Biological filter material by utilizing sugar mill mud and method

A technology of biological filter material and sugar filter mud is applied in the field of porous ceramic materials, which can solve the problems of small specific surface area and high cost, and achieve the effects of large specific surface area, improved strength and favorable surface electrostatic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

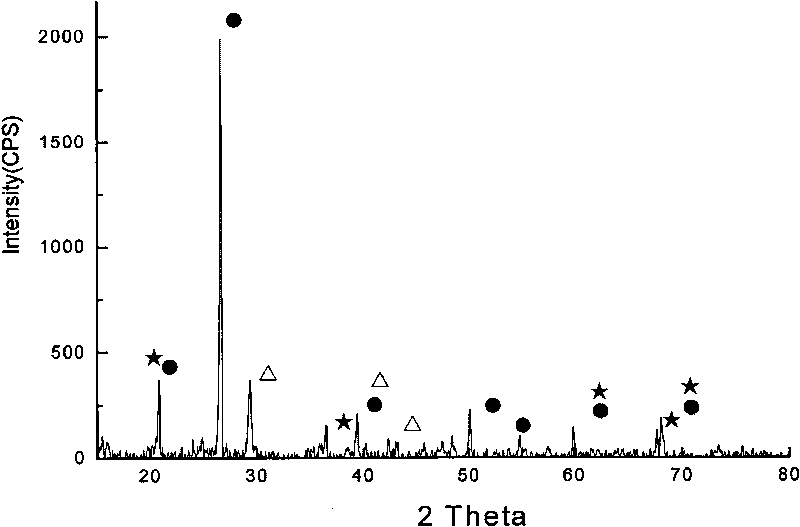

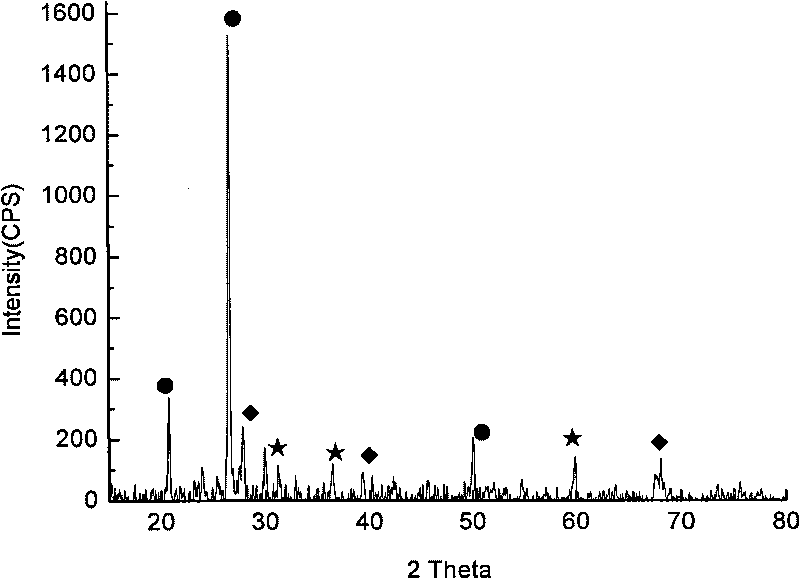

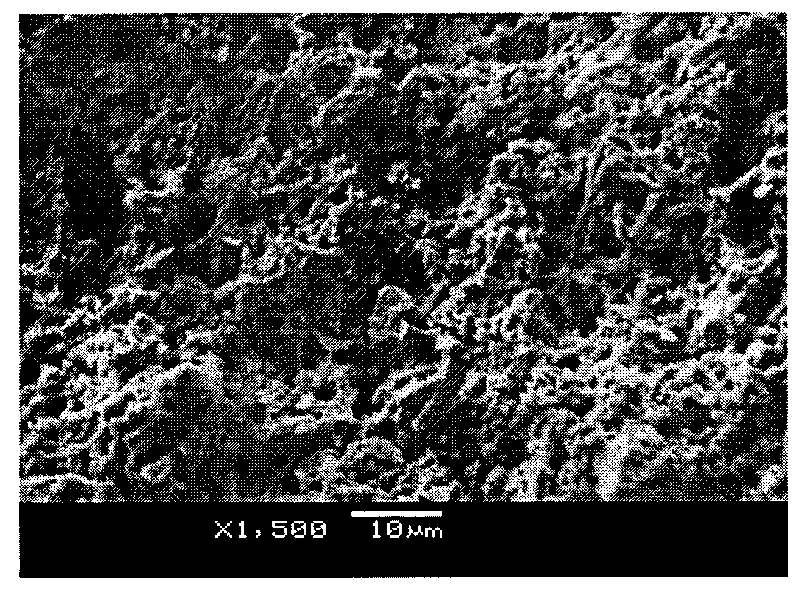

Image

Examples

Embodiment 1

[0029] 1. Pretreatment of raw materials: dry the wet sugar filter mud naturally in the sun to make its moisture content below 13%, and store it in a closed container. The recycled waste ceramics are cleaned and crushed so that the particle size is less than 1mm.

[0030] 2. Weighing according to the mass ratio of raw materials, i.e., 30-35% of sugar filter mud: 15-20% of waste ceramics, 40-45% of clay, and 5-10% of pore-forming agent. The mass ratio of the material to the grinding body is set at 1:2, and water with a weight of 20-30% of the material is added, and then sugar filter mud, waste ceramics and clay are ball-milled. After ball milling, the material passes through a 100-mesh sieve.

[0031] 3. After the ball-milled material is properly dehydrated, the weighed pore-forming agent is added and kneaded repeatedly to make it meet the requirement of uniform mixing, and it is aged for 24 hours.

[0032] 4. Mold the stale mud material through a mold to prepare a spherical b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com