Patents

Literature

74results about How to "Strong bean flavor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nutritive soybean milk and method for preparing same

InactiveCN101518314AEliminate fatigueFull of nutritionFood preparationMilk substitutesNutrientSteaming

The invention discloses nutritive soybean milk and a method for preparing the same and provides a beverage food popular among customers for the catering industry. The nutritive soybean milk is prepared by milling soybeans, peach seed, fragrant rice and other two raw materials. The processing method of the nutritive soybean milk comprises the five steps of raw material preparation, soybean steaming, raw material soaking, mixed milk grinding, and swelling and heating. The nutritive soybean milk retains the original fresh palatability of soybean milk, overcomes the drawbacks of strong soybean flavor and slightly acerbic taste of the conventional soybean milk, has a palatability with strong soybean fragrance, whiteness and softness, smoothness and strong flavor and rich nutrients, is novel inprocess and low in cost, and is a popular beverage food people have for a meal and dinner party.

Owner:张黑喜

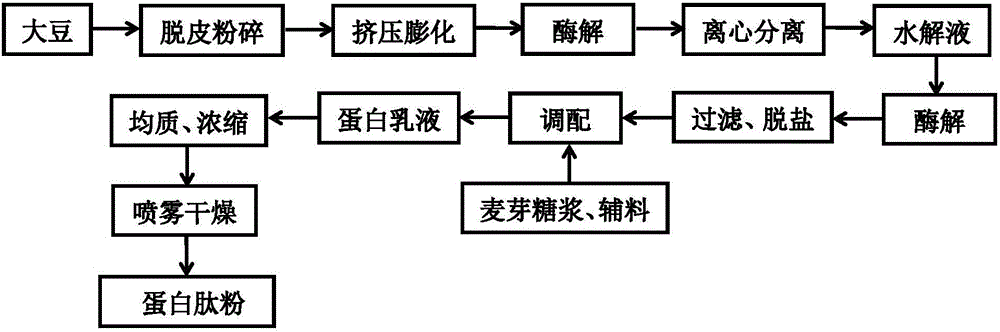

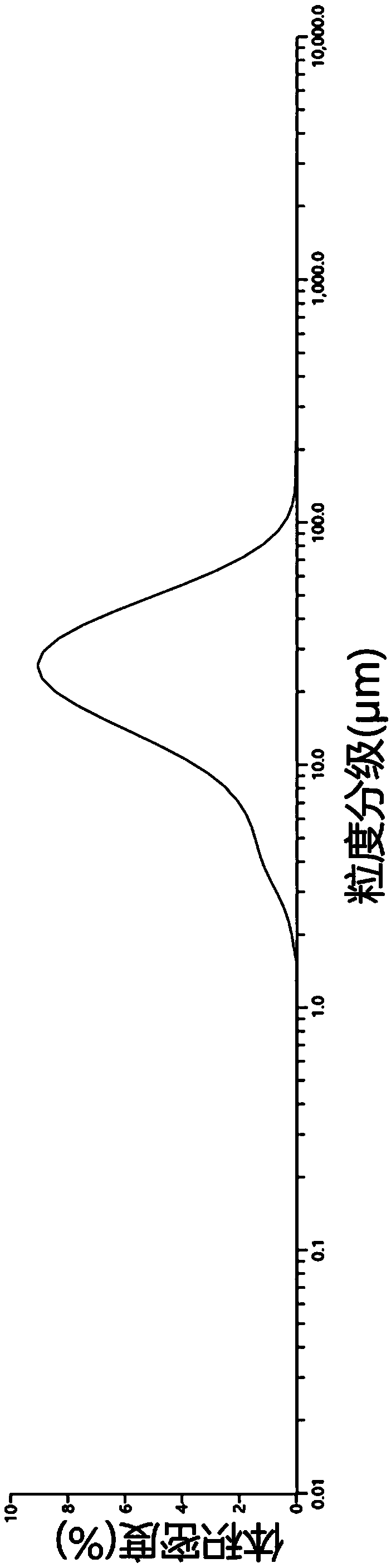

Method for synchronously extracting soybean oil, soybean milk powder and soybean dietary fiber by aqueous enzymatic method

InactiveCN105505558AEffective destructionStrong bean flavorFatty-oils/fats productionMilk substitutesFiberHydrolysate

The invention relates to a method for synchronously extracting soybean oil, soybean milk powder and soybean dietary fiber by an aqueous enzymatic method, which belongs to the technical field of plant grease processing. The method comprises the following steps: 1) dehulling soybeans and crushing the soybeans, extruding and puffing the material to obtain a puffed product; 2) adding water into an enzymatic hydrolysis reaction vessel, heating steam and adding the puffed product to obtain a mixed liquor, performing alkaline extraction on the mixed liquor, adding alkali protease for performing enzymatic hydrolysis, using a horizontal centrifuge after enzymatic hydrolysis is carried out for performing centrifugation to obtain an emulsified oil, a hydrolysate and residues; 3) using a disk centrifuge for performing centrifugation on the emulsified oil to obtain the soybean oil and a water phase, adding the water phase into the hydrolysate for concentration, and drying the material to obtain the soybean milk powder; and 4) adding water for mixing the water and the residues for homogenizing and drying a mixture to obtain the soybean dietary fiber. The method has the advantages of simple process, less enzyme usage amount, short reaction time, and low cost. The prepared high-quality soybean oil can obtain the high-nutrition partly-defatted soybean milk powder and high-oil high-protein soybean dietary fiber, and is suitable for industrial continuous production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Altitude adaptive soya-bean milk manufacture method and soya-bean milk machine thereof

The invention relates to an altitude adaptive soya-bean milk manufacture method and a soya-bean milk machine thereof. In a heating stage, the altitude adaptive soya-bean milk manufacture method comprises an altitude judgment step of providing an overflow-proof electrode, a temperature sensor and a control device with at least two soya-bean milk manufacturing procedures, wherein the overflow-proofelectrode and the temperature sensor are electrically connected with the control device; the temperature sensor detects the practical temperature value of preheated water and soya-bean contained materials till foams touch the overflow-proof electrode; the control device is preset with a temperature set value; and according to a comparison result between the practical temperature value and the preset temperature value, the soya-bean milk manufacturing procedure is selected. Compared with the prior art, the boundedness for people to use the soya-bean milk machine in the highland is solved, and people in the highland can drink the soya-bean milk with higher quality.

Owner:JOYOUNG CO LTD

Method for producing green pollution-free bean sprouts through combination gas preparing way

ActiveCN103081790AStimulus formationGrowth inhibitionCultivating equipmentsHorticulture methodsSoybean sproutMixed gas

The invention discloses a method for producing green pollution-free bean sprouts through a combination gas preparing way. The method includes the following steps: enabling seed beans to be swelled up in strong-magnetism weak-base water, wherein a potential of hydrogen (PH) value of the strong-magnetism weak-base water is 7-7.5, and magnetic induction strength of the strong-magnetism weak-base water is 500-10000 gauss; placing the seed beans which are processed through the above step into a sprout cultivation chamber for cultivating; after the seed beans are cultivated in the sprout cultivation chamber for 48 hours, continuously pumping mixed gas of carbon dioxide and ozone into the sprout cultivation chamber for 1 hour, wherein concentration of the carbon dioxide is 800 parts per million and concentration of the ozone is 10 parts per million; after gas pumping in the above step is completed for 11 hours, opening the sprout cultivation chamber for ventilating for 40 minutes; and after the seed beans are cultivated in the sprout cultivation chamber for 60 hours, pumping mixed gas of carbon dioxide and ethylene into the sprout cultivation chamber so as to enable the concentration of the carbon dioxide to be maintained in 1000 parts per million and the concentration of the ethylene to be maintained in 5-10 parts per million. The bean sprouts which are produced through the method are high in quality, good in appearance, and free of pollution.

Owner:兰州朝阳农产品开发有限公司

Drunkenness-dispelling and liver-protecting bean product and its manufacturing method

InactiveCN101077154AIncrease hangover effectFresh and delicate tasteNervous disorderFood preparationCITRUS MEDICA FRUITSide effect

The present invention is one kind of sobering-up and liver protecting bean product and its making process, and aims at increasing the nutritious components and health functions of bean product. The sobering-up and liver protecting bean product is produced with soybean 100 weight portions, kudzuvine flower 3-6 weight portions, kudzu vine root 5-13 weight portions, bitter orange seed 3-10 weight portions, finger citron 0.5-1 weight portion. The product of the present invention has no side effect and is suitable for eating regularly.

