Patents

Literature

41results about How to "Increase winding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

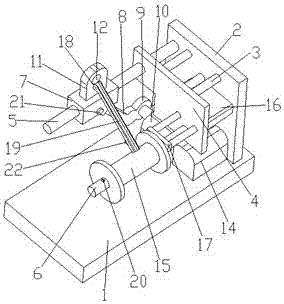

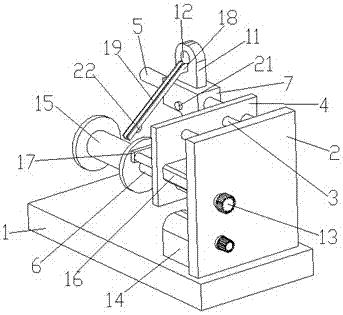

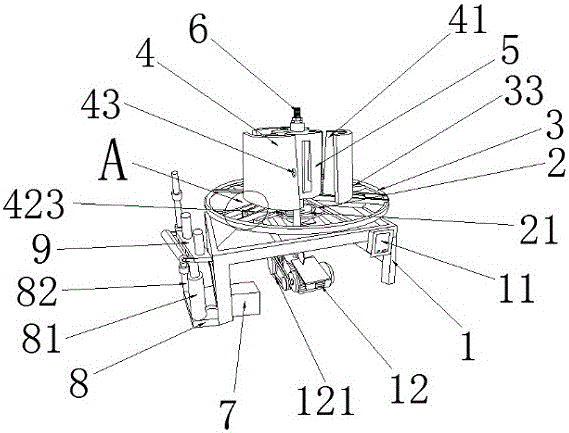

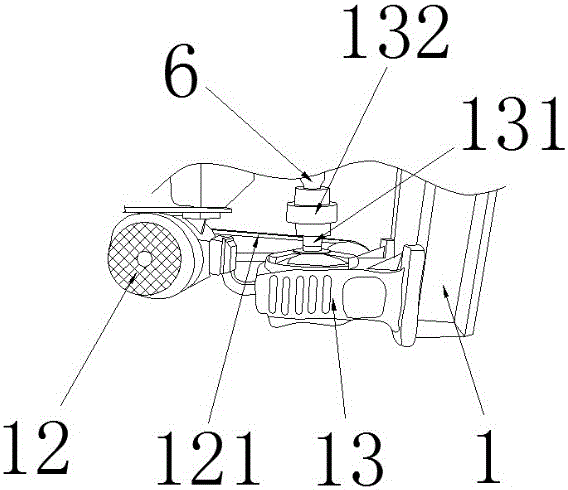

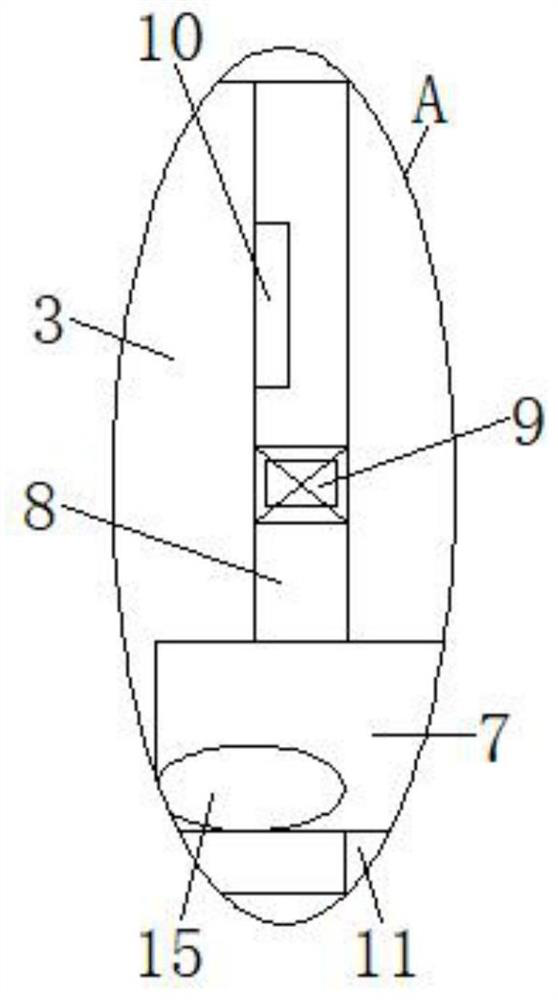

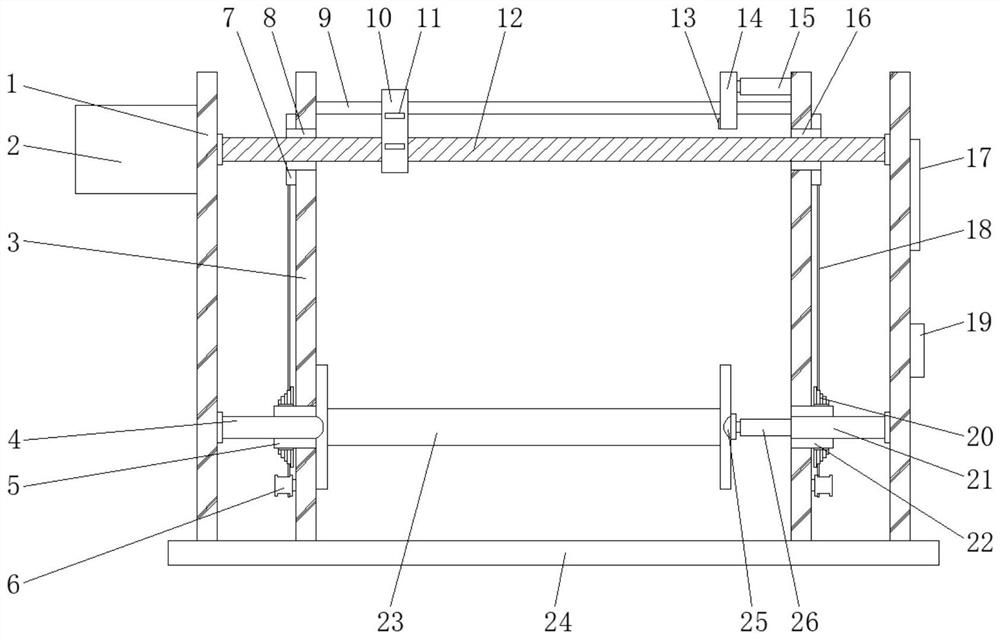

Textile automatic pushing and take-up device with locating function

ActiveCN107285122ARealize the take-up functionIncrease winding speedFilament handlingTextile disintegration and recoveryEngineeringDrive motor

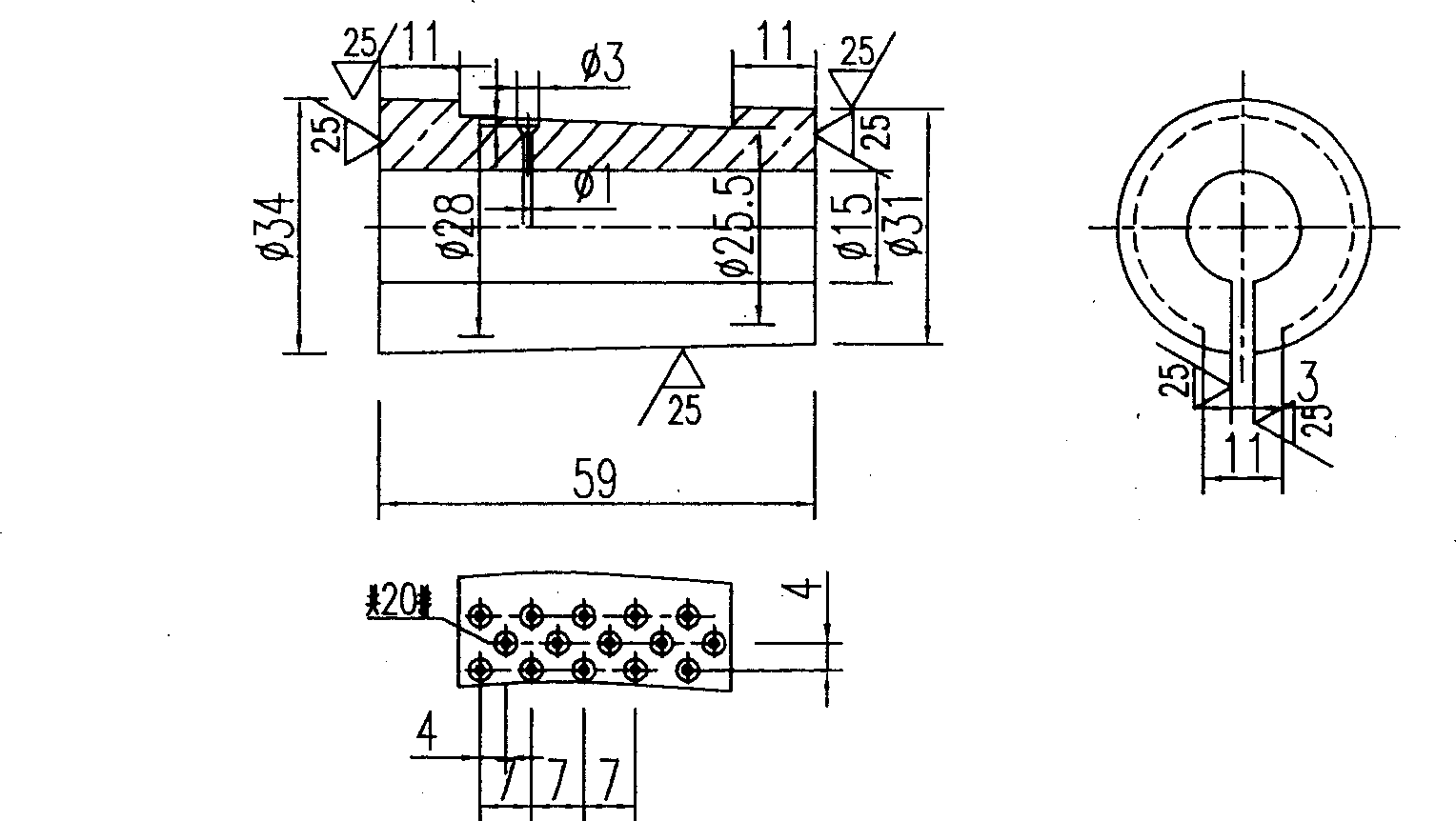

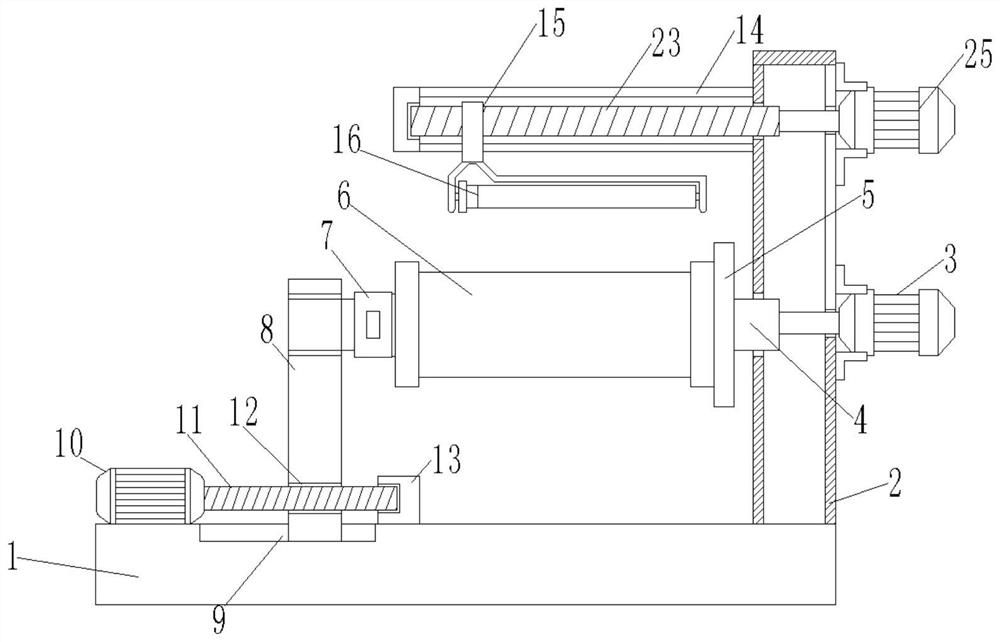

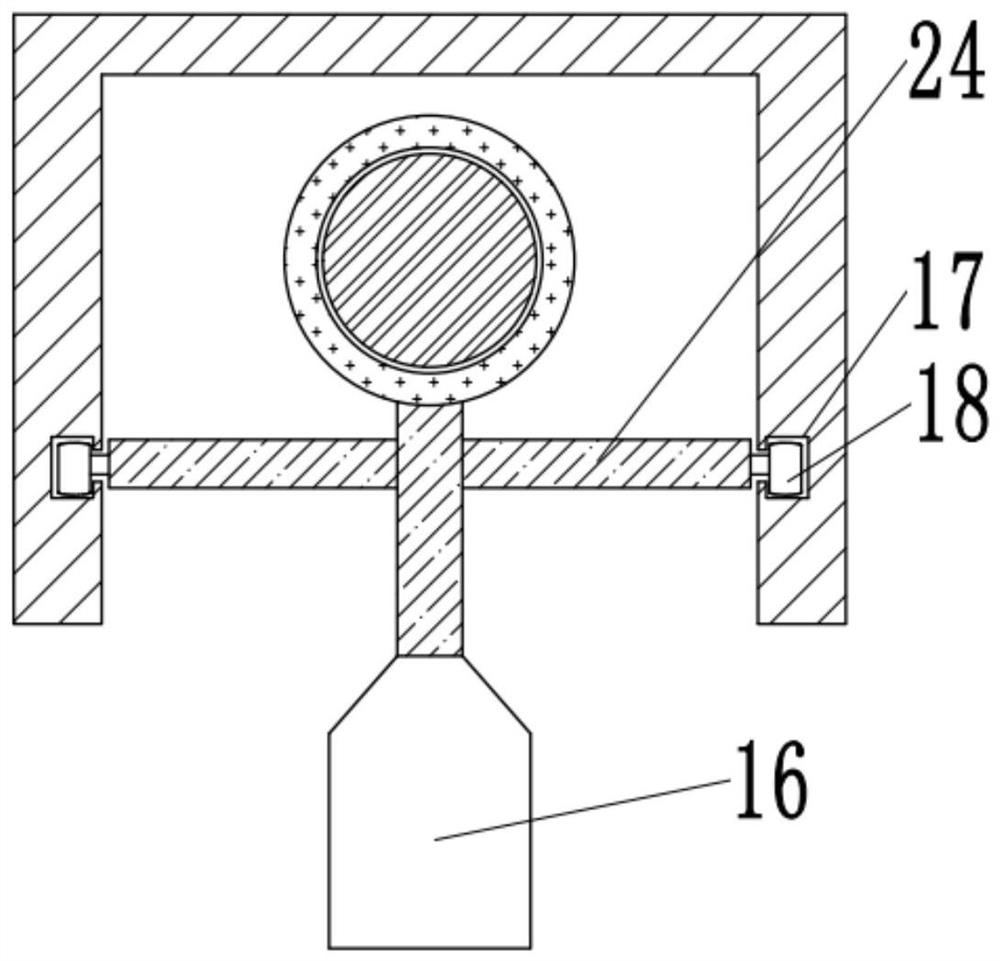

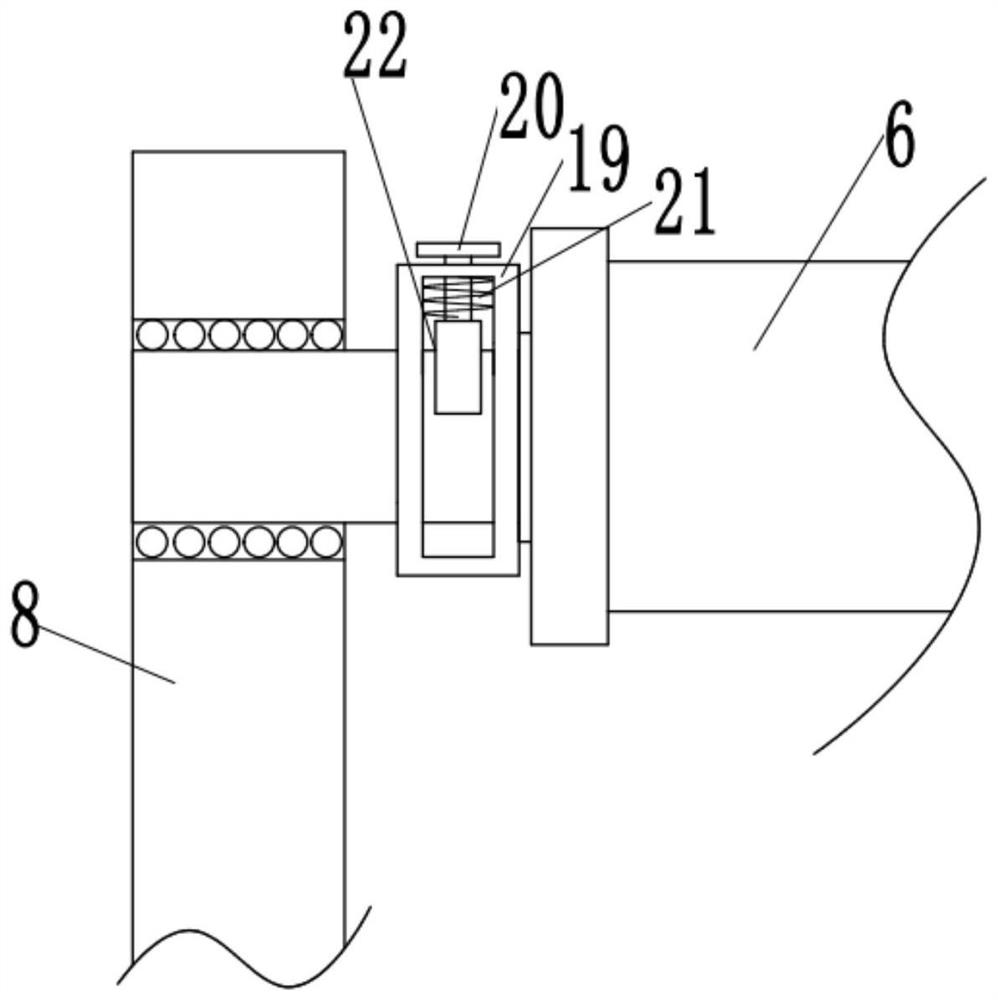

The invention relates to a textile automatic pushing and take-up device with a locating function. The textile automatic pushing and take-up device comprises a base. A supporting plate is arranged on one side of the base. One side of the supporting plate is connected with a fixed plate through supporting rods. A connecting rod and a rotating rod are vertically arranged on the supporting plate. A moving seat is arranged on the connecting rod. The bottom of the moving seat and an eccentric wheel are fixed through a linkage rod. The eccentric wheel is connected to a rotating shaft of a drive motor. A wire plate is further arranged on the moving seat and provided with a wire hole. One end of the rotating rod stretches out of the supporting plate and is provided with a rotating gear. A rotating motor is arranged below the rotating rod. A pushing air cylinder is arranged between the supporting plate and the fixed plate. A piston rod of the pushing air cylinder stretches out of the fixed plate and is provided with a locating baffle. A take-up column is mounted on the rotating rod. A telescopic protrusion is arranged at the position, close to the take-up column, of the rotating rod. A lead rod is arranged on the wire plate. According to the scheme, the production efficiency is greatly improved, and the manual cost is reduced.

