Patents

Literature

32results about How to "No water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

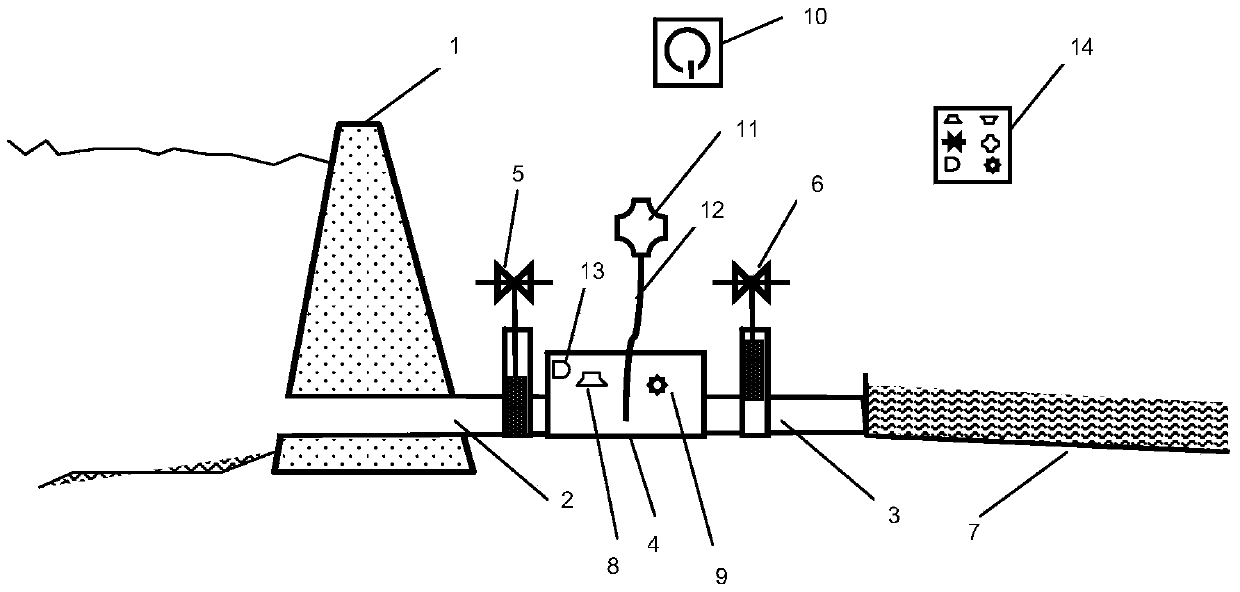

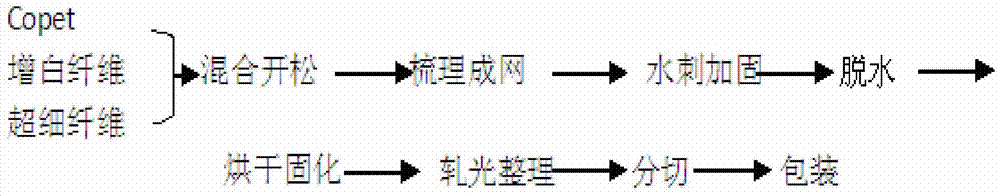

Spunlaced nonwovens and machining method for composite fiber curtain filtration

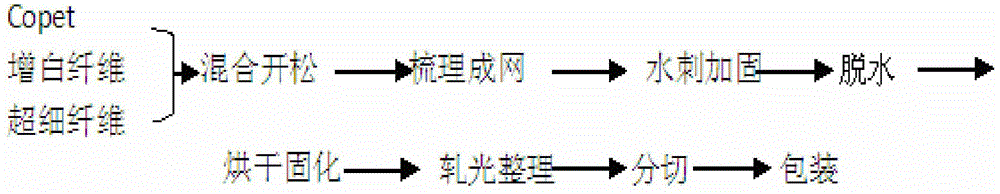

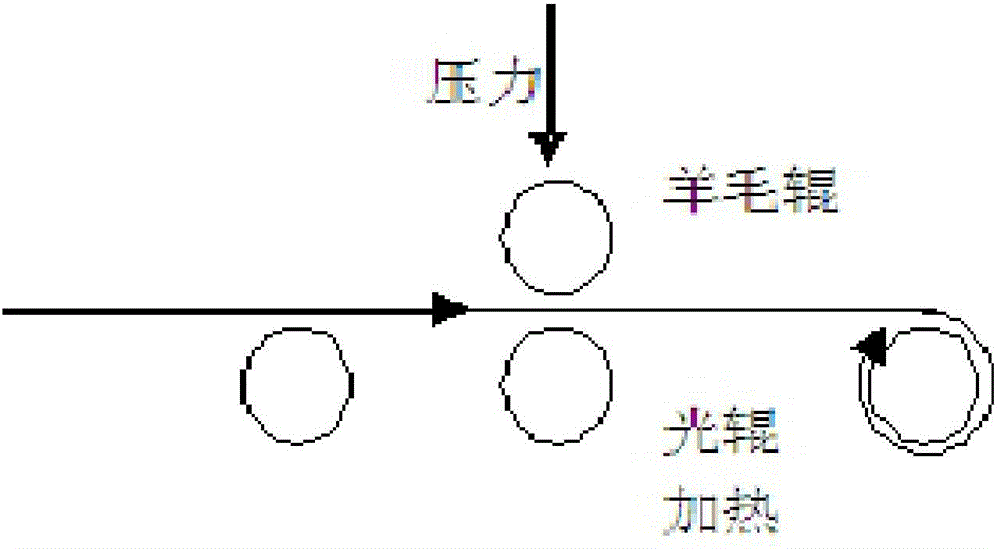

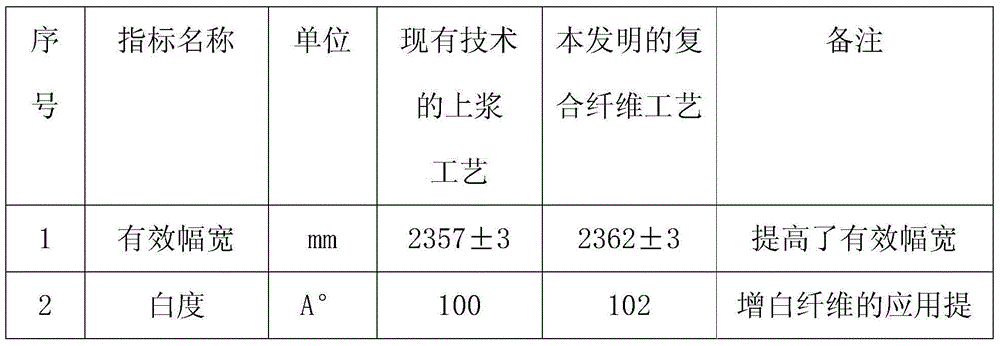

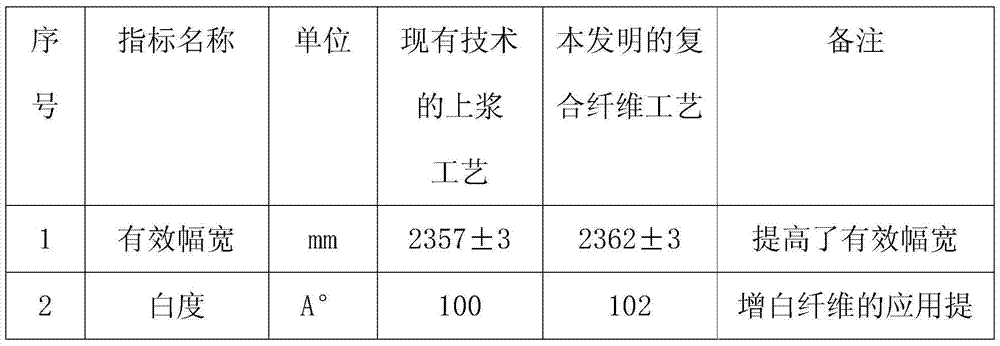

The invention discloses spunlaced nonwovens and a machining method for composite fiber curtain filtration. According to the method, copet composite fiber, whitening polyester fiber and superfine polyester fiber in the weight proportion 1.5: 2.5:1 are subjected to the following steps to form the spunlaced nonwovens, 1, the copet composite fiber, the whitening polyester fiber and the superfine polyester fiber are mixed in the weight proportion 1.5: 2.5:1; 2, the mixed material is conveyed to an air pressure cotton box carding machine through a draught fan after being subjected to mixing opening; 3, the mixed fiber is subjected to carding to form a mesh, and the mesh is conveyed to a spunlace machine; 4, spunlace machining is conducted on the mixed fiber on a spunlace machine; 5, dehydration treatment is conducted; 6, the mixed fiber is transferred to a dryer to be subjected to continuous drying solidification after the spunlace machining, the solidification temperature of a first drying oven is 160+-3 DEG C, the solidification temperature of a second drying oven is 170+-3 DEG C, and the speed is 45-50 m / min; 7, calendering finish is conducted; 8, the working procedures of slitting and packaging are conducted. The spunlaced nonwovens and machining method for the composite fiber curtain filtration has the advantages that the effects of printing and dyeing, bending and polishing are achieved, no sizing agent exists, and the cost is low.

Owner:SHANDONG PROVINCE WINSON NON WOVEN MATERIALS

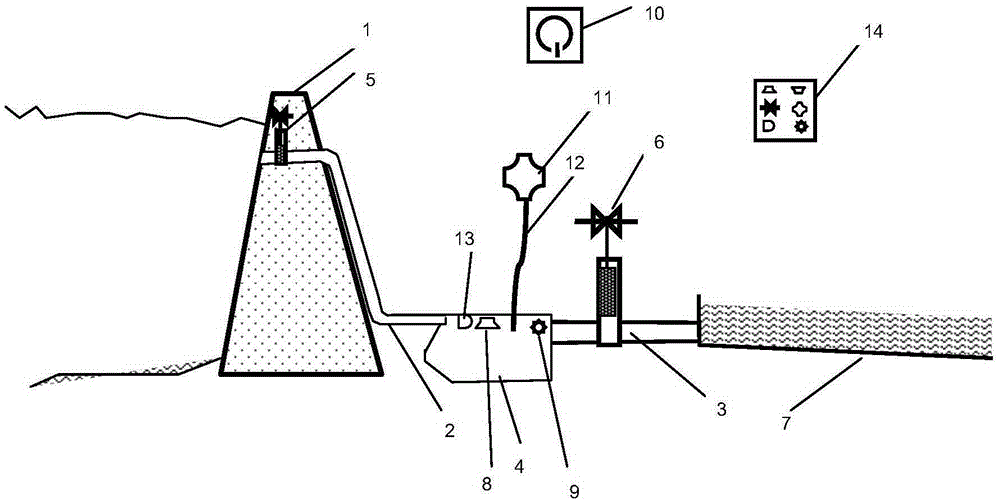

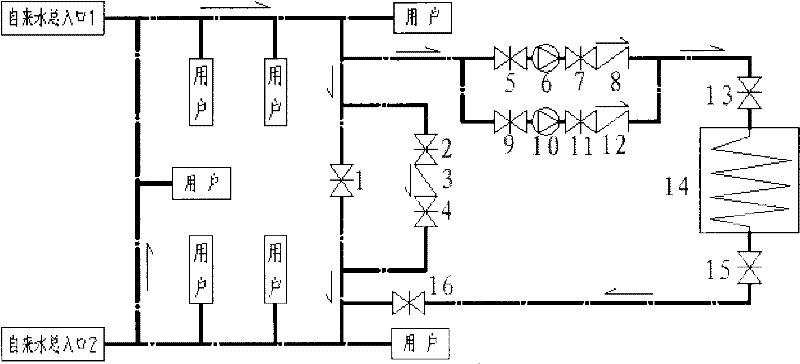

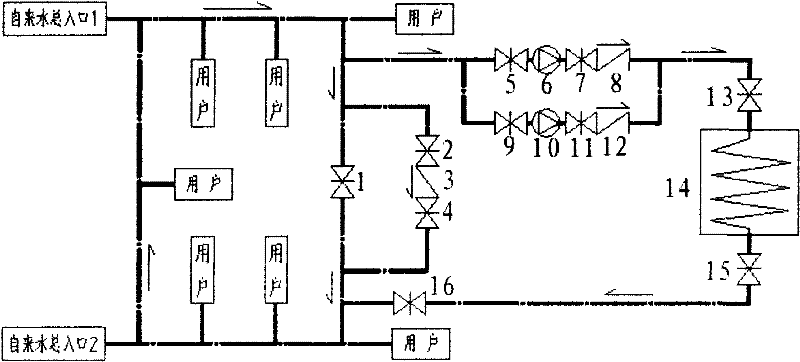

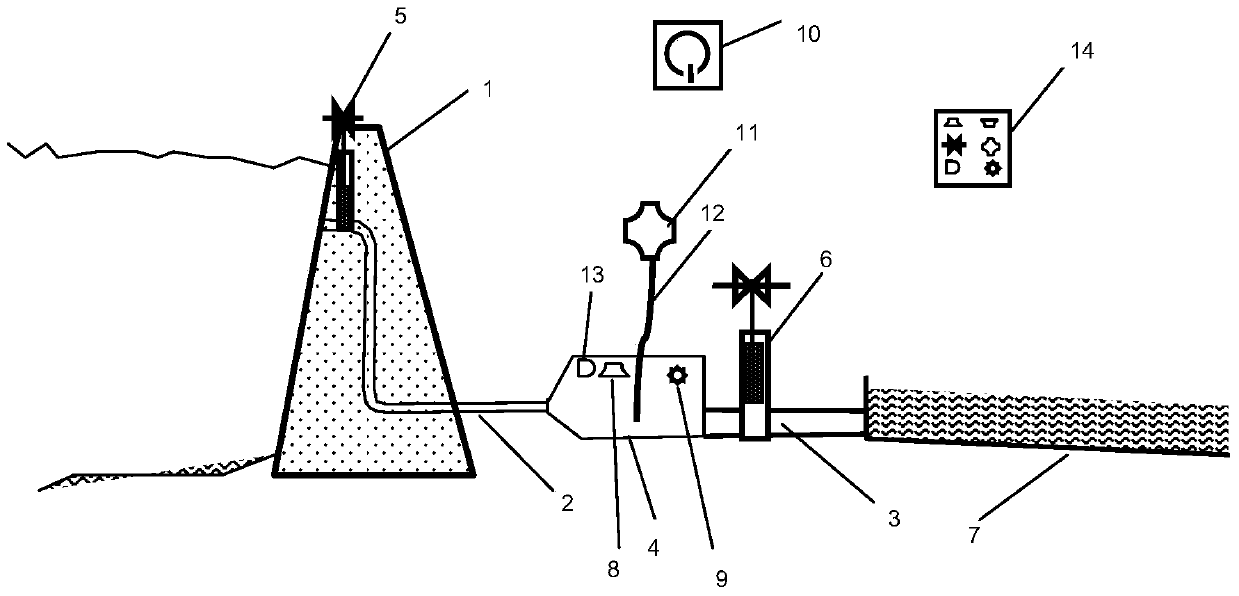

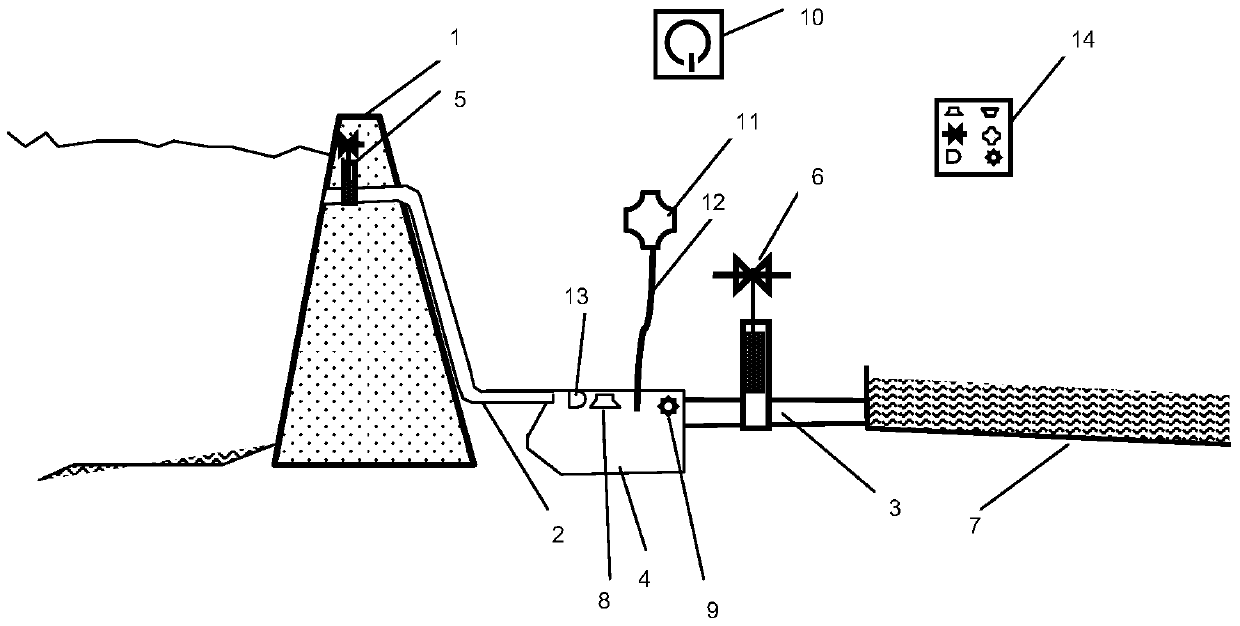

Fish passing system and method free of water resource losses and free water surfaces

InactiveCN105256772AImprove fish passing efficiencySmall scaleBarrages/weirsClimate change adaptationEngineeringDesign methods

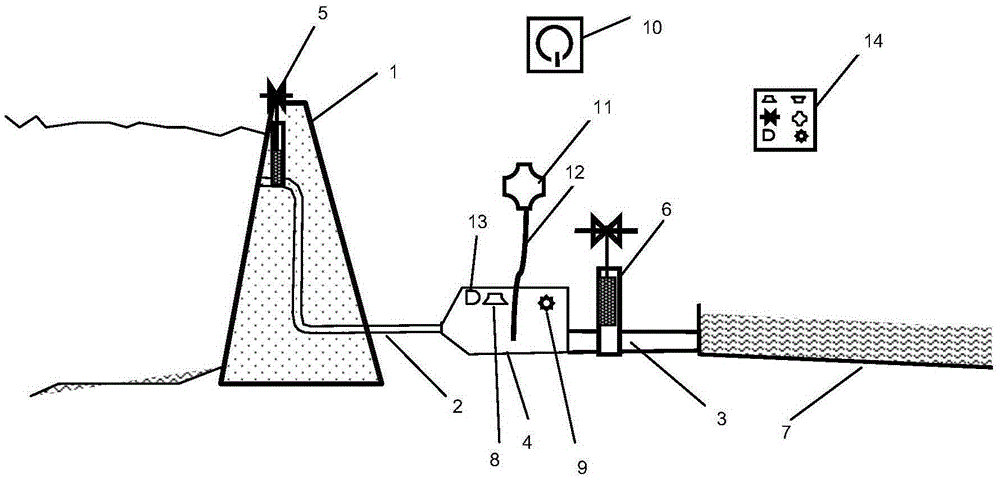

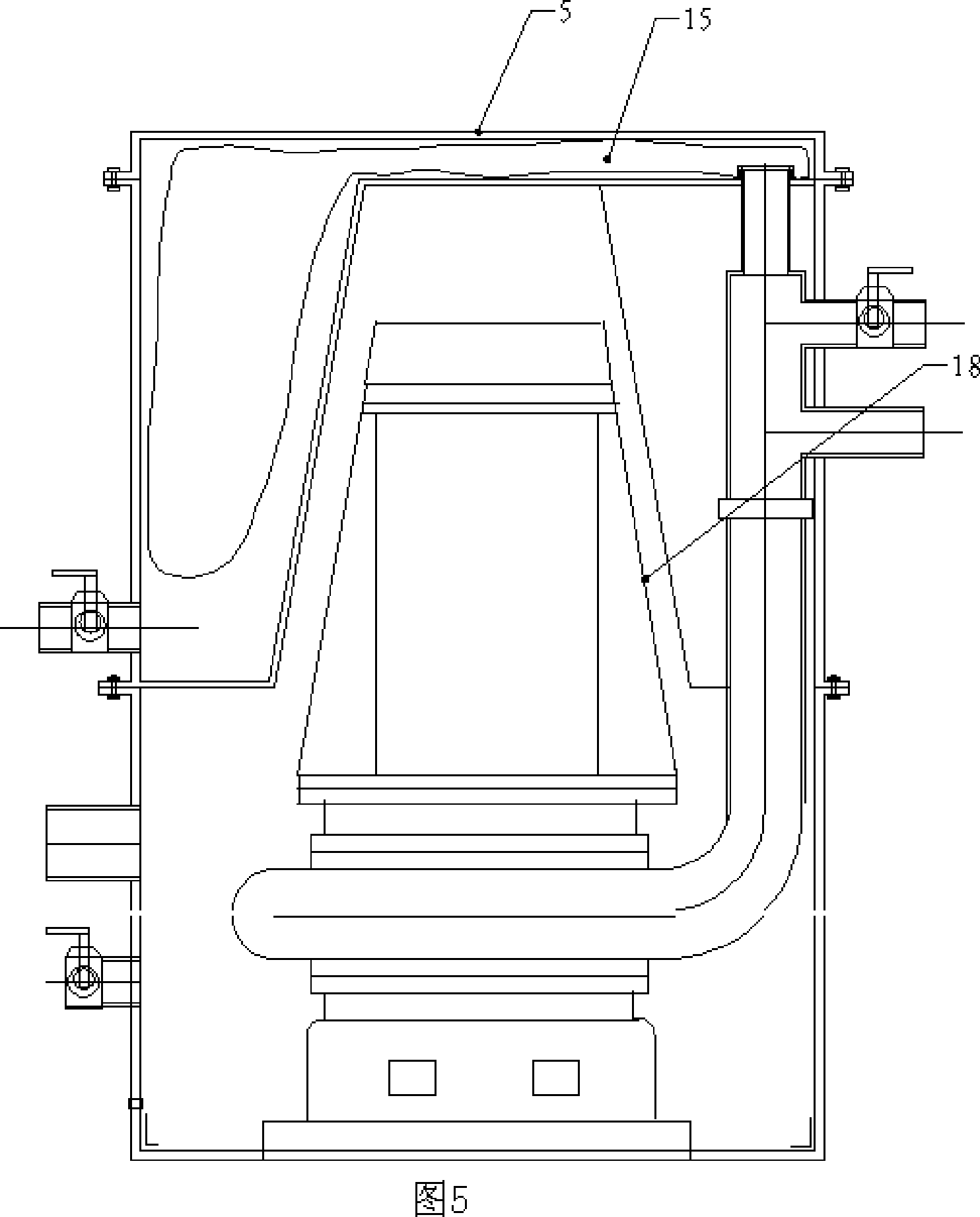

The invention provides a fish passing system and method free of water resource losses and free water surfaces. The fish passing system is composed of a dam, a fish outlet tunnel, a fish inlet tunnel, a fish collection chamber, a fish outlet gate, a fish inlet gate, a downstream river channel, a sound making unit, a light-emitting unit, a power supply, a material injection machine, a material injection pipe, a fish exploration radar and a master control system. Compared with an existing fish way design method, the fish passing system has the remarkable differences that because the fish passing system is provided with fish passing tunnels and the fish collection chamber which have pressure and are free of free water surfaces, fish way establishment and maintenance expenses are remarkably reduced, project construction lands are greatly saved, almost no water resources are consumed by fish passing, and the fish passing efficiency is improved. A designed fish way can be used for temporary food discharge as well.

