Patents

Literature

113results about How to "Guaranteed denitrification efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

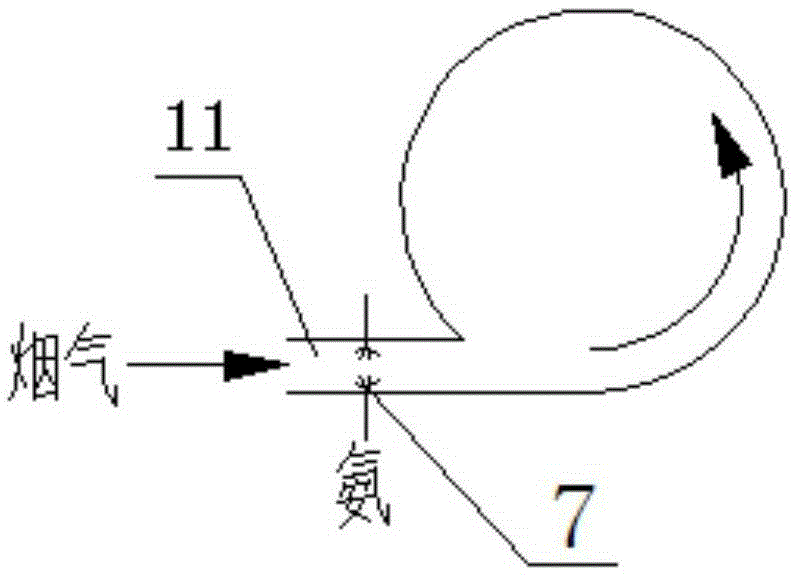

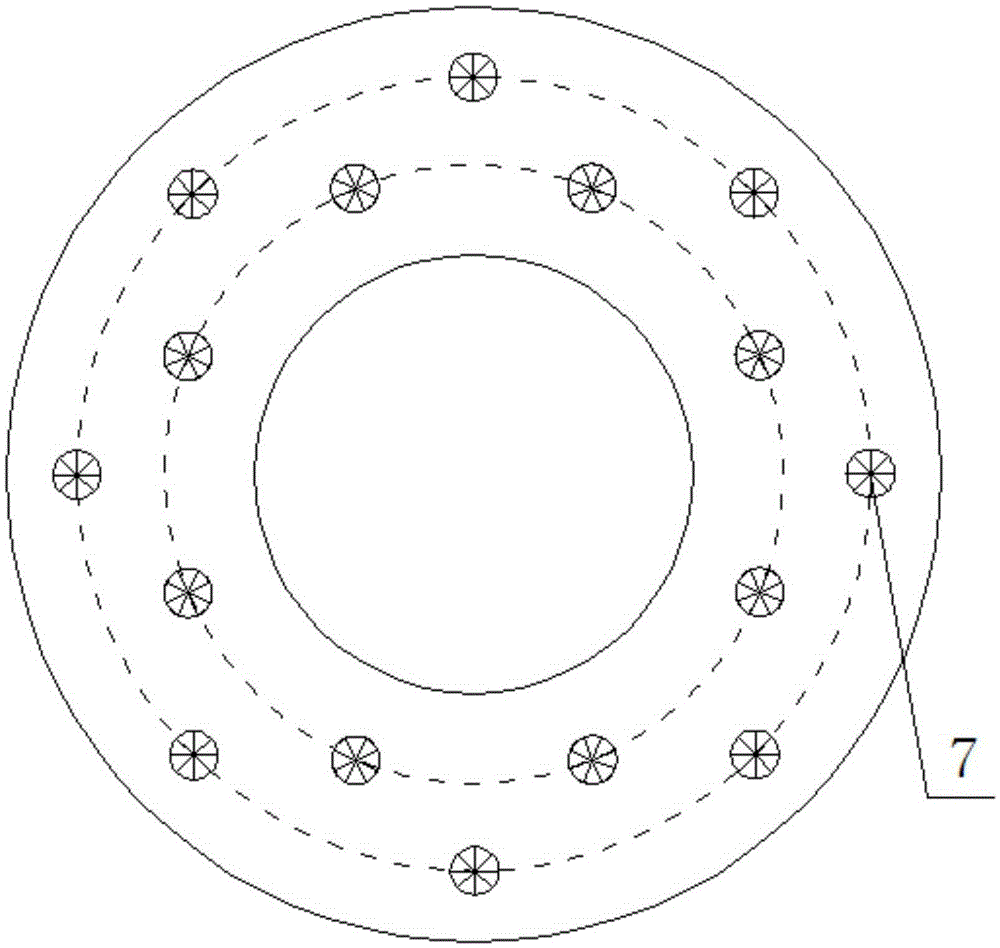

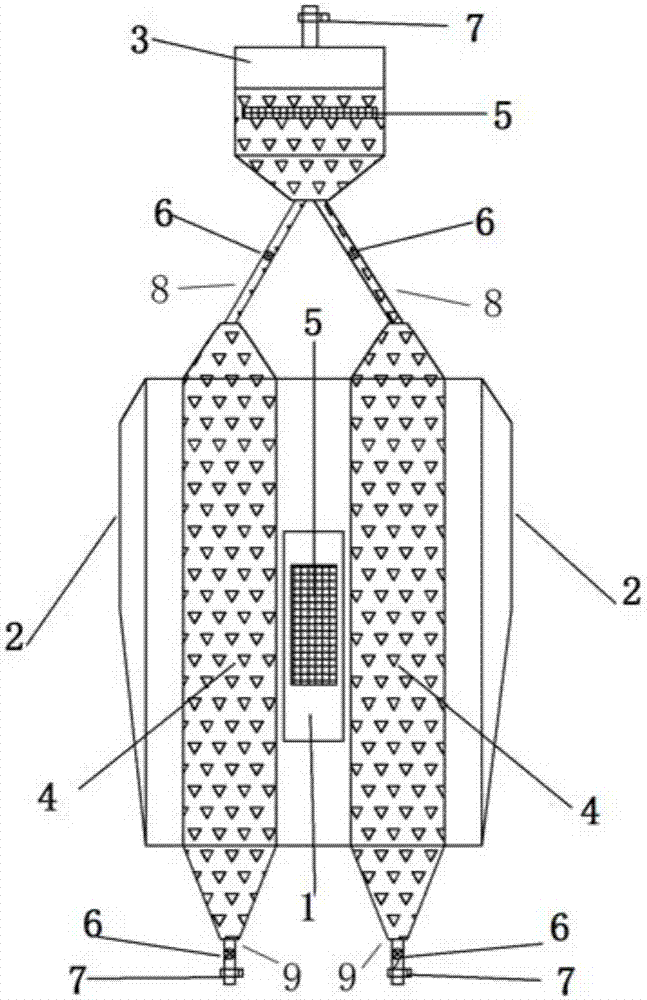

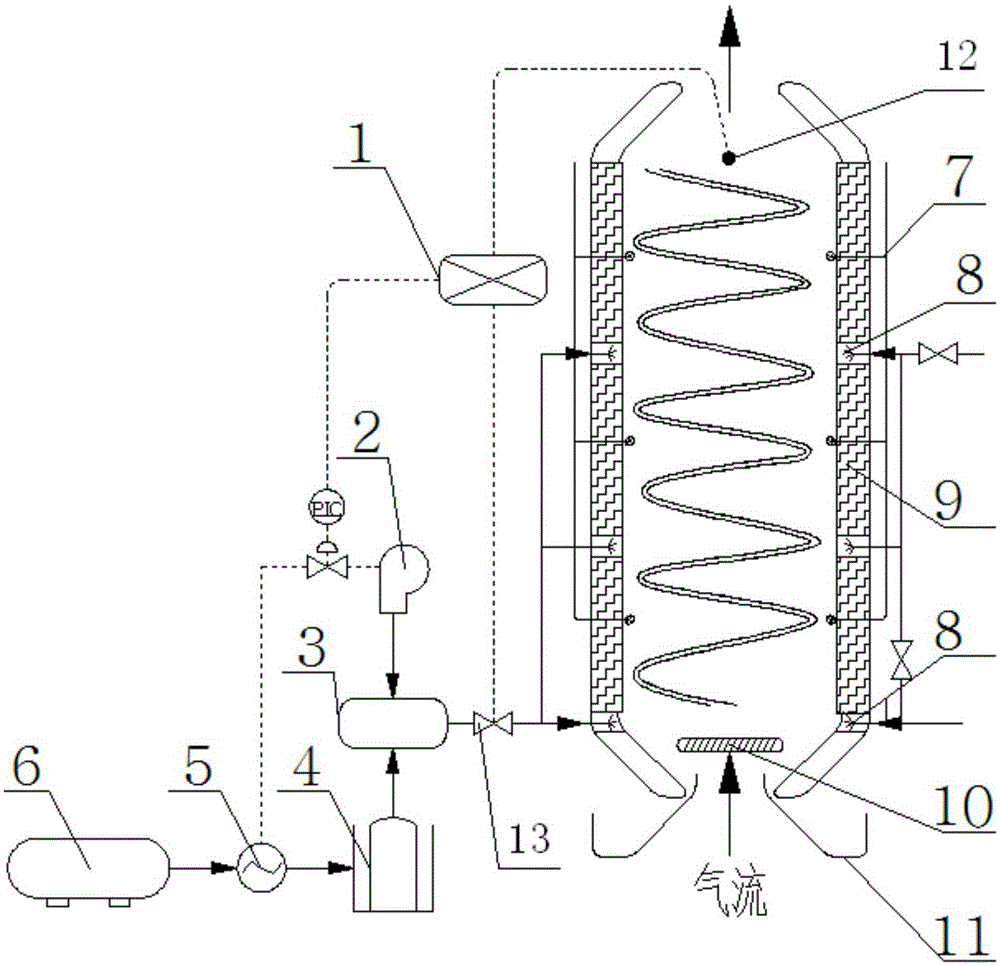

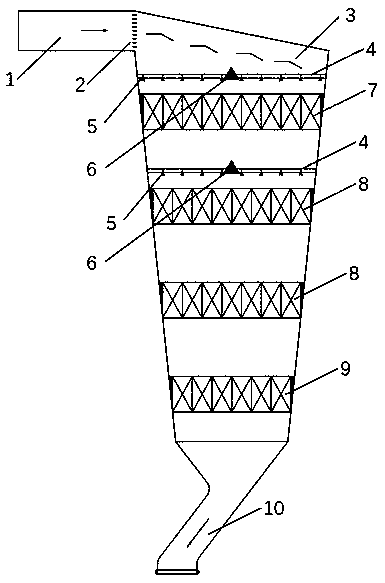

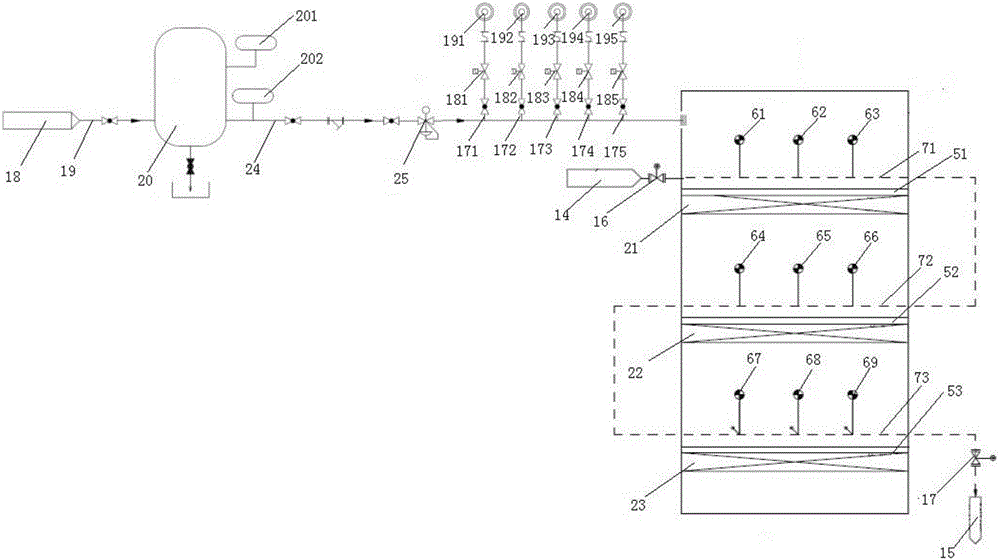

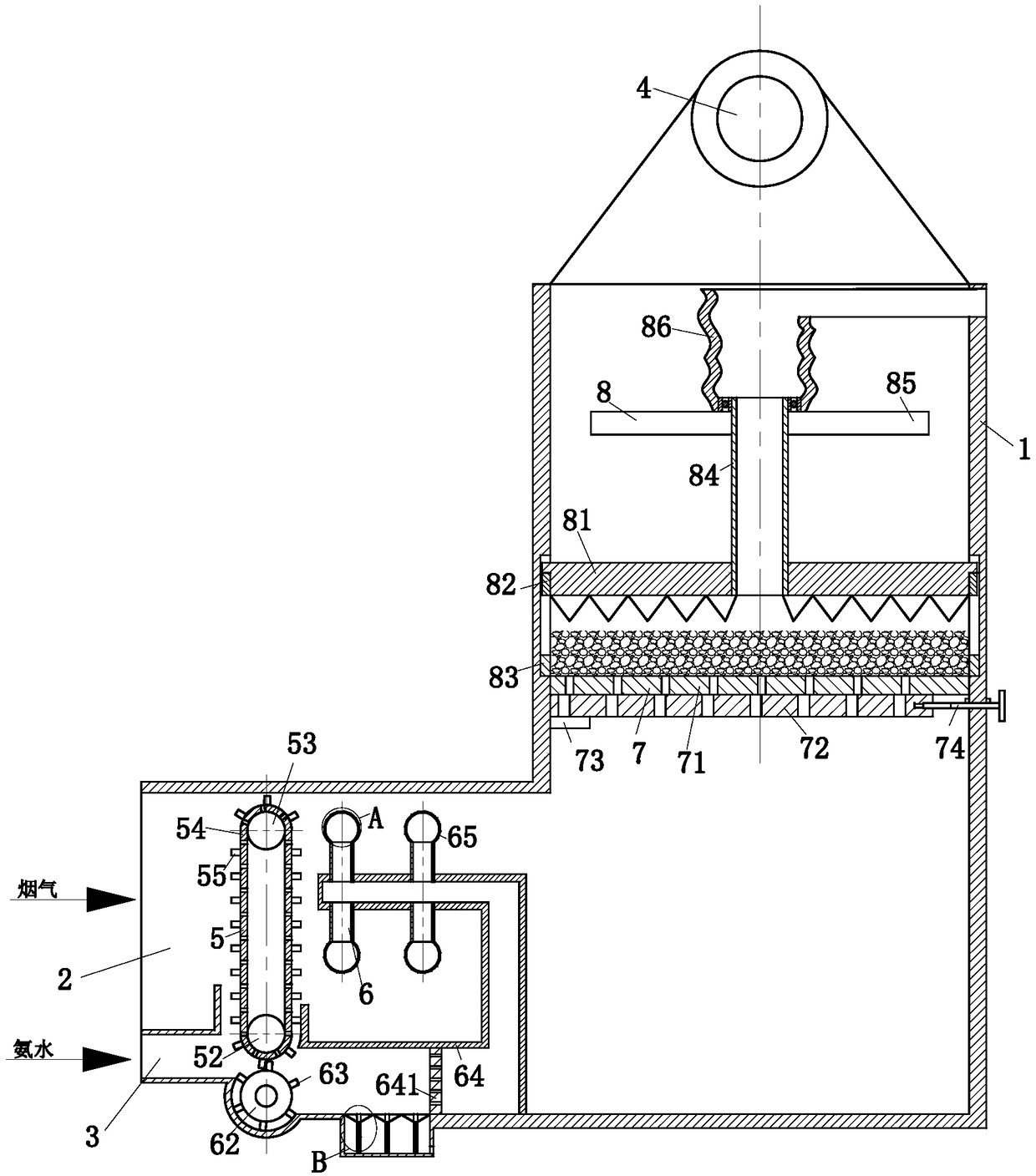

Double-rotation SCR denitration method and apparatus thereof

ActiveCN105289301AImprove denitrification efficiencyIncrease contact timeDispersed particle separationCycloneFlue gas

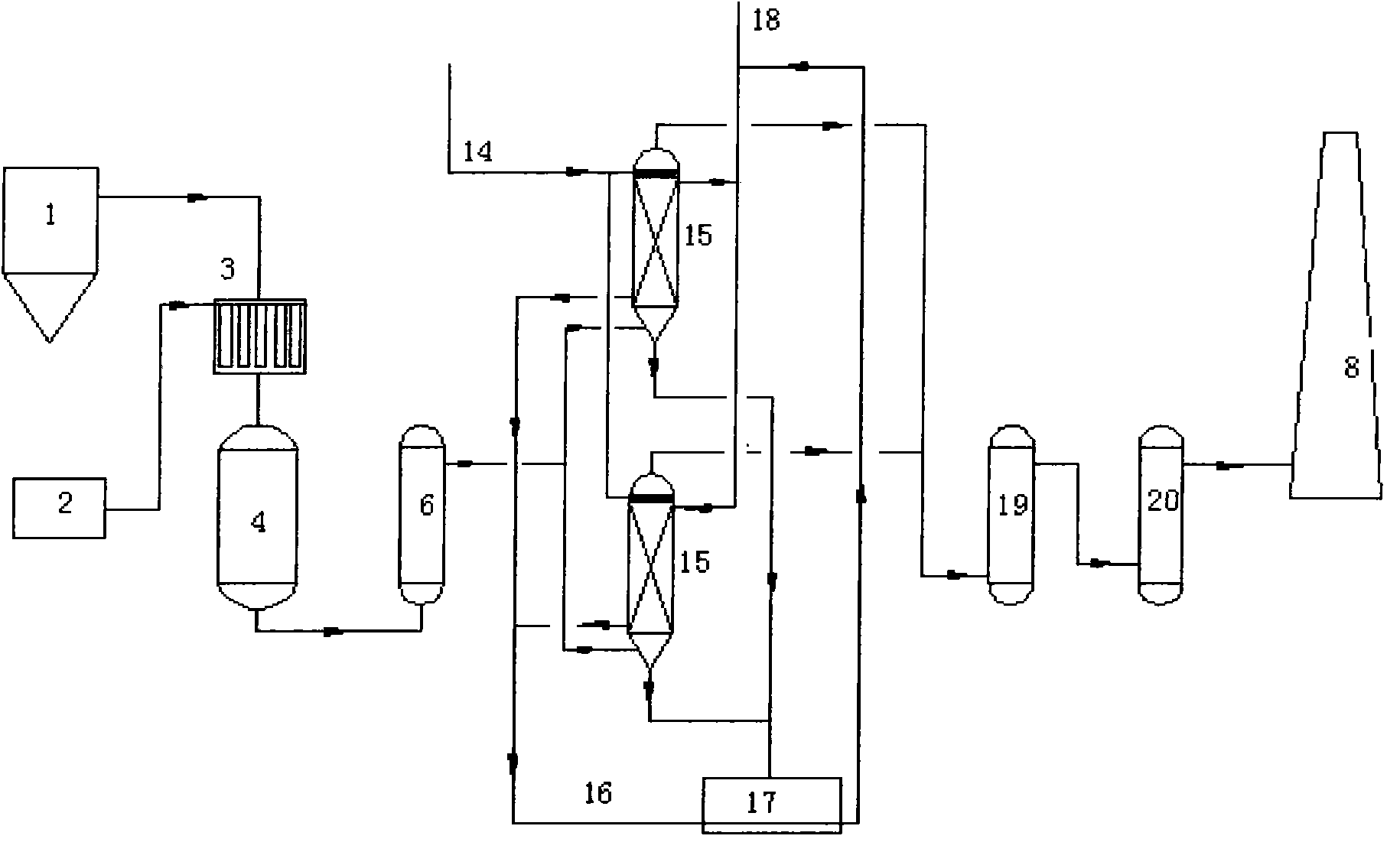

The invention discloses a double-rotation SCR denitration method and an apparatus thereof. According to the invention, a first eddy flow catalytic reaction chamber and a second eddy flow catalytic reaction chamber are arranged along a denitrating tower body; a flue gas introduction pipeline is arranged on a sidewall of the denitrating tower body; several eddy flow atomizing nozzles are respectively arranged on inner periphery of the flue gas introduction pipeline and the inner periphery at top of the first eddy flow catalytic reaction chamber; when flue gas is introduced into the flue gas introduction pipeline, the flue gas and ammonia gas injected by the eddy flow atomizing nozzle are mixed, and a mixture enables spiral sinking along circumference of the first eddy flow catalytic reaction chamber from up to down in a tangent circle mode, under effect of a cyclone, and then the mixture enable spiral rise along circumference of the second eddy flow catalytic reaction chamber from down to up in the tangent circle mode. Under prerequisite that high efficiency denitration is ensured, catalyst amount is less, operation of technical means is simple and easy, compared with the prior art, a denitrating tower structure is simple, cost of the apparatus is low, denitration efficiency is high, energy consumption is low, escapement ratio of ammonia is reduced, denitration cost is greatly reduced, and economic benefit is obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