Owner:孝感安华纺织有限公司

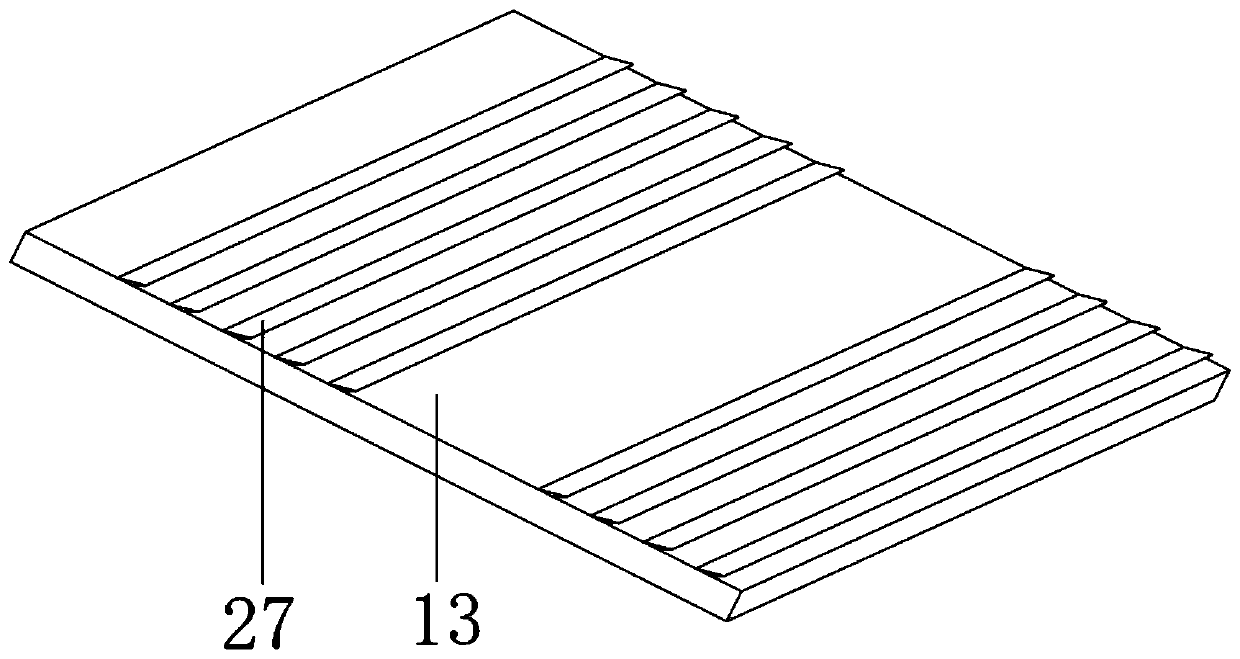

Preparing method of PET/PTT parallel complex filament with high self-crimpiness

InactiveCN110565184AIncrease draft ratioImprove mechanical propertiesArtificial filament washing/dryingArtificial filament heat treatmentUltimate tensile strengthHeat setting

The invention discloses a preparing method of a PET / PTT parallel complex filament with high self-crimpiness. PET and PTT are sliced, dried and crystallized, afterwards, the PET and PTT are fused separately and subjected to extrusion molding through a parallel-type spinneret plate, oil is applied after cooling, then level 1-3 drafting and heat setting treatment are adopted, during drafting, the total drafting rate is controlled to be 3-3.5, the level-1 drafting rate is 2.8-3.0, and the temperature is controlled to be 75-80 DEG C. According to the preparing method of the PET / PTT parallel complexfilament with high self-crimpiness, methods like multi-level drafting for increasing the drafting rate are adopted, and the effects of improving the fiber strength, moderately lowering the elongationat break, and greatly improving the self-crimpiness are achieved.

Owner:TONGKUN GRP +1

Energy-saving yarn-singeing burner

The invention relates to an energy-saving yarn-singeing burner. Structurally, a burning cover which is a reburning area is arranged on the upper part of the burning area of a flame tube; and a small door is arranged on the burning cover. Compared with the structure without the reburning area, the energy-saving yarn-singeing burner has the following advantages: under the conditions of the same mixed gas (i.e., flow and pressure are the same at the mixed gas inlet of an item I fire hole seat), the length of flame is increased, consequently, on the premise of achieving the same yarn-singeing effect, the yarn-winding speed can be increased, so that the singeing output can be increased and the consumption of liquefied petroleum gas can be saved. Since the small door is arranged on the burning cover, in the normal process of yarn singeing, after the small door is closed, the influence of wind on flame can be reduced in a workshop, so that the singeing effect can be more stable.

Owner:JIANGNAN UNIV

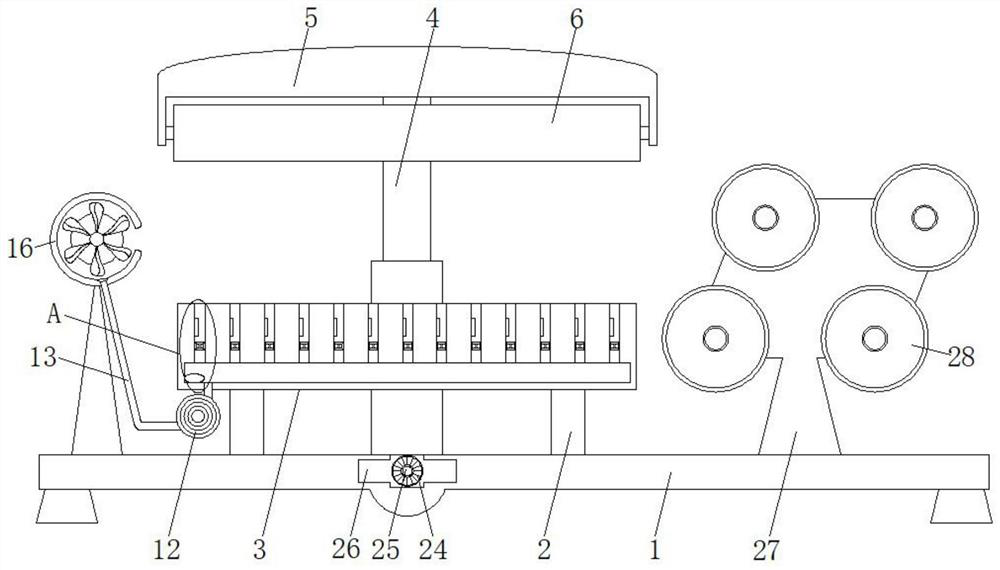

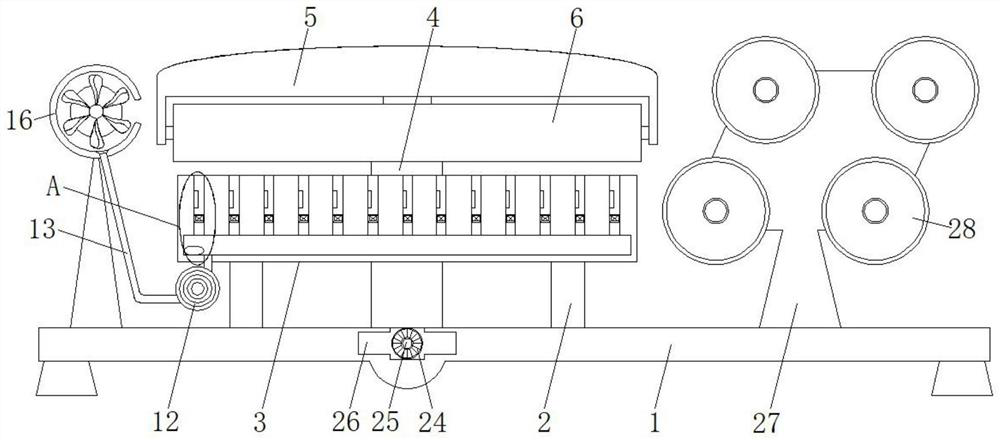

Rolling mechanism of coating machine

InactiveCN112573302AImprove stabilityIncrease winding speedFilament handlingElectric machineryMachine

The invention discloses a rolling mechanism of a coating machine. The rolling mechanism comprises a base, wherein a supporting rack is welded to an outer wall of one side of the top of the base, a first motor is mounted on the outer wall of one side of the supporting rack through bolts, a roll shaft is welded to an output end of the first motor, a fixed plate is welded to the outer wall of one side, close to the first motor, of the roll shaft, a rolling roller is movably connected to the outer wall, close to the fixed plate, of the roll shaft, and a fixing assembly is arranged on the outer wall, close to the rolling roller, of the roll shaft and comprises a sleeve. The rolling mechanism can be used for replacing the rolling roll. When a movable block is inserted into a slot, the sleeve isfixed to a rolling shaft, a distance between the sleeve and the rolling shaft is decreased and a spring is in a compressed state, such that the spring will generate some push forces to the rolling roll and the rolling roll and the rolling shaft are attached tightly together, and thus, the stability of the rolling roll is improved, and meanwhile, non-uniform rolling as a coated product winds a sameposition of the rolling roll all the time is avoided.