Owner:HEILONGJIANG UNIV

Health care nutrition powder

InactiveCN103125547AFull of nutritionGood nutrition and health careDough treatmentSorghumGround corn

Health care nutrition powder comprises main material and auxiliary material. The main material comprises, by weight, 30%-40% of wheat powder, 30%-40% of buckwheat powder, 10%-20% of corn powder, 3%-8% of sorghum powder and 5%-10% of barley powder, and the auxiliary material comprises, by weight, 2%-4% of walnut powder, 2%-4% of sesame powder and 3%-3% of soybean powder. The health care nutrition powder is scientific and reasonable in formula matching, easy to produce and manufacture, and abundant in nutrition, the main material and the auxiliary material are packed in a separated mode, and the walnut powder, the sesame powder and the soybean powder in the auxiliary material are respectively processed, smashed and packed in a separated mode. According to types of food manufacture or requirements of eaters, various auxiliary materials are added simultaneously and wholly, alternatively, one or two of the walnut powder, the sesame powder and the soybean powder can be chosen to be added, and use is convenient.

Owner:曹松和

Preparation technology of soybean germ tea

The invention discloses a preparation technology of soybean germ tea, which comprises the following steps: skin of soybean is separated through an air classification sizer, and bean grains are removed by sieving through a 10-mesh sieve ; soybean germs are cleaned up, after dewatering, surface moisture is dried by strong wind rapidly; the soybean germs cleaned up are steamed for 25 to 35 minutes; the soybean germs are placed into a forced-air oven with the temperature of 100 to 110 DEG C for baking for 2 to 3 hours; and packaging is performed after graded screening. The prepared soybean germs not only keep the original shapes and are free from aleuron grains, but also are crisp, have a better dissolution effect after water soaking, are light yellow in color, and have aromatic flavor.

Owner:谷神生物科技集团有限公司

Method for making oil bean curd

InactiveCN106720446ADelicate and smooth tasteGood foam expansionCheese manufactureFood scienceChemistryFlavor

The invention relates to a method for making bean curd, and in particular relates to a method for making oil bean curd. The method includes steps of screening, soaking, grinding into milk, filtering the milk, boiling the milk, solidifying, molding, cutting, cooling, frying with oil, cooling, encapsulating and the like. In the process of boiling of the milk and solidifying, CO2 gas is introduced to activate milk, the made oil bean curd tastes more delicate and tender; at the same time, by use of N2 for cooling the oil bean curd, the N2 is absorbed into oil bean curd blocks, after oil frying, the oil bean curd is more soft, good in foaming and expanding properties, and the prepared oil bean curd is thin in skin, soft, glutinous and elastic, and has good crispy property and skin gloss and rich bean flavor and oil fragrance.

Owner:嘉禾县亮亮豆制品加工有限公司

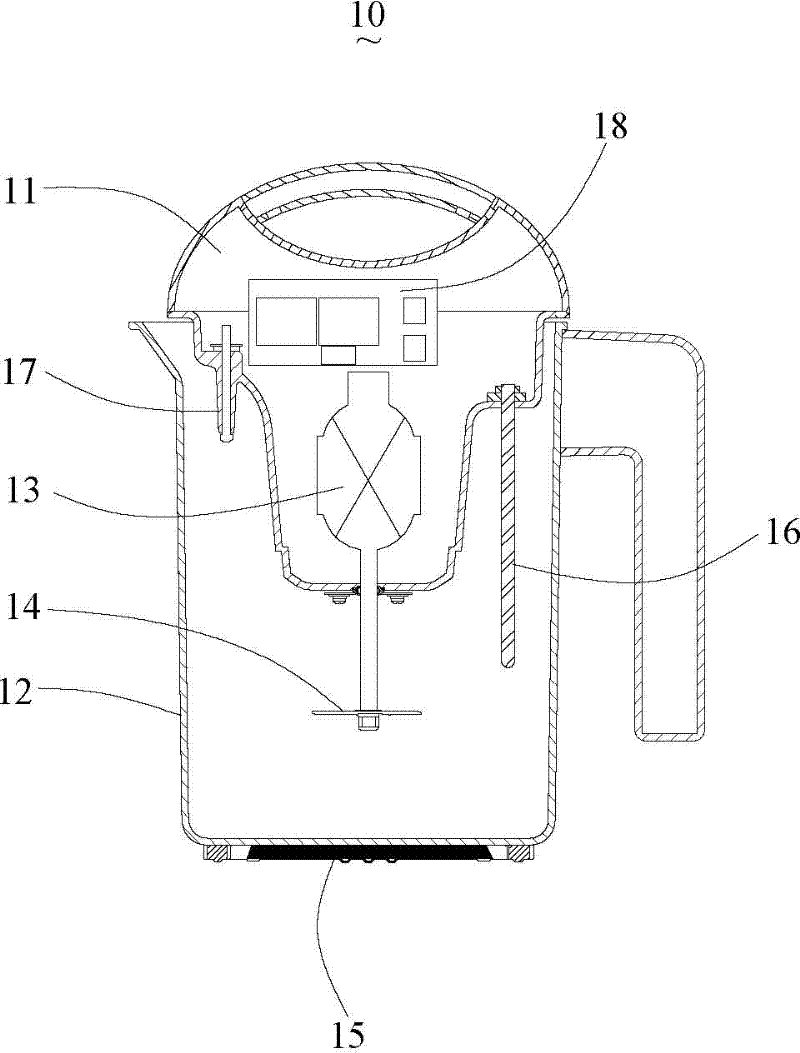

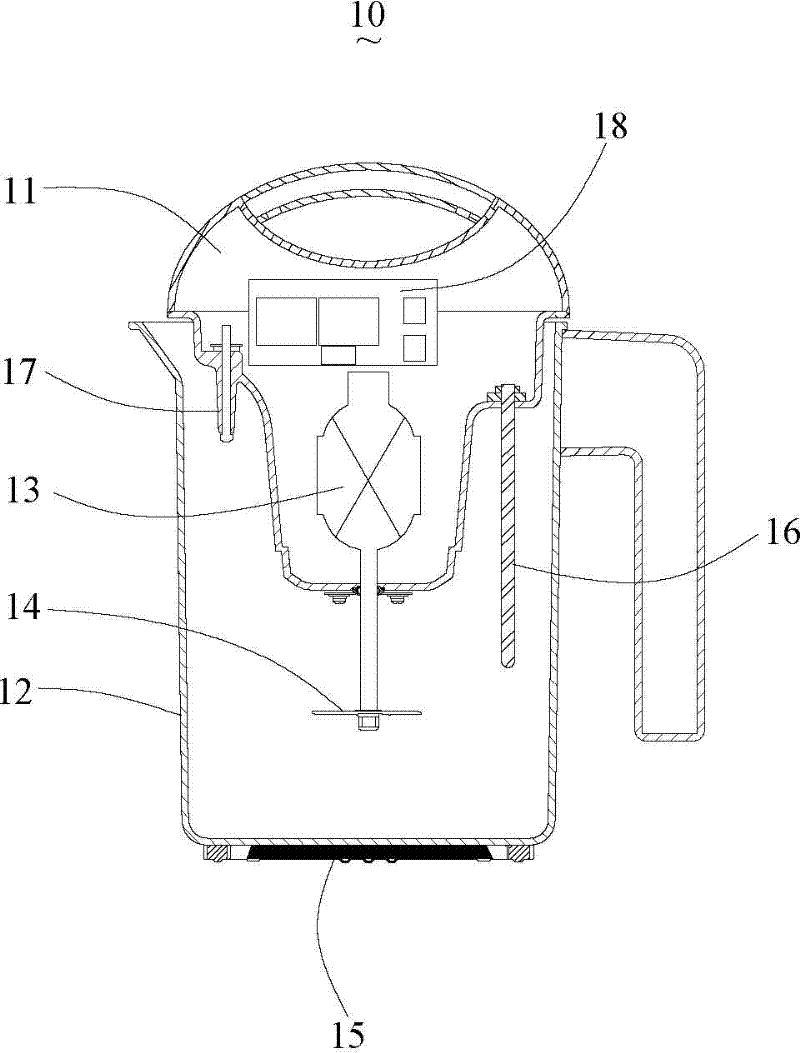

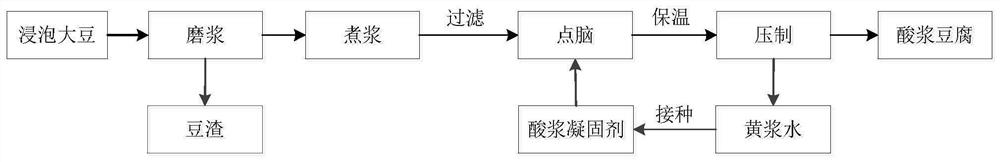

Acid pulp tofu rich in aglycone-type isoflavones and preparation method of acid pulp tofu