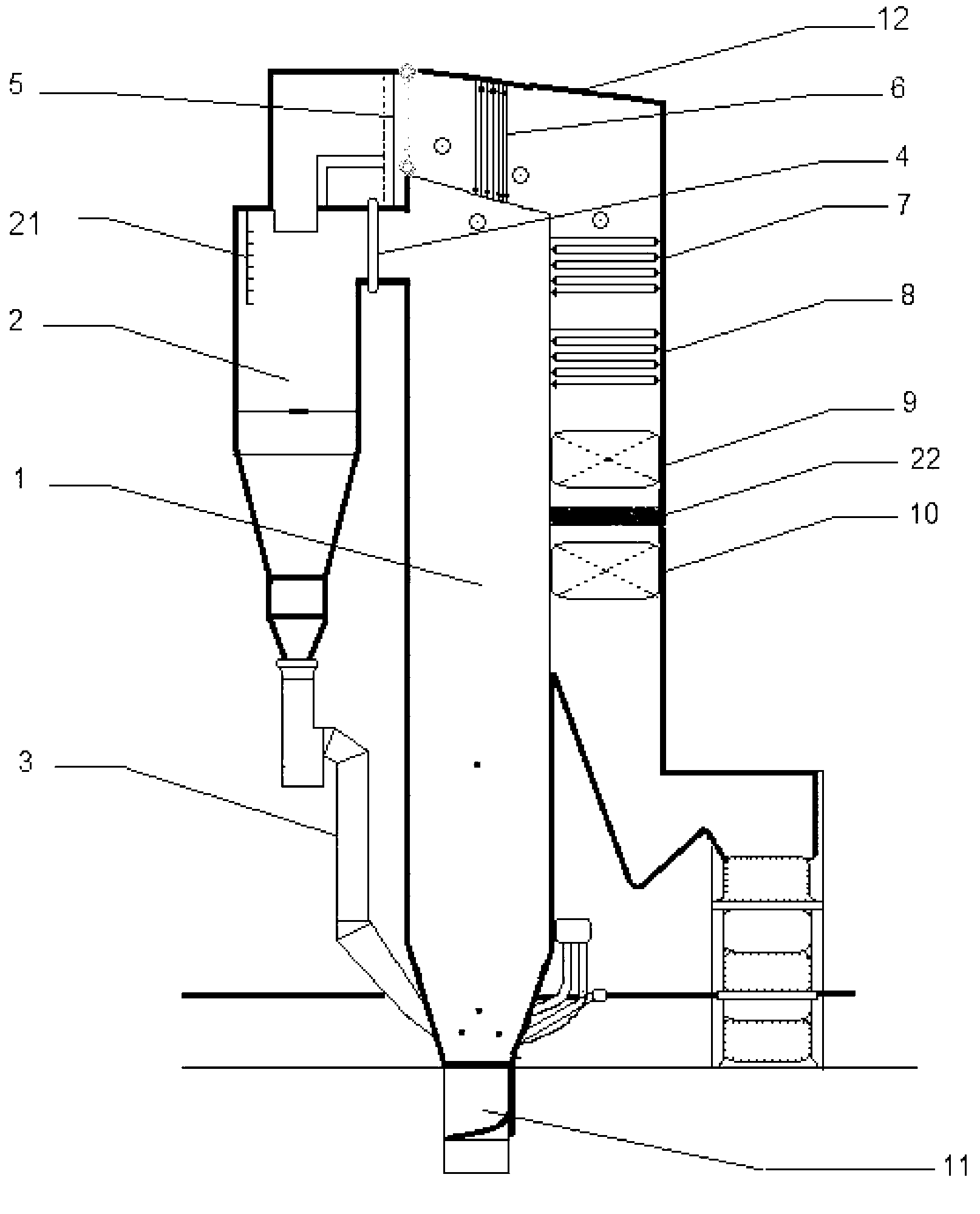

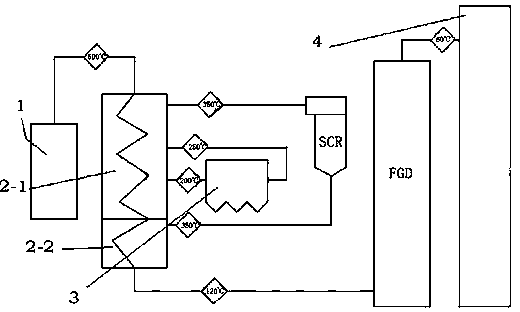

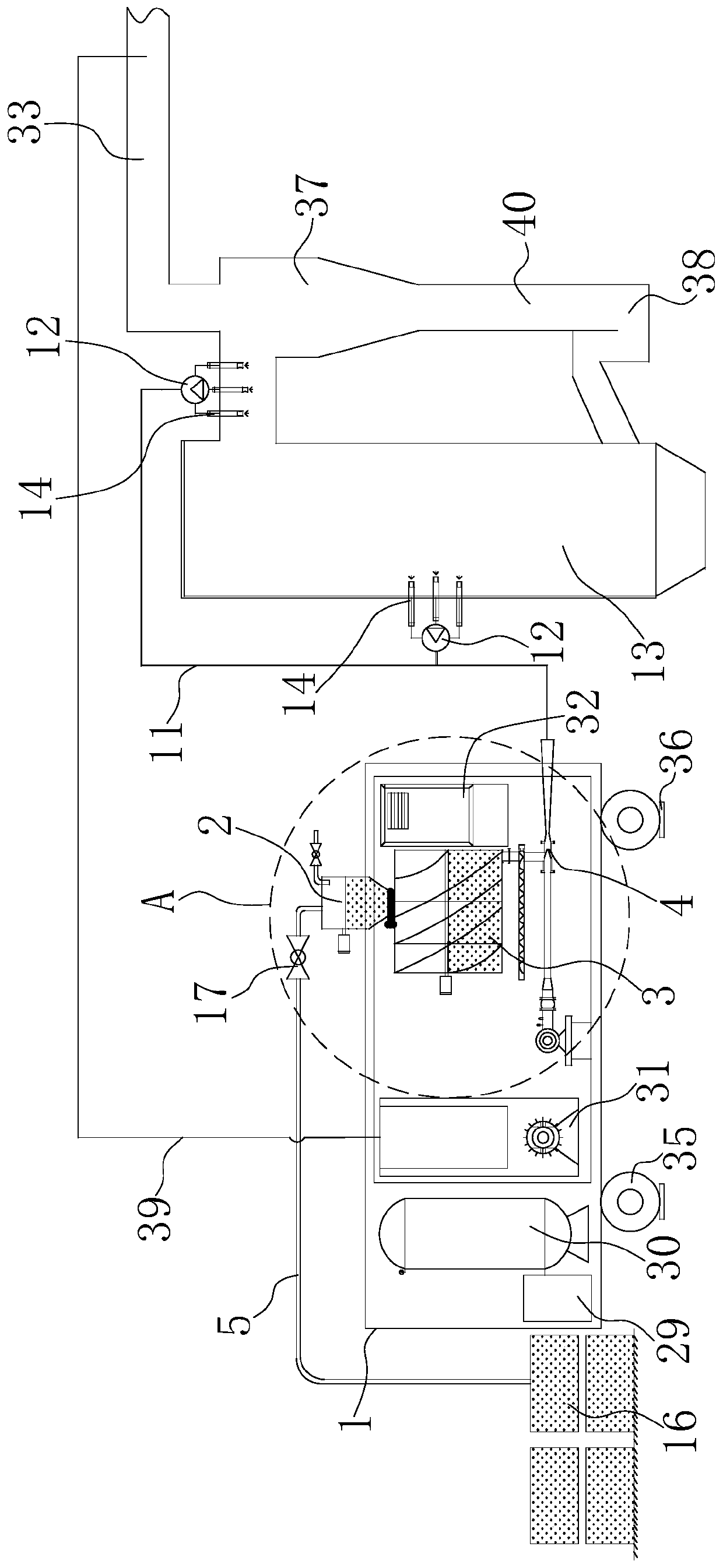

Fume gas denitration system of coal-fired boiler based on SNCR (Selective Non-catalytic Reduction) and SCR (Selective Catalytic Reduction) combination method

The invention discloses a fume gas denitration system of a coal-fired boiler based on an SNCR (Selective Non-catalytic Reduction) and SCR (Selective Catalytic Reduction) combination method. The system comprises a boiler and a SCR denitration device, wherein the boiler comprises a hearth, a fume outlet of the hearth, a cyclone separator, returning charge device and a rear smoke channel; the fume outlet of the hearth is connected with the inlet of the cyclone separator; the lower part outlet of the cyclone separator is connected with a dense-phase zone of the hearth through the returning charge device; the rear smoke channel is connected with the upper part outlet of the cyclone separator; a primary economizer and a secondary economizer are arranged inside the rear smoke channel; an SNCR reducing agent ejecting device is arranged at the inlet of the cyclone separator, and / or at the outlet of the hearth, and / or at the upper part of the cyclone separator; the SCR denitration device is arranged between the primary economizer and the secondary economizer, and / or ahead the primary economizer, and / or behind the secondary economizer; and the SCR denitration device comprises an SCR denitration catalyst layer.

Owner:SHANGHAI LVCHENG ENVIRONMENTAL PROTECTION TECH

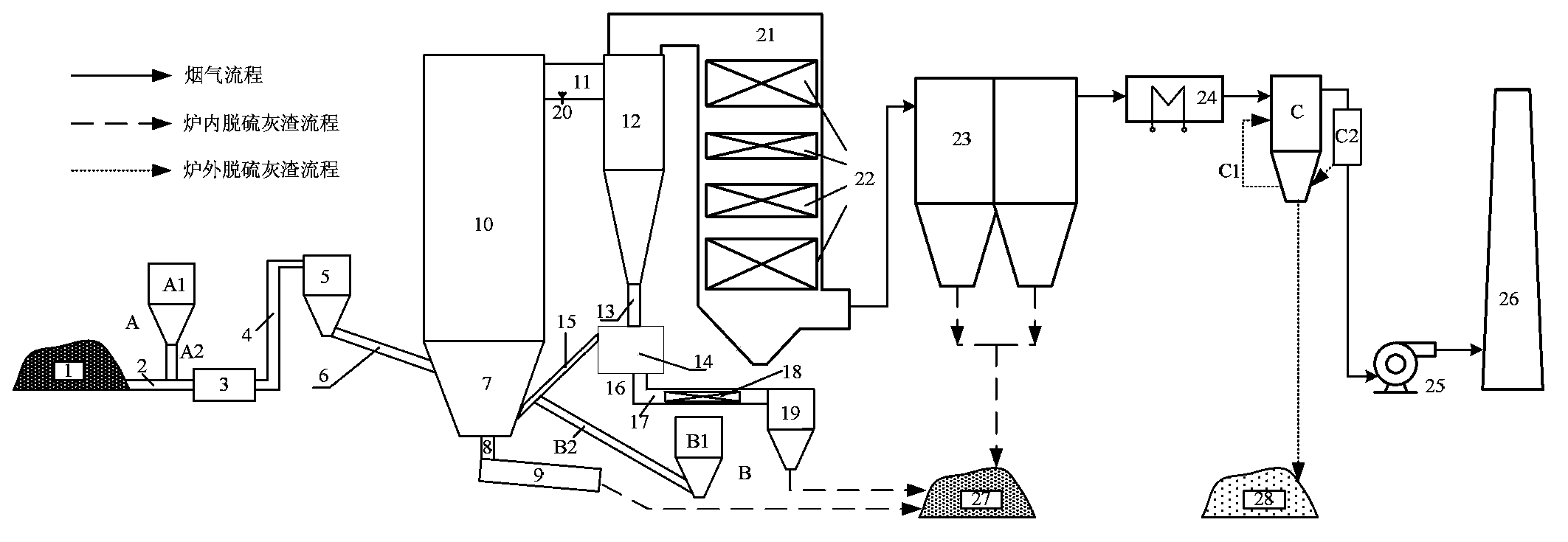

Ultra-low emission circulating fluidized bed boiler with three stages of desulfurization systems

ActiveCN103453538ARetrofitting workload is smallReduce space consumptionLighting and heating apparatusDispersed particle separationFlue gasThree stage

The invention discloses an ultra-low emission circulating fluidized bed boiler with three stages of desulfurization systems. The three stages of desulfurization systems include a front desulfurizing agent adding system, an inner desulfurizing agent conveying system and a deep flue gas desulfurization system, the front desulfurizing agent adding system is positioned in a coal yard area in front of the boiler, the inner desulfurizing agent conveying system is positioned in a plant area of the boiler, and the deep flue gas desulfurization system is positioned in a tail area of the boiler; the front desulfurizing agent adding system comprises a front desulfurizing agent bin and a front desulfurizing agent gravimetric adding machine below the front desulfurizing agent bin, the inner desulfurizing agent conveying system comprises an inner desulfurizing agent bin and an inner desulfurizing agent conveying feeder below the inner desulfurizing agent bin, and an efficient desulfurizing agent circulating system and a flue gas supplementary dust removing device are further arranged on the deep flue gas desulfurization system. The ultra-low emission circulating fluidized bed boiler has the advantages that the systems are simple, are low in running energy consumption, can be regulated and controlled easily and conveniently, are high in desulfurizing agent utilization rate and desulfurization efficiency and free of water resource consumption and are widely suitable to be used with new circulating fluidized bed boilers in an environment-friendly manner and to modify existing circulating fluidized bed boilers in an environment-friendly manner, and space and equipment investment can be effectively saved.

Owner:HUANENG CLEAN ENERGY RES INST

Preparation method of mixture of polyester and thermoplastic starch rich in starch and application thereof

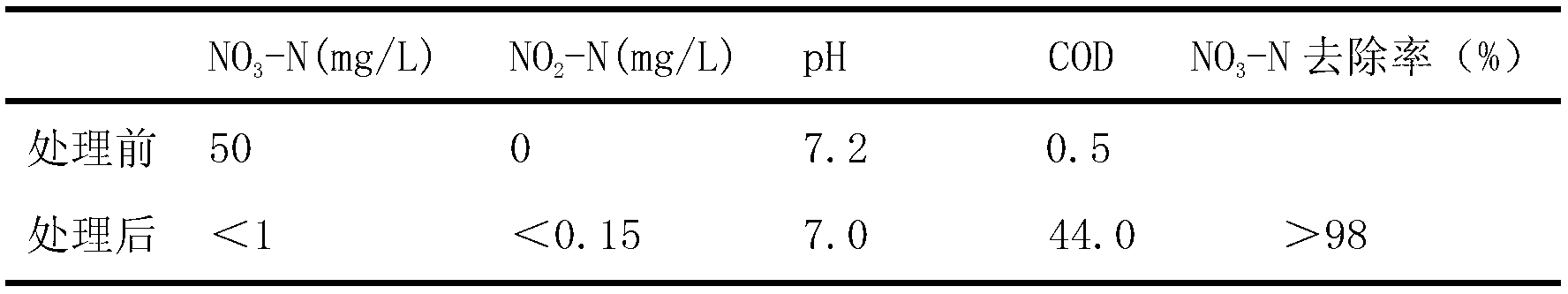

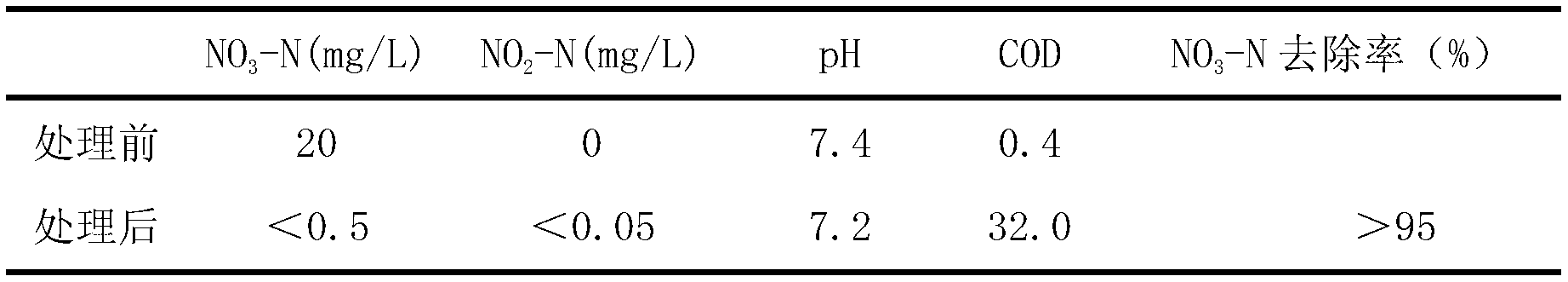

ActiveCN103194050AImprove the mixing effectStrong mechanical propertiesWater contaminantsBiological water/sewage treatmentSolid carbonThermoplastic

The invention discloses a preparation method of a mixture of polyester and thermoplastic starch rich in starch and an application thereof, belonging to the technical field of environment protection. According to the method, the polyester and the thermoplastic starch rich in starch are taken as the raw materials, and addition agents such as aluminic acid ester coupling reagent and the like are added, thermoplastic starch / polyester blending material is prepared through banburying by a torque rheometer, and then a product is prepared through smashing, extrusion and pelleting. The thermoplastic starch base mixture rich in starch can be used as both a carbon source and a biofilm carrier for denitrification in the water treatment deep denitrification technology, so that the defect that the carbon source dosage is not easy to control in a conventional denitrification technology is overcome, the defects that the microorganism is difficult to form a membrane, the cost is high and the staring time is long when only biodegradable polymer is taken as a solid carbon source are overcome, and the thermoplastic starch base mixture rich in starch has strong adaptability to both water dissolved oxygen concentration and pH.

Owner:CHONGQING UNIV

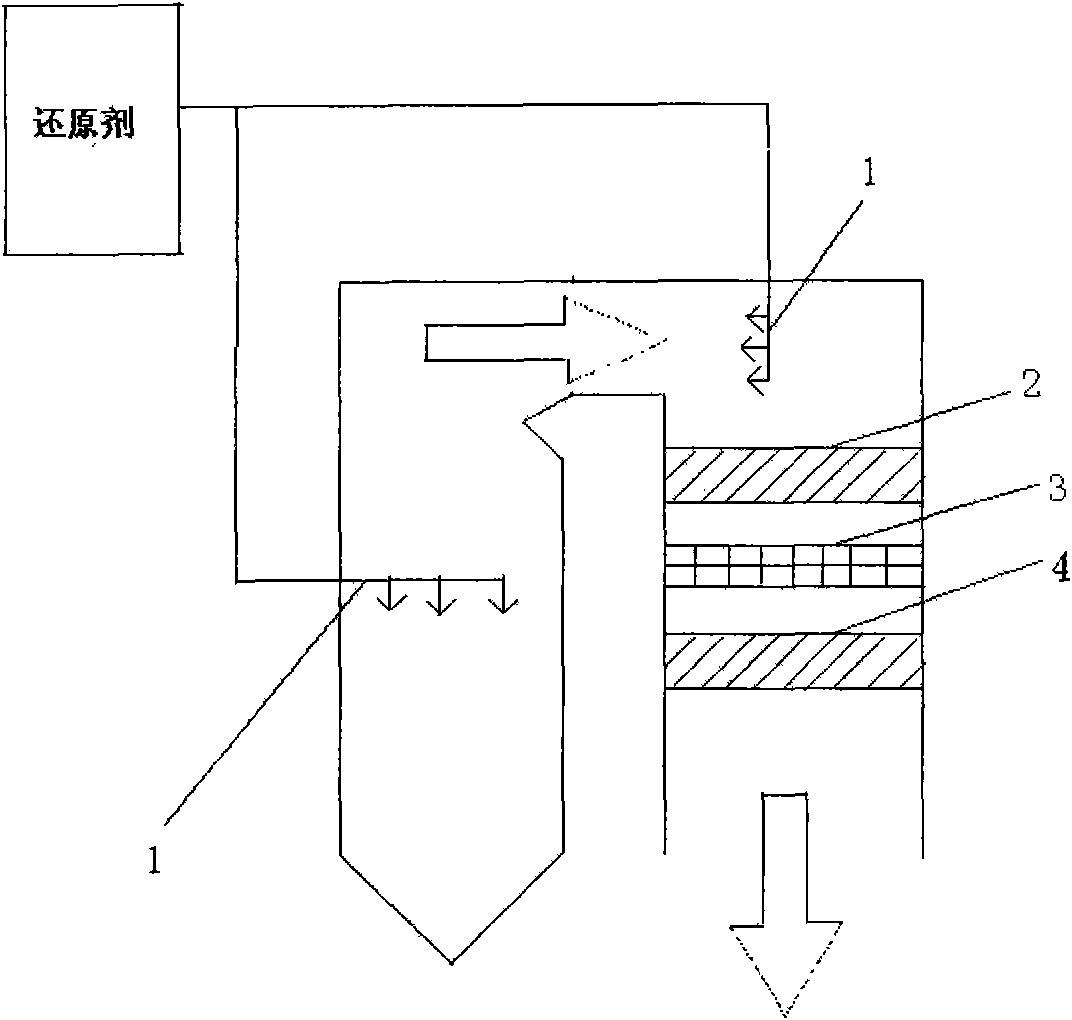

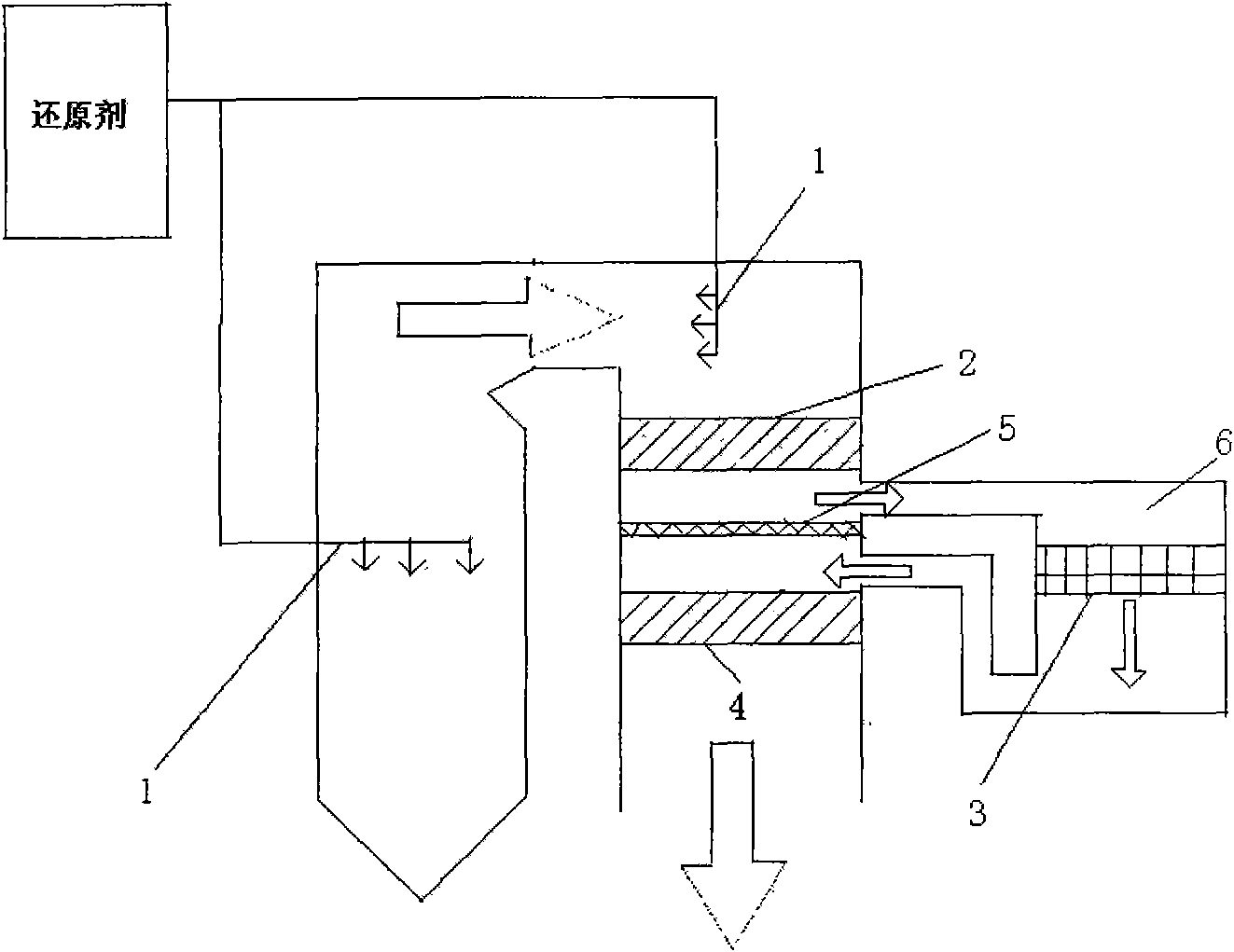

Device and method for denitration on flue gas by coupling selective non catalytic reduction and catalytic reduction

InactiveCN102091511AReduce dosageEfficient use ofDispersed particle separationAir preheaterNitrogen oxides

The invention discloses a device and a method for denitration on flue gas by coupling selective non catalytic reduction and catalytic reduction and relates to a technology for removing nitrogen oxides in burned flue gas of fossil fuels. The invention adopts a scheme 1 that the denitration device comprises a plurality of spray guns for spraying a reducing agent, economizer, a mesothermal catalyst and an air preheater, wherein the spray guns are arranged in a furnace in a layered mode; and the economizer, the mesothermal catalyst and the air preheater are arranged in a flue sequentially along the flowing direction of the flue gas. Compared with the prior art, the device and the method mainly utilize the denitration capacity of an SNCR (Selective Non Catalytic Reduction) system, utilize an SCR (Selective Catalytic Reduction) system as supplement and have the characteristics of high denitration efficiency, low ammonia escape rate, equipment conservation, investment reduction, space conservation and the like.