Owner:JIUJIANG FLEX

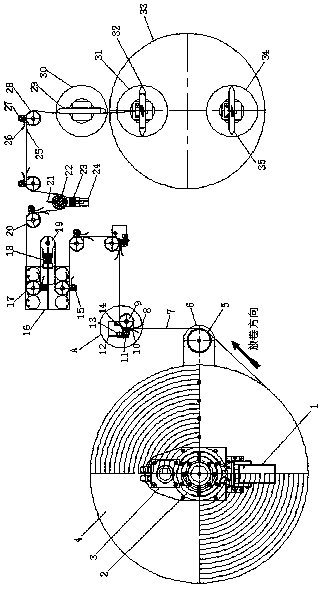

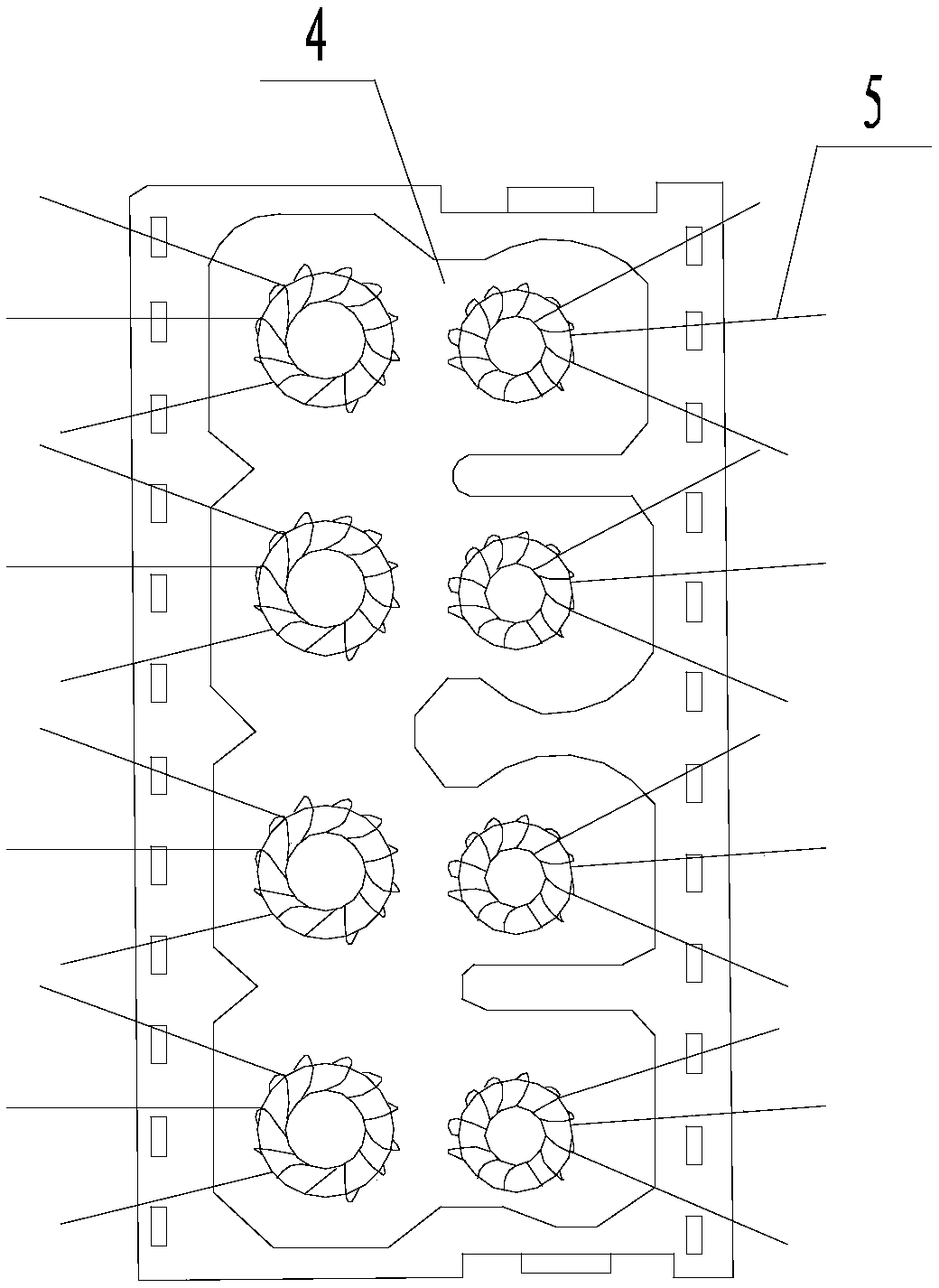

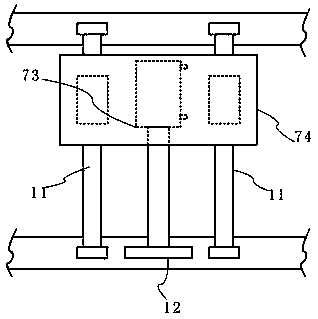

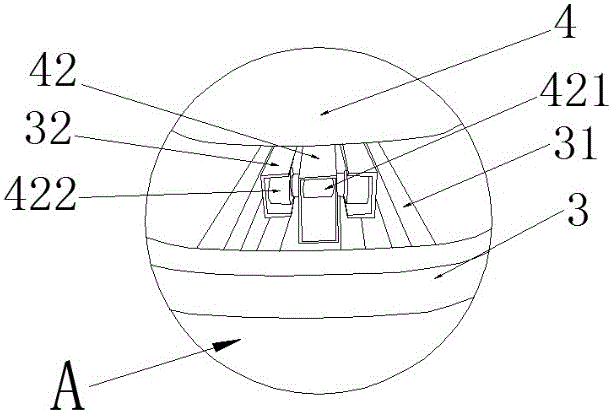

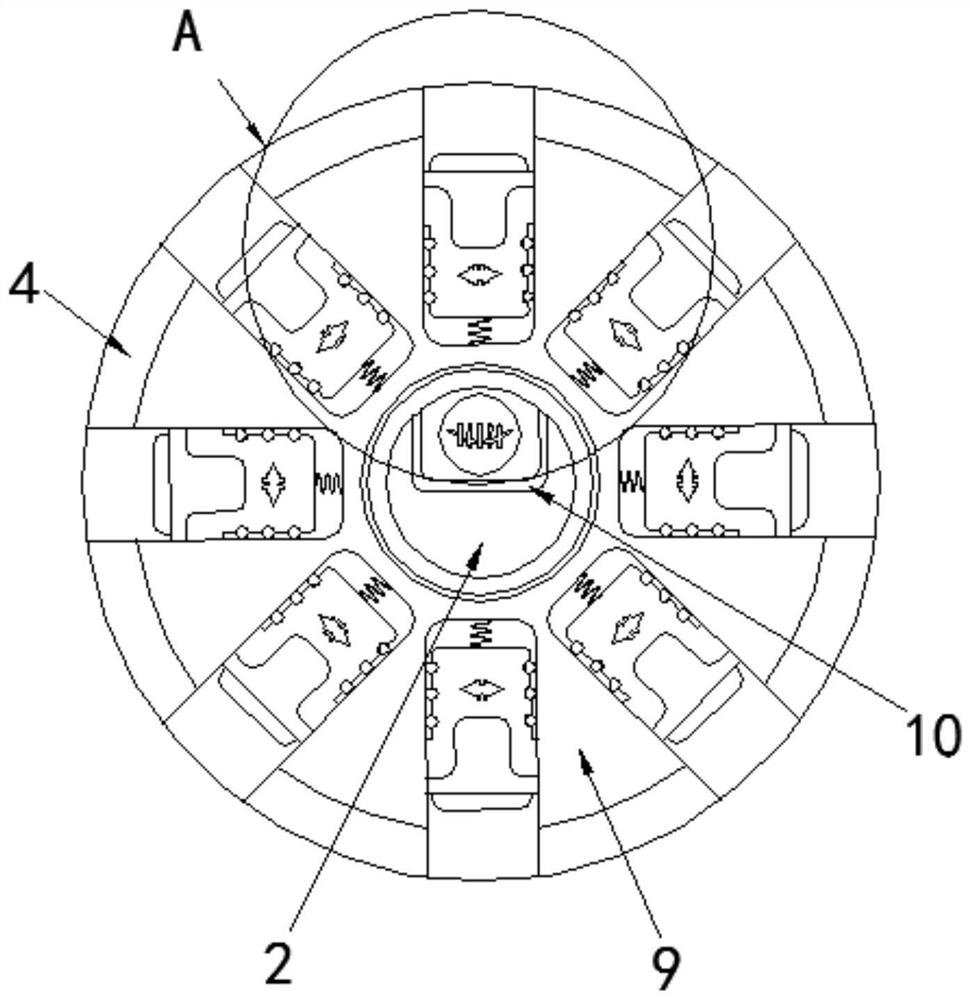

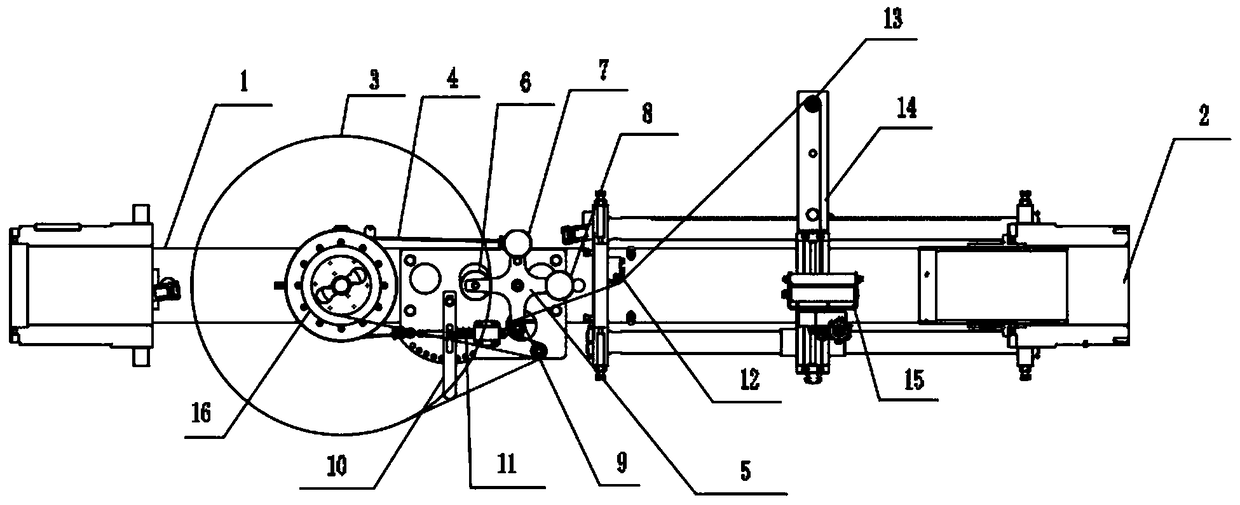

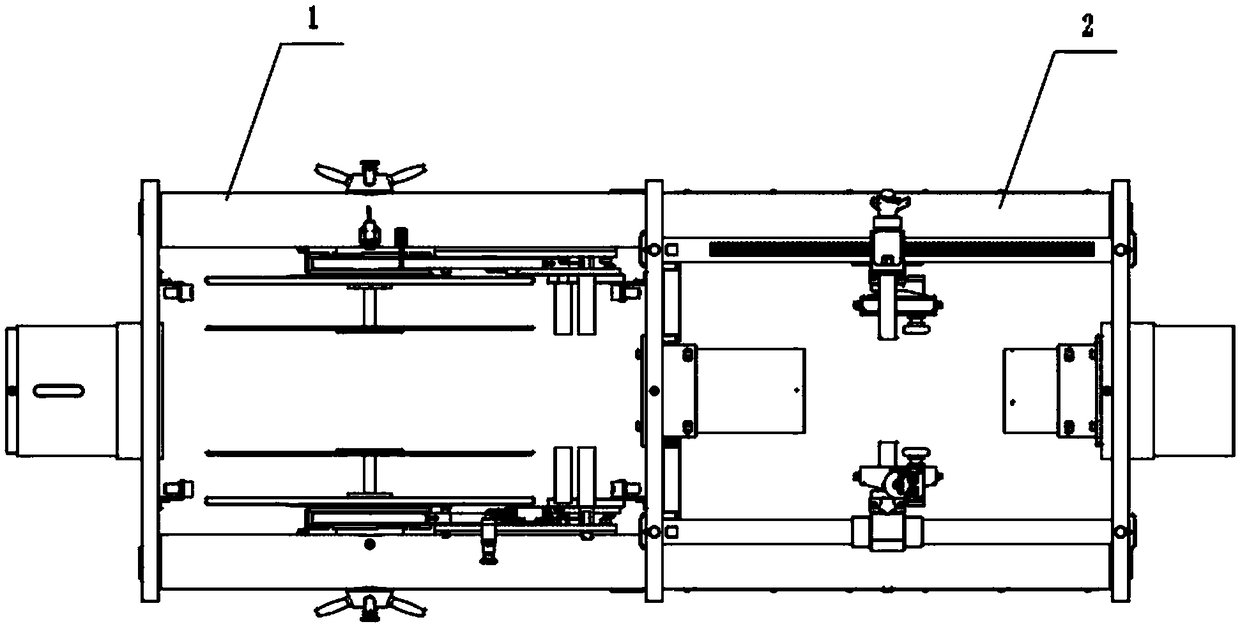

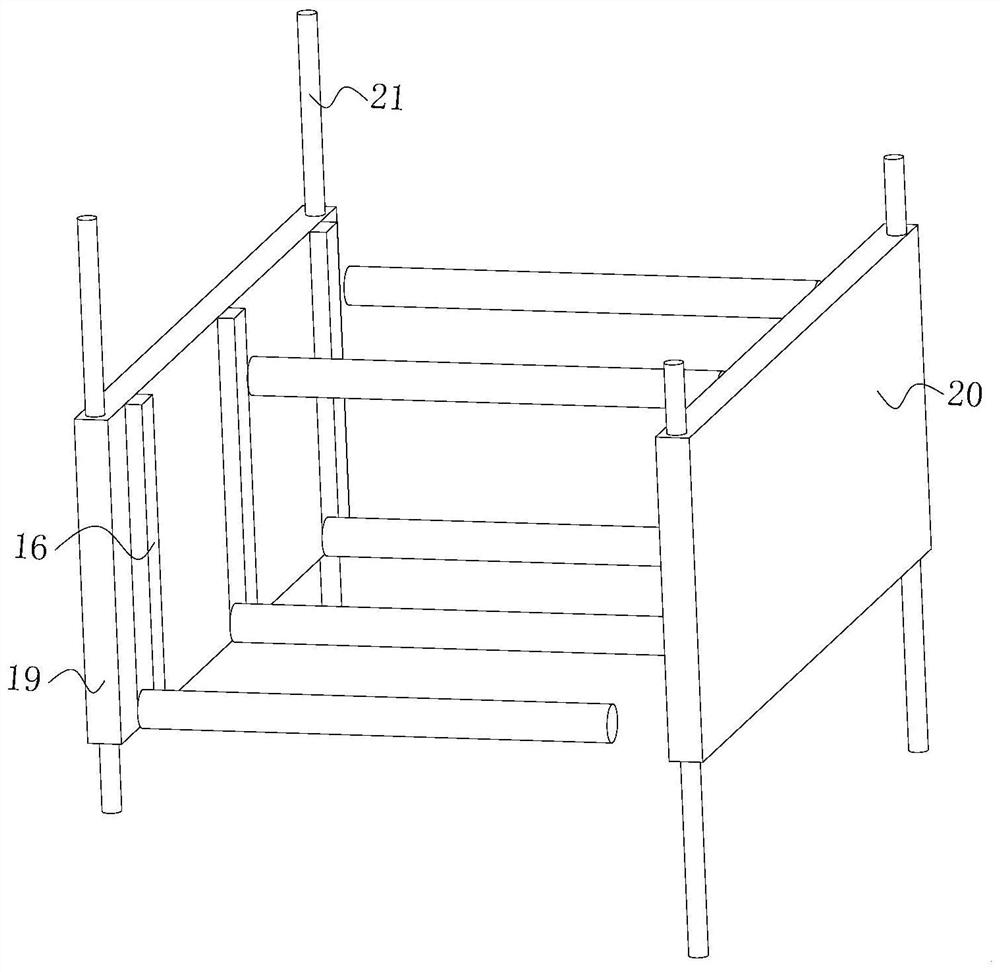

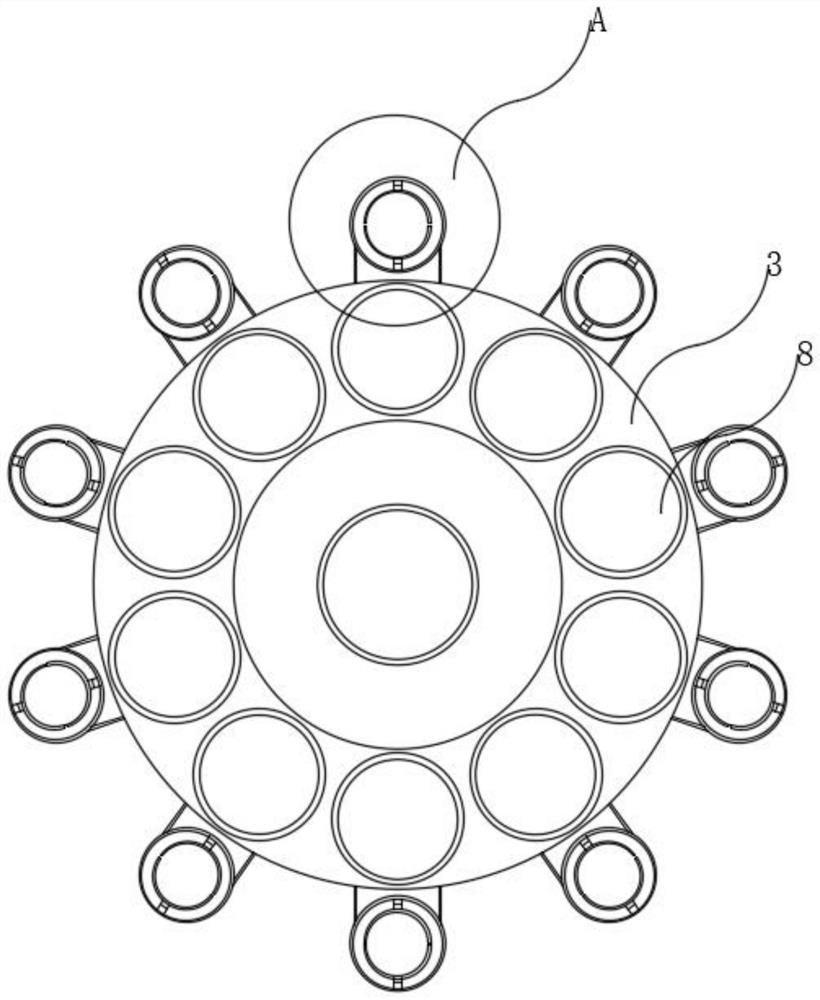

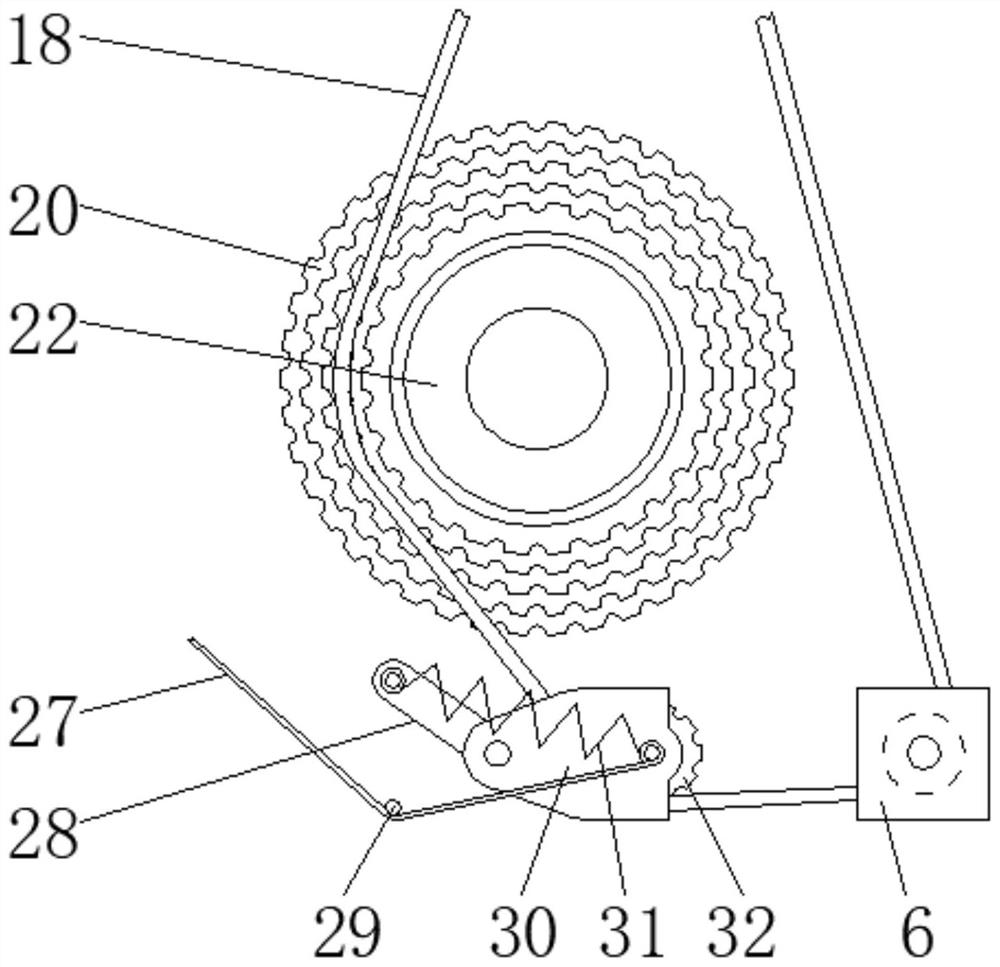

Constant-speed winding type winding needle combination mechanism

PendingCN108461826AIncrease winding speedConsistent tightnessFinal product manufactureSecondary cellsPole pieceWind speed

The invention relates to a constant-speed winding type winding needle combination mechanism. The constant-speed winding type winding needle combination mechanism comprises an unwinding correction execution mechanism, wherein a battery pole piece is arranged at the outside wall of an unwinding servo motor; an unwinding passing roll support plate is arranged above a first unwinding passing roll; theoutside wall of the unwinding passing roll support plate is connected with an unwinding pole piece; the top end of the unwinding pole piece is connected with a pole lug flattening plate A of a pole piece passing roll; the pole piece passing roll is arranged at the upper side wall of the pole lug flattening plate A of the pole piece passing roll; a pole lug flattening plate B of the pole piece passing roll is arranged at the left side wall of the pole piece passing roll; a pole lug flattening adjusting mechanism is arranged at the side wall of the top part of the pole lug flattening plate B ofthe pole piece passing roll; a pole piece dedusting mechanism is arranged above the pole lug flattening adjusting mechanism. The constant-speed winding type winding needle combination mechanism has the advantages that the winding speed is effectively improved; a battery cell is wound within constant tension value; the looseness of the inner layer and outer layer of the battery cell is uniform; the quality of the wound finished product battery cell is stable; the efficiency is improved by one time or more; the winding speed can reach 1400mm / s.