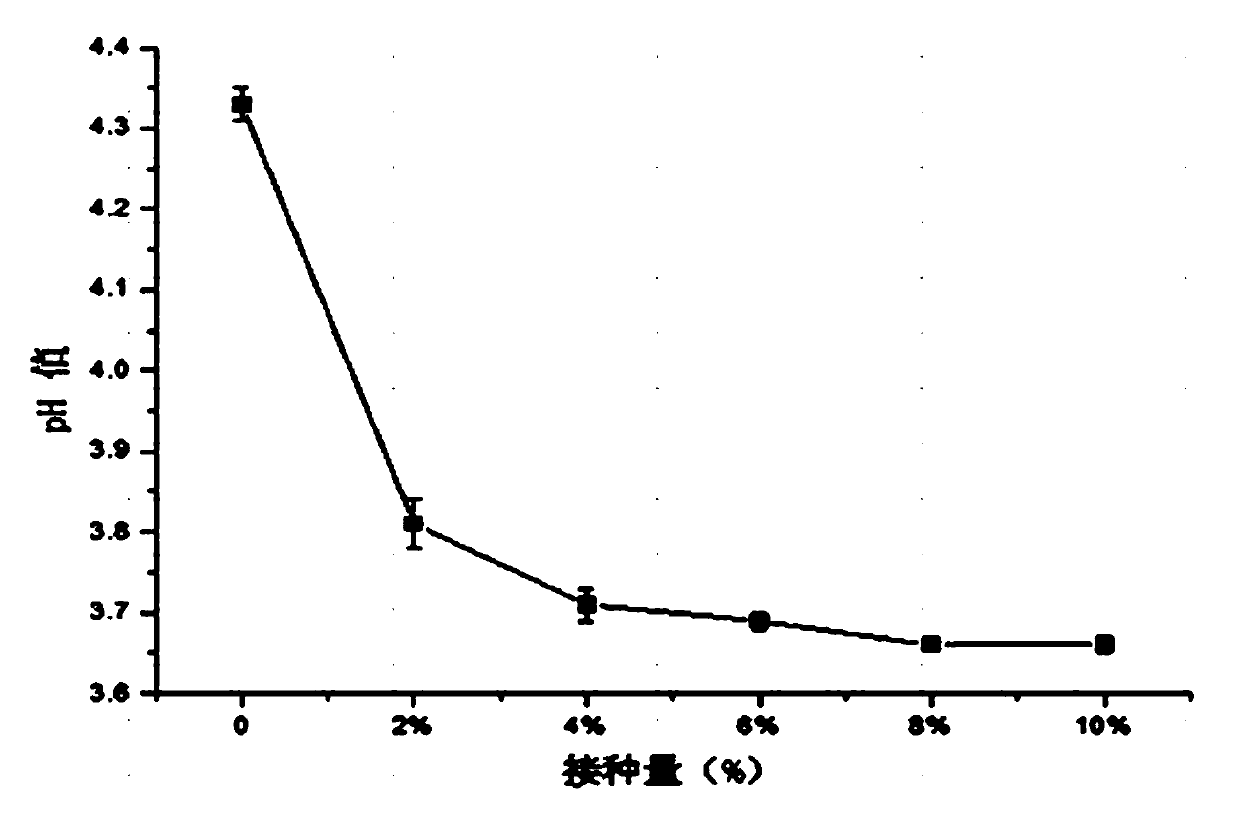

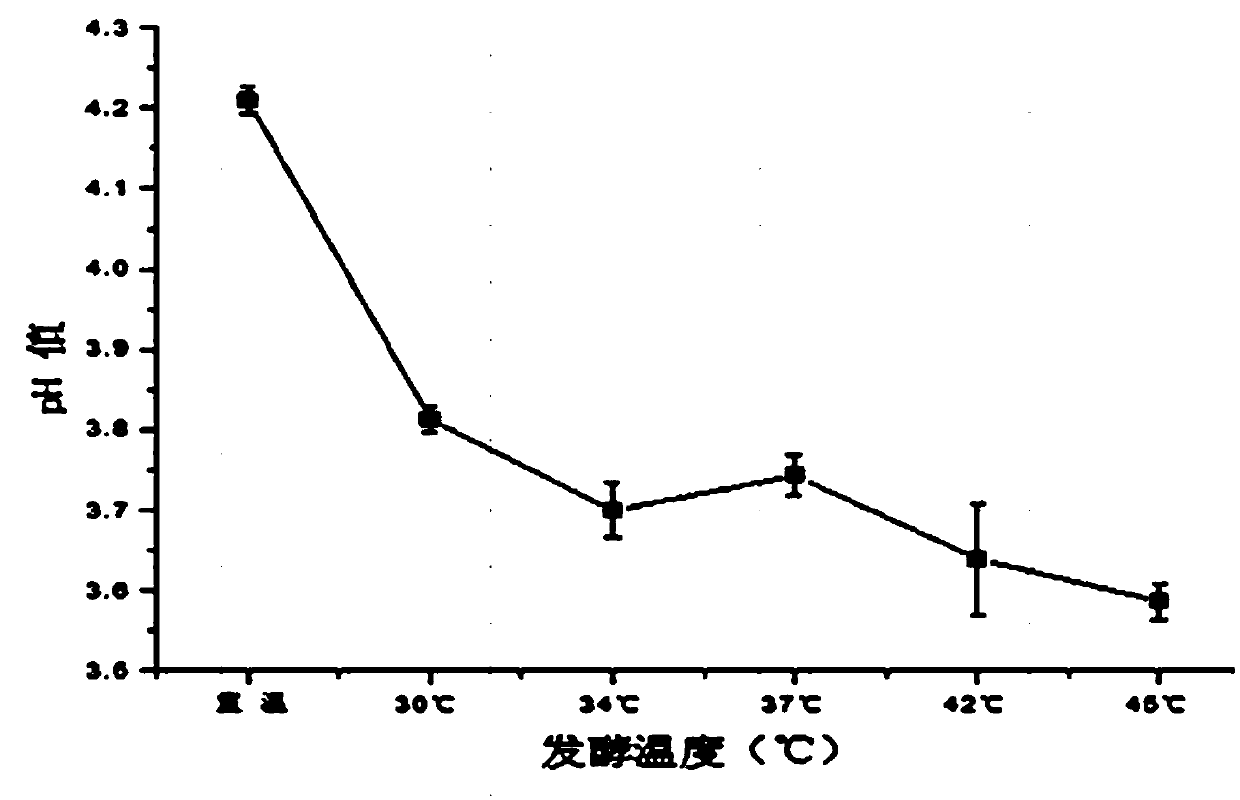

PendingCN111616227AProduction specificationRegulatory usabilityBacteriaMicroorganism based processesBiotechnologyLactobacillus

The invention relates to the technical field of food processing, in particular to an acid pulp tofu rich in aglycone-type isoflavones and a preparation method of the acid pulp tofu. The preparation method of the acid pulp tofu rich in aglycone-type isoflavones includes the following steps that an acid pulp coagulant is prepared, specifically, Lactobacillus casei and / or lactic acid bacteria are inoculated into yellow serofluid for fermentation to prepare the acid pulp coagulant; and the acid pulp tofu is prepared, specifically, the acid pulp coagulant obtained in the step of preparing the acidpulp tofu is added to soy milk to obtain the acid pulp tofu. Lactobacillus casei is utilized to ferment yellow serofluid to convert glucoside-type isoflavones in yellow serofluid into aglycone-type isoflavones in the largest extent to obtain the acid pulp coagulant rich in high-active aglycone-type isoflavones, the acid pulp coagulant is used for the production and processing of the acid pulp tofu, the acid pulp tofu rich in aglycone-type isoflavones can be prepared, and the nutritional value of tofu is improved.