Owner:SHANGHAI JIAO TONG UNIV +1

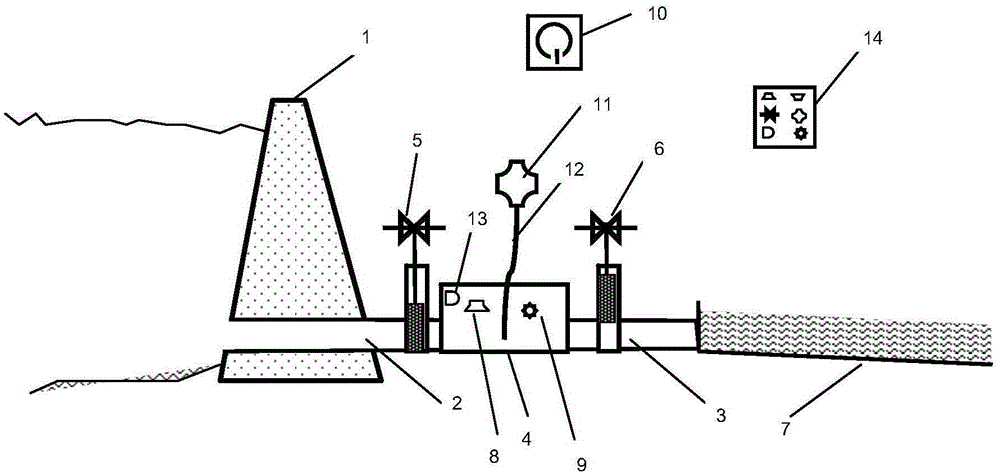

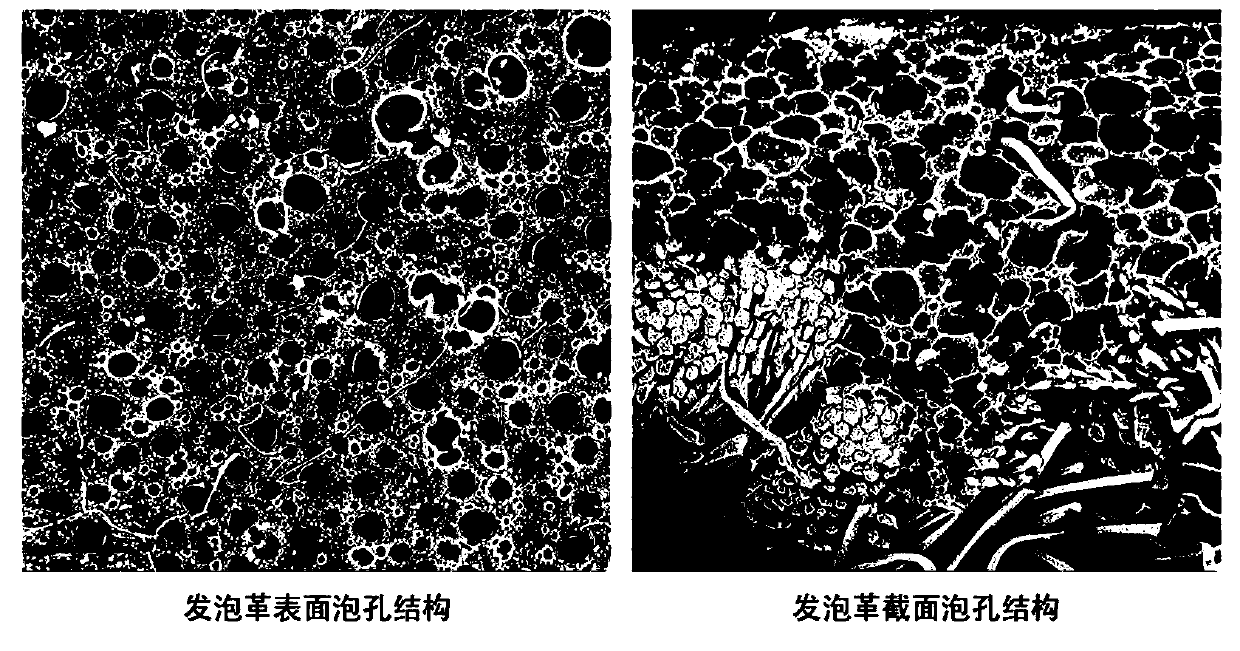

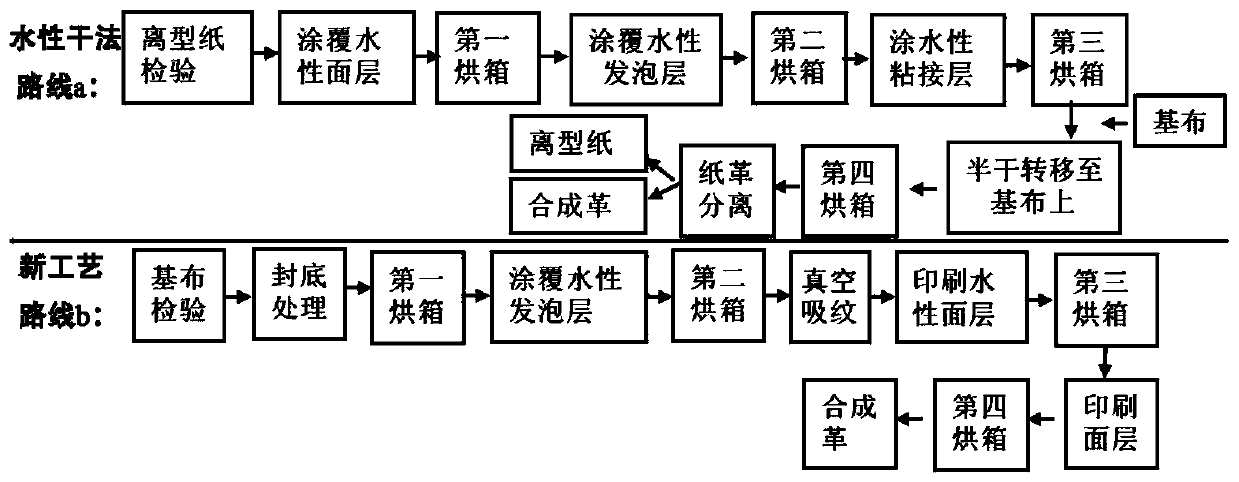

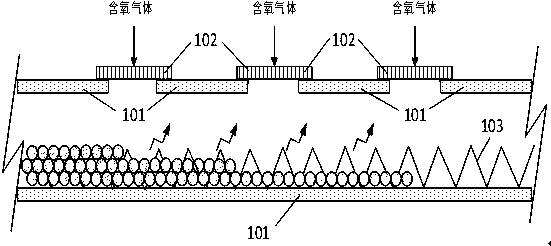

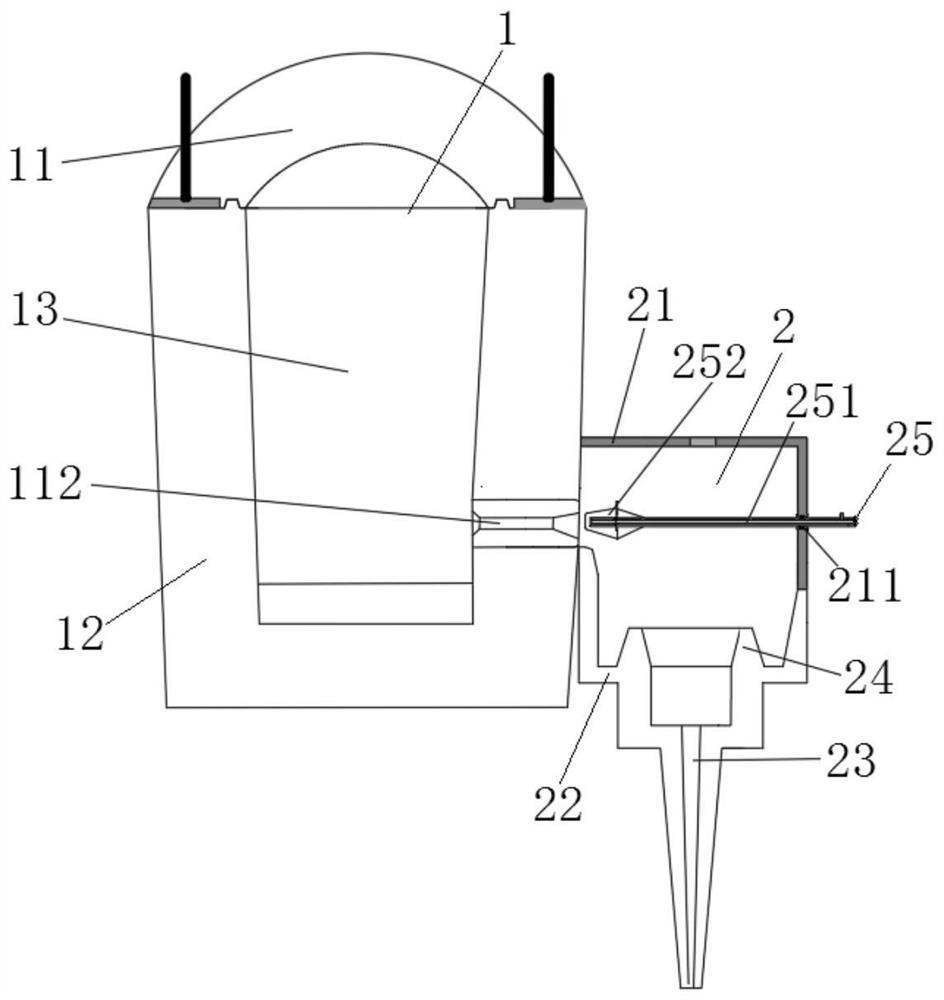

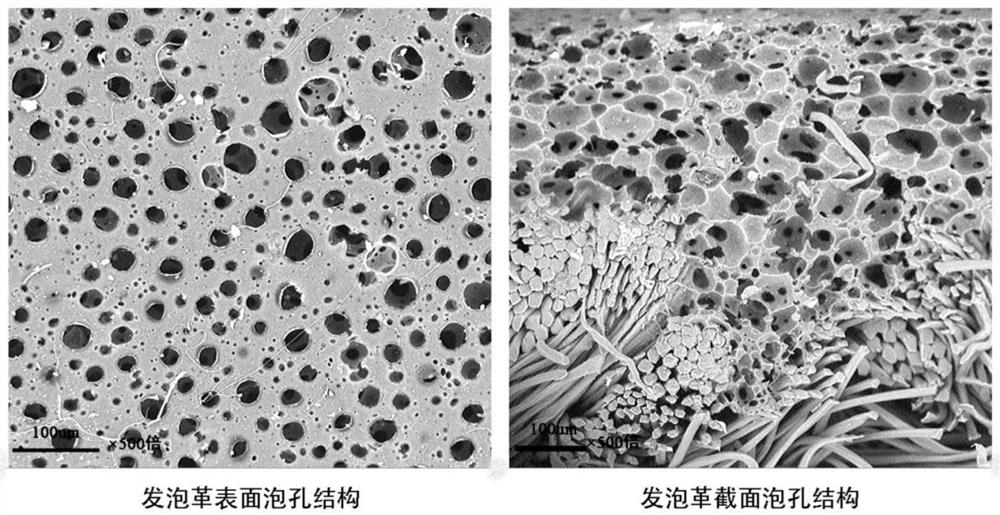

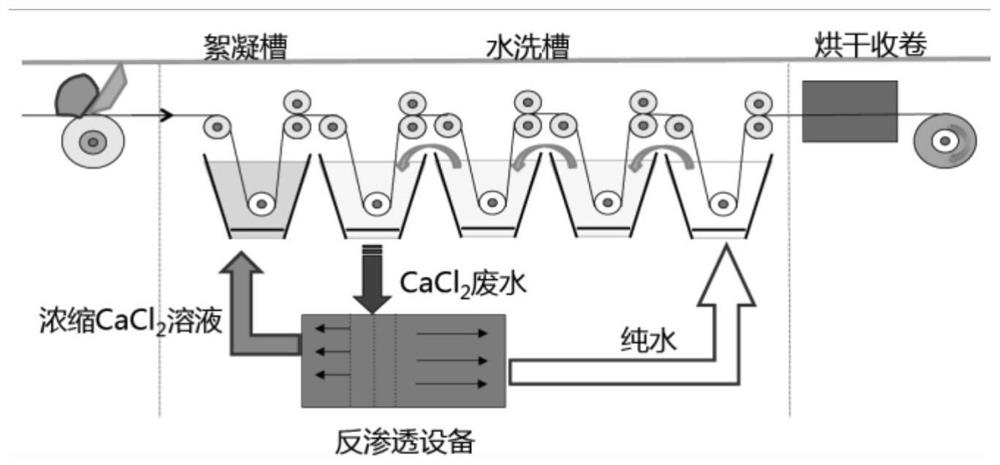

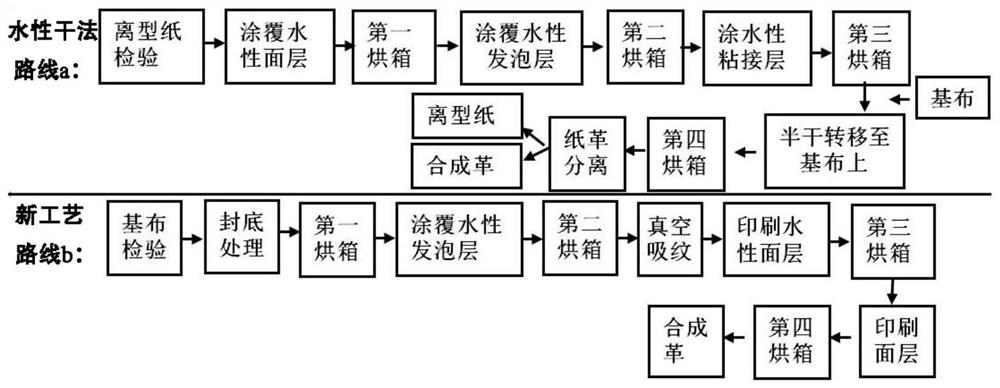

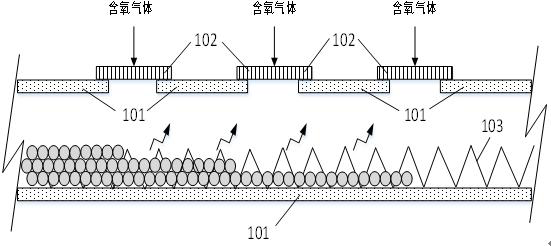

Short-flow, water-free and release-paper-saving method for manufacturing water-based synthetic leather

ActiveCN109898341ANo water consumptionNo pollution in the processTextiles and paperWater basedManufacturing technology

The invention discloses a short-flow, water-free and release-paper-saving method for manufacturing water-based synthetic leather. The method is characterized in that a base with the bottom sealed is directly coated with a foaming coating and a surface layer to produce the water-based foamed synthetic leather; the synthetic leather produced by the method is of a porous structure, and accordingly, the breathability and moisture permeability of the water-based polyurethane synthetic leather (as shown in . 1) are improved; the specific peeling strength of the finished leather is greatly improved by a special bottom sealing technique. Compared with a water-based wet solidification process, the method has the advantages that processes of solidification, water washing, and the treatment of saltywastewater are omitted, so that the effects of saving water, reducing emission and simplifying the process are achieved. Compared with a dry coating-transfer method for manufacturing synthetic leather, the method has the advantages that the resource of release paper is saved, the whole process is short, the production technique is a short-flow, water-free, pollution-free and release-paper-saving technique for manufacturing the synthetic leather, and the application prospect is broad.