Owner:GUANGDONG JITI SMART EQUIP CO LTD

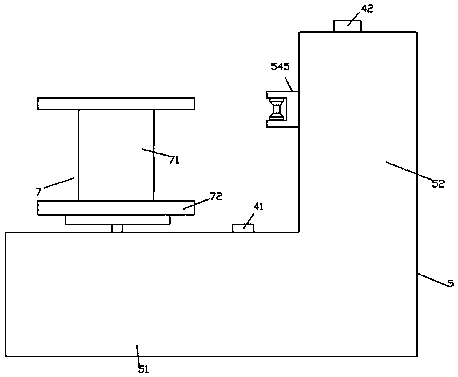

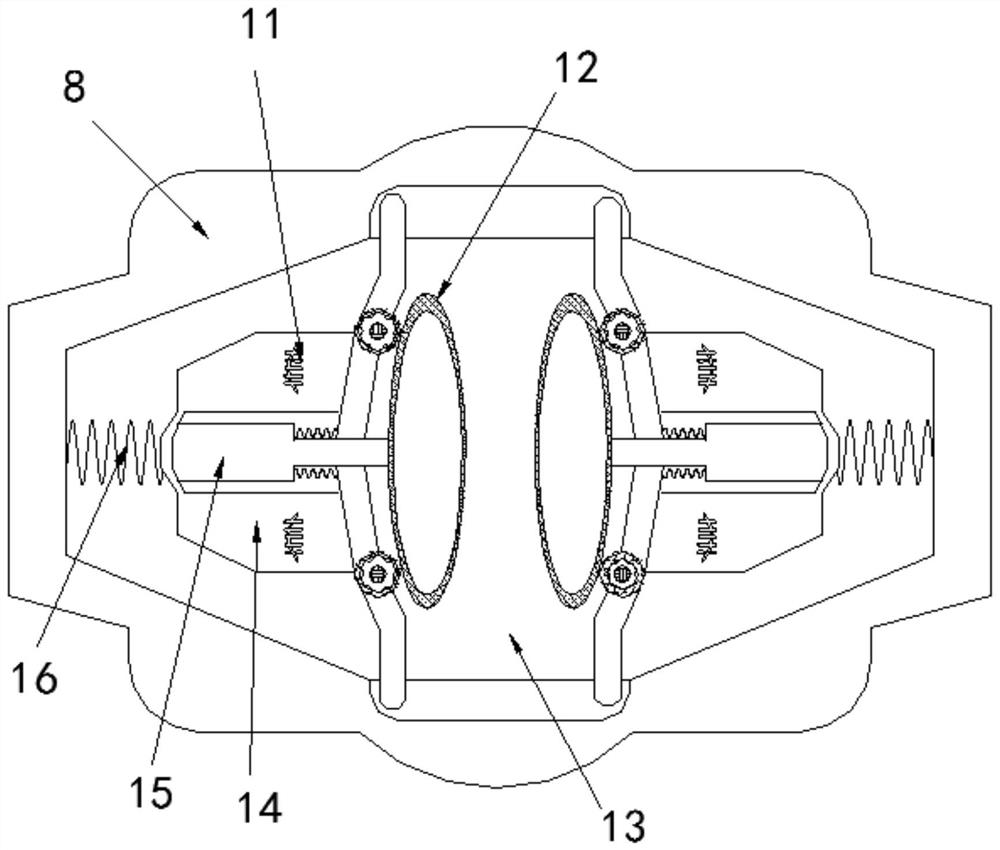

Flying fork type winding machine and working method thereof

PendingCN111130287AHigh precisionIncrease winding speedManufacturing dynamo-electric machinesWinding machineMachine

The invention relates to a flying fork type winding machine and a working method thereof. The machine comprises a machine body, and a main shaft box capable of moving front and back is installed on the table board of the machine body. A main shaft with a threading hole in the center is mounted in the main shaft box; a winding mechanism for winding is mounted at the front end of the main shaft; a mounting mechanism which is positioned in front of the winding mechanism and is used for mounting a stator iron core is also mounted on the tabletop of the machine body; the winding mechanism comprisesa flying fork arranged at the front end of the main shaft and a trapezoidal wire sliding block which is used for forcing the enameled wire to slide into the tooth part of the stator iron core and hasa small front part and a large rear part; a liftable positioning mechanism used for guiding the wire sliding block to move back and forth is arranged below the wire sliding block, and a pair of wireprotection rods used for blocking between the stator iron core and the winding mechanism to prevent the enameled wire from touching the stator iron core is arranged in front of the winding mechanism.The flying fork type winding machine can effectively protect an enameled wire, avoids the problems of enameled wire deformation, paint removal and the like caused by collision between the enameled wire and the stator iron core in the winding process, and reduces coil damage.