Owner:SOUTH CHINA AGRI UNIV

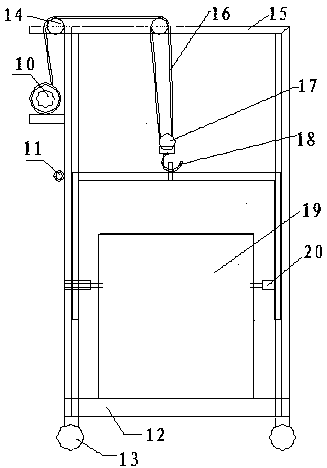

Method for processing egg bean curd with three-grinding and slurry punching machine technology

The invention relates to a method for processing egg bean curd with a three-grinding and slurry punching machine technology. The method comprises the following steps of: (1) selecting high-quality soybean, and dipping for 4-12 hours according to season, air temperature and water temperature; (2) extracting high-quality soy milk with three-grinding slurry purifying technology; (3) heating the soy milk inside a cooking pot to more than 120 DEG C with high pressure and high temperature steam so as to perform antivirus sterilization, and then putting the cooked soy milk in an iron large fire pot; (4) boiling the soy milk with the large iron fire pot, and removing beany flavor in the soy milk; (5) filtering the cooked soy milk through a filter screen and then putting in a slurry barrel of a slurry punching machine; and (6) putting in discs at a proper time, and then putting in a pressure rack for pressing and forming so as to obtain the finished product of egg bean curd. The egg bean curd is prepared from soy milk and egg liquid through a protein solidifier with a new technology, and reaches the standard of high-quality bean curd.

Owner:东营市鲁唐八福豆制品有限公司

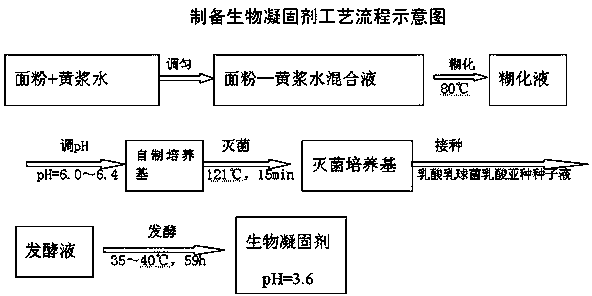

Biological coagulator, preparation method thereof and application thereof

InactiveCN103355570AHigh nutritional valueExtended shelf lifeFood preparationBiotechnologyStaphylococcus lactis

The invention discloses a biological coagulator, a preparation method thereof and an application thereof, and belongs to the technical fields of food and food processing. The biological coagulator is prepared by a step of adding flour according to a ratio into yellow serofluid that is used as a culture medium, wherein the weight ratio of the flour to the tofu yellow serofluid is 4-8:100; a step of adjusting pH of the tofu yellow serofluid to 6.0-6.4; a step of inoculating 9-15% of a lactococcus lactis stock solution; and a step of fermenting at a culture temperature of 35-40 DEG C for 50-70 h. The invention further discloses the preparation method of the biological coagulator and the application of the biological coagulator in preparing tofu. The tofu prepared by using the biological coagulator has suitable hardness, fine and smooth texture, no collapse after being cut and strong bean smell. A shelf life of the tofu at 4 DEG C is 11-12 days which is 3-4 days longer than a shelf life of a common acid-fluid tofu.

Owner:GUIZHOU UNIV

Bean jelly and preparation method thereof

The invention discloses bean jelly. The bean jelly comprises the following components in parts by weight: 15-25 parts of pea meal, 90-110 parts of water and 0.02-0.04 part of rapeseed oil. The invention further provides a preparation method of the bean jelly. The preparation method comprises the following steps: slurrying, weighing, stirring, brushing oil, decocting, sizing in a basin, stewing for ageing and shredding. The prepared finished product bean jelly is in the color of rice flower, is bright but not transparent, soft and continuous and is unique in taste.

Owner:四川川北凉粉饮食文化有限公司

Method for preparing novel soybean yogurt

InactiveCN103891901AHigh nutritional valueSensual color brighteningMilk preparationMilk substitutesFlavorRoom temperature

The invention discloses a method for preparing novel soybean yogurt. The method comprises the following steps: soaking soybeans in an aqueous solution containing NaHCO3, and soaking for 10-12 hours; dehulling the soaked soybeans; soaking the dehulled soybeans in hot water at the temperature of 80-90 DEG C for 5-10 minutes, pulping at the temperature of 80-90 DEG C, filtering by using 120-mesh filter cloth; adding a flavoring agent into the filtrate; sterilizing in a high-pressure steam sterilization pot at the temperature of 121 DEG C for 20-30 minutes; cooling to room temperature, and inoculating a novel leavening agent with the weight which accounts for 4-5 percent of the total weight under sterile conditions, wherein the novel leavening agent is formed by combining lactobacillus bulgaricus and lactobacillus acidophilus according to a rate of 1:(2.5-3.5), and fermenting under the condition of 39-42 DEG C for 5-6 hours; and refrigerating and preserving fermented soya-bean milk at the temperature of 0-4 DEG C. The soybean yogurt prepared by adopting the method disclosed by the invention has the advantages of bright sensory color, fine and smooth curd structure, strong bean flavor and unique flavor and taste.

Owner:SHENZHEN FUYIN FOOD GRP

Preparation method of instant soybean protein powder

PendingCN111587948AImprove dissolution rateLow energy consumptionProtein composition from vegetable seedsVegetable proteins working-upNutritionMaltodextrin

The invention discloses a preparation method of instant soybean protein powder. The method comprises the following steps of S1, selecting plump soybeans without worm damage, and putting the soybeans into water for soaking; S2, adding water into the soaked soybeans, grinding the soybeans into thick liquid, and centrifugally separating and deslagging the obtained thick liquid to obtain slurry; S3, adjusting the pH of the slurry to 6.5, and adding neutral protease into the slurry for enzymolysis to obtain enzymatic hydrolysate; S4, treating the enzymatic hydrolysate in a high-frequency electromagnetic field to obtain a solubilizing solution; S5, performing rapid heating, flash evaporation and rapid cooling on the mixed solution to obtain a sterilized solution; S6, adding lecithin, beta-cyclodextrin and maltodextrin into the obtained sterilized solution, and performing uniform mixing to obtain a mixed solution; S7, homogenizing the mixed solution for three times to obtain a homogenized solution; S8, carrying out spray drying on the homogenized solution to obtain soybean protein powder; and S9, adding silicon dioxide powder into the obtained soybean protein powder, and performing uniform mixing so as to obtain the instant soybean protein powder. The dispersibility and solubility of the soybean protein powder are improved, nutrition is balanced, and protein is more easily and efficiently absorbed by the human body.