Owner:SICHUAN UNIV

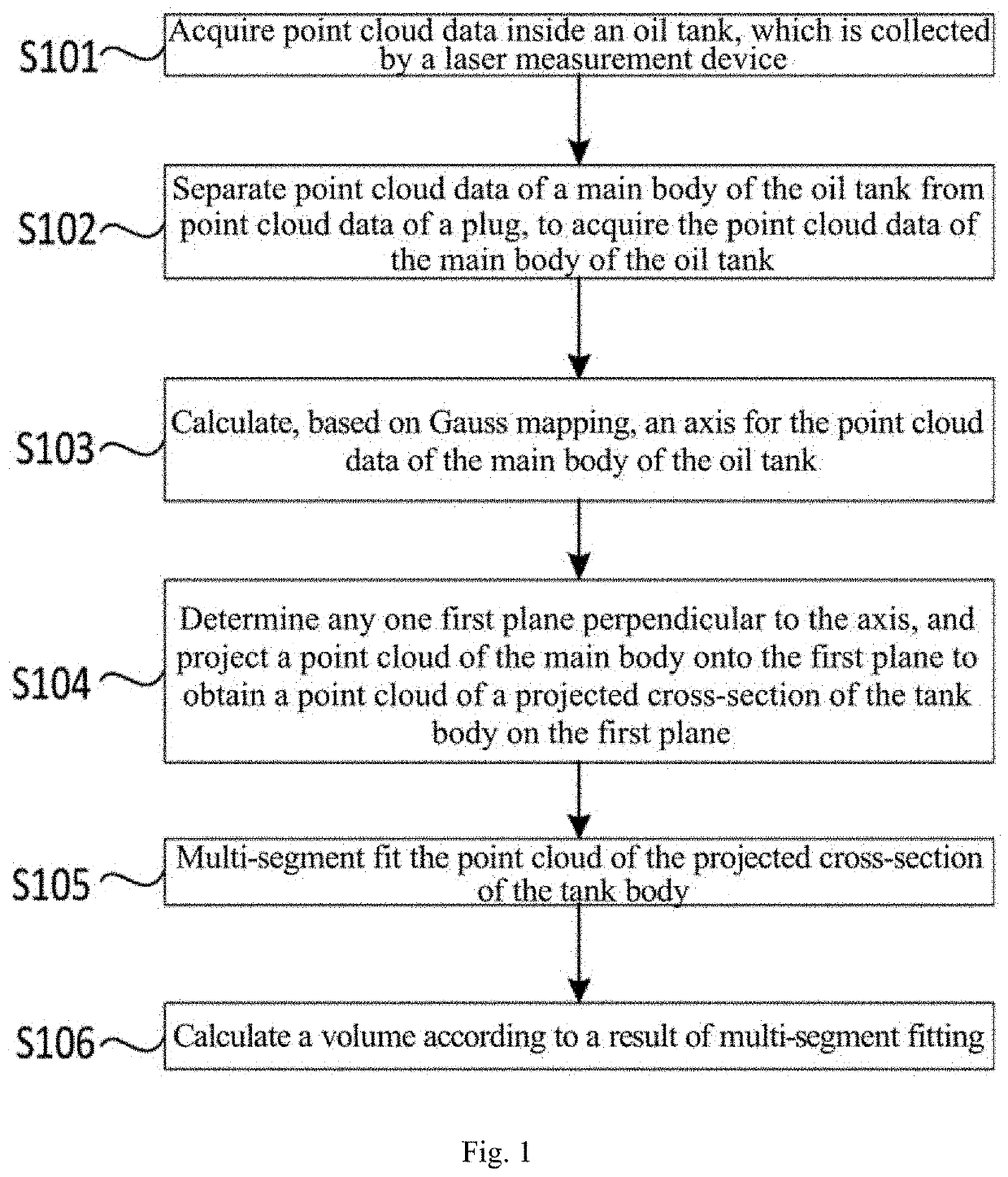

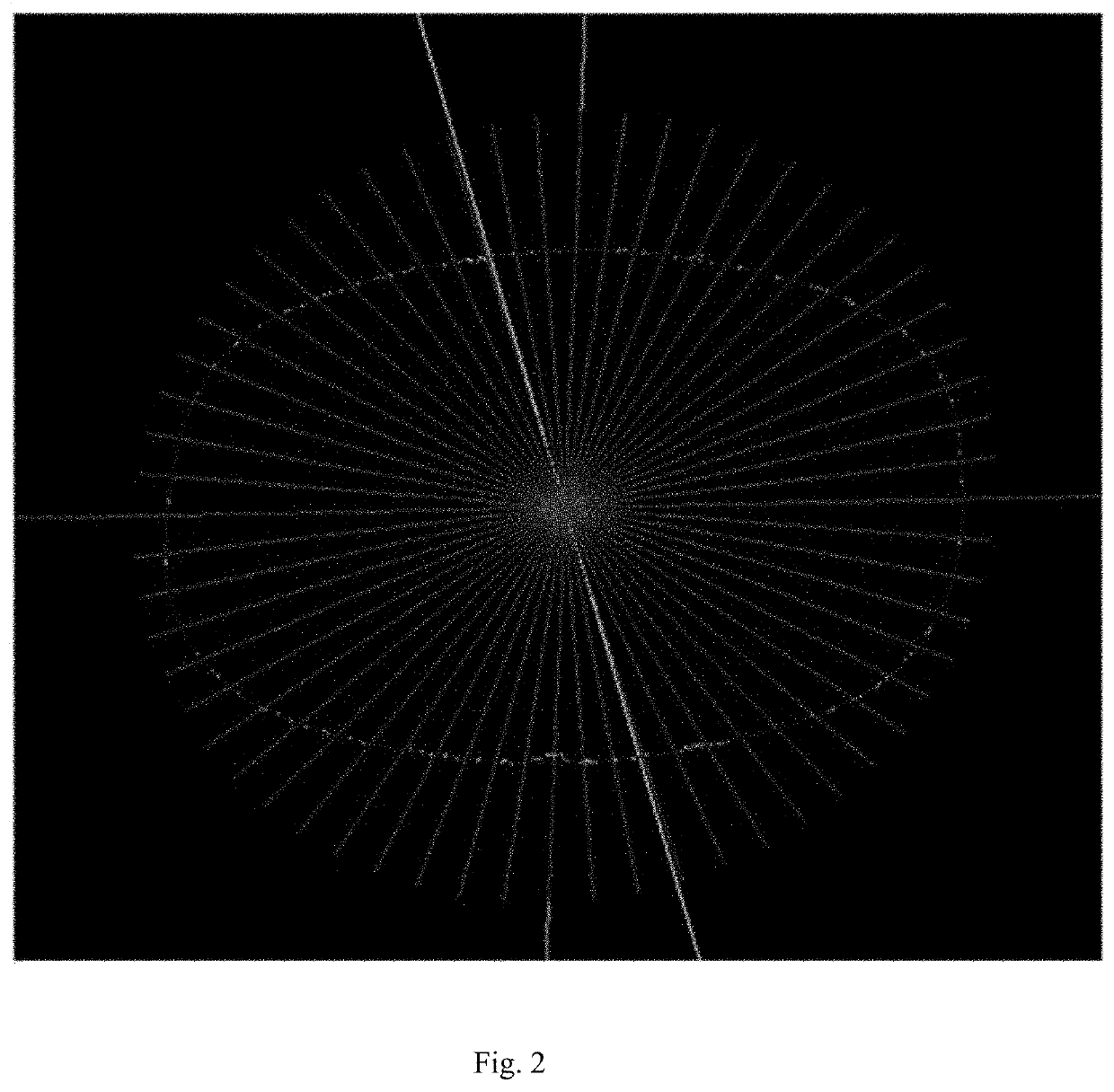

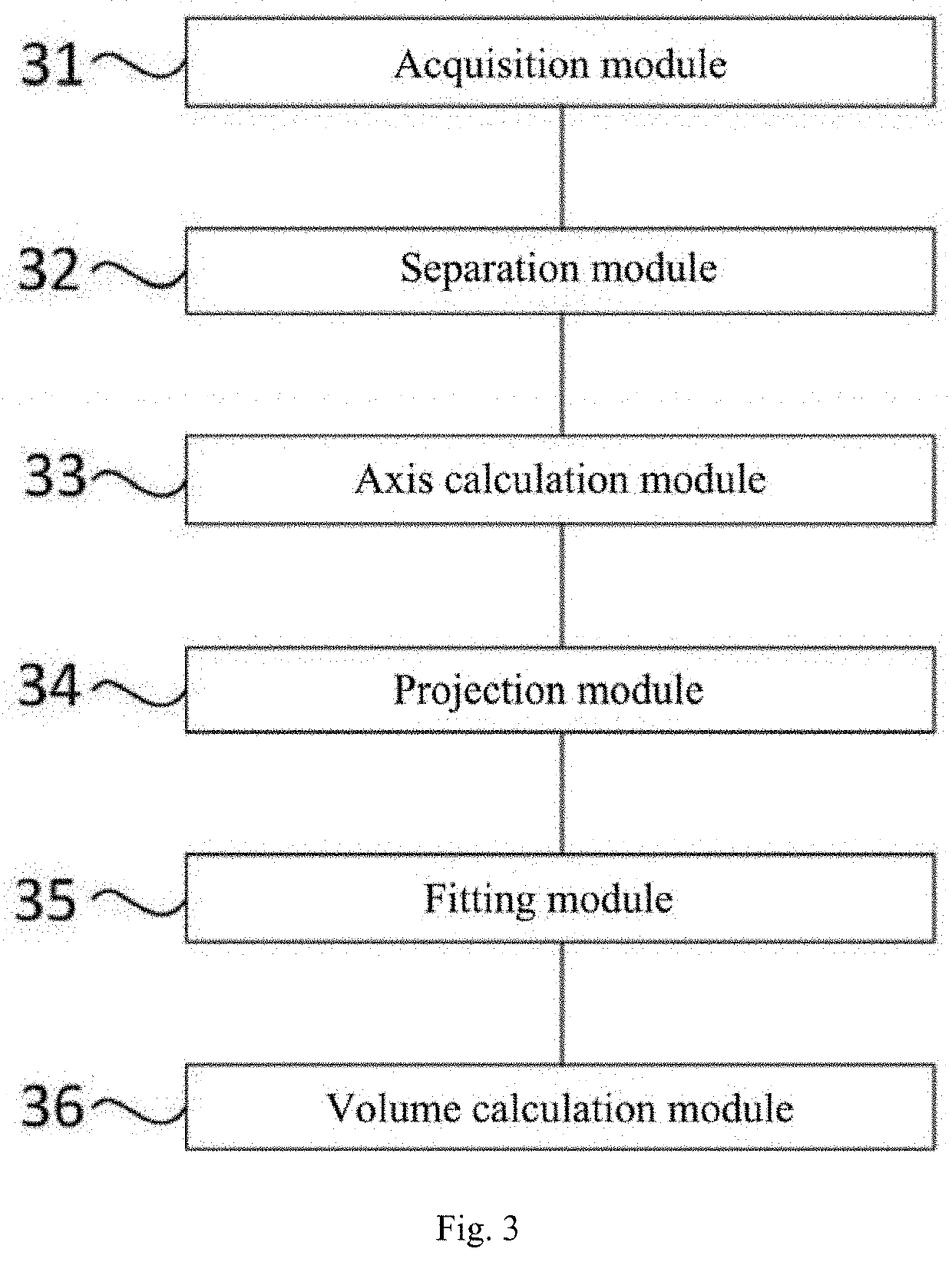

Oil tank measurement method and system based on laser point cloud analysis

ActiveUS20200292368A1No water consumptionImprove measurement efficiencyContainer/cavity capacity measurementElectromagnetic wave reradiationGeophysicsPoint cloud

The invention provides an oil tank measurement method and system based on laser point cloud analysis, comprising: acquiring point cloud data inside an oil tank, which is collected by a laser measurement device; separating point cloud data of a main body of the oil tank from point cloud data of a plug, to acquire the point cloud data of the main body of the oil tank; calculating, based on Gauss mapping, an axis for the point cloud data of the main body of the oil tank; determining any one first plane perpendicular to the axis, and projecting a point cloud of the main body onto the first plane to obtain a point cloud of a projected cross-section of the tank body on the first plane; multi-segment fitting the point cloud of the projected cross-section of the tank body; and calculating a volume according to a result of multi-segment fitting.

Owner:ZHOUSHAN INST OF CALIBRATION & TESTING FOR QUALITY & TECHNICAL SUPERVISION

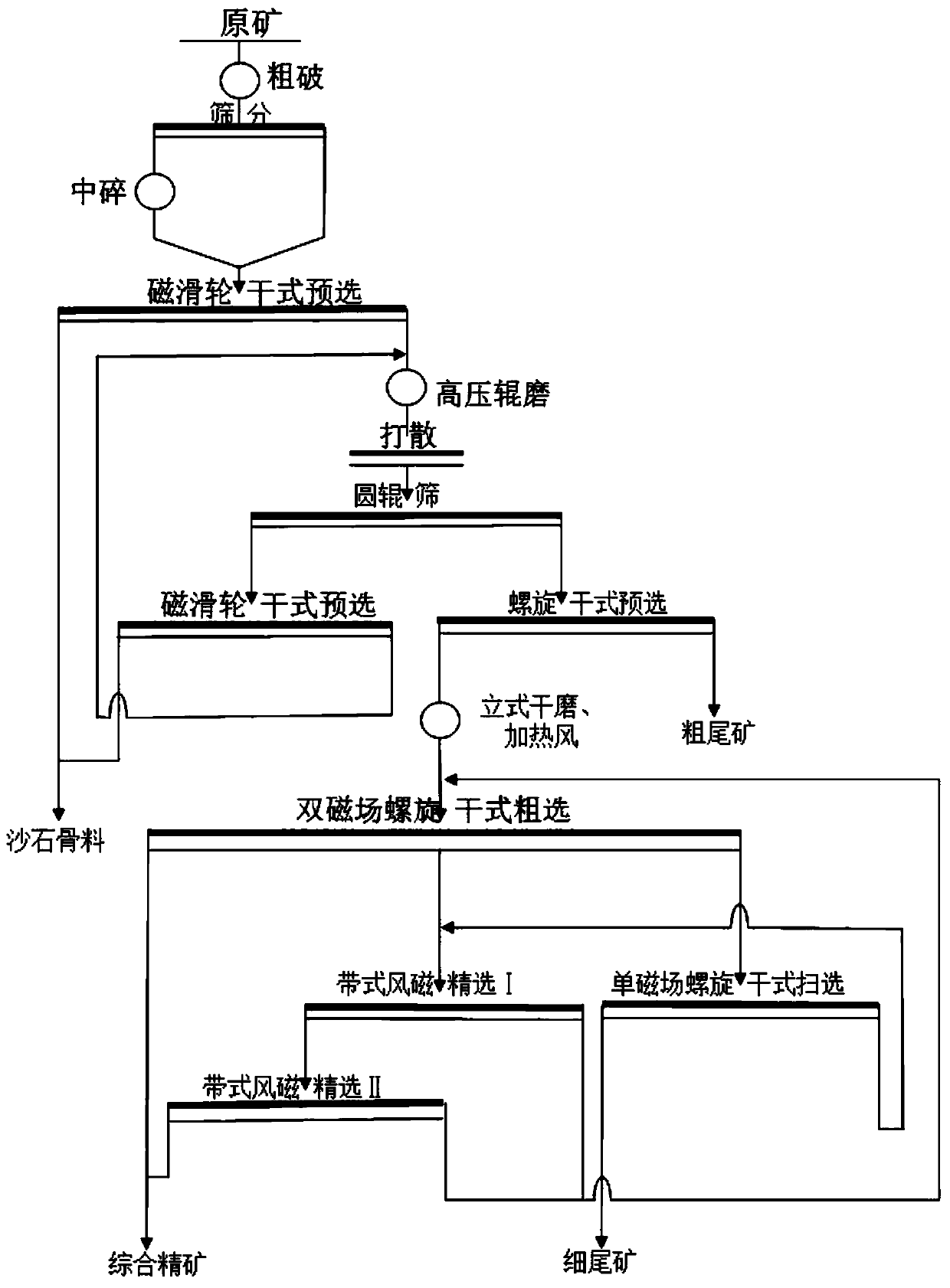

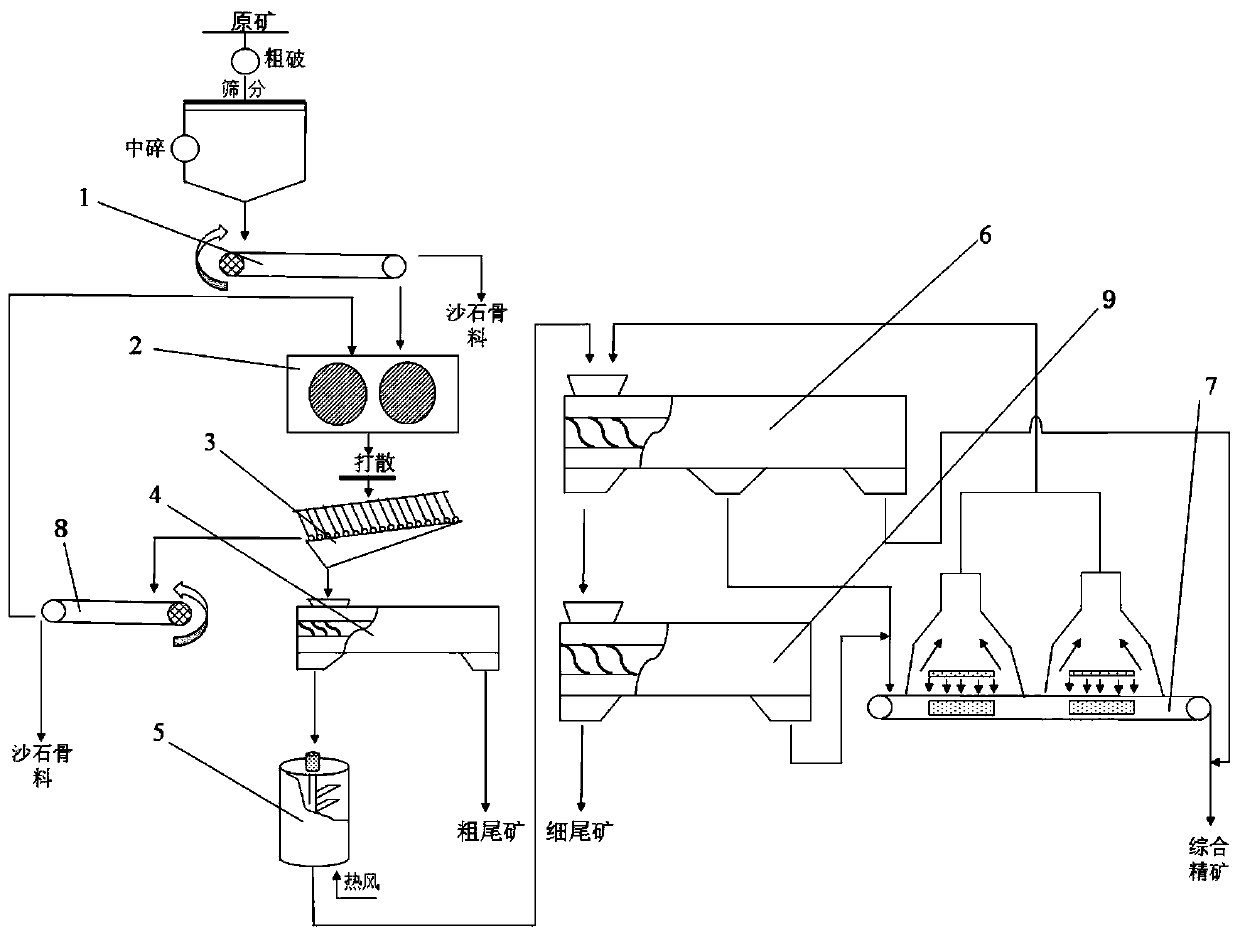

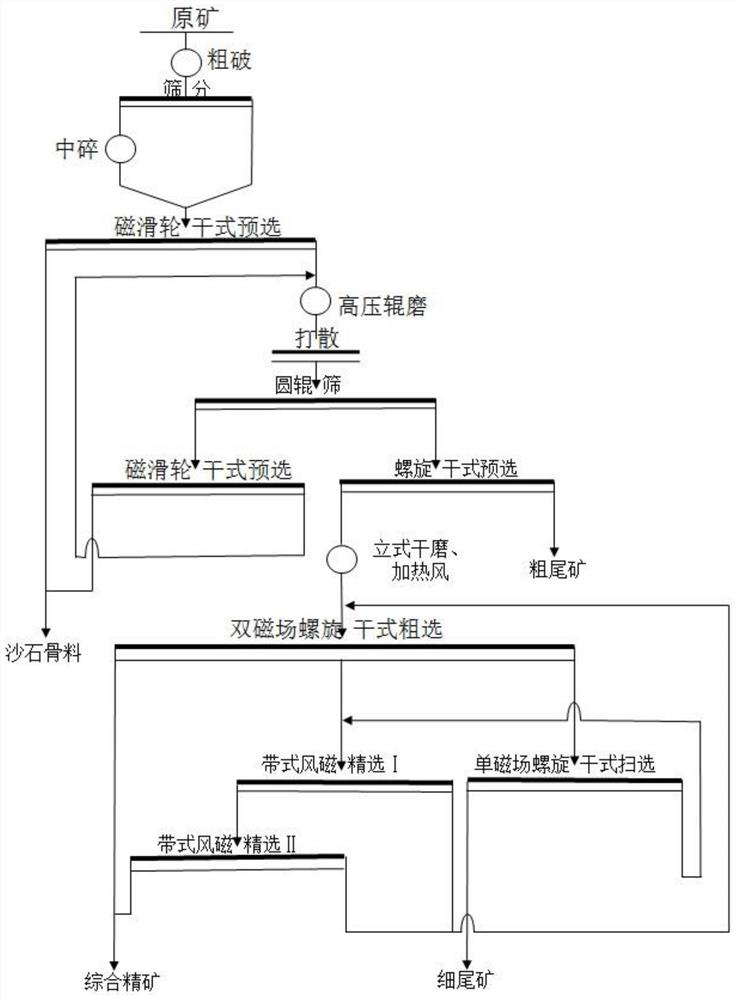

Absolutely-dry type sorting method for iron ores

ActiveCN110586315AReduce processingReduce equipment maintenance and disposal costsWet separationOre concentrateTailings dam

The invention discloses an absolutely-dry type sorting method for iron ores. The absolutely-dry type sorting method comprises the following steps: roughly breaking and screening iron-containing raw ores, enabling oversize products and undersize products to perform magnetic slide wheel dry type pre-sorting after the oversize products are subjected to intermediate crushing, performing high-pressureroller grinding on pre-sorted concentrate, and taking pre-sorted tailings as sand aggregates; dispersing the roller-grinded pre-sorted concentrate and then screening the roller-grinded pre-sorted concentrate through a round roller screen, performing one-section magnetic slide wheel dry type pre-sorting on the oversize products, returning the pre-sorted concentrate to a feeding end of a high-pressure roller mill, and taking the pre-sorted tailings as sand aggregates; adopting spiral dry type pre-sorting for undersize products of the round roller screen, taking the spiral dry-type pre-sorted tailings as rough tailings, and adding the pre-sorted concentrate into a hot air vertical type drill mill; roughly sorting dry-milled products through a dual-magnetic-field spiral dry type magnetic sorting machine, performing two-section belt type wind magnetic selection on roughly-sorted middlings, and finally forming comprehensive concentrate by the belt type wind magnetic concentrate and roughly-sorted concentrate. The absolutely-dry type sorting method for iron ores adopts an absolutely-dry type ore dressing process, is simple in process, is low in water consumption, is high in tailings building materializing utilization rate, and does not need a tailings dam.

Owner:WUHAN UNIV OF SCI & TECH

Submarine decontamination machine

InactiveCN101092853ANo water consumptionSoil-shifting machines/dredgersGymnasiumSprayerWater channel

This invention discloses an underwater cleaner cleaning various dirt closely adhered to the bottom of water including a working mask with a lower open-end composed of a close peripheral and top, a backwater orifice and a sprayer towards the open-end is set in the mask, the sprayer is connected with a pump via a sprayer pipe to form a return water channel, the backwater orifice is connected with the container of the working mask to form a channel set with a filter device, in which the high pressure water-flow from the pump is sprayed from the sprayer to form a high speed water flow to flush dirt adhered on the scree surface of the bottom.

