Low temperature processing technique for sugar mill mixing liquor by sulfurous acid method

A sulfite method sugar factory, low-temperature treatment technology, applied in the direction of oxidation/reduction purification, etc., can solve the problems of reducing the filtration performance of filter cloth, achieve high clarification effect, fast precipitation speed, and reduce the precipitation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

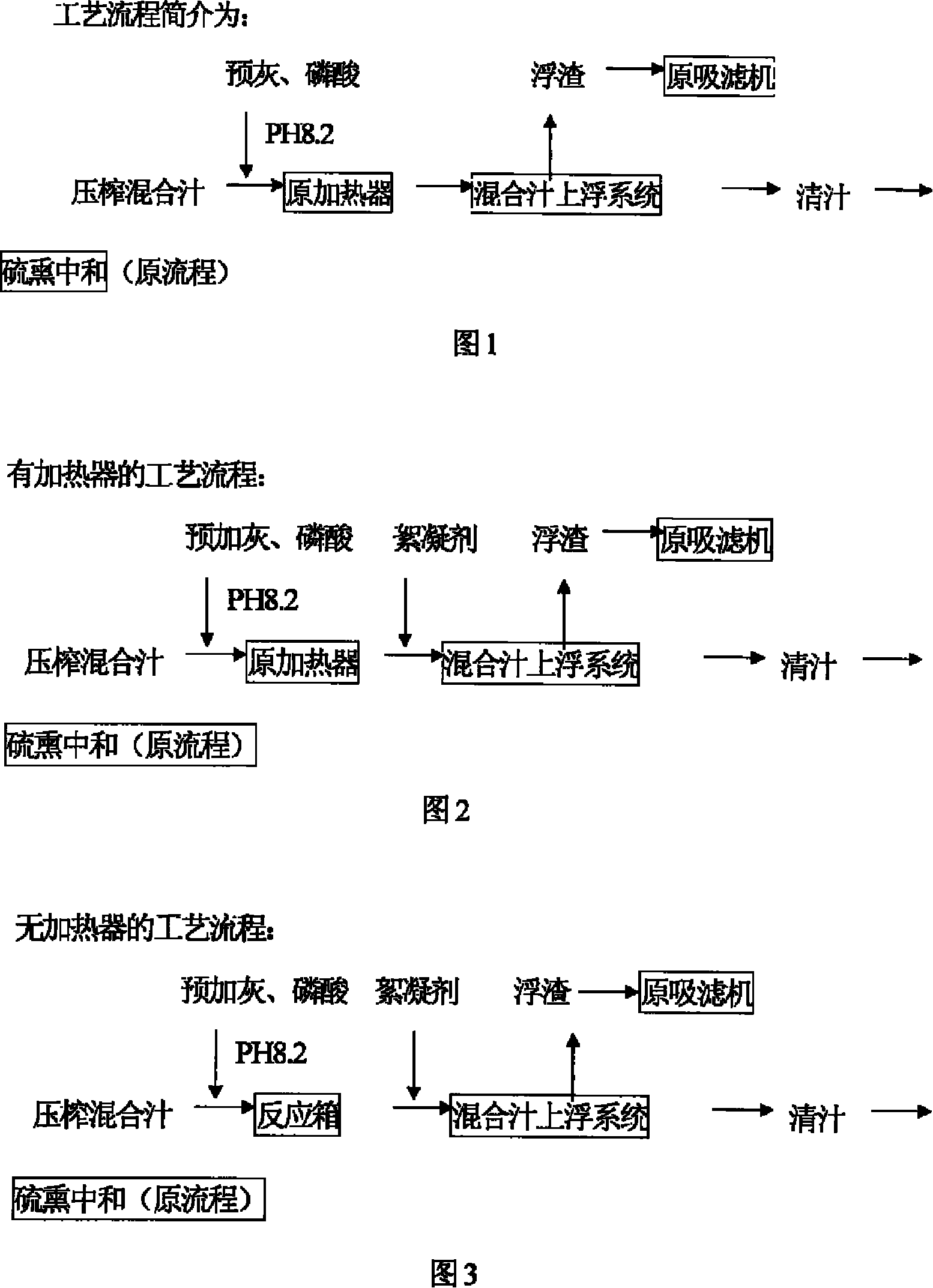

[0040] First kind of technological process of the present invention is:

[0041] (1) Add 2-10 Baumé milk of lime aqueous solution to the squeezed mixed juice, mix the solution and prepare a solution with a pH value (6-12);