Owner:PINGDINGSHAN TIANJING PLANT ALBUMEN

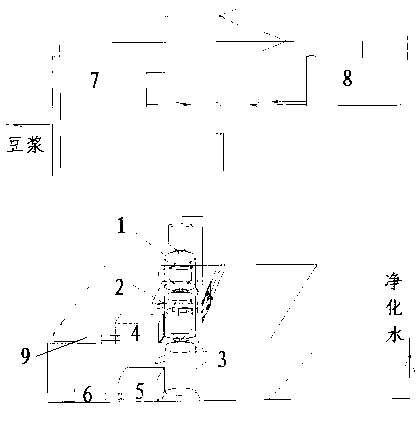

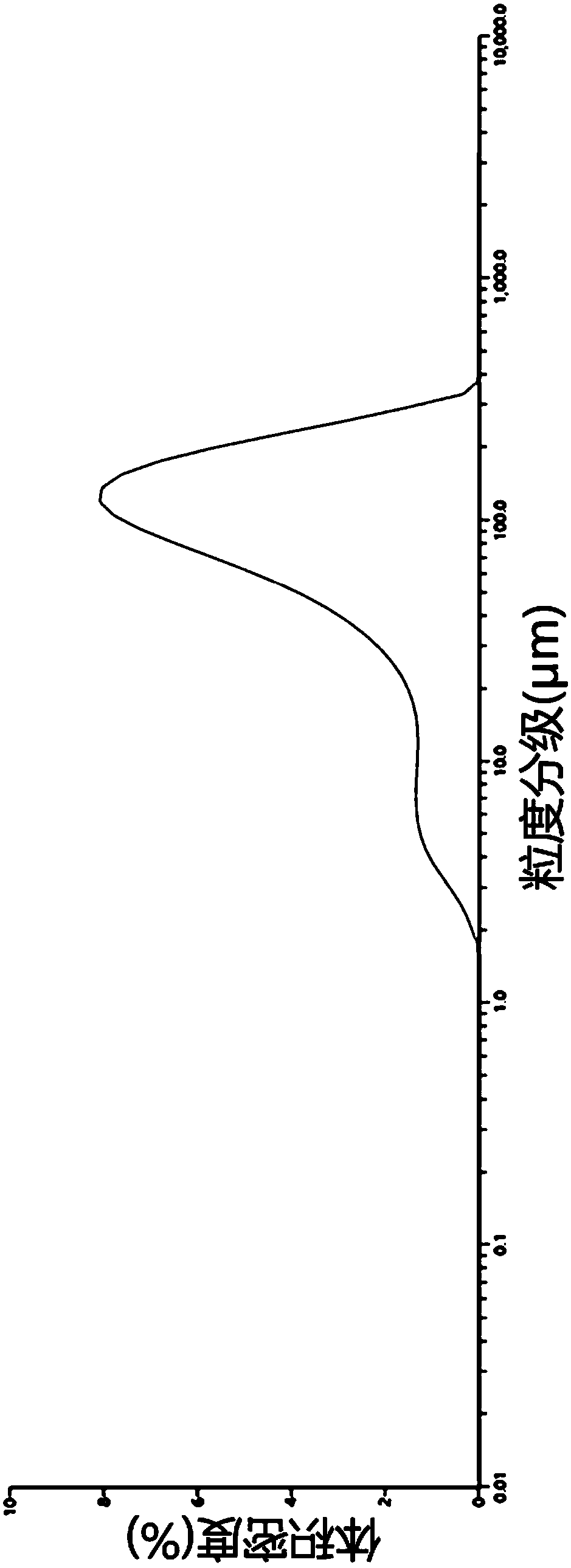

Preparation method of whole-soybean nutritive soybean milk

The invention discloses a preparation method of whole-soybean nutritive soybean milk. The whole-soybean nutritive soybean milk is processed through an advanced colloid mill. Through the colloid mill, foods can be ground into granules of 2-50 microns. Compared with a conventional mechanical mill, the colloid mill has the advantages that distinct granules are not generated, bean dregs are not produced, and all the nutrients of soybeans are made into the soybean milk, so that resources are saved, the nutrient value of the soybean milk is also increased, and the whole-soybean nutritive soybean milk has important significance on improving the constitutions of residents. The whole-soybean nutritive soybean milk disclosed by the invention is rich in mouth feel, fine, smooth, refreshing, rich in bean fragrance and free from beany flavor, and the total points of the whole-soybean nutritive soybean milk on sensory evaluation are higher than that of conventional soybean milk; according to the whole-soybean nutritive soybean milk processed through the colloid mill, inherent ingredients of the soybeans are wholly processed into the soybean milk, no bean dregs are discarded, the nutrient value is greatly increased, protein, fat, carbohydrate, vitamins and mineral substances of the whole-soybean nutritive soybean milk are notably improved than those of conventional soybean milk, particularly the total dietary fibers are obviously increased, and the dietary fibers have good effects of preventing diabetes, tumors and cardiovascular and cerebrovascular diseases.

Owner:CANGZHOU MEDICAL COLLEGE

Aqueous enzymatic method for preparing protein peptide powder from soybean hydrolysate

The invention relates to an aqueous enzymatic method for preparing protein peptide powder from soybean hydrolysate and belongs to the technical field of soybean product processing. The method comprises the steps as follows: (1) soybeans are peeled and crushed, extrusion treatment is performed, and an extruded product is obtained; (2) water is injected into an enzymatic hydrolysis reaction tank, steam heating is performed, the extruded product is added, a mixed solution is obtained, the pH value of the mixed solution is adjusted, and alkaline protease is added for enzymolysis; (3) centrifugal separation is performed with a horizontal centrifuge after enzymolysis, and emulsified oil, a hydrolysate I and residues I are obtained; (4) isolated soy protein is added to the hydrolysate I, the pH value is adjusted, pepsin is added for enzymolysis, centrifugal separation is performed after enzymolysis, soybean oil, a hydrolysate II and residues II are obtained, alkali is added to the hydrolysate II for neutralization until the pH is neutral, and desalination is performed with an ultrafiltration membrane; (5) malt syrup, maltodextrin and other auxiliary materials are added to desalinated hydrolysate for blending, uniform mixing is performed, a protein emulsion is formed, homogenization, vacuum concentration and spray drying are performed, and protein peptide powder is obtained. The method adopts a simple process and is low in cost, the prepared protein peptide powder has high nutritional value, has strong milk aroma, tastes fine and has good digestibility, besides, the instant solubility of the protein peptide powder is significantly improved, and the protein peptide powder is suitable for industrial continuous production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

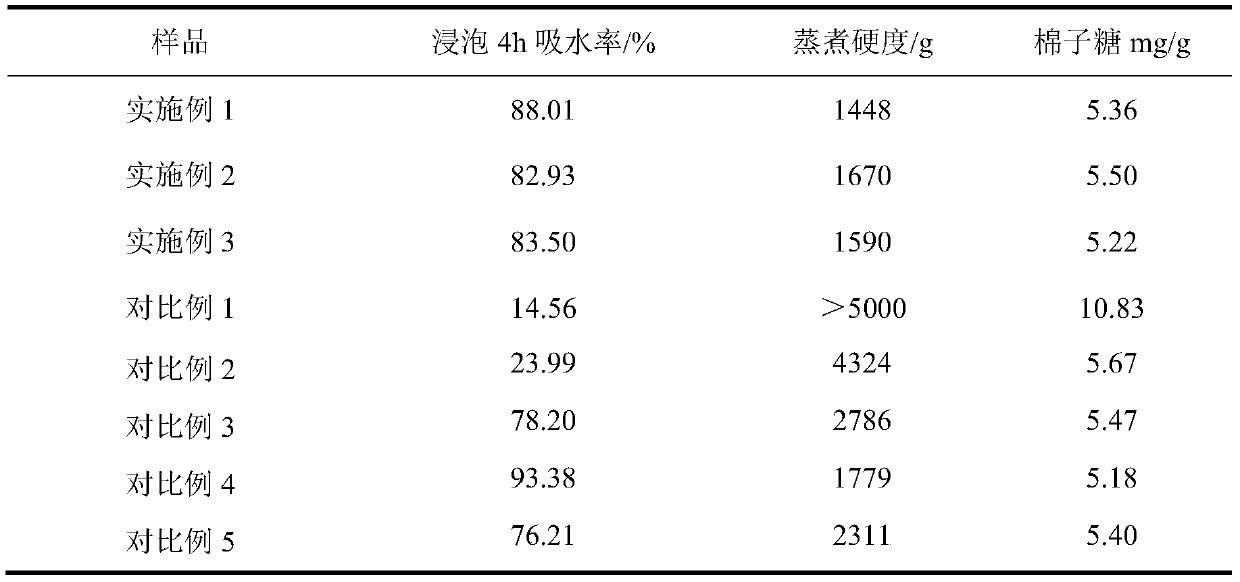

Processing method of soaking-free mixed beans

PendingCN110495567AImprove water absorptionDecreased cooking hardnessFood thermal treatmentFlavorEmbryo

The invention discloses a processing method of soaking-free mixed beans, and belongs to the technical field of grain deep processing. By combining water supplementing and high-temperature fluidizationtreatment on mixed beans, a micro-slit of 0.5-1mm is formed in one side of a mixed bean embryo, and the diameter of capillary pores among cells in seeds is increased by two times or more; meanwhile,through the treatment, the internal structure of the seeds becomes loose, the integrity of cell walls is damaged, and starch is partially gelatinized; and due to the changes, the water absorption performance of the mixed beans is remarkably improved, the cooking hardness is remarkably reduced, the problem that staple food consumption is hindered due to difficult water absorption, long cooking time, hard mouth feel and a poor flavor of the mixed beans is effectively solved, the purpose that the mixed beans can be well cooked together with white rice without being soaked is achieved, and staplefood consumption of the mixed beans is promoted. When cooked together with the white rice, the mixed bean product is soft, fine and smooth in mouth feel, free from granular sensation and rich in beanflavor. In addition, the content of raffinose in the mixed beans is remarkably reduced, and the flatulence problem after the mixed beans are eaten can be effectively solved.