Owner:杨敏

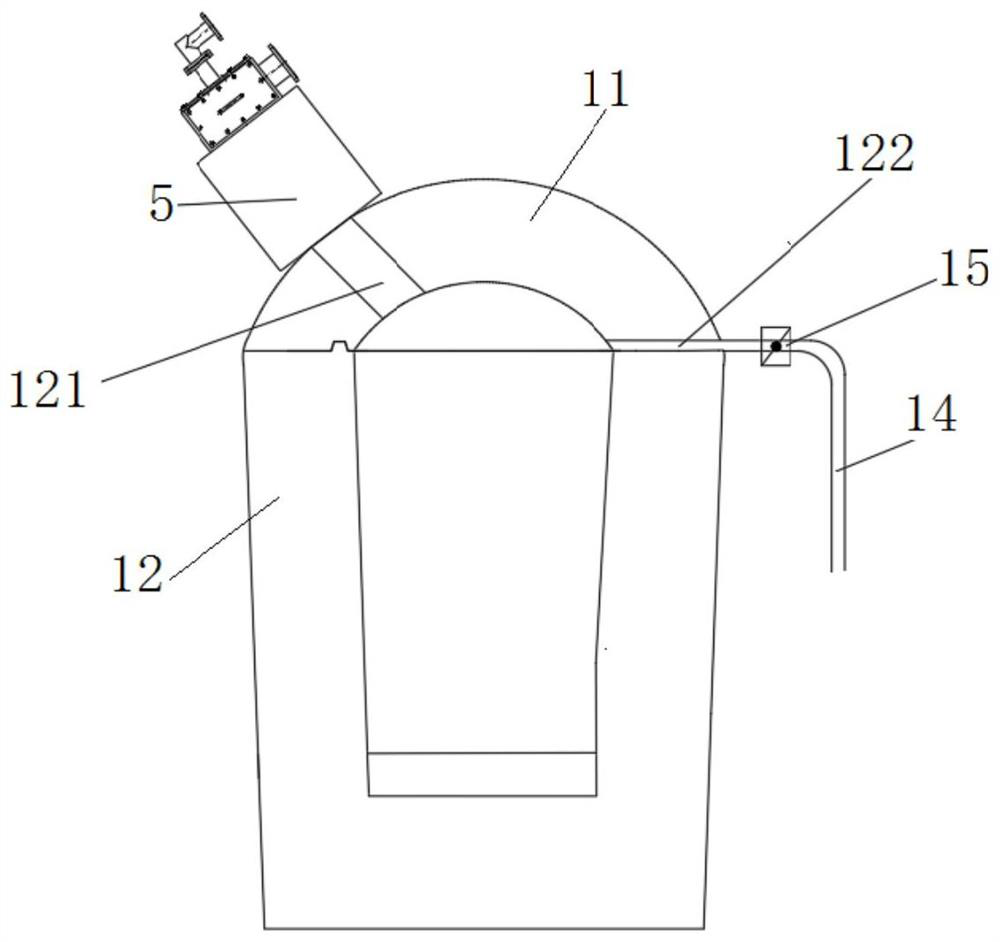

Fish elevator device for collecting fishes by utilizing tail water of hydropower station and fish collecting method applying same

PendingCN109736255AOvercome the shortcomings of low fish collection efficiencyHigh trafficBarrages/weirsClimate change adaptationWater channelEngineering

The invention discloses a fish elevator device for collecting fishes by utilizing tail water of a hydropower station. The device comprises a water guide wall, a fish collecting pond, a fish collectingbox and a lifting mechanism, wherein the water guide wall is arranged on a tail water tunnel / pipe bottom plate and a stilling pond and / or a tail water channel bottom plate, the fish collecting pond is arranged on the downstream side of the tail water tunnel / pipe or in the stilling pond, the fish collecting box is connected with the lifting mechanism, and the lifting mechanism is arranged on a tail horizontal platform and the fish collecting pond. The fish elevator device has the advantages of improving the fish collecting efficiency and better protecting fishes. The invention also discloses afish collecting method adopting the fish elevator device for collecting fishes by utilizing the tail water of the hydropower station.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

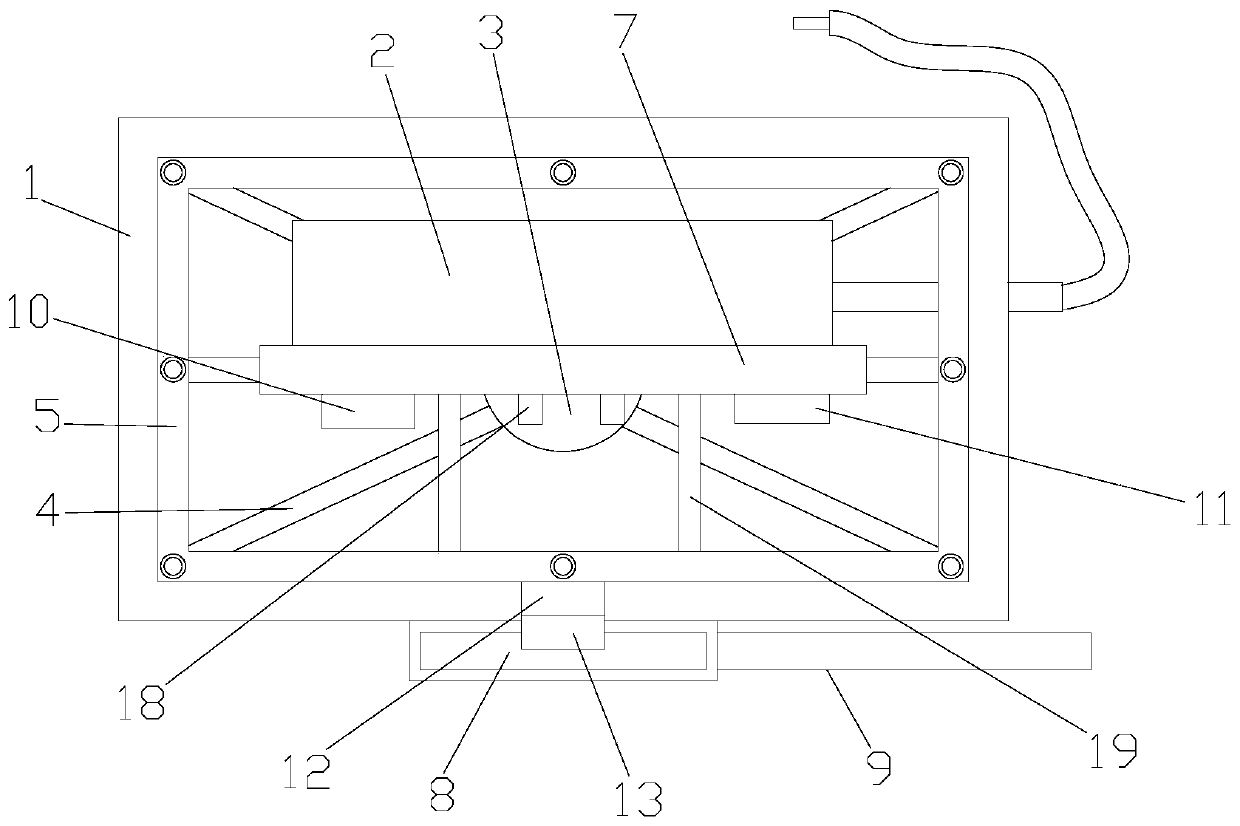

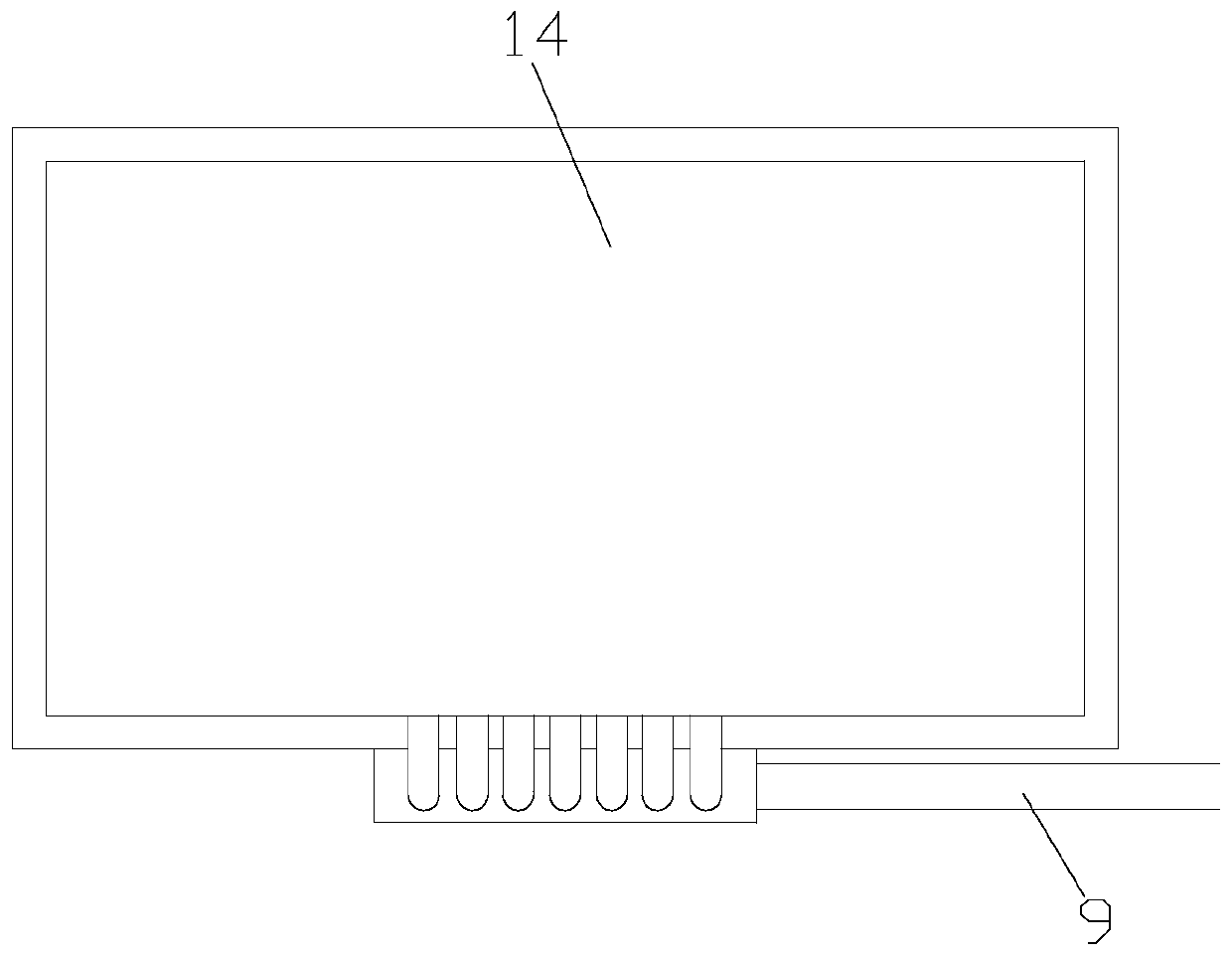

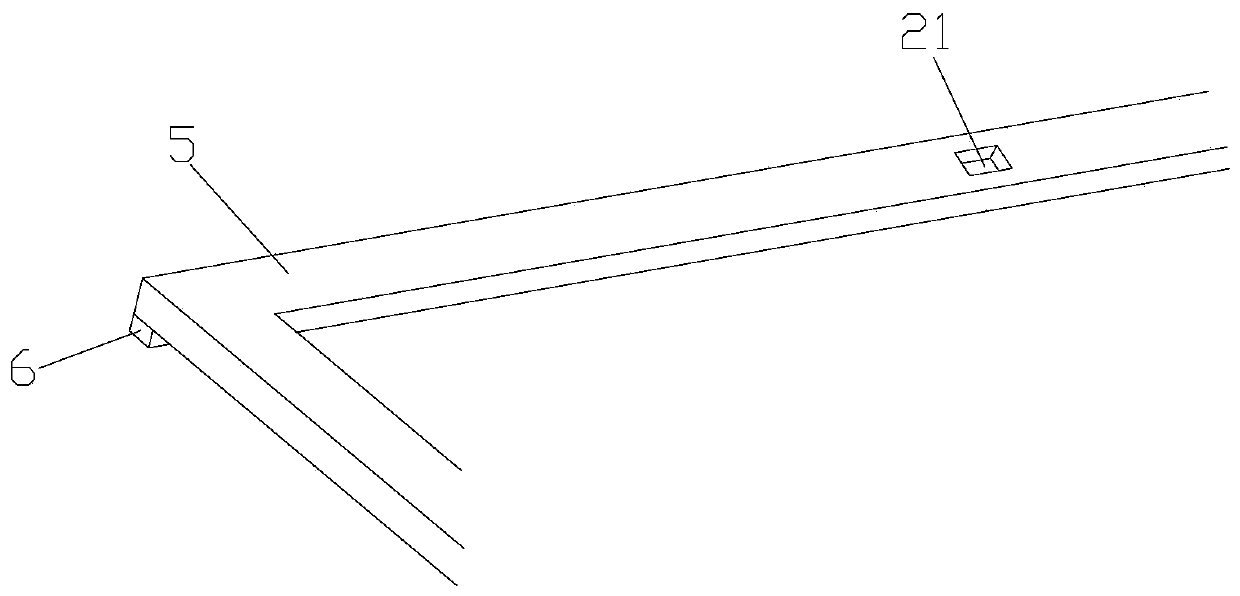

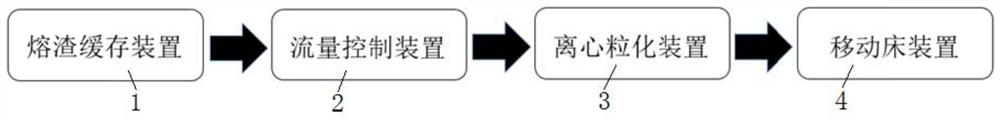

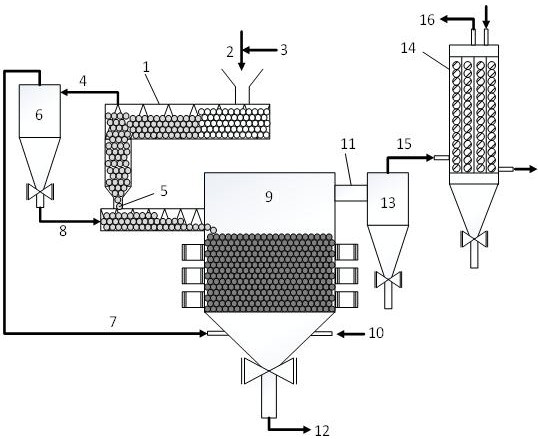

Liquid-state molten slag waste heat recycling system

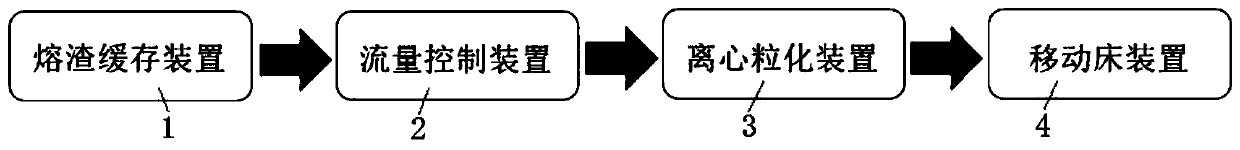

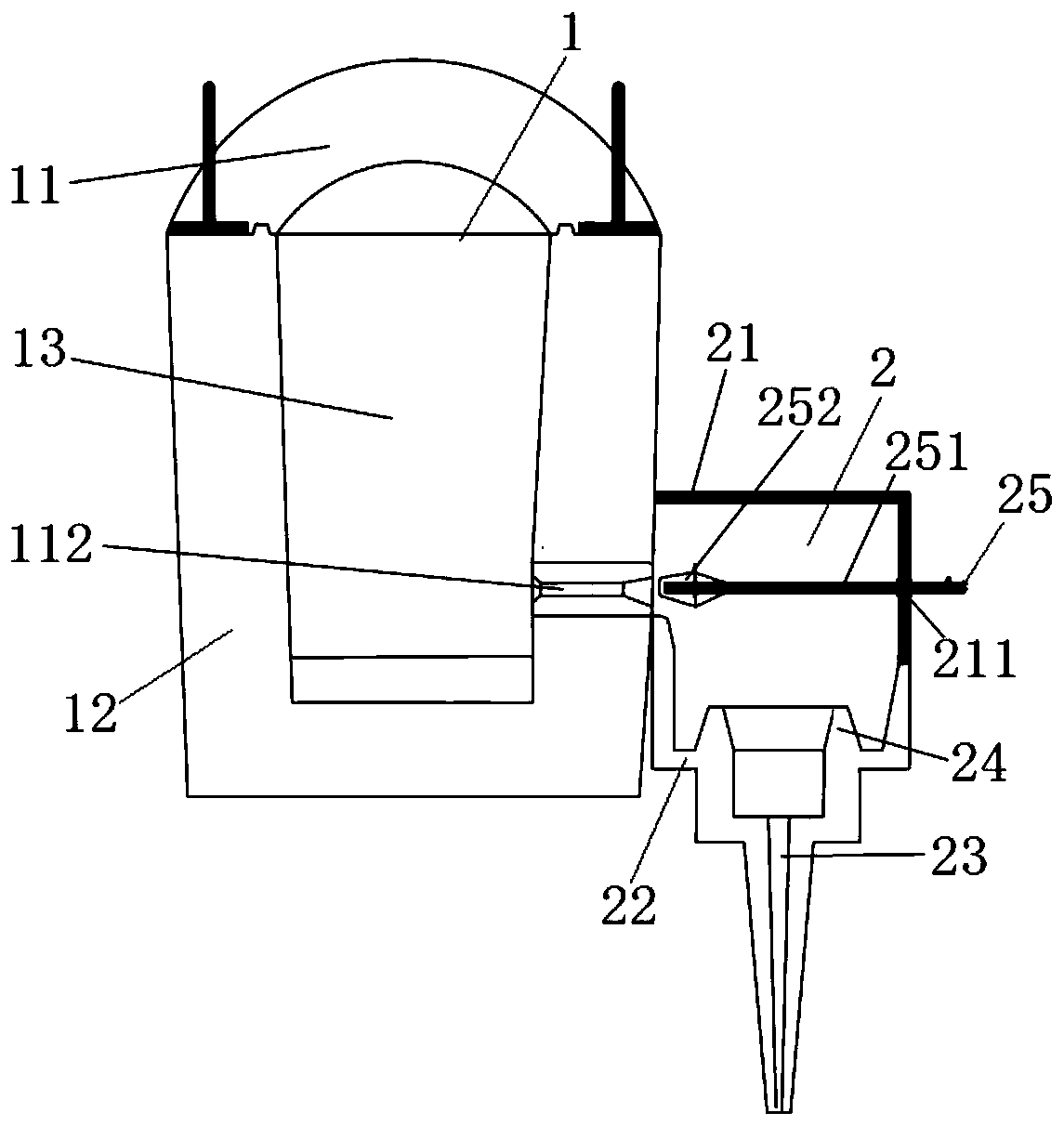

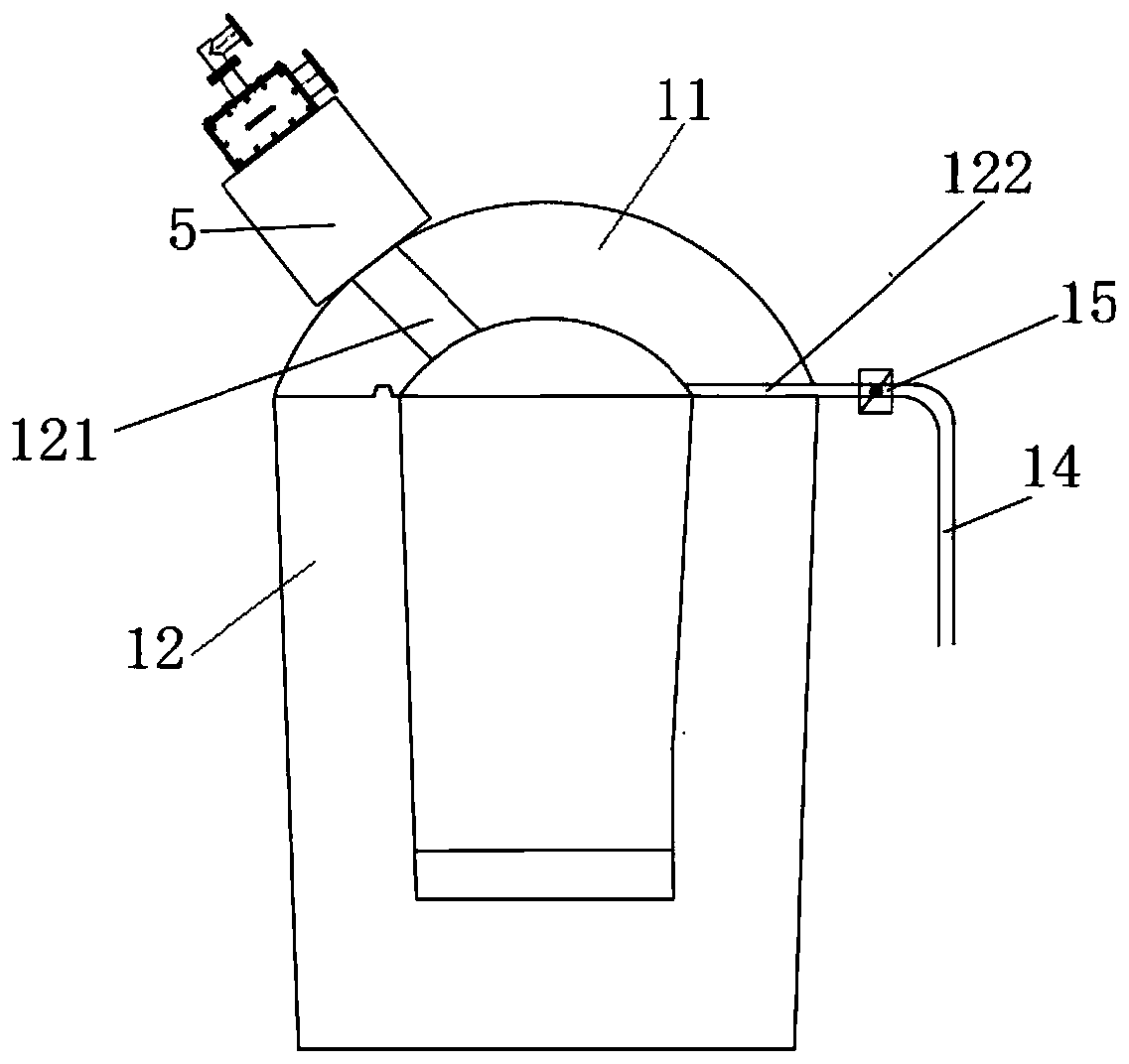

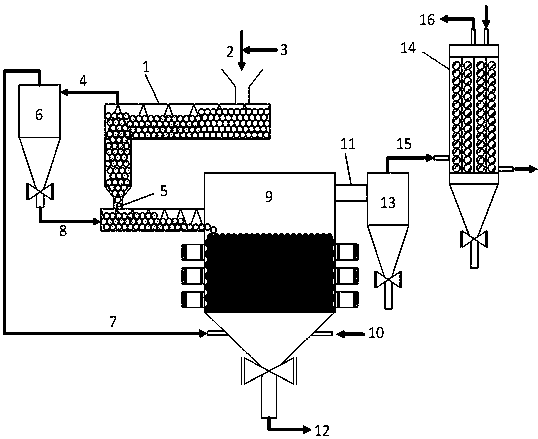

ActiveCN111020077AGuaranteed uptimeImprove qualityRecycling and recovery technologiesLiquid stateProcess engineering

