Patents

Literature

100results about How to "Reduce the amount of enzymes used" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

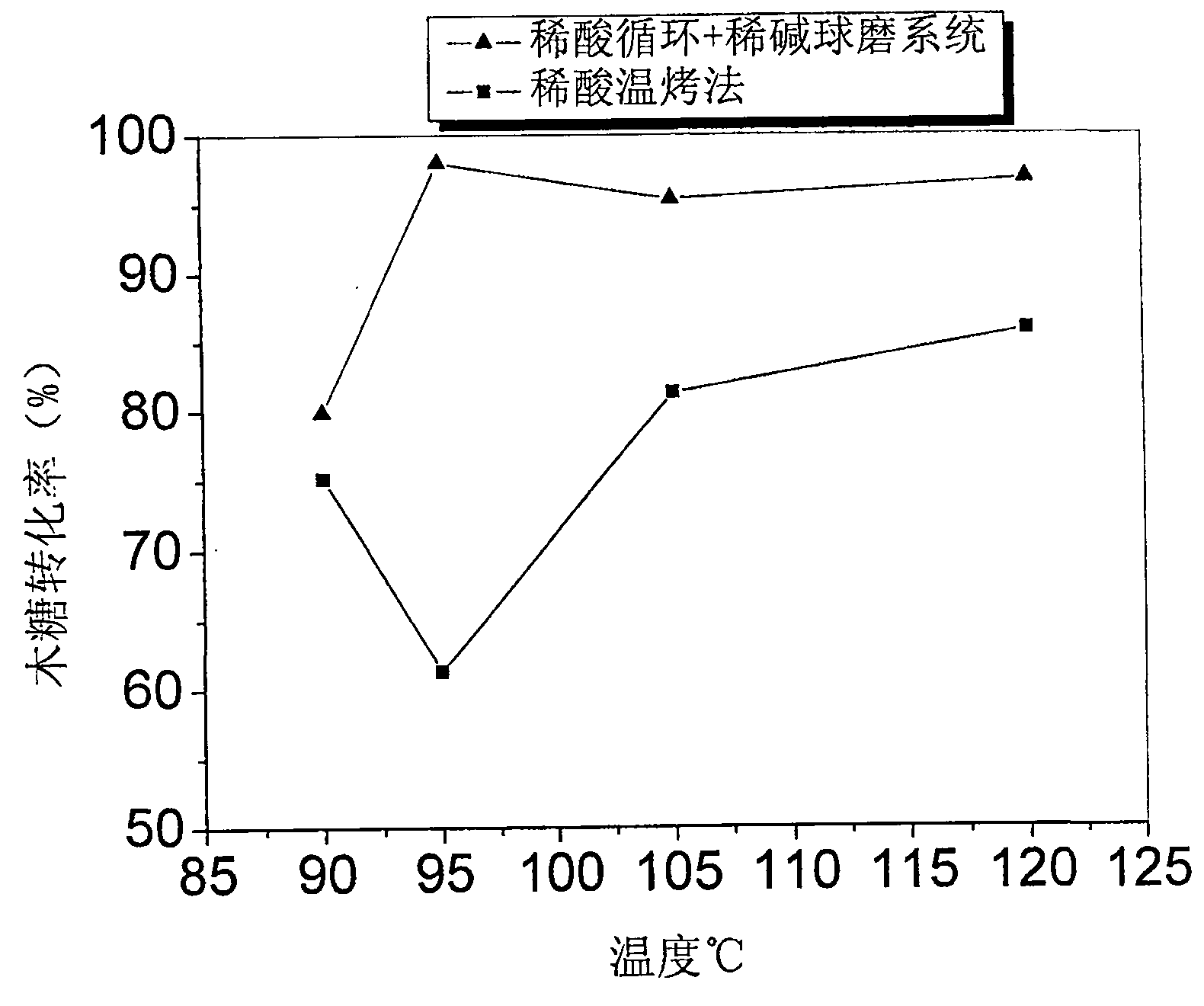

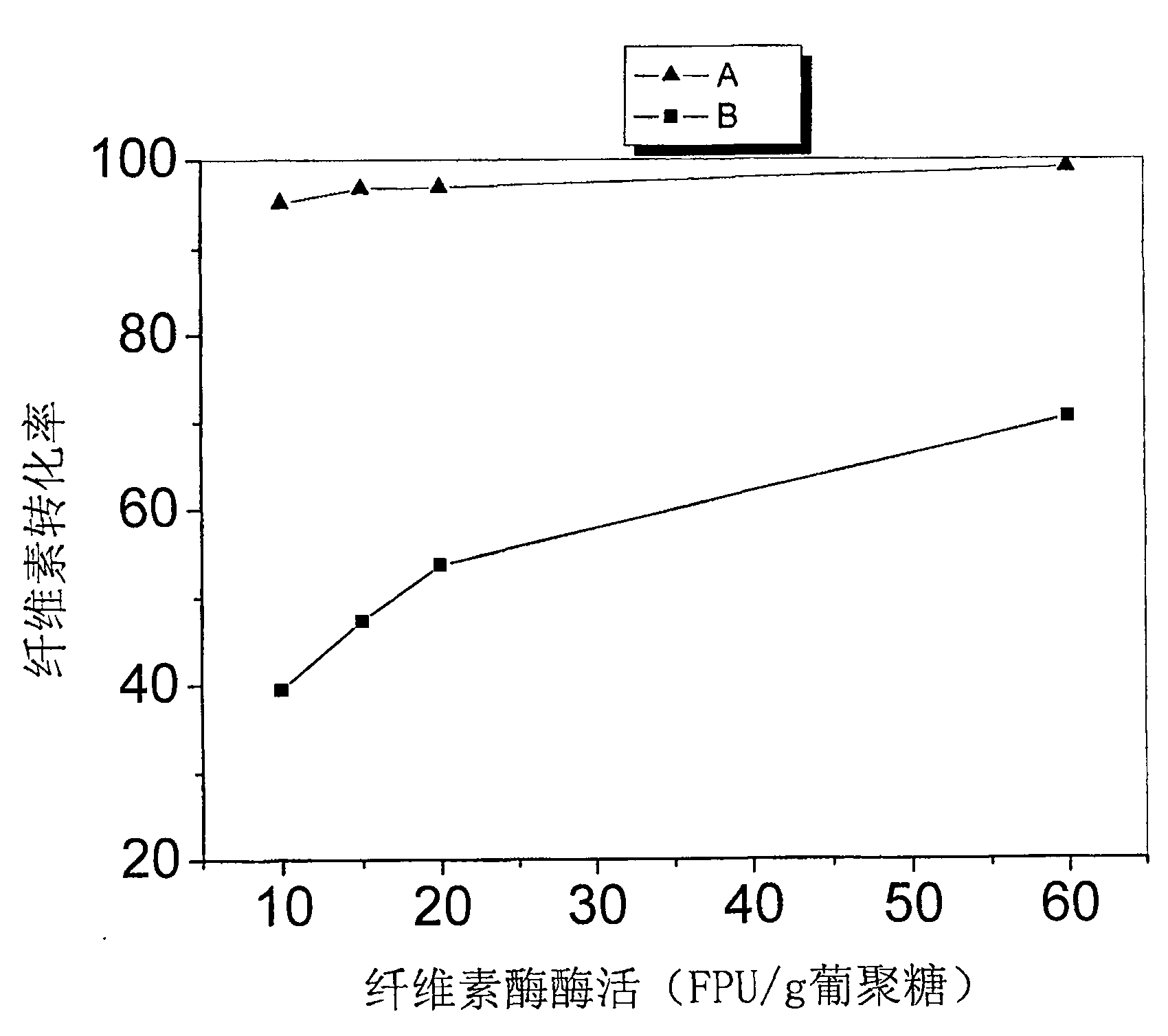

Combined pretreatment method of wood cellulose and system thereof

InactiveCN101230546AImprove hemicellulose conversion rateCellulose enzymatic conversion rate decreasedPaper material treatmentChemistryStart up

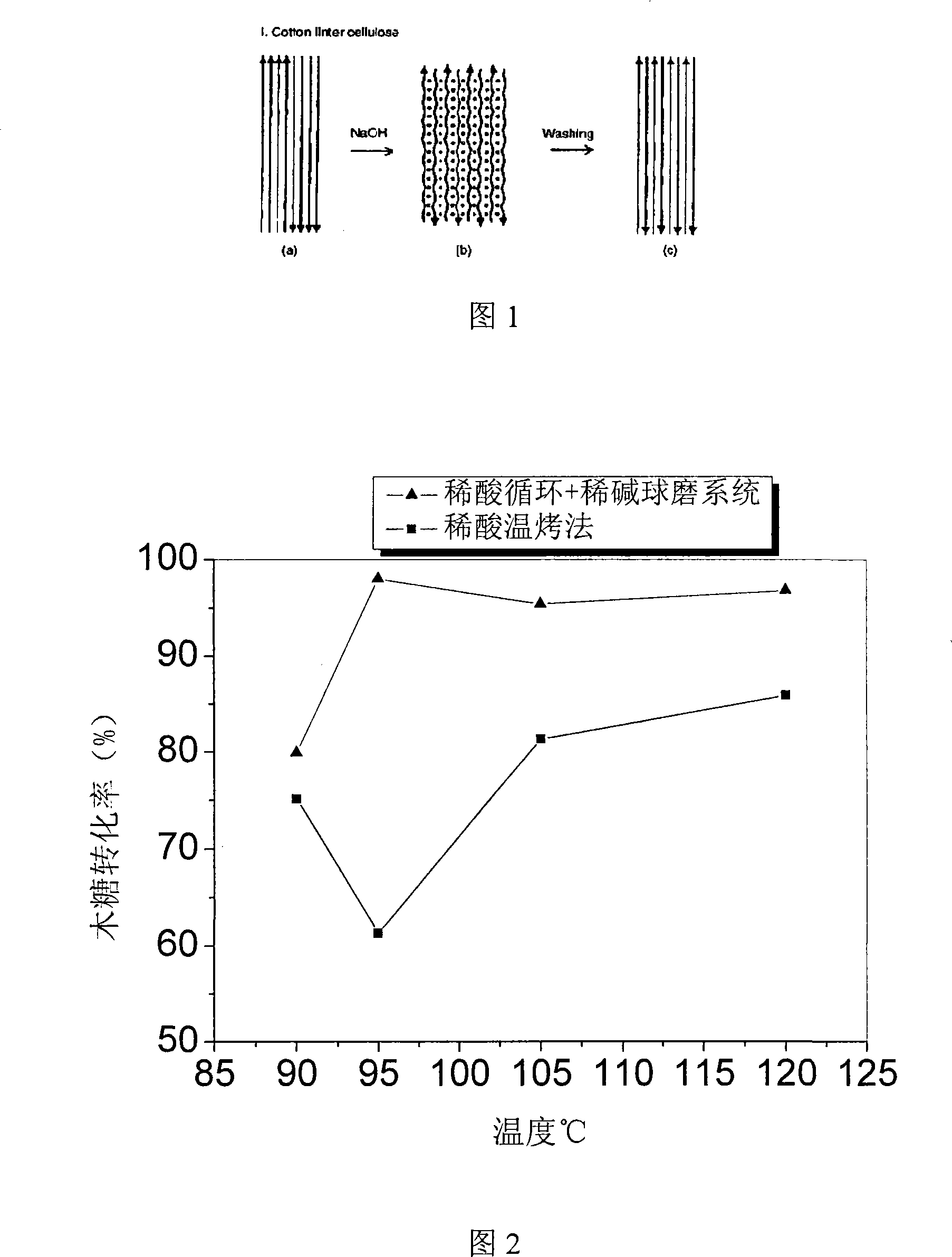

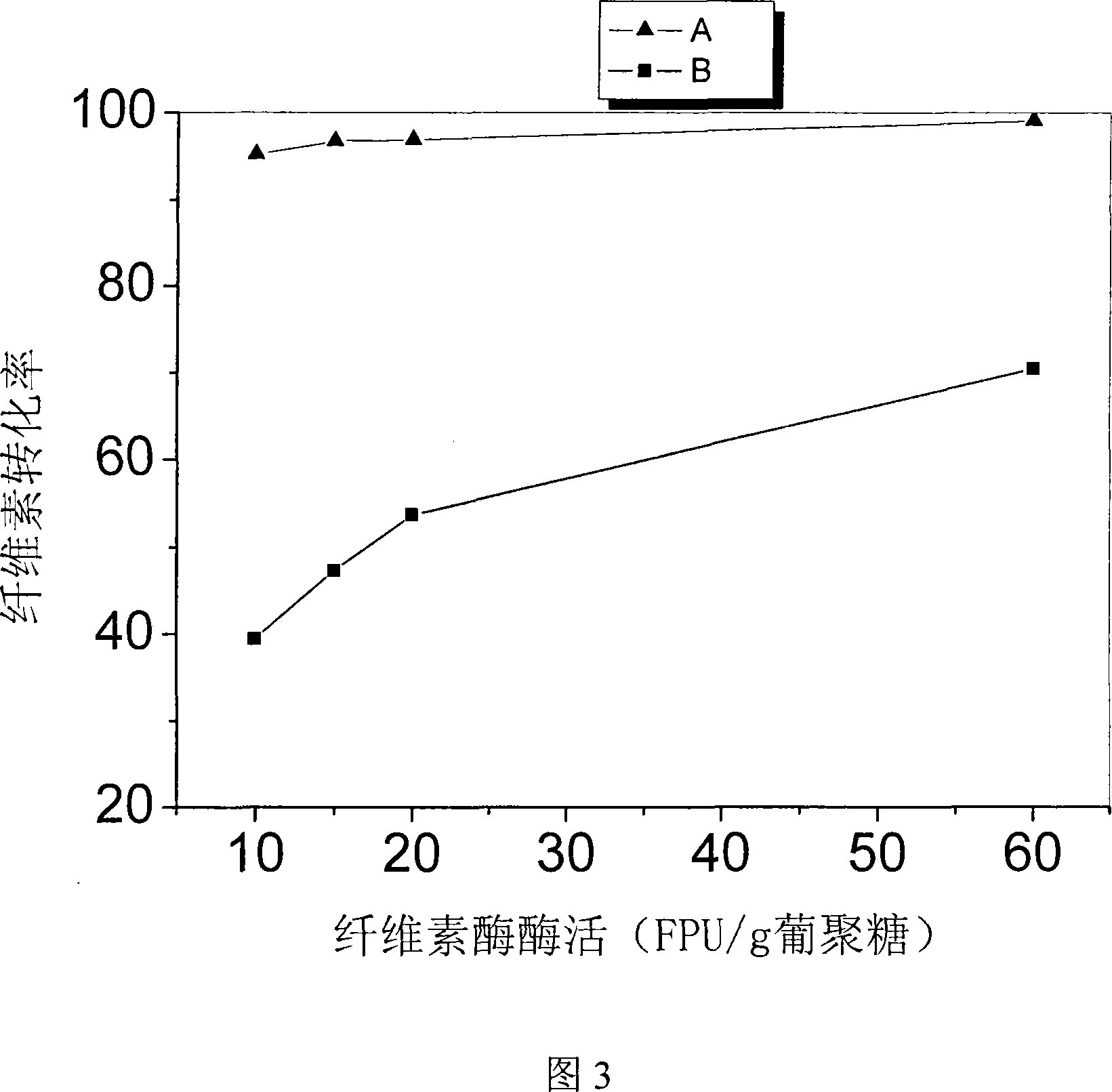

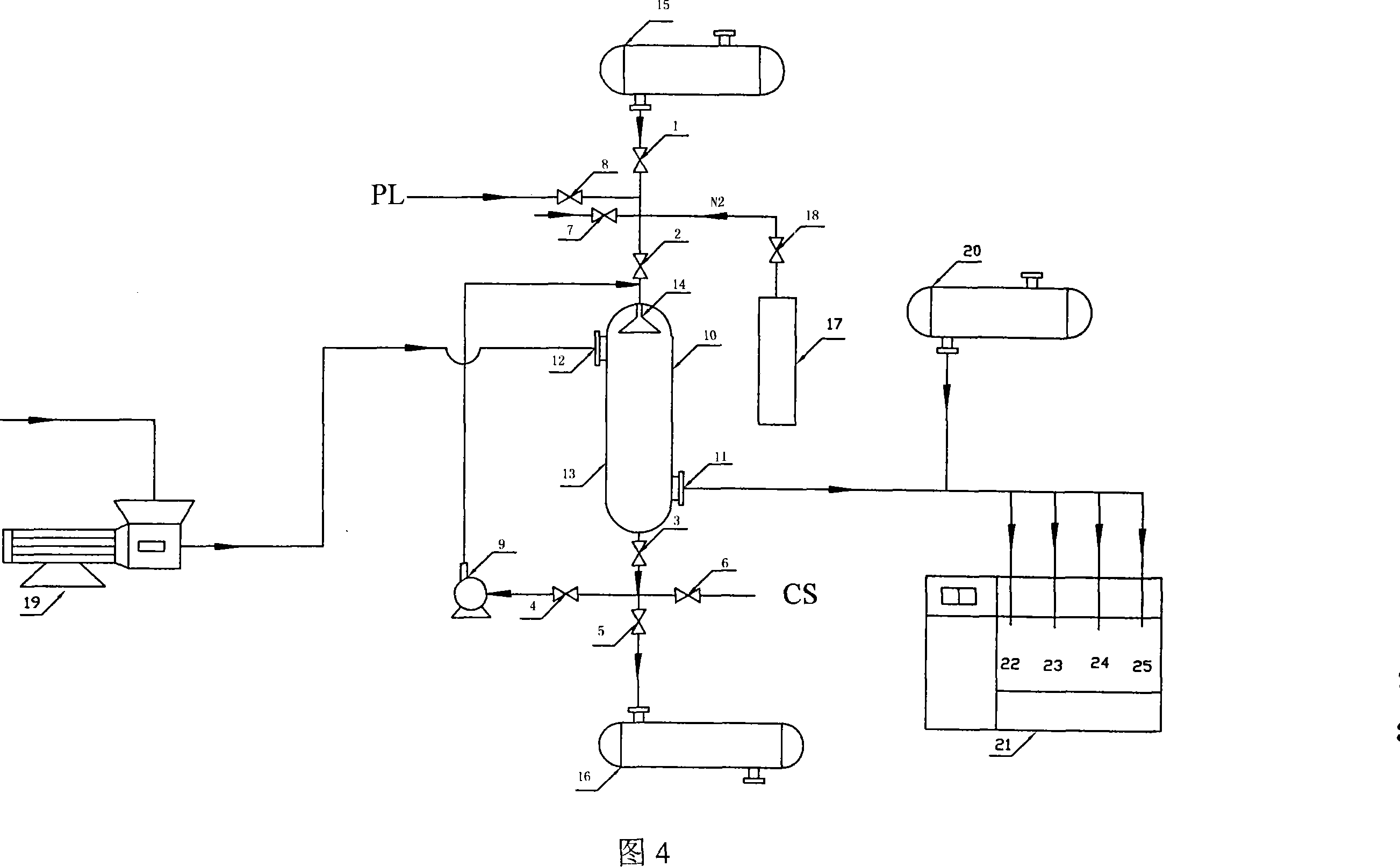

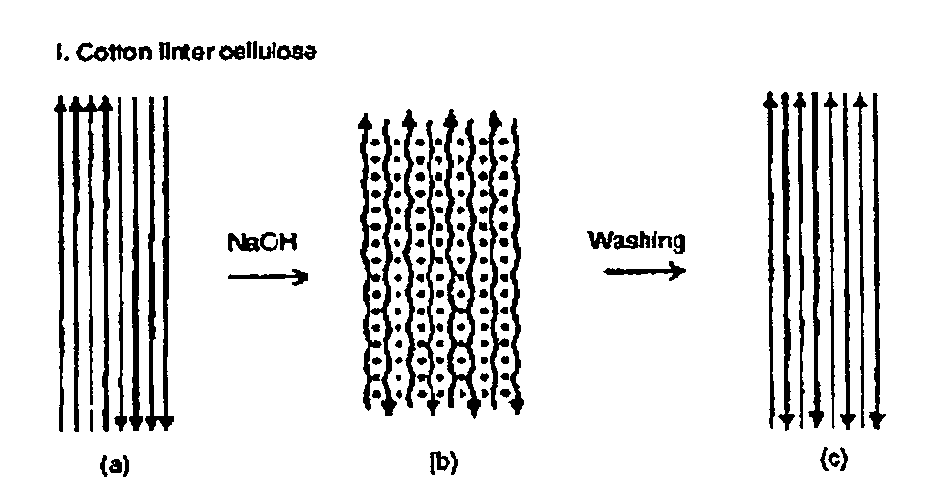

The invention discloses a combined preprocessing method of lignocellulose. The lignocellulose is arranged in a recycle reactor after being crushed, and dilute acid is injected; a recycle pump starts up, the circular reaction is acted under the temperature ranging from 50 DEG C to 200 DEG C, and the obtained hydrolysate is disacidified and then is used for ferment after the reaction is finished; the surplus lignocellulose in the recycle reactor is put in a globe mill for ball milling through adding lye after the surplus lignocellulose is washed, and the surplus lignocellulose is used in subsequent zymohydrolysis after ball milling and alkali removing. The invention effectively increases the hemicellulose percent conversion, the lignin removal rate and the cellulose zymohydrolysis percent conversion in the lignocellulose, reduces fermentation inhibition products, and reduces the enzyme usage when in zymohydrolysis, shortens the reaction time and increases the sugar consistence at the same time; in addition, the invention can set the water consumption during the preprocessing according to the needs of subsequent ferment consistence.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined pretreatment method of wood cellulose and system thereof

