Method and device for comprehensively utilizing water from boiling sugar production

A technology for producing water and boiling sugar, which is applied in sucrose production, sugar production, lighting and heating equipment, etc., to save production water and reduce harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

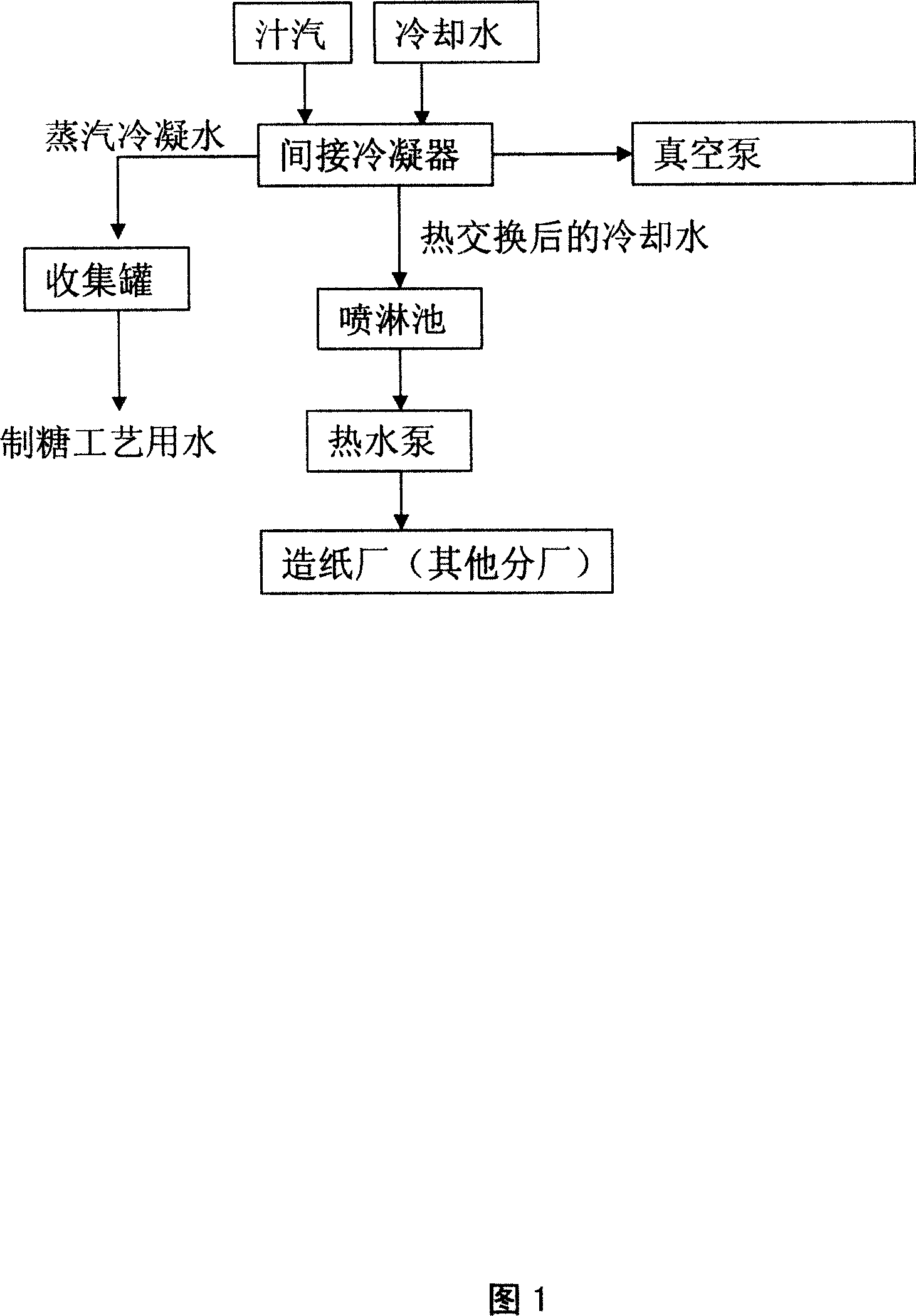

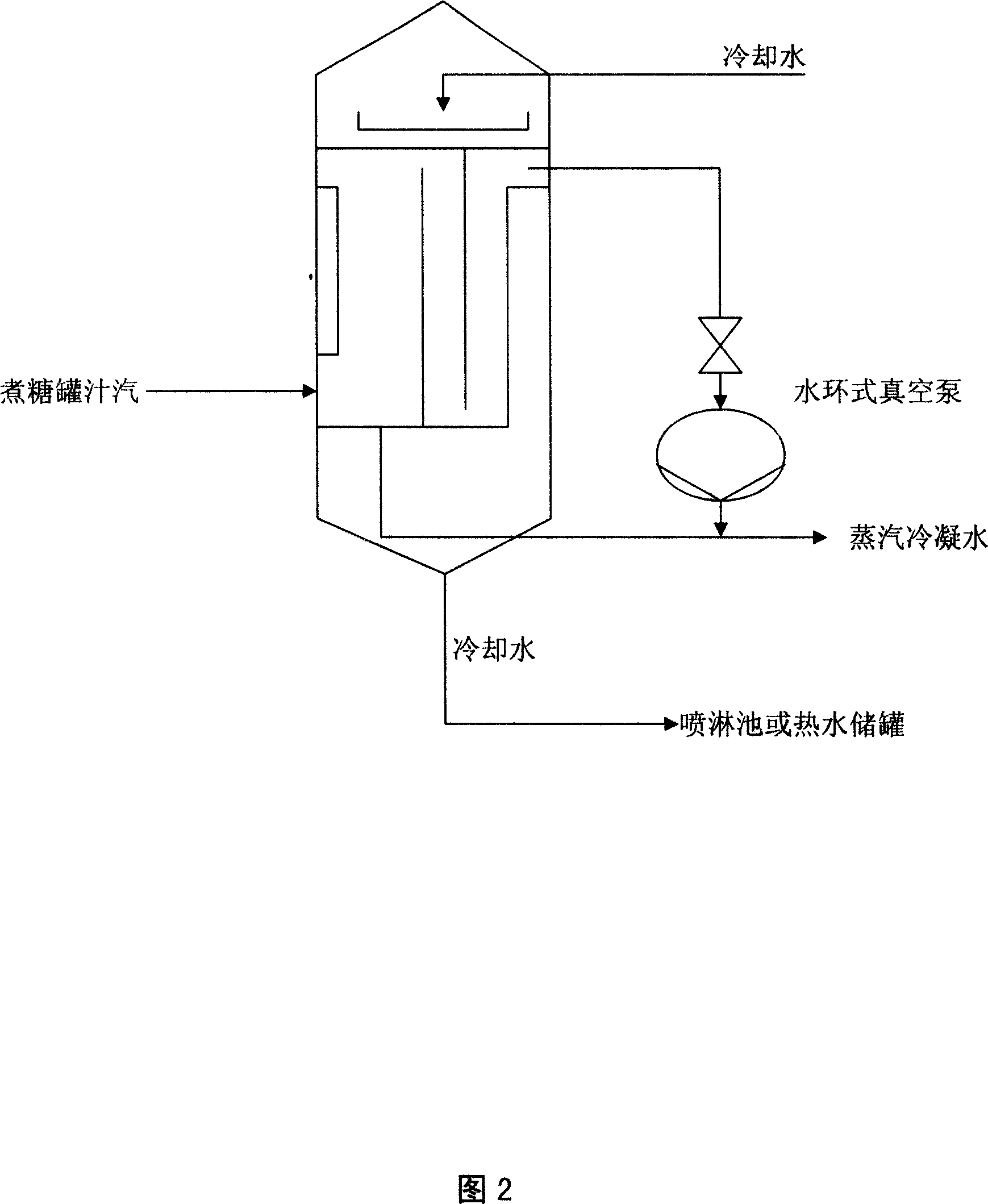

[0017] Water ring vacuum pump + clapboard condenser replaces the water jet condenser of the existing sugar boiling tank in the sugar factory to evacuate, completely avoiding the contact between boiling sugar juice vapor and water during the condensation process, and collecting cooling water and condensed water separately . Boiling sugar spray water (cooling water) rises from 20-30°C at the inlet of the plate condenser to 45-85°C without any sugar and impurities. No matter it is primary water or secondary water, it is all supplied to papermaking The plant is used as bagasse cooking or pulp washing, and the juice vapor condensate water is used as a high-quality process water to reuse the first sugar sieving and washing water in the sugar factory.

Embodiment 2

[0019] Use a centrifugal vacuum pump + tube condenser to replace the existing water jet condenser in the sugar boiling tank of the sugar factory to evacuate the vacuum, completely avoiding the contact between the boiled sugar juice vapor and water during the condensation process, and collecting the cooling water and condensed water separately. Spraying water (cooling water) for boiling sugar rises from 20-30°C at the inlet of the plate condenser to 45-85°C, without any sugar and impurities. Whether it is primary water or secondary water, spray water After treatment, all of it will be used as preheating boiler water (use the heat exchanger to heat the soft water to reduce the fuel consumption of the boiler), and the juice vapor condensed water will be reused as a high-quality process water for pressing or washing filter cloth in sugar factories .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com