The invention discloses a liquid-state molten slag waste heat recycling system. The system comprises a molten slag temporary storage device, a flow control device, a centrifugal graining device and amoving bed device. One end of the molten slag temporary storage device is connected with a slag trough, the other end of the molten slag temporary storage device is connected with the inlet end of theflow control device, the outlet end of the flow control device is connected with the inlet end of the centrifugal graining device, the outlet end of the centrifugal graining device is connected withthe moving bed device, through the molten slag temporary storage device, influence of blast furnace intermittent deslagging on a centrifugal graining system can be effectively avoided, stable runningof the centrifugal graining system can be ensured, the capacity of accident emergency treatment of the waste heat recycling system can be improved, through the flow control device, the centrifugal graining device and the moving bed device, the slag grain sufficient heat exchange and system discharging smoothness can be effectively improved, and the heat exchange efficiency can be effectively improved.

Owner:XI AN JIAOTONG UNIV

Auxiliary agent for biomass treatment and biomass gasification treatment method

ActiveCN111378513AReduce the degree of fractureInhibition formationGasification catalystsGasification processes detailsMANGANESE ACETATEManganese sulphate

The invention discloses an auxiliary agent for biomass treatment and a biomass gasification treatment method. The auxiliary agent comprises a component A, a component B and a component C, wherein thecomponent A comprises Lewis acid and one or more of optional organic acid and protonic acid, the component B is a salt of group IA, IIA and IIIA metals and ammonium, and the component C is one or moreof manganese acetate, manganese sulfate and manganese nitrate. The gasification treatment method comprises the following steps: mixing a biomass raw material and an auxiliary agent, and carrying outa reaction to obtain a volatile component and biological semicoke; performing a reaction on the solid-phase materials obtained after gas-solid separation of volatile components and the biological semicoke respectively in a biological coke microwave gasification reactor to obtain crude synthesis gas and activated carbon; and feeding the synthesis gas obtained after gas-solid separation of the crudesynthesis gas into a purification reactor to be treated, thus preparing purified synthesis gas. According to the biomass gasification treatment method and system, the yield of the synthesis gas can be increased, and the tar content in the obtained synthesis gas product is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

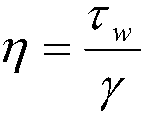

Modified CO2 dry fracturing fluid for shale gas reservoir fracturing transformation, and preparation and evaluation methods thereof

The invention belongs to the field of oil field chemical fracturing fluid, and particularly relates to modified CO2 dry fracturing fluid for shale gas reservoir fracturing transformation, and preparation and evaluation methods thereof. The modified CO2 dry fracturing fluid comprises the following raw materials in percent by mass: 1.5 to 3 percent of a surfactant thickening agent, and CO2 for the surplus, wherein the surfactant thickening agent comprises one head group and two double-tail groups; the head group adopts a hydrophilic group comprises metal ion Co2+ or Ni2+; the tail group adopts afluorinated CO2-philic group. Performing fracturing through the modified CO2 dry fracturing fluid does not consume water resource, is small in damage to a reservoir, does not pollute the environment,and ensures that CO2 becomes gaseous state and is rapidly changed from the reservoir after construction is accomplished. Compared with the conventional fracturing technology, the modified CO2 dry fracturing fluid is obvious in shale gas reservoir yield-increasing effect.

Owner:XI AN JIAOTONG UNIV

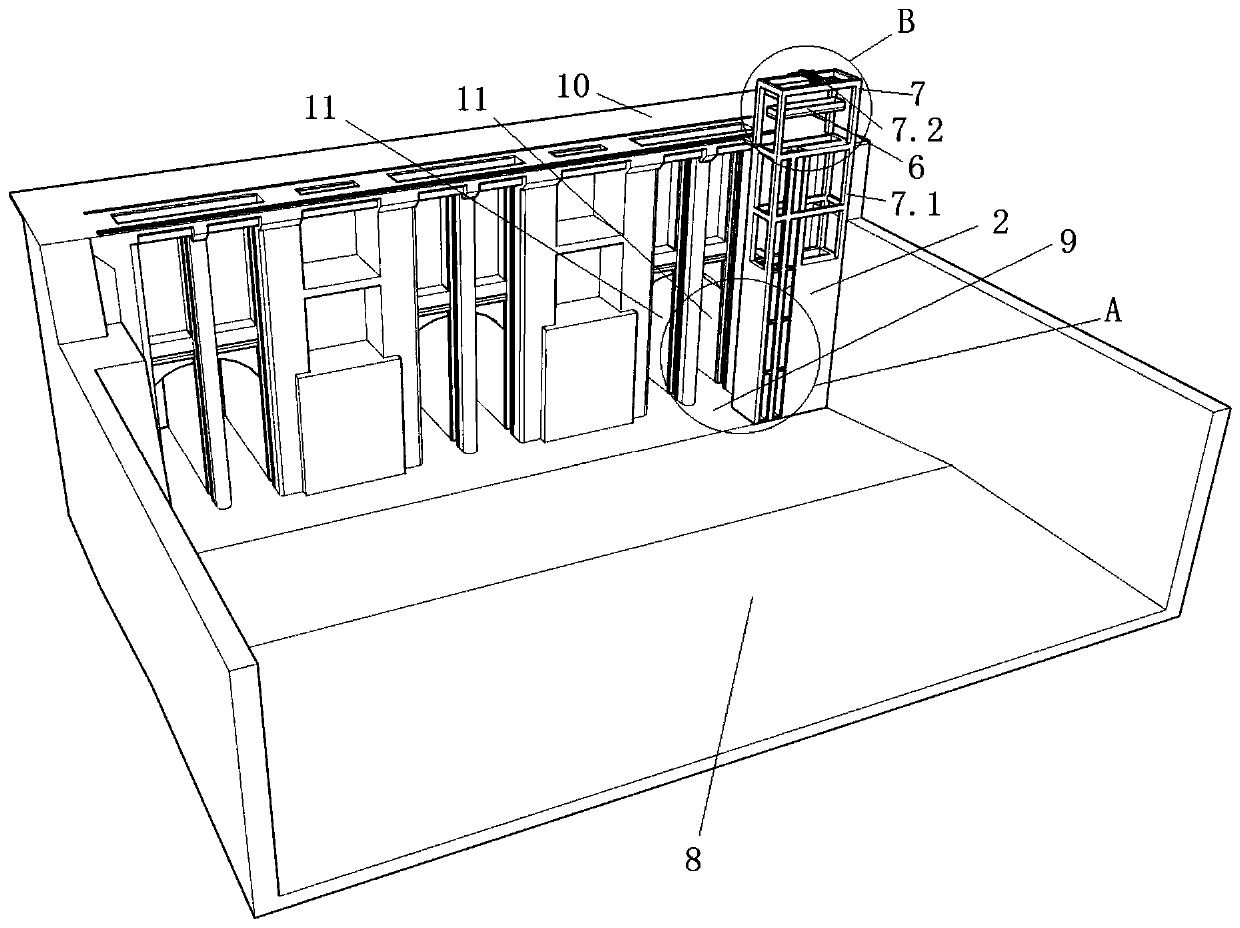

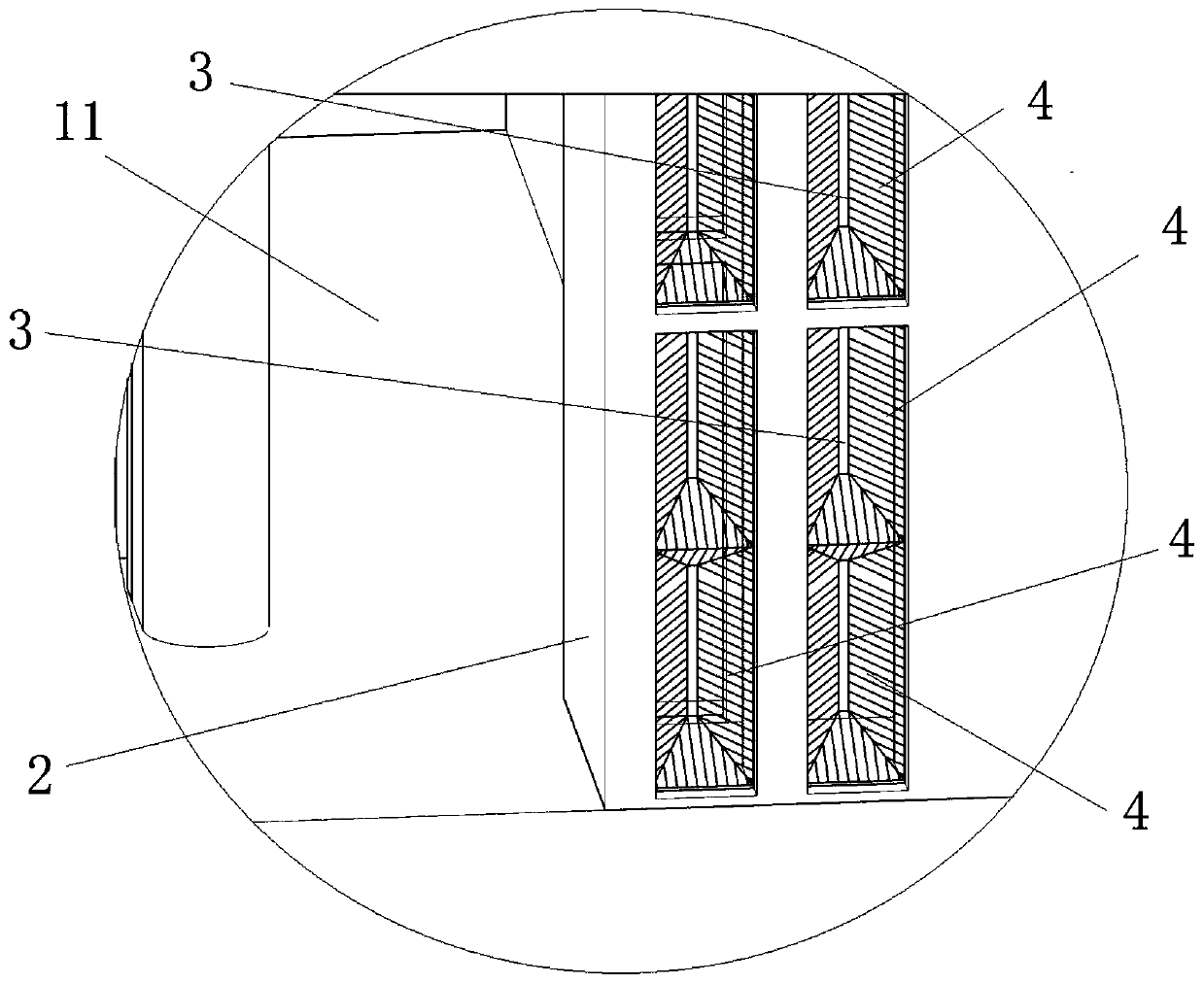

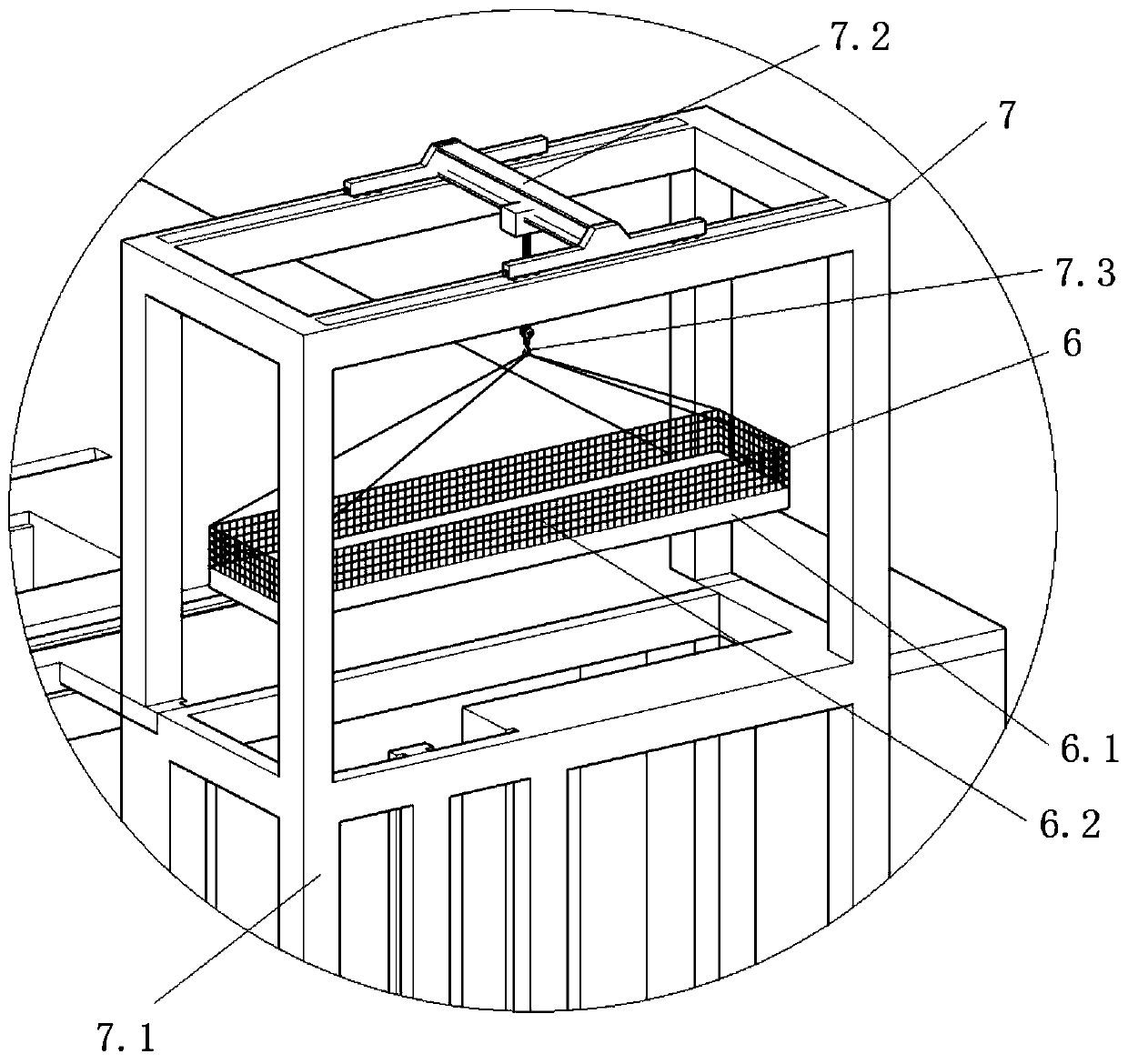

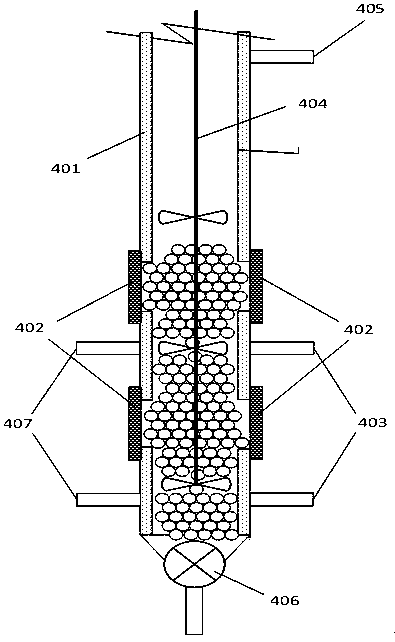

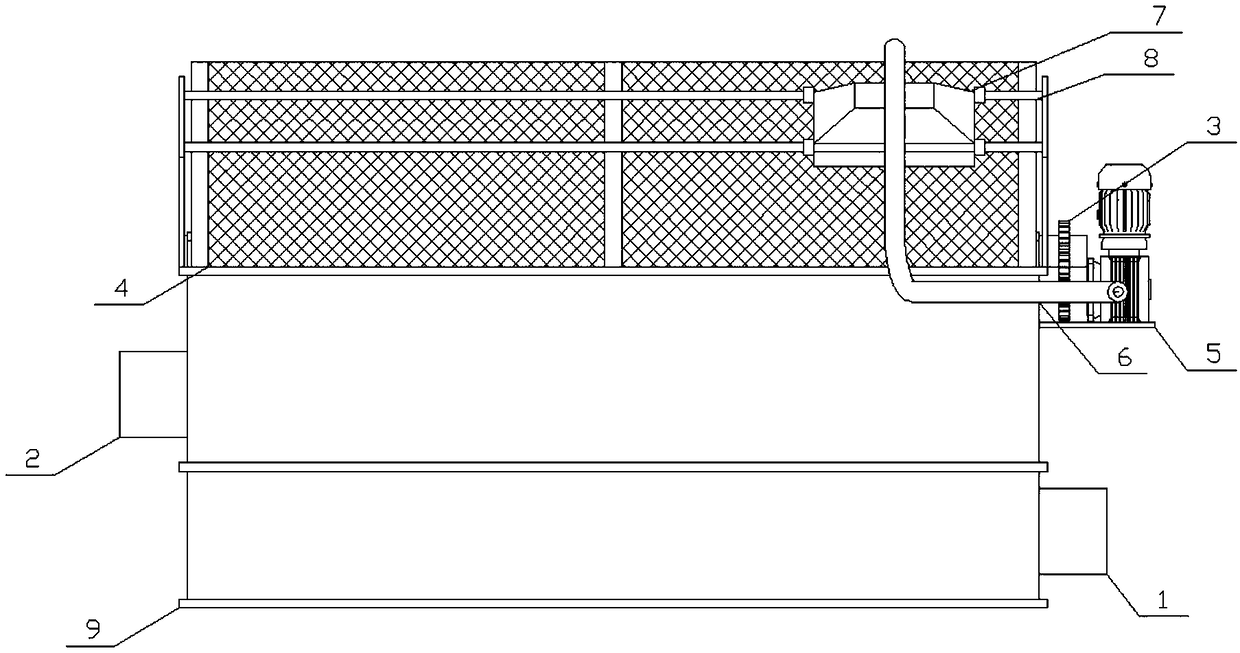

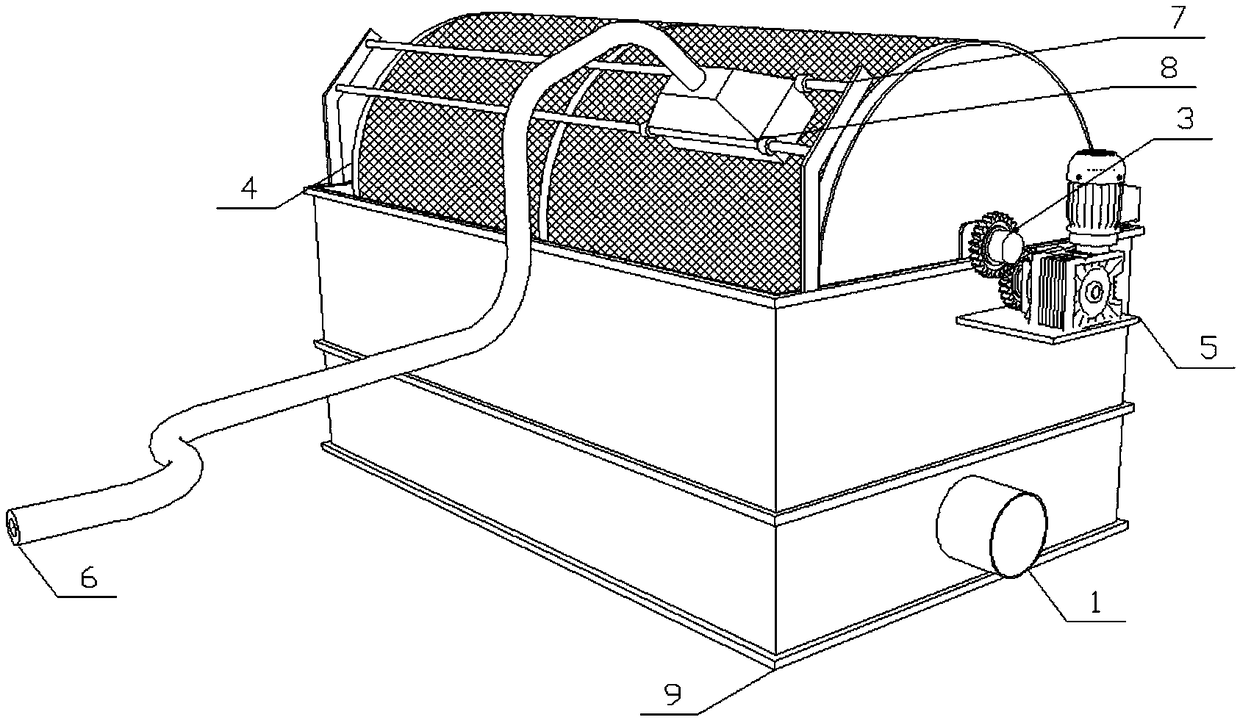

Device and method for removing and collecting microparticles in aquaculture water