InactiveCN100564667CImprove conversion rateHigh removal ratePaper material treatmentPretreatment methodEnzymatic hydrolysis

Owner:CHINA PETROLEUM & CHEM CORP +1

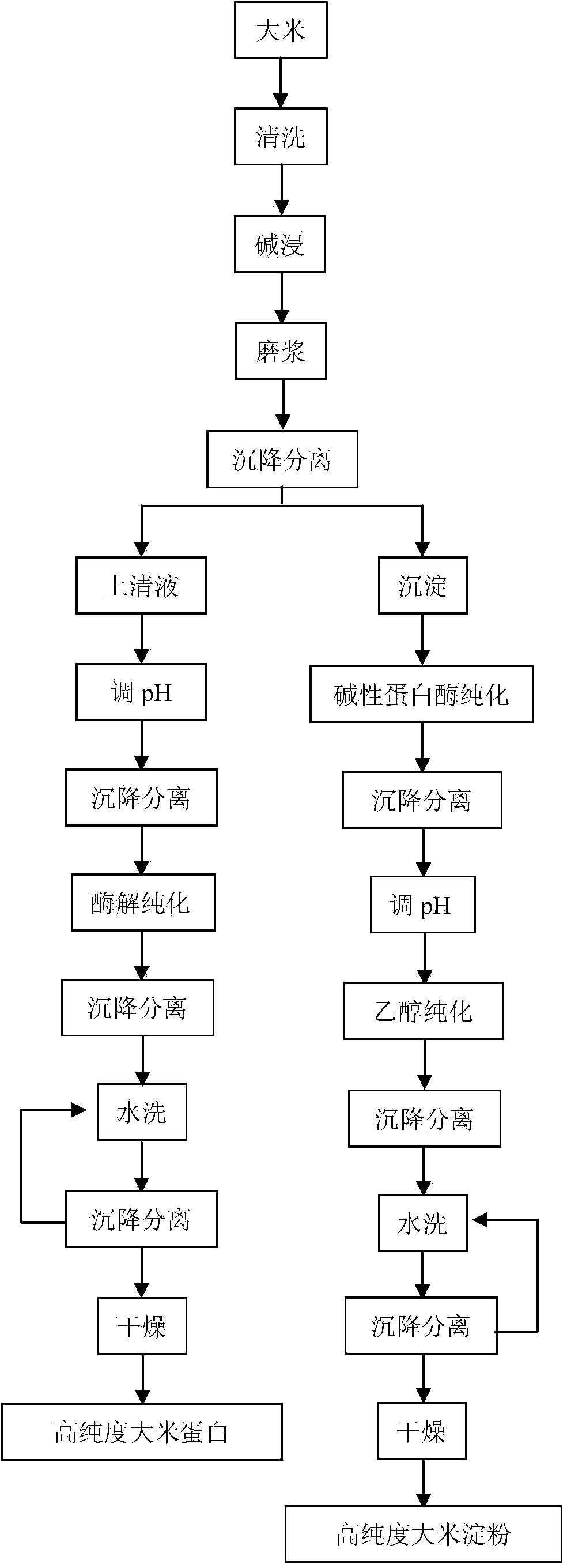

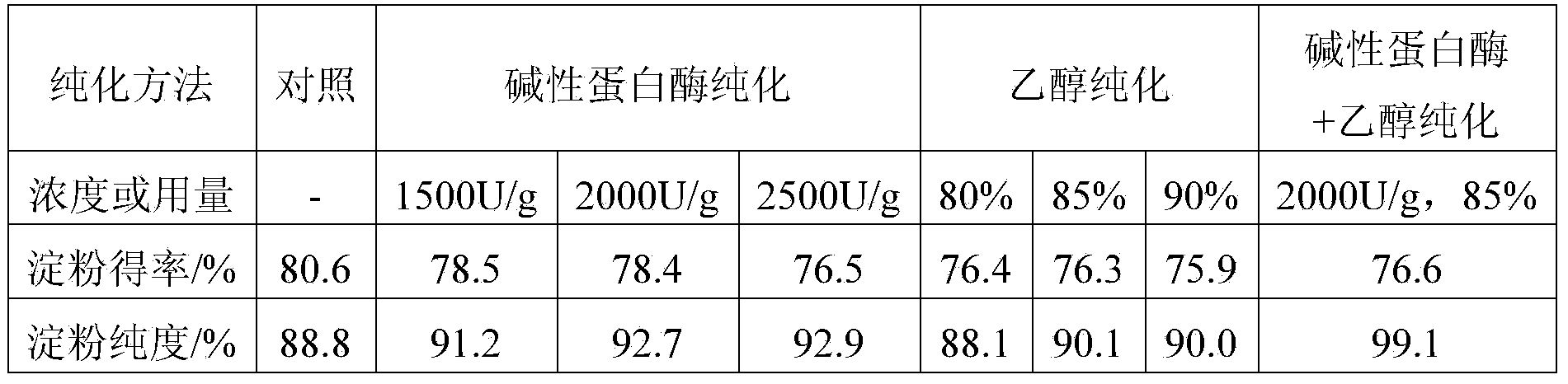

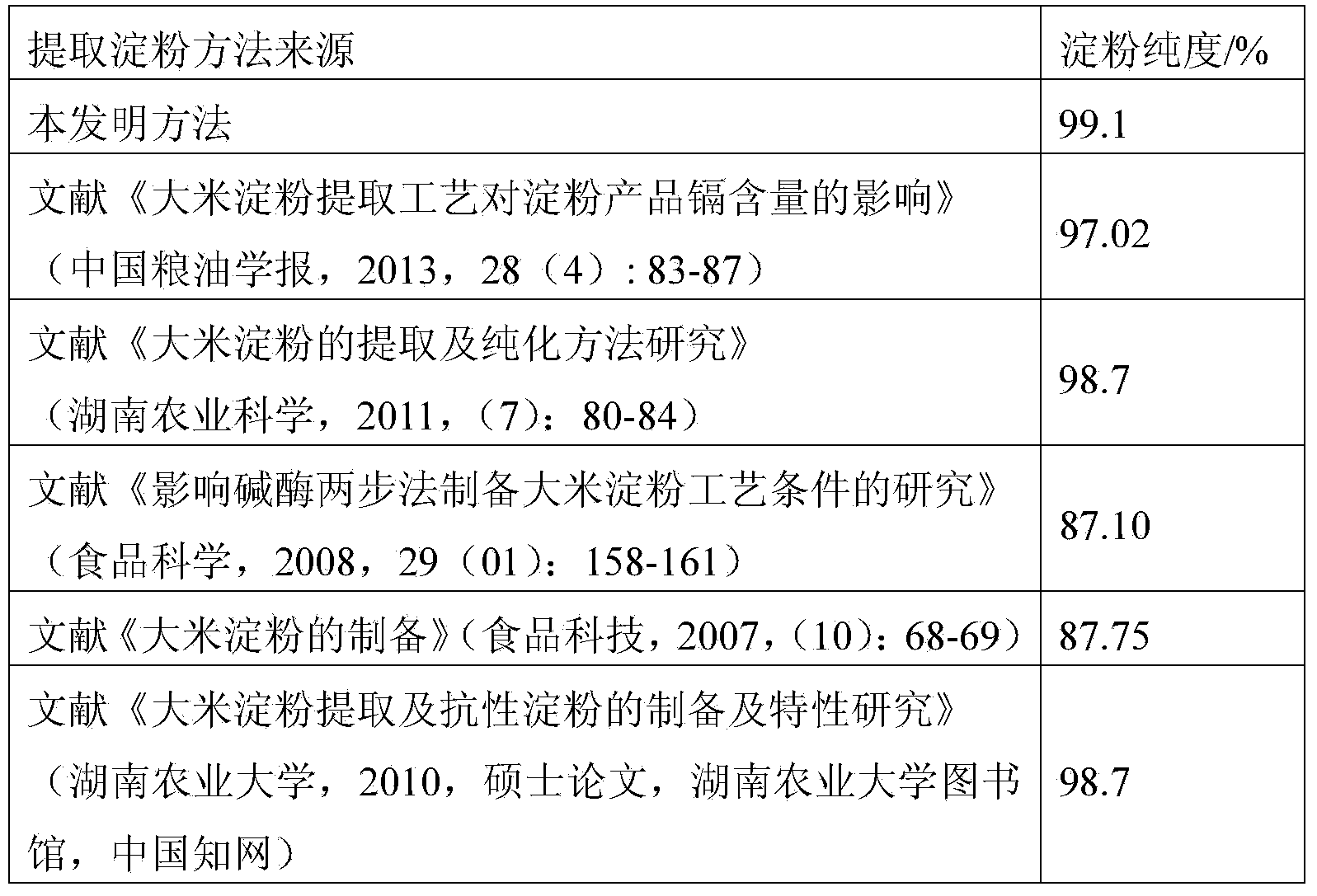

Method for co-producing high-purity rice starch and rice protein

ActiveCN103555795AHigh purityEasily damagedPeptide preparation methodsFermentationAlkaline proteaseRice protein

The invention belongs to the field of rice deep processing technologies and in particular relates to a method for co-producing the high-purity rice starch and rice protein. The method is characterized in that washing rice used as a raw material, soaking, grinding to obtain thick liquid, separating, adjusting the pH of liquid supernatant, performing enzymolysis, washing, performing settlement separation, and then drying to obtain the high-purity rice protein; or obtained precipitate is subjected to alkaline protease purification, pH adjustment, ethanol purification, washing, settlement separation, drying to obtain a high-purity rice starch product. The method can be used for co-producing the rice starch and rice protein, and can effectively improve the purity and increase the yield of the product. The product obtained by using the method can be used as the raw material for deep processing of food.

Owner:HUAZHONG AGRI UNIV

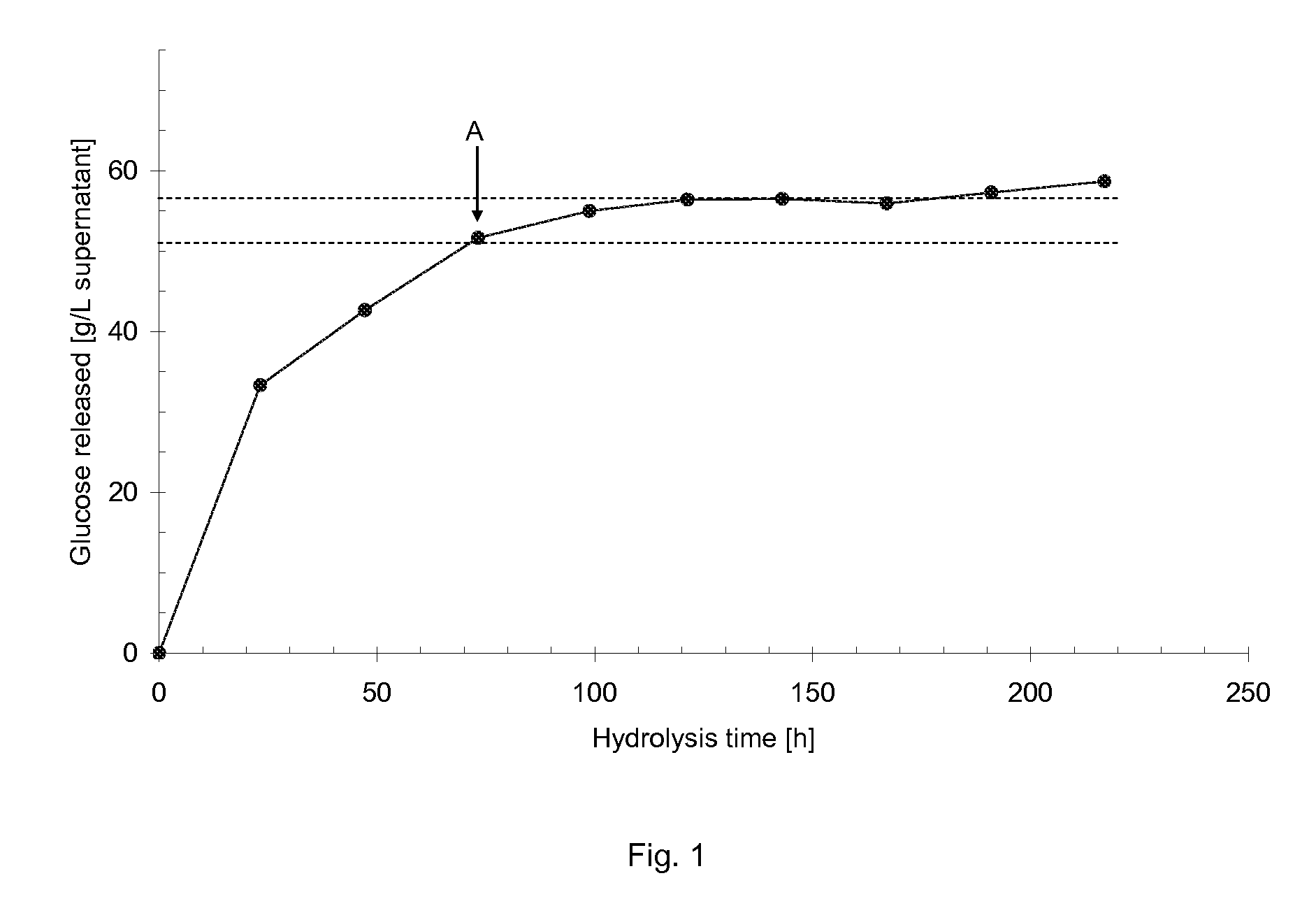

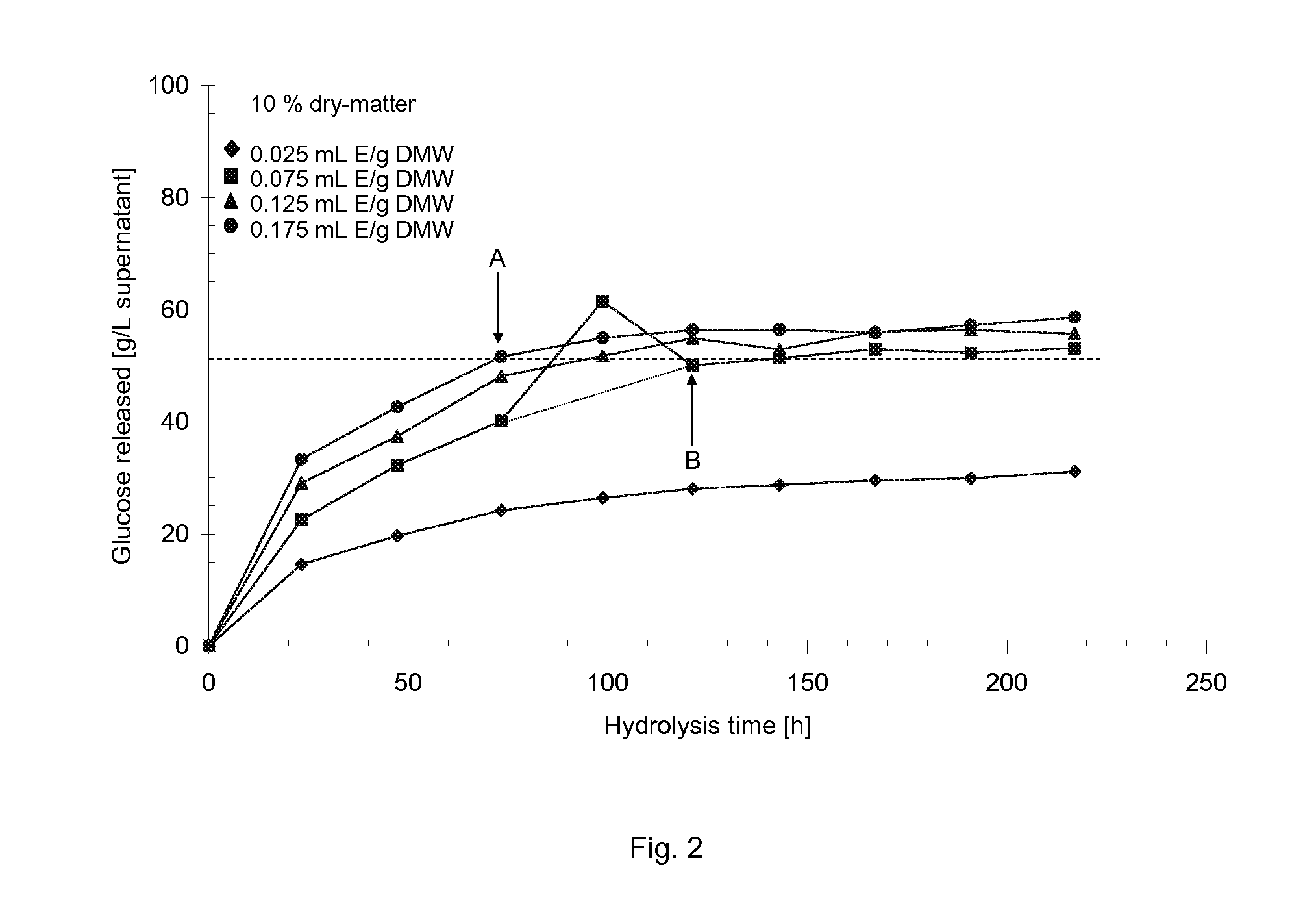

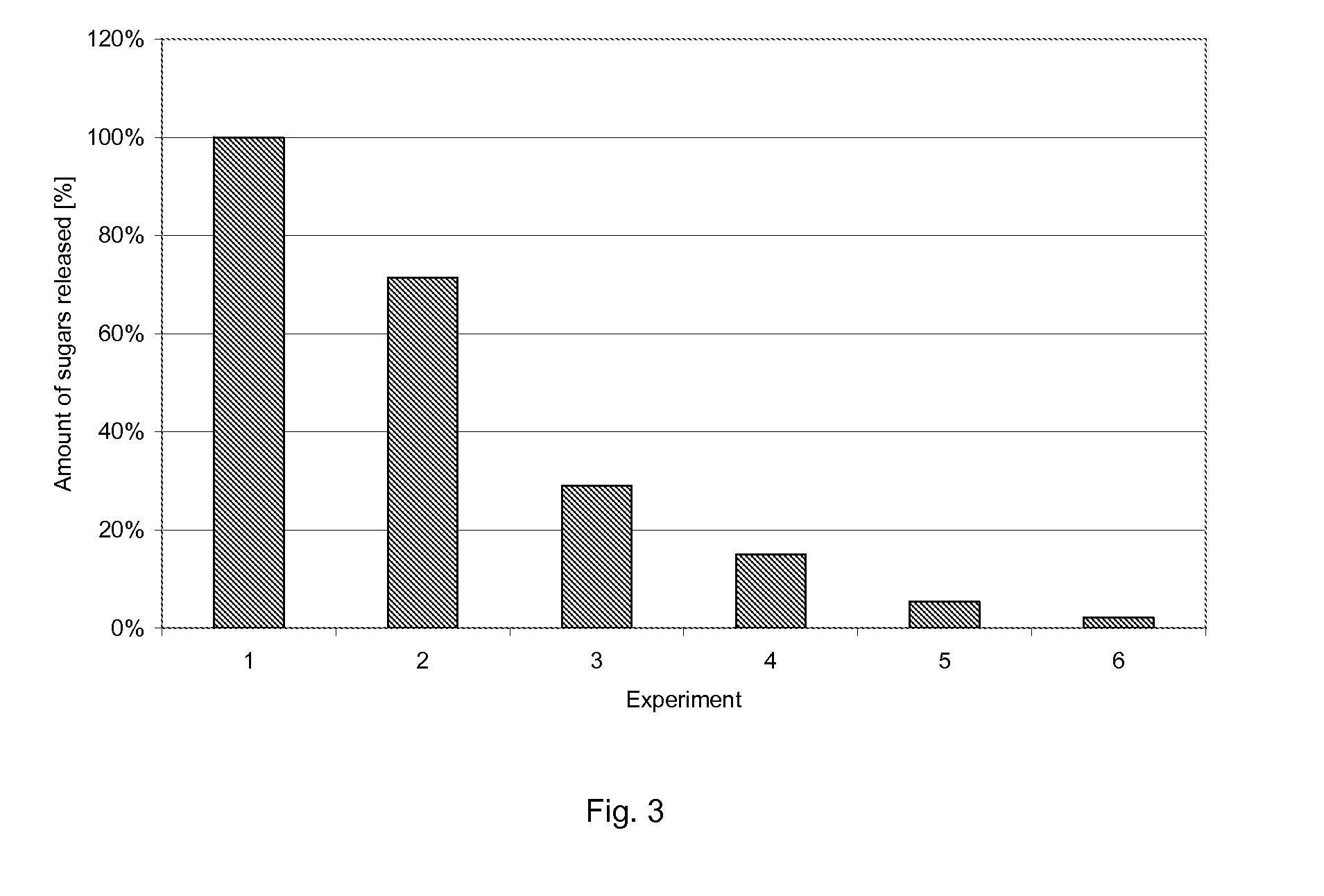

Process for enzymatic hydrolysis of lignocellulosic materila and fermentation of sugars

InactiveUS20120183993A1Reduce processing timeDosage of enzyme may be reducedHydrolasesTransferasesCelluloseEnzymatic hydrolysis

The invention relates to a process for the preparation of a fermentation product from ligno-cellulosic material, comprising the following steps:a) optionally pre-treatmentb) optionally washing;c) enzymatic hydrolysis;d) fermentation; ande) optionally recovery of a fermentation product;wherein in step c) an enzyme composition is used that has a temperature optimum of 55 degrees C. or more, the hydrolysis time is 40 hours or more and the temperature is 50 degrees C. or more.

