Biological soil conditioning agent containing sugar mill alcohol waste liquid, filter residue or peat

A technology of sugar factory alcohol waste liquid and biological soil, which is applied in the field of biological soil conditioners, can solve the problems of poor pertinence and unsatisfactory effects, and achieve the effects of increasing crop yield, optimizing structural balance, and reducing heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

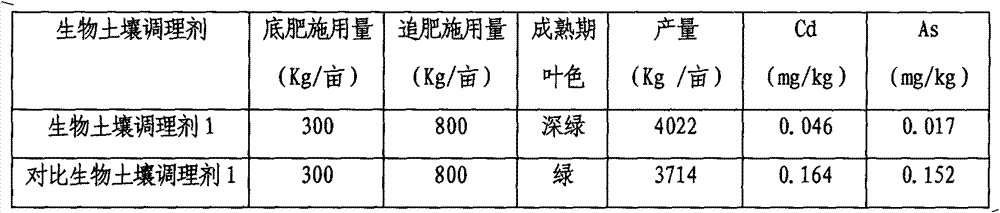

Examples

Embodiment 1

[0032] Embodiment 1 biological soil conditioner

[0033] Store 10 tons of sugar factory alcohol waste liquid in the storage tank, add 37.5%wt dilute sulfuric acid, stop adding dilute sulfuric acid when the pH in the waste liquid is less than 1, then store it at room temperature for 10 days, then add ammonia water to adjust the pH to 6-7 , to obtain acid-alkali treated sugar factory alcohol waste liquor;

[0034] 4 kg of Bacillus subtilis powder, 1 kg of Pseudomonas aeruginosa powder, 1.5 kg of Aspergillus niger powder, 1.5 kg of Aspergillus oryzae powder and 2 kg of Streptomyces luteus powder were fully mixed to prepare filter sludge microbial starter. The above-mentioned bacteria powder is purchased from the market and requires bacteria powder with a live bacteria content of 10-20 billion / gram.

[0035] 1 ton of sugar factory filter mud and 2 kg of the above filter mud microbial starter were mixed and fermented for 15 days to obtain microbially fermented sugar factory filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com