InactiveCN108654182AStrong ability to removeReduce energy consumptionMoving filtering element filtersWater resourcesMicroparticle

The invention relates to a device and a method for removing and collecting microparticles in aquaculture water. The device comprises a tank body for accommodating the aquaculture water, wherein a horizontal filter drum is arranged inside the tank body; a spacing distance is formed between the lower part of the filter drum and the bottom of the tank body; the filter drum can rotate under driving ofa power mechanism; a water inlet and a water outlet are formed in the side wall of the tank body; the water inlet is positioned outside a part corresponding to the end surface of the filter drum; thewater outlet is positioned inside the part corresponding to the end surface of the filter drum; sliding rails are arranged on the tank body; the sliding rails are arranged in the generatrix directionof the filter drum; a dirt sucking device capable of sliding along the sliding rails is arranged thereon; a set spacing distance is formed between a suction port of the dirt sucking device and the filter drum. The particle removing treatment capacity is high, and the energy consumption is low; backflushing is not required, and in the treatment process, a water resource is not consumed; manual maintenance is not required, and particle discharge is accurate; the particles collected after removal are substantially free of water and can be recycled.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

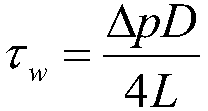

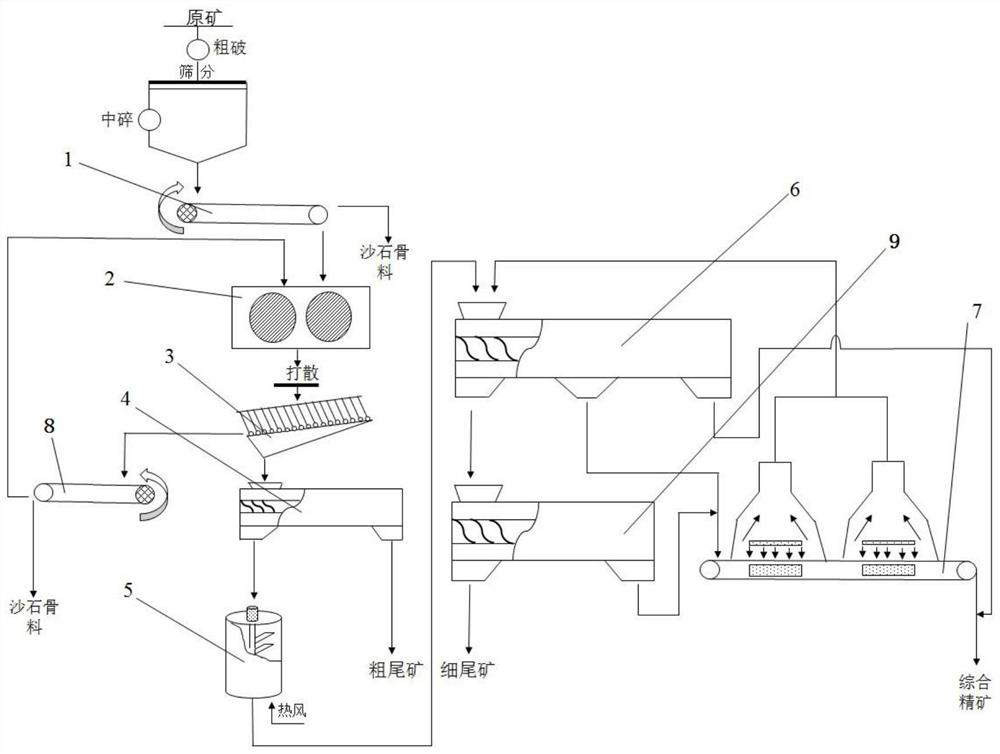

Technology method and device of pneumatic separation and magnetic separation for dry method ore grinding of iron ores

PendingCN108187895AEasy to sortOvercome the disadvantages of single roller crushing processGas current separationDrying gas arrangementsMaterials scienceMagnetic separation

The invention discloses a technology method and a device of pneumatic separation and magnetic separation for dry method ore grinding of iron ores. The technology method includes the steps that the crushed iron ores are grinded to form a mixture of ore grains and ore powder through a dry vertical milling machine; the ore powder is separated from particles through a multi-stage lifting windowing machine; and the ore grain is subjected to multi-stage magnetic separation through a multi-stage magnetic roller concentrating machine to be sorted to good-taste fine ore, ordinary-taste middling and low-taste tailings, and the middling is placed in the dry vertical milling machine to be grinded again. The device includes the dry vertical milling machine which is connected with the multi-stage lifting windowing machine through an ore grain transport mechanism, the multi-stage lifting windowing machine is connected with a powder collecting device and the multi-stage magnetic roller concentrating machine, and the multi-stage magnetic roller concentrating machine is connected with a fine ore collecting device, a tailings collecting device and the dry vertical milling machine. According to the technology method and the device of the pneumatic separation and the magnetic separation for dry method ore grinding of the iron ores, ore grinding and ore separation can be carried out under the condition of dry or less water consumption.

Owner:MOUNTOP GRP CO LTD

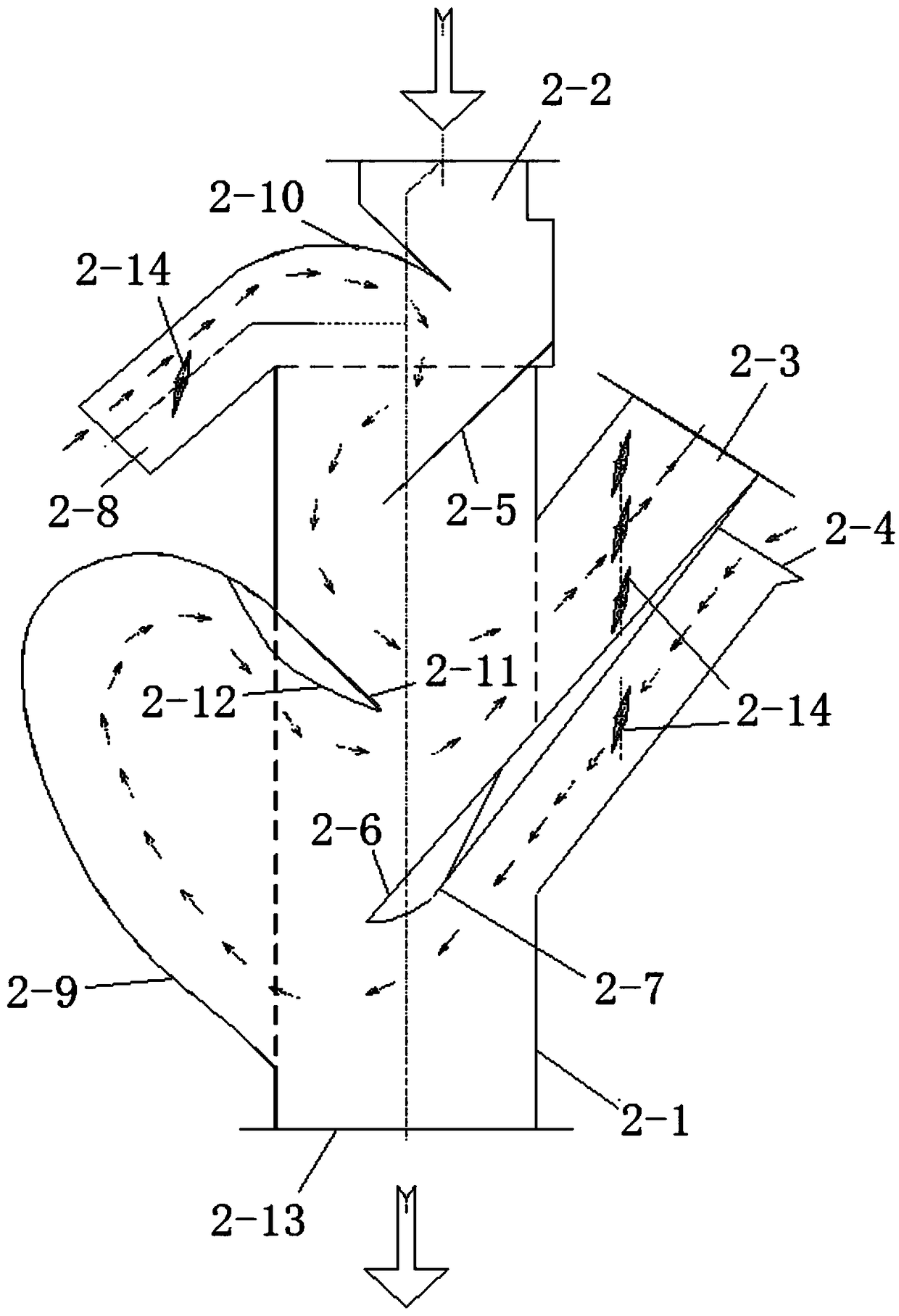

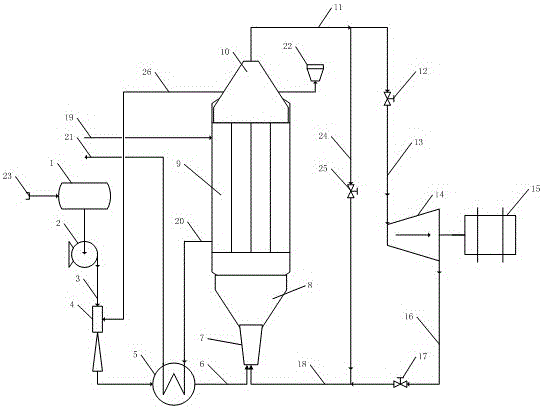

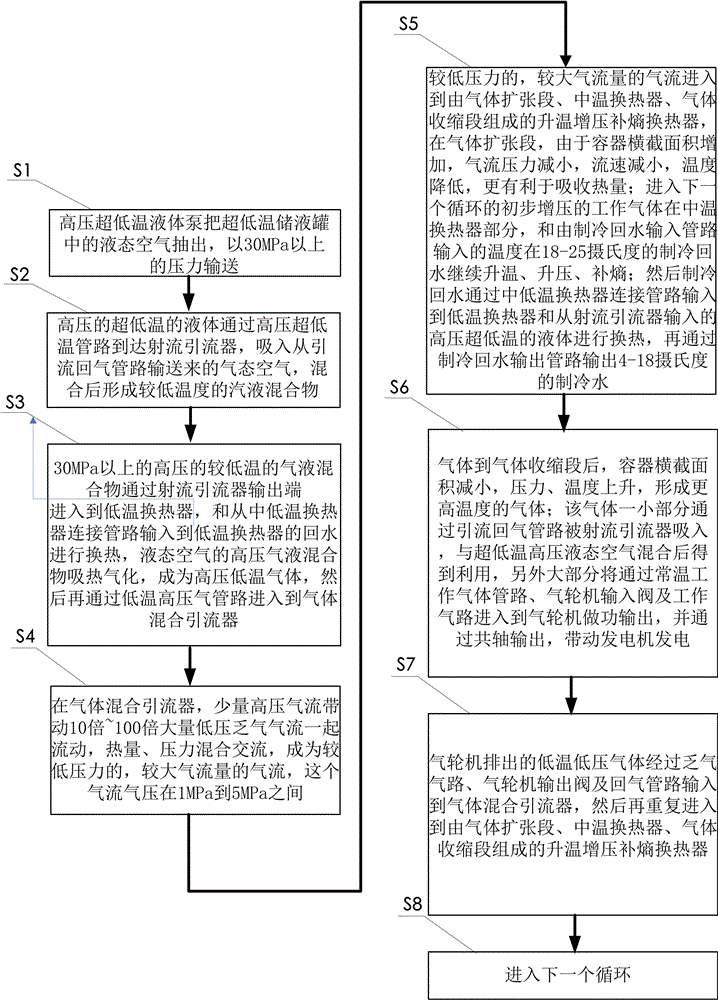

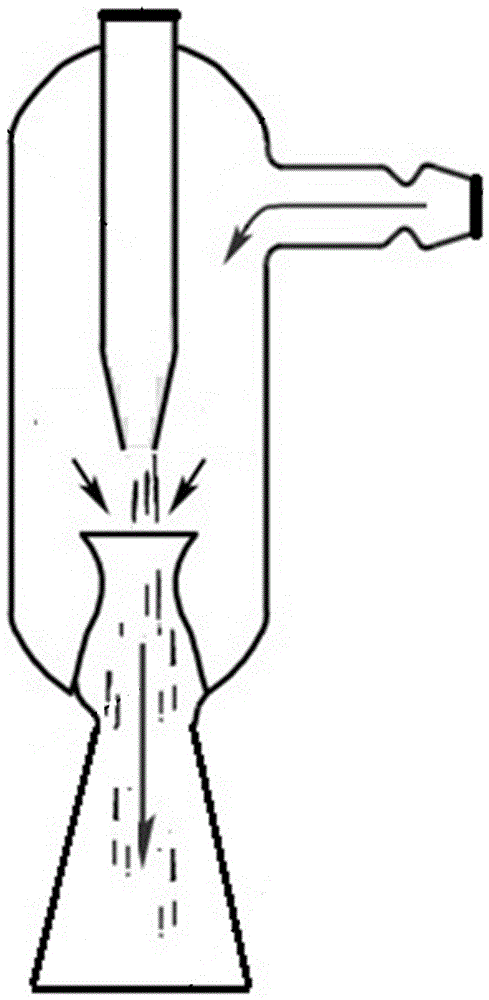

A liquid air refrigeration power generation device for a data center and its working method

InactiveCN103883398BReduce procurement costsReduce power consumptionCompression machinesGas turbine plantsData centerLiquid storage tank

The invention discloses a liquid air refrigeration power generation device for a data center, and a working method. The liquid air working medium refrigeration power generation device for the data center comprises an ultralow-temperature liquid storage tank, a high-pressure and ultralow-temperature liquid pump, a high-pressure and ultralow-temperature pipeline, a jet flow drainage apparatus, a low-temperature heat exchanger, a low-temperature and high-pressure gas pipeline, a gas mixing drainage apparatus, a temperature-rising, pressure-increasing and entropy-compensating heat exchanger consisting of a gas expansion section, a medium-temperature heat exchanger and a gas contraction section, a normal-temperature working gas pipeline, a gas turbine input valve, a working gas path, a gas turbine, a generator, an exhaust gas path, a gas turbine output valve, a gas return pipeline, a refrigeration water return input pipeline, a low-and-medium-temperature heat exchanger connection pipeline, a refrigeration water return output pipeline, an after-gas discharging opening, a liquid gas injection opening, an overhaul short circuit pipeline, an overhaul short circuit gas valve and a drainage gas return pipeline. According to the liquid air refrigeration power generation device for the data center, the refrigeration unit purchase cost and the backup generator set purchase cost can be reduced; due to modes of reduction of the power consumption of a refrigeration unit in the data center, auto-using power generated by the low-temperature generator set and the like, the power consumption of the data center is greatly reduced.

Owner:苟仲武

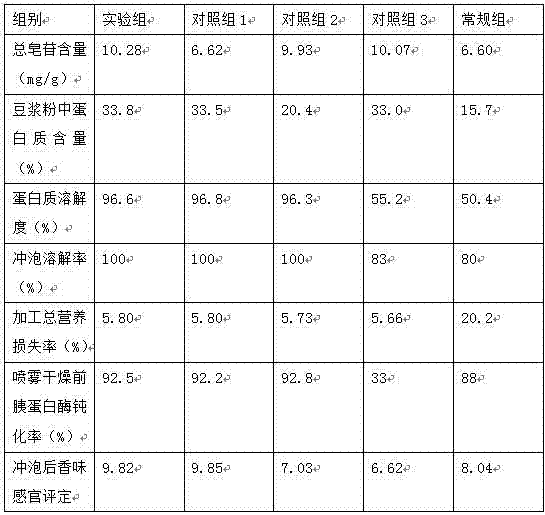

Instant health-care anti-aging soybean milk powder

The invention relates to the technical field of production of agricultural products, in particular to instant health-care anti-aging soybean milk powder. During production, the following steps are carried out: carefully selecting soybeans, cleaning, proportionally uniformly mixing thearubigin, maltitol and water as sprinkling liquid, sprinkling the surface layers of the soybeans by adopting a high-pressure spray gun till the soybeans grow hypocotyls, pulping, inflating oxygen into soybean milk till a saturated state at high pressure, fully dissolving out protein in soybean residues, centrifuging to remove the residues to obtain soybean milk, adding seaweed gel, controlling the pressure of a stirring kettle to be 60-65MPa and the temperature to be 100 DEG C, stirring at high speed, performing vacuum freezing and spray drying on the soybean milk, sterilizing, and bagging to obtain the soybean milk powder. The soybean milk powder provided by the invention is light orange, and is free of a beany flavor, strong in beany fragrance, good in solubility and free of a precipitating phenomenon.

Owner:蚌埠市星光豆制品厂

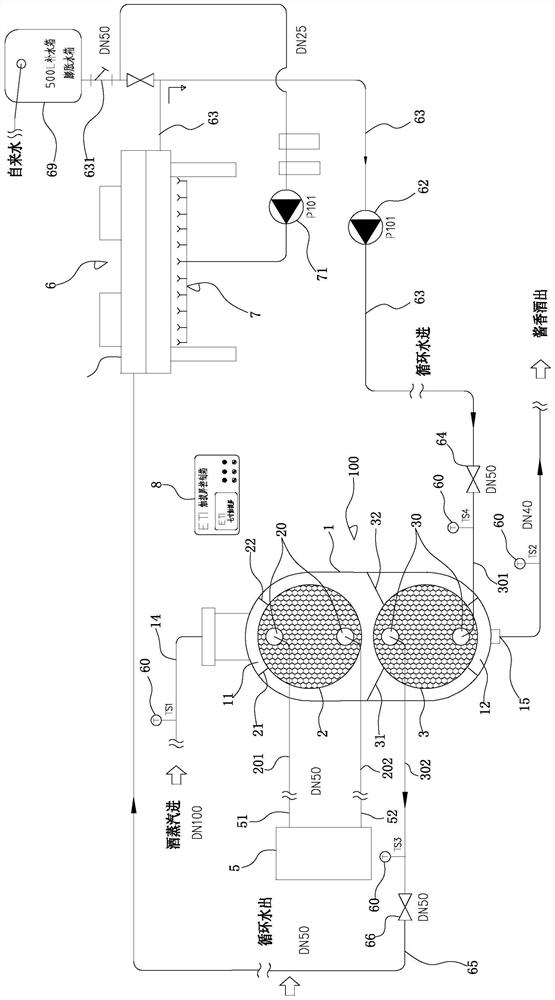

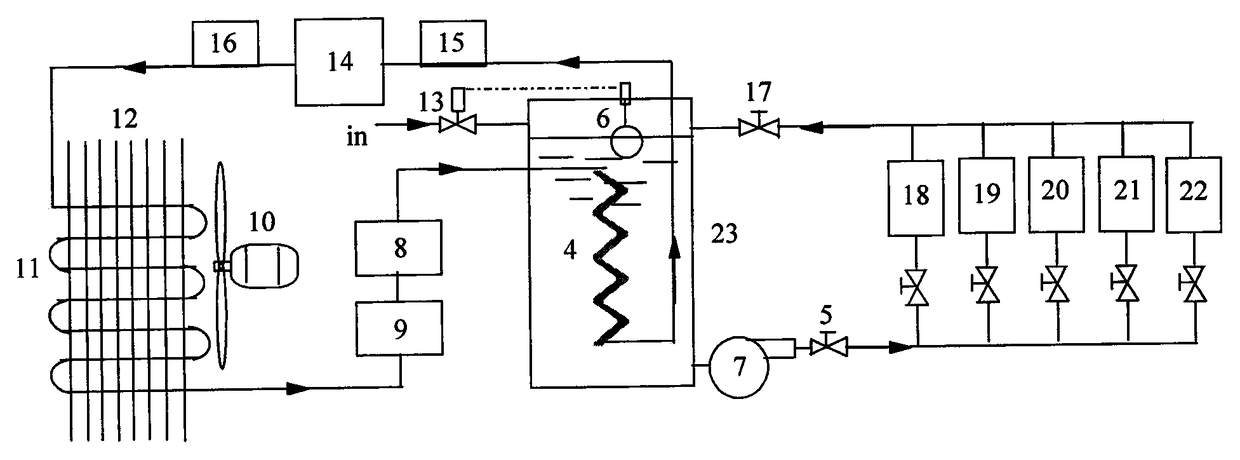

Dry type heat recovery wine cooling system and method

PendingCN113046212AInnovative waySimple structureAlcoholic beverage preparationWater pipeEngineering

The invention discloses a dry type heat recovery wine cooling system and method. The wine cooling system comprises a heat exchange device, a heat recovery module and a circulating water cooling module, wherein the heat exchange device comprises a shell, a first-stage heat exchange core and a second-stage heat exchange core, a first shell pass flow channel and a second shell pass flow channel which communicate with each other are formed between the inner wall of the shell and the first-stage heat exchange core and between the inner wall of the shell and the second-stage heat exchange core respectively, and a wine steam inlet is formed in the upper end of the shell; a Maotai-flavor liquor outlet is formed in the lower end of the shell; a first plate pass flow channel and a second plate pass flow channel which are isolated from the first shell pass flow channel and the second shell pass flow channel are formed in the first-stage heat exchange core and the second-stage heat exchange core respectively, and a first inlet and a first outlet which communicate with the first plate pass flow channel and a second inlet and a second outlet which communicate with the second plate pass flow channel are formed in the side face of the shell; the heat recovery module is connected with the first inlet and the first outlet through a cold water pipe and a hot water pipe respectively; the circulating water cooling module comprises a surface air cooler or a dry air cooler, a first water pump, a first water supply pipe, a first control valve, a first water return pipe and a second control valve, and the first water supply pipe is connected with the second inlet; and the first water return pipe is connected with the second outlet, and the first water supply pipe is connected with a water compensation tank.