Owner:DSM IP ASSETS BV

Method for producing glucose and cellobiose using cellulose complex enzyme

InactiveCN101603065AIncrease saccharification rateSatisfy productionMicroorganism based processesFermentationFiberConcentrations glucose

A method for producing glucose and cellobiose using cellulose complex enzyme is the technology using the cellulose complex enzyme as a catalyst and realizing the high saccharification rate conversion of cellulose by adding cellulose enzyme activator at the optimized stirring speed. Glucose concentration can reach 150g / L after using cellulose enzymatic hydrolysis, and the method is a cellulose saccharification production technology with economic feasibility. With the technology used, low cost, low usage of enzyme and high saccharification rate can be realized, and the productions of cellulose alcohol and biochemical products (lactic acid, succinic acid and the like) are satisfied. In the whole technology, no beta-glucosaccharase is added additionally, no sugar concentrating device is added, and the technology is simple, the equipment cost is low and the industrialized prospect is good.

Owner:CHINA THREE GORGES UNIV

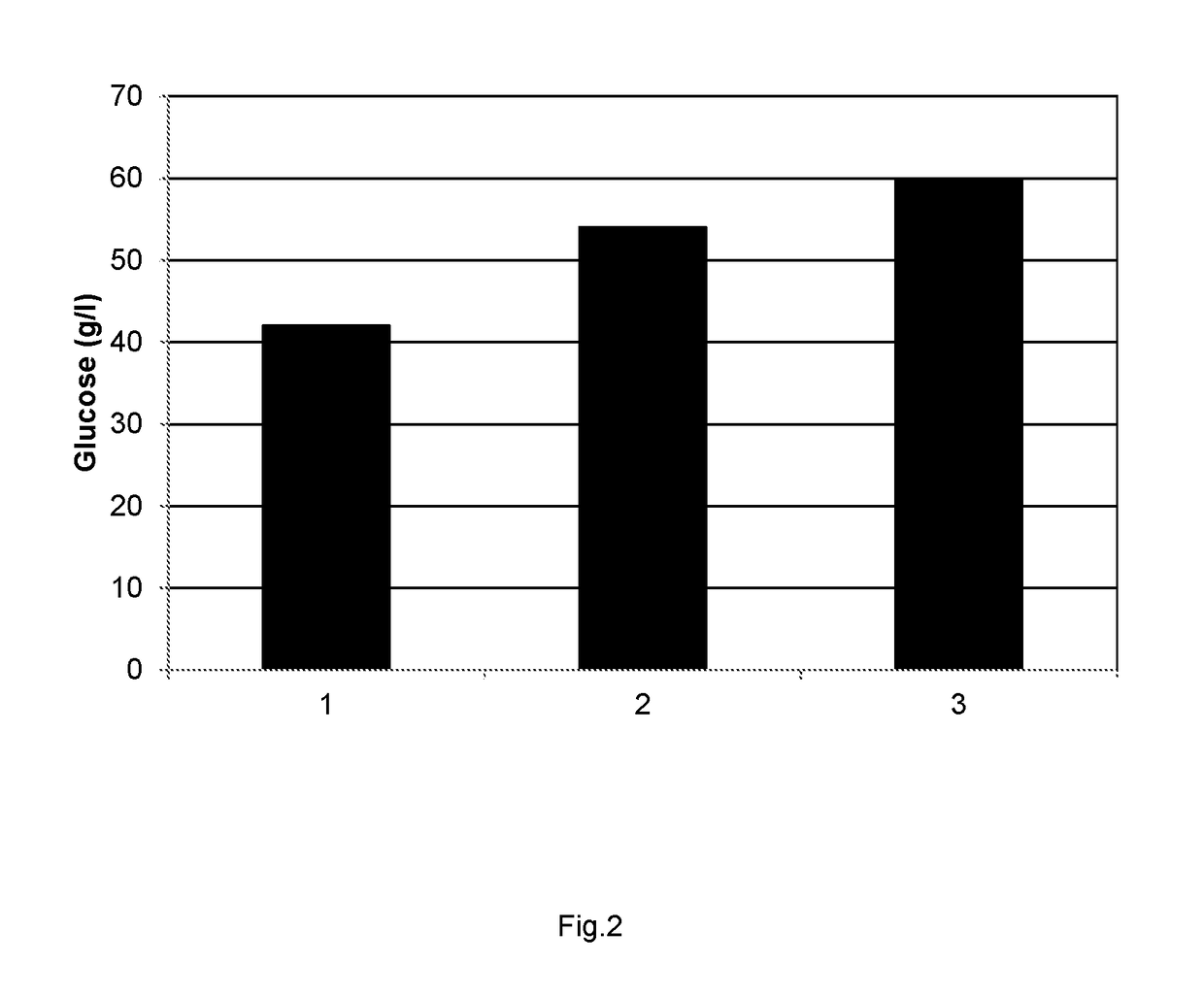

Process for enzymatic hydrolysis of lignocellulosic material and fermentation of sugars

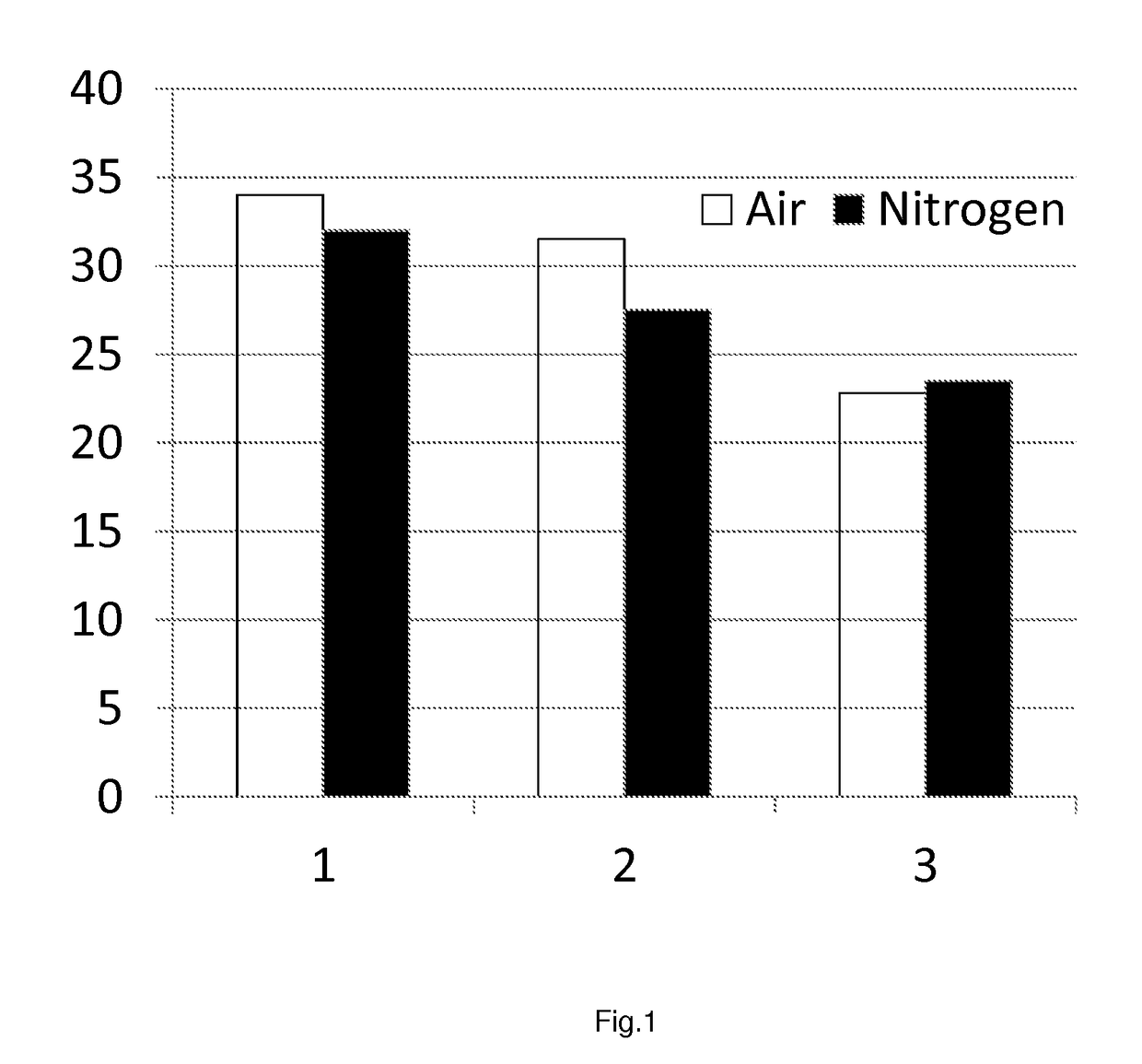

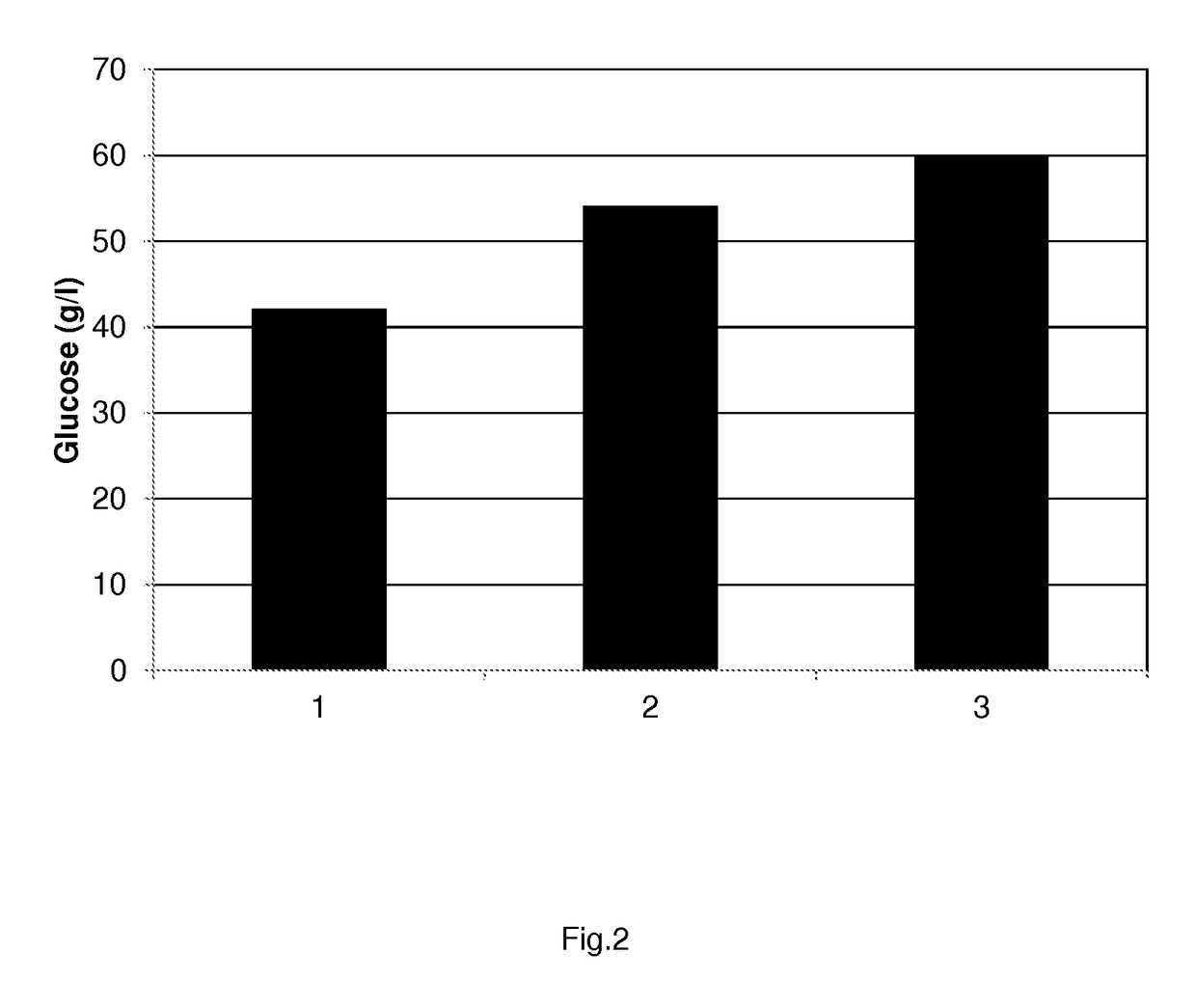

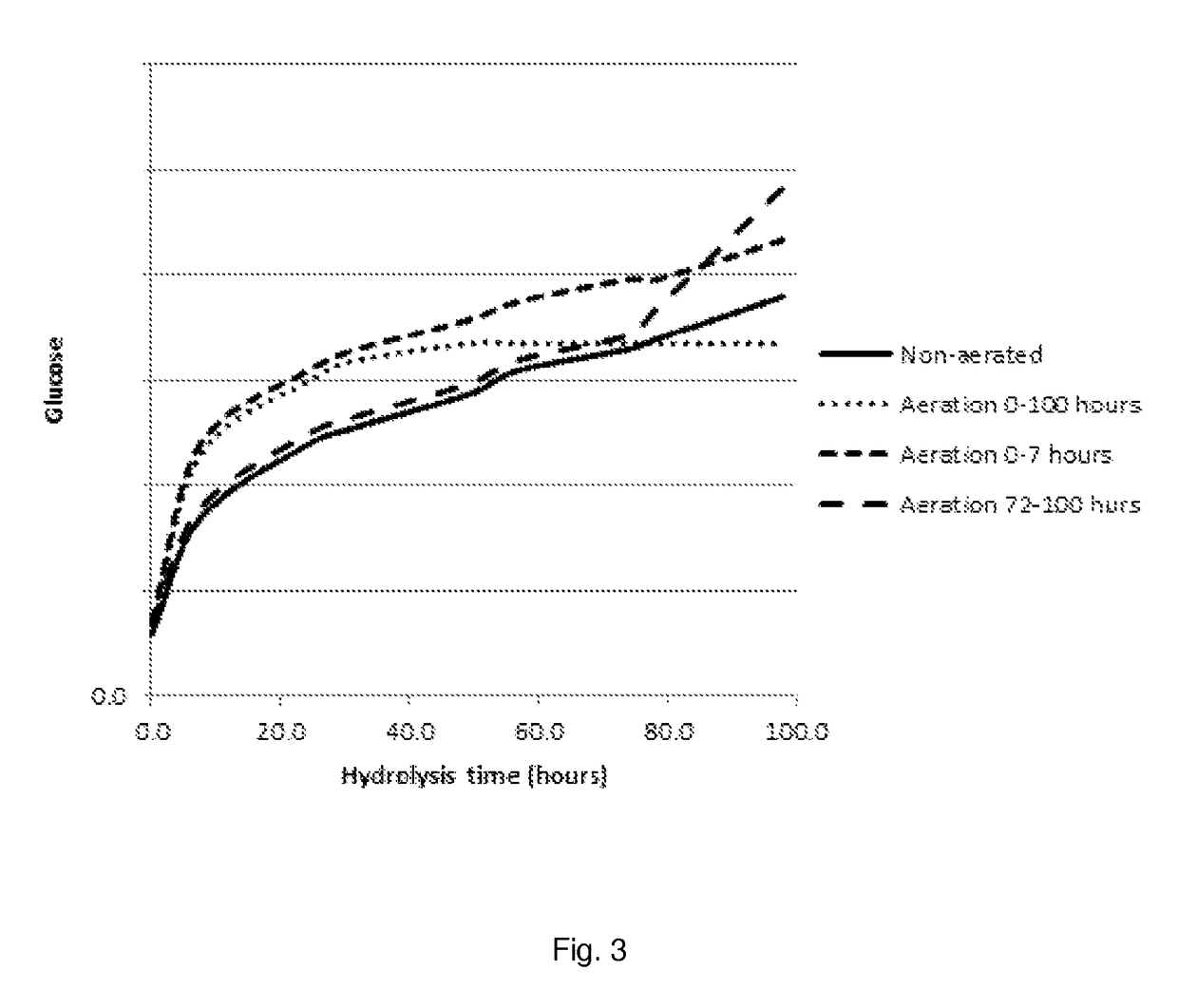

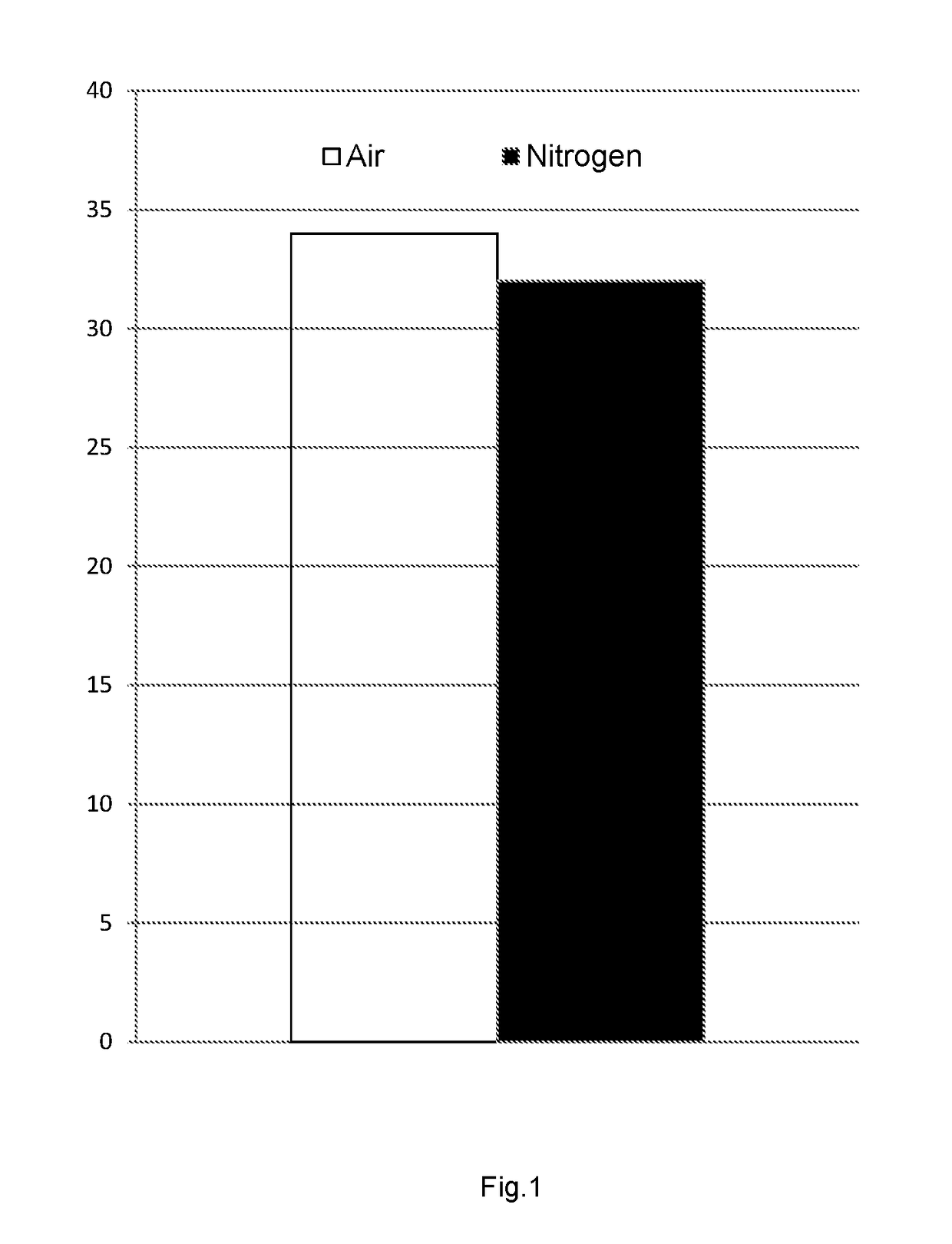

ActiveUS9957528B2Reduce processing timeReduce the amount of enzymes usedBiofuelsWaste based fuelEnzymatic hydrolysisCellulase