[0042] (2) After the above solution is prepared, a flocculant solution with a concentration of 0.01-0.2% is added therein for mixing, and the addition amount is 1-4ppm;

[0043] (3) The mixed solution is sent to the floater;

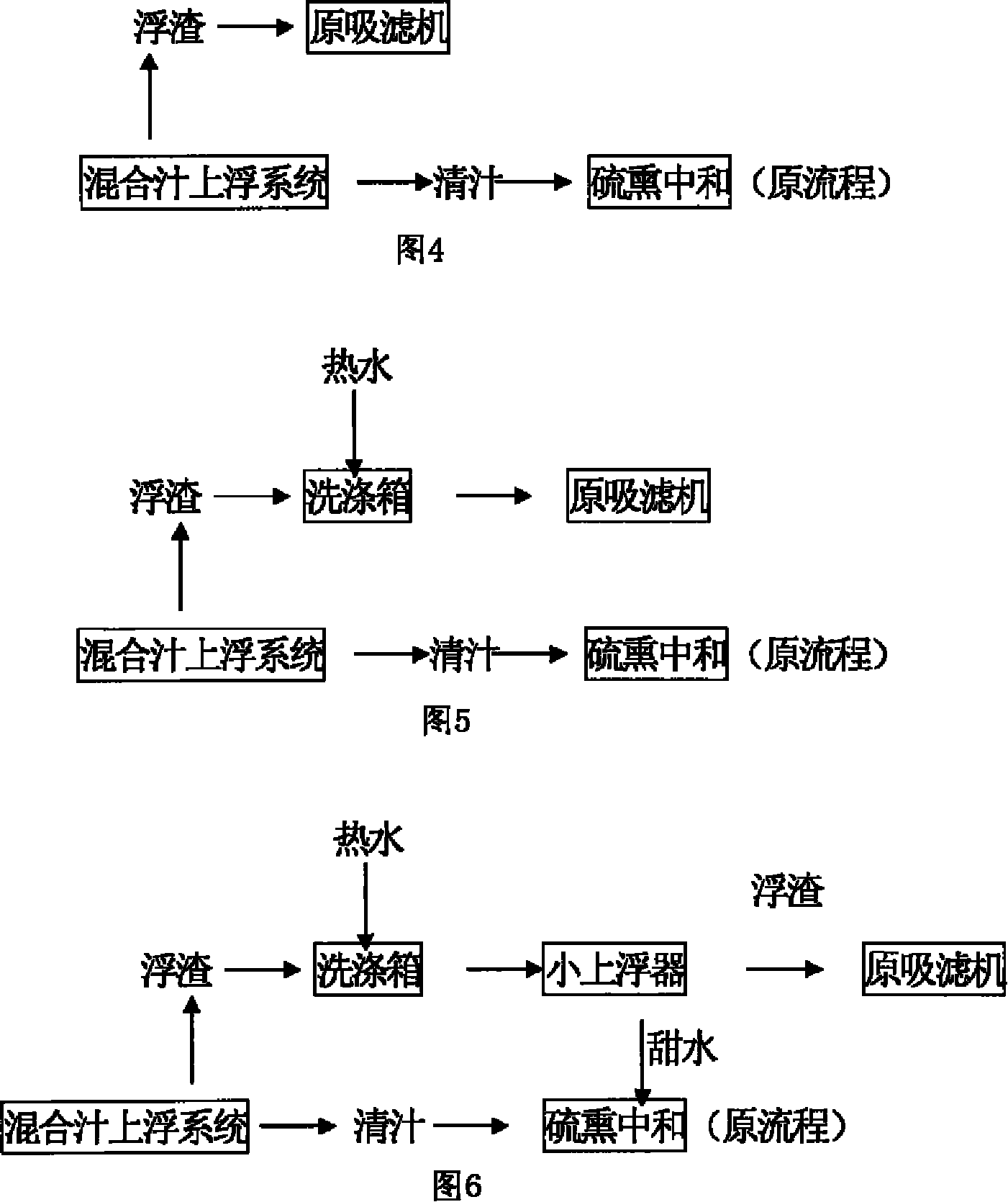

[0044] (4) The scum is discharged to the suction filter or treated with another small floater, and the clear juice is sent to the sulfur fumigation for neutralization.

[0045] In addition to the above-mentioned technical scheme, after adding 2-10 Baume degrees of lime milk aqueous solution into the squeezed mixed juice, you can also add:

[0046] (1) Phosphoric acid with a total phosphoric acid value of 50-2000ppm is prepared into a solution with a pH value (6-12) after mixing the solutions. Add a flocculant solution with a conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com