Humic acid type fluid compound fertilizer composition utilizing wastes from sugar mills, alcohol plants, gourmet powder factories and yeast plants

A compound fertilizer and humic acid technology, applied in the direction of fertilizer mixture, application, fertilization methods, etc., can solve the problems of high energy consumption, high water content of filter mud, time-consuming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

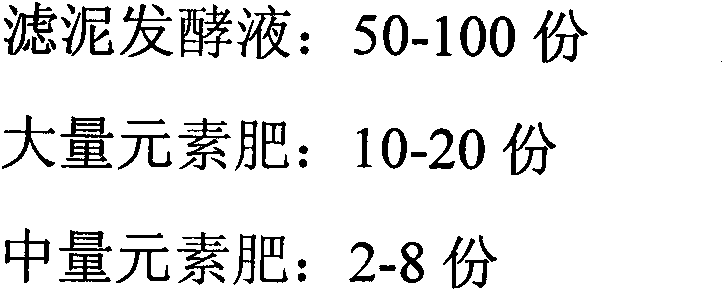

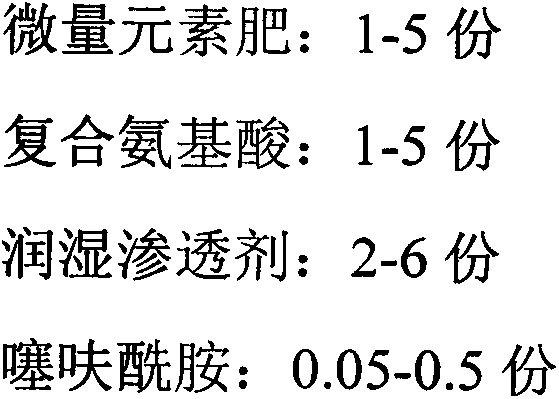

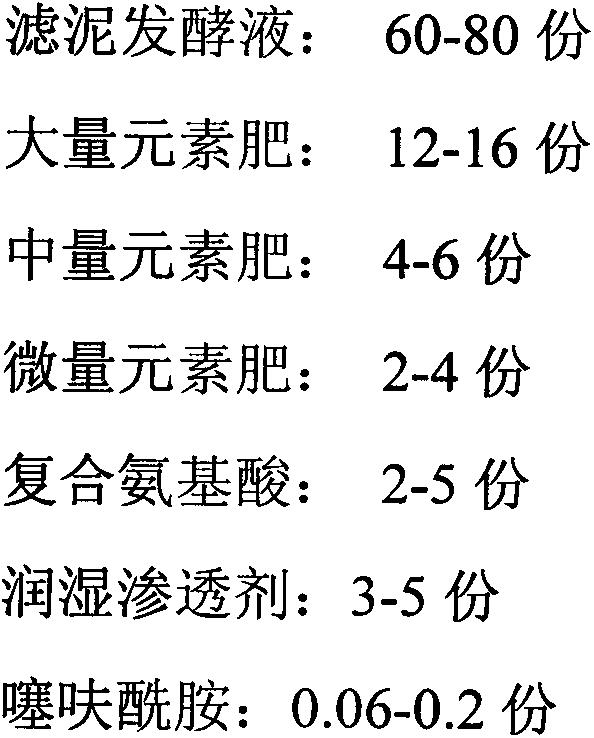

Method used

Image

Examples

Embodiment 1

[0112] Take by weighing 300kg of sugar cane sugar factory fresh filter mud, 6kg of fermented bacteria powder (wherein Aspergillus niger, Bacillus megaterium and nitrogen-fixing rhizobia are each 2kg, and the live bacteria content is greater than 10 billion / g) for subsequent use.

[0113] Clean the fermenter, and add 1000kg of water to the fermenter, then raise the temperature of the fermenter to 70°C; after that, add weighed fresh filter mud and fermentation bacteria powder to the fermenter in turn, and stir evenly; then filter the mud Fermentation was carried out, wherein the temperature of the fermentation liquid was maintained at 70° C., and the fermentation was continued for 8 days, with stirring once every 0.5 days.

[0114] After the fermentation is completed, let the fermented liquid stand at room temperature for 8 hours, collect the fermented liquid, and discard the sediment at the bottom; concentrate the obtained fermented liquid at 70°C until it reaches about 150kg, s...

Embodiment 2

[0117] Take by weighing 200kg beet sugar factory fresh filter mud, 4kg fermented bacteria powder (wherein each 2kg of Candida thermogelist and nitrogen-fixing rhizobia, and live bacteria content is greater than 10 billion / g) for subsequent use.

[0118] Clean the fermenter, add 700kg of water to the fermenter, then raise the temperature of the fermenter to 60°C; after that, add weighed fresh filter mud and fermentation bacteria powder to the fermenter in turn, and stir evenly; then filter the mud Fermentation was carried out, wherein the temperature of the fermentation liquid was raised to 75° C., and the fermentation was continued for 10 days, stirring once every 0.5 days.

[0119] After the fermentation is completed, let the fermented liquid stand at room temperature for 10 hours, collect the fermented liquid, and discard the sediment at the bottom; concentrate the obtained fermented liquid at 80°C until it reaches about 120kg, stop concentrating at this time, and lower the c...

Embodiment 3

[0122] Take by weighing 300kg of sugar cane sugar factory fresh filter mud, 6kg of fermented bacteria powder (wherein Aspergillus niger, Bacillus megaterium and nitrogen-fixing rhizobia are each 2kg, and the live bacteria content is greater than 10 billion / g) for subsequent use.

[0123] Clean the fermenter, and add 1000kg of water to the fermenter, then raise the temperature of the fermenter to 70°C; after that, add weighed fresh filter mud and fermentation bacteria powder to the fermenter in turn, and stir evenly; then filter the mud Fermentation was carried out, wherein the temperature of the fermentation liquid was maintained at 70° C., and the fermentation was continued for 8 days, with stirring once every 0.5 days.

[0124] After the fermentation is completed, let the fermented liquid stand at room temperature for 8 hours, collect the fermented liquid, and discard the sediment at the bottom; and concentrate the obtained fermented liquid at 70°C to 1 / 6 of the initial weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com