Owner:VERSALIS SPA

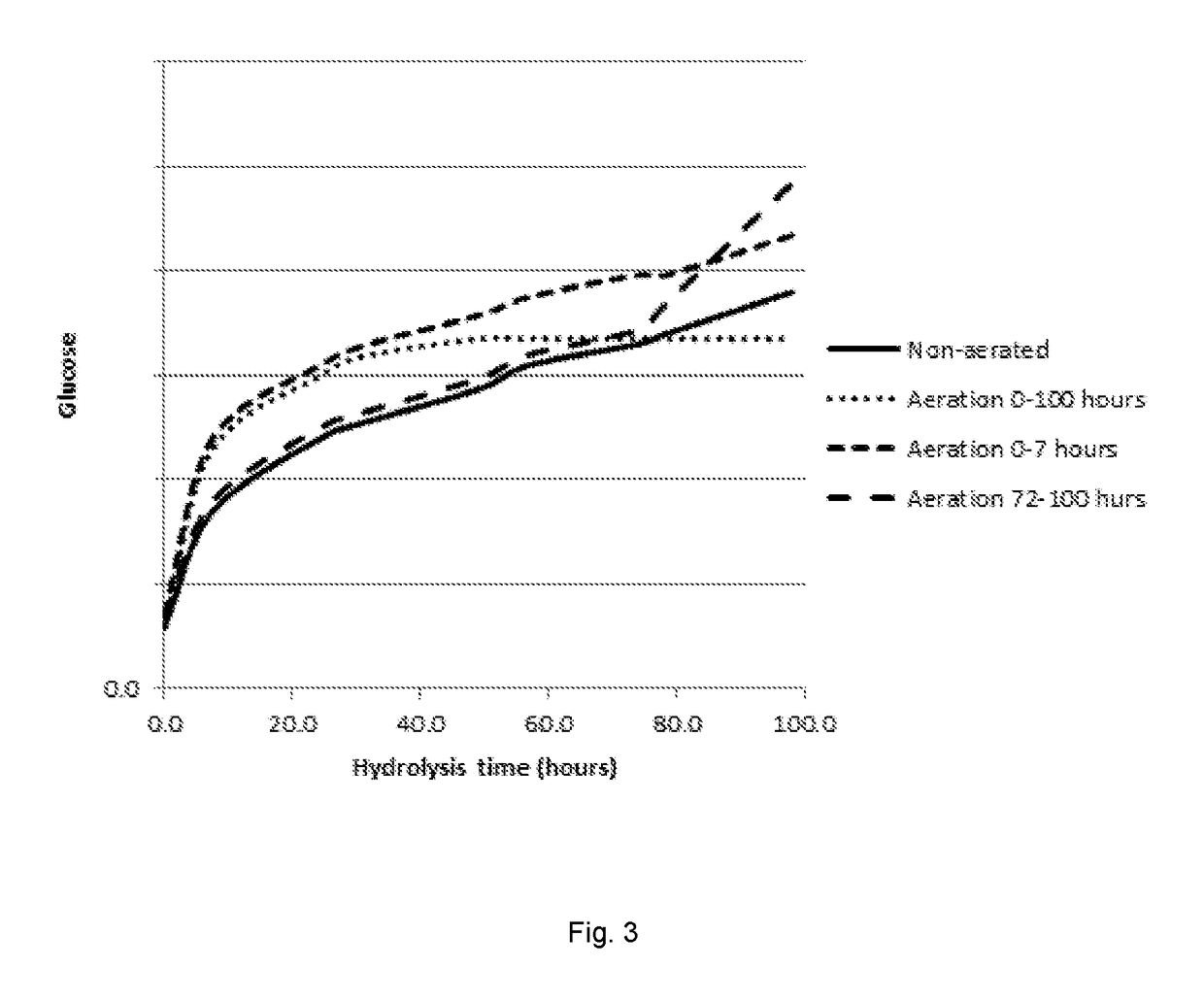

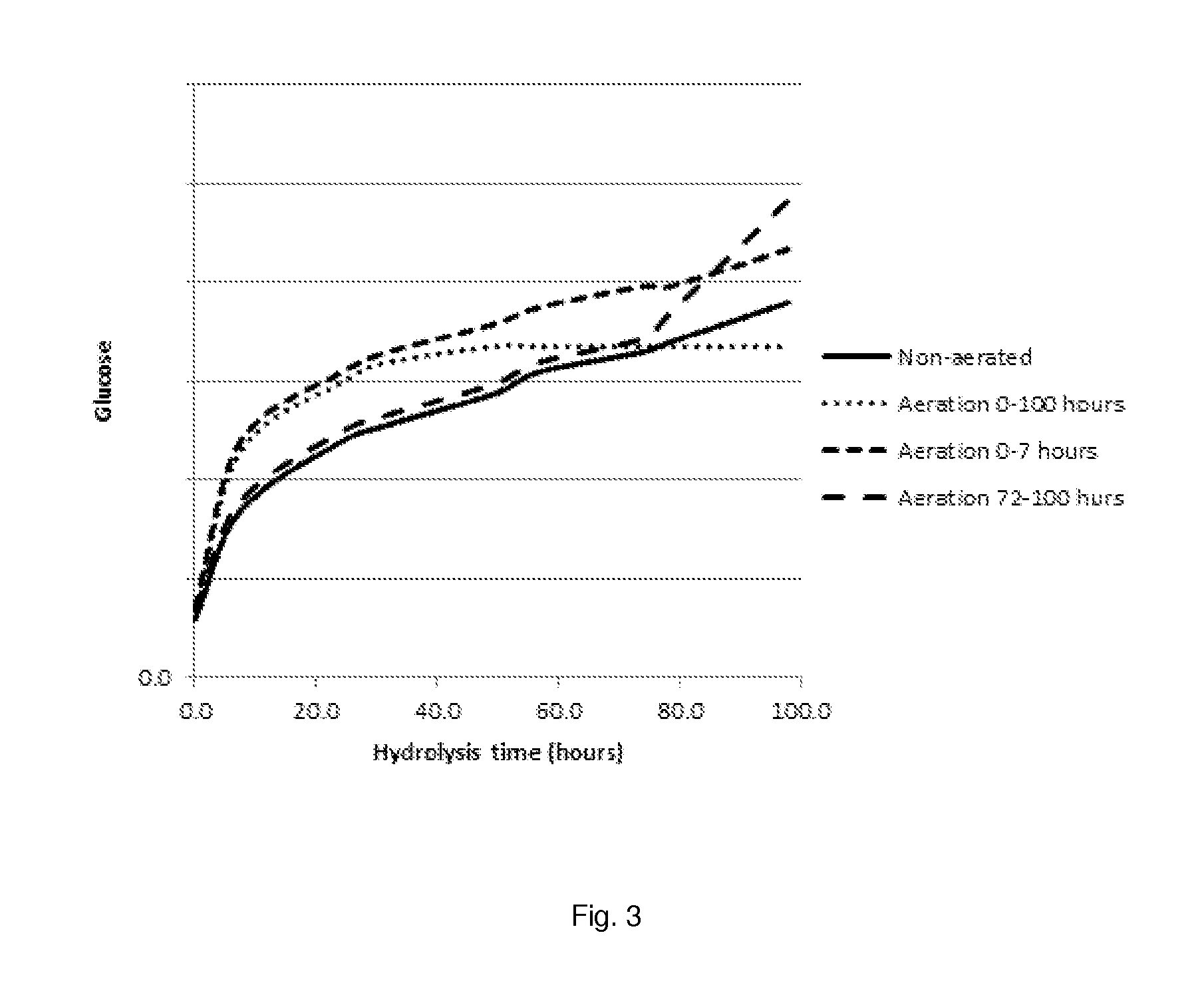

Process and apparatus for enzymatic hydrolysis of lignocellulosic material and fermentation of sugars