Owner:TONGFANG ENVIRONMENT

Flue gas purifying and absorbing tower and treatment method thereof

The invention provides a flue gas purifying and absorbing tower and a treatment method thereof. The absorbing tower comprises a tower body, an air inlet, an air outlet, an adsorbent buffer bin, an adsorbent layer, ammonia spraying points, a material inlet and a material outlet, wherein the adsorbent buffer bin is arranged above the absorbing tower and is connected with the tower body through the material inlet; a flue is formed in the tower body and is an in-tower space separated by the adsorbent layer; the ammonia spraying points are arranged in the adsorbent buffer bin and on the flue of the tower body. The treatment method comprises the following steps: spraying ammonia into the ammonia spraying point in the adsorbent buffer bin so as to introduce an adsorbent into the adsorbent layer; spraying ammonia into the ammonia spraying point on the flue of the tower body so as to introduce to-be-treated flue gas into the absorbing tower from the air inlet, and after the to-be-treated flue gas flows through the flue and the adsorbent layer, discharging the to-be-treated flue gas out from the air outlet; and after the adsorption of the adsorbent is finished, discharging the adsorbent. According to the flue gas purifying and absorbing tower and the treatment method, an ammonia spraying process of the absorbing tower is improved, so that the denitration efficiency is guaranteed, the use amount of ammonia gas and the escaping of ammonia are reduced, and the clean and efficient flue gas purifying process is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

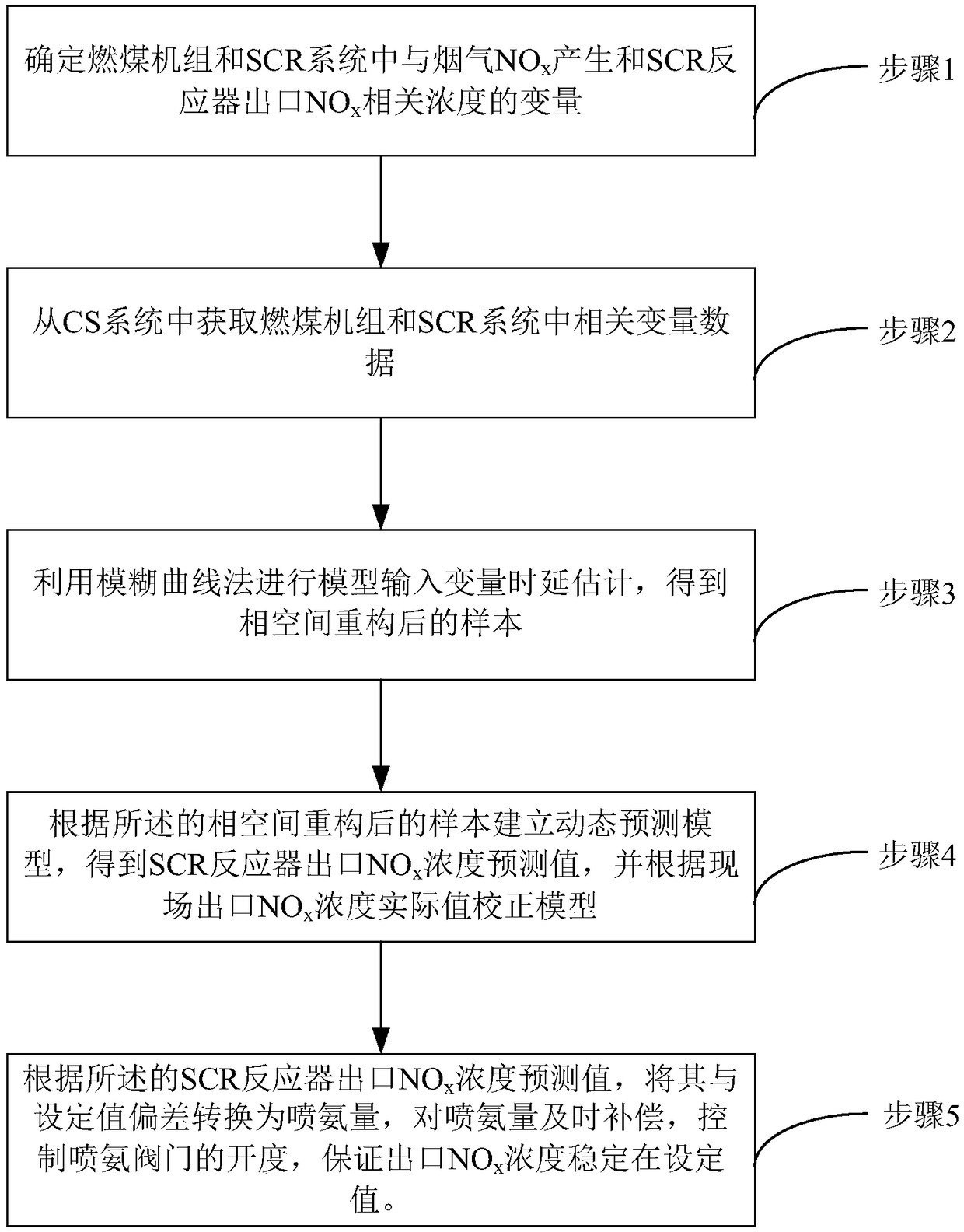

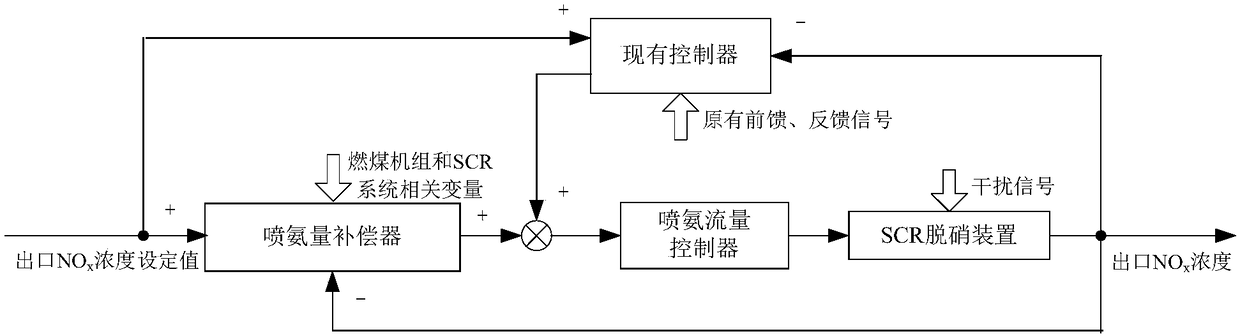

SCR flue gas denitration optimization control system and method based on ammonia spraying amount compensator

ActiveCN109343349AReduce escape rateReduce adverse effectsTotal factory controlAdaptive controlControl systemFlue gas

The invention discloses an SCR flue gas denitration optimization control method based on an ammonia spraying amount compensator. The method comprises the following steps of 1, determining variables related to the flue gas NOx generation and the outlet NOx concentration of an SCR reactor in a coal-fired unit and an SCR system; 2, acquiring related variable data in the step 1 from a DCS system; 3, performing input variable time delay estimation of a model by utilizing a fuzzy curve method, so that a sample after phase space reconstitution is obtained; 4, building an outlet NOx concentration dynamic prediction model according to the sample after the phase space reconstitution in the step 3, obtaining an outlet NOx concentration prediction value of the SCR reactor, and correcting the outlet NOx concentration dynamic prediction model according to an actual value of the field outlet NOx concentration; and 5, according to the outlet NOx concentration prediction value of the SCR reactor, obtained in the step 4, converting a deviation between the outlet NOx concentration prediction value of the SCR reactor and a set value into an ammonia spraying amount, timely compensating the ammonia spraying amount, and controlling the opening degree of an ammonia spraying valve to ensure that the outlet NOx concentration is stabilized to be the set value.

