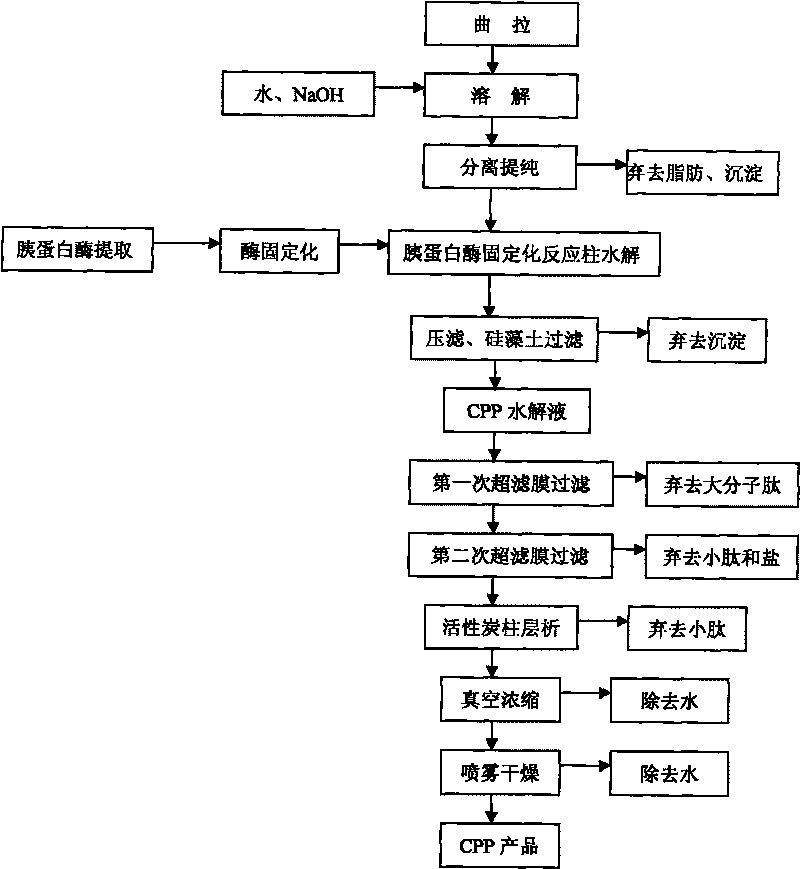

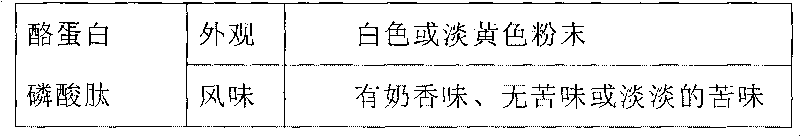

Casein phosphopept continuous production process by adopting immobilized enzyme hydrolysis crude cheese and ultrafiltration membrane separation method

A casein phosphopeptide, immobilized enzyme technology, applied in protein food processing, animal protein processing, protein food ingredients and other directions, can solve the problems of affecting the flavor and quality of the final product, difficult to industrialize production, expensive carrier, etc. Fixed cost, improved utilization rate, high product purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for continuous production of casein phosphopeptides by hydrolyzing crude cheese with immobilized enzymes and ultrafiltration membrane separation, the steps of which are divided into:

[0032] a. Extraction of trypsin Take 10kg of fresh bovine pancreas, remove the fat and connective tissue manually, grind it with a meat grinder and immediately immerse it in a 50L interlayer reaction tank with 1L of 0.1mol / L ammonium sulfate solution at 0℃~4℃ After stirring, it becomes a slurry, add 0.1mol / L ammonium sulfate twice the volume of the slurry, extract in a jacketed reaction tank at 0°C to 4°C for 20 hours, and slowly stir every half hour. Filter through an air filter press, collect the filtrate, and repeat the leaching of the residue once with 0.1 mol / L ammonium sulfate 1 times the volume of the slurry, combine the two filtrates, and discard the residue.

[0033] Add 0.2kg / L solid ammonium sulfate to the filtrate in the 50L interlayer reaction tank at 0°C to 4°C to a...

Embodiment 2

[0066] a. Extraction of trypsin

[0067] Take 100kg of fresh bovine pancreas, manually remove fat and connective tissue, grind it with a meat grinder, and immediately immerse it in a 500L interlayer reaction tank with 10L of 0.1mol / L ammonium sulfate solution at 0°C to 4°C. After stirring, it becomes For the slurry, add 0.1 mol / L ammonium sulfate 3 times the volume of the slurry and extract in a jacketed reaction tank at 0°C to 4°C for 30 hours, stirring slowly every half hour. Filter through an air filter press, collect the filtrate, and repeat the leaching of the residue once with 0.1 mol / L ammonium sulfate 1 times the volume of the slurry, combine the two filtrates, and discard the residue.

[0068] Add 0.2kg / L solid ammonium sulfate to the filtrate in the 500L interlayer reaction tank at 0°C to 4°C to a concentration of 1.5mol / L, stir and let it stand for 10 hours, filter and remove the precipitate. Continue to add 0.27kg / L solid ammonium sulfate to the filtrate to a conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com