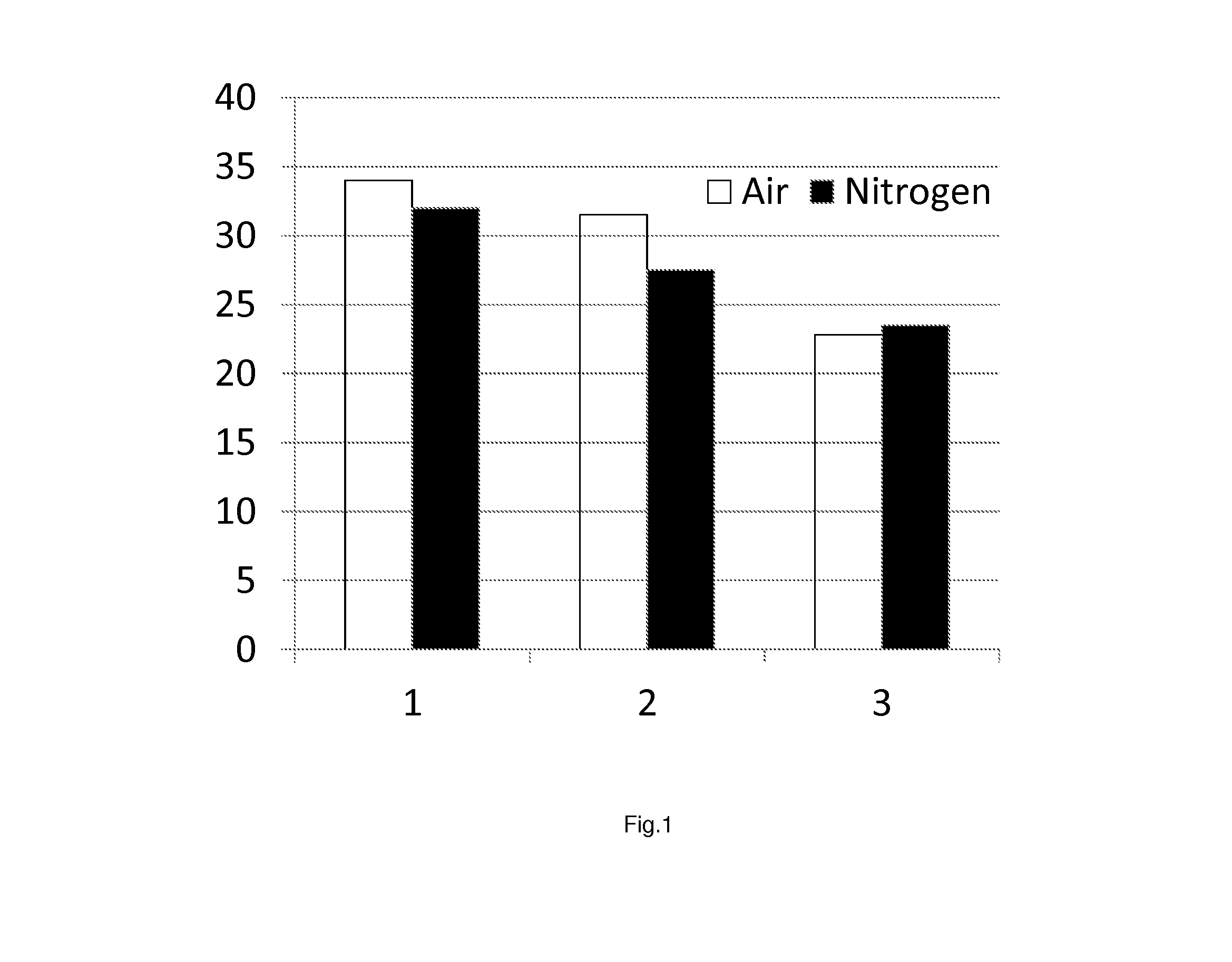

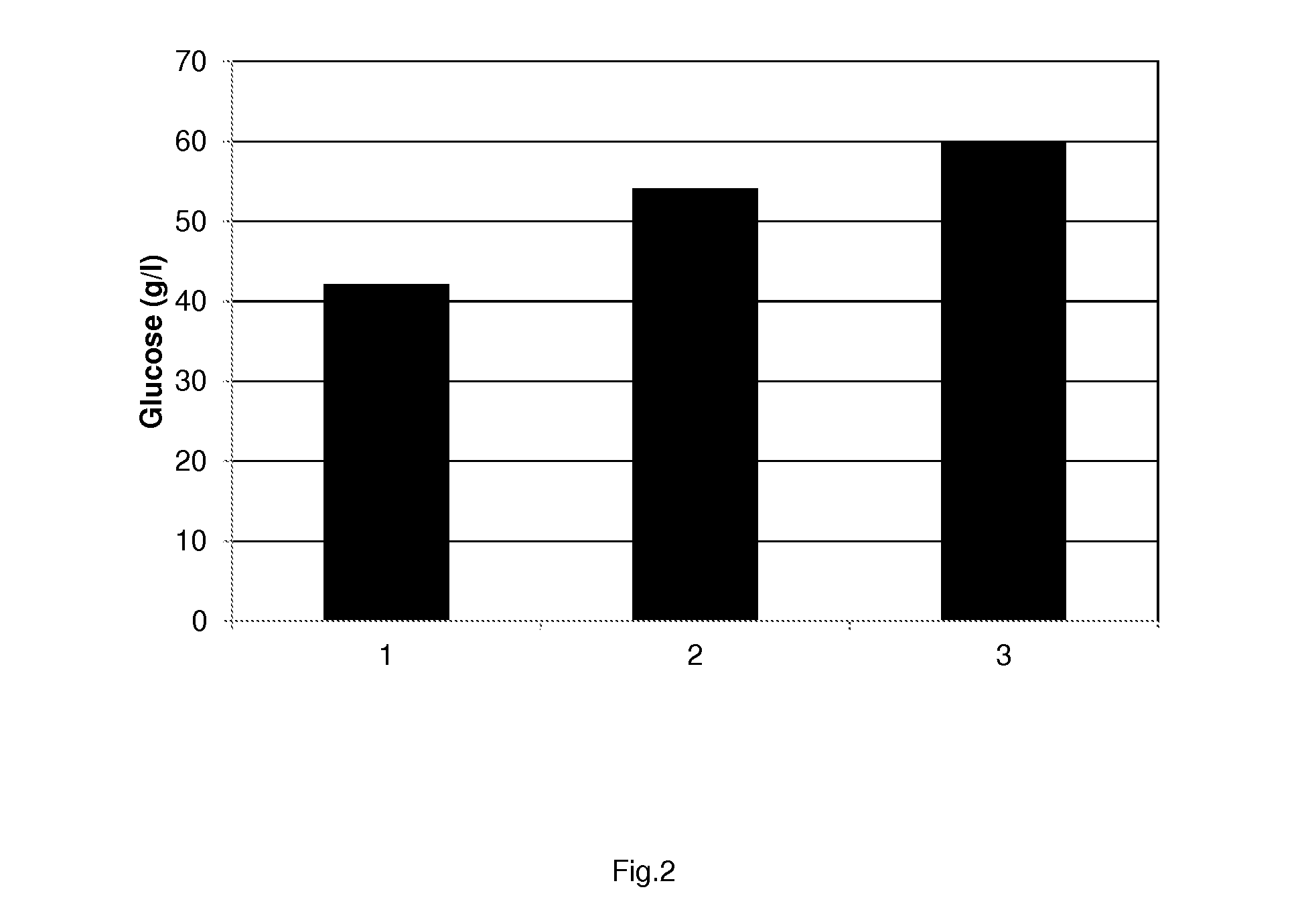

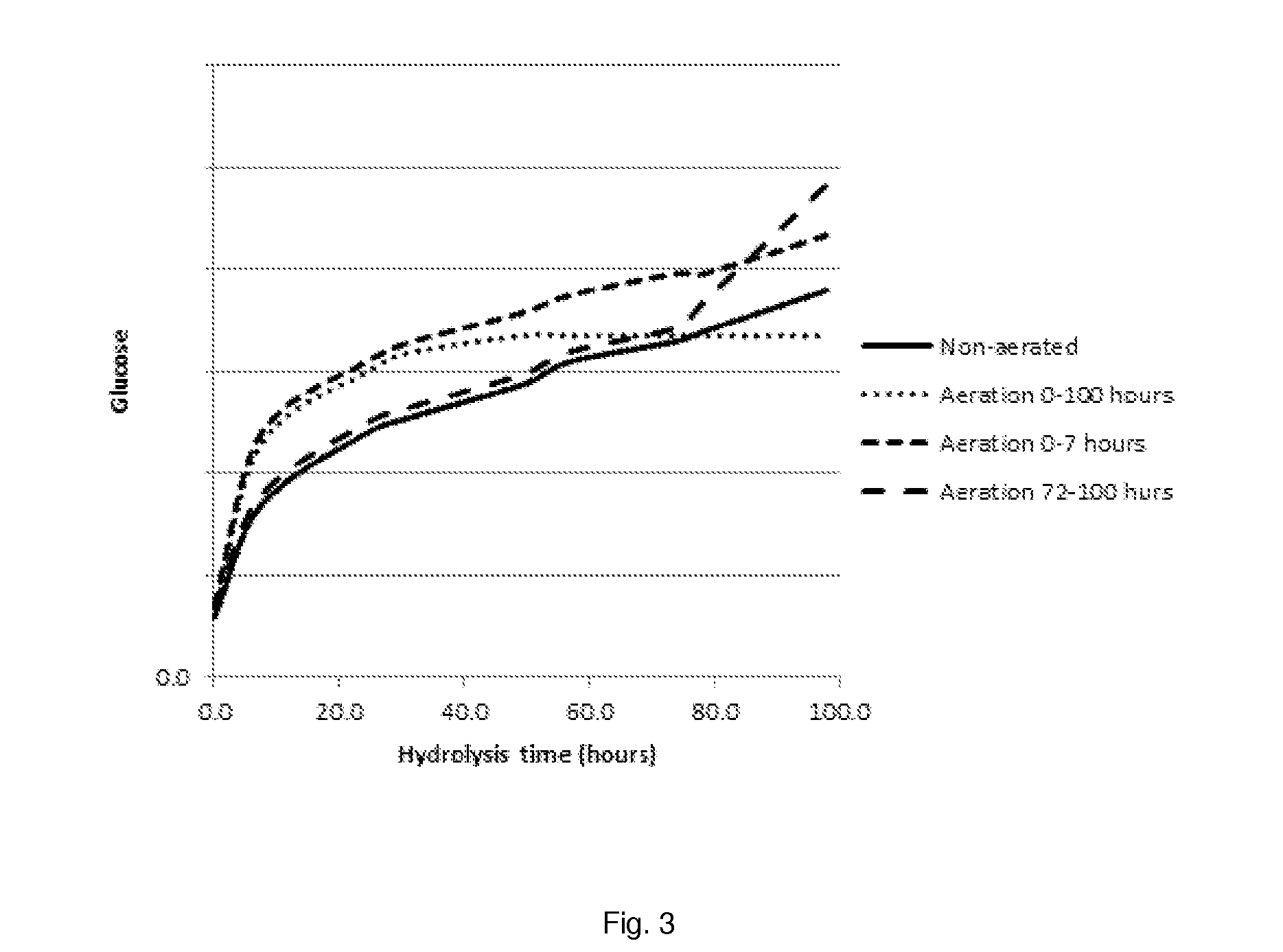

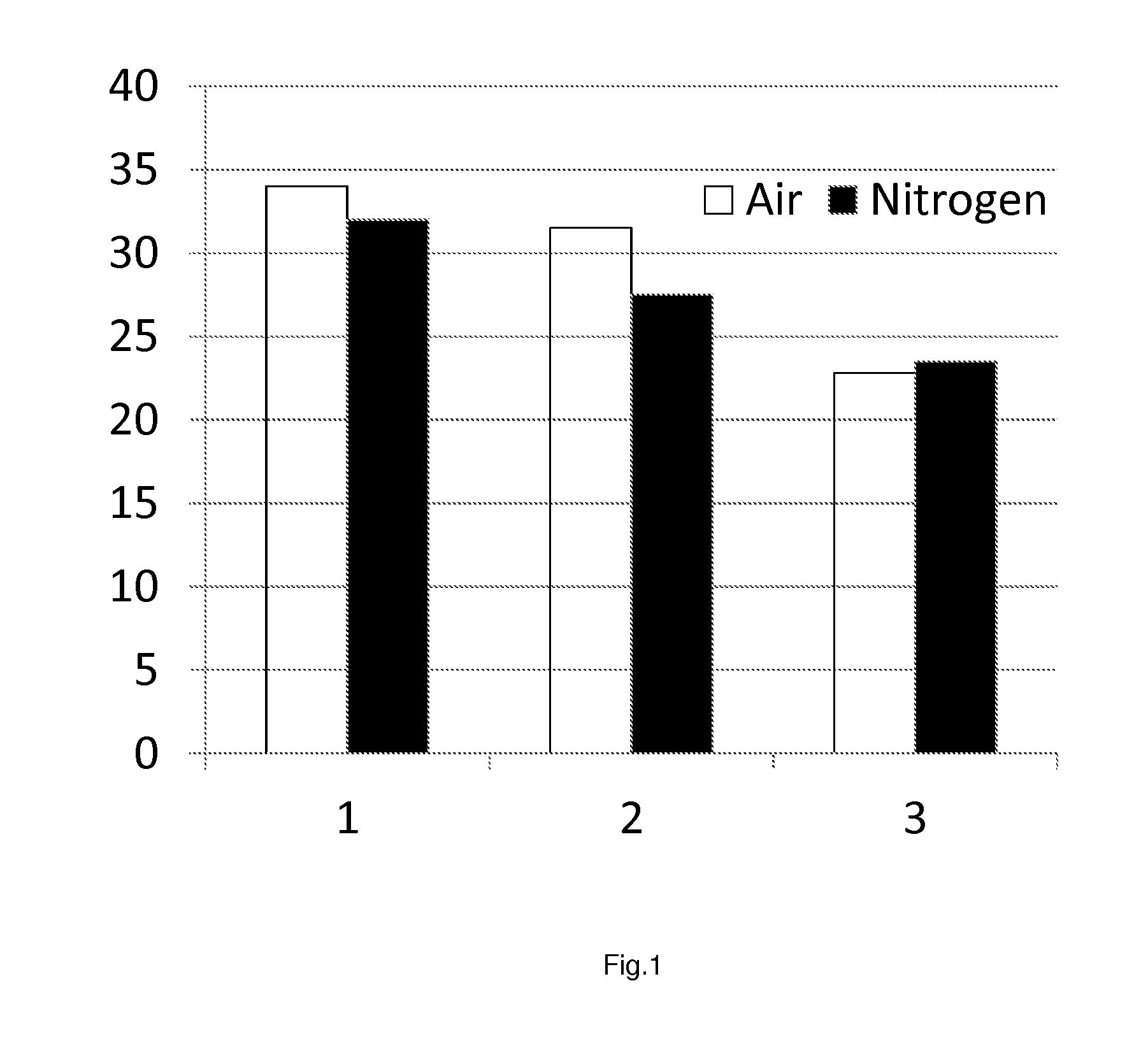

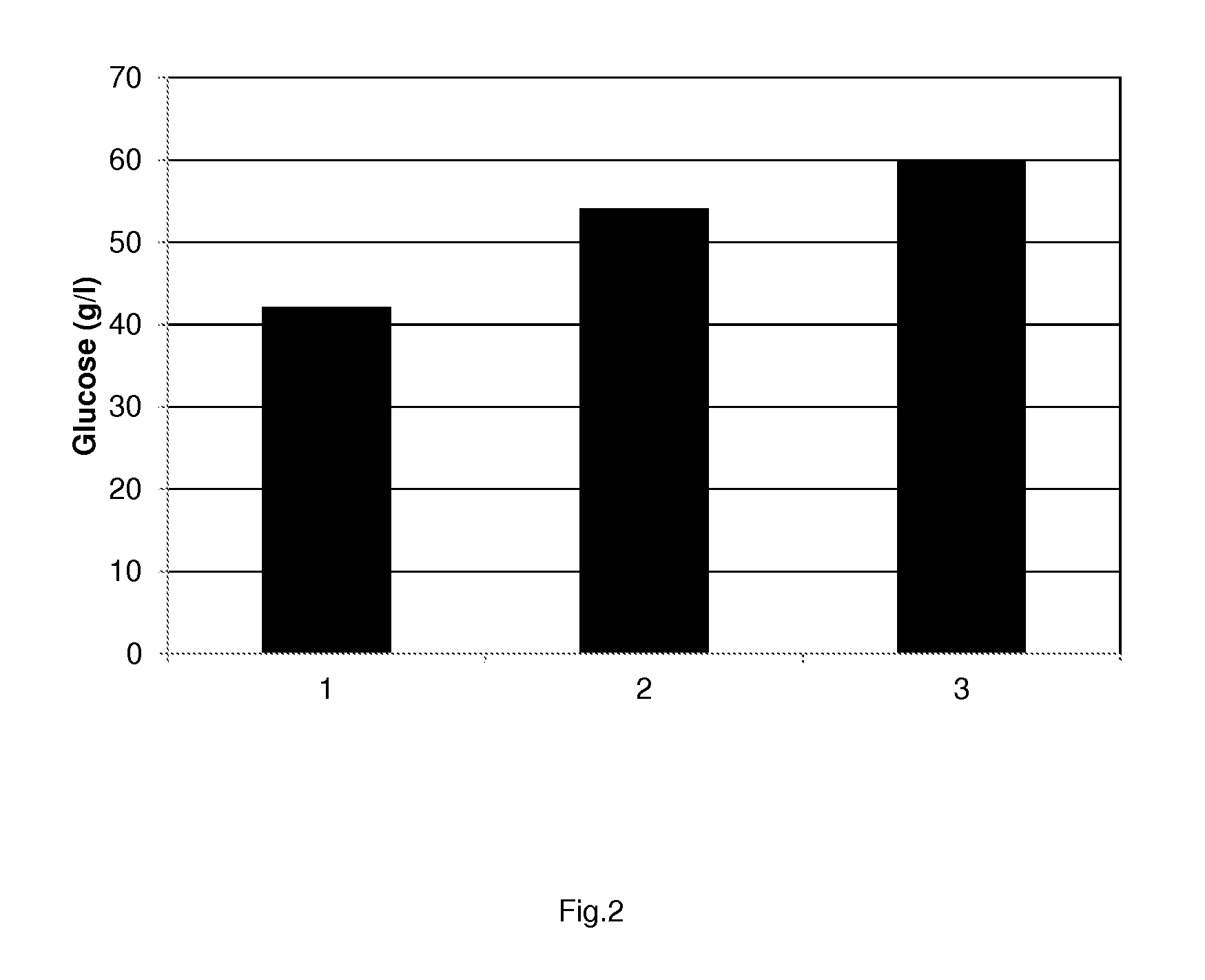

ActiveUS10087475B2Reduce processing timeReduce the amount of enzymes usedBioreactor/fermenter combinationsBiological substance pretreatmentsEnzymatic hydrolysisProcess engineering

The disclosure relates to a process for the preparation of a sugar product from lignocellulosic material, comprising the following steps:a) optionally, pretreatment of the lignocellulosic material;b) optionally, washing of the optionally pretreated lignocellulosic material;c) enzymatic hydrolysis of the optionally washed and / or optionally pretreated lignocellulosic material in a hydrolysis reactor using an enzyme composition comprising at least two cellulase; andd) optionally, recovery of a sugar product;wherein during the enzymatic hydrolysis oxygen-containing gas is added to the lignocellulosic material in the hydrolysis reactor and wherein part of the oxygen-containing gas, added to the lignocellulosic material, is gas originating from the headspace of the reactor,preferably during part of the time of the enzymatic hydrolysis less oxygen is added to the lignocellulosic material compared to the other part of the time of the enzymatic hydrolysis, or preferably during part of the time of the enzymatic hydrolysis no oxygen is added to the lignocellulosic material.

Owner:DSM IP ASSETS BV

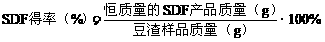

Method for preparing soluble dietary fibers of bean dregs

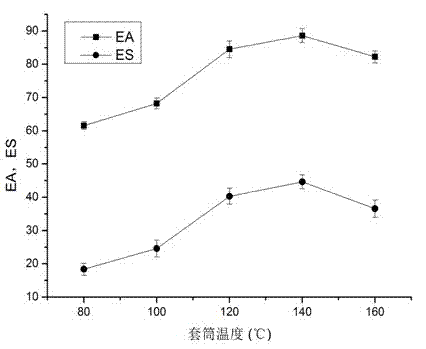

The invention provides a method for preparing soluble dietary fibers of bean dregs, which solves the problems of low yield and high cost of the soluble dietary fibers of the bean dregs in the prior art. According to the method, mechanical, chemical and enzyme methods are creatively combined, so compared with the conventional single or two-method combined preparation method, the method has the advantages of high product yield, high quality and low cost; the sequence is a continuous operating process, and the three kinds of treatment is sequential and synergetic; and the method has the greatest significance that the yield and the quality of the soluble dietary fibers in the bean dregs are improved, and the yield is improved by 42 to 43.8 percent. The method is simple, easy to operate and short in period, and does not require complex equipment. In the double-screw extrusion process, the conventional thought of high-temperature extrusion is broken, and an extrusion mode of low temperature and high shear is utilized; and cellulose, xylanase and pectinase are creatively combined and used in a specific ratio and used for preparing the soluble dietary fibers of the bean dregs together to achieve a good effect.

Owner:迟玉杰

Soya-dregs water soluble diet fiber preparation method using nano filtration and spray-drying method

InactiveCN101455398AImprove conversion rateIncrease dosageFood shapingFood preparationFiberEnzymatic hydrolysis

The invention relates to a meal fiber, provides a method for preparing soybean residue water-soluble meal fiber by combining nano-filtration and spray drying, which comprises: preparing insoluble soybean residue meal fiber; steaming, boiling and the insoluble soybean residue meal fiber, and modifying it by enzymatic hydrolysis; nano-filtering, spray drying, nano-filtering the supernatant and collecting trapped fluid; spray drying the trapped fluid and collecting the spray dried powder which is he soybean residue water-soluble meal fiber product. The product achieves the advantages of good quality, simple preparation process and convenient operation, is easy to be realized in industrial production.

Owner:SHENZHEN POLYTECHNIC

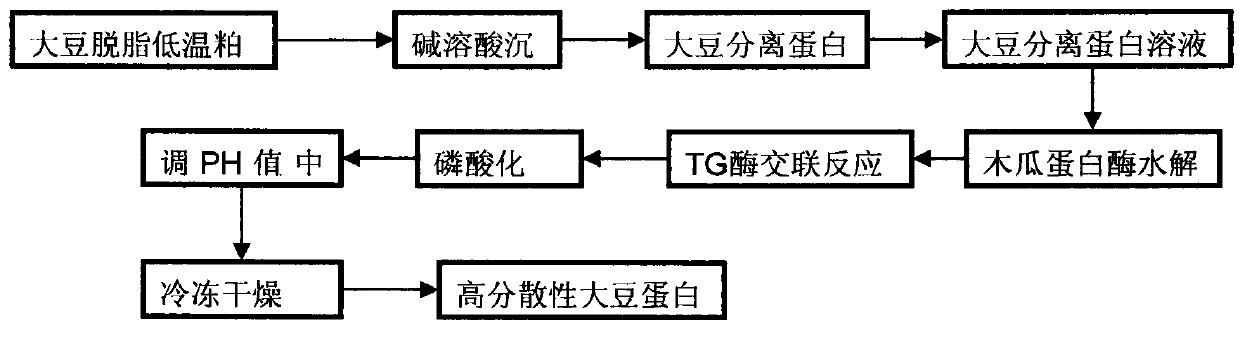

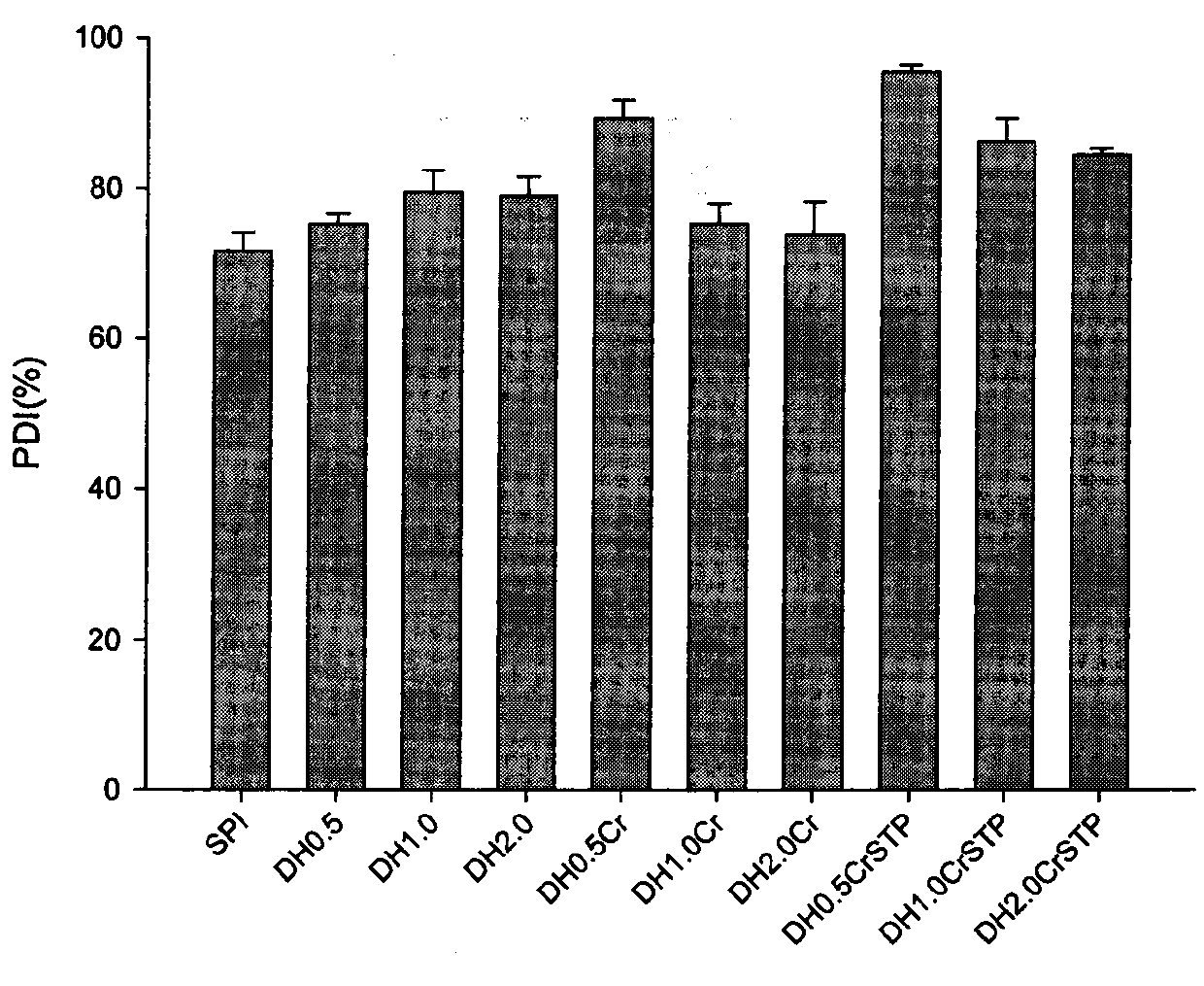

Preparation method for high-dispersity soybean proteins

ActiveCN104186920AGood dispersionEasy to operateVegetable proteins working-upDispersityPhosphorylation

The invention discloses a preparation method for high-dispersity soybean proteins, and belongs to the technical field of soybean protein processing. The preparation method comprises the steps of (1) dissolving isolated soybean proteins into water according to a certain ratio to obtain a soybean protein solution, and performing limited enzymolysis by papain; (2) adding transglutaminase into enzymatic hydrolysate in the step (1) for crosslinking, and performing enzyme deactivation, centrifugation and freeze-drying to obtain enzymolysis-crosslinking modified soybean proteins; (3) performing phosphorylation treatment on the enzymolysis-crosslinking modified soybean proteins in the step (2), and then performing freeze-drying to obtain high-dispersity soybean proteins. An experiment result shows that the modified soybean proteins prepared by the method are extremely high in dispersity; furthermore, equipment is simple and is convenient to operate; the using amount of enzyme is small, and the high-dispersity soybean proteins are very suitable for application in food processing.

Owner:黑龙江省绿色食品科学研究院

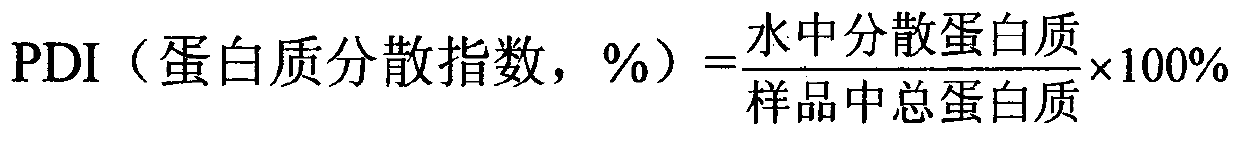

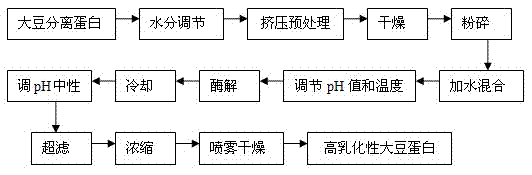

Preparation method of highly emulsified soybean protein

InactiveCN102965424ASmall molecular weightGood emulsifying effectFermentationHydrolysateRoom temperature

The invention relates to a preparation method of highly emulsified soybean protein, belonging to the technical field of soyabean protein process. The preparation method comprises the following steps of: (1) regulating moisture of isolated soybean protein, and carrying out extrusion pretreatment; and (2) crushing the protein subjected to extrusion pretreatment in the step (1); adding water according to certain proportions, and mixing to prepare a protein solution; adjusting the pH and the temperature; adding trypsase for limited trypsinization; after trypsinization, cooling to room temperature, adjusting the pH to neutrality, then conducting ultrafiltration on an enzymatic hydrolysate to obtain the soyabean protein with intercepted molecular weights of 30kDa, condensing intercepted protein, and conducting spray drying to obtain the highly emulsified soyabean protein. The soyabean protein obtained by the method has high emulsification capability and good emulsification stability, few enzymes in production are needed, the enzymolysis time is short, the cost is low, and the highly emulsified soyabean protein has excellent market prospects and economical benefits.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for synchronously extracting soybean oil, soybean milk powder and soybean dietary fiber by aqueous enzymatic method

InactiveCN105505558AEffective destructionStrong bean flavorFatty-oils/fats productionMilk substitutesFiberHydrolysate

The invention relates to a method for synchronously extracting soybean oil, soybean milk powder and soybean dietary fiber by an aqueous enzymatic method, which belongs to the technical field of plant grease processing. The method comprises the following steps: 1) dehulling soybeans and crushing the soybeans, extruding and puffing the material to obtain a puffed product; 2) adding water into an enzymatic hydrolysis reaction vessel, heating steam and adding the puffed product to obtain a mixed liquor, performing alkaline extraction on the mixed liquor, adding alkali protease for performing enzymatic hydrolysis, using a horizontal centrifuge after enzymatic hydrolysis is carried out for performing centrifugation to obtain an emulsified oil, a hydrolysate and residues; 3) using a disk centrifuge for performing centrifugation on the emulsified oil to obtain the soybean oil and a water phase, adding the water phase into the hydrolysate for concentration, and drying the material to obtain the soybean milk powder; and 4) adding water for mixing the water and the residues for homogenizing and drying a mixture to obtain the soybean dietary fiber. The method has the advantages of simple process, less enzyme usage amount, short reaction time, and low cost. The prepared high-quality soybean oil can obtain the high-nutrition partly-defatted soybean milk powder and high-oil high-protein soybean dietary fiber, and is suitable for industrial continuous production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

