Method for preparing fertilizer effect type molasses alcohol waste mash bacterial liquid through triple fermentation

A technology of molasses alcohol and triple fermentation, applied to fertilizers made of biological waste, organic fertilizers, fertilization devices, etc., can solve problems such as aggravating soil deterioration, soil compaction, and damage to plant roots, stems, and leaves, and achieve increased rhizosphere activity. Fertility, Improve crop fertilizer efficiency and reduce pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

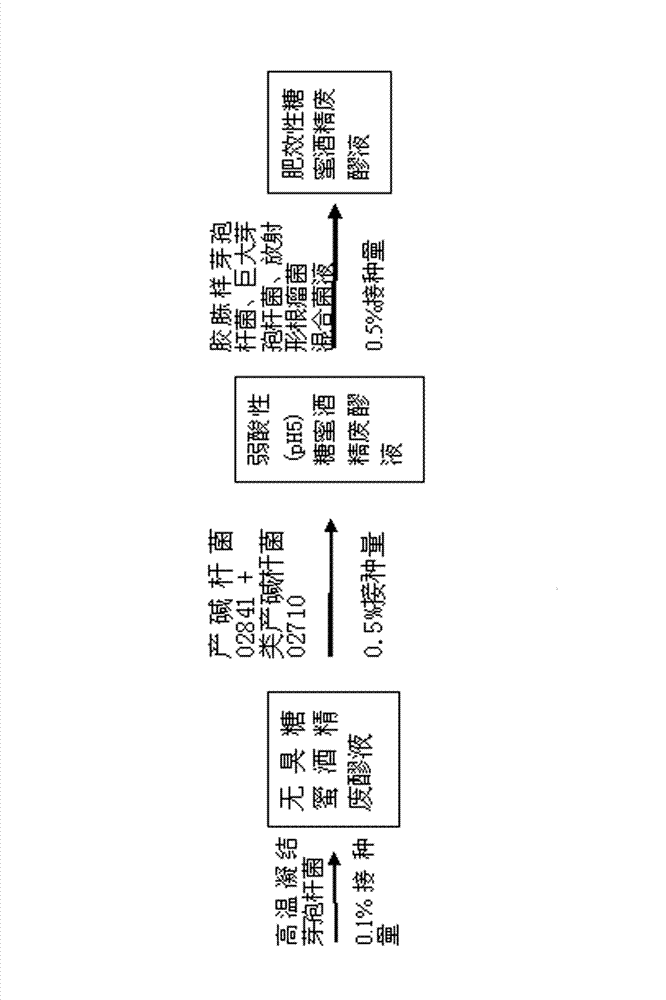

Method used

Image

Examples

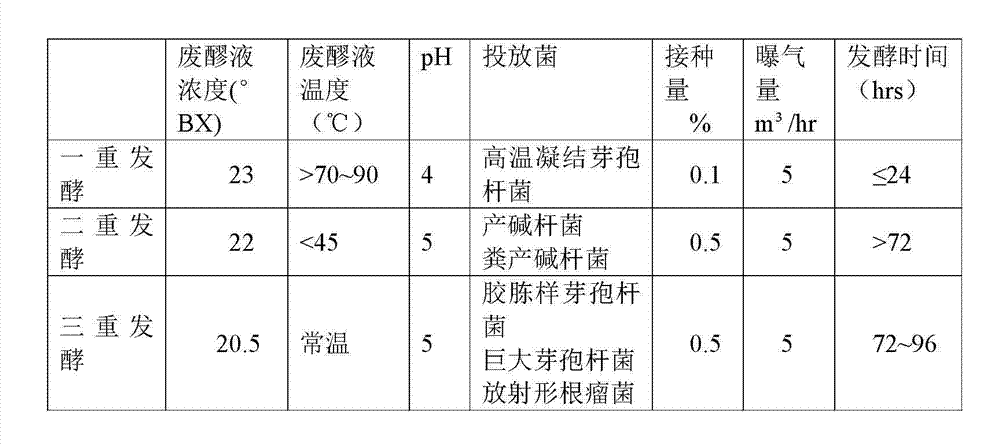

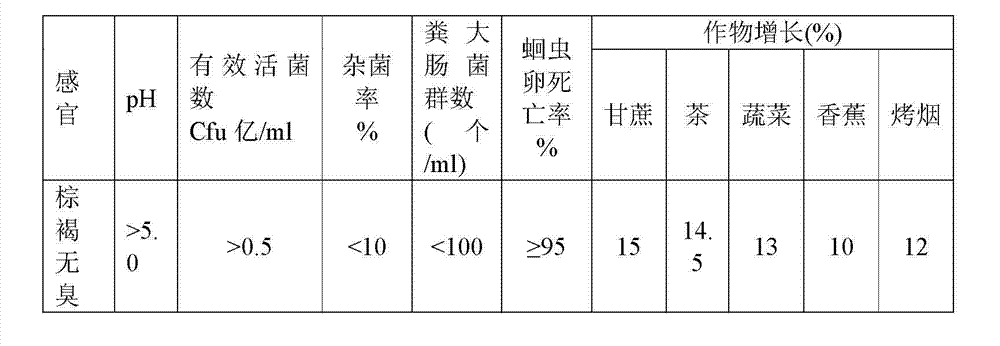

Embodiment 1

[0014] Example 1 The high-temperature Bacillus coagulans bacterial liquid (>1×10 7 / ml) evenly mixed into the bagasse, then put into a woven bag, and fixed at the outlet of the high-temperature waste mash. After the waste mash is filled with the pool, the liquid temperature drops below 45°C, and 0.5% of the waste mash is added to produce alkali Bacillus 0841 and Alcaligenes faecalis 01720 (1:1) mixed bacterial solution (>1×10 7 / ml) ferment for more than 72hrs at an aeration rate of 5m3 / hr, and when the pH reaches 5, add 0.5% of the waste mash to Bacillus peptiformis, Bacillus megaterium and Rhizobium radiata (1:1:1) Mixed bacteria solution (>1×10 7 / ml) was fermented at 5m3 / hr ventilation for 72~96hrs, the waste mash liquid was applied to sugarcane field at 10 tons / mu, and tea, bananas, etc. were applied at more than 1 ton / mu, and the yield increase rate was more than 10~15%.

