Soil conditioner containing sugar refinery alcohol waste liquor, filter mud and peat

A technology of alcohol waste liquor from sugar mills and soil conditioner, which is applied in fertilizer mixture, fertilization device, application and other directions, can solve the problems of huge energy and poor product effect, etc., to increase sugarcane yield, reduce application cost, and increase sugarcane content. effect of sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

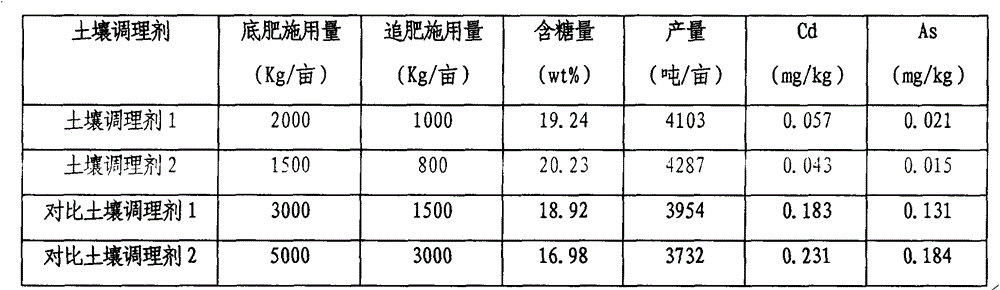

Examples

Embodiment 1

[0021] Example 1 Soil conditioner 1

[0022] 500kg of sugar factory filter mud is piled up in the yard in advance, covered with plastic film for natural fermentation, and fermented for 30 days to become decomposed sugar factory filter mud. 5000kg of sugar factory ethanol waste liquid is stored in storage tank, add the dilute sulfuric acid of 37.5%wt, the add-on of dilute sulfuric acid is 500kg, add ammoniacal liquor after storage 5 days and adjust pH to be 6.0-6.5, obtain and handle sugar factory ethanol waste liquid; Treatment of storage tanks Add fermented and mature sugar factory filter mud to the sugar factory alcohol waste liquid, and then add 150kg of peat and stir thoroughly to obtain soil conditioner 1.

Embodiment 2

[0023] Embodiment 2 Soil conditioner 2

[0024] 500kg of sugar factory filter mud is piled up in the yard in advance, covered with plastic film for natural fermentation, and fermented for 30 days to become decomposed sugar factory filter mud. 5000kg of sugar factory ethanol waste liquid is stored in storage tank, add the dilute sulfuric acid of 37.5%wt, the add-on of dilute sulfuric acid is 500kg, add ammoniacal liquor after storage 5 days and adjust pH to be 6.0-6.5, obtain and handle sugar factory ethanol waste liquid; Treatment of storage tanks Add fermented decomposed sugar factory filter mud to the sugar factory alcohol waste liquid, then add 150kg of peat and 10kg of chitosan and stir thoroughly to obtain soil conditioner 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com