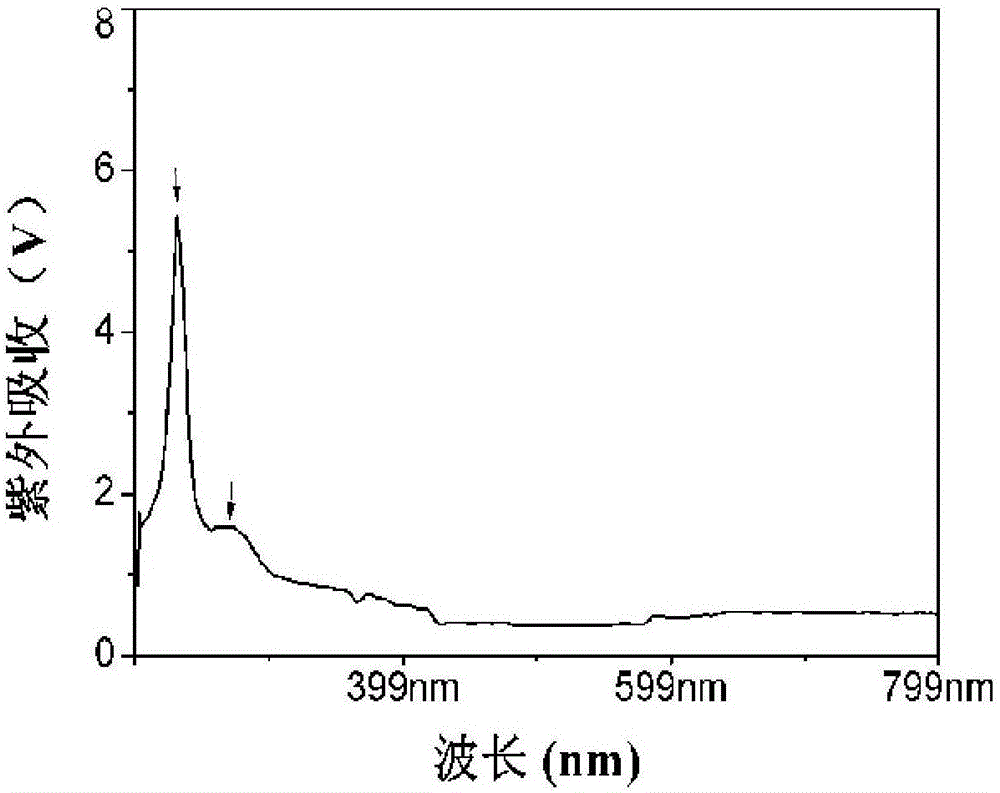

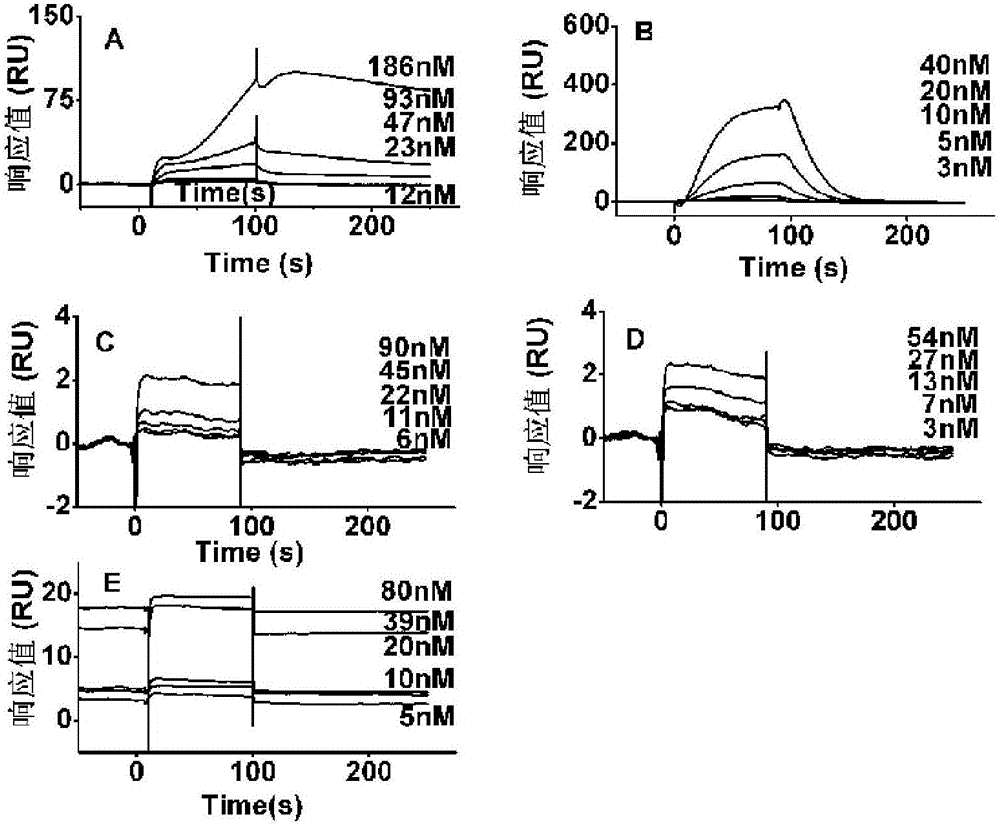

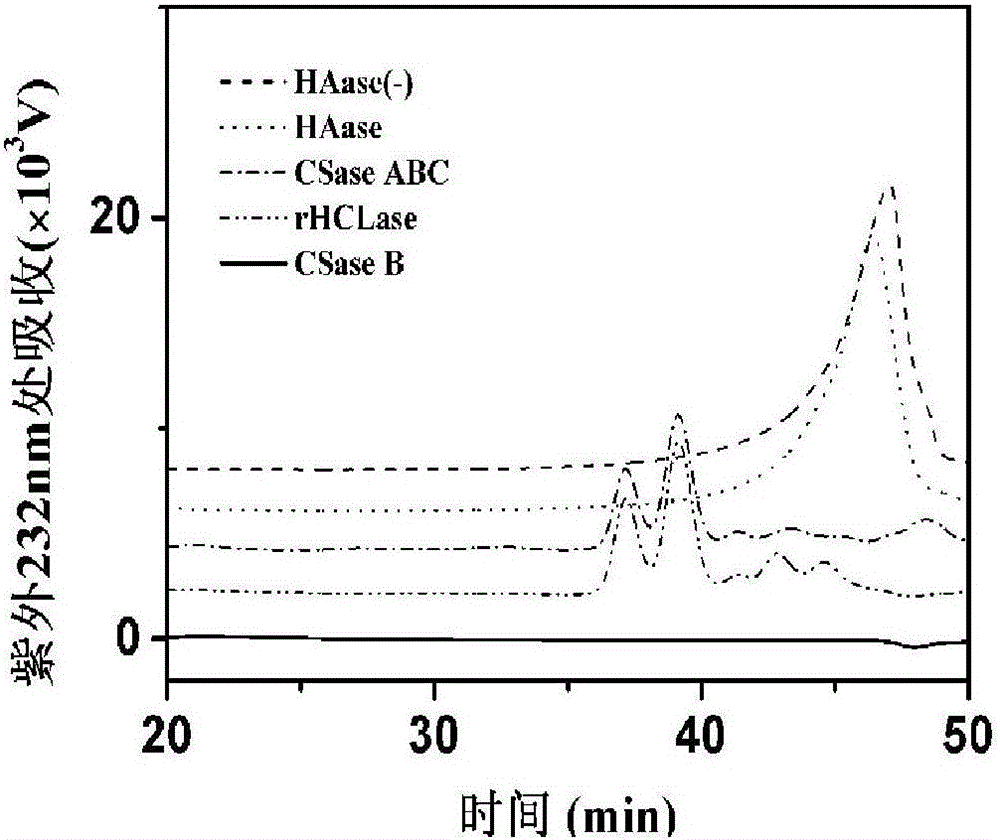

High-sulfating chondroitin sulfate (CS) and preparing method and application thereof

ActiveCN105924544AShorten the growth cycleIncrease productionOrganic active ingredientsAntineoplastic agentsSulfationChondroitin

The invention relates to a high-sulfating chondroitin sulfate (CS) and a preparing method and application thereof. According to the high-sulfating CS, the molecular weight is 100 KDa to 800 KDa, the sulfating degree is 0.7 to 1.43, and disaccharide compositions are O-units, C-units, A-units and E-units. The high-sulfating CS is a CS which is extracted from cartilage of dosidicus gigas and is rich in E-unit, and is a DG-CS with the specific disaccharide compositions, specific carbohydrate chain arranging and the specific molecular weight. An experiment proves that the high-sulfating CS has quite good anti-tumor metastasis activity.

Owner:SHANDONG UNIV

Process for enzymatic hydrolysis of lignocellulosic material and fermentation of sugars

ActiveUS20180073048A1Reduce processing timeReduce the amount of enzymes usedBiofuelsFermentationEnzymatic hydrolysisCellulase

The invention relates to a process for the preparation of a fermentation product from ligno-cellulosic material, comprising the following steps:a) optionally pre-treatment of the ligno-cellulosic material;b) optionally washing of the optionally pre-treated ligno-cellulosic material;c) enzymatic hydrolysis of the optionally washed and / or optionally pre-treated ligno-cellulosic material using an enzyme composition comprising at least two cellulase and whereby the enzyme composition at least comprises GH61;d) fermentation of the hydrolysed ligno-cellulosic material to produce a fermentation product; ande) optionally recovery of a fermentation product; wherein before and / or during the enzymatic hydrolysis oxygen is added to the ligno-cellulosic material.

Owner:VERSALIS SPA

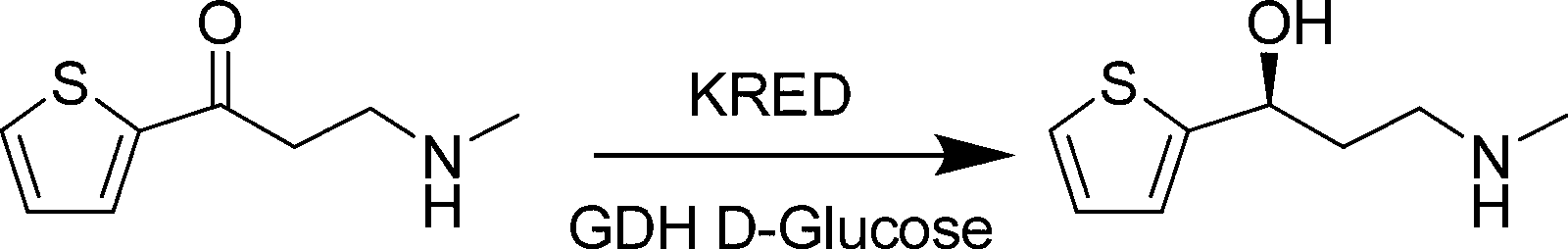

Biological preparation method of (S)-3-methylamino-(2-thienyl)-1-propyl alcohol

InactiveCN103014088AIncrease concentrationReduce the amount of enzymes usedFermentationAlcoholProcess conditions

The invention relates to a biological preparation method of (S)-3-methylamino-(2-thienyl)-1-propyl alcohol. According to the biological preparation method, 3-methylamino-1-(2-thienyl)-1-acetone is used as a substrate; under the condition that a biocatalyst, a cofactor and a cofactor regeneration system exist, the substrate performs the asymmetric reduction to generate (S)-3-methylamino-(2-thienyl)-1-propyl alcohol; the biocatalyst is ketoreductase; the cofactor regeneration system comprises glucose and glucose dehydrogenase; the asymmetric reduction is carried out in water-phase buffer solution with the pH of 6 to 8; and in a reaction system in an initial state, the concentration of the substrate is 100 to 150 mg / mL and the mass ratio of the ketoreductase to the substrate is 1 to 2 percent. According to the invention, by optimizing the process condition, the concentration of the substrate is improved and the enzyme dosage is reduced, so that production cost is reduced, the high-efficiency biological conversion process is realized and the biological preparation method is suitable for industrial production.

Owner:ENZYMEWORKS

Process for enzymatic hydrolysis of lignocellulosic material and fermentation of sugars

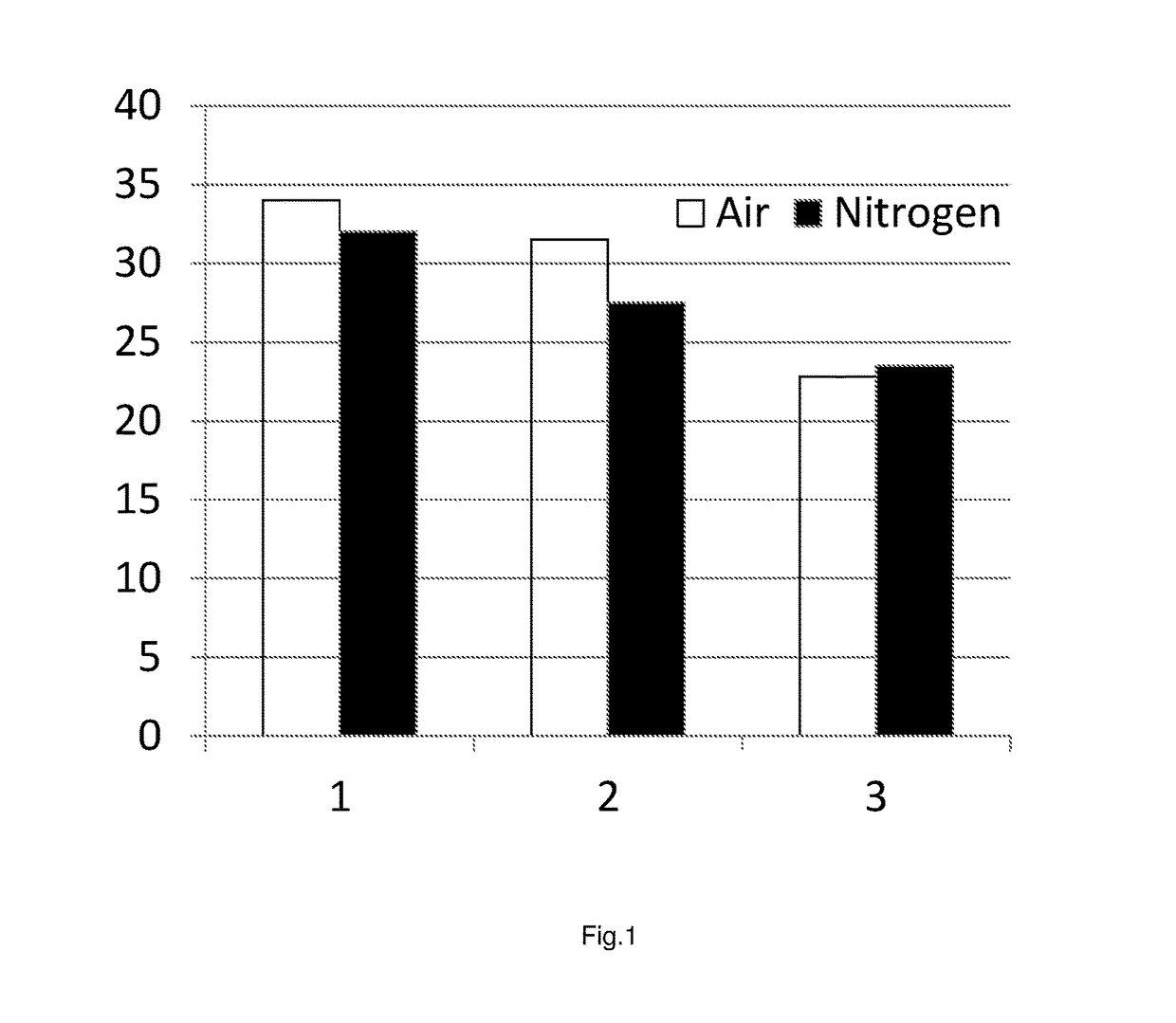

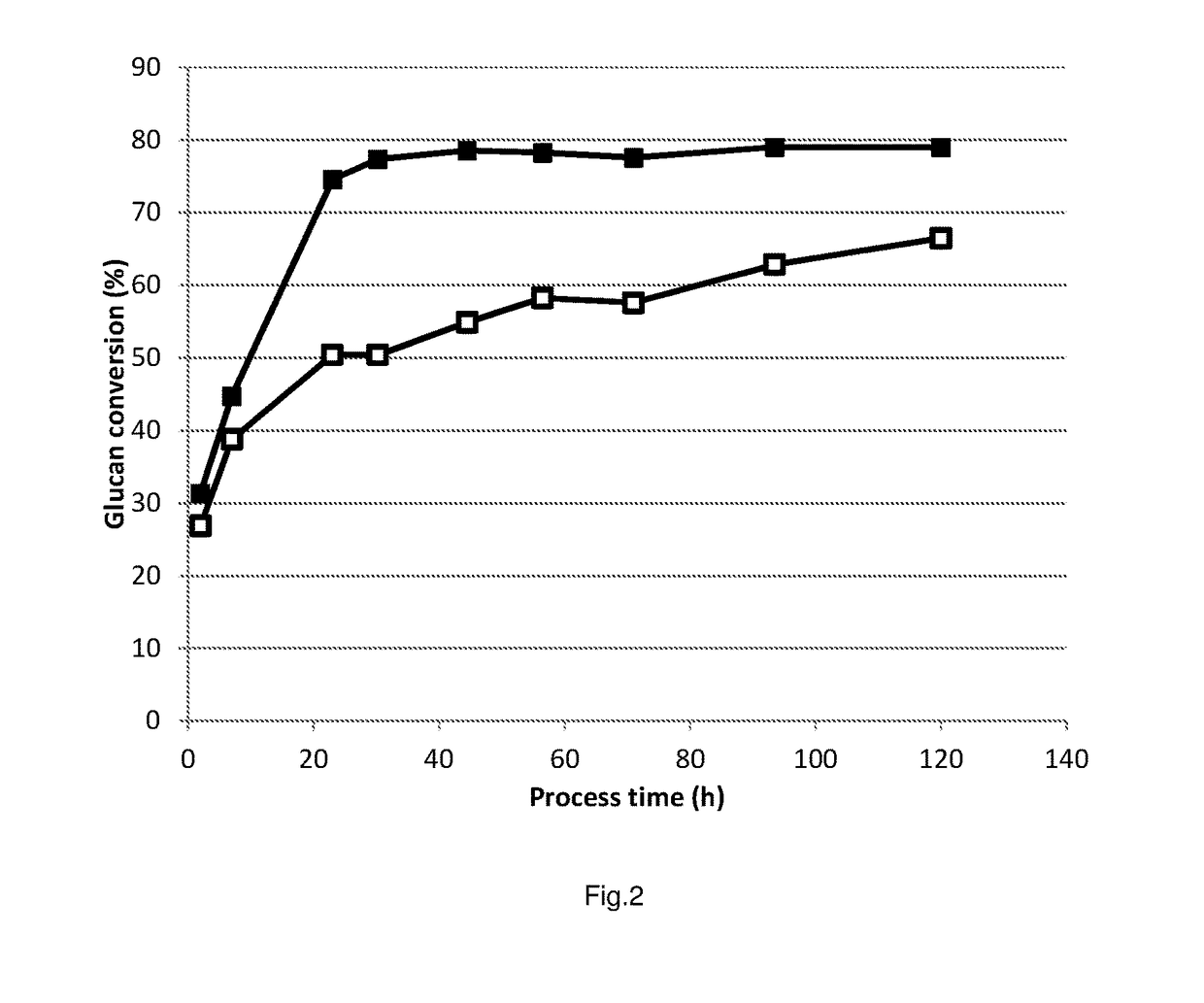

ActiveUS20150299749A1Reduce processing timeReduce the amount of enzymes usedHydrolasesTransferasesEnzymatic hydrolysisSugar

The invention relates to a process for the preparation of a sugar product from ligno-cellulosic material, comprising the following steps:a) optionally pre-treatment of the ligno-cellulosic material;b) optionally washing of the optionally pre-treated ligno-cellulosic material;c) enzymatic hydrolysis of the optionally washed and / or optionally pre-treated ligno-cellulosic material using an enzyme composition comprising at least two cellulase and whereby the enzyme composition at least comprises GH61; andd) optionally recovery of a sugar product;wherein during part of the time of the enzymatic hydrolysis, oxygen is added to the ligno-cellulosic material and during part of the time of the enzymatic hydrolysis less oxygen is added to the ligno-cellulosic material compared to the other part of the time of the enzymatic hydrolysis, preferably no oxygen is added to the ligno-cellulosic material.