Owner:广东一钛科技有限公司

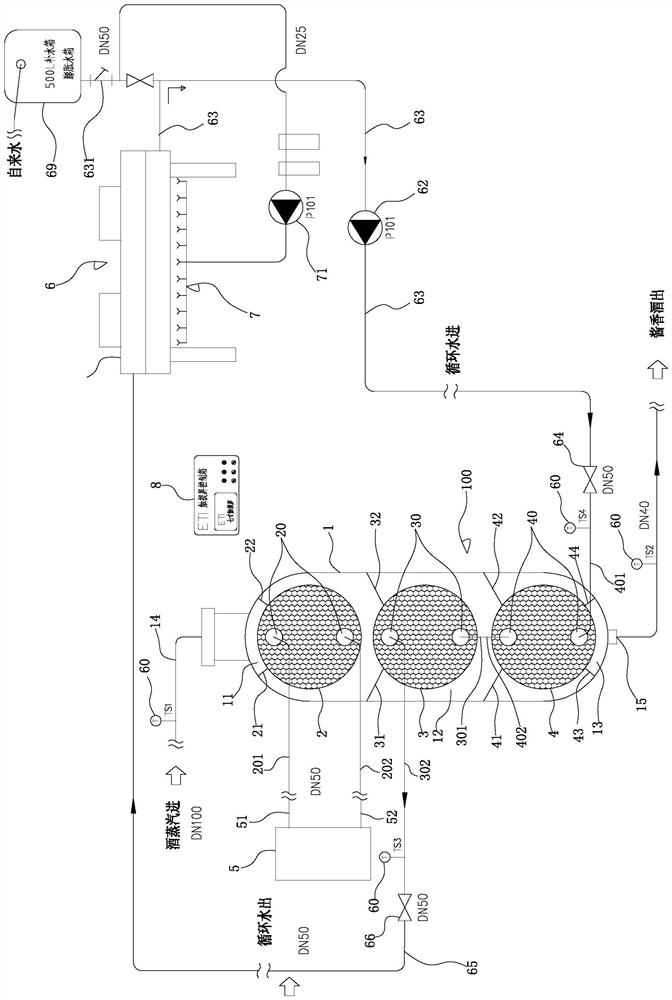

System and method for avoiding low temperature corrosion of air preheater by using phase change heat

ActiveCN103557532BReduce volumeLess investmentCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

Owner:HARBIN INST OF TECH

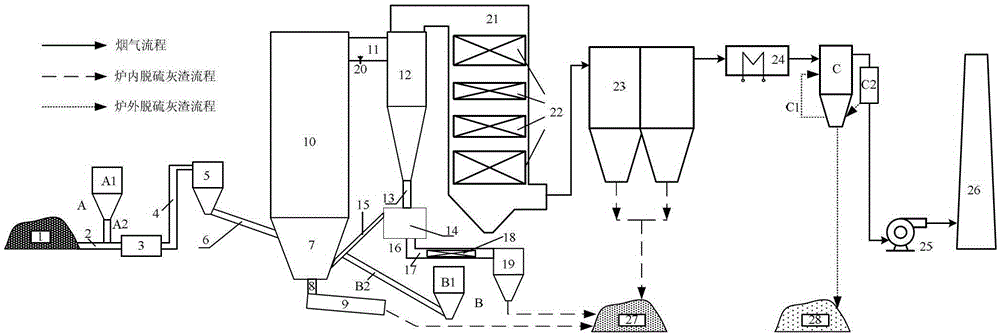

An ultra-low emission circulating fluidized bed boiler with three-stage desulfurization system

ActiveCN103453538BRetrofitting workload is smallReduce space consumptionLighting and heating apparatusDispersed particle separationEngineeringCoal

The invention discloses an ultra-low emission circulating fluidized bed boiler with three stages of desulfurization systems. The three stages of desulfurization systems include a front desulfurizing agent adding system, an inner desulfurizing agent conveying system and a deep flue gas desulfurization system, the front desulfurizing agent adding system is positioned in a coal yard area in front of the boiler, the inner desulfurizing agent conveying system is positioned in a plant area of the boiler, and the deep flue gas desulfurization system is positioned in a tail area of the boiler; the front desulfurizing agent adding system comprises a front desulfurizing agent bin and a front desulfurizing agent gravimetric adding machine below the front desulfurizing agent bin, the inner desulfurizing agent conveying system comprises an inner desulfurizing agent bin and an inner desulfurizing agent conveying feeder below the inner desulfurizing agent bin, and an efficient desulfurizing agent circulating system and a flue gas supplementary dust removing device are further arranged on the deep flue gas desulfurization system. The ultra-low emission circulating fluidized bed boiler has the advantages that the systems are simple, are low in running energy consumption, can be regulated and controlled easily and conveniently, are high in desulfurizing agent utilization rate and desulfurization efficiency and free of water resource consumption and are widely suitable to be used with new circulating fluidized bed boilers in an environment-friendly manner and to modify existing circulating fluidized bed boilers in an environment-friendly manner, and space and equipment investment can be effectively saved.

Owner:HUANENG CLEAN ENERGY RES INST

A kind of fully dry sorting method for iron ore

ActiveCN110586315BReduce processingReduce maintenance costsWet separationTailings damMining engineering

The invention discloses an iron ore full-dry sorting method, which comprises the following steps: coarsely crushing and screening iron-containing raw ore, performing intermediate crushing on the product on the screen, and performing dry pre-selection with a magnetic pulley together with the product under the screen , the pre-selected concentrate is then subjected to high-pressure roller milling, and the pre-selected tailings are used as sand and gravel aggregates; the pre-selected ore after roller milling is broken up and then screened through a round roller sieve, and the product on the screen is subjected to a magnetic pulley dry pre-selection, pre-selected The concentrate returns to the feeding end of the high-pressure roller mill, and the pre-selected tailings are also used as sand and gravel aggregates; the products under the round roller screen are pre-selected by spiral dry type, and the spiral dry pre-selected tailings are used as coarse tailings, and the pre-selected concentrate enters the heating air In the vertical dry mill; after dry grinding, the product is roughed with a double-magnetic field spiral dry magnetic separator, and the rough beneficiation is subjected to two-stage belt-type magnetic separation, and the final belt-type wind-magnetic concentrate is composed of the rougher concentrate Comprehensive Concentrate. The invention adopts an all-dry beneficiation process, has simple process, low water consumption, high utilization rate of tailings building materials, and no tailings dam.

Owner:WUHAN UNIV OF SCI & TECH

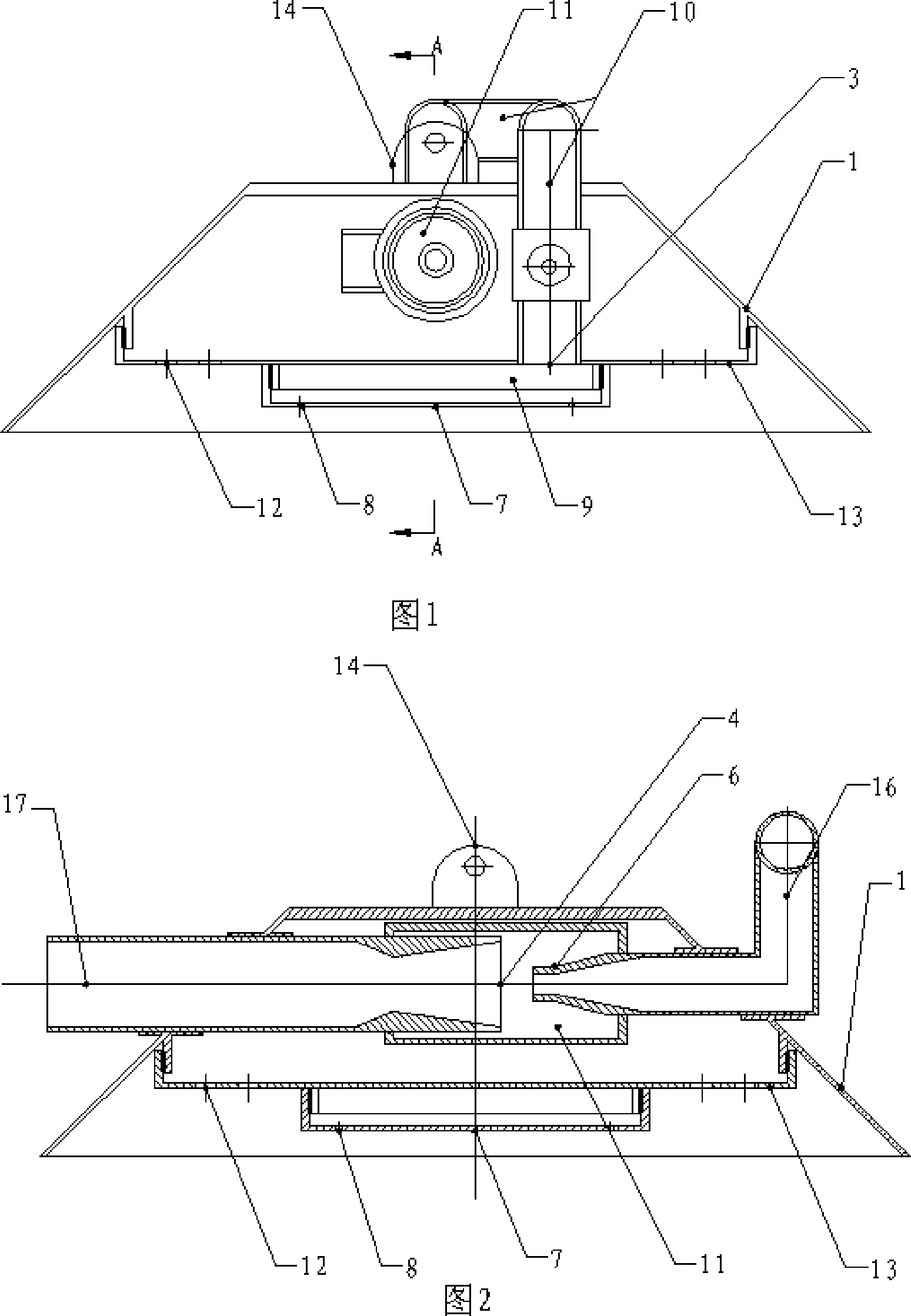

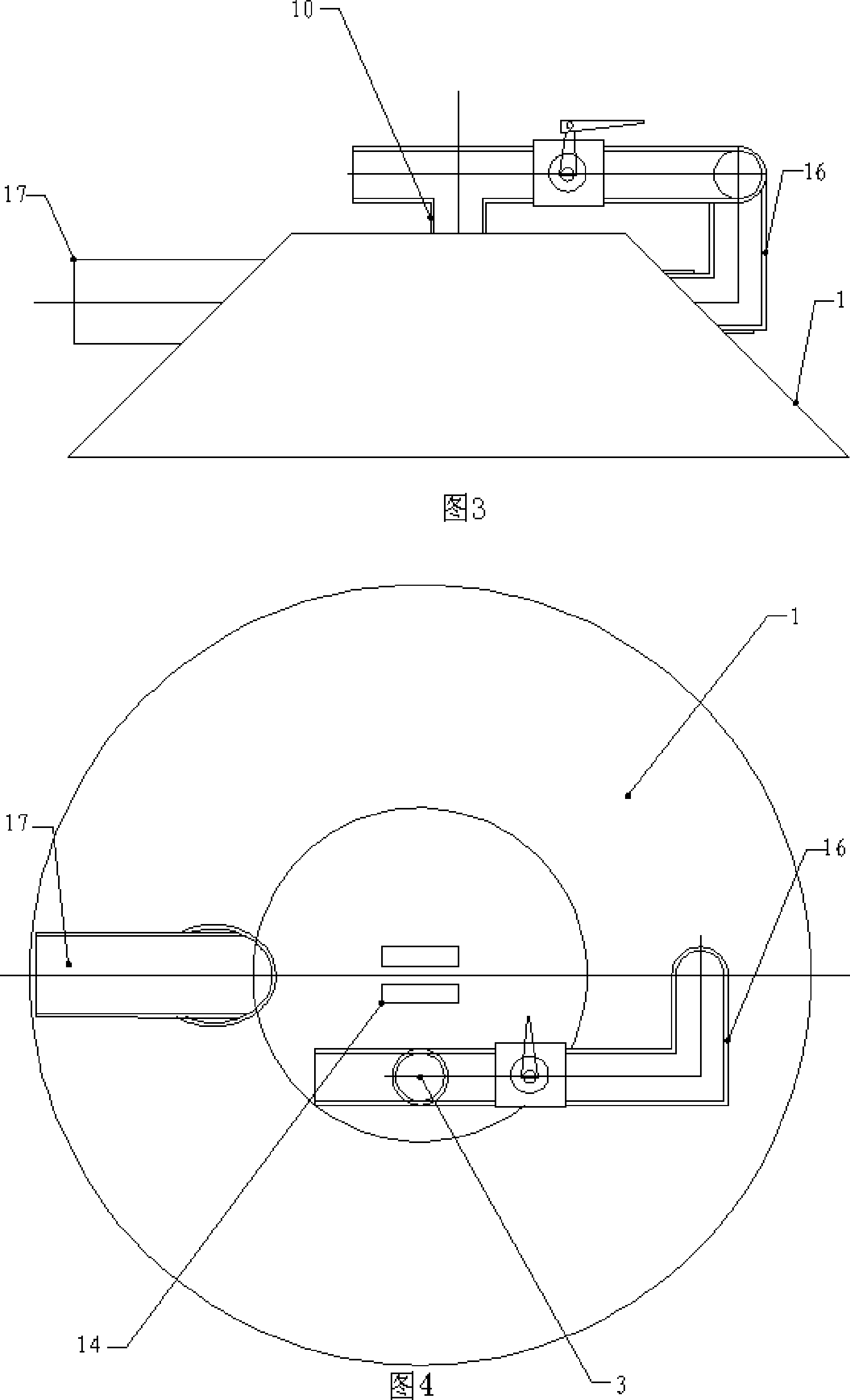

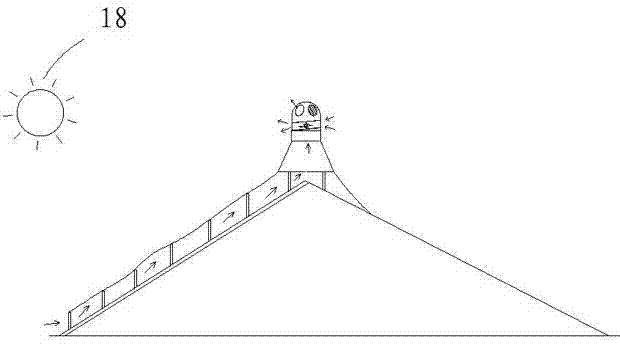

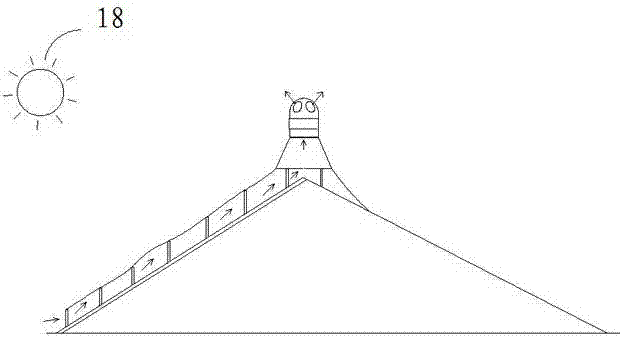

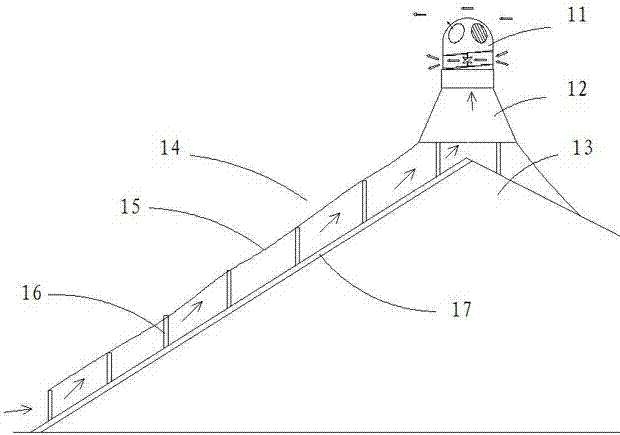

Water consumption free integrated power generation device capable of comprehensively utilizing wind energy and solar light thermal energy

ActiveCN102213187BImprove efficiencyNo water consumptionWind motor controlMachines/enginesSolar lightControl system

The invention discloses a comprehensive integrated power generation device with no water consumption, wind and solar thermal energy. The power generation device includes a tower body device built on the top of a mountain or a slope. It is provided with a vertical air duct, a horizontal air duct, an airflow generator and a ventilation control system for controlling the separate ventilation of the two air ducts. The vertical air duct and the horizontal air duct are independently ventilated to drive the airflow generator to generate electricity independently. The present invention designs an integrated device for comprehensive utilization of solar energy, light heat and wind energy, which has the characteristics of no water consumption, high comprehensive efficiency, multi-purpose with the same device, and the like.

Owner:北京绿贝区块链科技有限公司

Dry-method ultra-clean emission dust removal device

PendingCN112646946AWith impact resistanceWith high temperature resistanceIncreasing energy efficiencyManufacturing convertersFiltrationSludge

The invention belongs to the technical field of dust removal application, and particularly discloses a dry-method ultra-clean emission dust removal device. The device comprises a high-temperature intermetallic compound filter bag dust remover, a blowback pipe, a first manual ball valve, a first nitrogen blowback gas bag, a first control valve, a first pneumatic valve, an auxiliary ash discharging pipe, a pneumatic ash conveying unit, a pneumatic ash conveying unit ash discharging pipe, a second control valve, a second pneumatic valve, a first guide pipe, a second guide pipe, a second manual ball valve, a third manual ball valve, a third pneumatic valve and the like. The device has the beneficial effects that 1, the device is safe and reliable and has perfect safety measures, and a high-temperature intermetallic compound filter bag has impact resistance, high temperature resistance, magnetization resistance, good conductivity and long service life; 2, energy is saved, the operation resistance is low, dry full-process filtration is achieved, water consumption, waste water and sludge are avoided, and economy and energy conservation are achieved; and 3, the expandability is good, the temperature of filtered gas is lower than 10 DEG C, and a proper temperature is created for subsequent catalytic removal of carbon monoxide in flue gas.