Owner:DATANG ENVIRONMENT IND GRP

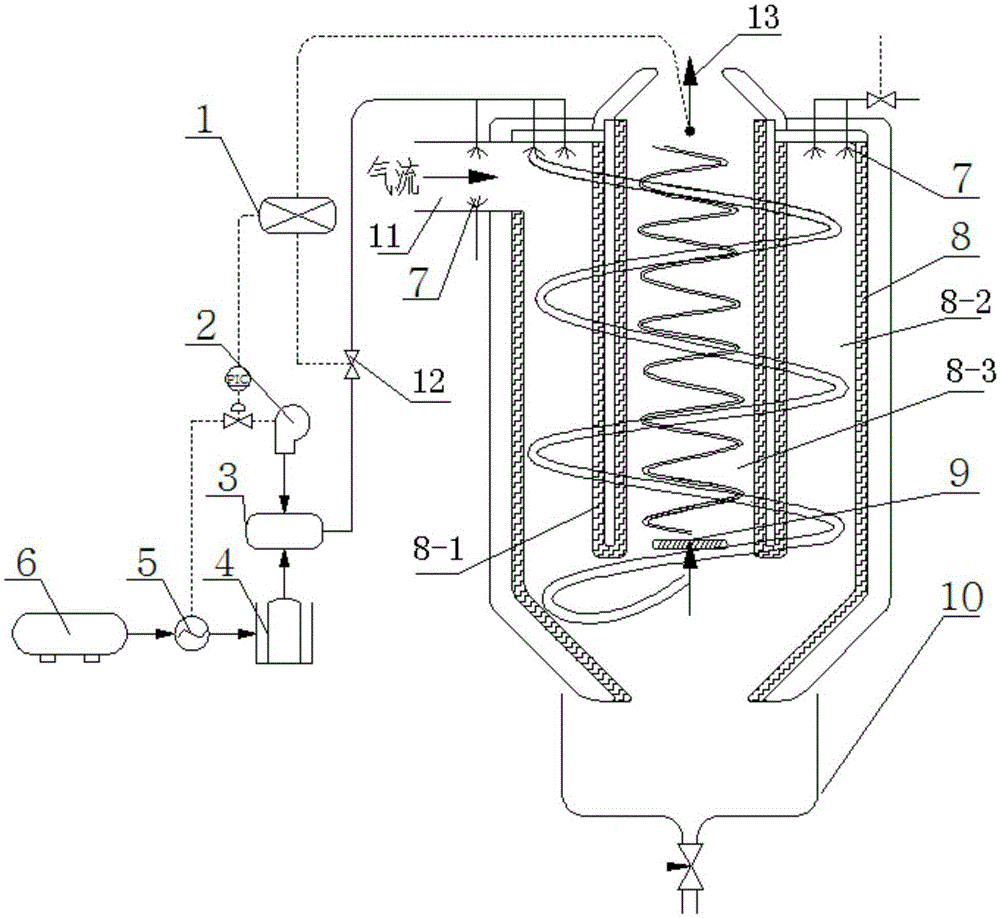

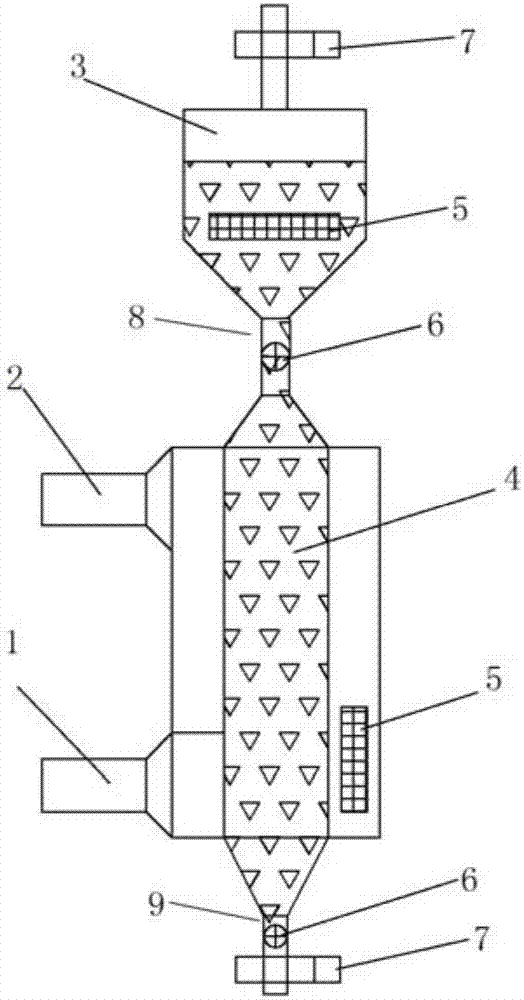

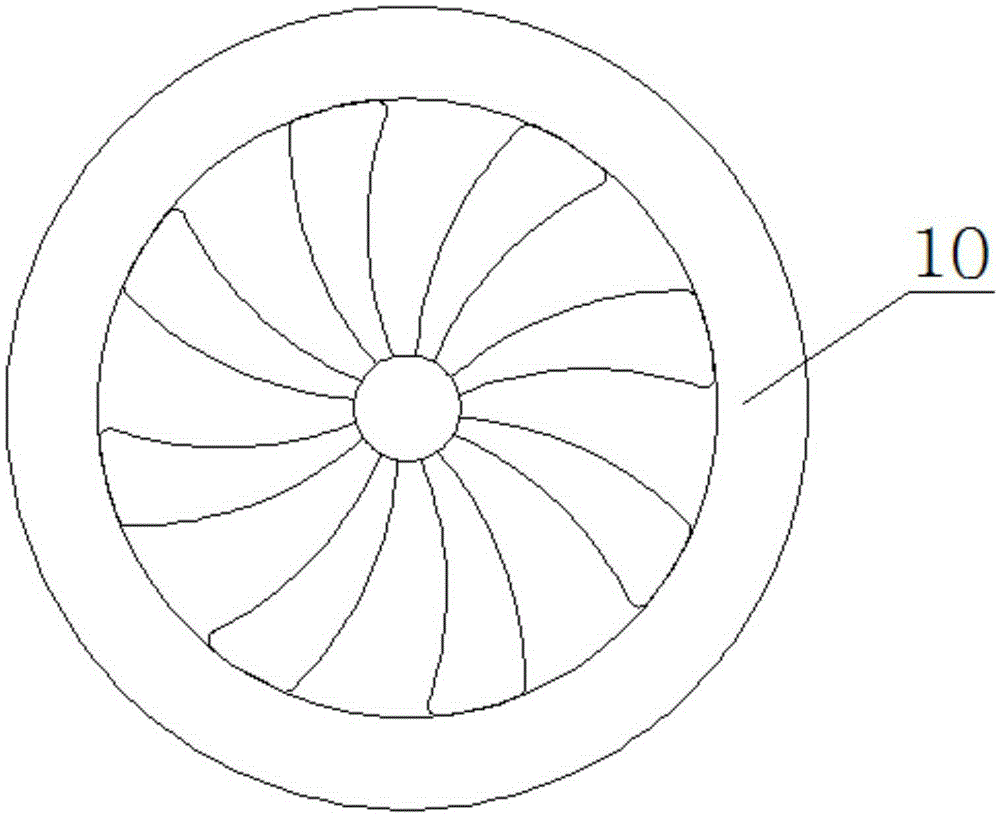

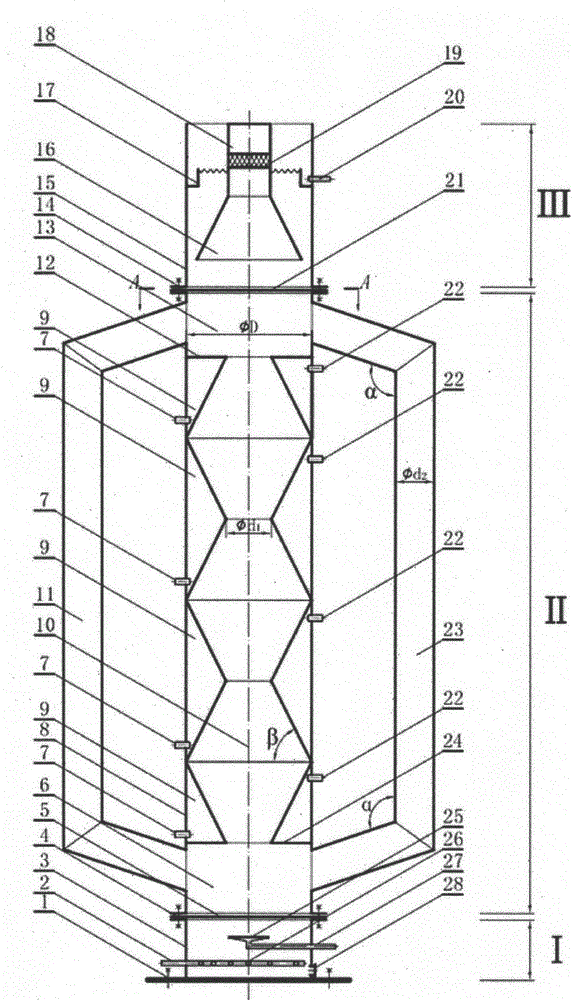

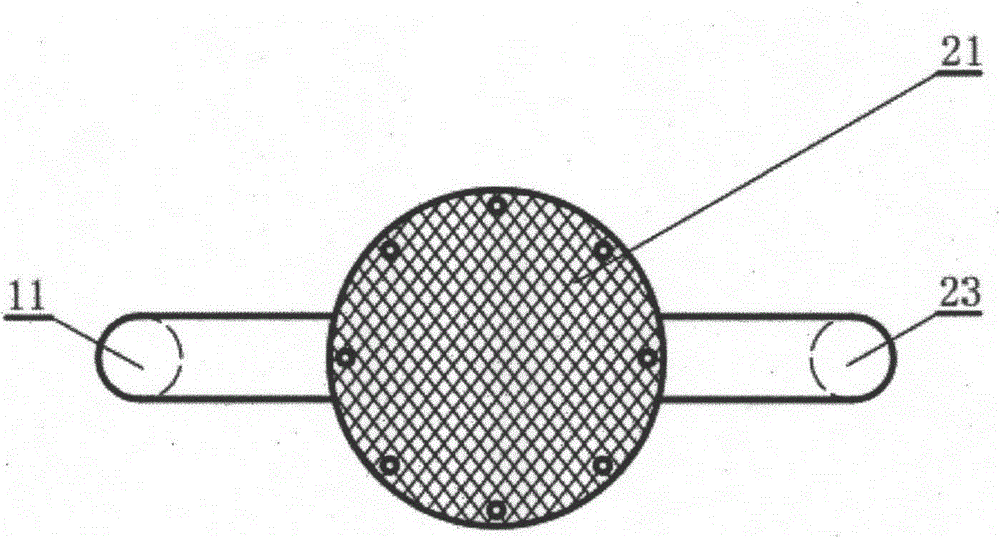

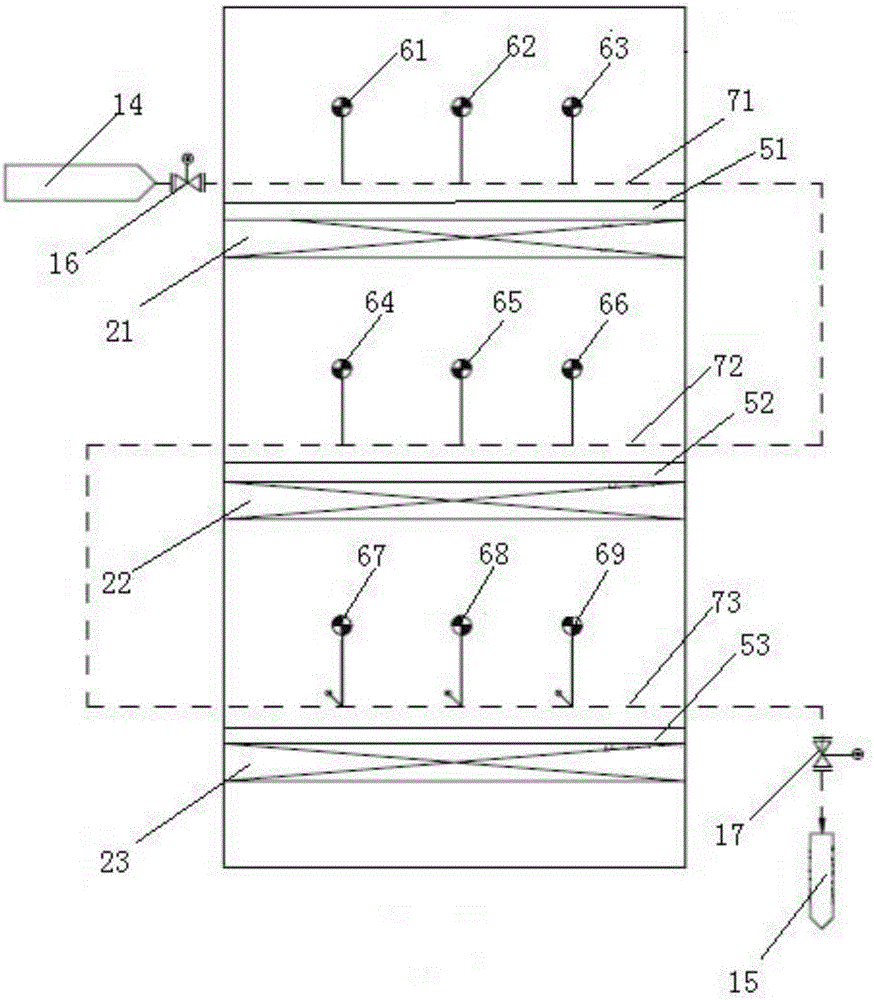

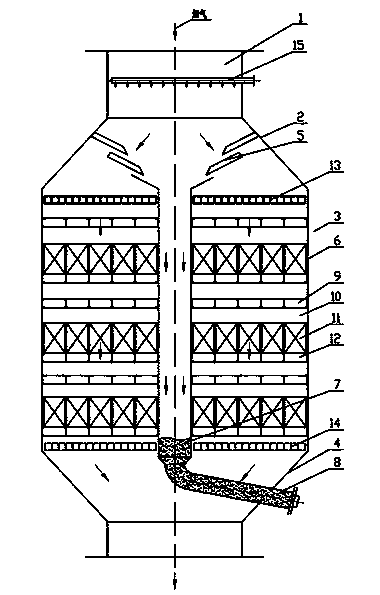

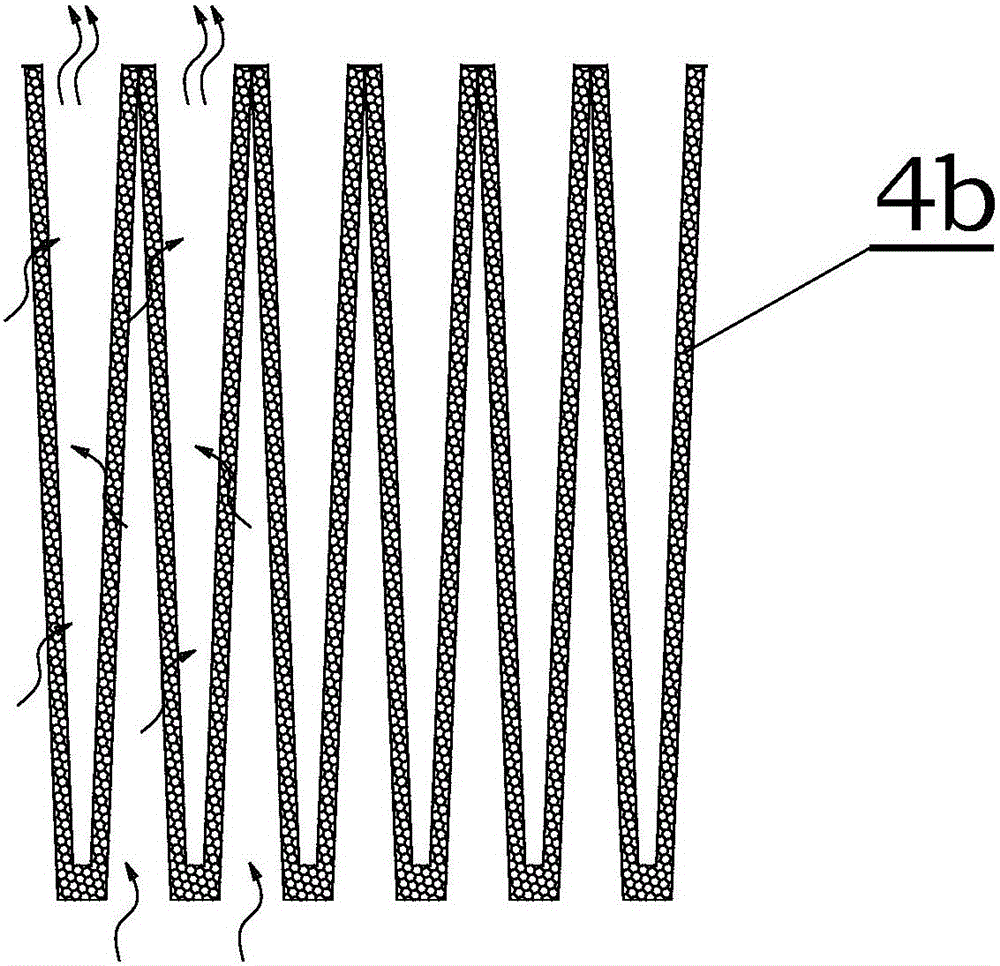

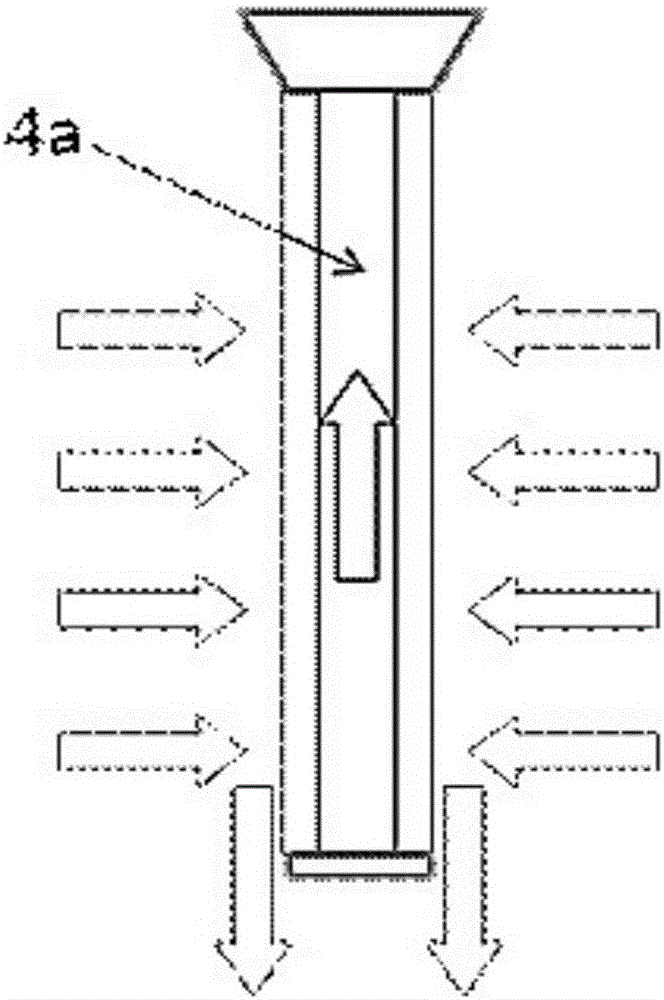

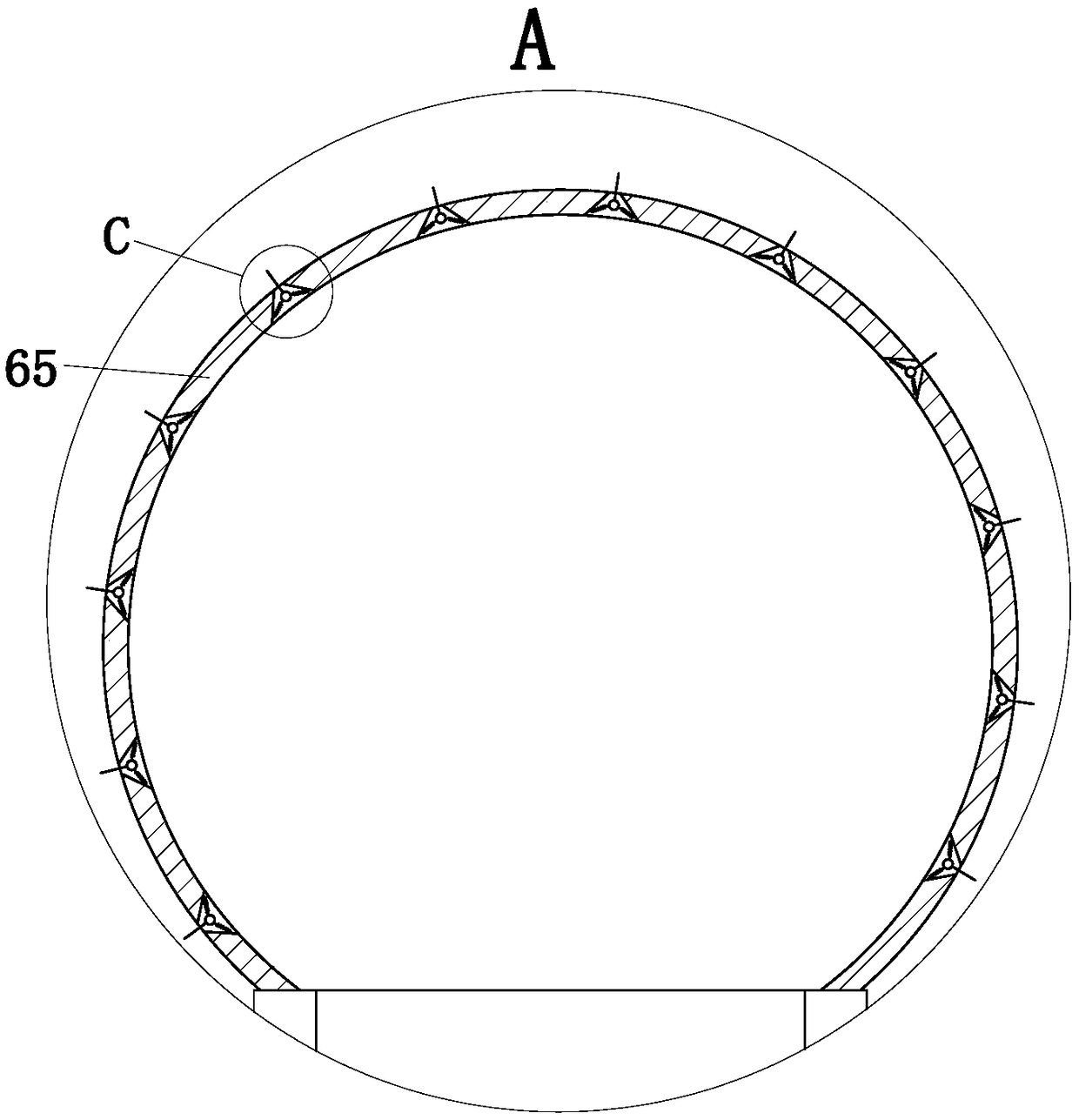

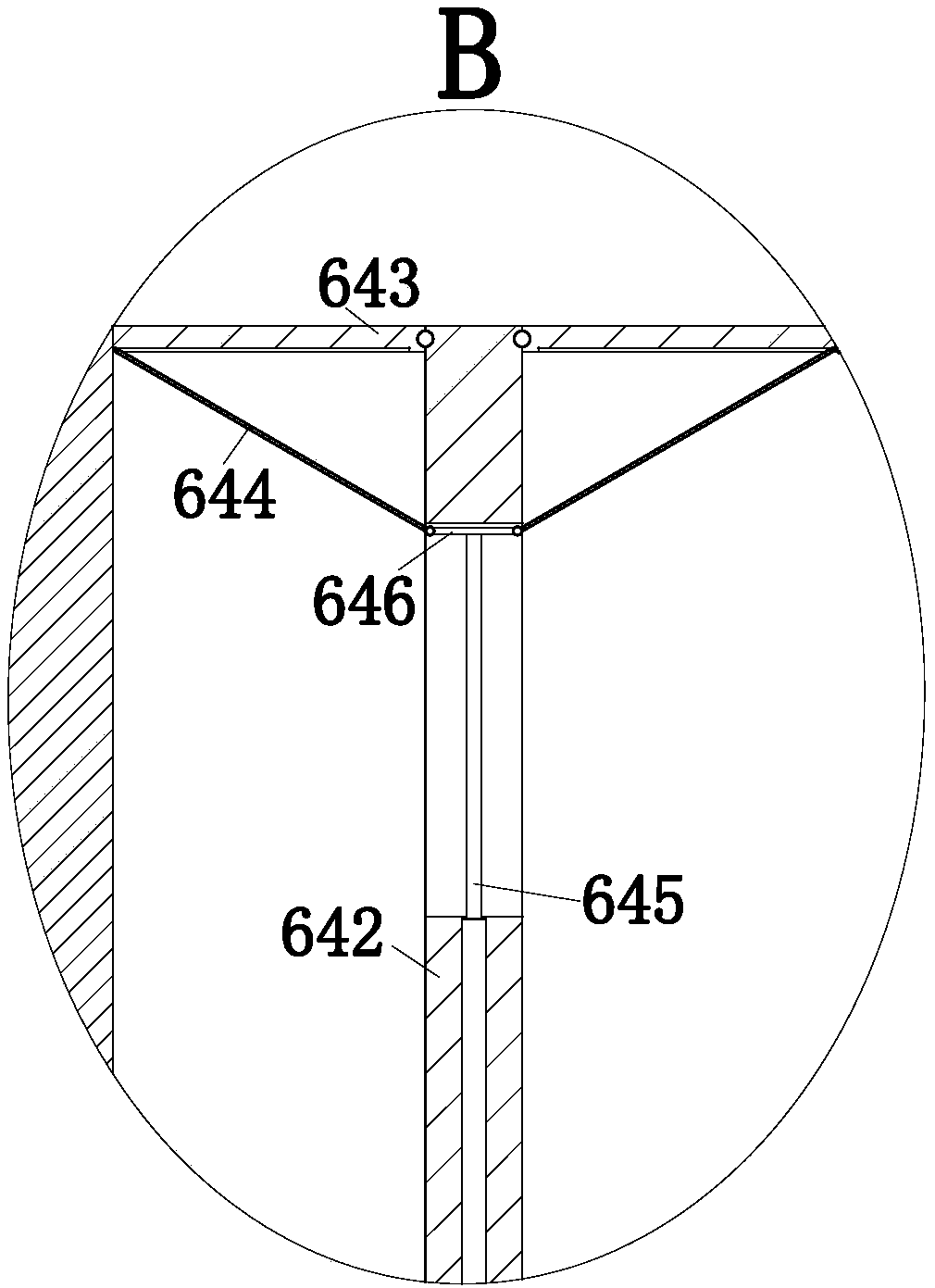

Rotational flow plate type SCR denitration tower and denitration method thereof

ActiveCN105289300AExtended stayThe catalytic reduction reaction is fullyDispersed particle separationFlue gasEscape rate

The invention discloses a rotational flow plate type SCR denitration tower and a denitration method thereof. The denitration tower comprises a denitration tower body and a corrugated plate type catalyst layer arranged along the inner circumference face of the denitration tower body, and the corrugated plate type catalyst layer forms a flue gas channel. A plurality of layers of rotational flow atomizing nozzles performing jetting in the contact circle direction are distributed on the circumference face of the corrugated plate type catalyst layer from bottom to top. When flue gas enters the flue gas channel from the bottom of the denitration tower body, and the flue gas encounters ammonia gas jetted by the whirlwind atomizing nozzles, the flue gas and the ammonia gas are mixed in an entrainment mode and spirally raises in the inner circumference direction of the flue gas channel in a contact circle mode because the ammonia gas is jetted in a rotational flow mode in the contact circle direction. On the premise that efficient denitration is guaranteed, the catalyst use amount of the denitration tower is small, the technical means is easy and convenient to use. Compared with the prior art, the denitration tower is simple in structure, low in manufacturing cost, high in denitration efficiency and low in energy consumption, reduces the ammonia escape rate, makes denitration cost greatly reduced, and remarkably improves economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

Low-temprature flue gas denitration and poisoning-prevention system

InactiveCN105498447AEfficient removalExtended service lifeGas treatmentDispersed particle separationWater vaporFlue gas

The invention discloses a low-temprature flue gas denitration and poisoning-prevention system. In an SCR (Selective Catalytic Reduction) denitration facility, a modified active carbon layer and a multilayered denitration catalyst are arranged along a flowing direction of flue gas in sequence; the modified active carbon layer is used for adsorbing water vapor, SO2, heavy metal and dust in flue gas through physical adsorption and chemical adsorption; the multilayered denitration catalyst is used for removing NOx in the flue gas; the denitration efficiency of a denitration catalyst is guaranteed so that the denitration rate of the denitration catalyst can be stabilized to be a relatively high numerical value; and the problem that a low-temperature catalyst is likely to cause poisoning is solved, active carbon can be cyclically used, byproducts can be utilized and the production cost is reduced.

Owner:WUHAN UNIV OF TECH

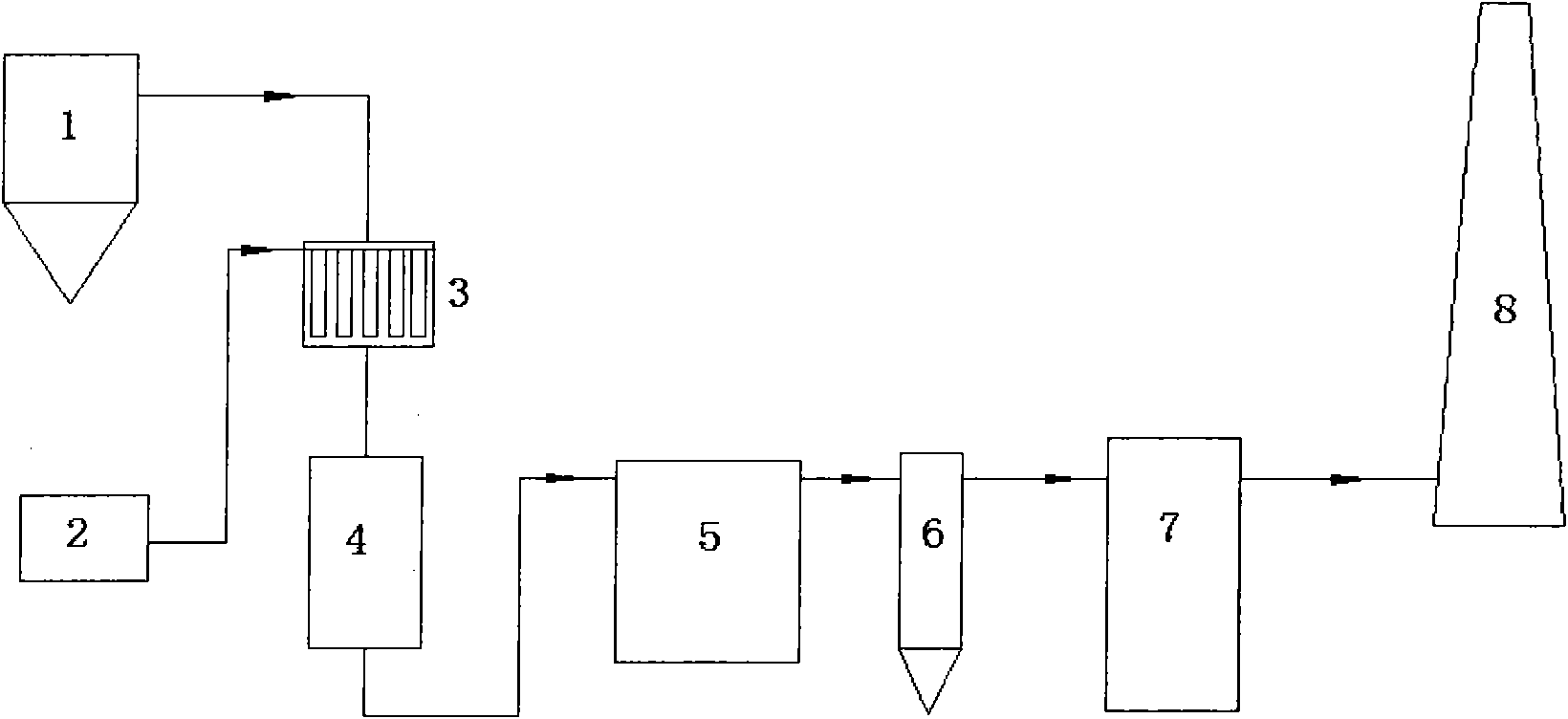

Glass kiln flue gas de-dusting, denitrification and desulfurization integral treatment process

ActiveCN104162352ALess investmentGuaranteed uptimeDispersed particle filtrationLighting and heating apparatusAtmospheric airFlue gas

The invention relates to a glass kiln flue gas de-dusting, denitrification and desulfurization integral treatment process. The process comprises the following steps: glass kiln high-temperature flue gas is subjected to heat absorption by using a residual heat boiler and is cooled; the flue gas is cooled to a temperature range of 250-300 DEG C through the residual heat boiler, and is delivered into a de-dusting device wherein the flue gas is subjected to de-dusting; standard flue gas after de-dusting is returned to the residual heat boiler and is heated to a selective catalytic reduction (SCR) temperature window of 300-420 DEG C, and is delivered into an SCR denitrification device; standard flue gas after denitrification is returned to the residual heat boiler where heat is recovered; when the temperature of the flue gas is approximately 120+ / -20 DEG C, the flue gas is delivered into a wet desulfurization device; and standard flue gas after a wet desulfurization treatment is discharged into the atmosphere through a chimney. According to the invention, the residual heat boiler is designed and modified, such that the boiler is provided with three sets of approximate temperature inlet and outlet, and thus various systems can work under appropriate temperature windows. Therefore, system reliability is endured, operation investment cost is reduced, and heat loss is minimized.

Owner:NANJING CEEP TECH

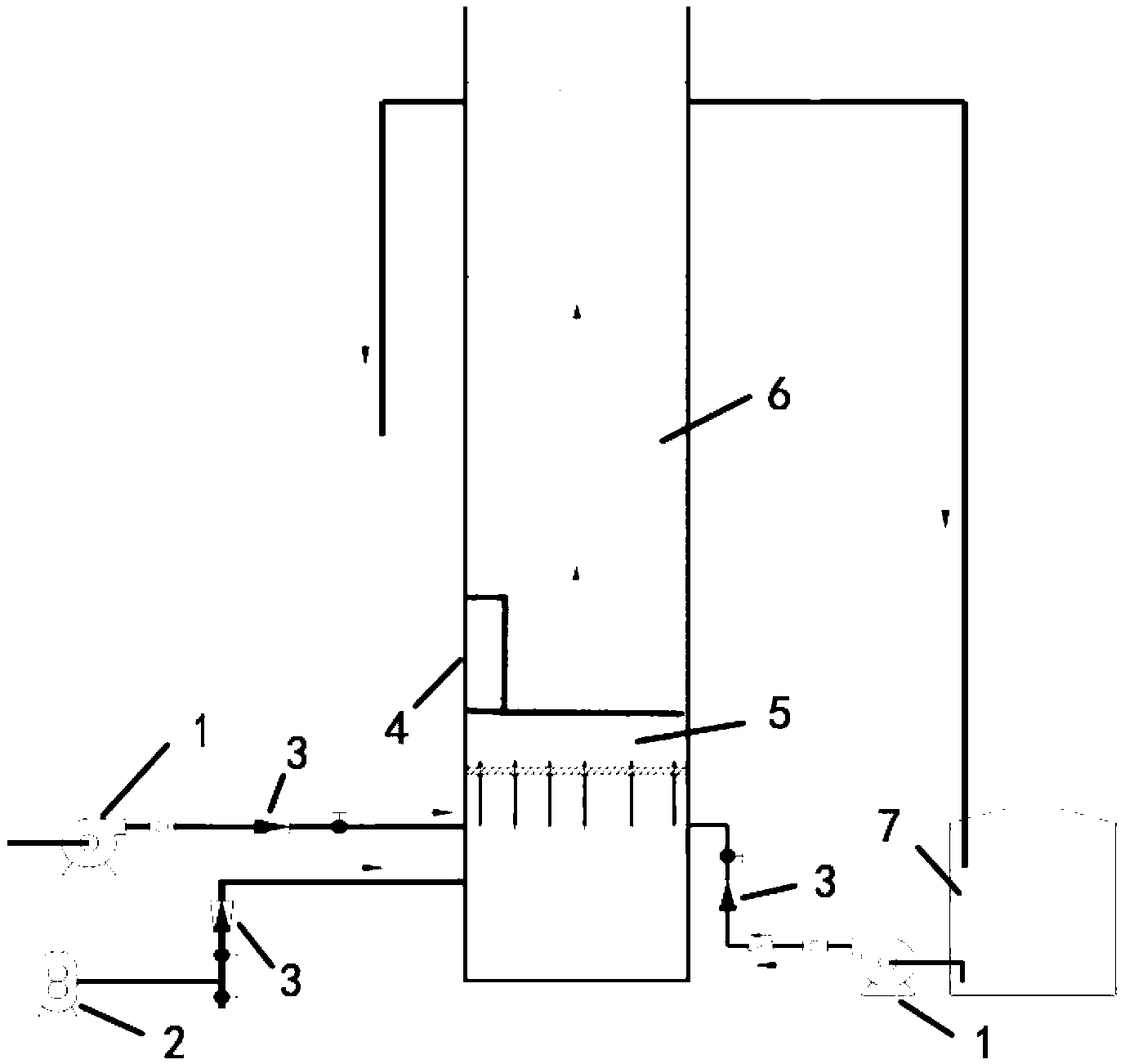

Air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor

InactiveCN104085986AImproved resistance to shock loadsSimple structureTreatment with aerobic and anaerobic processesNitrogen removalOxygen

The invention discloses an air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor. The air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor is characterized by comprising a water distributing section, a reaction section and a separating section, wherein the water distributing section comprises a lower short circular barrel; a water distributor and a microporous aeration plate are arranged in the barrel, and the water distributor is communicated with a water inlet tube; the microporous aeration plate is communicated with a gas inlet tube; the reaction section comprises a long circular barrel, and a multi-stage Venturi tube is arranged in the long circular barrel; a flow-splitting region and a mixing region are respectively formed between the two ends of the multi-stage Venturi tube and the port of the long circular barrel, and are communicated by left and right circulating tubes to form circulation; the separating section comprises an upper short circular barrel, and a water outlet and gas outlet system is arranged in the barrel. By virtue of arranging the microporous aeration plate, the mixing region and the multi-stage Venturi tube, vortex flow fields are formed in the multi-stage Venturi tube, so that the mass transfer efficiency among gas, liquid and solid phases is effectively enhanced. Besides, the structure is combined with the flow-splitting region, the left circulating tube and the right circulating tube to form external circulation, so that an aerobic-anoxic alternating environment is formed, and therefore, the reactor has a nitrification and denitrification biological nitrogen removal function.

Owner:DONGHUA UNIV +1

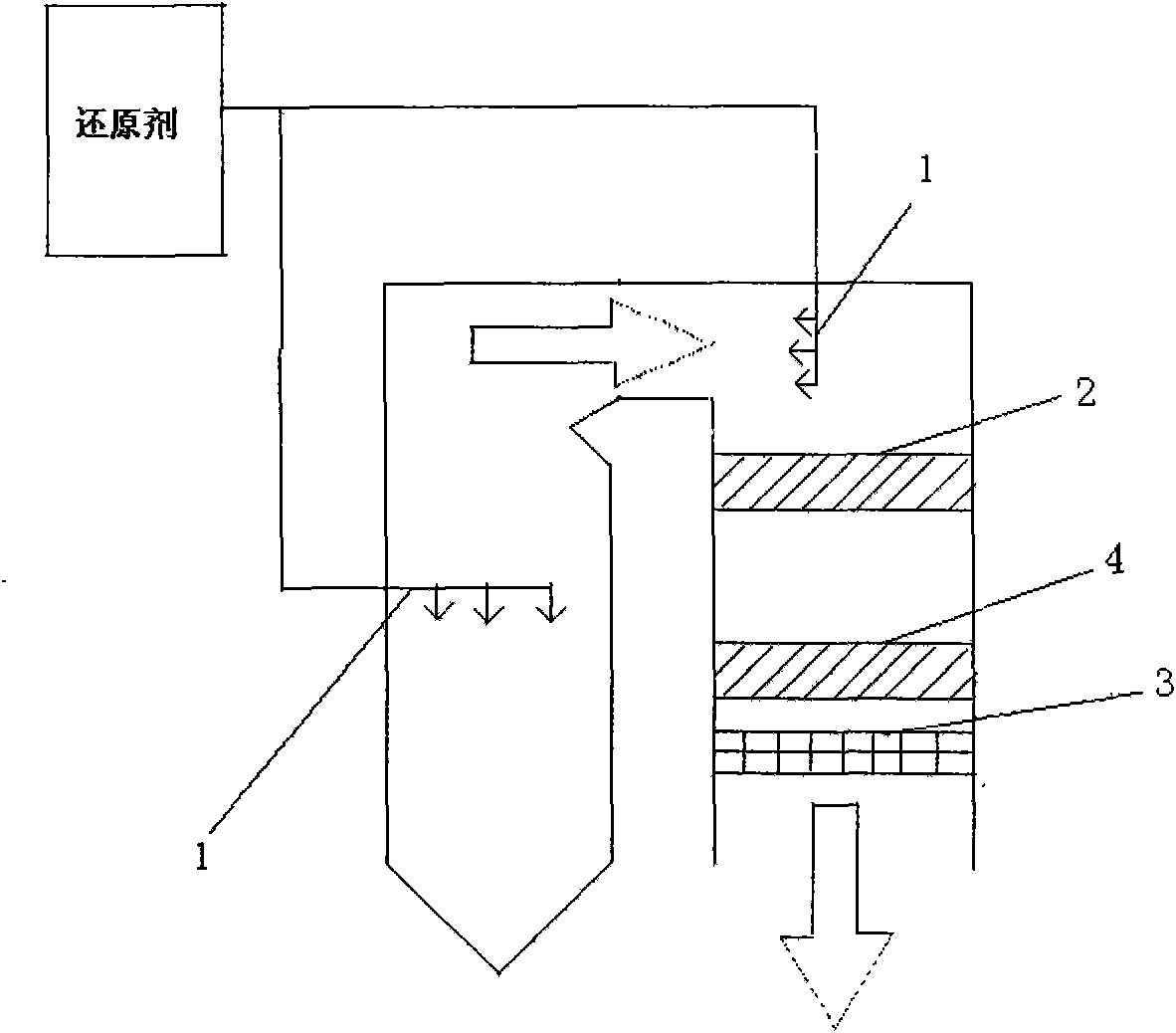

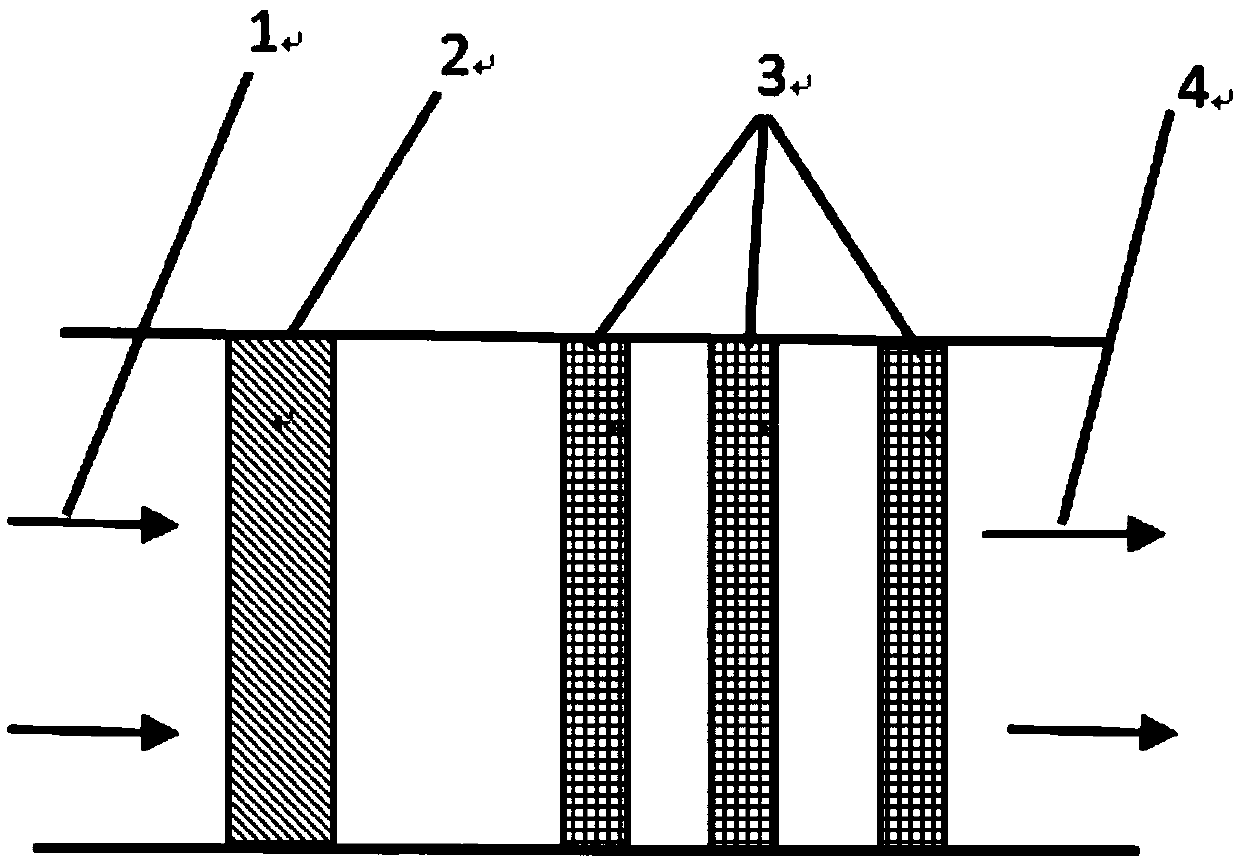

Medium and low temperature wide-load SCR (Selective Catalytic Reduction) denitration device and method

