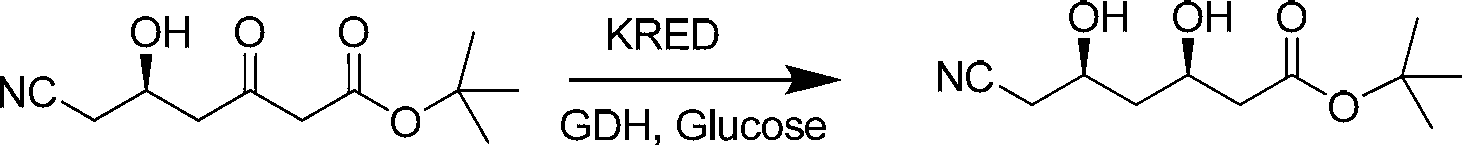

Biological preparation method of 6-cyano-(3R, 5R)-dihydroxyhexanoate

A technology of tert-butyl hydroxyhexanoate and tert-butyl hexanoate is applied in the field of biological preparation of tert-butyl 6-cyano-(3R,5R)-dihydroxyhexanoate, which can solve the problem of large amount of enzyme and substrate Low concentration, high production cost and other problems, to achieve the effect of reducing enzyme dosage, increasing substrate concentration and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment one: reaction monitoring method

[0022] A LC-MS detection method was developed for the determination of tert-butyl 6-cyano-(5R)-hydroxy-3-oxohexanoate to tert-butyl 6-cyano-(3R,5R)-dihydroxyhexanoate transform. For detection, take 50 μL of reaction solution at different time points, add 950 μL of methanol, mix well, filter with 0.45 μm microporous membrane, and then inject for detection (injection volume 1 μL). Chromatographic conditions: chromatographic column SB-C182.1×50mm, 3.5μm; mobile phase A water (10mM HCOONH4-0.1%HCOOH), B acetonitrile; flow rate 0.3mL / min; mobile phase gradient 0-0.5min 22%B, 0.5 -0.6min 22%B-100%B, 0.6-1.0min 100%B, 1.0-1.1min 100%B, 1.1-5.0min 22%B. The retention time of 6-cyano-(5R)-hydroxy-3-oxohexanoic acid tert-butyl ester is 2.7min, and the retention time of 6-cyano-(3R,5R)-dihydroxyhexanoic acid tert-butyl ester is 1.8 min. Mass spectrometry conditions: dry gas flow rate 12L / min; sheath gas pressure 40PSI; dry gas tempe...

Embodiment 2

[0023] Embodiment two: product content detection method

[0024] Preparation of reference substance solution: Weigh 125 mg of 6-cyano-(5R)-hydroxy-3-oxohexanoic acid tert-butyl ester reference substance, and weigh 6-cyano-(3R,5R)-dihydroxyhexanoic acid tert-butyl Butyl ester reference substance 125mg was transferred to a 50mL volumetric flask, dissolved in methanol to volume. Take 3mL, 4mL, 5mL, 6mL, 7mL from the mother liquor and add it into a 10mL volumetric flask, set the volume to the mark, filter to the liquid phase vial, and inject 8μL. Preparation of sample solution: Weigh 100 mg of tert-butyl 6-cyano-(5R)-hydroxy-3-oxohexanoate and 100 mg of tert-butyl 6-cyano-(3R,5R)-dihydroxyhexanoate to 50mL volumetric flask, dissolved in methanol to volume. Filter into a liquid phase vial and inject 8 μL. The content was calculated according to the external standard method. Chromatographic conditions: chromatographic column eclipse XDB-C18, 4.6×150mm, 5μm; mobile phase A water ...

Embodiment 3

[0025] Embodiment three: Gram-level preparation process

[0026] Add 8.0g of glucose and 10.00mL of buffer solution (100mM, pH=7.00 triethanolamine hydrochloride solution) to a 100.0mL three-neck flask in sequence, and place the mixed system on a 30°C water bath with magnetic stirring to dissolve it. , drop 6.83g of the substrate, stir evenly, adjust the pH to 7.0 with 2.0M NaOH solution, then add 0.15g of glucose dehydrogenase lyophilized powder and 0.05g of ketoreductase-101 lyophilized powder at a stirring speed of 900rpm, Adjust the pH to 7.0, and then add 5 mg of NADP freeze-dried powder; at the same time, use 2.0M NaOH solution to maintain the pH at 7.0 to start the reaction. Sampling of the control reaction every 2-3 hours, after 24 hours, LC-MS showed that the conversion rate was >97%, and the reaction was terminated, and then the content of the product was detected by the method described in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com