Owner:JIANGNAN UNIV

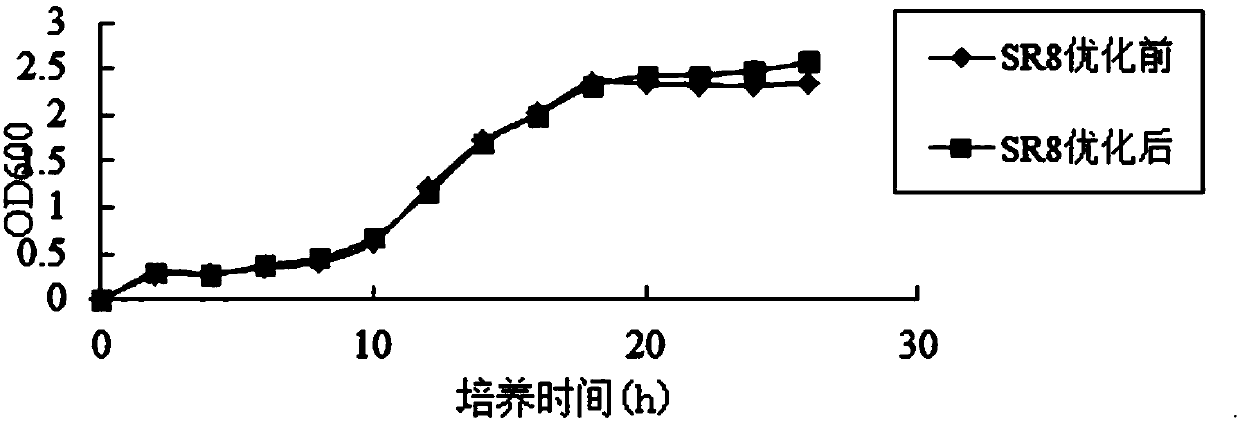

Compounded coagulating agent of soft tofu

ActiveCN108013154AFast acid productionImprove food safetyBacteriaMicroorganism based processesActivation methodMicrobiology

The invention relates to a compounded coagulating agent of soft tofu. The agent is prepared through fermenting one or more yellow serofluid, wash rice and vegetable pickled water by an activated Lactobacillus strain to obtain physalis alkekengi and compounding the physalis alkekengi and calcium sulfate proportionally. The Lactobacillus strain is collected in CCTCC on September 26, 2016, has a collection number of CCTCC No: 2016528 and has a classification name of SR8 (Lactobacillus kimchi SR8). An activation method of the Lactobacillus comprises the steps of inoculating an MRS liquid culture medium with the strain which is collected at the temperature of 4 DEG C, carrying out culture for 24 hours at the temperature of 37 DEG C, and carrying out continuous passage for 3 to 5 times for lateruse. According to the compounded spot-marinating agent of the soft tofu, the Lactobacillus rapidly produces acid by using carbohydrates, thus, the acidification time is shortened, the stability of acidity is improved, the process is simple, and the operation is simple and convenient; the agent has the advantages of safety, low cost, no pollution, continuousness in production, high production efficiency, good product bioactivity and stability and the like.

Owner:GUIZHOU UNIV

Red bean nourishing composite health-care coarse cereals and preparing method thereof

InactiveCN103519194ASweet tasteStrong bean flavorFood ingredient functionsFood preparationPolygonum fagopyrumAcute hyperglycaemia

The invention discloses red bean nourishing composite health-care coarse cereals and a preparing method of the red bean nourishing composite health-care coarse cereals. The red bean nourishing composite health-care coarse cereals are composed of raw materials including red beans, buckwheat, maize, broomcorn, millets, wheat germs, sweet potatoes, green beans, peanuts, sesames, hazelnut kernels, pecans, sweet basil, zornia gibbosa, cistanche and the like. The prepared red bean nourishing composite health-care coarse cereals have the advantages that the red beans are pure, fragrant and sweet in taste and capable of avoiding tooth adhesion, the fragrance of the red beans is obvious and strong, and the red bean nourishing composite health-care coarse cereals are particularly suitable for being eaten by the old and the patients with hyperglycemia, hypertension, hyperlipidemia and obesity.

Owner:HEFEI CAIJIN FOOD

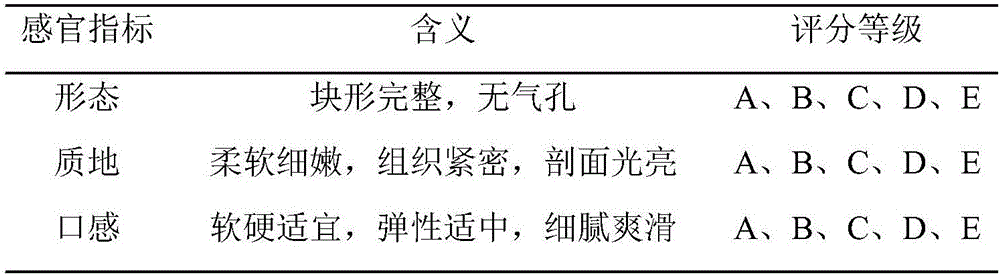

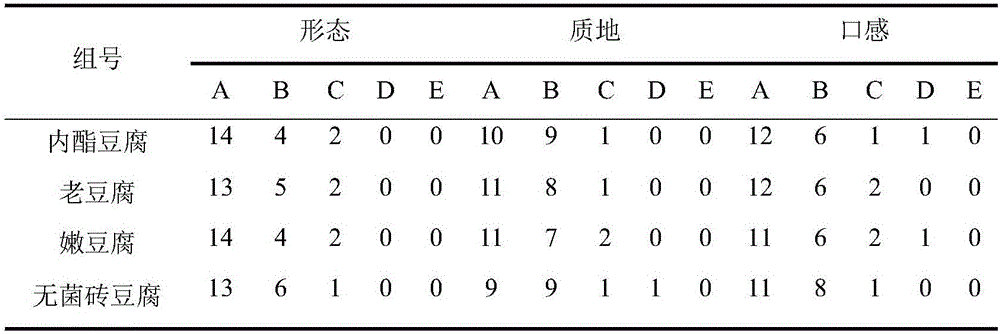

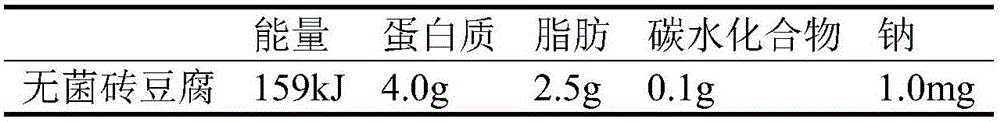

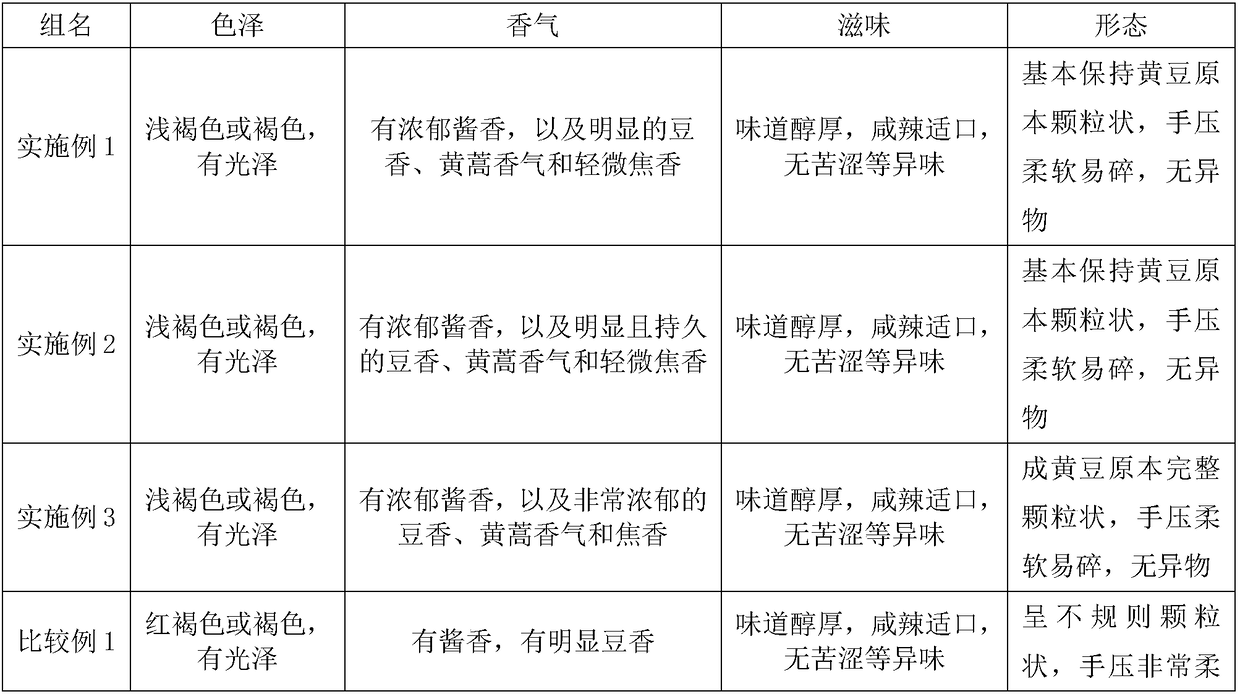

Production method for aseptic brick tofu

ActiveCN106070683AStrong bean flavorWhite and tenderCheese manufactureFood scienceSoybean productProcess engineering