ActiveCN108854530AGuaranteed denitrification efficiencyEfficient denitrificationDispersed particle separationElectricityFlue gas

The invention discloses a medium and low temperature wide-load SCR (Selective Catalytic Reduction) denitration device and method. The medium and low temperature wide-load SCR denitration device comprises a high-temperature electric precipitation rear flue, a flue guide plate, an inlet guide plate, an outlet flue, rectifying grids, ammonia spraying grids, a medium and low temperature catalyst layerand a medium and high temperature catalyst layer, wherein the rectifying grids and the ammonia spraying grids are arranged above the medium and low temperature catalyst layer and between the medium and low temperature catalyst layer and the medium and high temperature catalyst layer; external flue gas flows into a denitration device body through the high-temperature electric precipitation rear flue and the flue guide plate, and is subjected to catalytic denitration through the medium and low temperature catalyst layer and the medium and high temperature catalyst layer; the gas subjected to the denitration is exhausted through the outlet flue; ammonia gas is sprayed through the ammonia spraying grids, and is subjected to a denitration reaction with NOx in the flue gas under the action of acatalyst. By adopting the medium and low temperature wide-load SCR denitration device and method provided by the invention for treating the NOx in the precipitated flue gas, so that efficient denitration under the conditions of variable load as well as flue gas temperature and flow fluctuation in a boiler is realized, and equipment investment and running cost can be reduced to the maximum extent.

Owner:YANCHENG ENVIRONMENTAL ENG TECH RES & DEV CENT TSINGHUA UNIV

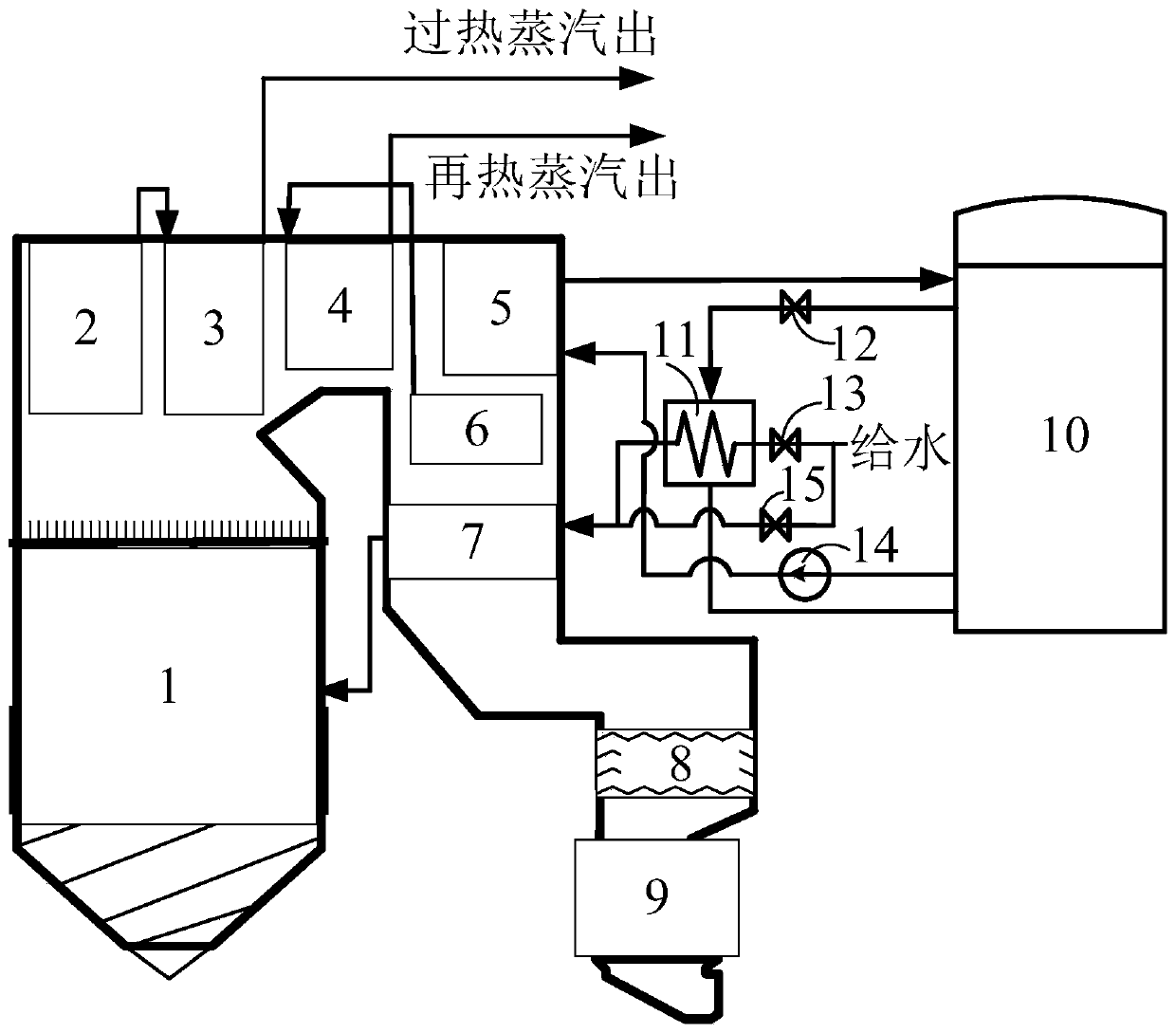

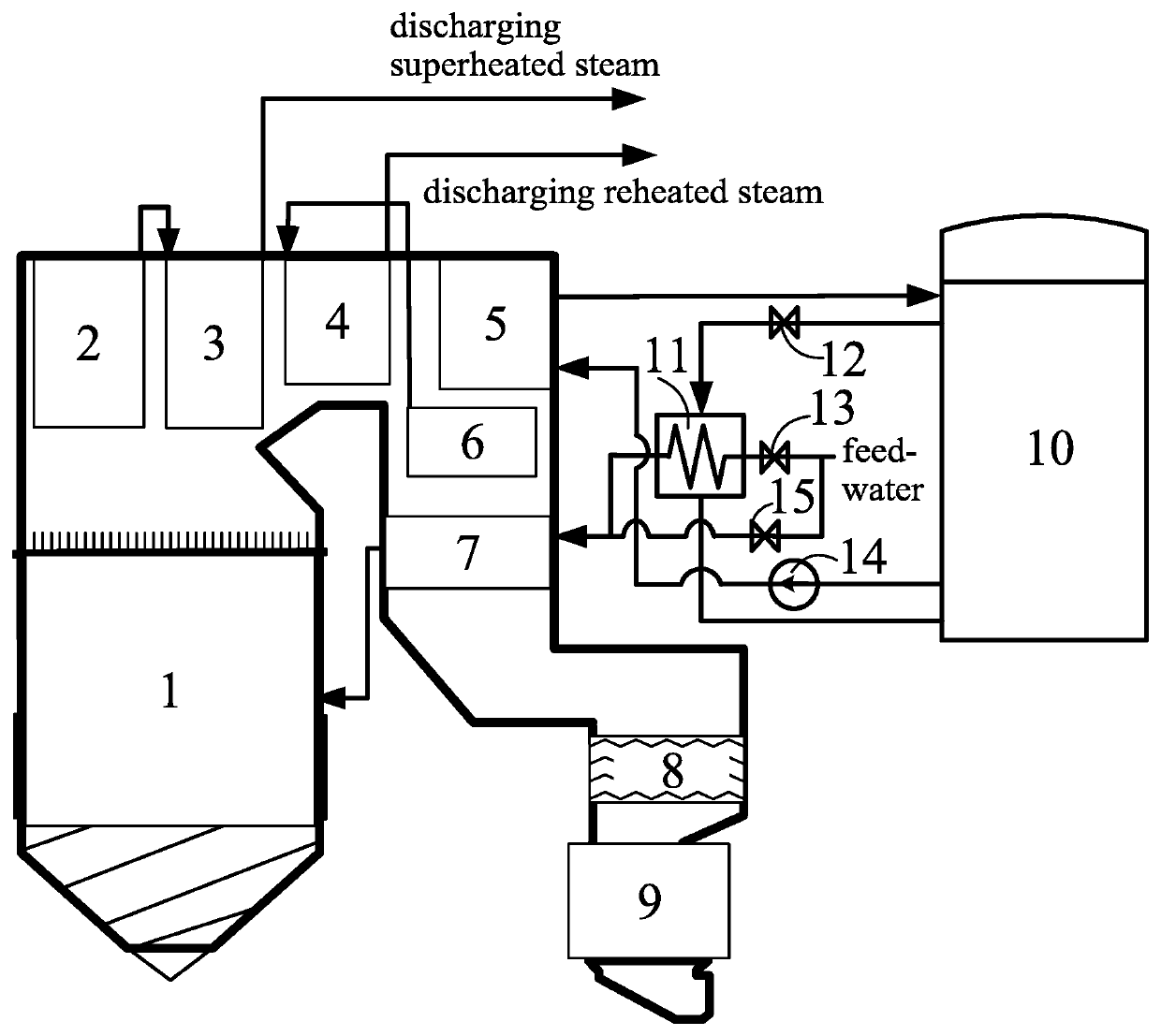

Full-working-condition auxiliary denitration system and running method

ActiveCN109945223AEmission reductionGuaranteed denitrification efficiencyGas treatmentBoiler water tubesAir preheaterWater flow

The invention discloses a full-working-condition auxiliary denitration system and a running method. The system comprises a water cooling wall, a platen superheater, a tail stage superheater, a tail stage reheater, a heat storage medium heater, a low-temperature reheater, an economizer, an SCR denitration device an air preheater and further comprises a heat storage medium tank and a heat storage medium and feed water heat exchanger; through a heat storage medium pump communicating with a cold heat storage medium outlet of the heat storage medium tank, the cold heat storage medium flow enteringthe heat storage medium heater is subjected to adjusting, the heat storage medium heat absorbing amount and boiler loads are matched, meanwhile, through a feed water adjusting valve and a heat heat-storage medium outlet adjusting valve communicating with the heat heat-storage heat medium outlet of the heat storage medium tank, the heat heat-storage medium flow and the feed water flow entering theheat storage medium and feed water heat exchanger are adjusted, through a bypass feed water adjusting valve, the main feed water flow is subjected to auxiliary adjusting, the smoke temperature entering the SCR denitration device is kept within the optimal running temperature range of the denitration system under the different boiler loads, and the denitration efficiency is ensured.

Owner:XI AN JIAOTONG UNIV

Denitrating coal economizer high-temperature bypass device

InactiveCN105716100ASuppress generationGuaranteed denitrification efficiencyEmission preventionDispersed particle separationAir preheaterGrating

The invention discloses a denitrating coal economizer coal economizer high-temperature bypass device which comprises a coal economizer and a coal economizer bypass flue, wherein the inlet end of the coal economizer bypass flue is connected with one side of the coal economizer; an electrically operated baffle door is arranged at the inlet end of the coal economizer bypass flue; a coal economizer inlet is formed in the top of the coal economizer; a coal economizer outlet is formed in one side of the bottom of the coal economizer; a coal economizer ash hopper is arranged at the bottom of the coal economizer; the coal economizer outlet and the outlet end of the coal economizer bypass flue are connected with a vertical flue; an ammonia spraying grating is arranged on the vertical flue; a first horizontal flue is connected with the top of a denitrating reactor; a denitrating reactor inlet ash hopper is arranged at the bottom of a second horizontal flue; the bottom of the denitrating reactor is connected with a denitrating reactor outlet flue; and the denitrating reactor outlet flue is connected with an air preheater. The denitrating coal economizer coal economizer high-temperature bypass device provided by the invention has the beneficial effects that the necessary denitrating efficiency can be guaranteed, and the generation of sulfate and ammonium hydrogen sulfate can be inhibited; and large-grain ash slag in smoke can be removed, so as to avoid obvious hole blockage and erosion to a catalyst.

Owner:DATANG ENVIRONMENT IND GRP

Method for removing NOx and SOx from fluid catalytic cracking (FCC) flue gas

ActiveCN102309920AGuaranteed denitrification efficiencyImprove absorption efficiencyDispersed particle separationAir quality improvementFluid catalytic crackingFlue gas

The invention provides a method for removing NOx and SOx from fluid catalytic cracking (FCC) flue gas. The method comprises the following steps of: mixing FCC flue gas and ammonia, performing selective reduction reaction of NOx in the presence of a catalyst, delivering the dust removed flue gas subjected to the selective reduction reaction to ammonium salt reclaiming and washing towers, delivering the flue gas cooled in the ammonium salt reclaiming and washing towers to an alkali liquor reverse contact desulfurization tower, and then discharging the treated flue gas, wherein the number of the ammonium salt reclaiming and washing towers is at least two, and the ammonium salt reclaiming and washing towers are used for flue gas heat exchange / ammonium salt washing switching operation and have heat exchange type structures. By the method, the denitration and desulfurization processes are finished, ammonium salt is produced, energy consumption is saved, alkali consumption in the desulfurization process is saved, and the desulfurization cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

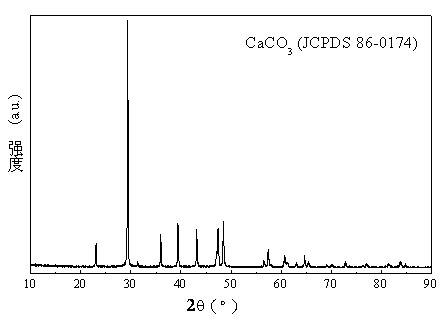

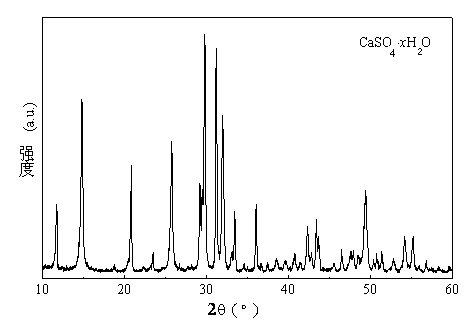

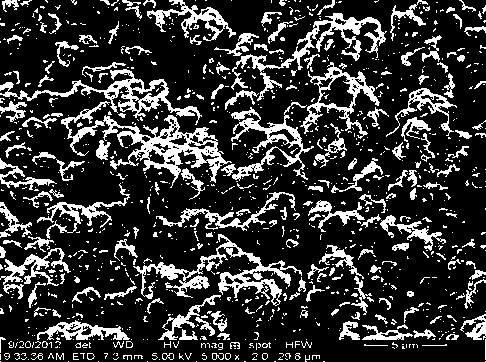

Application of sugar-mill lime sludge in wet flue gas desulfurization

The invention discloses the application of sugar-mill lime sludge in wet flue gas desulfurization. The application of the sugar-mill lime sludge is characterized in that the sugar-mill wet lime sludge is directly mixed with water to prepare slurry liquid, and the slurry liquid serves as an absorbing agent in a limestone-gypsum wet desulfurization method; the desulfurization absorbing agent is the waste lime sludge (namely filter residue or yellow mud) generated by the sugar prepared by a carbonic acid method in a sugar mill, mixed with water to form the slurry liquid with the proportion of 1:10-1:12, and used for absorbing sulfur dioxide (SO2) discharged by a coal burning boiler; and when the calcium-sulfur ratio is 1-1.1, the removal ratio of SO2 is up to more than 95 percent, the national desulfurization standard is met. The application of the sugar-mill lime sludge in the wet flue gas desulfurization adopts the waste residue of enterprises as the desulfuration absorbing agent, so as to be convenient and economic for material taking, simple in processing, and universal with the limestone-gypsum wet desulfurization method in requirements for equipment. The method not only saves the cost of purchasing an desulfurization agent, but also finds a way out for safe disposal of the lime sludge, so as to realize the purposes of treatment of wastes by other wastes, energy conservation and emission reduction, and have larger social environment benefits and economic benefits.

Owner:UNIV OF JINAN

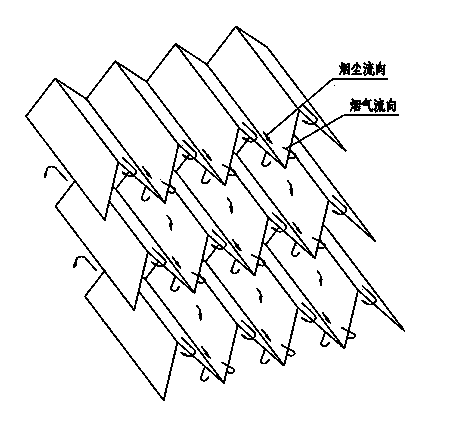

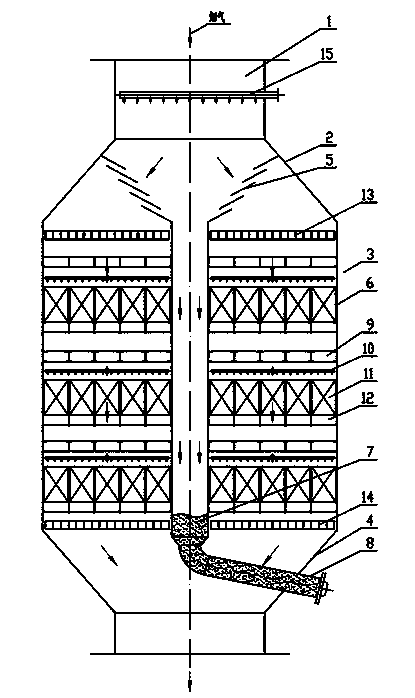

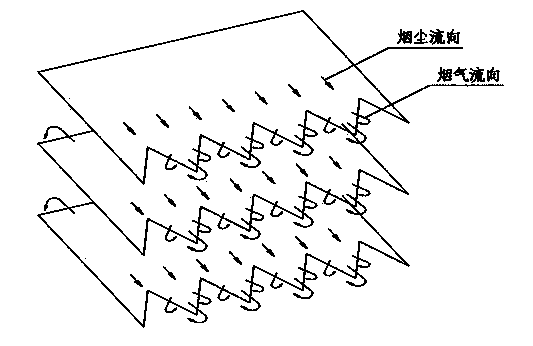

FCC regenerated flue gas dustproof denitration reactor

ActiveCN103768930ALarge flow areaReduce gas velocityDispersed particle separationFlue gasProcess engineering

The invention relates to a FCC regenerated flue gas dustproof denitration reactor. The FCC regenerated flue gas dustproof denitration reactor comprises a mixed flue gas inlet segment, a denitration segment, and a purified flue gas exhaust segment; the denitration segment is provided with a denitration unit; a dedusting segment is arranged between the mixed flue gas inlet segment and the denitration segment; dust blocking plates are arranged in the dedusting segment; the dust blocking plates are corrugated blocking plates which are arranged in a multi-layer staggered manner; a dust collector is arranged in the denitration segment; the center line of the dust collector and the center line of the FCC regenerated flue gas dustproof denitration reactor are overlapped; and the lower end of the dust collector is connected with a dust discharging pipeline. According to the FCC regenerated flue gas dustproof denitration reactor, the dust blocking plates are arranged in the FCC regenerated flue gas dustproof denitration reactor, so that flue dust in the mixed flue gas is removed effectively before the mixed flue gas is delivered into the denitration unit, blocking of catalyst channels in the denitration unit by flue dust is avoided, denitration efficiency and denitration effects are improved; and the FCC regenerated flue gas dustproof denitration reactor is provided with drainage grilles and rectifier grilles, so that laminar flow states of the flue gas in the FCC regenerated flue gas dustproof denitration reactor are maintained, and denitration efficiency is increased further.

