Ultra-low emission circulating fluidized bed boiler with three stages of desulfurization systems

A circulating fluidized bed and desulfurization system technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of poor quality of fly ash that cannot be comprehensively utilized, heavy transformation workload, and low desulfurization efficiency. The effect of high utilization rate of desulfurization agent, small modification workload and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

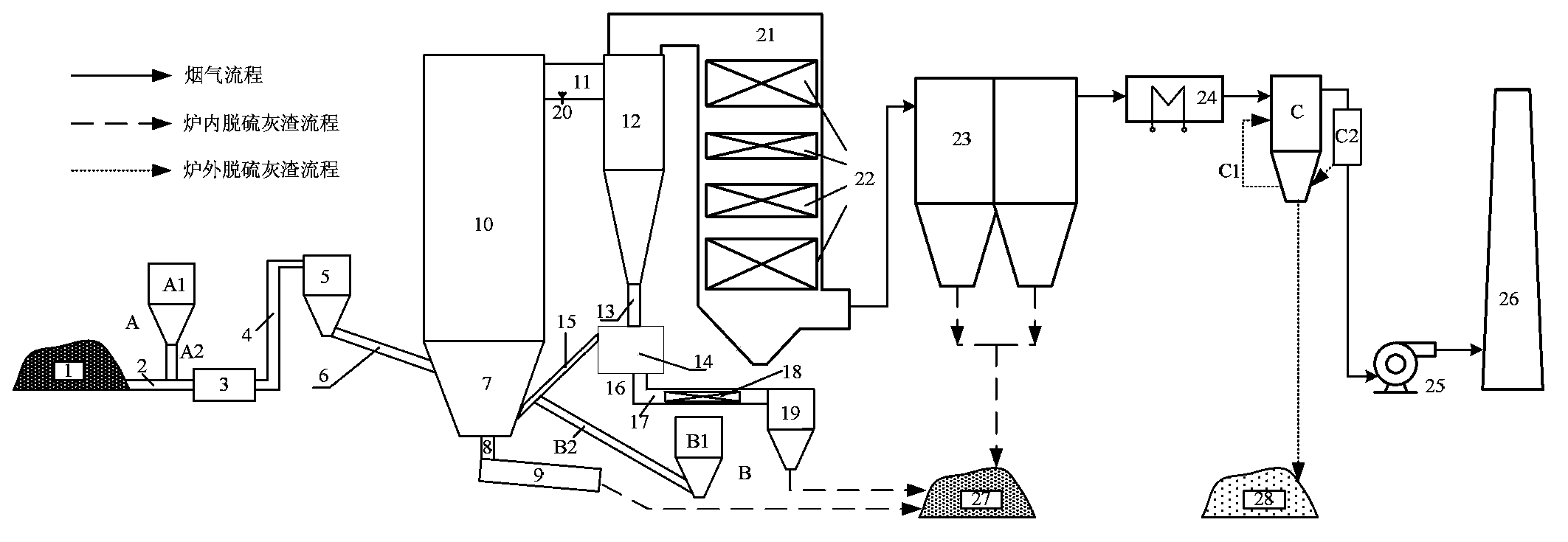

[0041] Such as figure 1 Shown is a newly built 300MW class circulating fluidized bed boiler with a three-stage desulfurization system. The combustion temperature of the boiler is 900°C, and the desulfurization agent addition system A in front of the furnace uses limestone particles with a median diameter of 3mm. District 7. The desulfurizer conveying system B in the furnace conveys limestone powder with a median diameter of 0.5 mm from the return pipe 15 to the dense-phase zone 7 of the furnace. The desulfurized flue gas in the furnace is cooled to 100°C by the exhaust gas temperature desuperheater 24, and then sent to the deep flue gas desulfurization system C for deep desulfurization. The desulfurization agent used in the deep flue gas desulfurization system C is slaked lime. The reducing agent nozzle 20 sprays the aqueous urea solution to the inlet flue 11 of the separator to further reduce the emission concentration of nitrogen oxides on the basis of the low-nitrogen com...

Embodiment 2

[0044] A newly built 135MW circulating fluidized bed boiler with a three-stage desulfurization system. The combustion temperature of the boiler is 935°C. The desulfurization agent addition system A in front of the furnace uses limestone particles with a median diameter of 2mm, and the desulfurizer delivery system B in the furnace uses limestone powder with a median diameter of 0.3mm. A desulfurizer is also added to improve the desulfurization efficiency. The total amount of 3% sodium chloride desulfurization enhancer reduces the decomposition rate of calcium sulfate during combustion and improves the desulfurization efficiency.

Embodiment 3

[0046] A remodeled 200MW circulating fluidized bed boiler. The boiler was originally equipped with a desulfurization agent delivery system B in the furnace. A pre-furnace desulfurization agent addition system A and a deep flue gas desulfurization system C were added to the boiler. Through three-stage desulfurization The final sulfur dioxide emission concentration of the boiler is lower than 100mg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com