Embodiment 2

[0015] Example 2 After the tank is filled with high-temperature waste mash, add high-temperature Bacillus coagulans bacterial liquid with 0.5% waste mash, and when the liquid temperature drops below 45°C, add Alcaligenes 0841 and feces with 0.5% waste mash The mixed bacterial liquid of Alcaligenes 01720 is fermented for more than 72hrs under the ventilation rate of 5m3 / hr, and when the pH reaches 5, the mixed bacteria of Bacillus peptiformis, Bacillus megaterium and Rhizobium radiata with 0.5% of the waste mash are added liquid, under 5m3 / hr aeration rate, fermented 72~96hrs, and this bacterium liquid all has more than 10~15% yield increase rate on different crops according to example 1 application rate.

Embodiment 3

[0017] Put the barreled high-temperature coagulum Bacillus coagulans liquid (>1×10 7 / ml), when the high-temperature waste mash above 90°C is just discharged, it flows into the waste mash from the outlet through a straw, and the others are injected into the pool mouth at the same time. When the liquid temperature drops to 45°C, add 0.5% of waste mash The mixed bacterial solution of Alcaligenes 0841 and Alcaligenes faecalis 01720 was fermented for 80hrs at an aeration rate of 5m3 / hr. When the pH reached 5, the same fertilizer-effect mixed bacterial solution was added according to the above ratio. Under the same aeration rate, , Fermented more than 80hrs, this bacterium liquid is applied on the same crop according to embodiment 1, all has the effect of increasing production of about 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com