Owner:CHINA PETROLEUM & CHEM CORP +1

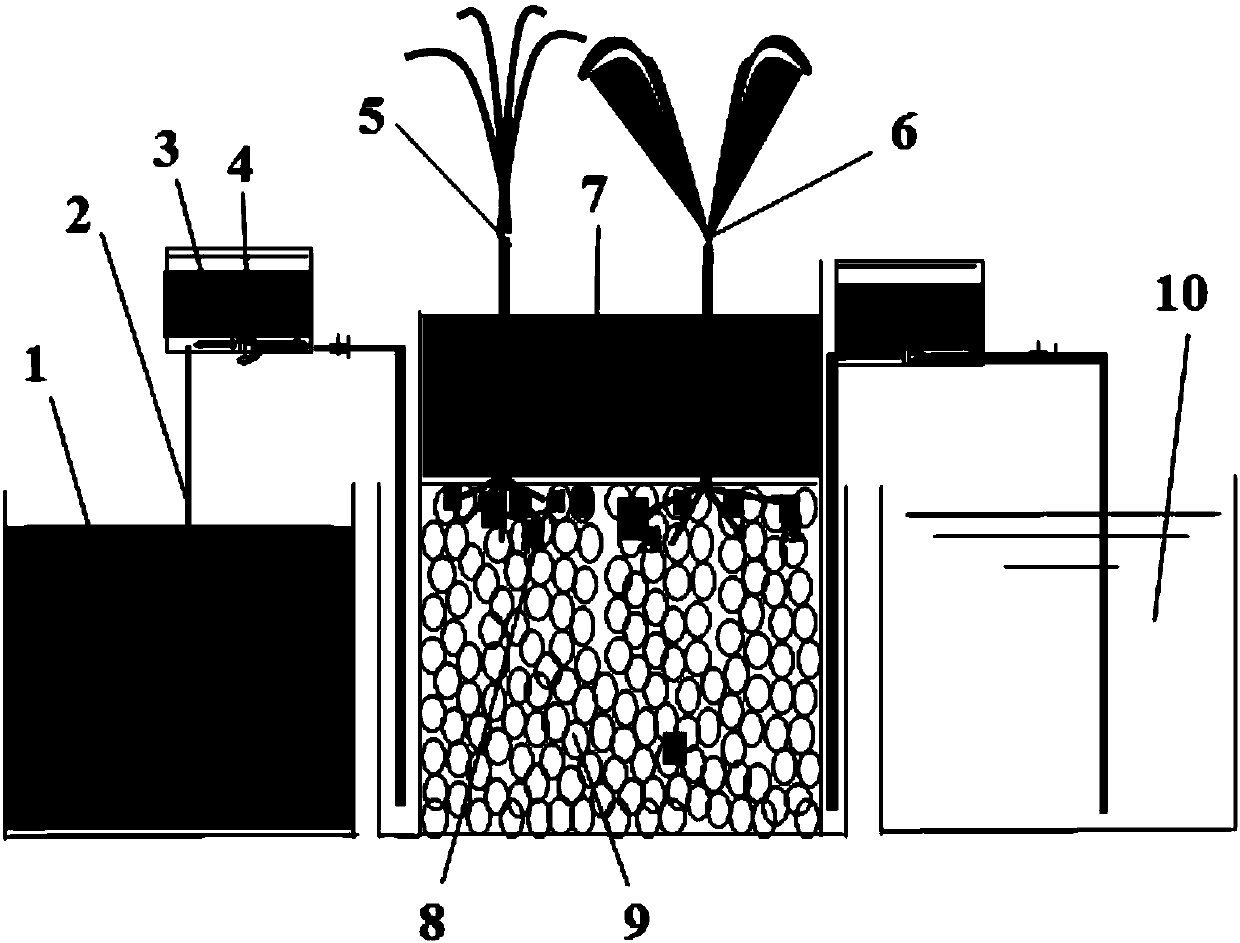

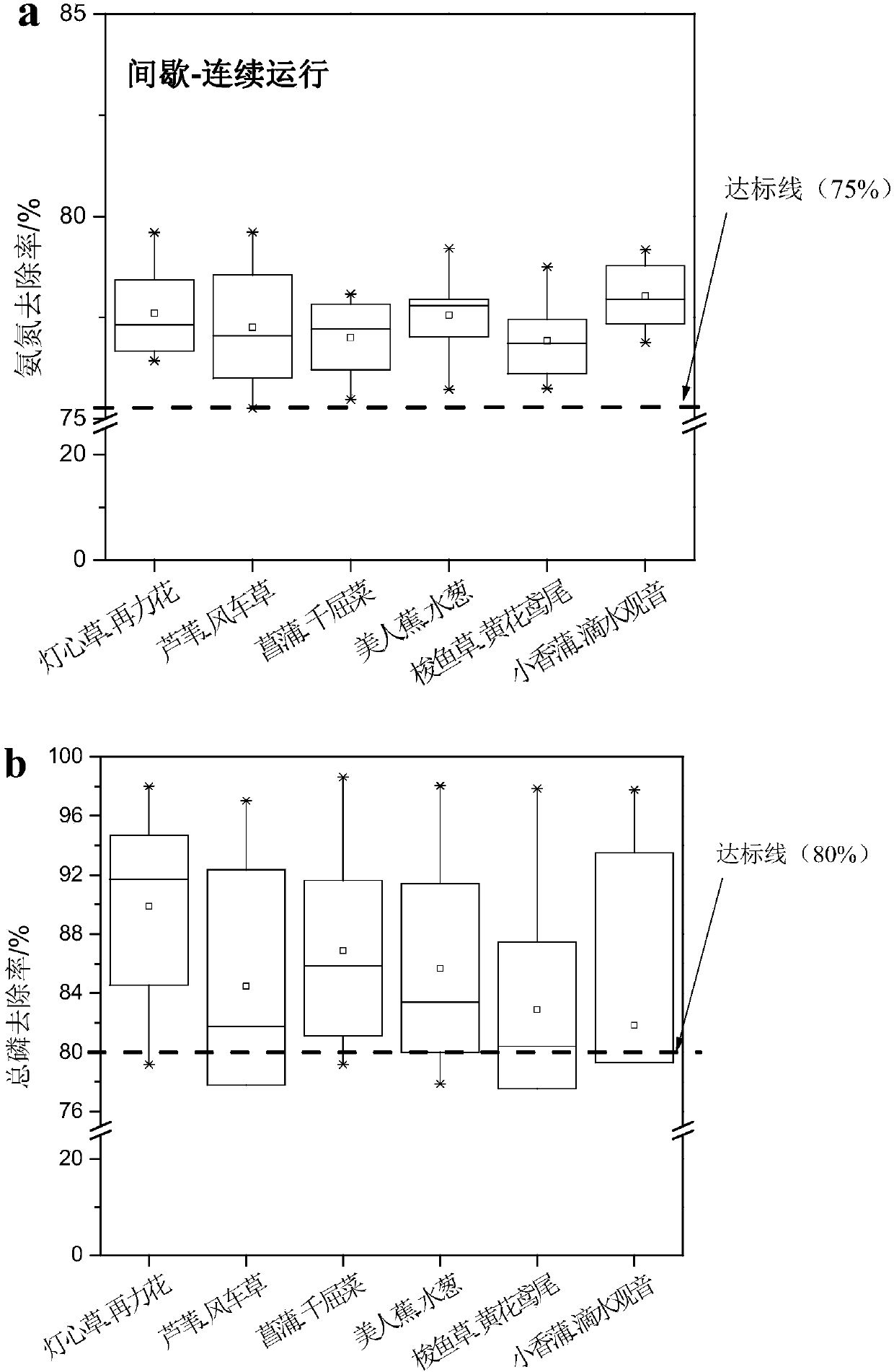

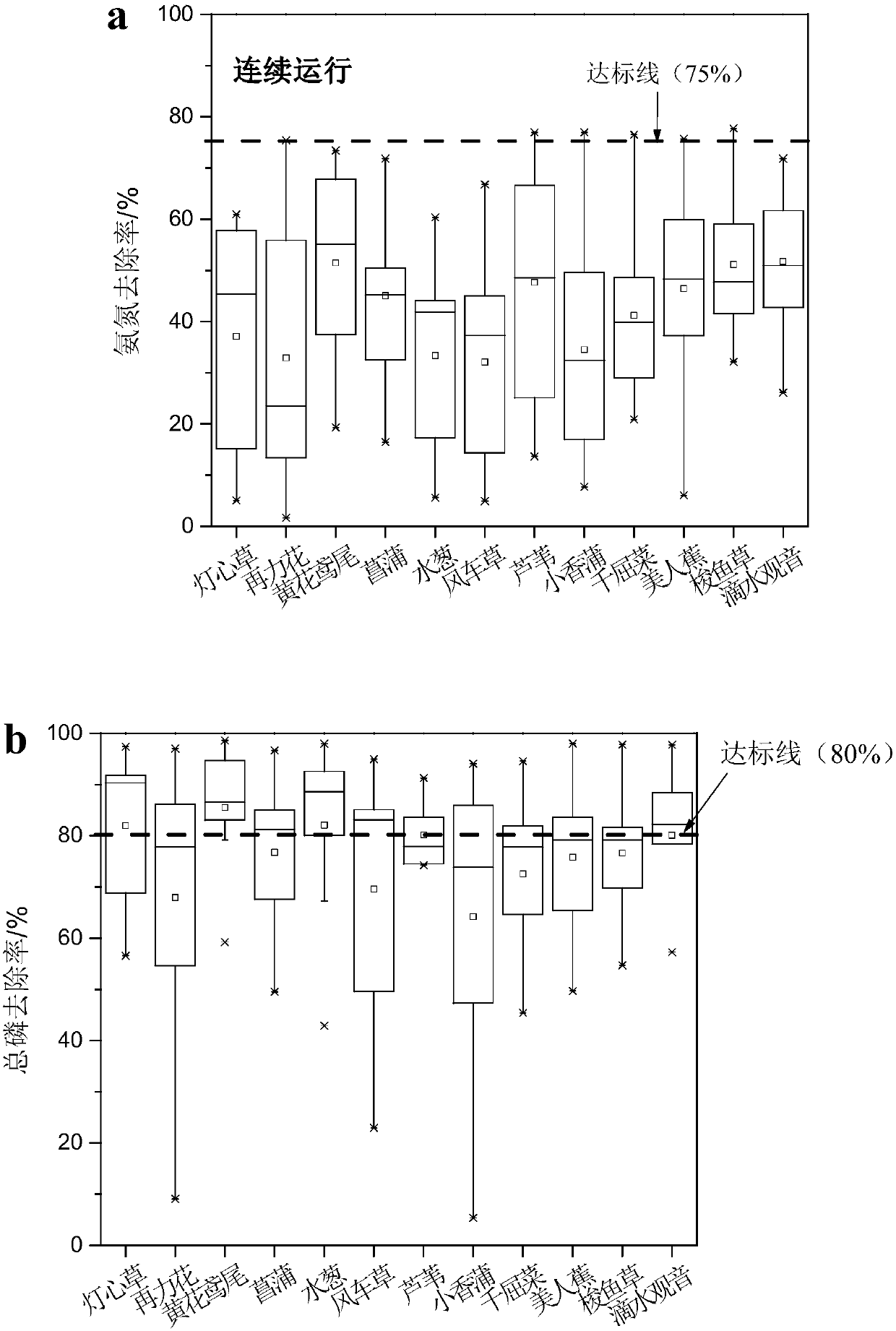

Underflow constructed wetland ecological system for disposing rural domestic waste and disposing method

ActiveCN107686167AGuaranteed denitrification efficiencyMaintain stable operationWater contaminantsBiological treatment apparatusRoot systemEcosystem

The invention discloses an underflow constructed wetland ecological system for disposing rural domestic waste and a disposing method. By adding root advantageous microorganisms in a canna water planting system, ratio of Alkaligenes, flavobacterium, lysobacter, Pseudomonas and other advantageous germs can be rapidly increased, the abundance of dioxygenase, dehydrogenase, phosphate dehydrogenase, urease, nitrate reductase, and dehydrogenase gene in catalase gene in the constructed wetland can be improved; two kinds of wetland plants can be planted in an intersecting manner, thus the different plant root secreta can be generated and a rich root microbial community structure is formed; the underflow constructed wetland ecological system can remove COD, ammonia nitrogen and total phosphorus atthe same time. Then the method of alternatively running continuous water feeding-intermittent water feeding is applied, thus the nitrogen removal efficiency is promoted while the system is stably operated. The method fully applies the advantages of the constructed wetland, strengthens the rapid construction of the constructed wetland ecological system, and optimizes the wetland running mode; the underflow constructed wetland ecological system is significant in environment, economic and social values.

Owner:ZHEJIANG METALLURGICAL RES INST +1

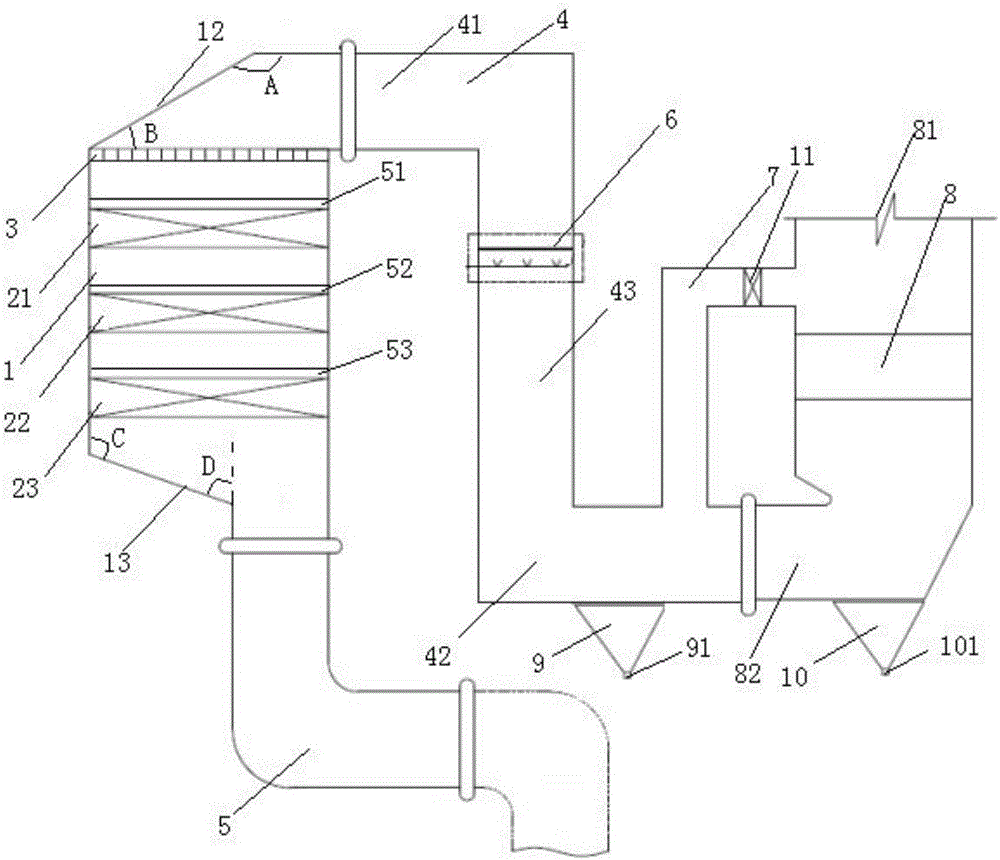

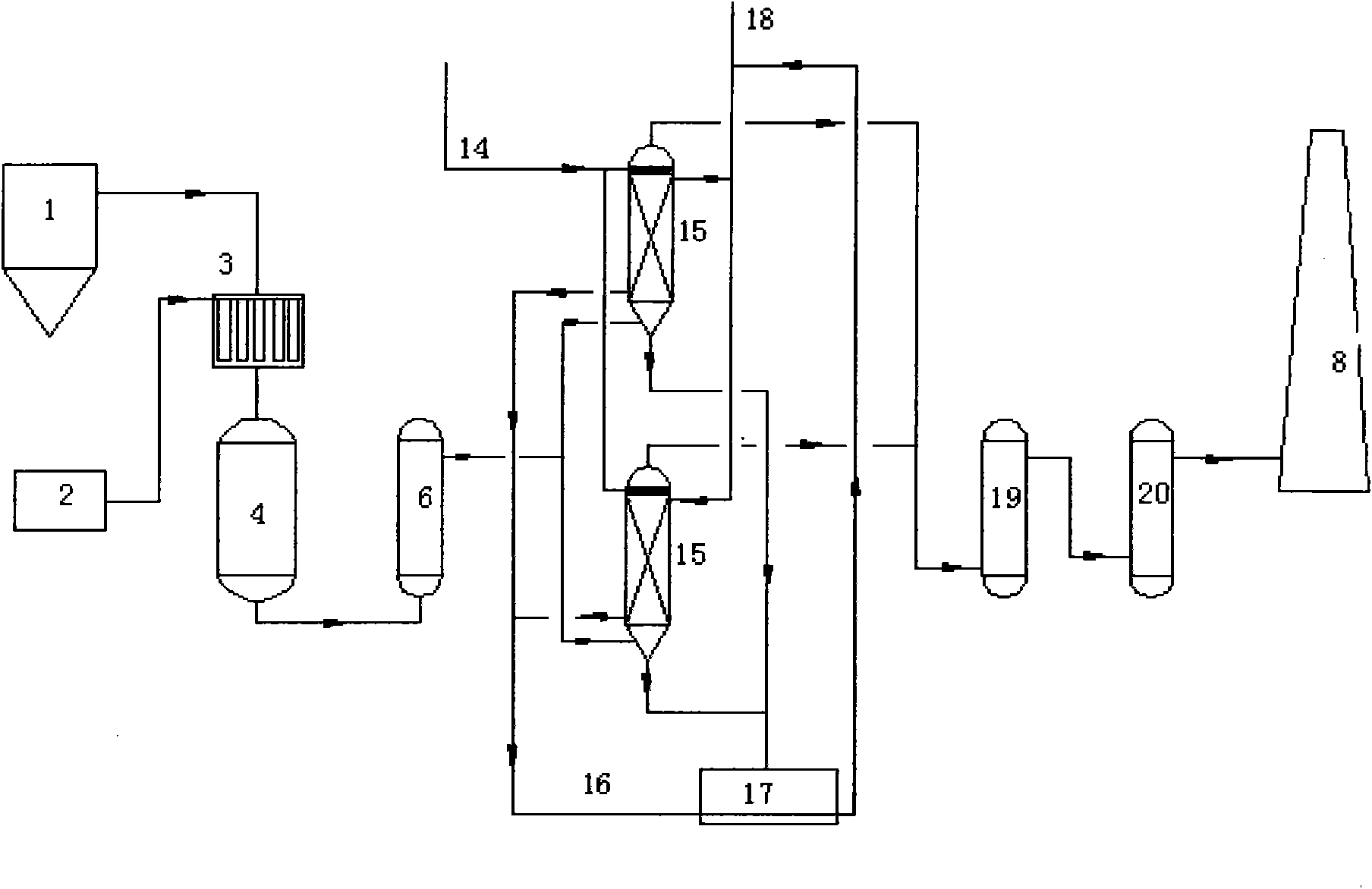

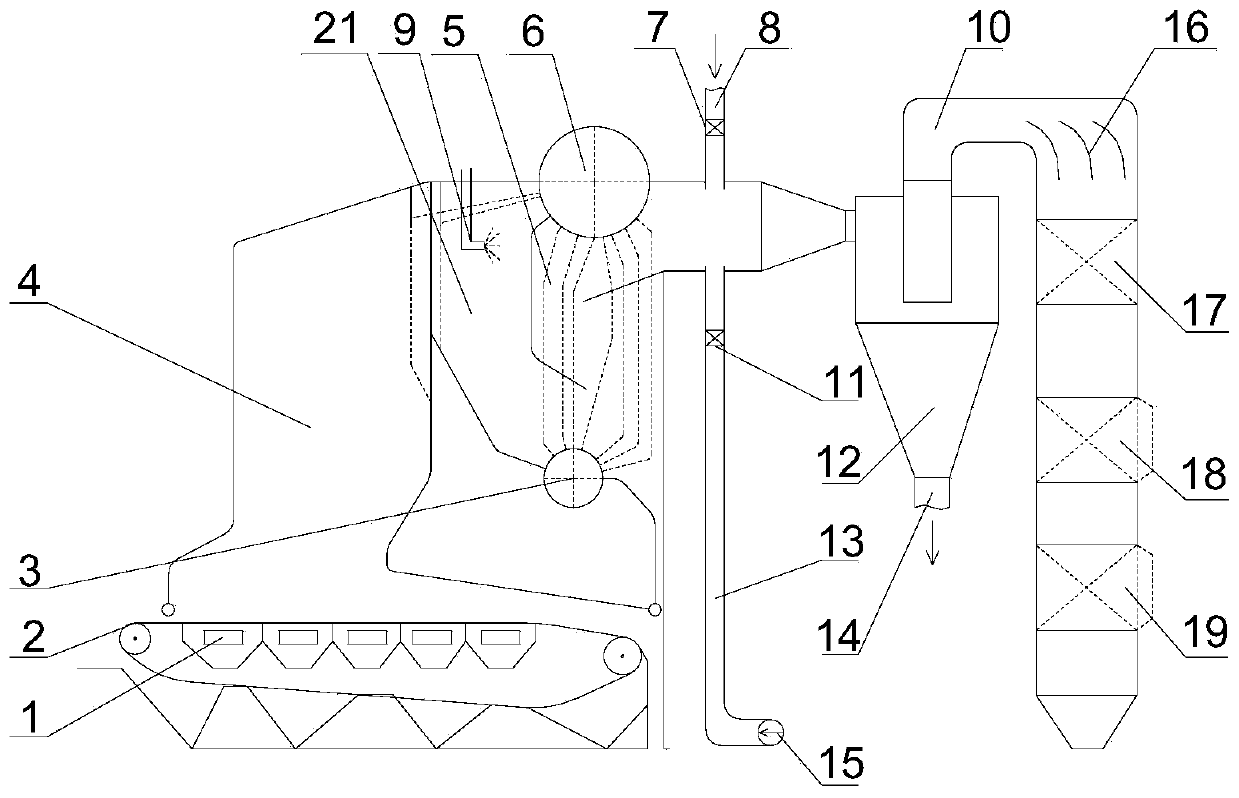

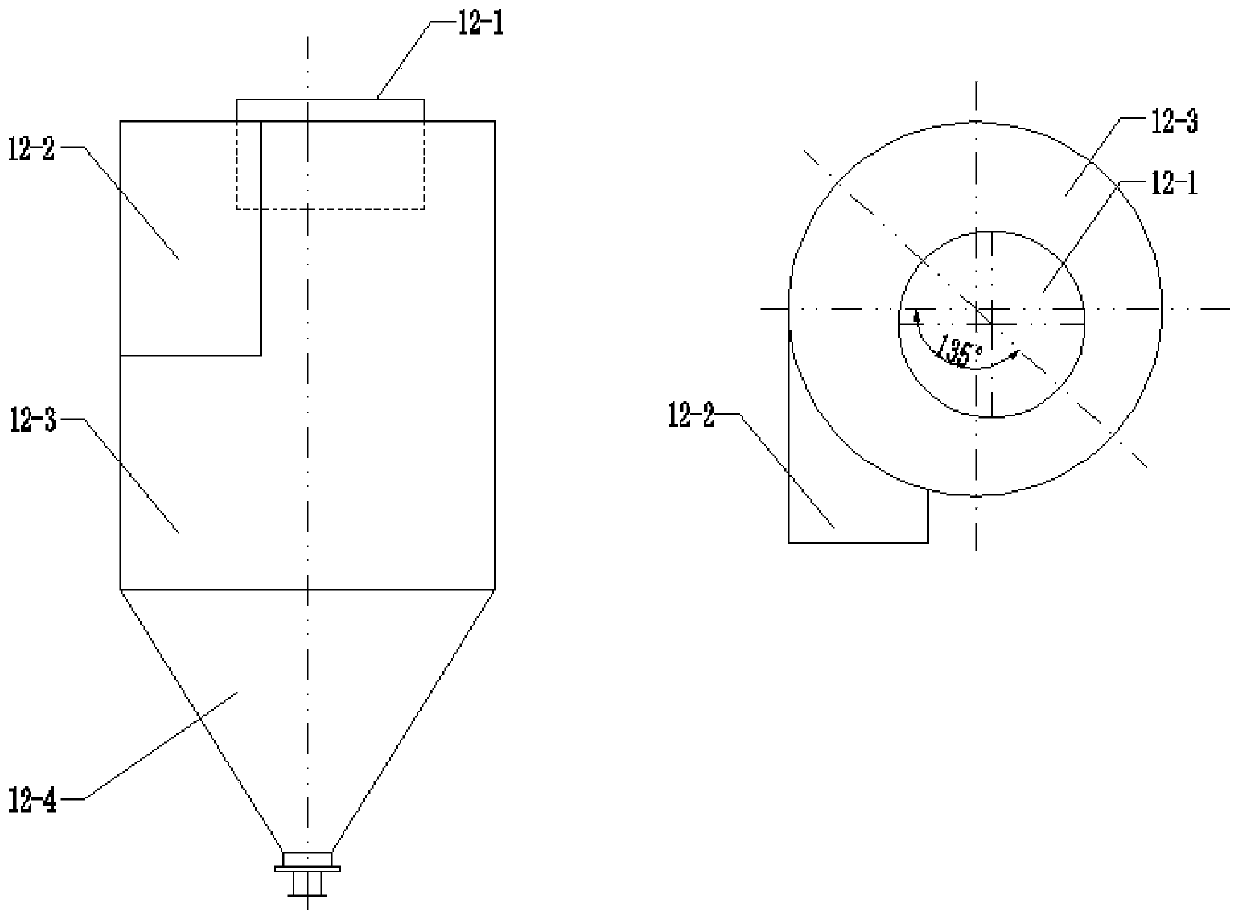

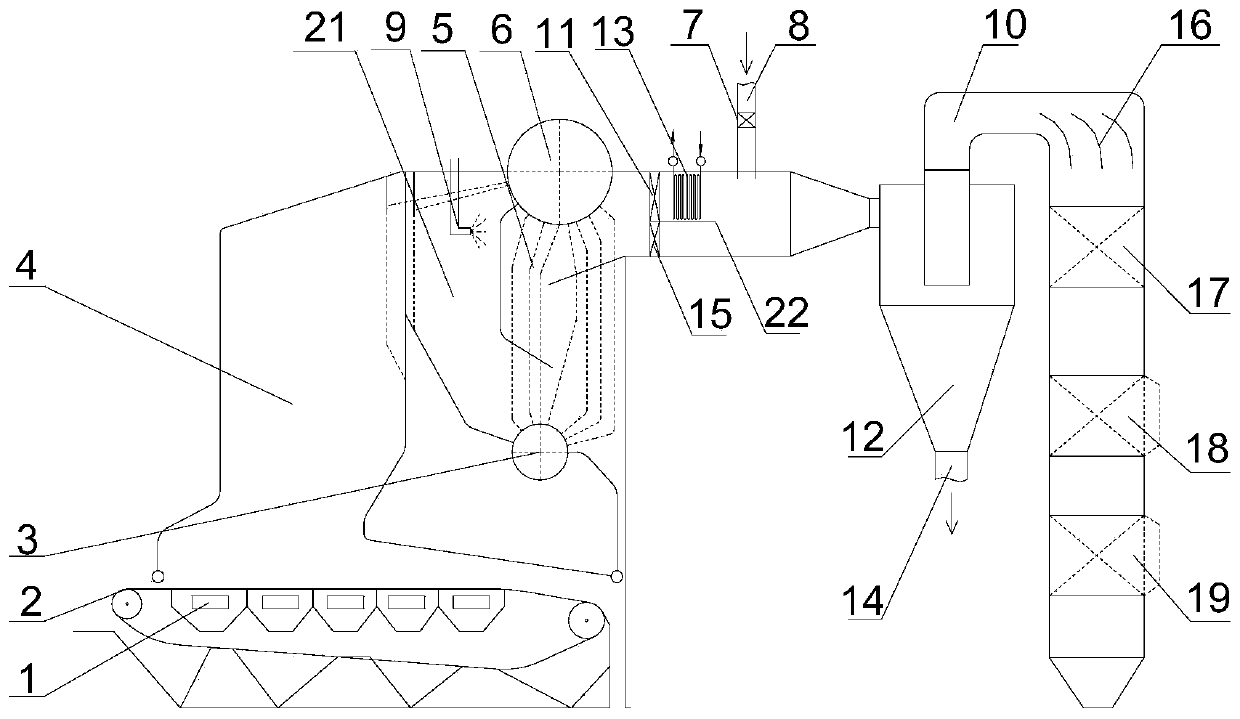

SCR inlet flue gas pre-treatment system and method

PendingCN110038433AUniform sectionSection NH

<sub>3</sub>

evenly distributedDispersed particle separationSolid fuel combustionAir preheaterHandling system

The invention relates to an SCR inlet flue gas pre-treatment system and method, relates to boiler pollutant control technology, and are used for new construction or renovation projects of ultra-cleanNOx emission of grate-firing coal-fired boilers. The SCR inlet flue gas pre-treatment system comprises a temperature regulating system, a urea solution or ammonia water solution ejector, and a cycloneequalization system. The system adopts a heating way of extracting high-temperature flue gas from a hearth outlet and then introducing the high-temperature flue gas into a cyclone tube, and a coolingway of adding a temperature-regulating economizer or extracting low-temperature flue gas from flue gas at a boiler dust collector outlet or an air preheater outlet and then introducing the low-temperature flue gas into the cyclone tube through a cold flue, and the average temperature of SCR inlet flue gas is controlled within the working range of catalysts. A urea solution is ejected in a burnoutchamber through the urea solution ejector; an ammonia water solution is ejected at an inlet pipe of a cyclone separator through the ammonia water solution ejector; NH3 is produced under the action ofthe high-temperature flue gas and mixed into the flue gas. Under the combined action of a flow equalization board and the cyclone tube, the flue gas and NH3 are mixed uniformly to achieve the effectsof equal temperature, equal concentration field and equal velocity, thereby meeting the requirements on the temperature, concentration field and velocity field at an SCR inlet.

