Novel technique for quality-preservation treatment of sugar plant circulation cooling water

A technology of circulating cooling water and new technology, applied in water/sewage treatment, food industry wastewater treatment, heating water/sewage treatment, etc., can solve the problems of long-term recycling, acid and odor of circulating water, zero water intake and zero discharge, etc. , to achieve the effect of ensuring long-term recycling, improving water quality and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

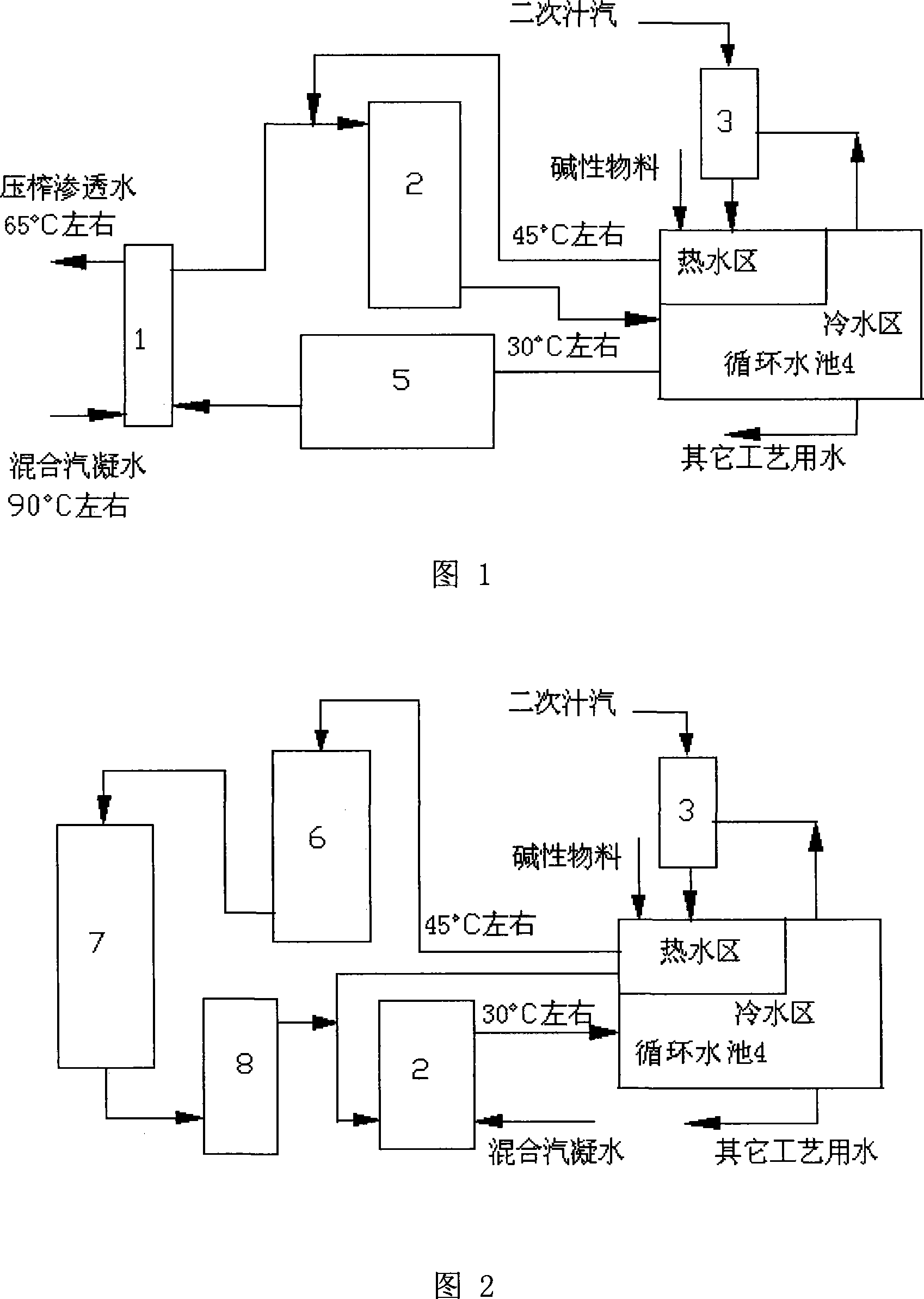

Embodiment 1

[0028]The mixed condensate water at about 90°C enters the plate heat exchanger 1, and the temperature drops after the heat exchange, and then enters the cooling tower 2 to continue cooling down, cools down to about 30°C, and enters the circulating water pool 4 as a supplementary water source for cooling water in the circulating water pool; The secondary juice vapor condensed water flowing out from the condenser 3 enters the circulating water pool 4 together with the cooling water, adds lime water or lime milk to make it reach neutrality (between pH about 7-7.5), and then enters the cooling tower 2 to cool to At about 30°C, it enters the circulating pool 4 for recycling; part of it passes through the ultrafiltration system 5 to remove suspended solids, microorganisms, and colloids, and then enters the heat exchanger 1 to heat up to about 65°C and send it to be squeezed as permeated water, and part of it can be used for other processes Water is used to lead out of the circulating...

Embodiment 2

[0030] The mixed condensate water at about 90°C enters the spiral plate heat exchanger 1, the temperature drops after the heat exchange, and then enters the cooling tower 2 to continue to cool down, cools down to about 30°C, and enters the circulating water pool 4 as a supplementary water source for cooling water in the circulating water pool ; The secondary juice vapor condensed water flowing out from the condenser 3 enters the circulating water pool 4 together with the cooling water, adds milk of lime or lime water to make it reach neutrality (between PH about 7-7.5), and then enters the cooling tower 2 for cooling When the temperature is about 30°C, it enters the circulating pool 4 for recycling; part of it passes through the ultrafiltration system 5 to remove suspended solids, microorganisms, and colloids, and then enters the spiral heat exchanger 1 to heat up to about 65°C and send it to be squeezed as permeated water, and part of it can be used as Other process water is d...

Embodiment 3

[0032] The secondary juice vapor condensed water flowing out from the condenser 3 enters the circulating water pool 4 together with the cooling water, adds milk of lime or lime water to make it reach neutrality (between pH about 7-7.5), and then enters the cooling tower 2 to cool to At about 30°C, it enters the circulating water pool 4 for recycling; part of the cooling water that has been circulated many times enters the boiler water film dust removal and ash flushing system 6, kills microorganisms at high temperature, and removes part of the colloid and sugar by the adsorption of ash. Then go through the sediment tank 7 and the filter system 8 to remove suspended solids and ash, then enter the cooling tower 2 to cool to about 30°C, and replenish the circulating cooling water; part of the circulating cooling water can also be used for other purposes, leading to the circulating water pool 4 to This promotes the rotation of circulating cooling water and improves the water qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com