Fermentation method for producing xylitol and ethanol by using undetoxified cellulose raw materials

A fermentation method and cellulose technology, applied in the field of bioengineering, can solve the problems such as the large difference in the optimum temperature of cellulase in the fermentation temperature, the cellulose raw material cannot be directly used by microorganisms, and the fermentation performance cannot meet the requirements of industrial production. Avoid inhibition, improve sugar utilization, high vitality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

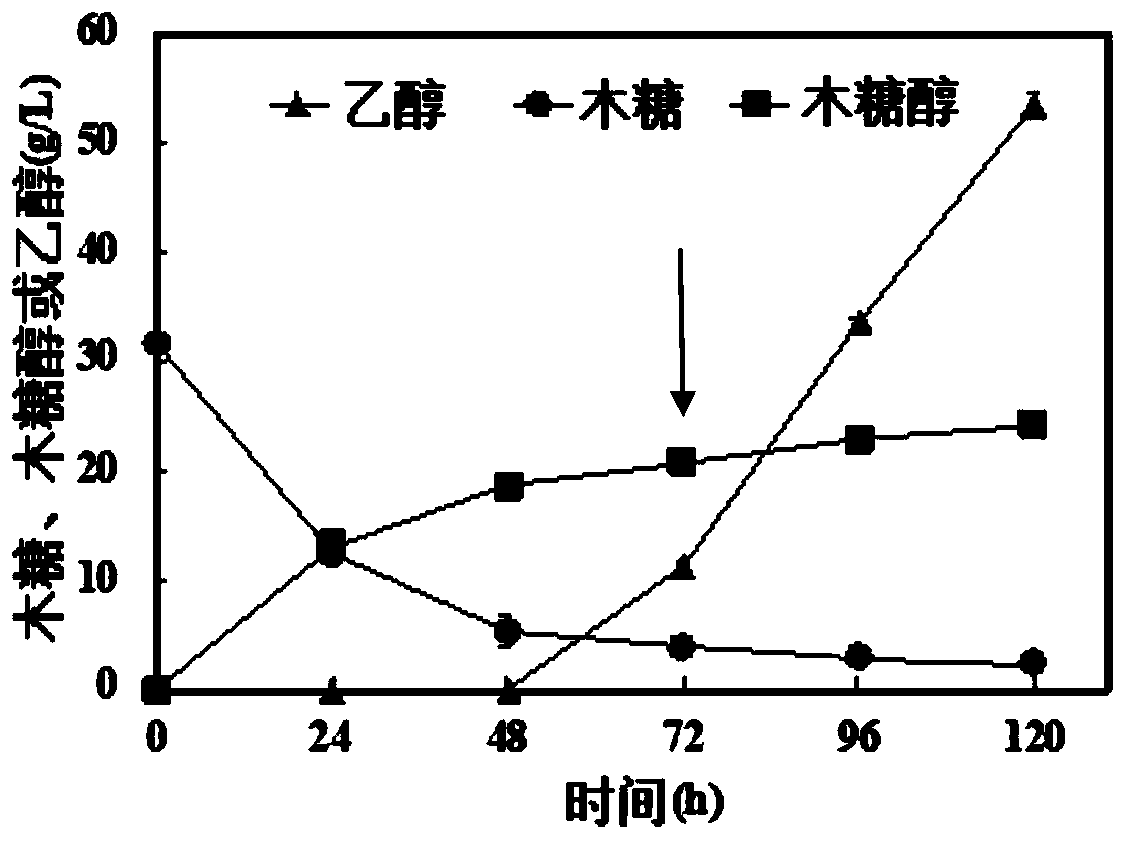

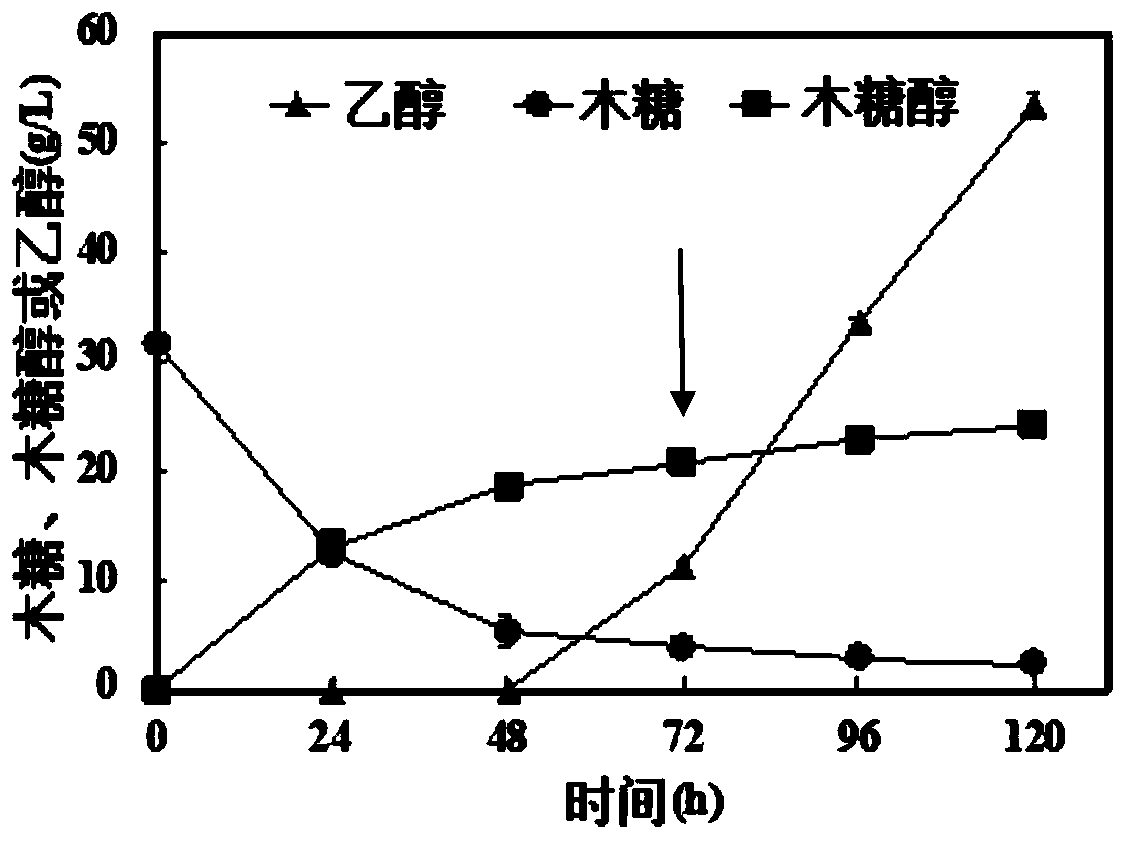

[0039] In this embodiment, xylitol and ethanol are produced by two-step fermentation of cellulose raw materials. Kluyveromyces marxianus 1727-5 (K.marxianus1727-5) strain is used for seed cultivation and expanded cultivation in the same manner as the comparative example, and The same fermentation broth and fermentation conditions were used for fermentation, the only difference being that cellulase was added after the fermentation was carried out for 48 hours; result: the corncob hydrolyzate pretreated with dilute acid was used as the fermentation medium, and the two-step fermentation method (Two-step ) and simultaneous saccharification and fermentation (SSCF) were significantly different in fermentation performance; the xylose consumption rate, xylitol yield and ethanol yield of two-step fermentation were higher than those of simultaneous saccharification and fermentation; the concentration of xylitol was 7.44g / L, and the yield of ethanol was 13.53 g / L. It shows that compared ...

Embodiment 2

[0041] The present embodiment adopts two-step method to ferment cellulose raw material to produce xylitol and ethanol, comprises the following steps:

[0042] 1) Take Kluyveromyces marxianus 1727-5 (K.marxianus1727-5) strain for seed cultivation and expansion cultivation; the cultivation process is specifically as follows:

[0043] Seed culture: Prepare the seed liquid culture medium by sterilizing 10g / L of yeast powder, 20g / L of peptone, and 20g / L of glucose at 121°C for 20min, and strain Kluyveromyces marxianus 1727-5 (K. Inoculate into the culture medium and culture for 18-24 hours until the strain concentration reaches OD 620 to 2~2.5;

[0044] Expansion cultivation: take the bacteria obtained in the seed cultivation, inoculate 10% of the inoculum into the shake flask containing the expansion culture medium, expand the cultivation temperature at 30°C, rotate at 150rpm, and cultivate for 36-48 hours until the strain concentration reaches OD 620 to 2~4;

[0045] The cultu...

Embodiment 3

[0049] In this embodiment, a two-step method is used to ferment cellulose raw materials to produce xylitol and ethanol. Kluyveromyces marxianus 1727-5 (K.marxianus1727-5) strain is taken, and the same method as in Example 2 is used for seed cultivation and expanded cultivation. And use the same fermentation broth and fermentation conditions for fermentation, the only difference is: the first step of fermentation aeration maintains 1.4vvm.

[0050] Results: Under the condition of dilute acid pretreated corncob hydrolyzate as the fermentation medium, with the increase of aeration, the sugar consumption rate increased, the corresponding production speed of xylitol and ethanol was accelerated, and the consumption of acetic acid was accelerated; at 0.2vvm and 1.4 Under the condition of vvm ventilation, the residual sugars were 20.06g / L and 4.13g / L after fermentation to 120h, and the consumption rate of xylose was significantly accelerated, and the utilization rate of xylose increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com