Owner:VERSALIS SPA

Method for simultaneously extracting soybean oil and soybean milk powder by aqueous enzymatic method

InactiveCN105505556AWon't happenImprove qualityFatty-oils/fats refiningFatty-oils/fats productionAlkaline proteaseEnzymatic hydrolysis

The invention relates to a method for synchronously extracting soybean oil and soybean milk powder by an aqueous enzymatic method, which belongs to the technical field of plant grease processing. The method comprises the following steps: 1) dehulling soybeans and performing ultramicro grinding on the soybeans, extruding the soybeans and puffing the ground material to obtain a puffed product; 2) adding water into an enzymatic hydrolysis reaction vessel, heating steam and adding the puffed product to obtain mixed liquor, adjusting pH value of the mixed liquor, adding alkali protease for performing enzymatic hydrolysis, using a horizontal centrifuge after enzymatic hydrolysis is carried out for performing centrifugation to obtain emulsified oil, a hydrolysate and residues; and 3) using a disk centrifuge for performing centrifugation on the emulsified oil to obtain the soybean oil and a water phase, adding the water phase into the hydrolysate for concentration, and drying the material to obtain the soybean milk powder. The method has the advantages of simple process, short reaction time, less enzyme usage amount and low cost, and the prepared soybean oil has no solvent residues and has high quality. The soybean milk powder can be prepared when the soybean oil is prepared, the soybean milk powder can keep partial fat, and has advantages of rich bean fragrance, abundant nutrition, and good brewing property, and is suitable for continuous industrial production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

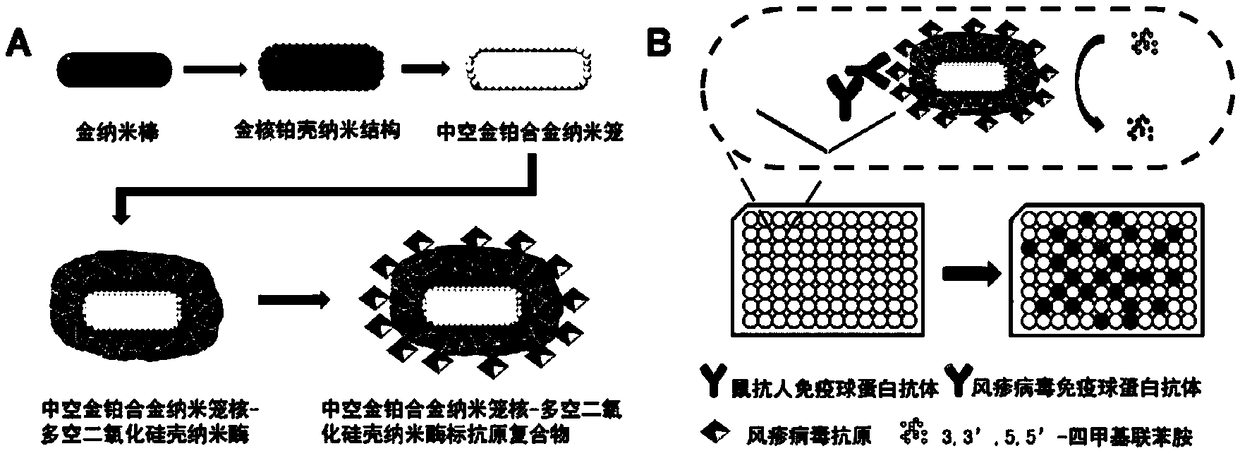

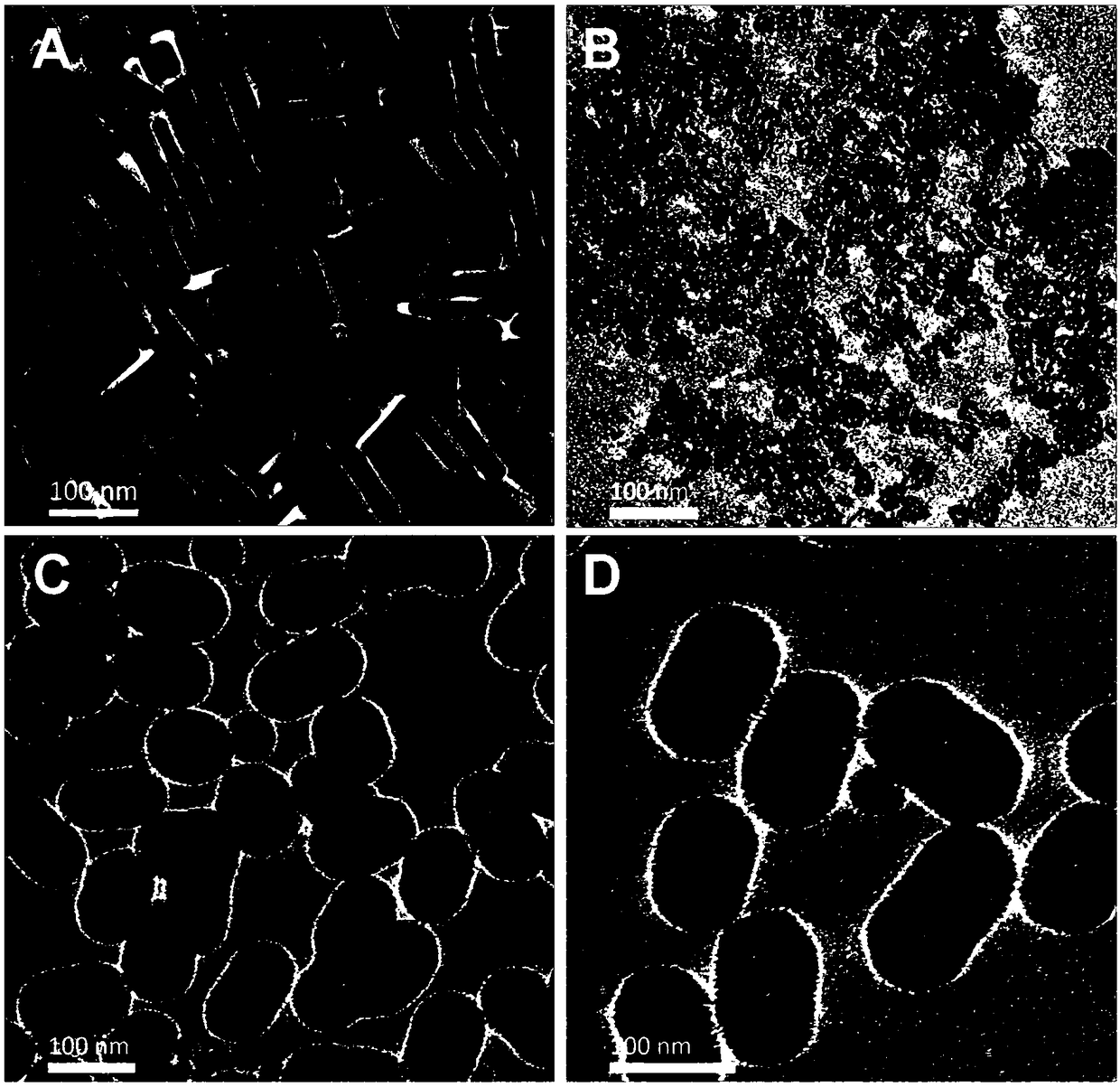

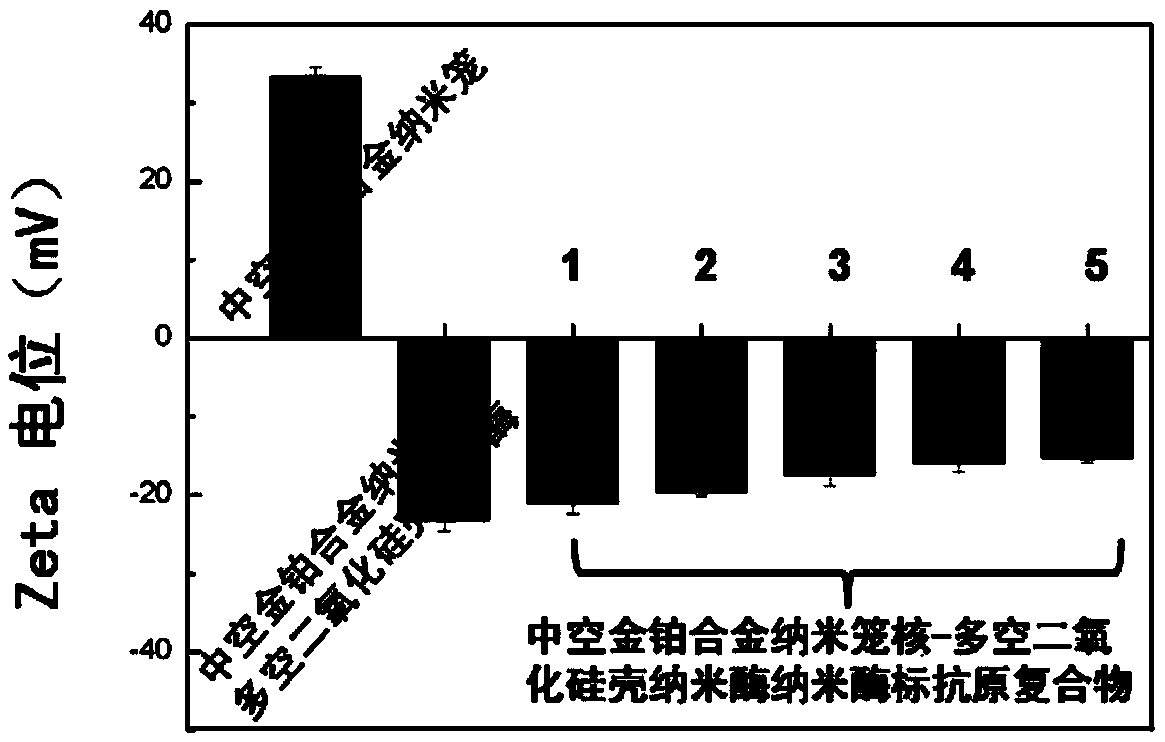

Nano enzyme with nanometer cage core of hollow gold-platinum alloy and shell of porous silicon dioxide, preparation method and application thereof

The invention provides a nano enzyme with a nanometer cage core of a hollow gold-platinum alloy and a shell of a porous silicon dioxide, a preparation method and an application thereof, and belongs tothe field of nanometer materials. The preparation method comprises the following steps: etching a gold core platinum shell nanostructure through potassium hexachloroplatinate to obtain a nanocage ofhollow gold-platinum alloy; coating silicon dioxide on the surface of the nanocage through tetraethyl silicate; and obtaining the nano enzyme taking the nanometer cage, in a round rod shape, of the hollow gold-platinum alloy as a core, and a silicon dioxide shell as the periphery of the core. The length of the core is 80 to 100 nm, and the diameter is 20 to 25 nm. The shell is provided with a channel of 3 to 5 nm. The nano enzyme is negatively charged. The antigen can be bound by an attractive effect of positive and negative electric charges to form a nano enzyme label antigen complex, which is used for performing enzyme linked immunoassay. According to the nano enzyme with the nanometer cage core of the hollow gold-platinum alloy and the shell of the porous silicon dioxide, the preparation method and the application thereof, the cost of a reagent of the natural enzyme label antigen complex is reduced, the working environment of enzyme linked immunodetection is extended, the defects that the natural enzyme is easy to deactivate and denature, etc., are overcame, and the nano enzyme can be widely applied to various enzyme linked immunodetection.

Owner:ZAOZHUANG UNIV

Method for extracting soybean blend oil and compound protein by using aqueous enzymatic method

InactiveCN105331439AEffective destructionNutritional diversityFatty-oils/fats refiningFatty-oils/fats productionSolid phasesChemistry

The invention relates to a method for extracting soybean blend oil and compound protein by using an aqueous enzymatic method, which belongs to the technical field of vegetable oil and fat and protein processing. The method comprises the following steps of (1) proportionally mixing soybeans and peanuts, then peeling, crushing, and then extruding and expanding, so as to obtain an expanded product; (2) adding water to an enzymolysis reaction kettle, heating with steam, then adding the expanded product, so as to obtain a mixed solution, regulating a pH value of the mixed solution, then adding alkaline protease for enzymolysis, and centrifuging after the enzymolysis, so as to obtain emulsified oil, hydrolysate and residues; (3) performing ethanol demulsification on the emulsified oil, and then centrifuging to obtain free oil and a solid phase; (4) adding the solid phase to the hydrolysate for alkali extraction and acid precipitation, and then centrifuging to obtain a liquid phase and sediments; (5) performing steam demulsification on the liquid phase, then centrifuging to obtain free oil, merging the free oil, so as to obtain the soybean blend oil, and dying the sediments, so as to obtain the compound protein. The method has the advantages of simple process and low cost, the prepared soybean blend oil has strong oil fragrance, the prepared compound protein has good functionality, and the method is favorable for being applied in a food industry.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

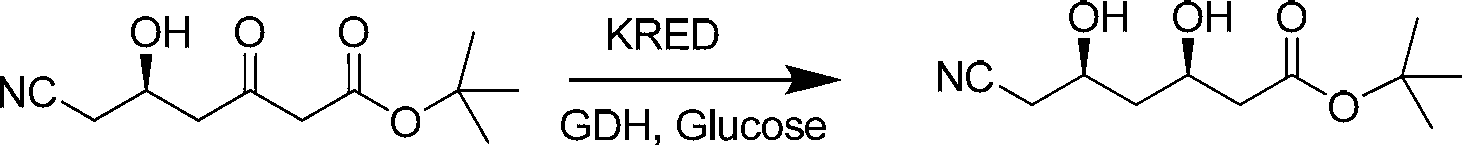

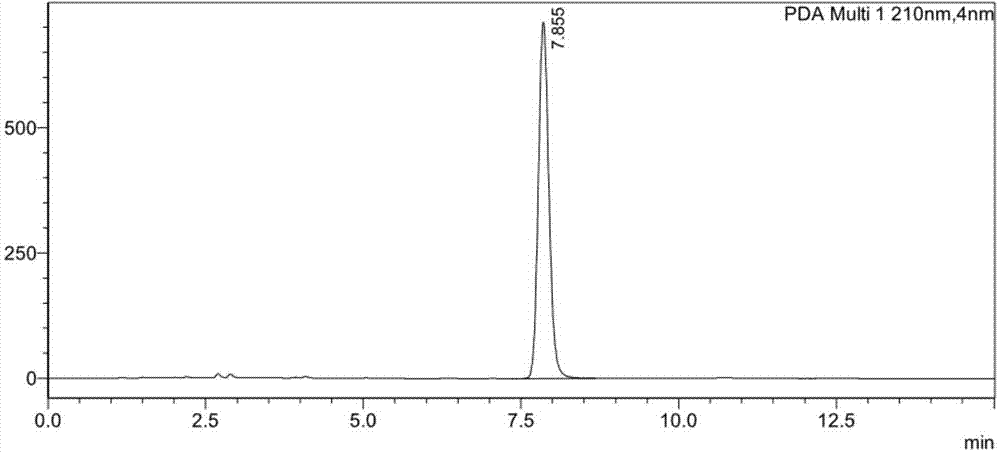

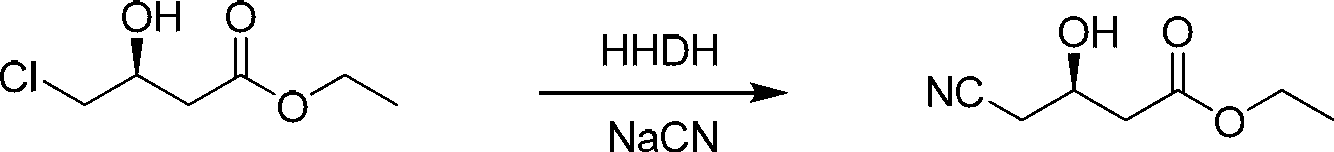

Biological preparation method of 6-cyano-(3R, 5R)-dihydroxyhexanoate

ActiveCN103014080AOptimizing Process ConditionsHigh substrate concentrationChemical recyclingFermentationSubstrate concentrationBiotransformation

The invention relates to a biological preparation method of 6-cyano-(3R, 5R)-dihydroxyhexanoate. According to the biological preparation method, 6-cyano-(6R)-hydroxyl-3-oxo-tertiary butyl hydroperoxide is used as a substrate; under the condition that a biocatalyst, a cofactor and a cofactor regeneration system exist, the substrate performs the reduction reaction to generate 6-cyano-(3R, 5R)-dihydroxyhexanoate; and the reduction reaction is carried out in water-phase buffer solution with pH of 6 to 8. According to the invention, by optimizing the process condition and mainly optimizing the pH of the reduction reaction, the concentration of the substrate is improved and the enzyme dosage is reduced, so that production cost is reduced and the high-efficiency biological conversion process is realized.

Owner:ENZYMEWORKS

Method for efficiently saccharifying xylose residue or furfural residue

ActiveCN101619333ALarge specific surface areaReduce the dosage of cellulaseFermentationXyloseSolid phases

The invention relates to a method for efficiently saccharifying biomass wastes such as xylose residue or furfural residue, comprising the following steps: performing steam exploding processing on biomass wastes such as xylose residue or furfural residue, then collecting materials after steam exploding, carrying out solid-liquid separation, and performing enzymolysis and saccharification on a solid phase obtained from separation. In the method of the invention, the crystallizing structure of cellulose is destroyed by steam exploding processing, the specific surface area of cellulose is increased, and the content of lignin is reduced, thereby reducing the use amount of cellulase during saccharification of lignocellulose materials, improving the enzymolysis efficiency, increasing sugar concentration in the enzymolysis solution, effectively reducing the cost for enzymolysis and sugar concentration utilizing lignocellulose materials, promoting industrialized recover and reuse to the waste, and being favorable for protecting the environment and saving resources.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Method for synthesizing medium-long-chain structure ester by enzymic method

InactiveCN107805647AImprove enzymatic hydrolysis efficiencyReduce generationFermentationMass ratioReaction temperature

The invention discloses a method for synthesizing medium-long-chain structure ester by an enzymic method. Crushed immobilized lipase is used as a catalyst; long-chain triglyceride and medium-chain triglyceride are fed according to a mass ratio of 6.4 to (2 to 10); the reaction temperature is 45 to 80 DEG C; the stirring reaction is performed for 1 to 10h in the vacuum state. When the method is used for preparing the medium-long-chain structure ester, the enzyme consumption can be reduced; the reaction time is shortened; the generation quantity of byproducts such as diglyceride is reduced; theproduct acid value is reduced; the high target product yield is maintained, so that the target product production cost is reduced; the economic benefits are improved.

Owner:GUANGZHOU HANFANG PHARMA

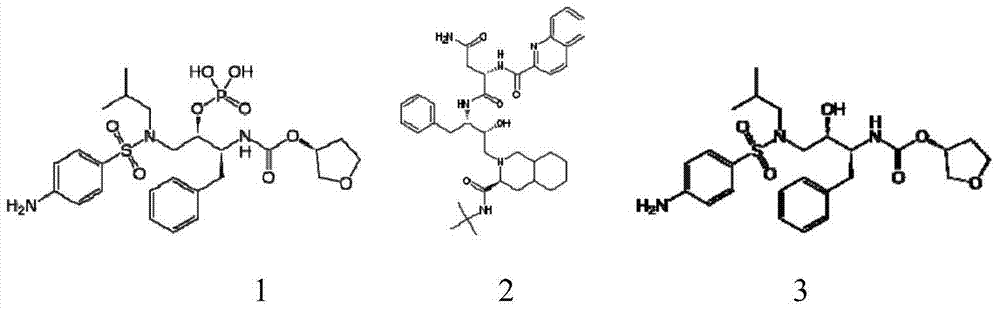

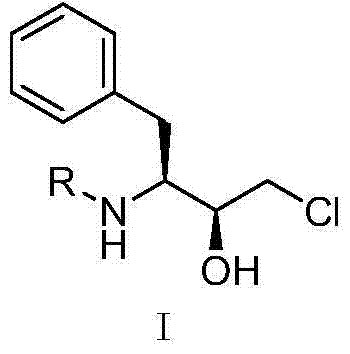

Preparation method of fosamprenavir intermediate

The invention relates to a preparation method of N-protected (2S, 3S)-3-amino-1-chloro-4-phenyl-2-butanol. The preparation method comprises the following steps: by taking N-protected (S)-3-amino-1-chloro-4-phenyl-2-butanone as a substrate, performing a reducing reaction on the substrate to generate the N-protected (2S, 3S)-3-amino-1-chloro-4-phenyl-2-butanol, wherein the reducing reaction is performed in the presence of a ketoreductase, a cofactor and a hydrogen donor, in an aqueous phase having the pH of 8-10 and at a temperature ranging from 30 to 50 DEG C; and the DNA sequence of the ketoreductase is as shown in any one of SEQ ID No. 1-20. According to the preparation method, as the specific ketoreductase is used for catalyzing the reduction reaction, the preparation method has the advantages of small enzyme dosage, mild reaction condition, simplicity in operation, short reaction time, high yield, and environmental protection. Compared with the chemical methods in the prior art, the preparation method is high in economic efficiency and low in pollution, and has an important application value.