Owner:FUJIAN UNIV OF TECH

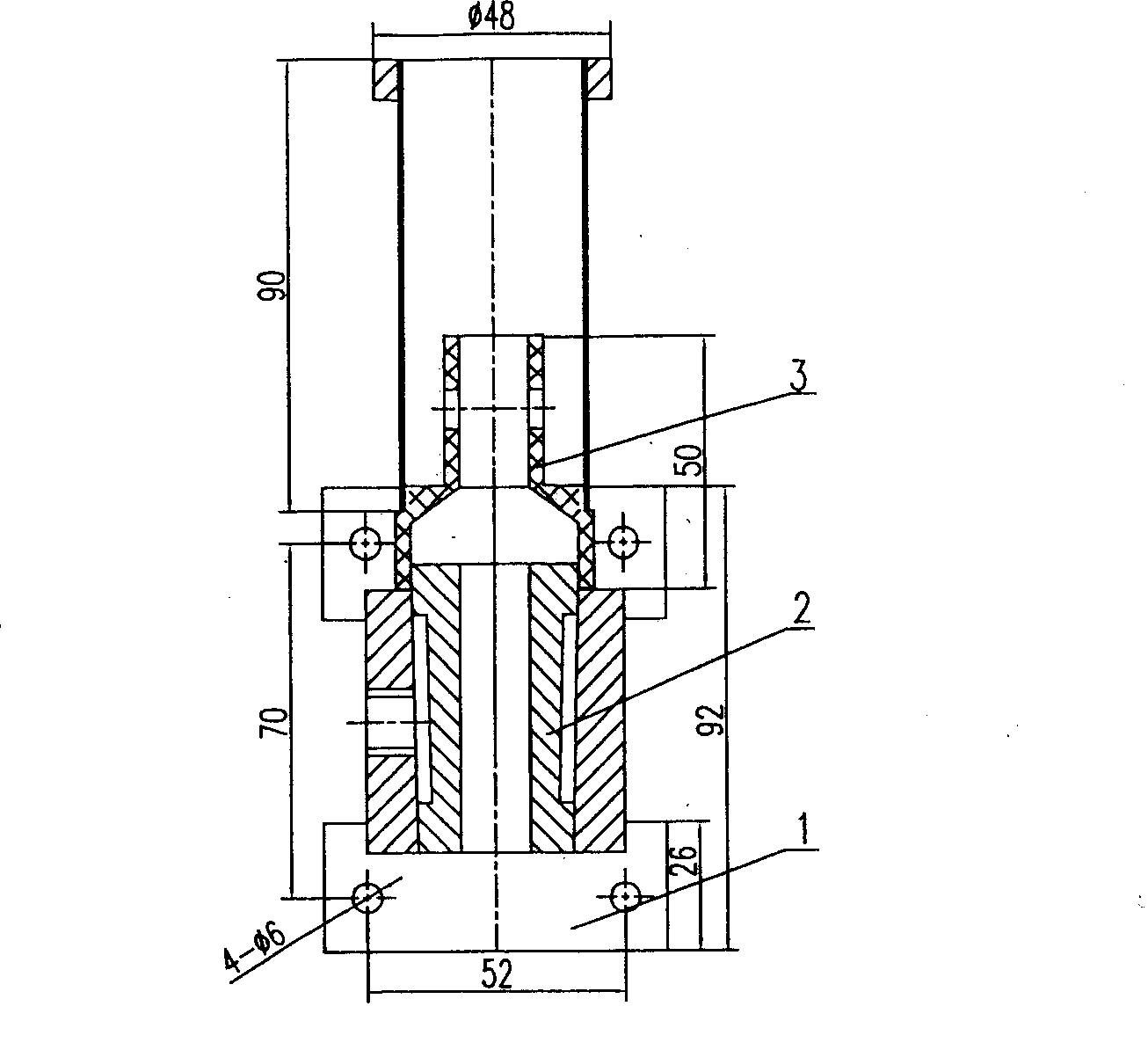

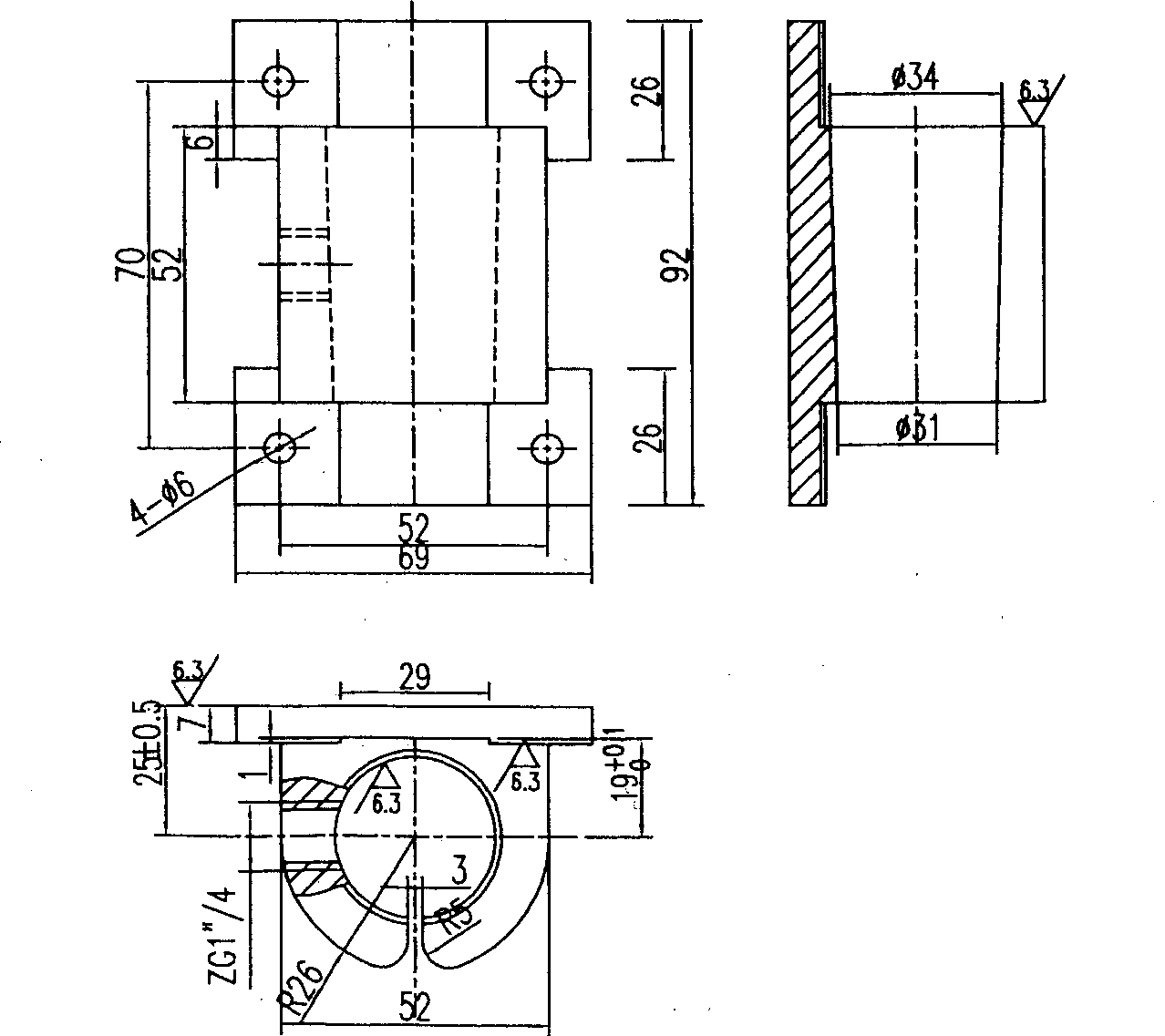

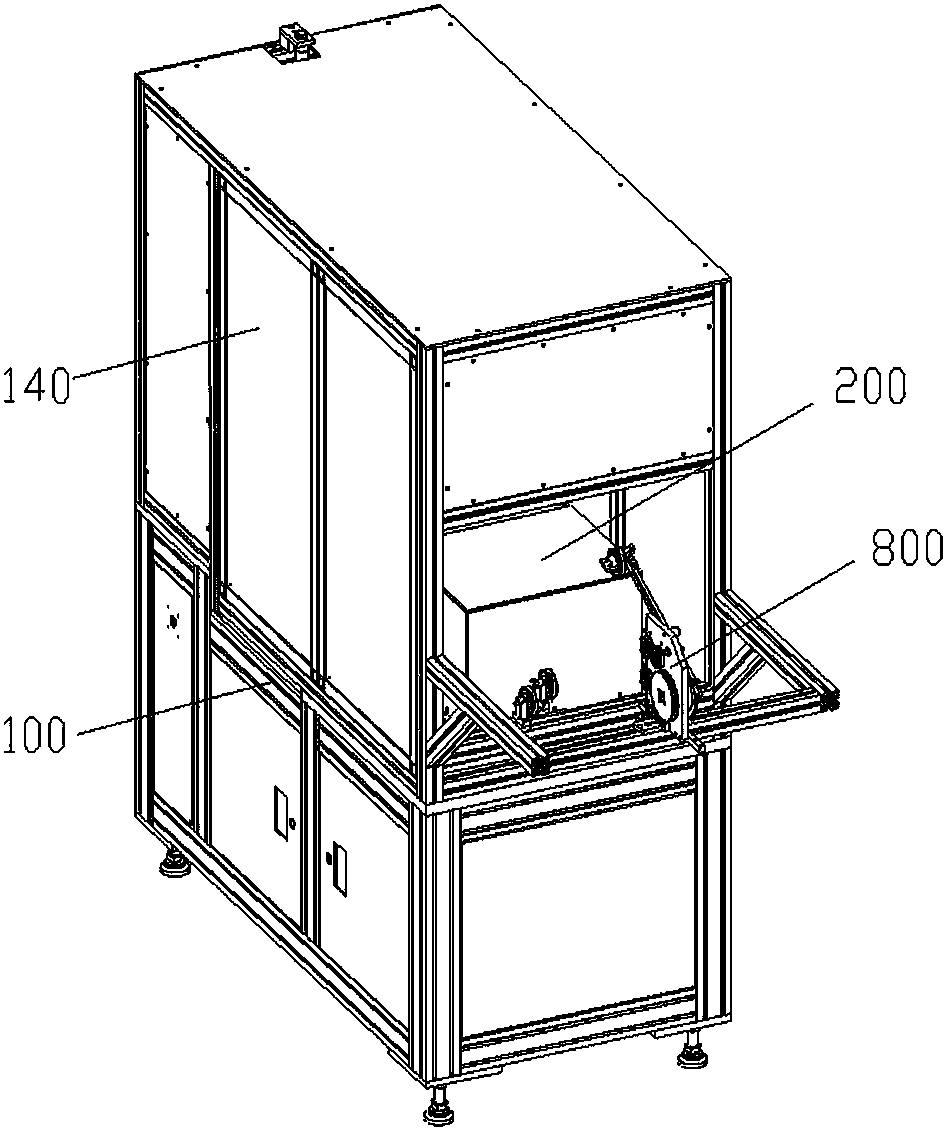

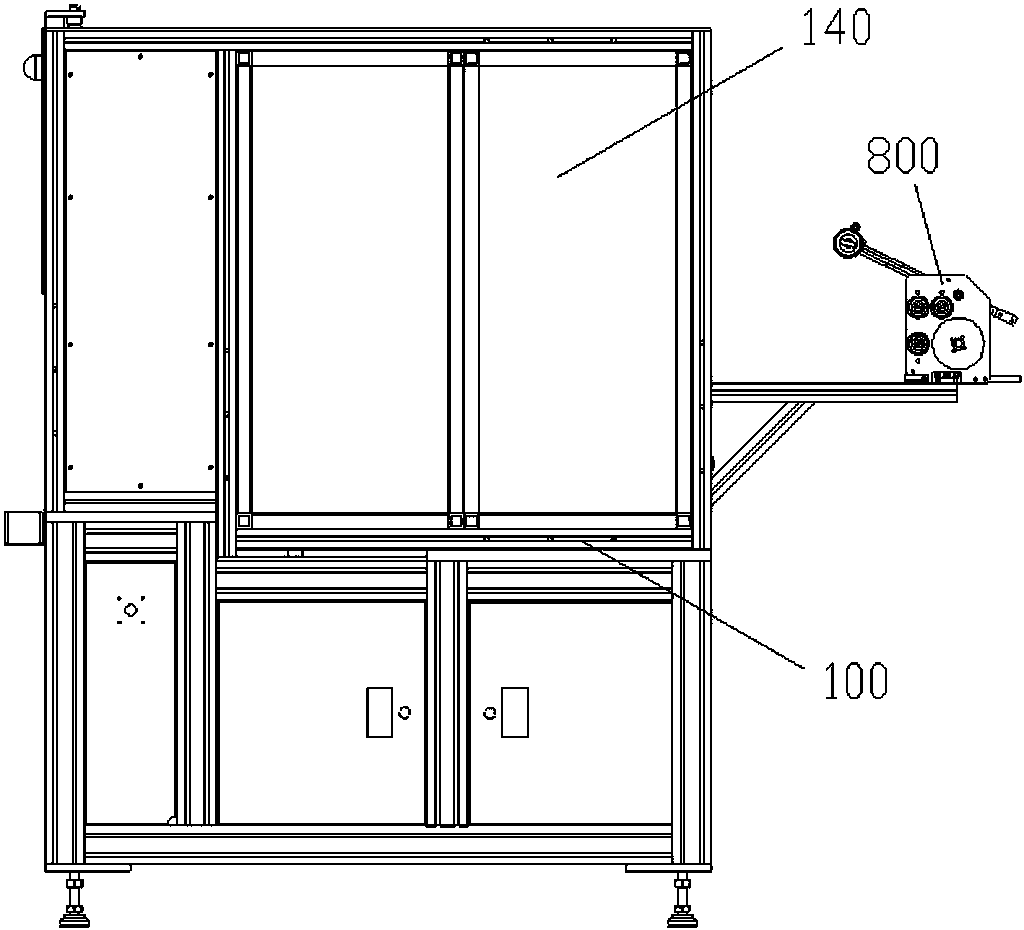

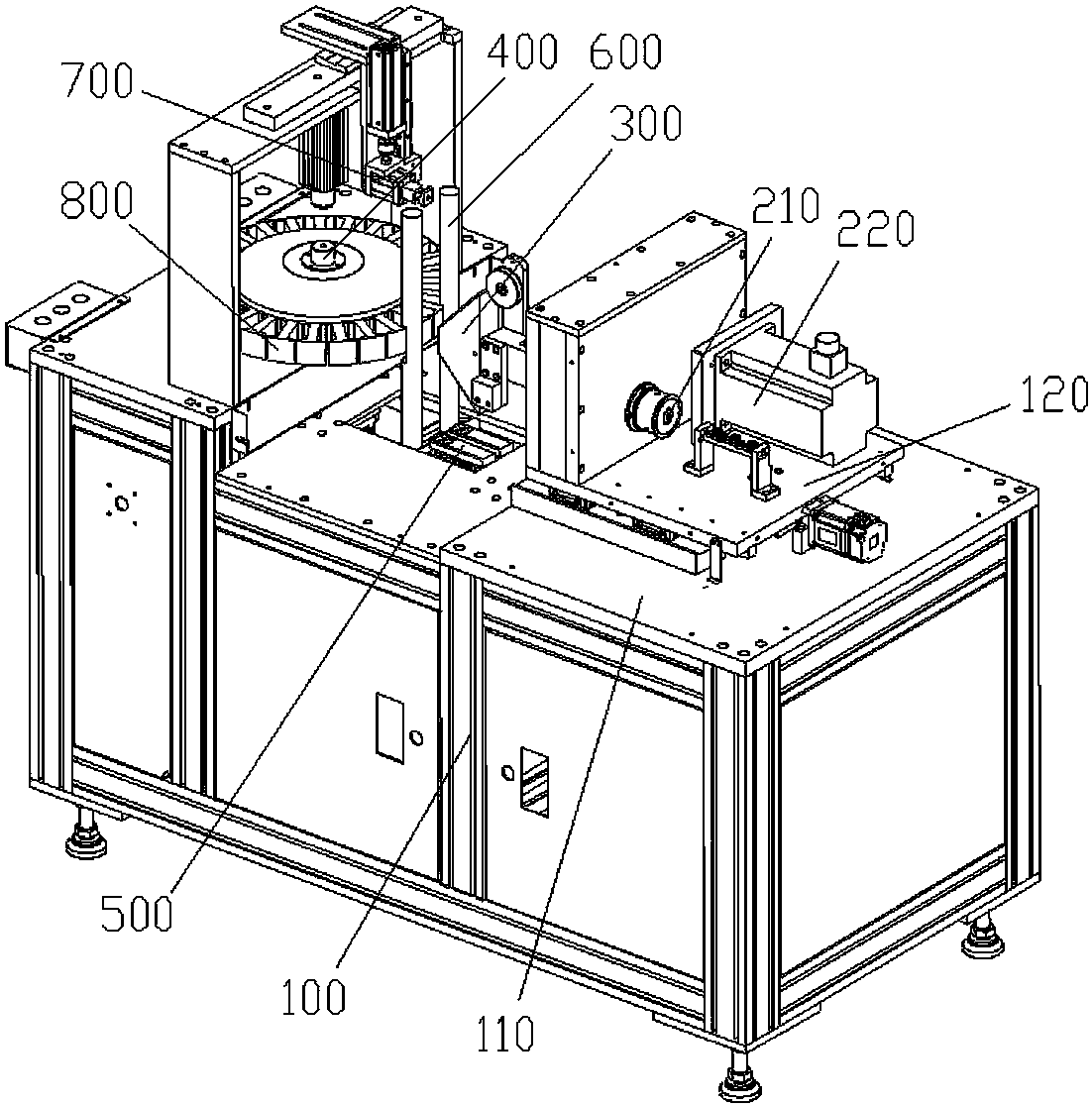

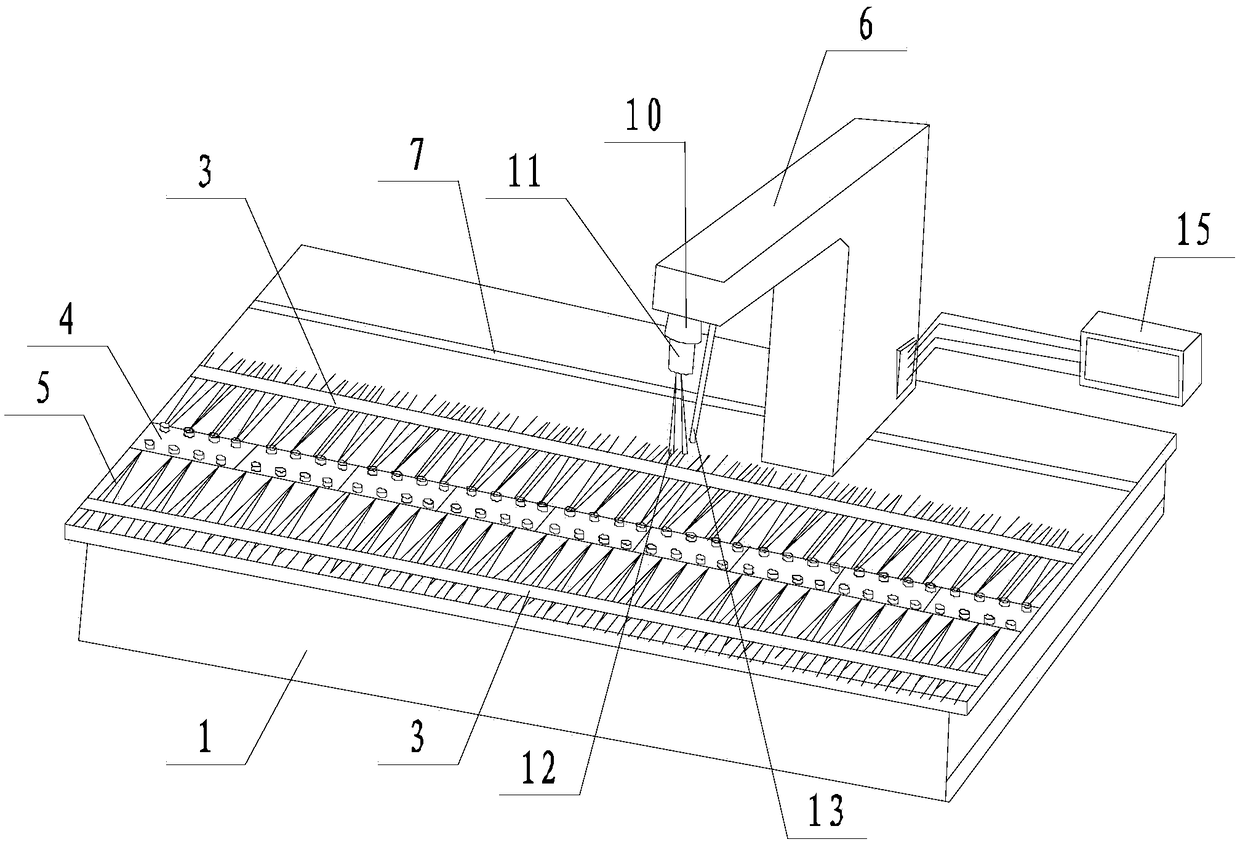

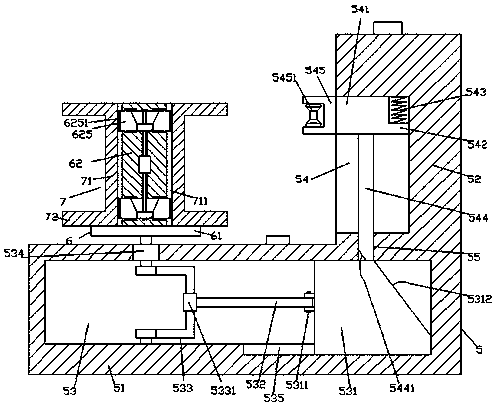

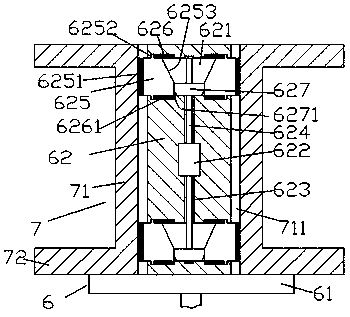

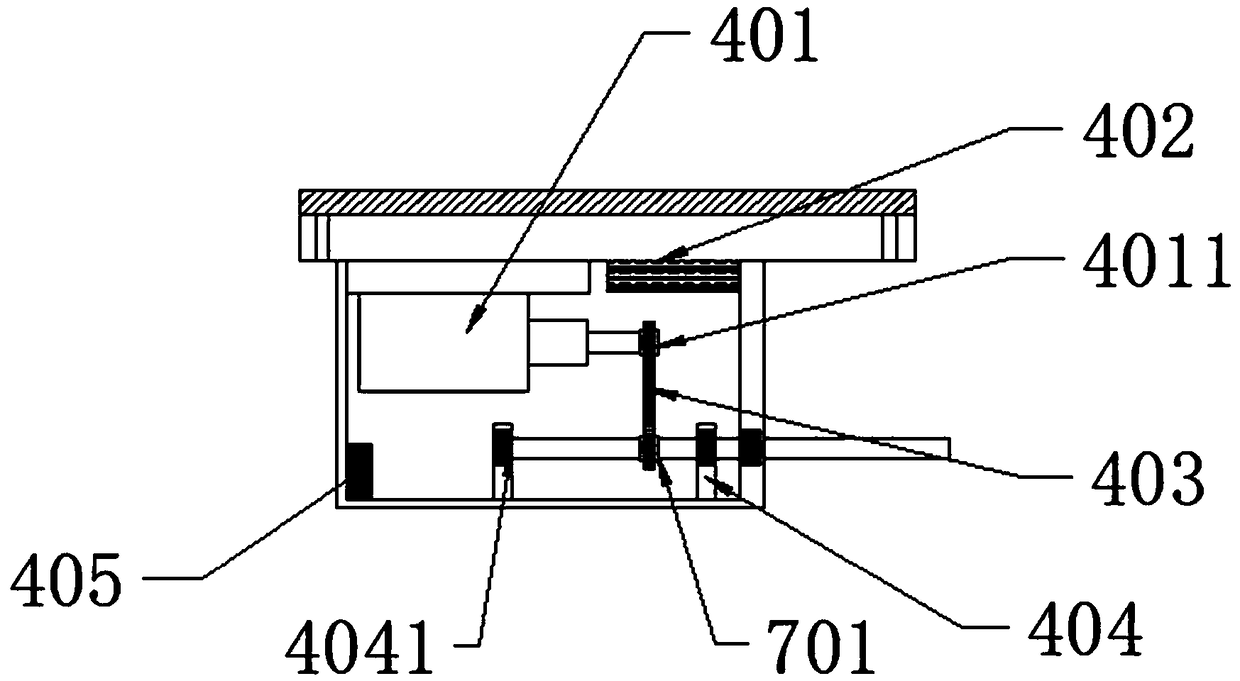

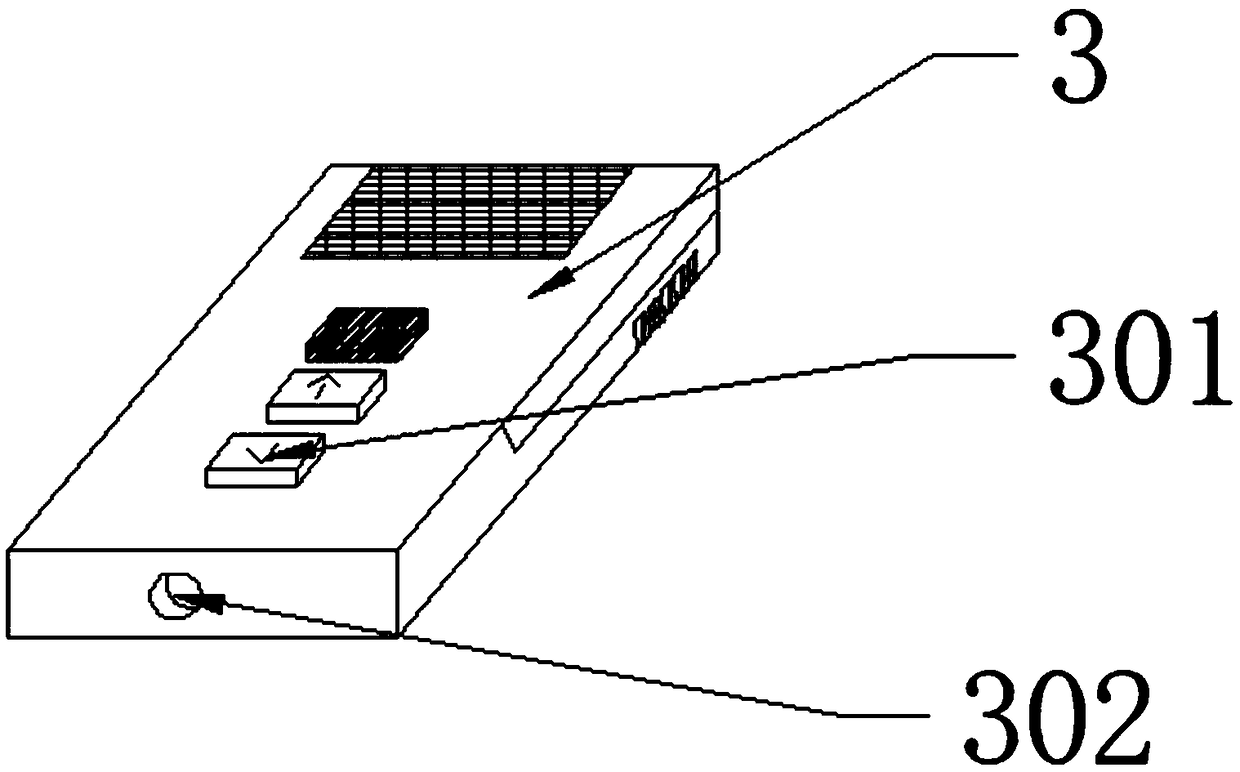

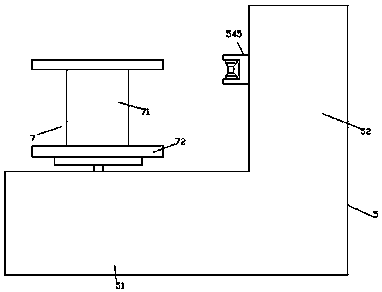

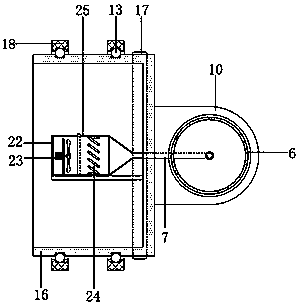

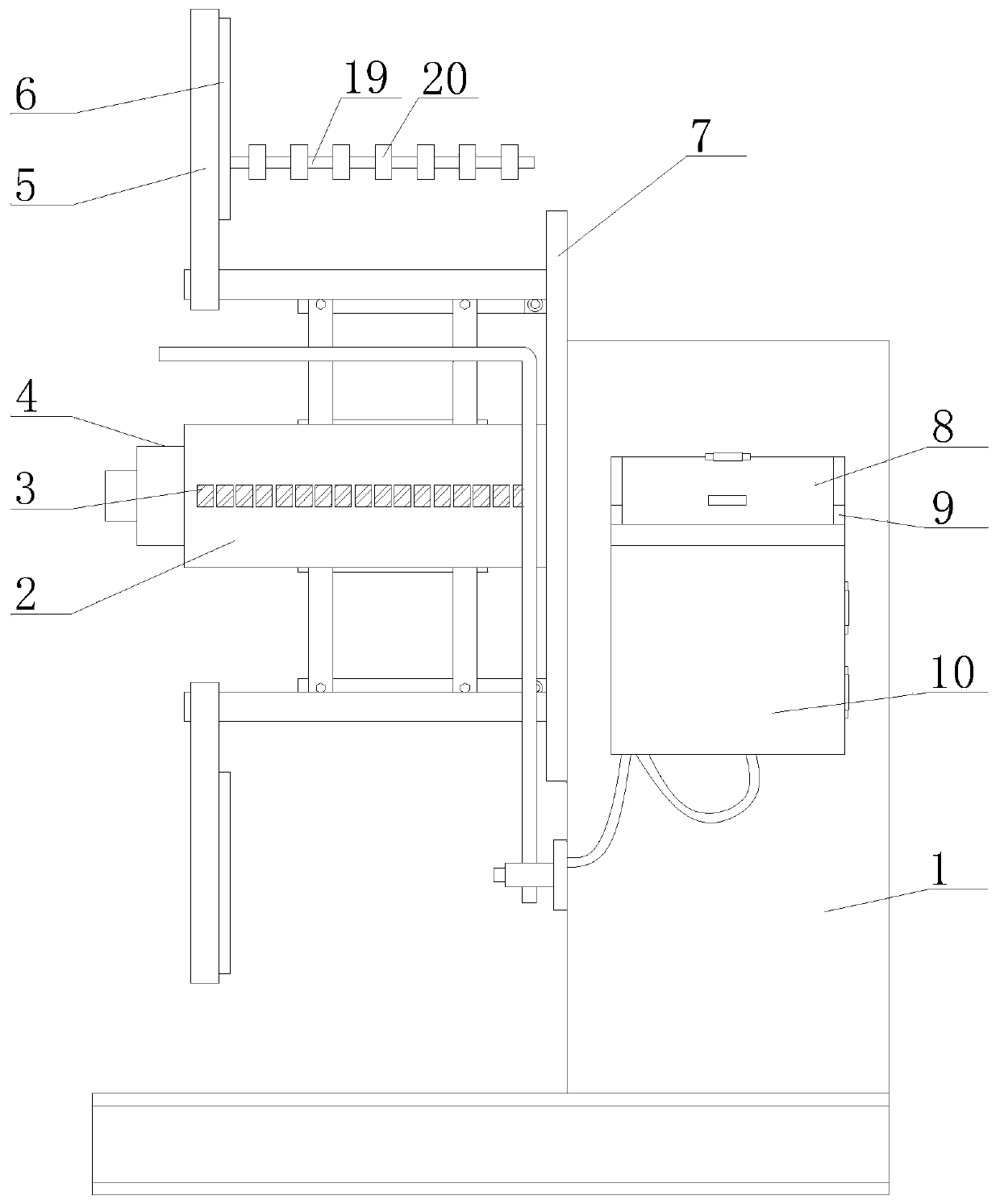

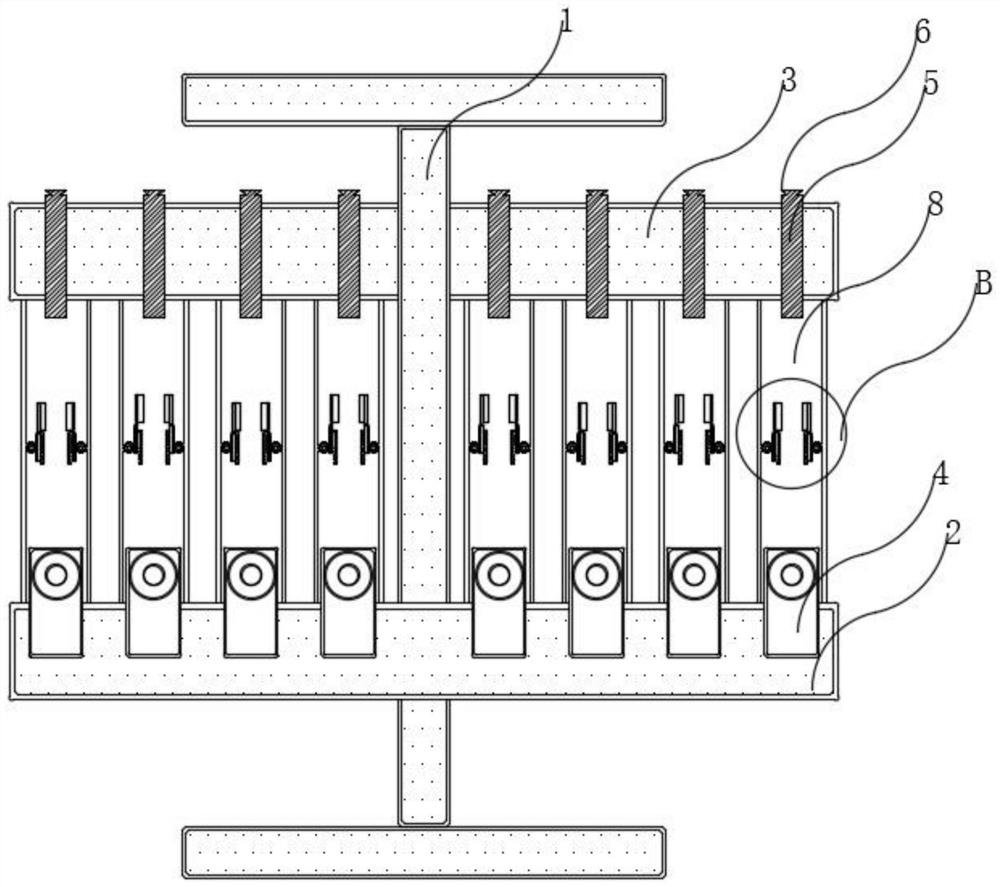

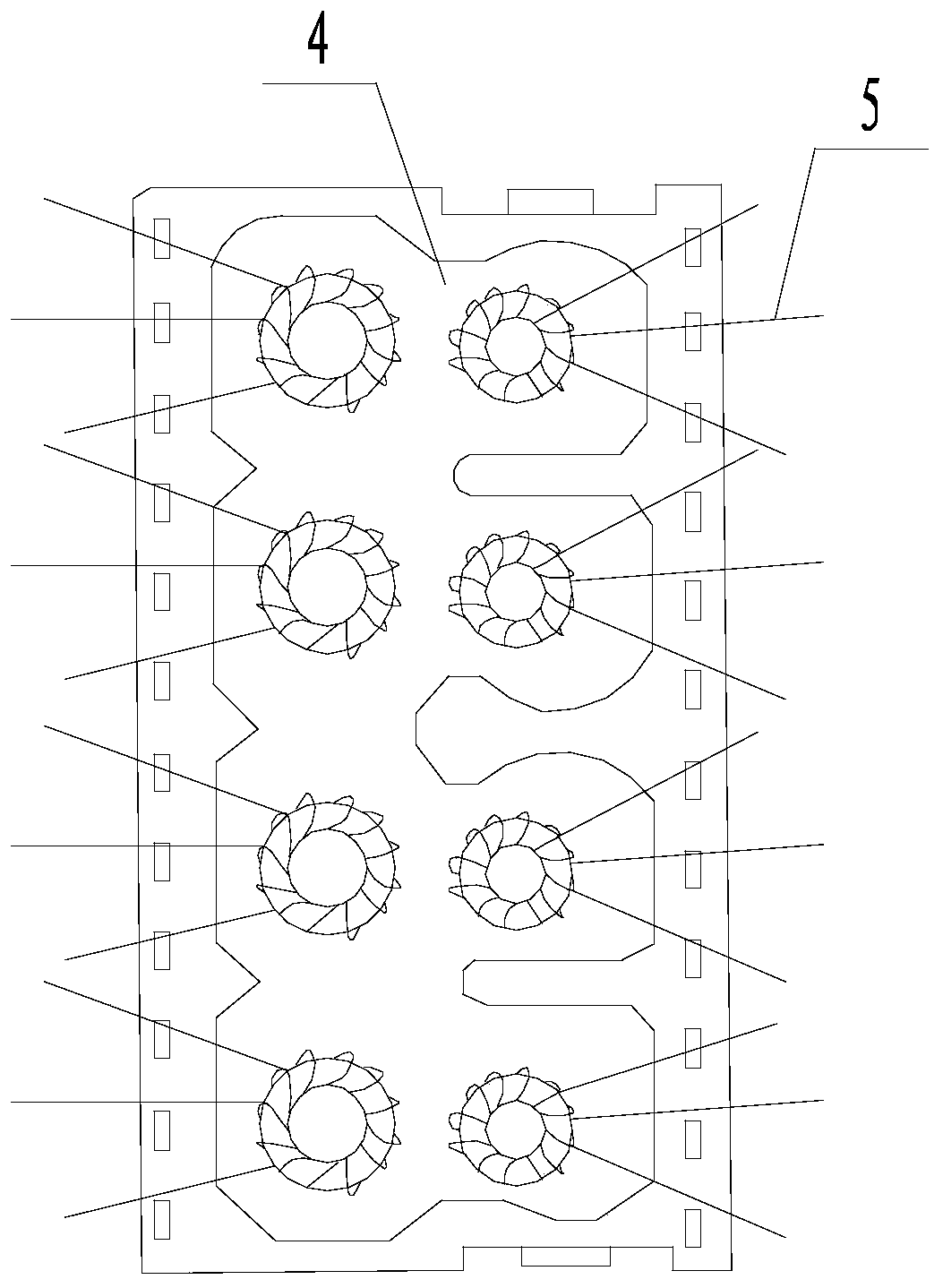

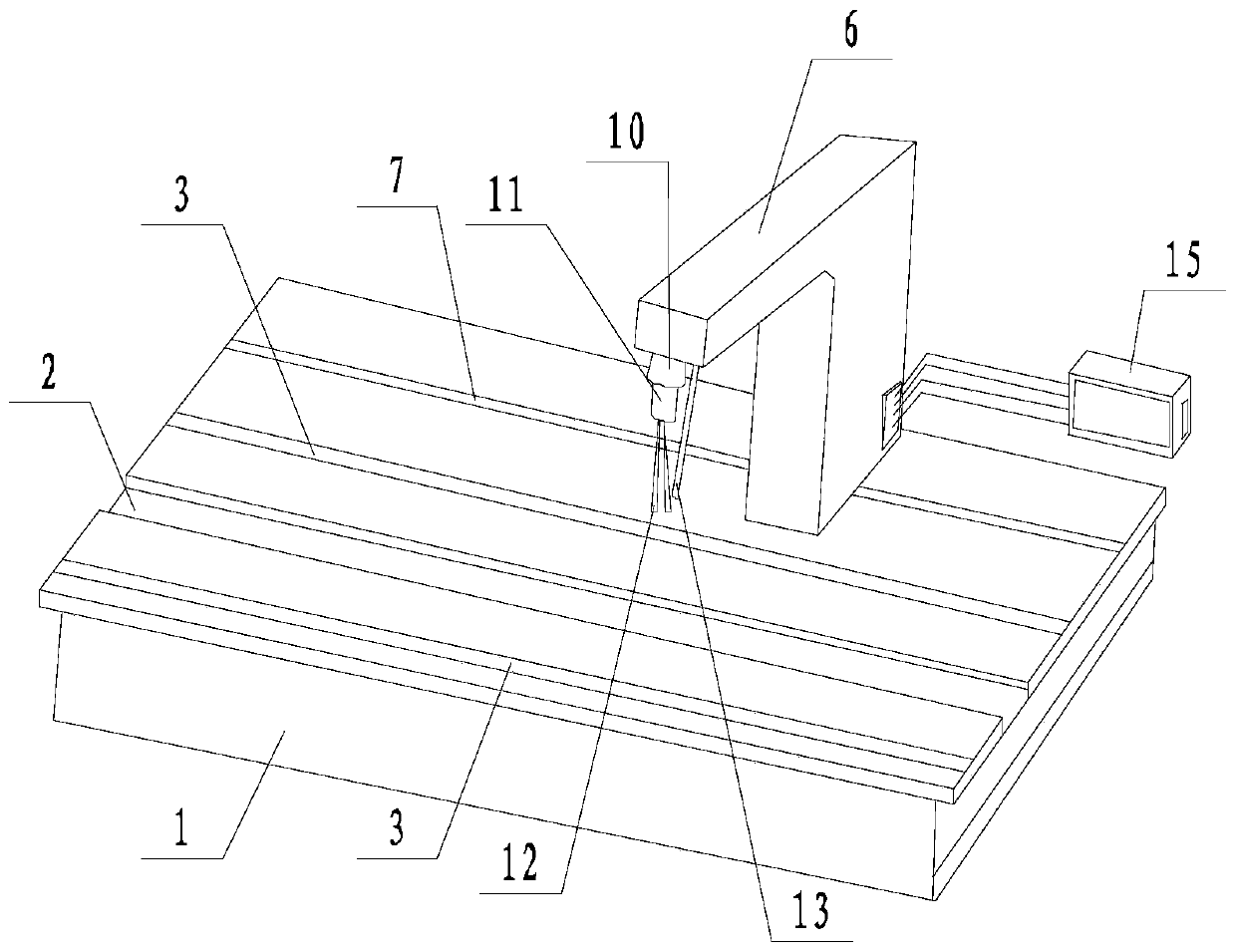

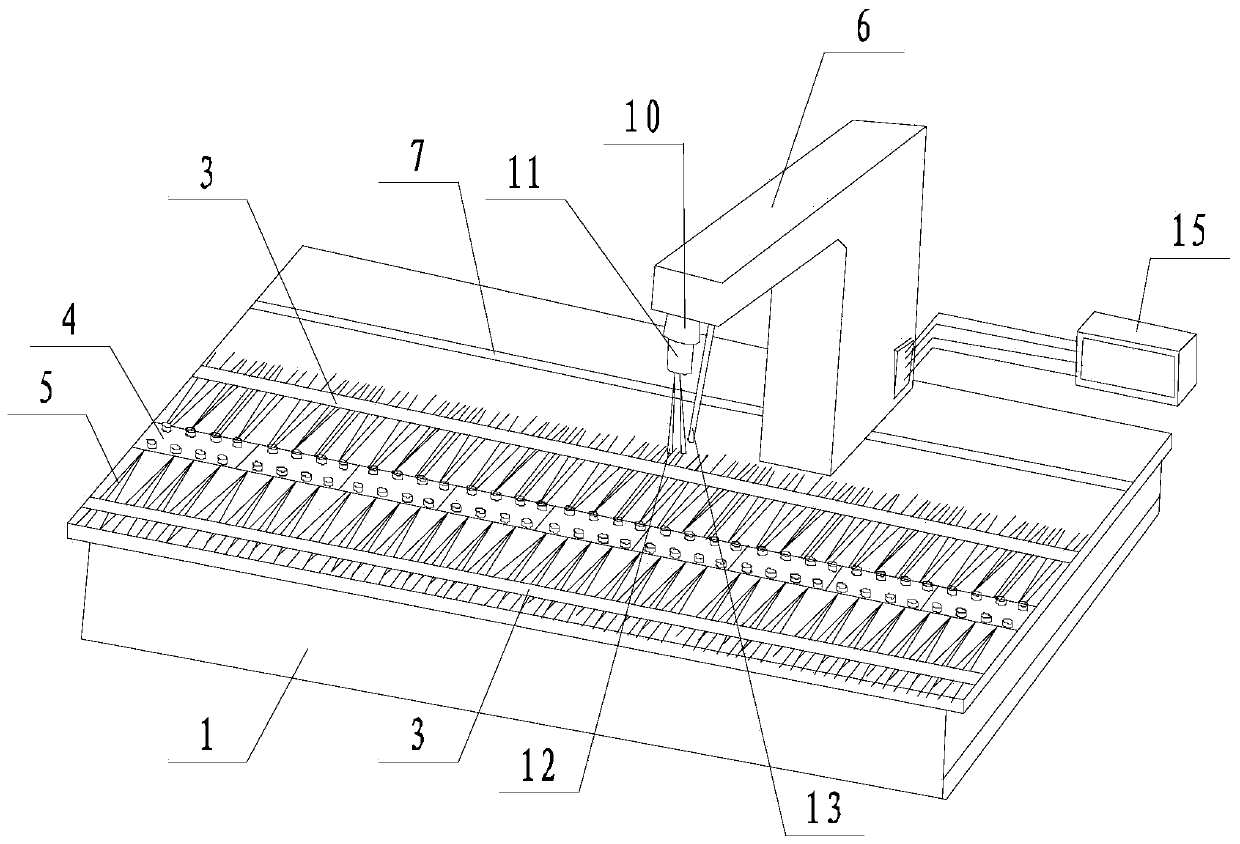

Network transformer pin automatic winding lead wire equipment and winding method thereof

InactiveCN108987101ASolve the problem of low winding efficiencyReduce labor intensityInductances/transformers/magnets manufactureTransformerConductor Coil

The invention discloses a network transformer pin automatic winding lead wire device and a winding method thereof, high automation level, greatly reducing the labor intensity of workers, and solves the problem of low winding efficiency of network transformer pins in the prior art, At the same time, the problem of unstable winding quality and high scrap rate is solved, and the purpose of increasingwinding speed, improving winding quality stability and reducing product scrap rate is realized, compared with the traditional process that manual operation depends on worker's skill and proficiency.