The invention discloses a production method for aseptic brick tofu and belongs to the technical field of bean product processing. The production method comprises the following steps that soybeans are screened, soaked, peeled and ground into milk; the milk is boiled, milk-residue separation is conducted, and homogeneity passing is conducted to obtain soybean milk meeting the requirements; the soybean milk is poured into an aseptic tank after subjected to UHV high temperature sterilization; a coagulator is dissolved to obtain a coagulator solution with the mass fraction being 15%-20%, the coagulator solution is poured into the aseptic tank after subjected to sterile filtration, the soybean milk and the coagulator are mixed evenly in a certain stirring mode, and evenness is kept; and an aluminum foil aseptic brick is adopted for aseptic filling, and the aseptic brick tofu is obtained through a dry heat forming method. The tofu produced through the production method is strong in soybean fragrance, white and tender in color, bright and clean in cutting face, rich in elasticity and moderate in hardness, and the problems that most tofu in markets is short in shelf life, liable to be subjected to external force compression deformation and difficult to carry are solved. In addition, the product is free of compression, so that the yield is increased significantly, and the standardization level and the automation degree are high.

Owner:JIANGNAN UNIV

Protoplasm soymilk and preparation method thereof

InactiveCN103621642AStrong bean flavorHigh nutritional valueMilk substitutesFood scienceProtoplasmFlavor

The invention discloses protoplasm soymilk and a preparation method thereof. The protoplasm soymilk comprises the following materials by percent: 86% of purified water, 10% of non-GMO (non-Genetically Modified Organism) soybean, 3.38% of saccharose, 0.3% of a stabilizer, 0.3% of soymilk oil and 0.02% of acesulfame. The preparation method comprises the following steps: cleaning and steeping raw materials, and refining, wherein the slurry obtained for the first time as the raw material; carrying out colloid grinding so that the thickness of the slurry is uniform, centrifuging to remove slag, boiling the slurry continuously, filtering the slurry, emulsifying and shearing, fully mixing an emulsifier with the slurry, sterilizing with UHT (Ultra Heat Treated) sterilization equipment, canning and carrying out pasteurization, quenching with ice water, and cooling the bottled protoplasm soymilk with ice water at the temperature of 2-5 DEG C for 30-35 minutes. According to the protoplasm soymilk and the preparation method thereof, the soymilk is ground by the most proper material ratio, and the protoplasm soybean milk is processed with the slurry obtained from soybean for the first time, so that the bean flavor is strong and the nutritive value is high.

Owner:SUZHOU JINJI FOODS

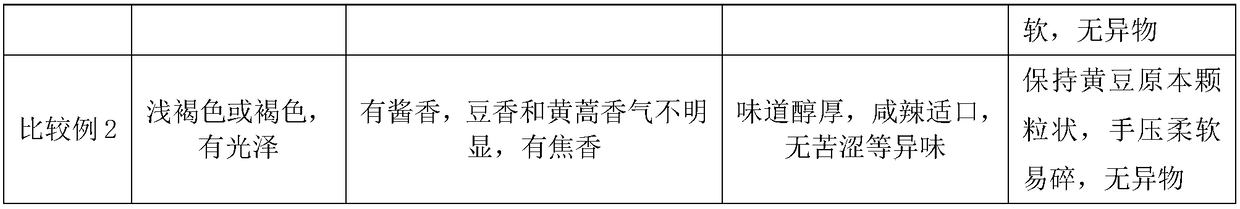

Preparation method of artemisia scoparia soybean sauce

The invention discloses a preparation method of artemisia scoparia soybean sauce. The preparation method comprises the following steps: soaking, stir-frying, boiling with water, peeling, carrying outfirst-time fermentation, charging, carrying out second-time fermentation and the like. In a stirring and frying process, soybeans are repeatedly stirred and fried with big fire and then are stirred and fried with small fire; in a first-time fermentation process, artemisia scoparia or pre-flowering artemisia scoparia is spread on the soybeans. The finally prepared artemisia scoparia soybean sauce has a scorched soybean aroma and prepared soybean sauce has a richer and attractive aroma; the soybean sauce has a flavor with better layering; the pre-flowering artemisia scoparia is selected and thecontent of volatile oil components in plants is the greatest; the special aroma of the artemisia scoparia is thicker; the soybeans are stirred and fried and the artemisia scoparia is spread, so that an obvious synergistic enhancement effect can be realized; the prepared soybean sauce has a thicker sauce flavor; the pre-flowering artemisia scoparia is spread and the aroma of the artemisia scopariais more obvious; the prepared soybean sauce keeps an original grain appearance so that people have better appetite after seeing the soybean sauce; more volatile oil components permeate into the soybeans so that the soybean sauce has more nutrients and better flavor.

Owner:HUBEI UNIV OF ARTS & SCI

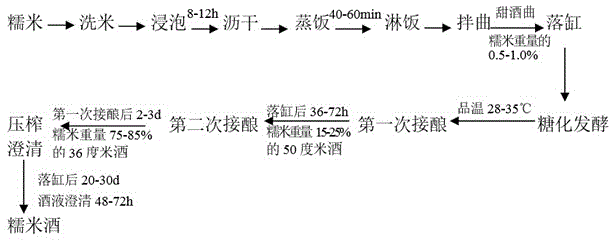

Brewing method of black bean and glutinous rice wine

InactiveCN105462787AFully fragrantWith health functionAlcoholic beverage preparationSocial benefitsHusk

The invention discloses a brewing method of a black bean and glutinous rice wine. The brewing method comprises the following steps: before a traditional glutinous rice wine broiling and boiling process, adding prepared black beans and gingers into wine liquid of a glutinous rice wine according to a bean-wine weight ratio of 1:(20-40) and a ginger-wine weight ratio of 1:(40-60); then performing broiling and boiling by using peanut shells and rice husks as a fuel, and when the temperature of the wine liquid reaches 75-95 DEG C, maintaining the temperature for 6-9 hours with slow fire; and then clarifying the wine liquid after broiling and boiling for 3-5 days, and then performing bending and storage. The brewing method disclosed by the invention is based on a traditional method combining the glutinous rice wine and black beans for drinking in Hakka areas, the black bean and glutinous rice wine produced after a long time of broiling and boiling can fully combine effects of the black beans and the glutinous rice wine, is tawny, clear and transparent, is mellow in mouthfeel, has strong bean fragrance and light ginger fragrance, is sweet-scented and pleasant in overall taste, is rich in nutrition, is convenient to drink, and has a healthcare function. The brewing method disclosed by the invention also can open up a new approach for deep processing of black beans and gingers, improve added values of products, and increase economic and social benefits of enterprises.

Owner:河源市绿纯酿酒厂

Formula of novel ecological coagulator for bean products and production technology thereof

InactiveCN102885164AStrong bean flavorFull of nutritionCheese manufactureFood scienceNutrientGluconolactone

A formula of a coagulator for bean products and a production technology relate to a method for processing the coagulator for bean products. The formula is compounded from three coagulators as follows: by weight, 60% of magnesium chloride, 35% of calcium sulfate and only 5% of gluconolactone. According to the method, various beans are ground into soya-bean milk, and the coagulator is used to solidify the soya-bean milk so as to obtain a bean product. Prepared bean products (Tofu, Tofu pudding and the like) have strong bean flavor, are rich in nutrients, and are endowed with a taste different from the taste of traditional bean products.