Owner:ENZYMEWORKS

Process for enzymatic hydrolysis of lignocellulosic material and fermentation of sugars

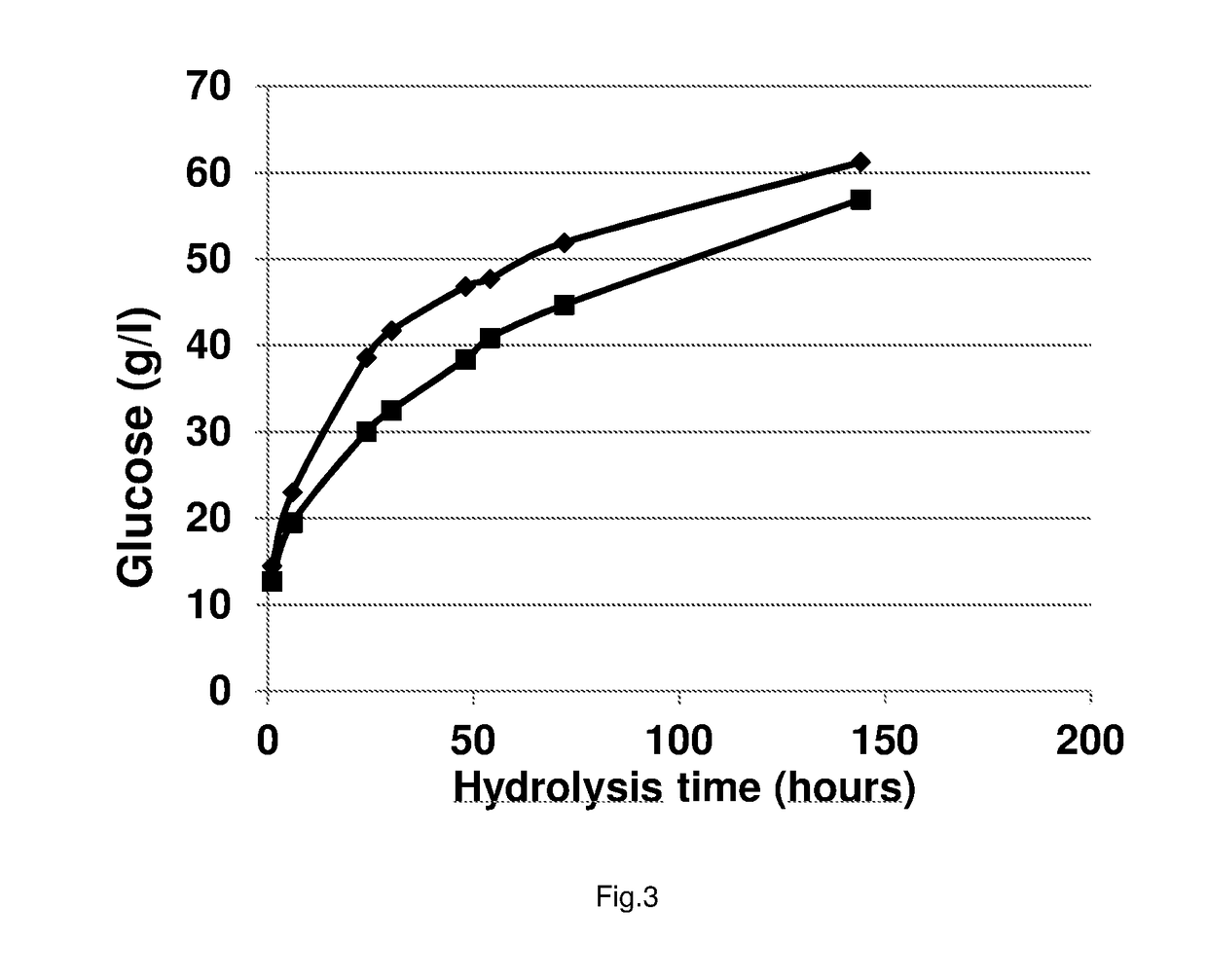

ActiveUS20150307903A1Reduce processing timeReduce the amount of enzymes usedBiofuelsWaste based fuelEnzymatic hydrolysisOxygen

The invention relates to a process for the preparation of a fermentation product from ligno-cellulosic material, comprising the following steps:a) optionally pre-treatment of the ligno-cellulosic material;b) optionally washing of the optionally pre-treated ligno-cellulosic material;c) enzymatic hydrolysis of the optionally washed and / or optionally pre-treated ligno-cellulosic material using an enzyme composition comprising at least two cellulase and whereby the enzyme composition at least comprises GH61;d) whereby less than 7.5 mg enzyme composition / g glucan (on dry matter and enzyme as protein) or less than 3.0 mg enzyme composition / g feedstock (on dry matter and enzyme as protein) is used; ande) fermentation of the hydrolysed ligno-cellulosic material to produce a fermentation product; andf) optionally recovery of a fermentation product;wherein before and / or during the enzymatic hydrolysis oxygen is added to the ligno-cellulosic material.

Owner:VERSALIS SPA

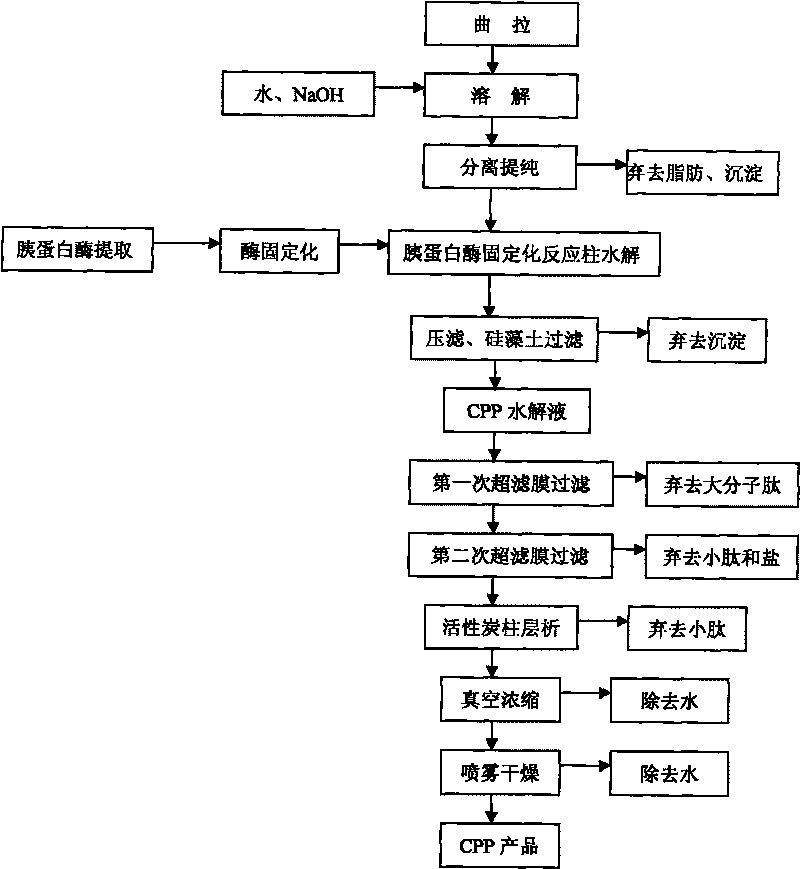

Casein phosphopept continuous production process by adopting immobilized enzyme hydrolysis crude cheese and ultrafiltration membrane separation method

The invention relates to a casein phosphopept continuous production process by adopting an immobilized enzyme hydrolysis crude cheese and ultrafiltration membrane separation method, comprising the following steps: a. extraction of tryptase; b. preparation of tryptase immobilized reaction column; c. crude cheese hydrolysis; d. separation and purification of the casein phosphopept (CPP) with an ultrafiltration membrane; e. column chromatography of CPP ultrafiltrate. The process has rational design, strong operability, short production process, high concentration of intermediate products and low production energy consumption; the main separation and purification processes are carried out at normal temperature, the evaporation capacity is less in the drying process, the energy consumption in the production can be greatly reduced, and the cost is saved; the product is obtained by vacuum concentration and spray drying, the main ingredient of the product is micromolecule bioactive polypeptides, the polypeptide with 2000-6000 of molecular weight accounts for more than 45 percent of the polypeptides.

Owner:甘南州科瑞乳品开发有限公司

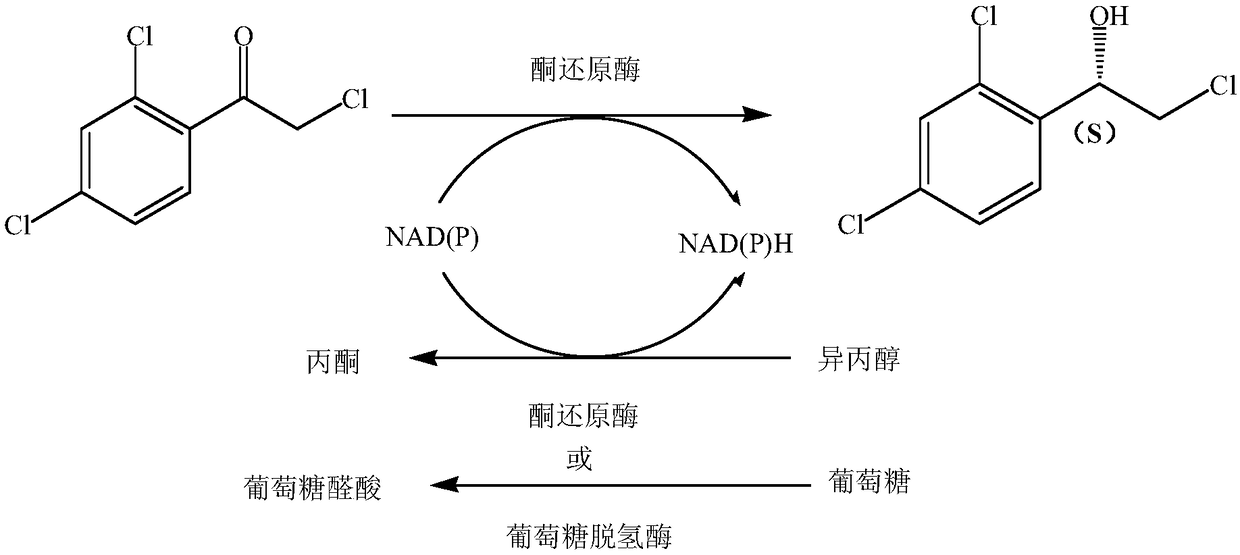

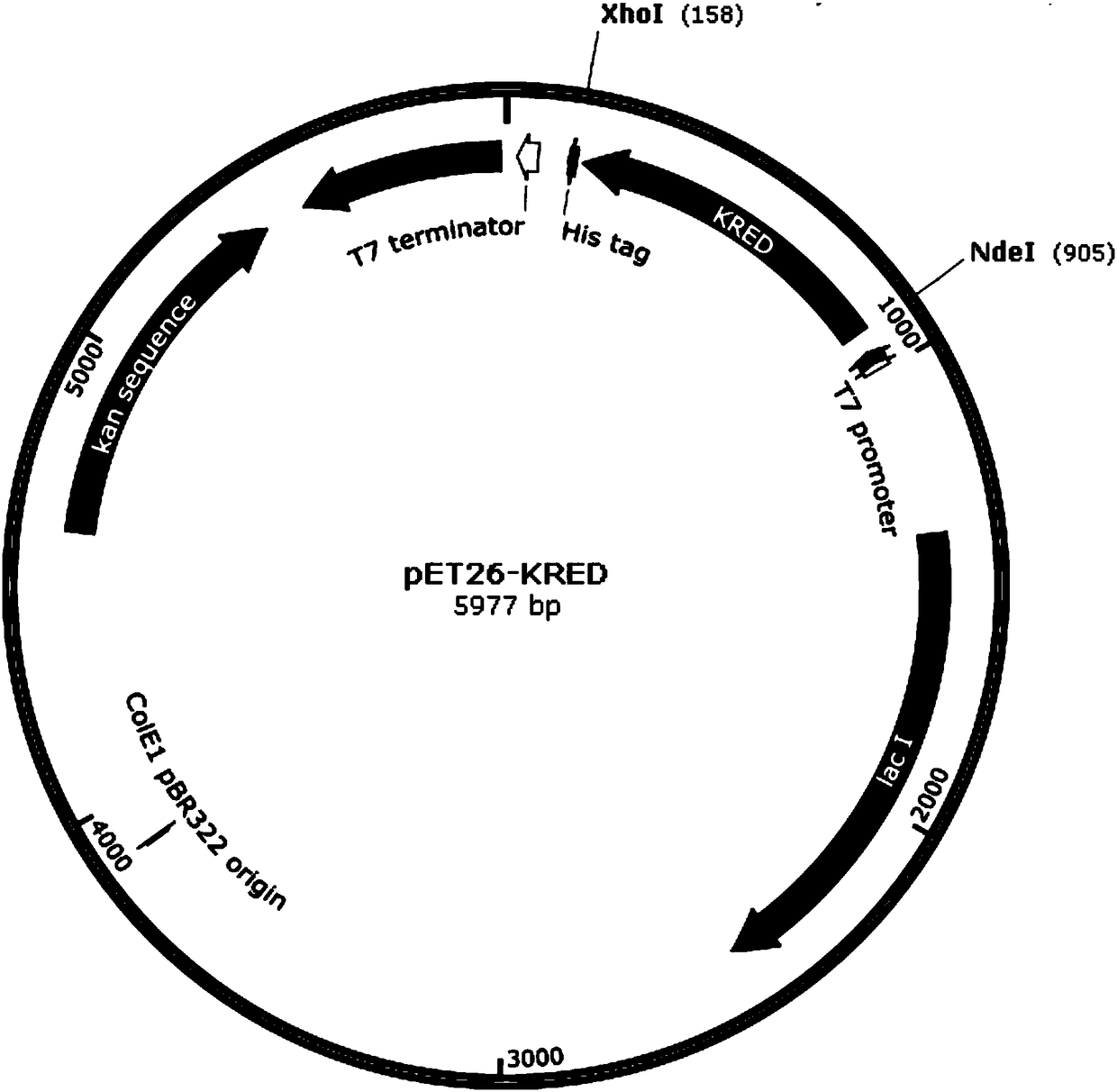

Enzymic preparation method of luliconazole intermediate

InactiveCN108285909ALess enzymeMild reaction conditionsMicroorganism based processesOxidoreductasesThallusRecombinant escherichia coli

An enzymic preparation method of a luliconazole intermediat is characterized in that 2-chlorine-1-(2, 4-dichlorophenyl) acetone is used as a substrate and is subjected to asymmetric reduction in the existence of ketoreductase, a cofactor and a hydrogen donor to obtain (S)-2-chlorine-1-(2, 4-dichlorophenyl) ethyl alcohol. The method comprises the following steps: (1) preparing ketoreductase, namely, inoculating single recombinant escherichia coli containing ketoreductase gene into liquid LB culture medium with kanamycin resistance; culturing under temperature of 37 DEG C, and staying overweight; inoculating the activated culture material into the kanamycin containing liquid LB culture medium; oscillating and culturing under the temperature of 37 DEG C until OD600 is 0.6-0.8; adding IPTG with final concentration of 0.1M; performing induced culture for 8-10h under the temperature of 25 DEG C; centrifuging; collecting thallus; and ultrasonically breaking walls to obtain the recombinant ketoreductase; and (2) preparing (S)-2-chlorine-1-(2, 4-dichlorophenyl) ethyl alcohol, namely, adding the substrate 2-chlorine-1-(2, 4-dichlorophenyl) acetone to a buffering solution, and adding certainamount of cofactor NAD(P) and isopropanol; adding the recombinant ketoreductase; reacting by biologically catalyzing under the temperature of 30 DEG C; and adding ethyl acetate for extracting after the reaction is finished, thus obtaining the (S)-2-chlorine-1-(2, 4-dichlorophenyl) ethyl alcohol.

Owner:ZHEJIANG OCEAN UNIV

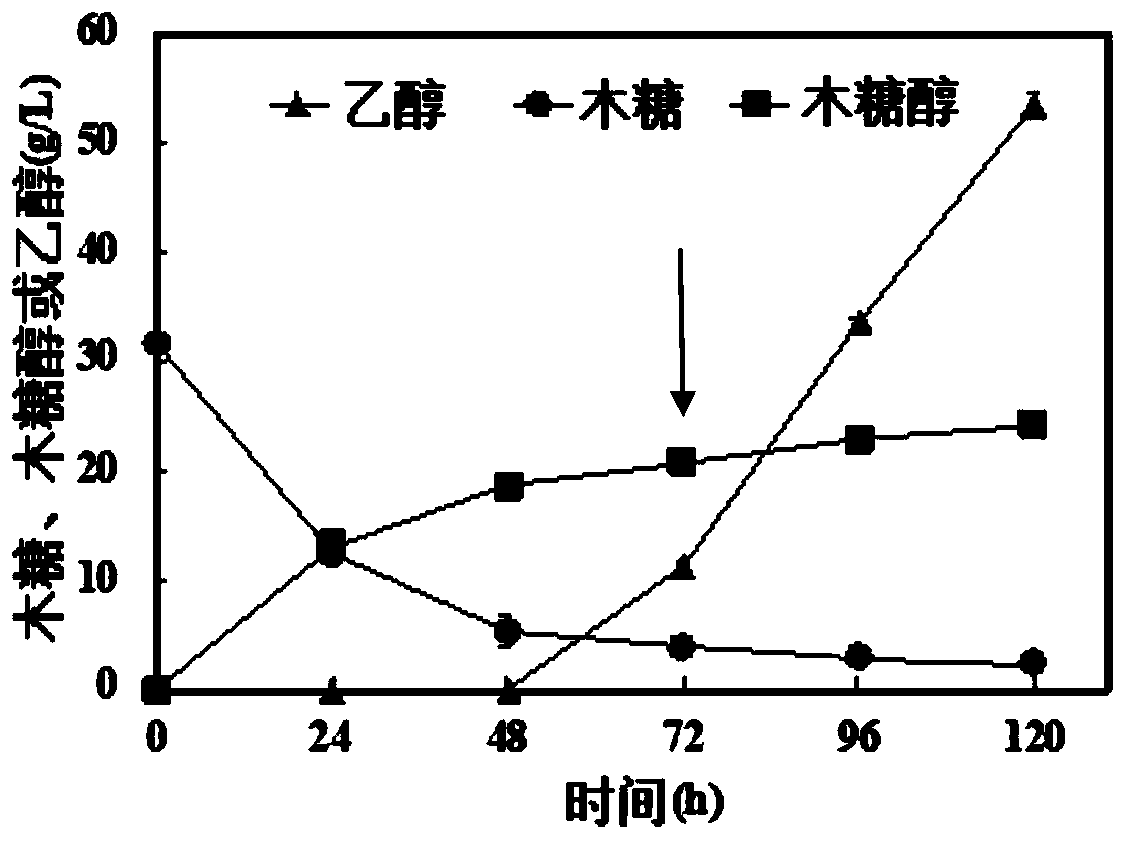

Fermentation method for producing xylitol and ethanol by using undetoxified cellulose raw materials

ActiveCN111118071AReduce dosageImprove sugar utilizationBiofuelsMicroorganism based processesBiotechnologyXylose fermentation

In view of problems in the existing cellulose ethanol preparation technologies that inhibitors in a cellulose hydrolyzate inhibit fermentation, xylose cannot be completely converted, glucose inhibitsfermentation of the xylose, and a cellulase acting temperature and a microbe fermentation temperature are non-uniform, the invention provides a fermentation method for producing xylitol and ethanol byusing undetoxified cellulose raw materials. The fermentation method comprises the steps of inoculum culture, xylose fermentation, cellulase adding, synchronous diastatic fermentation and the like. According to the method, simultaneous utilization of the xylose and the inhibitors is achieved by adopting an acetic acid and xylose co-utilization based Kluyveromyces marxianus strain, and thus, the problem in inhibitor removal is avoided; by adopting high-temperature synchronous diastatic fermentation, the problem that the cellulase is unmatched with a fermentation temperature is avoided; and compared with the existing cellulose ethanol fermentation technologies, the production cost can be remarkably reduced.

Owner:DALIAN UNIV OF TECH

Method for extracting peanut oil and peanut butter through aqueous enzymatic method

InactiveCN105419930ASimple processLess enzymeFood homogenisationFood hydrolysisChemistrySucrose measurement

The invention provides a method for extracting peanut oil and peanut butter through an aqueous enzymatic method and belongs to the technical field of vegetable oil and fat processing. The method includes the following steps that 1, peanuts are subjected to extrusion and puffing processing after being peeled and crushed, and a puffing product is obtained; 2, water is added into an enzymolysis reaction kettle, after steam heating is conducted, the puffing product is added, mixed liquid is obtained, after the pH of the mixed liquid is adjusted, alkaline protease is added for enzymolysis, after enzymolysis is conducted, a horizontal centrifuge is adopted for conducting centrifugation, and a liquid phase and residuals are obtained; 3, a disk centrifuge is adopted for conducting centrifugation on the liquid phase, the peanut oil and the water phase are obtained, the residuals are mixed with water after being crushed, mixed slurry is obtained, and the mixed slurry is subjected to heat treatment; 4, the mixed slurry obtained after heat treatment is placed into a blending tank, then saccharose, salt, essence and agar are added for blending, the blended slurry is subjected to homogeneity, concentration and sterilization, and the peanut butter is obtained. The method is simple in process, low in cost and suitable for industrialized continuous production, and the high-quality peanut oil and the low-fat high-protein peanut butter can be obtained at the same time.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Biological preparation method of (R)-4-cyano-hydroxybutanoate

ActiveCN103014082AIncrease concentrationHigh purityFermentationSodium cyanideSubstrate concentration

The invention relates to a biological preparation method of (R)-4-cyano-hydroxybutanoate. According to the biological preparation method, (S)-4-chlorine-3-hydroxybutanoate is used as a substrate; under the action of a biocatalyst, the substrate reacts with sodium cyanide to generate a target product (R)-4-cyano-hydroxybutanoate; the biocatalyst is recombination halohydrin dehalogenase; and the reaction is carried out in a water phase with the pH of 6 to 8. According to the invention, by adopting the recombination halohydrin dehalogenase, the concentration of the substrate is improved and the enzyme dosage is reduced, so that production cost is reduced. Moreover, by optimizing the process, both purity and yield of the product are improved.

Owner:ENZYMEWORKS

Production of an instant coffee product in high yield

Disclosed herein is a process for production of an instant coffee product in a high yield, comprising the steps of extracting roast and ground coffee beans with water having a temperature of 80° C. or less, to produce a first extract and spent coffee grounds, adding water to the spent coffee grounds to produce an aqueous suspension, hydrolysing the aqueous suspension using a hydrolysing enzyme to produce a second extract and spent remains, adding the first extract to the second extract, optionally after concentration and / or drying of the second extract, to obtain a combined extract, and drying the combined extract to obtain an instant coffee product. The high yield is obtained due to the reduction of enzyme inhibiting substances.

Owner:GEA PROCESS ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com