Owner:张洪

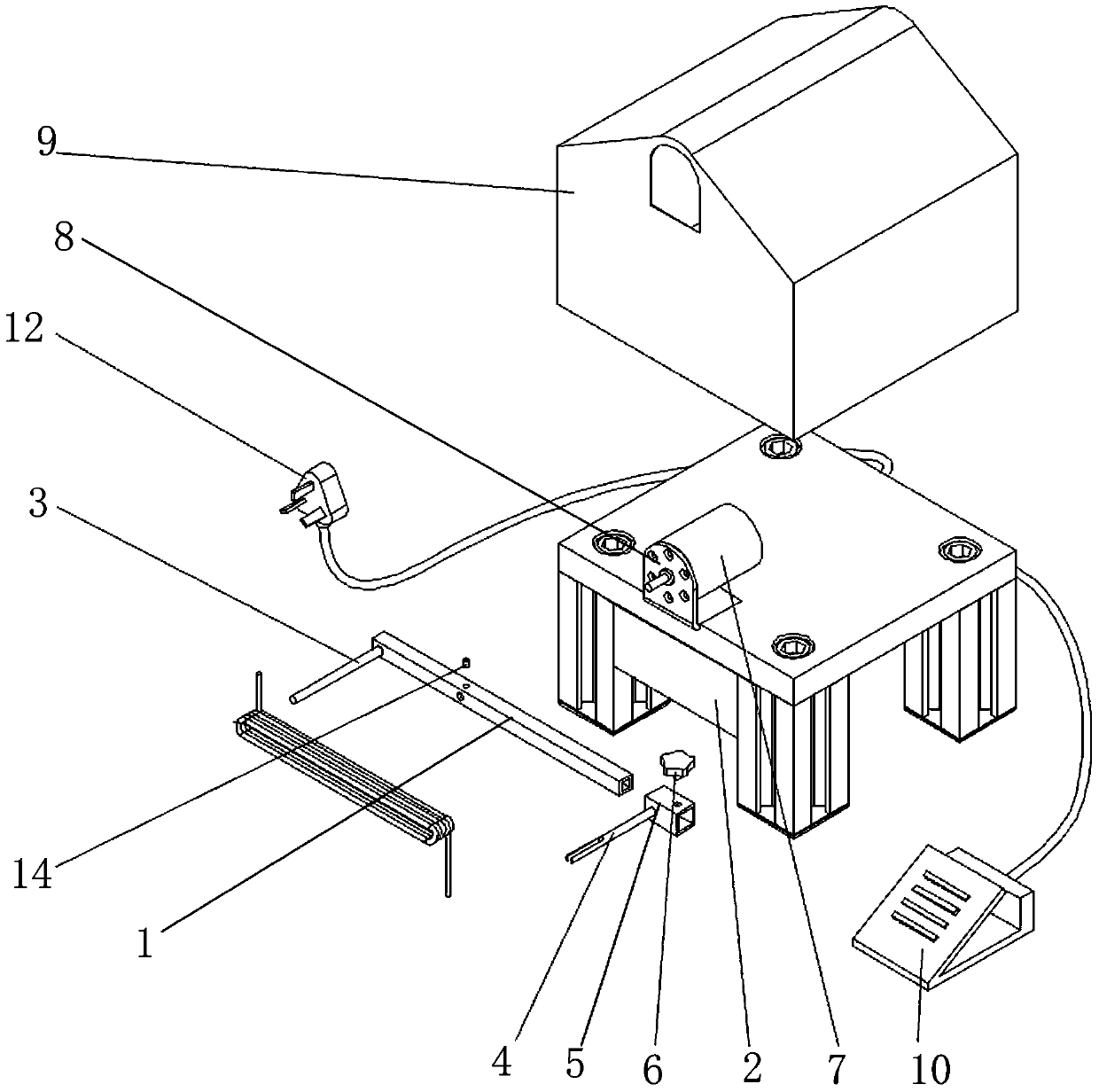

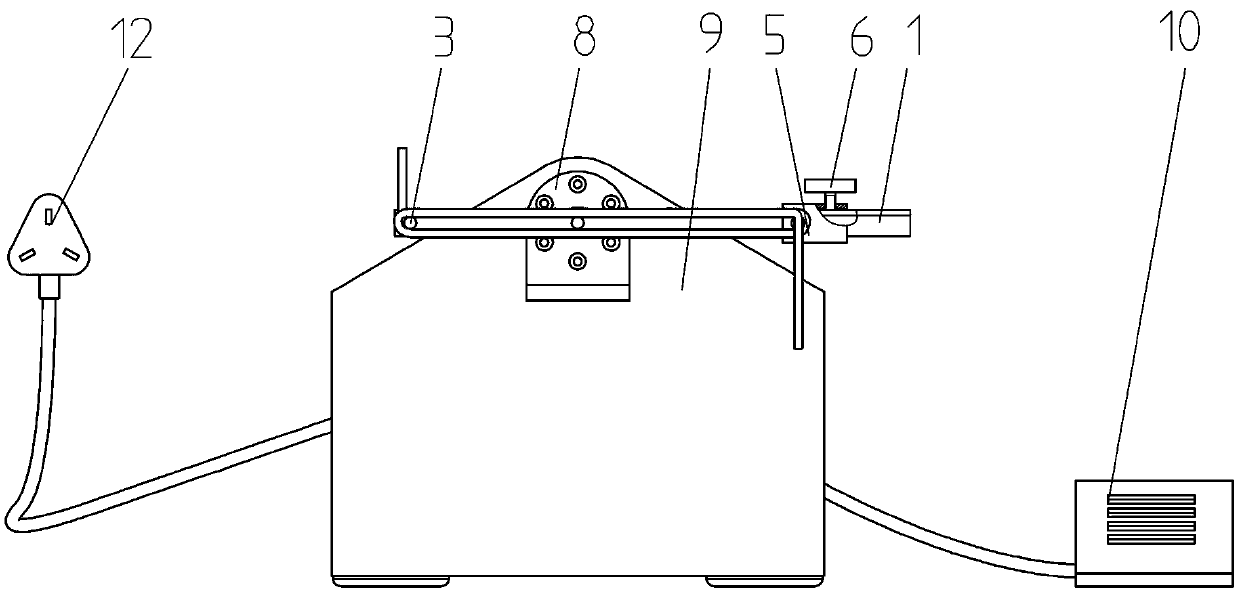

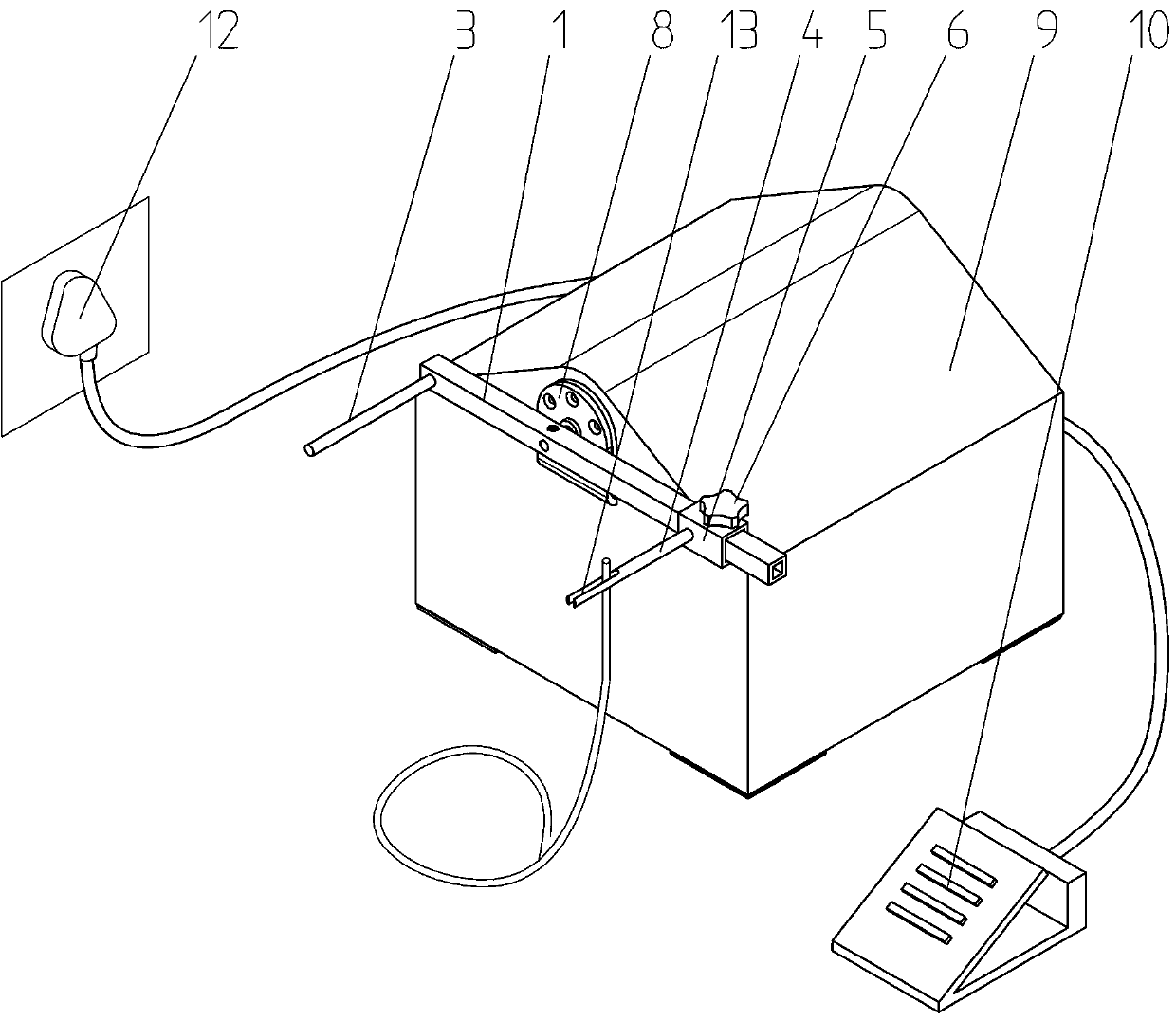

Semi-automatic pedal-type winding device with adjustable center distance

The invention belongs to the field of winding equipment, and particularly relates to a semi-automatic pedal-type winding device with the adjustable center distance. The semi-automatic pedal-type winding device comprises a fixing frame, a driving mechanism for driving the fixing frame to rotate and a rack for installing the driving mechanism, one end of the fixing frame is provided with a fixed winding portion, and the other end of the fixing frame is movably provided with a movable winding portion, and the movable winding portion is fixed to the fixed frame through a locking mechanism. The semi-automatic pedal-type winding device can improve the winding speed and efficiency, has a wide application range, is small in size, has good safety and is suitable for clean workshop operation.

Owner:浙江量子医疗器械有限公司

Convenient type textile winding machine

InactiveCN107673119AImprove running stabilityIncrease winding speedFilament handlingWinding machineBobbin

The invention discloses a portable textile winding machine, which comprises a winding frame body composed of a first frame body and a second frame body. A cavity extending left and right is arranged in the first frame body, and a cavity on the right side of the cavity The inner front wall is provided with a first sliding groove, the first sliding groove is provided with a rear side extending into the cavity and slidingly fitted to connect the sliding block, a hinge is provided on the left end surface of the sliding block in the cavity, and the hinge is hinged There is a hinged push rod extending to the left side, the left end of the hinged push rod is provided with a hinge sleeve, and the inner sleeve of the hinge sleeve is provided with a U-shaped hinge rod. The rear end of the U-shaped articulated rod is connected with the winding motor, the outer surface of the winding motor is embedded in the rear inner wall of the cavity and fixedly connected, and the left end surface of the second frame body is provided with a second sliding groove extending forward and backward. A moving block is arranged in the second sliding groove; the invention has a simple structure, can realize fast installation and disassembly, improves the replacement speed of the wire barrel, and can evenly wind the wire.

Owner:CIXI QICHENG MACHINERY TECH CO LTD

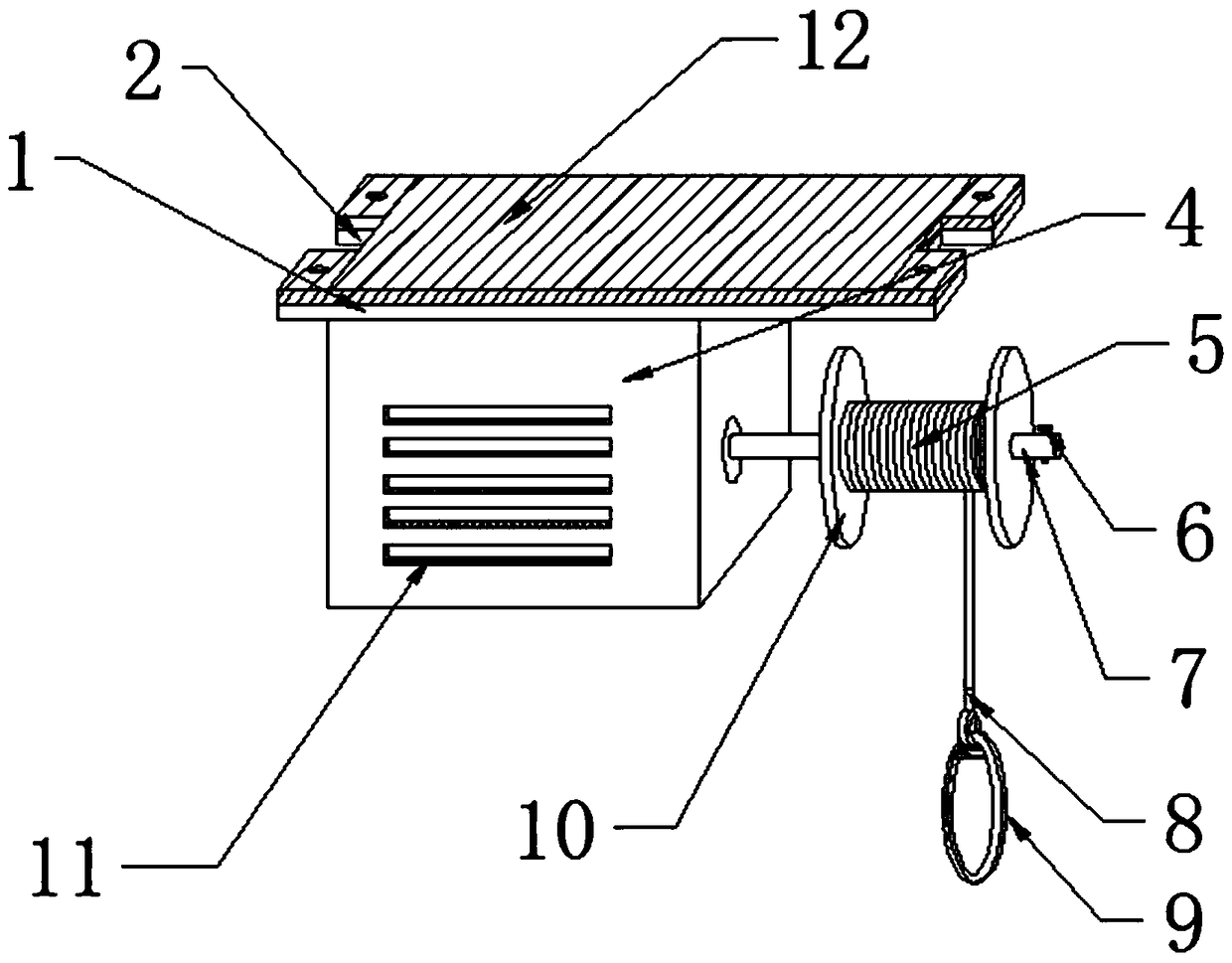

Chain type parallel lifting device for industrial manufacturing

InactiveCN109052202AIncrease winding speedReduce risk of sheddingWinding mechanismsElectricityGear drive

The invention discloses a chain type parallel lifting device for industrial manufacturing, comprising a shell and a remote controller. A signal receiver is arranged in the shell, a signal transmitteris arranged on a front surface of the remote controller, and the remote controller is connected with the signal receiver through the signal transmitter. A motor, a main gear, a chain and an auxiliarygear are arranged in the chain type parallel lifting device for industrial manufacturing. During operation of the device, electric energy is converted to kinetic energy, thereby driving the main gearto rotate clockwise, and thus the main gear drives the auxiliary gear to rotate clockwise through the chain since the main gear and the auxiliary gear are connected through the chain. The main gear and the auxiliary gear are connected with the chain through the gear of the outer wall, so that a slipping phenomenon can be prevented, thereby improving the kinetic energy conversion rate of the device. The size of the main gear is larger than that of the auxiliary gear, and the rotating speed of the auxiliary gear is higher than that of the main gear, thereby improving the winding speed of the reel on the cable.

Owner:新沂城北新区城市建设发展有限公司

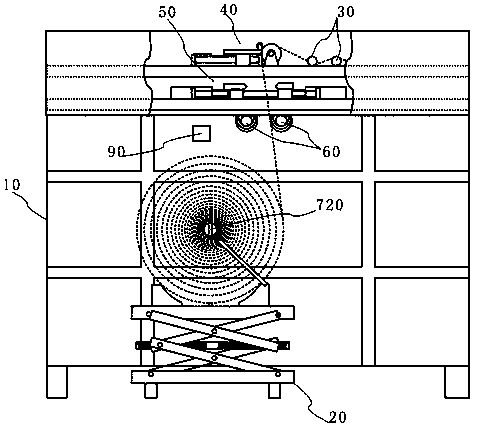

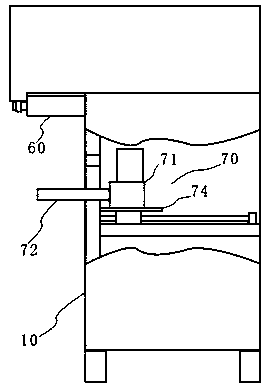

Automatic counting winding and cutting machine and braid winding and cutting method

PendingCN108689211AAppropriate tensionDecrease the tilt angleArticle deliveryElectronic control systemEngineering

The invention relates to an automatic counting winding and cutting machine which comprises an electronic control system, a braid winding mechanism, a receiving disc lifting table, a braid guide rollerset, a fusing mechanism, a limiting assembly and a traction mechanism, the braid guide roller set, the fusing mechanism, the limiting assembly and the traction mechanism are sequentially arranged inthe braid running direction, the center of a braid winding station of the braid winding mechanism is located on any one of the left and right sides of a fusing station, the limiting assembly is located under the fusing station and is provided with a braid walking space, the receiving disc lifting table is correspondingly arranged under the braid winding station, a meter counting wheel and a photoelectric detector are electrically connected with the signal input end of the electronic control system. By means of the automatic counting winding and cutting machine, the inclined angle between a braid and the vertical line can be smaller during full winding, fusion is facilitated, the braid descending angle is limited, and accidental fusion is avoided; and a pneumatic rolling shaft is tightly attached to a traction roller to enable the braid to keep appropriate tension force without corrugation or displacement, and the smooth implementation of braid winding and orderly and attractive braid discs are guaranteed. According to the automatic counting winding and cutting machine, the braid can be automatically cut off and rolled into a disc cake shape according to the set length, the accuracyis high, and the load weight is large.

Owner:福建锦特新材料科技有限公司

Convenient textile winding mechanism

InactiveCN107673121AImprove running stabilityIncrease winding speedFilament handlingBobbinEngineering

The invention discloses a convenient textile winding mechanism, which comprises a winding frame body composed of a first frame body and a second frame body. A cavity extending left and right is arranged in the first frame body, and the inner cavity on the right side of the cavity The front wall is provided with a first sliding groove, the first sliding groove is provided with a rear side extending into the cavity and slidingly fitted to connect the sliding block, a hinge is arranged on the left end surface of the sliding block in the cavity, and a hinge is hinged in the hinge. The hinged push rod extending to the left is provided with a hinged sleeve at the left end of the hinged push rod, and a U-shaped hinged rod is arranged inside the hinged sleeve. The rear side end of the type hinged rod is connected with the winding motor, the outer surface of the winding motor is embedded in the inner wall of the rear side of the cavity and is fixedly connected, and the second sliding groove extending forward and backward is provided in the left end surface of the second frame body. The second sliding groove is provided with a moving block; the invention has a simple structure, can realize fast installation and disassembly, improves the replacement speed of the wire barrel, and can evenly wind the wire.