Owner:HARBIN INST OF TECH

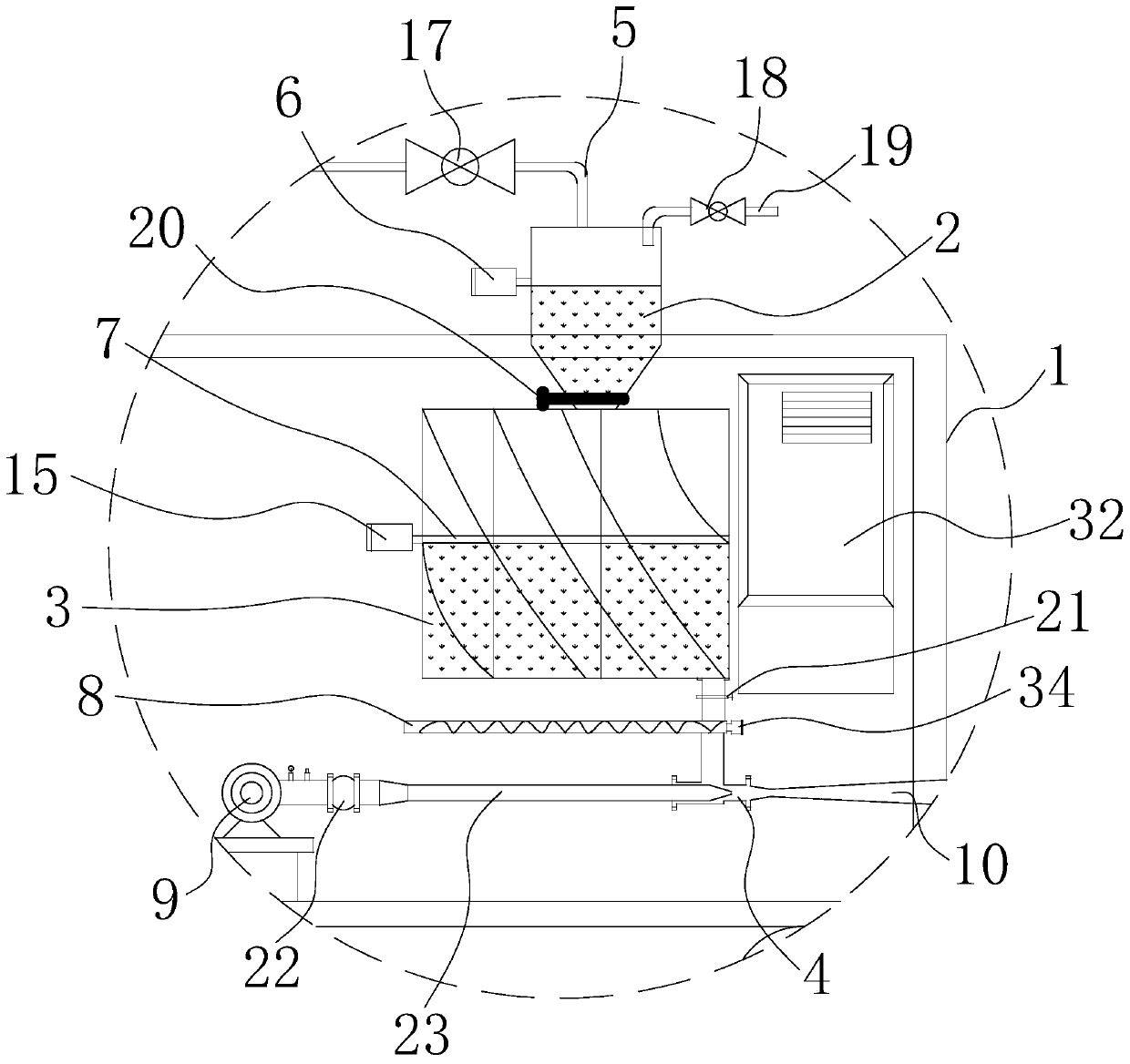

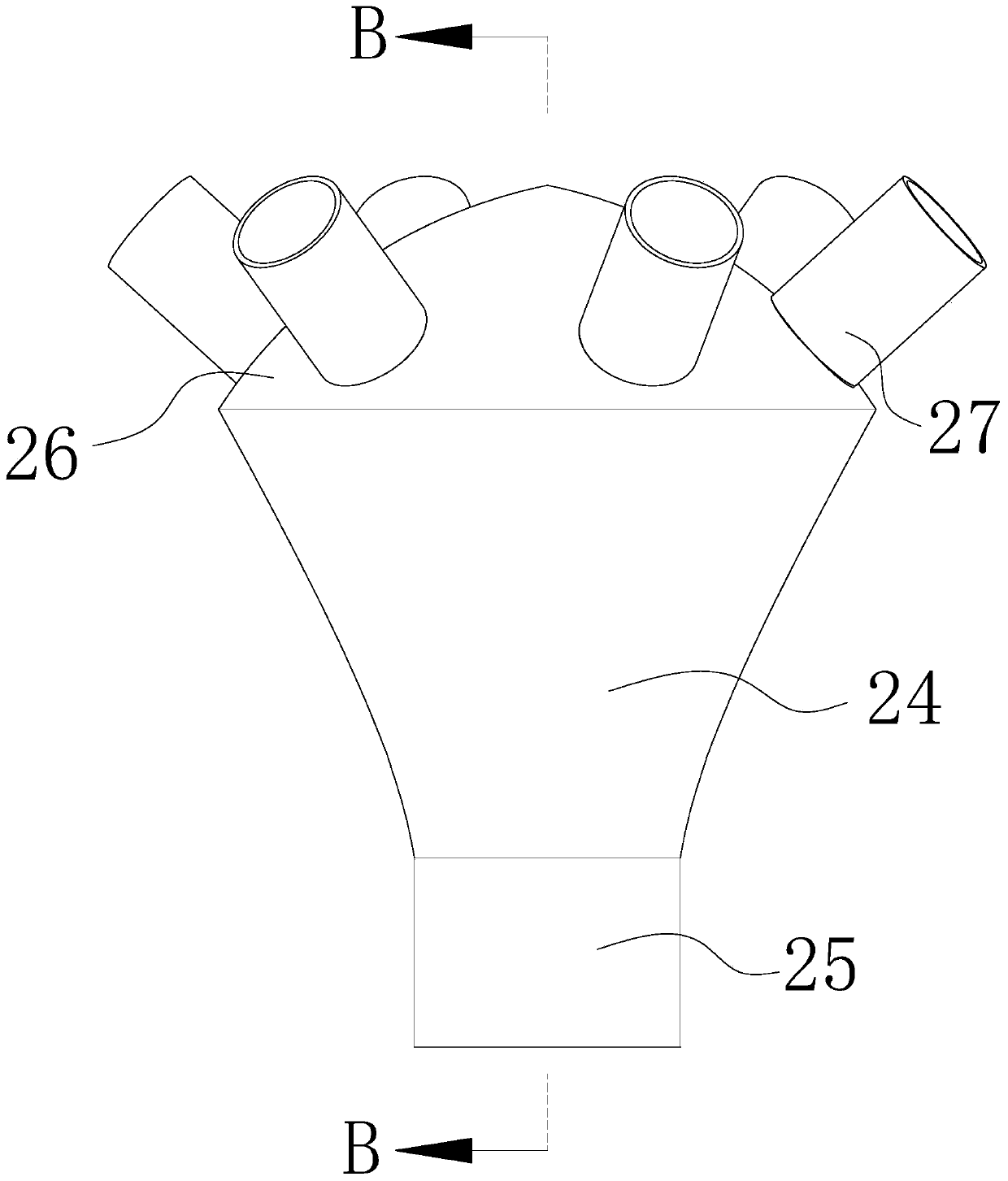

Integrated high-molecular dry denitration agent conveying device and integrated high-molecular dry denitration agent conveying method

PendingCN110575746ASimple structureSmall footprintGas treatmentTransportation and packagingEngineeringDistributor

The invention relates to an integrated high-molecular dry denitration agent conveying device and an integrated high-molecular dry denitration agent conveying method. The device comprises a small stockbin, a large stock bin and a mixing cabin which are integrated in the same device box, the small stock bin is connected with a material suction tube and a material suction motor, the large stock binis connected with the material discharge port of the small stock bin, a stirring auger is mounted in the large stock bin, the discharge port of the large stock bin is connected with the mixing cabin through a discharge auger, the mixing cabin is connected with a Roots blower and a Venturi tube respectively, the outlet of the Venturi tube is connected with a denitration agent conveying pipeline, and the end part of the denitration agent conveying pipeline is connected with a plurality of spray guns extending into a denitration hearth through at least two spherical distributors. The integrated high-molecular dry denitration agent conveying device has the advantages of simple structure and low comprehensive cost, and the conveying method has the advantages of convenience in operation, automatic conveying of the denitration agent, reduction of the labor intensity, improvement of the conveying efficiency, and improvement of the utilization rate of the denitration agent.

Owner:路超

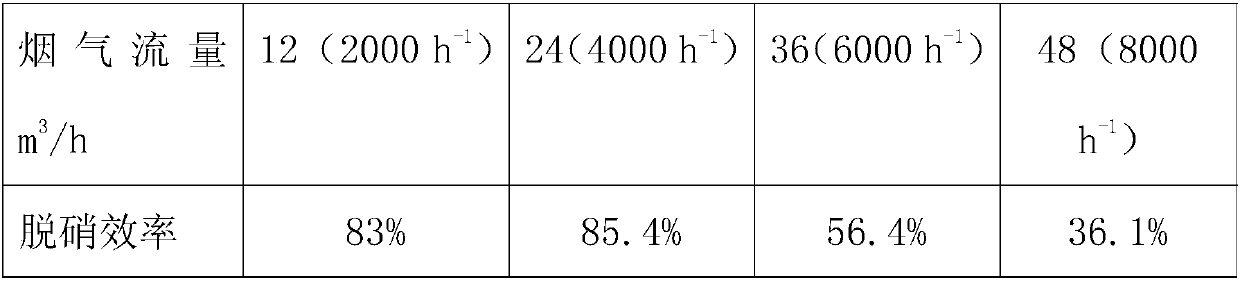

Honeycomb type low-temperature denitration method and device thereof

PendingCN107855002ARaw materials are easy to getNon-toxicDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFixed bed

The invention relates to a honeycomb type low-temperature denitration method and device thereof. The method comprises the following specific steps: mixing oxygen, nitrogen, carbon dioxide, carbon monoxide gas and nitrogen monoxide gas according to certain proportion, and preheating; mixing the preheated gas mixture with an ammonia gas according to certain proportion, and enabling the mixed gas topass through a fixed bed reactor with a honeycomb type catalyst according to certain flow rate, so as to realize catalytic denitration treatment; finally, cooling the treated gas and discharging through a tail gas fan. By adopting the technical scheme, the method provided by the invention, in which impregnation coating is applied, has the advantages of simple technology, low energy consumption and perfect application prospect. After being loaded with a catalyst, the specific surface area of honeycomb cordierite is remarkably increased, and the active components are uniformly distributed on the carrier surface. Through shaking treatment, the active components are tightly combined with the carrier. Meanwhile, the raw materials of the Mn-CeO2 / Al2O3 catalyst are easily available without toxicand harmful effects, and the preparation cycle is relatively short.

Owner:SHIHEZI UNIVERSITY

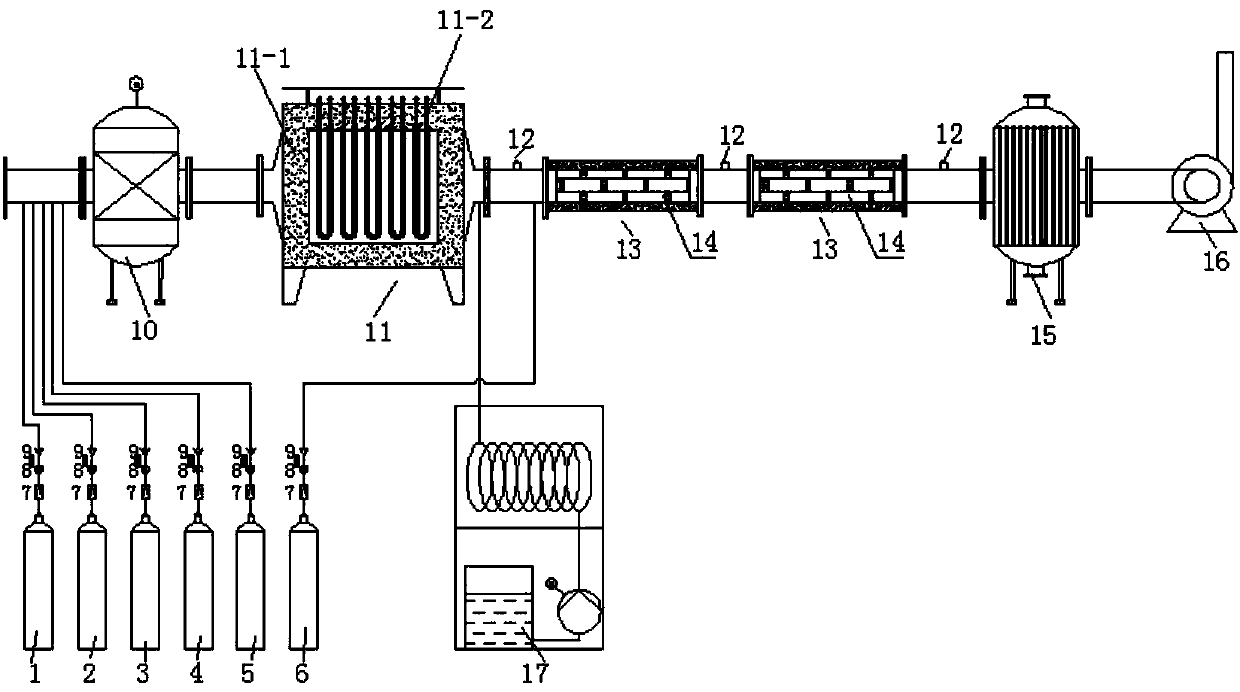

A low-temperature coke oven flue gas desulfurization and denitrification process

ActiveCN103816796BReduce efflux concentrationAvoid cloggingDispersed particle separationCoking plantFine powder

The invention relates to a low-temperature coke oven flue waste gas desulphurization and denitration process. According to the process, fluidized NaHCO3 fine powder is jetted into a flue gas conveying pipeline, so as to remove most of SO2 in the flue gas through the dry process; meanwhile, a denitration catalyst structure layer and an ammonia removal catalyst structure layer are combined for use, so that NOx in the coke oven flue gas is effectively removed; a denitration catalyst adopts a filtering-bag-shaped structure, and the ammonia removal catalyst adopts a V-shaped structure. The process utilizes a system consisting of an induced draft unit, a desulphurization unit, an ammonia preparation unit, a denitration and ammonia removal unit, a compressed air unit and a particle conveying unit to realize efficient denitration and desulphurization; compared with the prior art, the process has the benefits that residual ammonia water in a coking plant is fully utilized, a process combining a dry desulphurization method with an SCR (Selective Catalytic Reduction) denitration method is adopted, and the denitration catalyst and the ammonia removal catalyst are combined together, so that the efficient low-temperature coke oven flue gas desulphurization and denitration is realized.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

FCC regenerated flue gas dustproof denitration reactor

ActiveCN103768937ALarge flow areaReduce gas velocityDispersed particle separationFlue gasProcess engineering

The invention relates to a FCC regenerated flue gas dustproof denitration reactor. The FCC regenerated flue gas dustproof denitration reactor comprises a mixed flue gas inlet segment, a denitration segment, and a purified flue gas exhaust segment; the denitration segment is provided with a denitration unit; a dedusting segment is arranged between the mixed flue gas inlet segment and the denitration segment; dust blocking plates are arranged in the dedusting segment; a dust collector is arranged in the denitration segment; the center line of the dust collector and the center line of the FCC regenerated flue gas dustproof denitration reactor are overlapped; and the lower end of the dust collector is connected with a dust discharging pipeline. According to the FCC regenerated flue gas dustproof denitration reactor, the dust blocking plates are arranged in the FCC regenerated flue gas dustproof denitration reactor, so that flue dust in the mixed flue gas is removed effectively before the mixed flue gas is delivered into the denitration unit, blocking of catalyst channels in the denitration unit by flue dust is avoided, denitration efficiency and denitration effects are improved; and the FCC regenerated flue gas dustproof denitration reactor is provided with drainage grilles and rectifier grilles, so that laminar flow states of the flue gas in the FCC regenerated flue gas dustproof denitration reactor are maintained, and denitration efficiency is increased further.

Owner:CHINA PETROLEUM & CHEM CORP +1

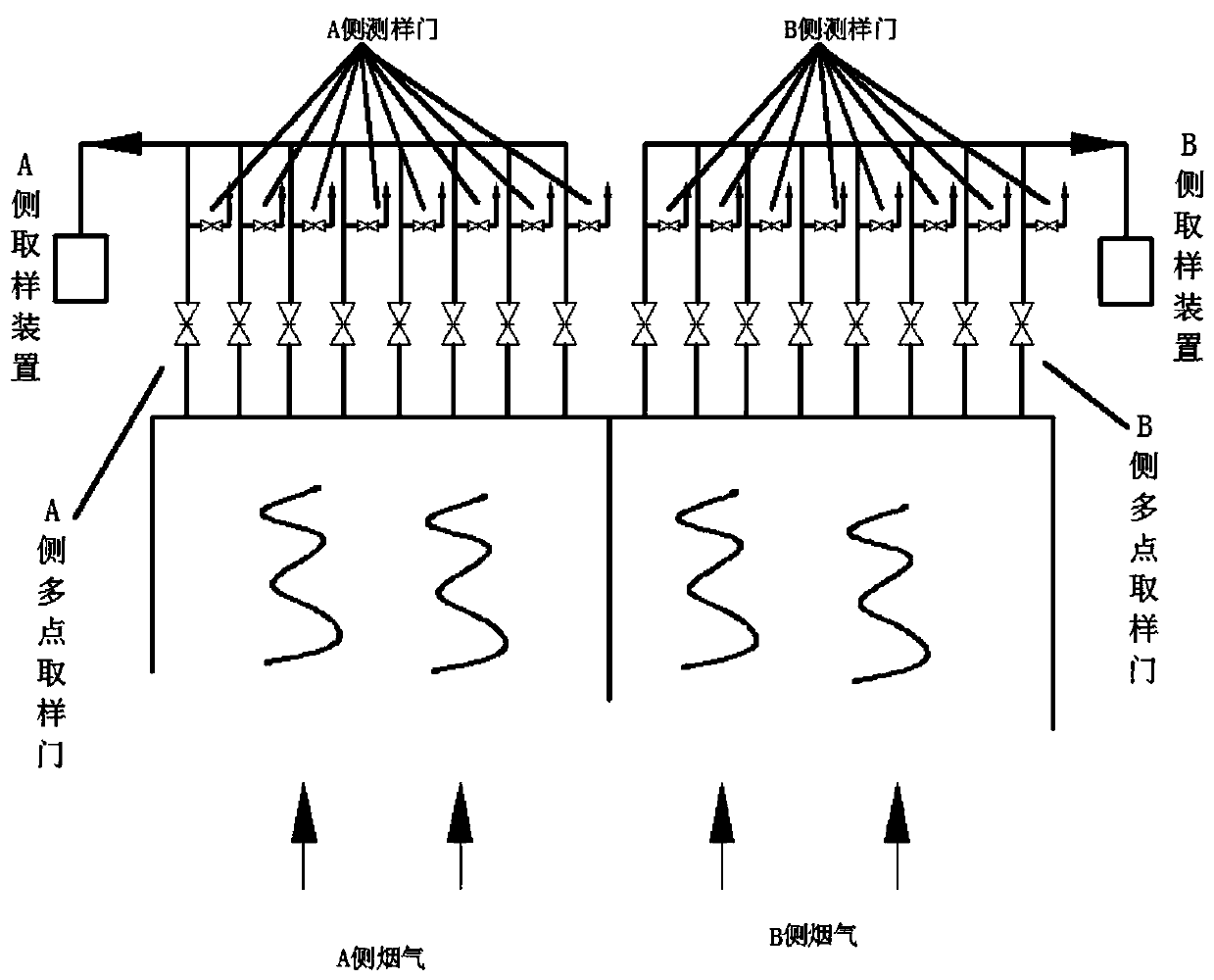

Optimizing system and method for denitration-system ammonia injection grating

InactiveCN109821417AEvenly distributedImprove mixing uniformityDispersed particle separationPtru catalystEnvironmental engineering

The invention provides an optimizing system and method for a denitration-system ammonia injection grating. The optimizing system comprises an A-side smoke outlet, a B-side smoke outlet, a sampling device and an ammonia injection control valve group; the ammonia injection control valve group is arranged in the A-side smoke outlet and the B-side smoke outlet, the sampling device is installed in theA-side smoke outlet and the B-side smoke outlet and located on the outer side of the ammonia injection control valve group, and comprises multiple sampling doors, and the sampling doors are evenly arranged in the A-side smoke outlet and the B-side smoke outlet. According to the optimizing system and method for the denitration-system ammonia injection grating, the multiple sampling doors are evenlyarranged at multiple sampling door outlets from the A side and the B side of a denitration outlet; through the adjusted denitration-reactor ammonia injection grating (AIG), the mixing uniformity of ammonia and smoke is improved, the using rate of a catalyst is increased, and the unit ammonia injection amount is decreased. By optimizing and adjusting the ammonia injection grating (AIG), outlets NOx are more evenly distributed, and denitration efficiency is better guaranteed; meanwhile, the ammonia consumption amount is decreased, the running cost is reduced, and the forming risk of ammonium bisulfate (ABS) is also reduced.

