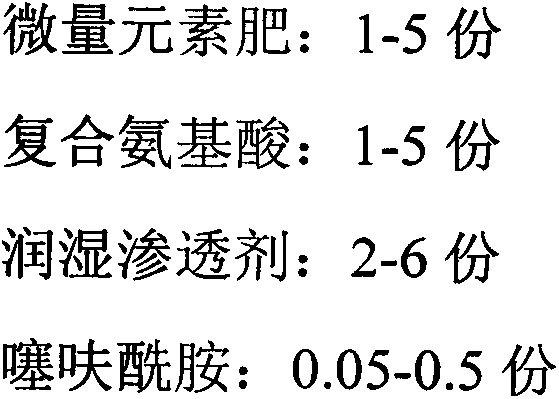

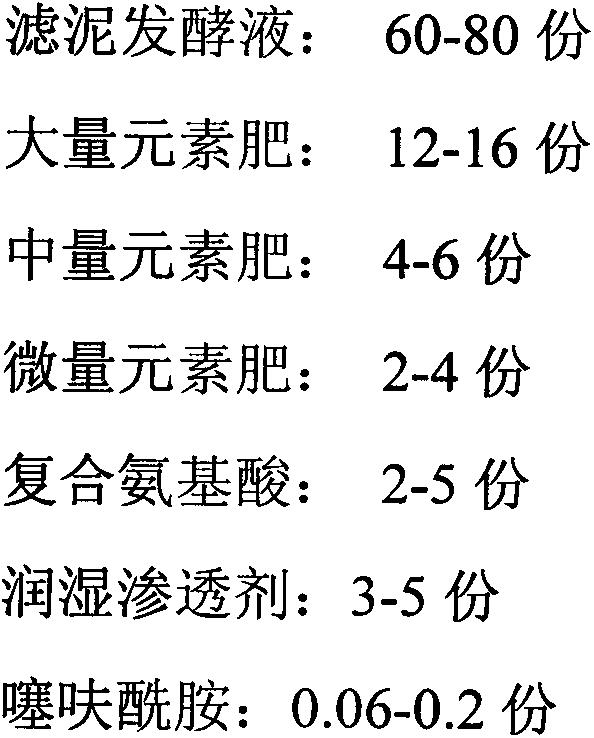

Humic acid type fluid compound fertilizer composition utilizing wastes from sugar mills, alcohol plants, gourmet powder factories and yeast plants

ActiveCN103896660ATake advantage ofIncrease chlorophyll contentFertilising methodsFertilizer mixturesMinor elementAlcohol

The invention relates to a humic acid type fluid compound fertilizer utilizing wastes from sugar mills, alcohol plants, gourmet powder factories and yeast plants and containing lime sludge and secondary and minor elements, which contains a lime sludge fermentation liquid, a secondary element fertilizer, a minor element fertilizer and the like. Preferably, the compound fertilizer also contains appropriate bactericide such as thifluzamide. The compound fertilizer can effectively increase the chlorophyll content of cucumber leaves, and can also increase the yield of cucumbers.

Owner:叶长东

Method for producing calcium formate from sugar mill filter mud

InactiveCN102924258ALess investmentReduce manufacturing costCarboxylic acid salt preparationCalcium formateSugar mill

The invention relates to the field of industrial waste reutilization, and particularly discloses a method for producing calcium formate from sugar mill filter mud. The method comprises the followings steps: crushing the raw material sugar mill calcium carbonate filter mud, grinding, and adding 70 wt% formic acid solution into the filter mud while stirring until no bubble is generated, thereby completing the reaction; and regulating the pH value to 6-7 with 25 wt% lime cream, separating the reaction solution, and drying to obtain the product. The invention has the advantages of simple production technique, low cost, short technical process, low energy consumption and low investment; the formic acid and calcium carbonate filter mud can be directly used as the raw materials to synthesize the ideal calcium formate product by one step; and the purity and quality of the product satisfy the general demands.

Owner:SHANDONG ZHONGGU STARCH SUGAR

Special fertilizer for kiwi fruit and production method thereof

InactiveCN106007854AHigh organic contentImprove breathabilitySuperphosphatesBio-organic fraction processingNutritionKiwi fruit

The invention relates to a special fertilizer for kiwi fruit and a production method thereof. The special fertilizer for kiwi fruit is prepared from the following raw materials in parts by weight: 50-80 parts of brewery waste, 40-60 parts of sugar mill residue, 30-40 parts of manioc waste, 15-20 parts of lime sludge, 5-7 parts of urea, 3-5 parts of ferrous sulfate, 5-8 parts of zinc sulfate, 10-15 parts of calcium superphosphate, 8-10 parts of potassium chloride, 5-8 parts of composite amino acid, 0.9-1.2 parts of secondary element, 0.1-0.2 part of minor element and 10-20 parts of alcohol slops. The special fertilizer for kiwi fruit has the effects of nitrogen fixation, phosphorus activation and potassium releasing; the secondary and minor elements contained in the fertilizer supplement the nutrients in the kiwi fruit growth process, and are capable of enhancing the organic content in the soil and improving the soil environment; and after the fertilizer is applied to the kiwi fruit, the kiwi fruit has favorable growth vigor, and the fruit quality is improved, thereby greatly enhancing the economic benefit.

Owner:象州县科学技术局

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com