Owner:夏述超

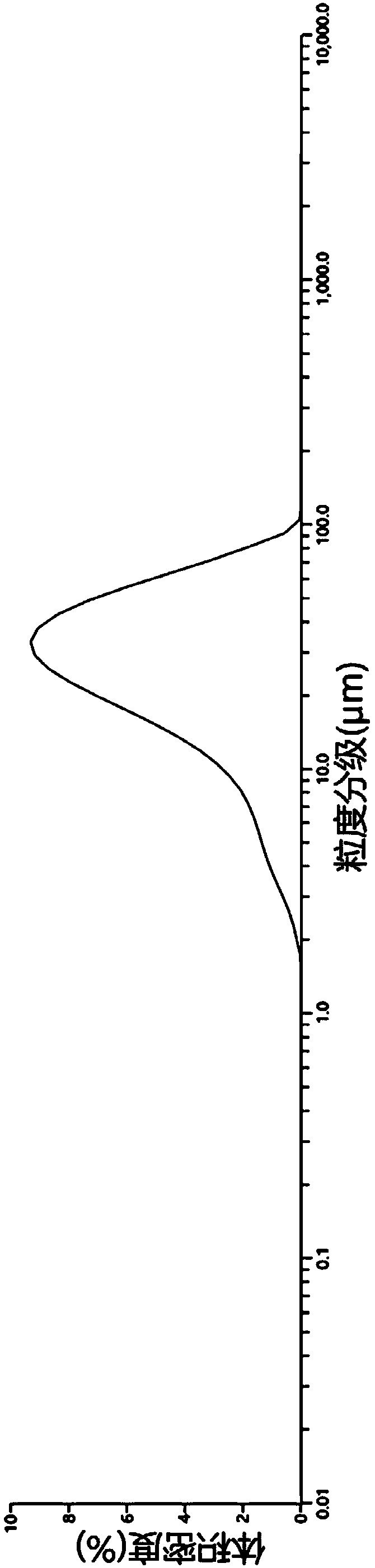

Whole soybean milk preparation method with high-pressure jet homogenization as main process

InactiveCN111134195AAvoid the potential risk of breedingReduce processing timeMilk substitutesFood scienceSoybean hullsProcess engineering

The invention provides a whole soybean milk preparation method with high-pressure jet homogenization as a main process. The method comprises the following steps: baking soybeans and performing soybeanhull separation; mixing the obtained soybeans after soybean hull separation with hot water, and performing dry refining; performing high-pressure jet homogenization on the soybean milk raw pulp obtained by dry refining; and performing pulp-boiling and enzyme inactivation on the soybean milk raw milk after high-pressure jet homogenization to obtain the whole soybean milk. The invention also provides the whole soybean milk prepared by the method. The invention provides the whole soybean milk preparation method using dry refining as a main refining manner and high-pressure jet homogenization asa main crushing manner. The method can meet high-capacity production of enterprises at present, and the production capacity of the method can be basically the same as that of common normal-temperaturedairy products. At the same time, the processing steps are greatly optimized, and the processing steps and energy consumption are greatly reduced. At the same time, the processing time is shortened,and the excessive loss of soybean nutrients caused by long-term high temperature in the process is reduced.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Preparation method of chickpea bean curd

InactiveCN111034811ARich varietyImprove organizationCheese manufactureFood scienceBiotechnologyCompression molding

The invention relates to the technical field of preparation of bean curd, in particular to a preparation method of chickpea bean curd, which comprises the following steps: (1) carrying out screening and removing impurities; (2) carrying out soaking with clear water for 8-10 hours; (3) carrying out grinding for at least two times; (4) filtering the pulp with a 120-mesh sieve; (5) boiling the pulp for at least 5 minutes, and then adjusting the pH value to 6.8-7.2; (6) carrying out curdling, namely, carrying out curdling by using bittern as a coagulator; (7) standing; and (8) pouring the uncongealed bean curd into a mold, and carrying out compression molding for 25-35 minutes to obtain the chickpea bean curd. The invention provides the preparation method of the chickpea bean curd, and an optimal process for preparing the chickpea bean curd is found, so that the product has an excellent solidification effect and a better tissue form, nutritional ingredients of chickpea and soybean supplement each other and are given full play to the maximum extent, and the variety of bean products is enriched.

Owner:JILIN AGRICULTURAL UNIV

Novel beancurd jelly and preparation process thereof

InactiveCN106819858AEffective Extraction ProcessingDelicate and smooth tasteFood ingredient functionsAdditive ingredientSweetness

The invention discloses novel beancurd jelly and a preparation process thereof. The novel beancurd jelly is prepared by the following steps: taking soybean, rose and black soya bean as raw materials, and then soaking, ultrasonically treating, pulping, burdening, performing enzymolysis, homogenizing, and spray-drying. By use of the beancurd jelly acquired through the preparation process disclosed by the invention, the effective ingredients in the raw material can be effectively extracted and treated in the premise of maintaining that the original taste and flavor of the bean curd jelly remain unchanged; the brewed beancurd jelly product is uniform in texture, good in clot elasticity, strong in soybean fragrance, delicate and smooth in taste, rich in nutrition, and moderate in sweetness; and the rose and the aloe are adapted as the raw material, so that the novel beancurd jelly has the effects of maintaining beauty, keeping young and detoxifying; and the added aloe grains add new taste for the product.

Owner:博罗罗浮山润心食品有限公司

Health-care soymilk and preparation method thereof

ActiveCN103651911AStrong bean flavorSmooth tasteMilk substitutesFood scienceMonoglycerideSweet flavor

The invention provides health-care soymilk and a preparation method thereof. The health-care soymilk comprises the following components in parts by weight: 1-4 parts of peony, 3-6 parts of aloe, 2-5 parts of honeysuckle, 1-3 parts of liquorice, 2-5 parts of momordica grosvenori, 1-3 parts of radix astragali, 1-3 parts of eucommia ulmoides, 1-3 parts of Chinese yam, 12-18 parts of soybeans, 0.1-0.3 part of salt, 0.05-0.15 part of fatty acid monoglyceride and 0.1-0.3 part of agar. The preparation method comprises the following steps: firstly, cleaning the soybeans, soaking, grinding the soybeans into fine slurry, filtering, and collecting the filtrate; secondly, adding the Chinese herbal components into water, boiling, filtering, and collecting the filtrate; finally, mixing the filtrates obtained in the above two steps, adding the salt, the fatty acid monoglyceride and the agar, heating to 80-95 DEG C, and preserving heat for 0.5h to obtain the health-care soymilk. The health-care soymilk contains rich proteins, amino acids and trace elements, breaks through the mainly-sweet flavor of the conventional soymilk, is strong in bean fragrance, smooth in taste and high in product stability, and can be stored at room temperature.

Owner:NANTONG SHUANGHE FOOD

Preparation technique of bean hilum tea

ActiveCN101301017AStrong bean flavorSoaking and dissolution effect is goodTea substituesFood preparationBiotechnologyGram

This invention disclosed a preparation technique of a bean embryo tea, comprising the following steps: peeling the selected bean embryos and removing the moldy bean, controlling the moisture-content within 9 to 11 percent, sieving with a 10 mesh sieve, putting the bean embryos into the explosion-puffing machine and heating hermetically for 8 to 12 minutes, releasing the air-pressure suddenly. The bean embryos are puffed and cooked during the processing. By the intermittent production using the processing and the last step of stage filtering package, the bean embryo tea is obtained. This invention employs a particular maturing processing, the puffed bean embryo has the advantages of being crisp, thick bean smell, high solubility and deep color. The production is fit for female health-care, which has the effect of anti-acne, softening skin and prolonging menopause by taking about 10 gram per day. This invention has the advantages of simple preparation technique, low cost and high quality.

Owner:山东嘉华生物科技股份有限公司

Processing method of soybean yogurt

InactiveCN106720386AStrong bean flavorGreat tasteMilk substitutesFood scienceNutritive valuesSucrose

The invention relates to a processing method of yogurt, particularly a processing technique of soybean yogurt. The soybean yogurt is characterized by comprising soybeans (commercially available), SH-481 lactobacillus (Nanjing Shenghe Science and Technology Ltd.), CM1011 pectin (Shanghai Tongyuan Food Technology Ltd.), S13 sucrose ester (Guangxi Nanning Sucrose Ester Plant) and sucrose (commercially available). The soybean yogurt prepared by the processing technique has the advantages of rich bean aroma, favorable mouthfeel, favorable appearance and high nutritive value.

Owner:SHAANXI YUHANG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com