Owner:DATANG GUIZHOU FAER POWER GENERATION

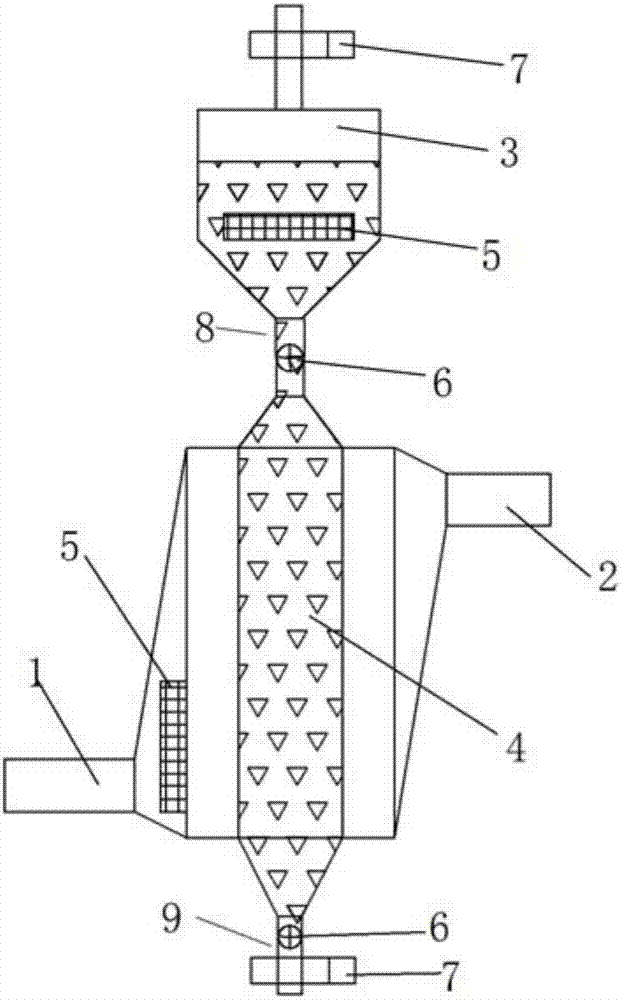

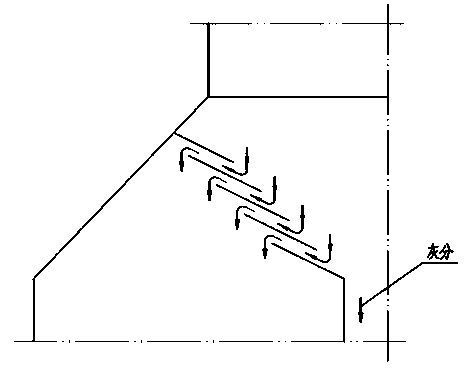

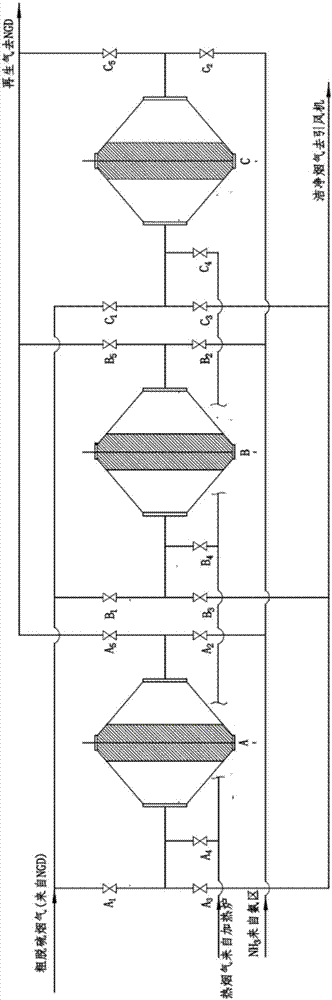

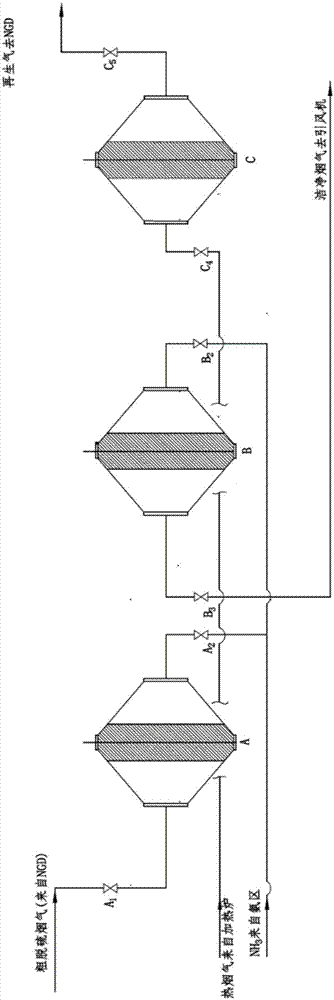

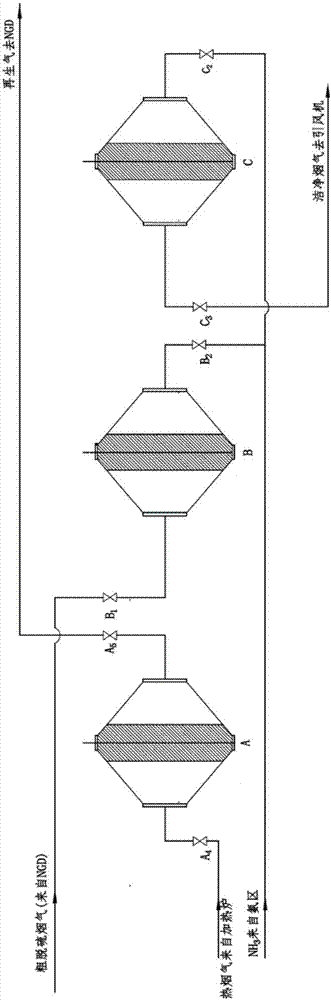

Low-temperature carbon-based combined desulfurization and denitrification flue gas system and use method thereof

PendingCN107321135AReduce the impactIncrease the windward areaGas treatmentDispersed particle separationActivated carbonFlue gas

The invention relates to a low-temperature carbon-based combined desulfurization and denitrification flue gas system and a use method thereof. The system comprises a first reactor, a second reactor and a third reactor and the reactors have the same structures. Each one of the first reactor, the second reactor and the third reactor comprises a central carbon-based bed, left and right air distribution grilles and left and right gas collection tanks in the outer side. The carbon-based bed is filled with an activated carbon material. The system utilizes the three same reactors and has functions of fine desulfurization, denitration and regeneration. The fine desulfurization and denitratio processes are connected in series and are connected to the regeneration process in parallel and the processes are carried out simultaneously so that in-situ regeneration is really realized. The reactor comprises the central carbon-based bed, left and right air distribution grilles and left and right gas collection tanks. The bed has a large windward area so that uniform gas distribution in the work and regeneration processes is guaranteed and a floor space is reduced. The system further improves the desulfurization and denitrification performances of the activated carbon material.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD +1

All-condition auxiliary denitration system and operation method thereof

ActiveUS20210016224A1Simple structureSmall investmentGas treatmentBoiler water tubesFlue gasProcess engineering

An all-condition auxiliary denitration system and an operation method. thereof are provided. The system includes a heat-storage medium heater, a low-temperature reheater, an economizer, and an SCR denitration device which are successively interconnected, and further including a heat-storage medium tank and a heat-storage medium and feedwater heat exchanger. A flow of a cold heat-storage medium entering the heat-storage medium heater is regulated, so that heat absorption of the heat-storage medium is matched with a boiler load. Flows of hot heat-storage medium and feedwater, which enter the heat-storage medium and feedwater heat exchanger, are regulated through a feedwater regulating valve and a hot heat-storage medium outlet regulating valve. A total feedwater flow is regulated with assistance of a bypass feedwater regulating valve, so that a temperature of flue gas entering the SCR denitration device is kept in an optimal operation range under different boiler loads, and denitration efficiency is ensured.

Owner:XIAN JIATONG UNIV

SCR denitration device used for heat-engine plant

PendingCN108704475AReduce volumeSmall footprintGas treatmentDispersed particle filtrationAmmonium hydroxideEngineering

The invention belongs to the technical field of flue gas denitration, and particularly relates to an SCR denitration device used for a heat-engine plant. The device comprises a box, a flue gas inlet,an ammonium hydroxide inlet pipe, a flue gas outlet, a dedusting module, an ammonium hydroxide spraying module, a filtering net module and a catalyst supplementing module; the flue gas inlet is formedin the left side of the box; the ammonium hydroxide inlet pipe is located under the flue gas inlet; the flue gas outlet is formed in the top of the box; the dedusting module is used for dedusting flue gas; the ammonium hydroxide spraying module is used for spraying ammonium hydroxide, and the ammonium hydroxide and the flue gas are mixed; the filtering net module is installed in the box; the catalyst supplementing module is located over the filtering net module, a annular groove is formed in the side wall of the box, and the catalyst supplementing module is installed in the annular groove ina sliding mode. The required flue gas denitration device is small in size and occupied space, a good flue gas dedusting effect and thorough dedusting are achieved, fast decline of the effect of a catalyst is relieved, a disabled portion on the surface layer of a catalyst is removed, and meanwhile, the catalyst is added freely.

Owner:彭圆

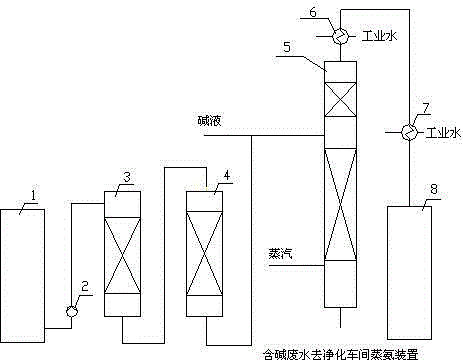

Process for preparing SCR reducing agent from coking residual ammonia wastewater as raw material

InactiveCN104556147ALess investmentGuaranteed denitrification efficiencyDispersed particle separationAmmonia preparation/separationChemistryNH3 compound

The invention provides a process for preparing an SCR reducing agent from a coking residual ammonia wastewater as a raw material. The process is characterized by comprising the following steps: condensing ammonia vapor generated by a dephlegmator of an ammonia stripping system of a gas purification workshop in a coking plant to obtain coking strong ammonia water; removing impurities from the coking strong ammonia water by a filter and deoiling by an adsorption tower; adding an NaOH alkali liquor to the ammonia water, mixing evenly, and then conveying to a distillation tower to carry out secondary distillation; processing the ammonia vapor at the tower top through the dephlegmator and then processing by the condenser, so as to obtain refined strong ammonia water; adopting coking ammonia water generated by ammonia distillation of the coking residual ammonia wastewater as a preparation raw material of the SCR reducing agent, and refining the coking strong ammonia water to reach the requirements of the reducing agent used for SCR catalytic reduction, so that the denitration cost is reduced when the denitration efficiency is ensured.

Owner:CHENGDU HUAXITANG INVESTMENT

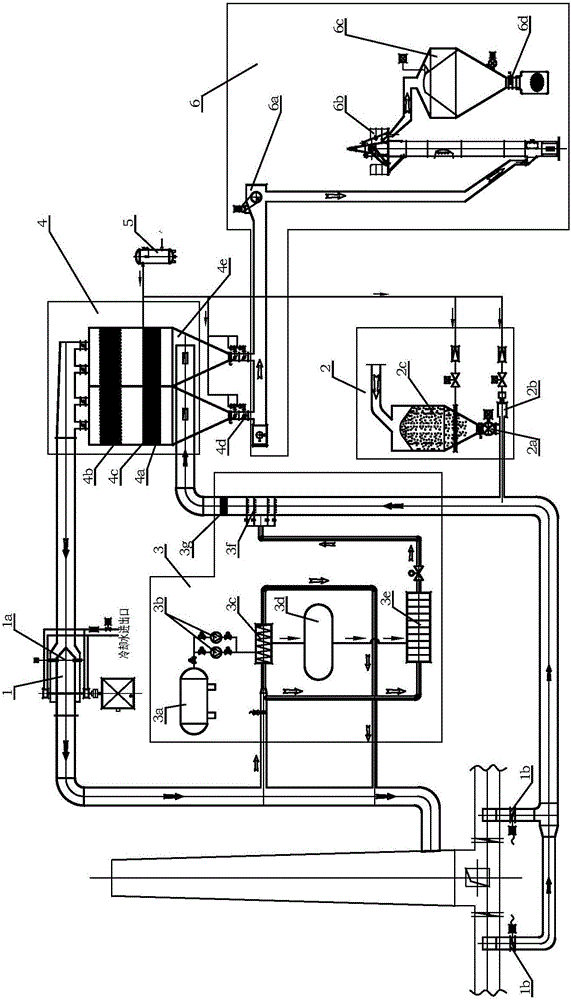

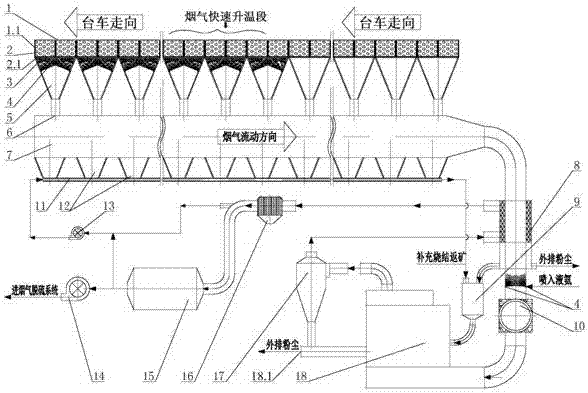

Sintering smoke self-catalyzing denitrifying system by coupling and utilizing residual heat of sintering smoke

ActiveCN107198962AReduce the cost of denitrificationGuaranteed denitrification efficiencyGas treatmentDispersed particle separationFluidized bedFlue gas

The invention relates to a sintering smoke self-catalyzing denitrifying system by coupling and utilizing residual heat of sintering smoke, which solves the problems of large investment, high running cost and lower denitrifying efficiency in the existing denitrifying system. The sintering smoke self-catalyzing denitrifying system adopts the technical scheme that the sintering smoke self-catalyzing denitrifying system comprises a sintering machine, wherein air bellows are arranged under a trolley of the sintering machine; an exit of the bottom part of each air bellow is communicated with a main flue; the sintering machine is sequentially provided with an ignition section, a machine head section, a flue gas quick heating section and a machine tail section along the moving direction of the trolley; the main flue is sequentially connected with a denitrifying reactor of a fluidized bed through a denitrifying flue gas heat exchanger shell or tube, and a flue gas heater; liquid ammonia spray nozzles are respectively arranged in the air bellows under the machine tail section to the flue gas quick heating section area, and in the flue gas exit pipeline of the flue gas heater. The sintering smoke self-catalyzing denitrifying system has the advantages that the system is simple, the additional purchase of the catalyst is avoided, the effective denitrifying and sintering process is realized, the recycling rate of residual heat is high, the energy-saving and consumption-reducing effects are realized, the land occupation area is small, and the equipment investment and running cost are low.

Owner:武汉钢铁有限公司 +2

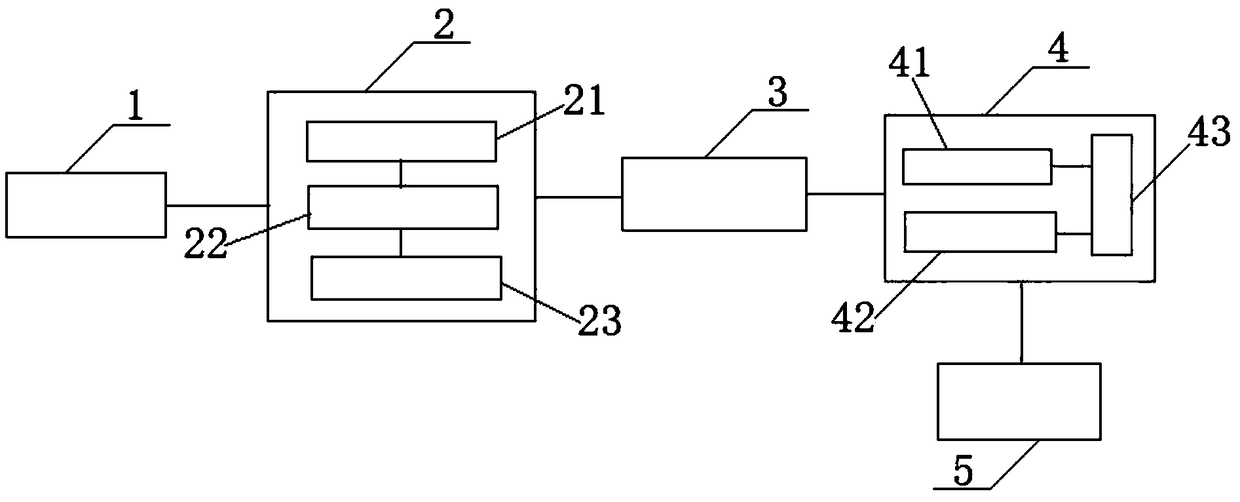

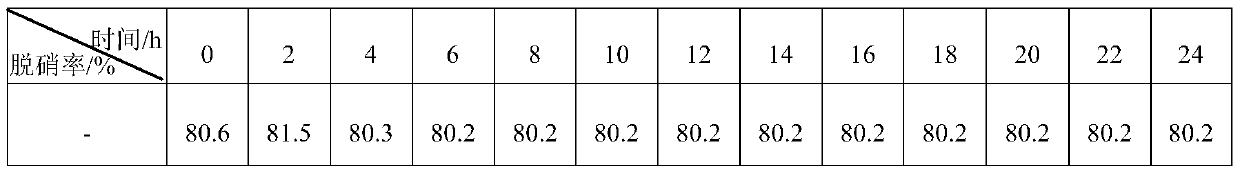

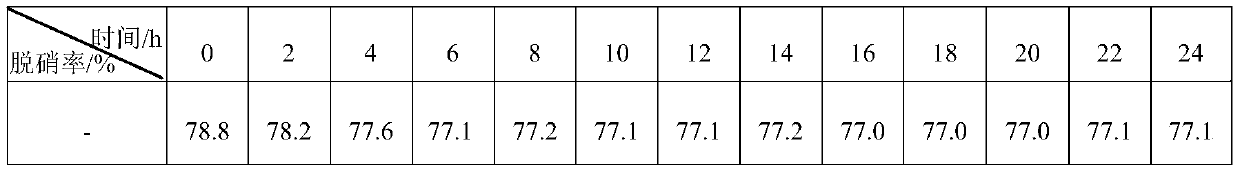

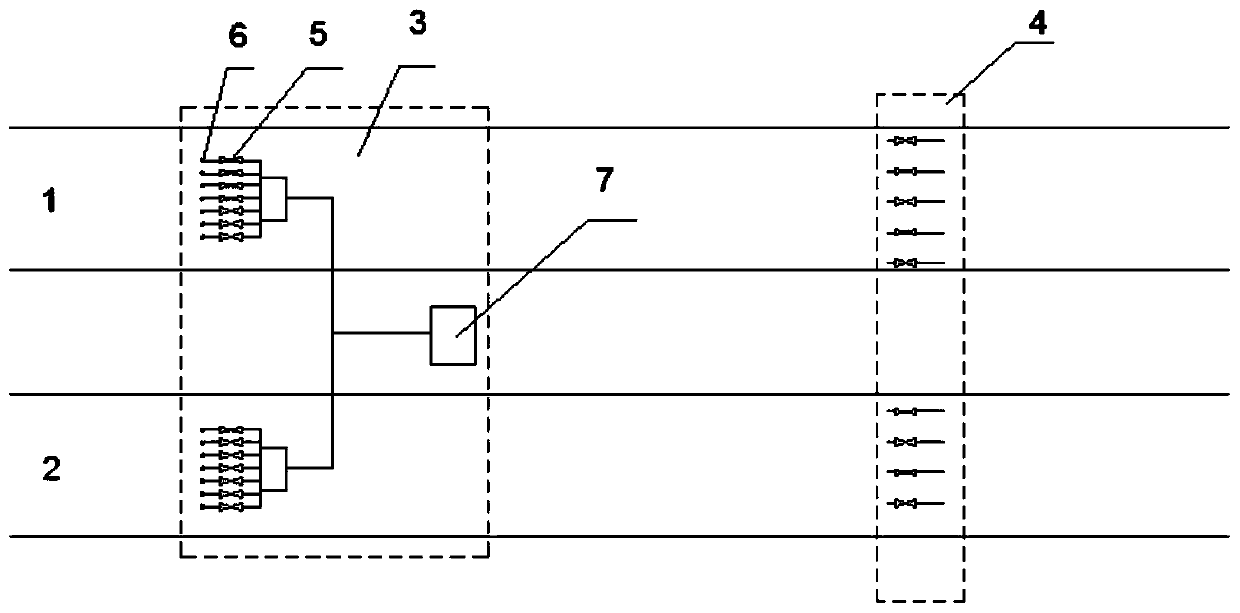

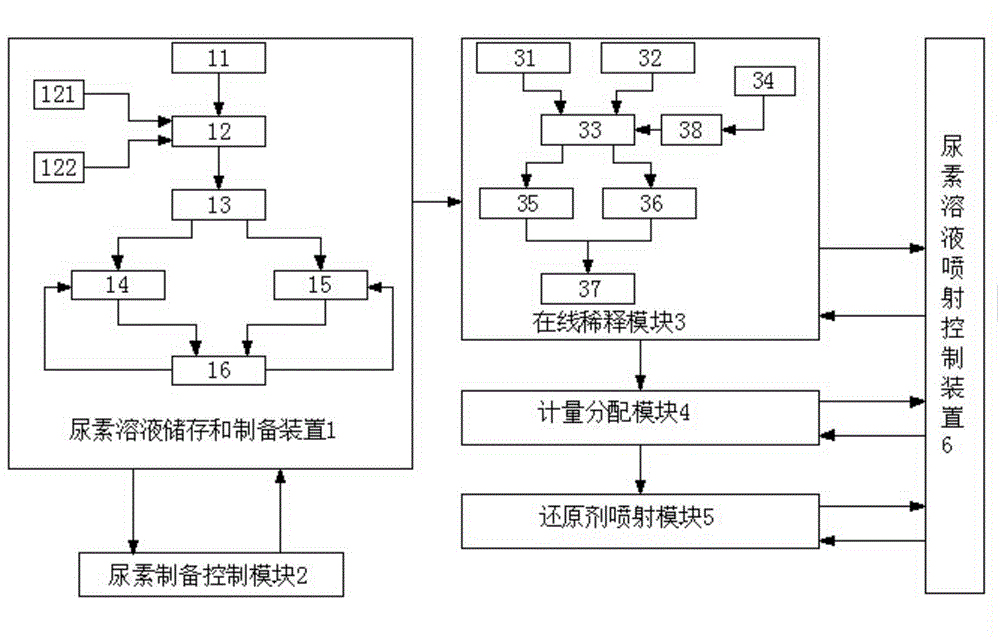

SNCR denitration method for urea solutions of double concentrations

InactiveCN104524949AEasy to adjustIncrease supplyDispersed particle separationUltrasound attenuationLiquid storage tank

The invention discloses an SNCR denitration method for urea solutions of double concentrations. A urea solution storage and preparation device (1), a urea preparation control module (3), an online attenuation module (3), a metering and distributing module (4), a reducing agent spraying module (5) and a urea solution spraying control device (6) are involved in the method, wherein the information input end of the urea solution storage and preparation device (1) is connected with the information input end of the urea preparation control module (2), and the control end of the urea preparation control module (2) is connected with the urea solution storage and preparation device (1). The urea solutions in two urea liquid storage tanks can be conveniently regulated to be of two different concentrations, and the concentration values are determined according to design calculation and site parameters; in this way, the regulation range is narrowed, accuracy is increased, and a denitration system conducts rapid reaction for the working condition changes of a boiler; particularly, under the low temperature of the downstream part of a window, the pure urea supply amount is rapidly increased, and the denitration efficiency is ensured.

Owner:广东红树林生态环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com