Owner:江苏苏仪集团有限公司 +1

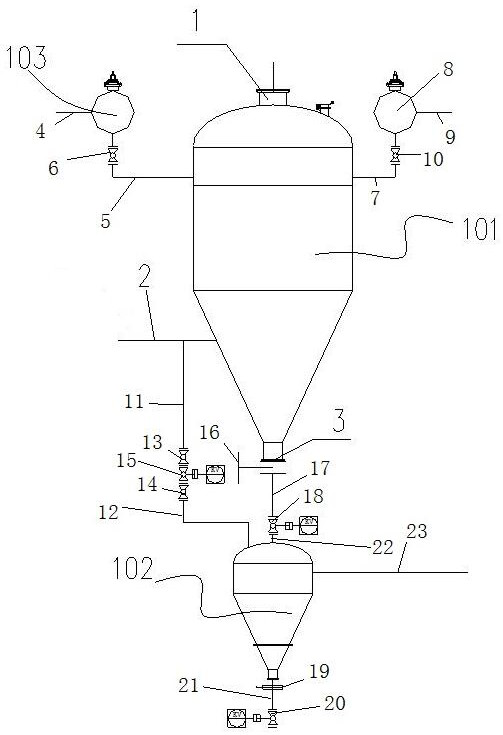

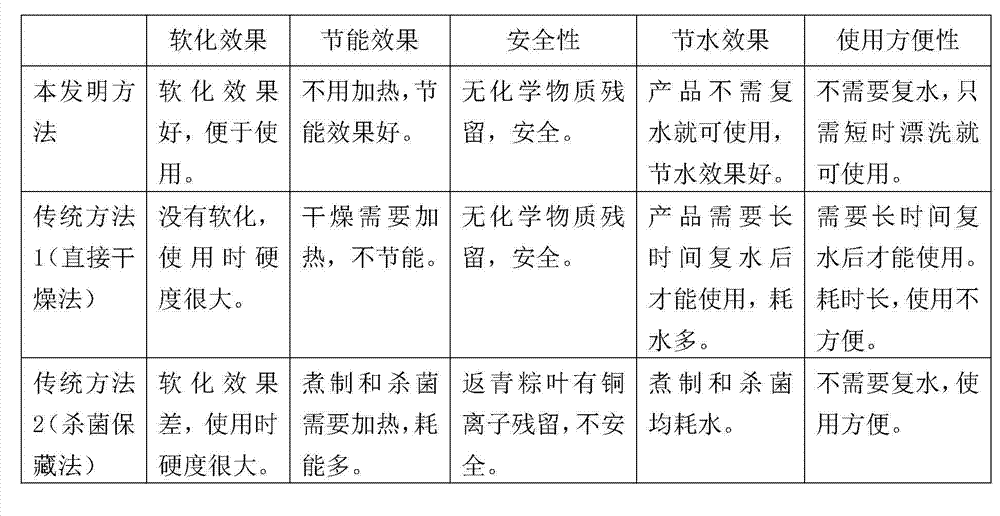

Non-hot processing method for zongzi leaves

InactiveCN102837888BReduce production energy consumptionNo water consumptionFlexible coversWrappersWaxFood safety

The invention relates to a non-hot processing method for zongzi leaves, which comprises the following steps of: soaking indocalamus leaves which sufficiently grow up, but are not provided with obvious wax layers in aqueous solution of sodium hydroxide so as to dewax, soften and clean the indocalamus leaves; taking out the indocalamus leaves, cleaning the indocalamus leaves, draining the indocalamus leaves and then pickling the indocalamus leaves in salt or aqueous solution of salt; and finally, taking out the indocalamus leaves, rinsing the indocalamus leaves in the aqueous solution of salt clean, then classifying the indocalamus leaves according to the standard of the zongzi leaves, respectively placing the indocalamus leaves into plastic bags for food packaging and carrying out vacuum sealing on the plastic bags. The method not only has no energy consumption caused by heating, but also has no water consumption caused by using the previous rehydration process, also has no food safetyhazard and is a processing method which is energy-saving, can be used for reducing the consumption and is convenient and safe.

Owner:HUNAN AGRICULTURAL UNIV

Improved charging pile for new energy automobile

PendingCN110962653AIncrease cooling areaGood cooling effectCharging stationsElectric vehicle charging technologyPhysicsWater pipe

The invention discloses an improved charging pile for a new energy automobile. The improved charging pile comprises a heat insulation box body and a charging module assembly, a mounting hole is formedin the bottom surface of the heat insulation box body; a connecting water tank is inserted into the mounting hole; a connecting pipe connected with a buried tap water pipe is arranged at the end, located outside the heat insulation box body, of the connecting water tank; a heat dissipation water pipe is arranged at one end, positioned in the heat insulation box body, of the connecting water tank;the connecting water tank is fixedly connected with the heat insulation box body; cooling fins are arranged in the heat insulation box body; the cooling fins are arranged in a square shapes; penetrating holes matched with the heat dissipation water pipe are formed in the cooling fins; supporting protrusions are arranged at the four corners of each cooling fin; gaps are formed between the coolingfins through the supporting protrusions; an installation frame is arranged on the heat insulation box body; and the charging module assembly is fixedly connected with the installation frame. The improved charging pile for the new energy automobile has a good heat dissipation effect, and meanwhile, the energy consumption for heat dissipation is relatively low.

Owner:商文辉

A liquid slag waste heat recovery system

ActiveCN111020077BGuaranteed uptimeImprove qualityRecycling and recovery technologiesLiquid slagCentrifugation

The invention discloses a liquid slag waste heat recovery system, which comprises a slag buffer device, a flow control device, a centrifugal granulation device and a moving bed device; one end of the slag buffer device is connected to a slag ditch, and the other end of the slag buffer device It is connected to the inlet end of the flow control device, the outlet end of the flow control device is connected to the inlet end of the centrifugal granulation device, and the outlet end of the centrifugal granulation device is connected to the moving bed device; the present invention effectively avoids the The impact of blast furnace intermittent slag discharge on the centrifugal granulation system ensures the stable operation of the centrifugal granulation system and improves the emergency response capability of the waste heat recovery system; through the installation of flow control devices, centrifugal granulation devices and moving bed devices, effective It improves the sufficient heat exchange of slag particles and the smooth discharge of the system, and effectively improves the heat exchange efficiency.

Owner:XI AN JIAOTONG UNIV

A short process, no water consumption and release paper saving water-based synthetic leather manufacturing method

ActiveCN109898341BNo water consumptionNo pollution in the processTextiles and paperWater savingManufacturing technology

The invention discloses a short process, no water consumption and release paper-saving water-based synthetic leather manufacturing method, the method is characterized in that the foam coating and surface layer are directly coated on the back cover to produce water-based foam Synthetic leather. The synthetic leather produced by this method has a porous structure, which improves the air and moisture permeability of water-based polyurethane synthetic leather (as shown in Figure 1). At the same time, the specific peel strength of the finished leather is greatly improved due to the special back cover technology. Compared with the water-based wet coagulation process, the process of coagulation, washing and salty wastewater treatment is omitted, which has the effect of saving water, reducing emissions, and reducing the amount of the process; Type paper resources and the entire manufacturing process is short, so its production technology is a short process, no water consumption, zero pollution, release paper-saving water-based synthetic leather manufacturing technology, and has broad application prospects.

Owner:SICHUAN UNIV

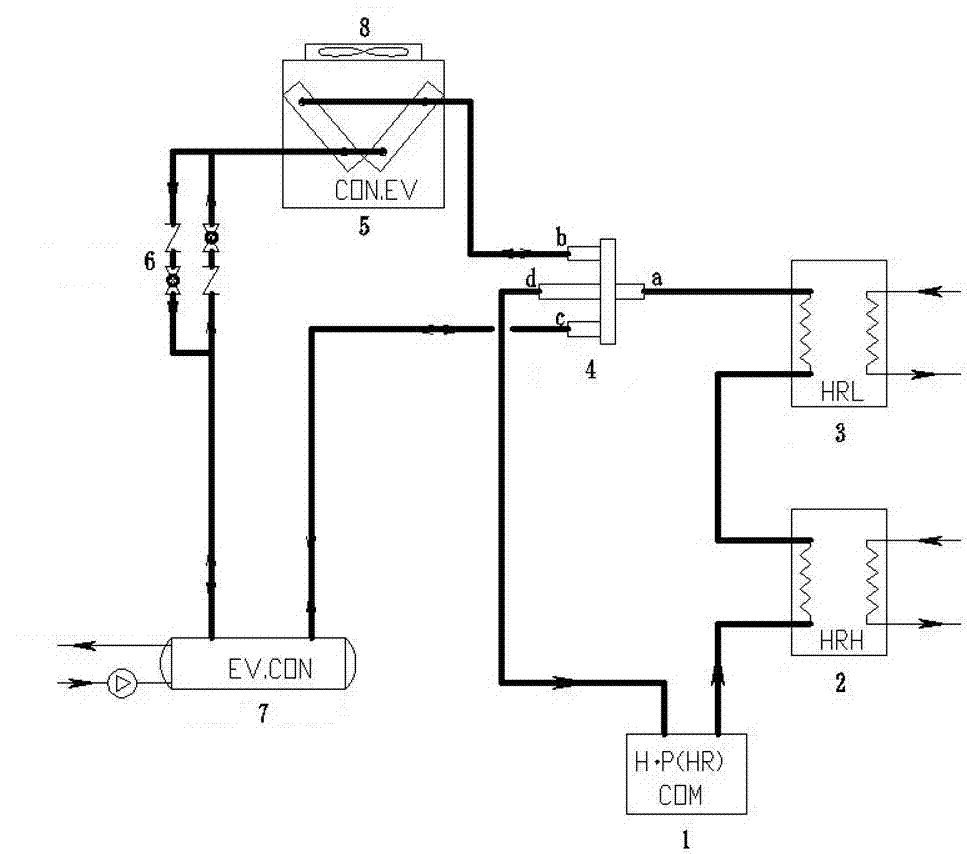

Solar-powered heat pump unit capable of freely recovering excess heat

ActiveCN102230690BMeet cooling and heating needsReduce consumptionHeat pumpsFluid circulation arrangementWaste heat recovery unitEngineering

The invention discloses a solar-powered heat pump unit capable of freely recovering excess heat, which relates to a two-stage heat recovering heat pump device taking atmospheric solar energy as an energy source. The solar-powered heat pump unit comprises an electric compressor, a first-stage heat recovery unit, a second-stage heat recovery unit, a four-way reversing valve, a condenser (serving asan evaporator in winter), an expansion valve, an evaporator (serving as a condenser in winter) and a fan arranged on the condenser (serving as an evaporator in winter). In the unit, two stages of heat recovery units are connected in series and then connected in series with the condenser, so that free recovery of condensation heat is realized on the premise of ensuring normal running of a refrigerating or heating working condition; supercooling heat is obtained during refrigeration, that is to say, excess heat consisting of total condensation heat and supercooling heat is obtained, so that therefrigerating and heating energy and efficiencies are further increased; and the two stages of heat recovery units can be used for preparing hot water of different temperatures, so that the requirements of different users are met and high practicability is achieved.

Owner:林昌元 +3

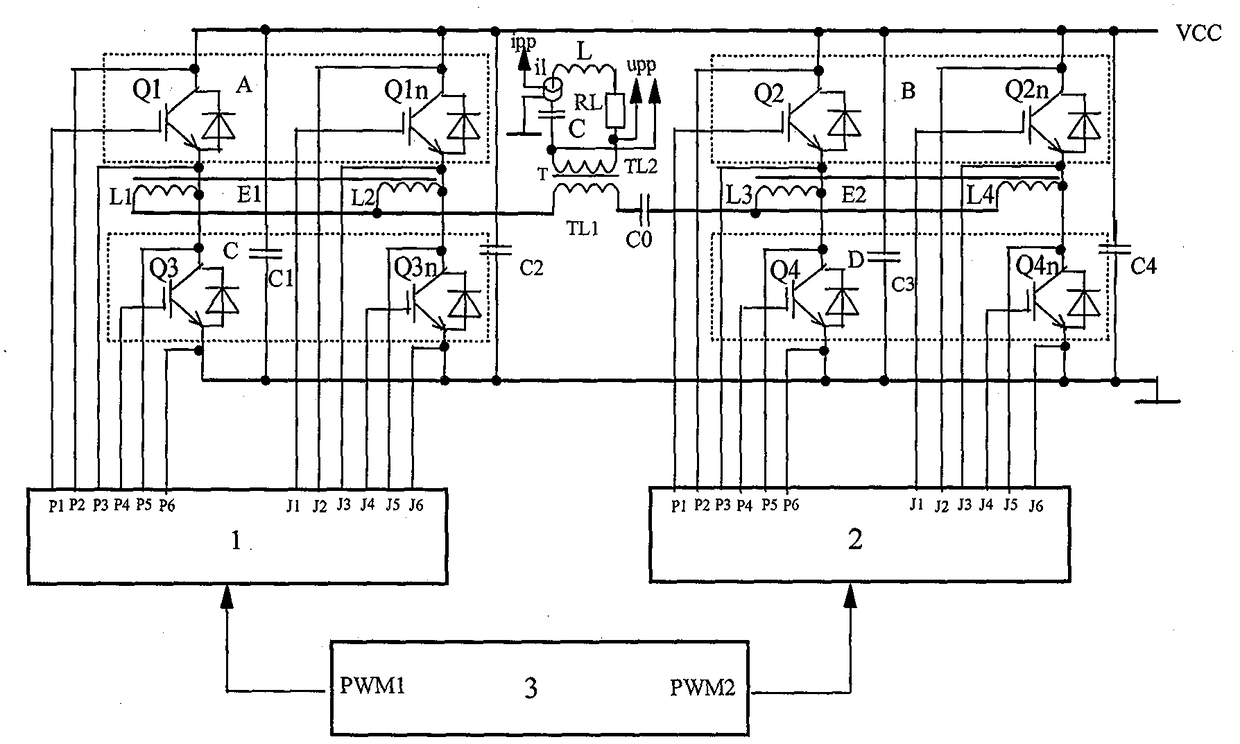

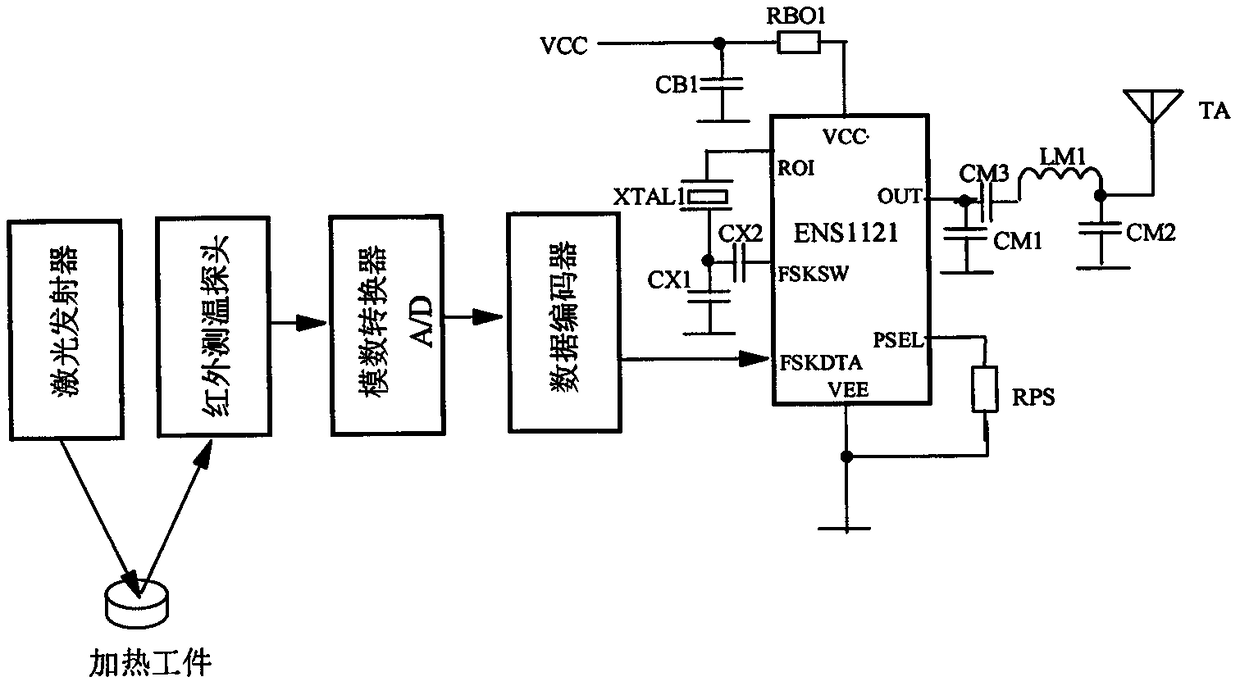

Heat treatment equipment and air cooling unit

PendingCN108539995AOvercome the defect of high power consumptionLarge cooling temperature adjustment rangeCompression machines with non-reversible cycleConversion constructional detailsTransformerH bridge inverter

The invention relates to the power electronic technology, and particularly relates to a heat treatment equipment and air cooling unit comprising laser beam guided infrared accurate temperature measurement and wireless data transmitting and receiving. Digital signal processing control panel DSP chip programmable phase control produces leading and lagging alternate phase shift two paths of pulse width modulation PWM1 and PWM2 signals. The upper pipe and the lower pipe set interlock dead time tDT which is coupled to two dual-path IGBT driving boards through optical fibers to form two half bridgeswhich are formed by parallel connection of dual-path IGBT modules and synthesized into an H-bridge inverter. The transformer matches and is connected in series with a resonance load circuit. Four bridge arm IGBT modules have balanced and equal alternate phase shift power consumption. Output power magnetic ring dual inductors suppress the ring current impact in a conjugated way. The water outlet pipe of the cooling water tank cyclically cools the three-phase rectifying module, the H-bridge IGBT modules, the impedance matching transformer, the induction furnace resonance inductors and the resonance capacitor through the water pump and the control valve so as to guarantee efficient and energy-saving, safe and reliable operation of heat treatment. The outstanding advantages of air cooling reside in no water consumption so as to meet the technical use requirements. The unit is suitable for heat treatment of wireless transmission infrared temperature measurement control and water-saving production.

Owner:阮树成

Method for cooling sand temperature regulator cooling water through earth cooling

ActiveCN102049466BSolve quality problemsNo water consumptionMould handling/dressing devicesWater resourcesEngineering

The invention relates to the technical field of temperature regulation for foundry recycled sand, in particular to a method for cooling recycled water for sand regeneration by utilizing underground low-temperature soil, which is a method for cooling sand temperature regulator cooling water through earth cooling. Foundry sand can meet the use requirement only by temperature regulation after being recycled. In the prior art, one way is to adopt a cooling tower to cool a circulating water system, the temperature of recycled water cooled in this way in summer is still higher, and the temperature of the recycled sand can not be lowered to be in the range required in the process and can only be regulated by adding running water, while the discharge of superfluous water of the system causes the waste of water resources; and the other way is to purchase cooling equipment for cooling, which results in large investment and more electricity consumption. In the invention, a sand temperature regulator cooling and circulating water system is connected to a running water main pipeline in parallel according to the principle of earth cooling, and sealed one-way circulation is carried out by utilizing running water as a cooling medium of the sand temperature regulator. Water absorbing heat transfers the heat to the earth through a buried running water pipeline, thereby the aims of no water consumption and energy resource saving can be achieved.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

A fish passing system and method without loss of water resources and free water surface

InactiveCN105256772BReduce constructionLow costBarrages/weirsClimate change adaptationRadarControl system

Owner:SHANGHAI JIAO TONG UNIV +1

Spunlaced nonwoven material for composite fiber curtain filtration and its processing method

The invention discloses a composite fiber curtain filtering spunlaced nonwoven material and a processing method. Copet composite fibers, whitened polyester fibers, and superfine polyester fibers are realized through the following steps according to the mass ratio of 1.5:2.5:1: 1) copet composite fibers , whitened polyester fiber and superfine polyester fiber are mixed according to the mass ratio of 1.5:2.5:1; 2) After the mixed raw materials are mixed and loosened, they are transported to the air box carding machine by a fan; 3) The mixed fibers are carded into a web and transported to the spunlace machine; 4) spunlace processing on the spunlace machine; 5) dehydration treatment; 6) transfer to the dryer for continuous drying and curing after spunlace processing, wherein the curing temperature of the first oven is 160±3°C, and the second The curing temperature of the second oven is 170±3°C, and the speed is 45-50m / min; 7) Calendering finishing; 8) Slitting and packaging processes. The invention can achieve the effects of printing and dyeing, discounting, polishing, etc., and has the advantages of no slurry and low cost.

Owner:SHANDONG PROVINCE WINSON NON WOVEN MATERIALS

A kind of auxiliary agent for biomass treatment and biomass gasification treatment method

ActiveCN111378513BReduce the degree of fractureInhibition formationGasification catalystsGasification processes detailsMANGANESE ACETATEManganese sulphate

The invention discloses an auxiliary agent for biomass treatment and a biomass gasification treatment method. The auxiliary agent includes component A, component B and component C; wherein, the component A includes Lewis acid, and any One or more of selected organic acids and protonic acids, the component B is a salt of IA, IIA, IIIA group metal and ammonium, and the component C is one of manganese acetate, manganese sulfate, manganese nitrate species or several. The gasification treatment method is to react the biomass raw material and the auxiliary agent after mixing, and obtain the volatile components and bio-semi-coke after the reaction; the solid-phase materials and bio-semi-coke obtained after the gas-solid separation of the volatile components are respectively fed into the After the biocoke microwave gasification reactor reacts, crude synthesis gas and activated carbon are obtained; the synthesis gas obtained after the gas-solid separation of the crude synthesis gas enters the purification reactor for treatment to obtain purified synthesis gas. The biomass gasification treatment method and system can increase the synthesis gas yield, and the tar content in the obtained synthesis gas product is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com