Method for preparing granular compound fertilizer

A kind of compound fertilizer and granular technology, applied in the direction of fertilization device, fertilizer mixture, application, etc., can solve the problems of limited application, limited fertility, etc., and achieve the effect of high mechanical strength, convenient transportation and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] a. Preparation of water-absorbent resin

[0023] Add 3 parts of sodium alginate into the reactor, add 200 parts of distilled water to dissolve, add 26.7 parts of acrylic acid, then add 10.4 parts of sodium hydroxide for neutralization, then add 13.3 parts of acrylamide, 4 parts of humic acid, 0.4 parts Ammonium persulfate and 0.024 parts of N,N'-methylenebisacrylamide were stirred evenly, then heated to 75°C, and reacted for 3 hours. After the reaction, the product is dried, pulverized, and passed through a 110-mesh sieve to obtain a water-absorbent resin for use.

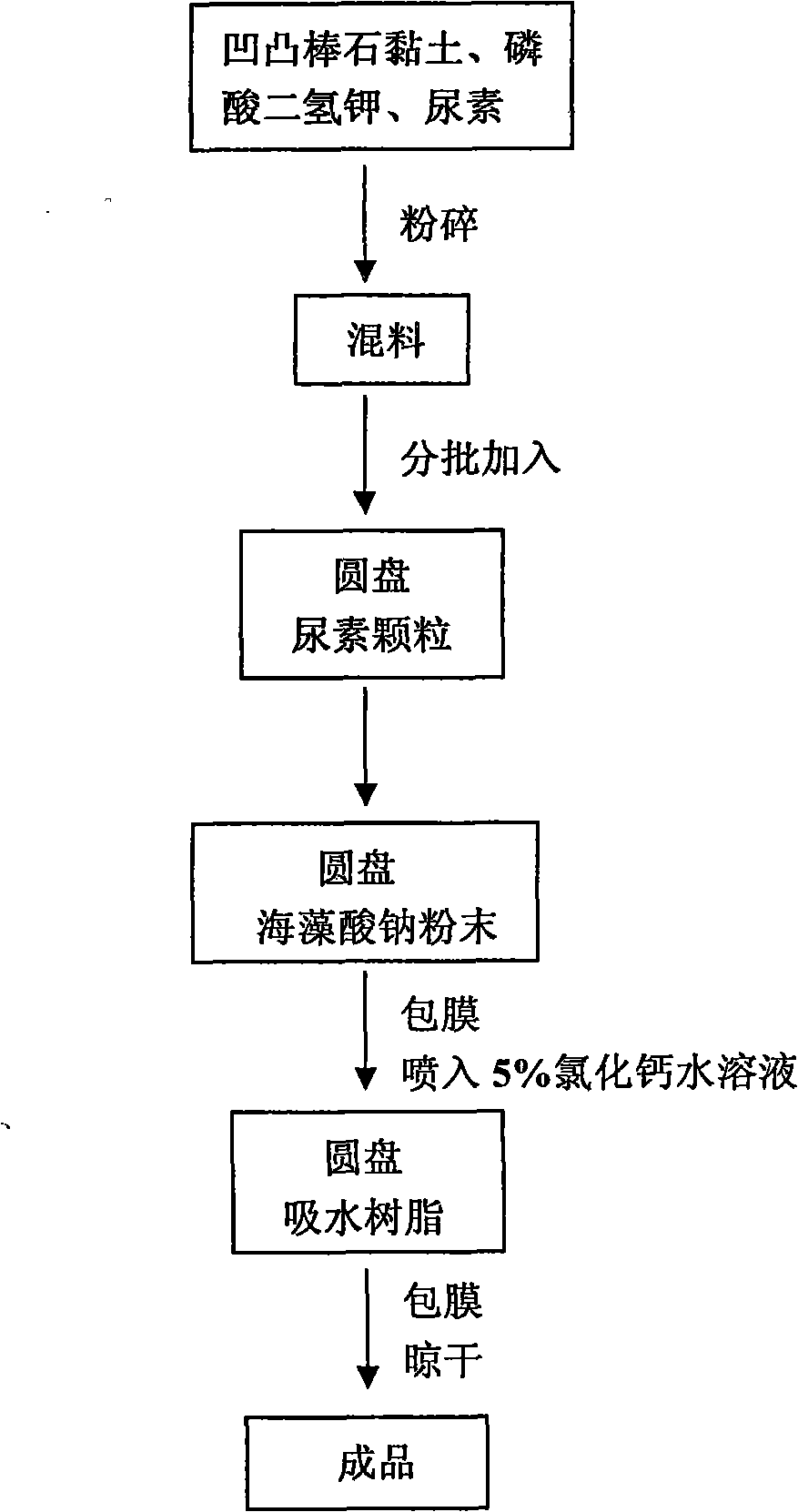

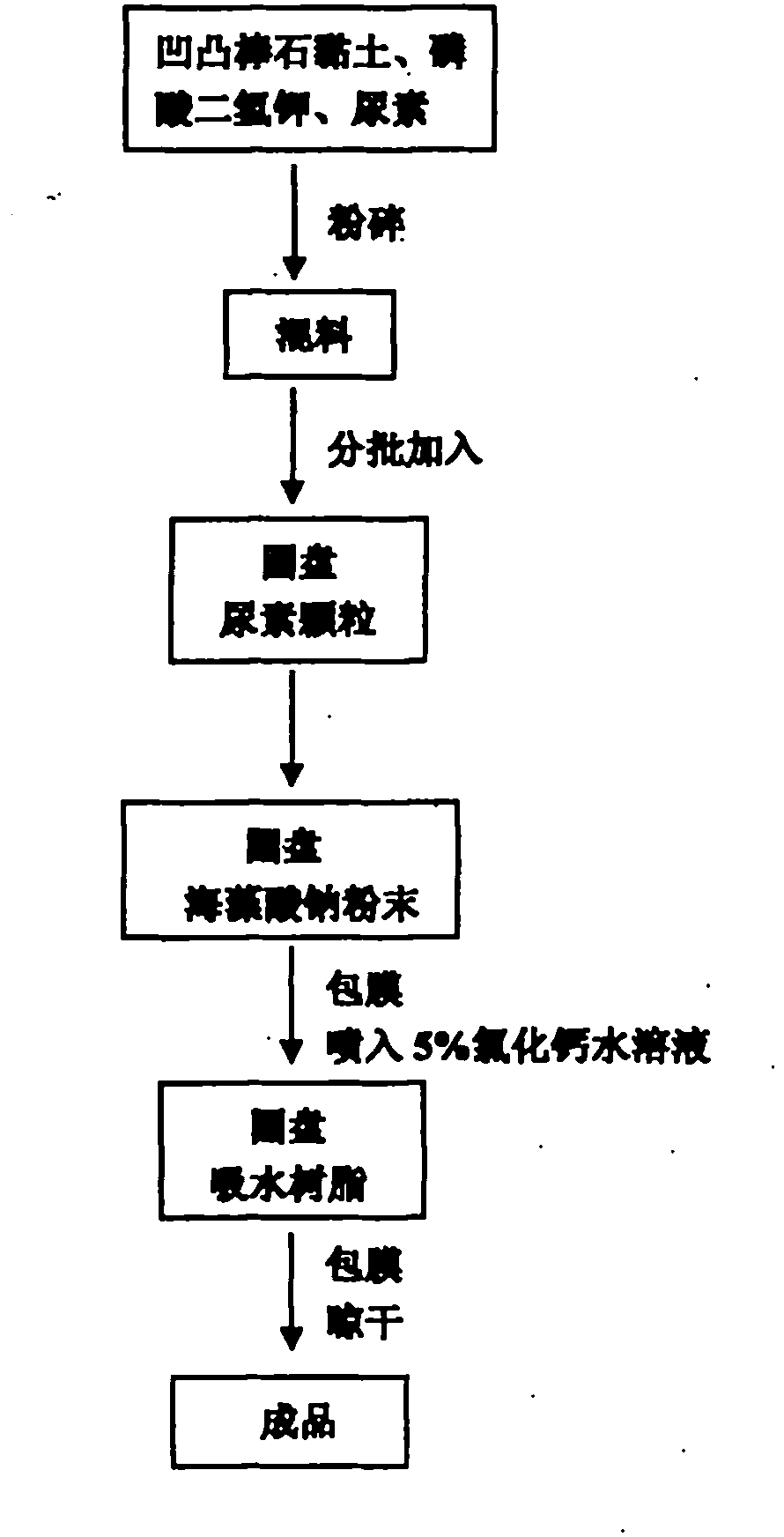

[0024] b. Preparation of Granular Compound Fertilizer

[0025] i. Crush 70 parts of attapulgite clay, 50 parts of urea and 50 parts of potassium dihydrogen phosphate, pass through a 150-mesh sieve, and mix well.

[0026] ii. Put 30 parts of urea granules with a diameter of 1-2mm in the disc granulator (Construction Research Institute of Xingyang City, Henan Province, model LZ25), spray atomized water to we...

Embodiment 2

[0031] Embodiment 2: The production conditions of the water-absorbent resin are the same as in Embodiment 1. Pulverize 60 parts of attapulgite clay, 60 parts of urea and 70 parts of potassium dihydrogen phosphate, pass through a 150-mesh sieve, mix evenly and add it in 9 times to a disc with 40 parts of granular urea with a particle size of 1-2mm , wrapped under the action of atomized water, so that the mixed powder is wrapped on the surface of granular urea. Next, 15 parts of sodium alginate powder passed through a 110-mesh sieve was added into the disc for rolling coating, and after the coating was completed, 5% calcium chloride aqueous solution was sprayed. Finally, 20 parts of the prepared water-absorbing resin powder are passed through a 110-mesh sieve, put into a disc for rolling coating, and dried to obtain a finished granular fertilizer with a particle size of 2.5-3.5 mm. The content of sodium alginate in the inner layer of the finished product is 9%, the amount of ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com