Owner:CIXI QICHENG MACHINERY TECH CO LTD

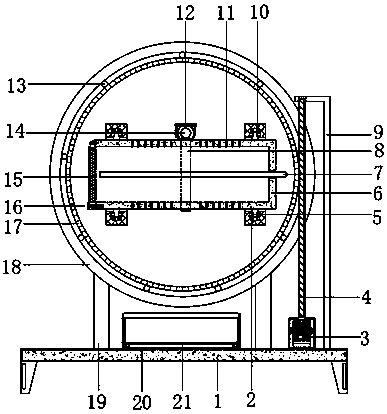

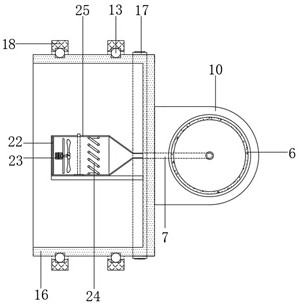

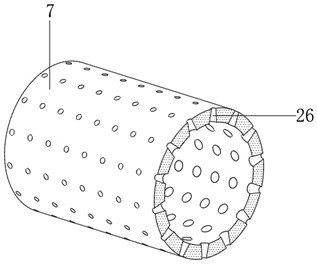

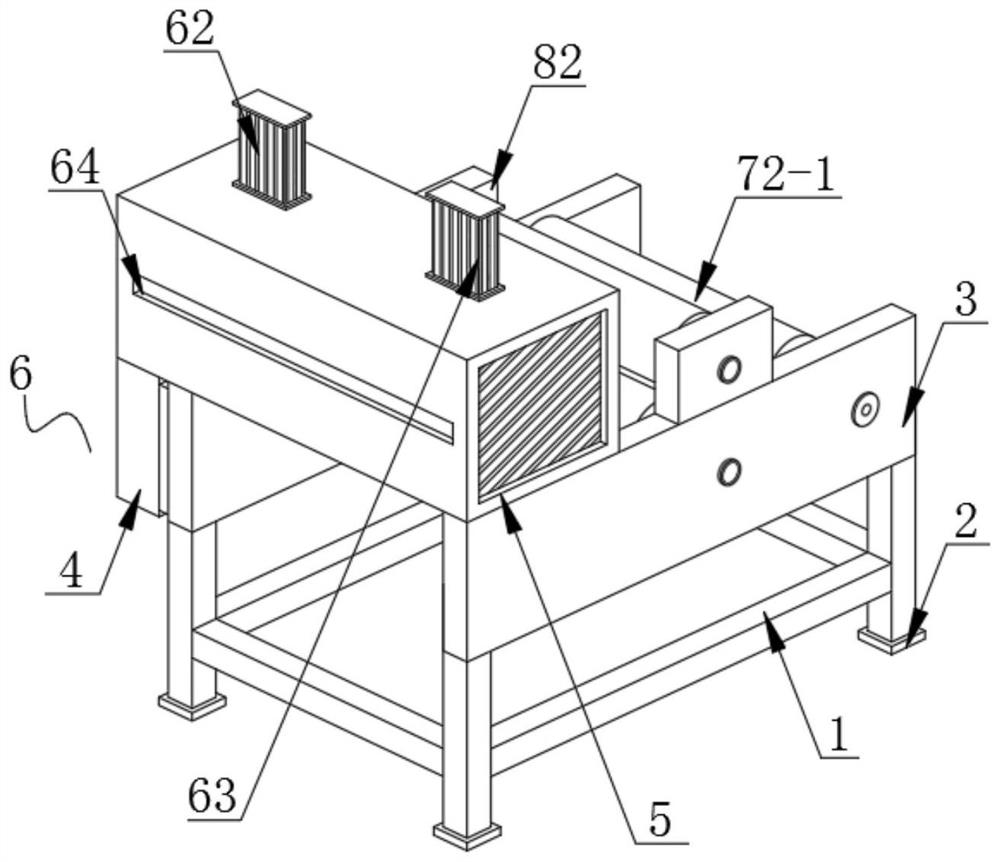

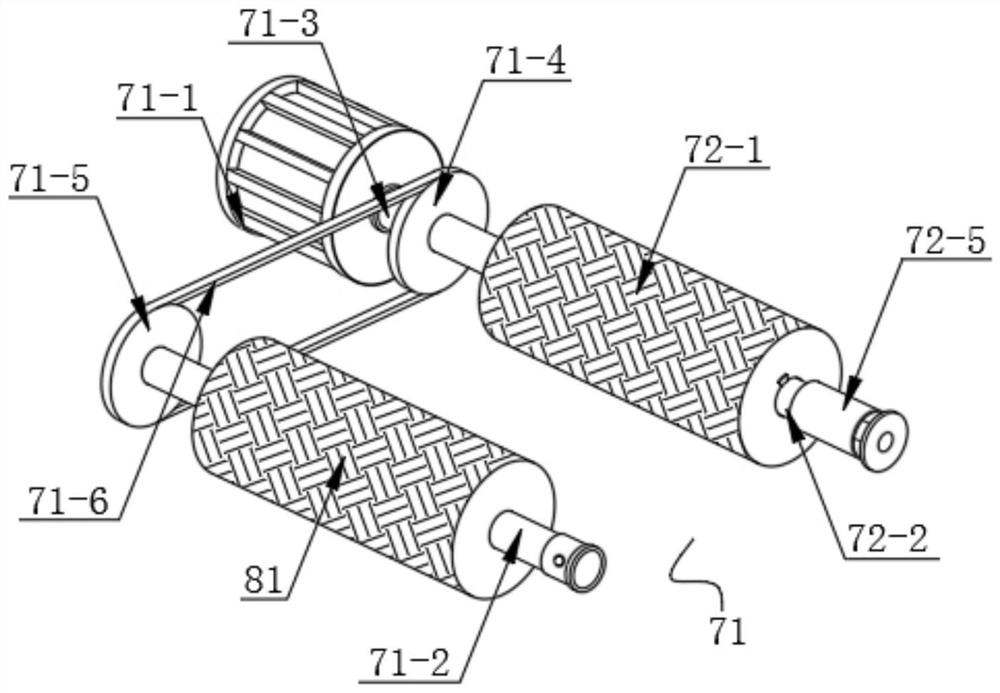

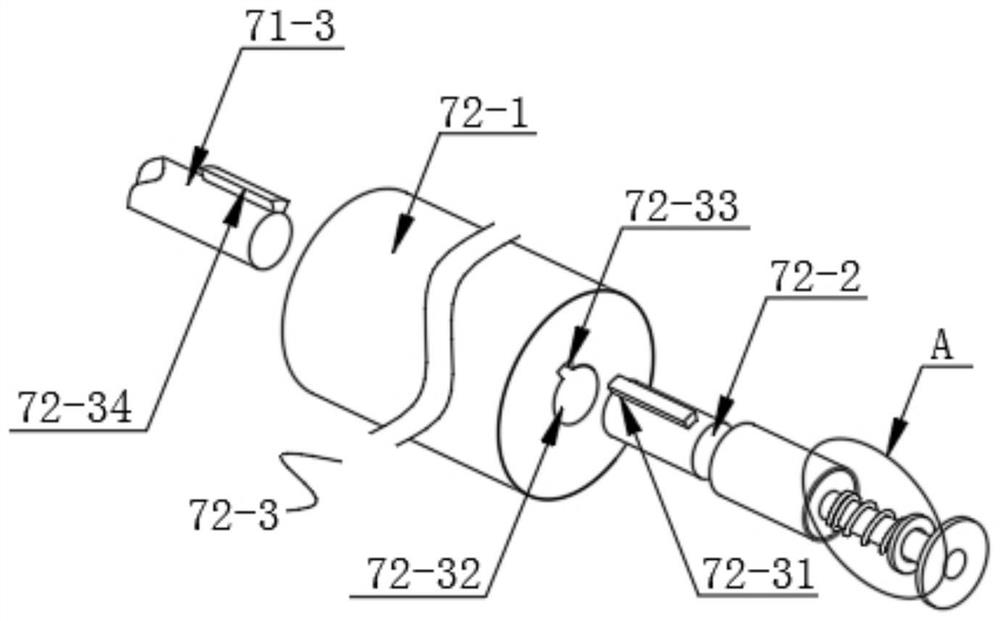

Drum-type drying device for dendrobium officinale processing

ActiveCN110906711AGuaranteed uniformityStable supportDrying gas arrangementsDrying chambers/containersStructural engineeringMechanical engineering

The invention belongs to the technical field of dendrobium processing, in particular to a drum-type drying device for dendrobium officinale processing. Aiming at the problems that the drying uniformity of a traditional dendrobium drying device is poor and the subsequent drying quality is influenced, the drum-type drying device for the dendrobium officinale processing comprises a rotary drum; a drying tank and bases with support legs welded at four corners at the bottom; two sides of the outer wall of one side of the rotary drum are vertically welded with fixed plates; one sides of the two fixed plates are respectively provided with mounting circular grooves used for mounting the drying tank; two ends of the rotary drum are respectively welded with fixed rings; and one sides, opposite to the mounting circular grooves, of the fixed rings are respectively provided with first annular grooves. According to the drum-type drying device for the dendrobium officinale processing, a second driving mechanism is arranged, the rotary drum can be driven to stably rotate through a second worm and a worm gear tooth ring, so that the drying tank is driven to overturn, due to the fact that a rise angle of the second worm and the worm gear tooth ring is smaller than a friction angle, the drying device has good self-locking property, stable overturning of the drying tank is realized, and the advantages of convenient loading and unloading are achieved.

Owner:花垣县大峡谷生态农业发展有限公司

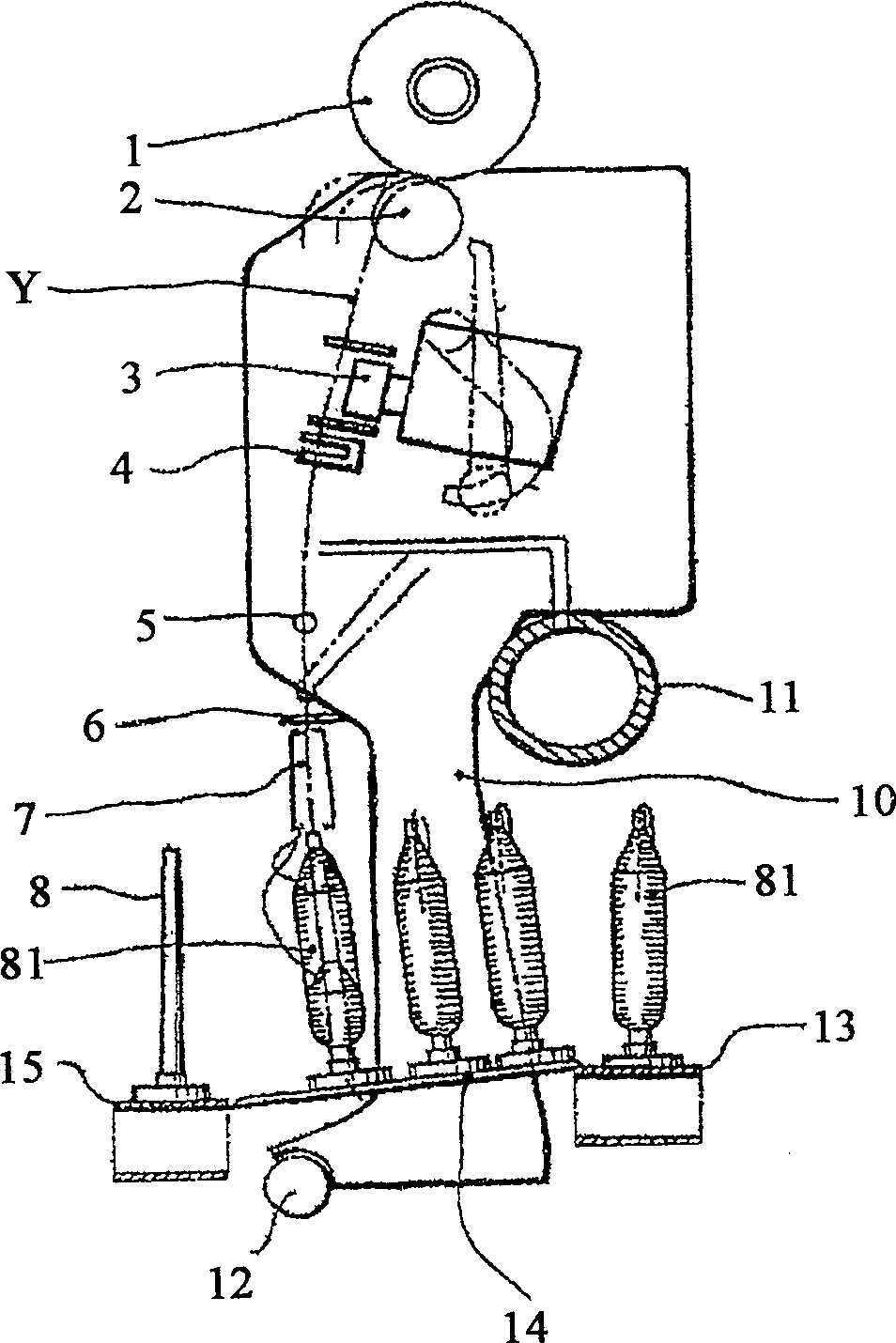

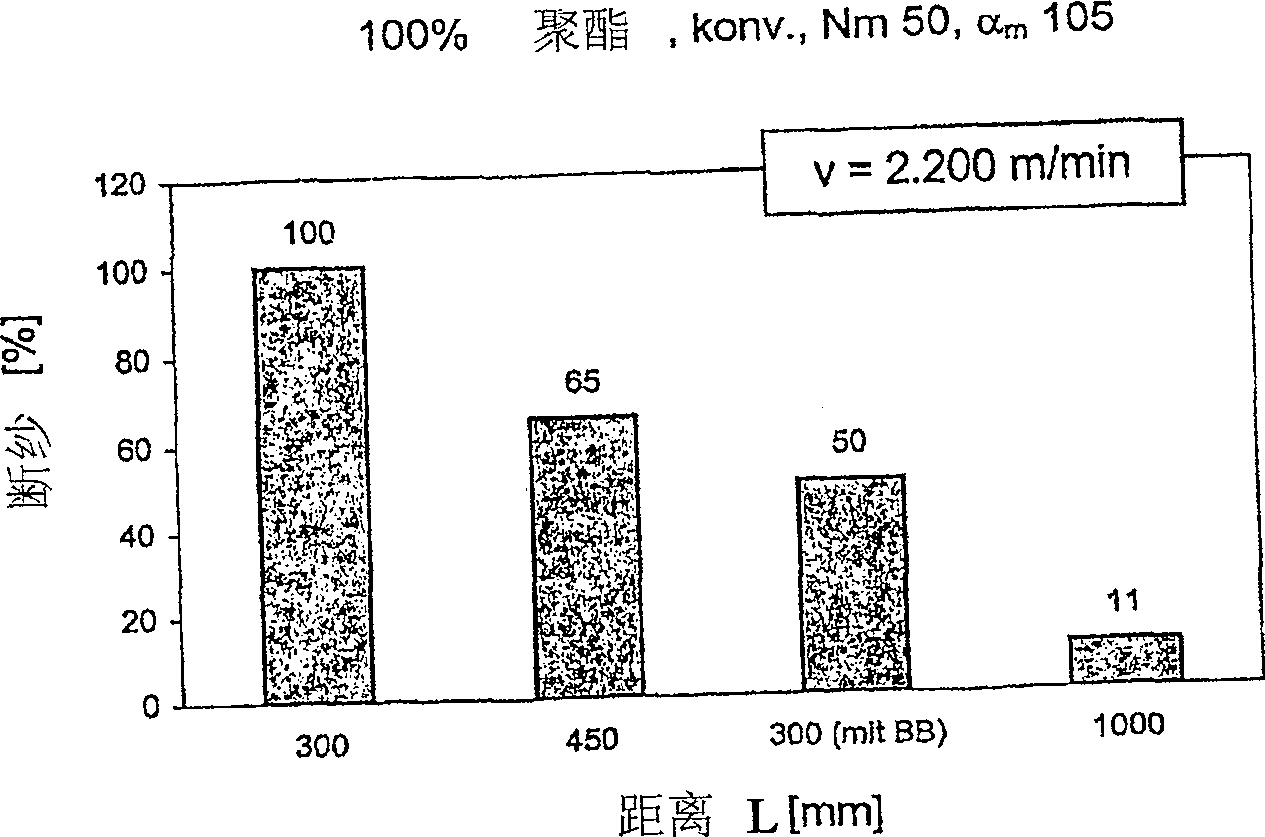

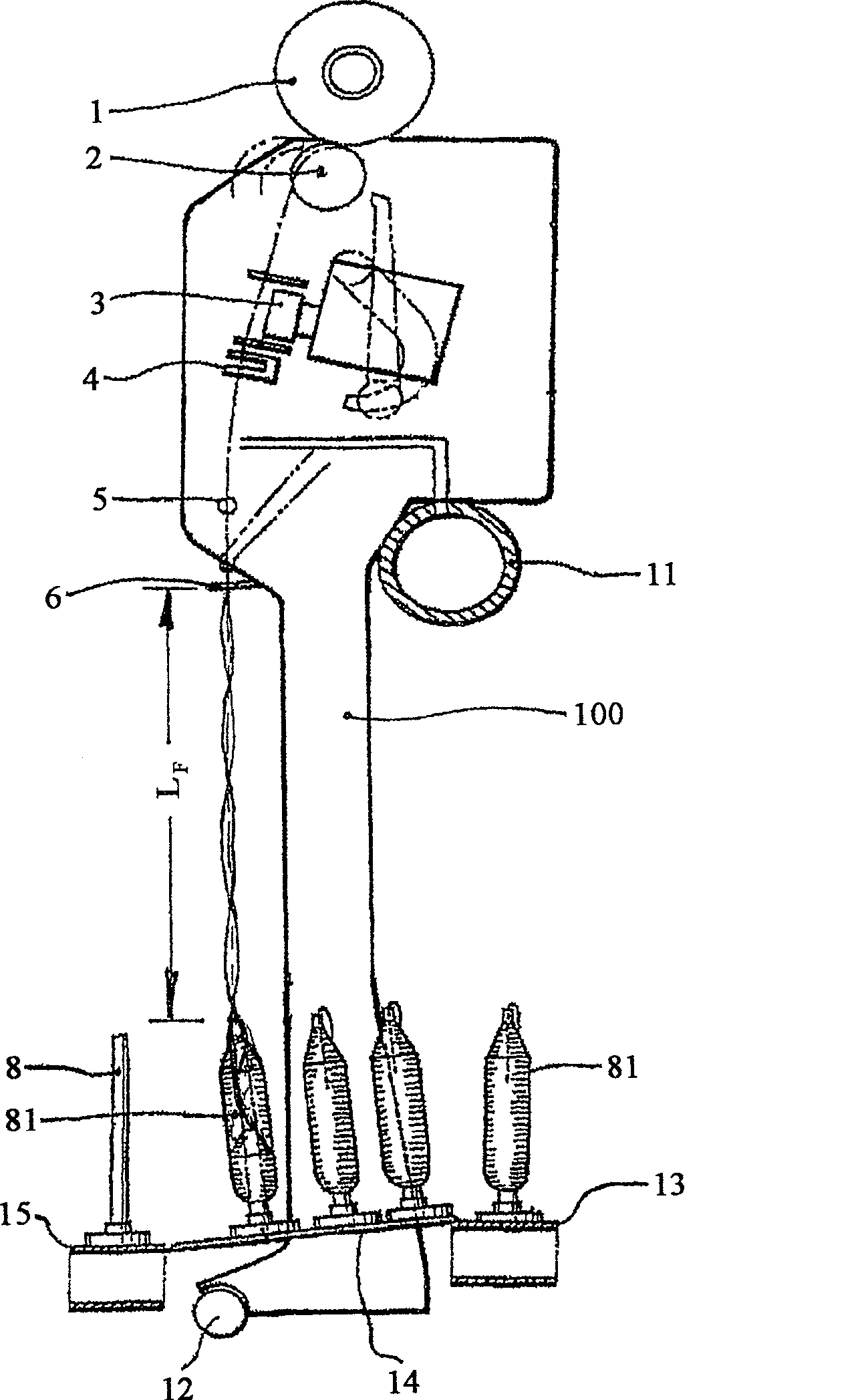

Process and device for rewinding feed spools

InactiveCN101437740AIncrease winding speedOptimizing Process ConditionsFilament handlingEngineeringBobbin

A process and device are disclosed for rewinding thread feed spools produced on a ring spinning machine, the spools having a cone at their upper end that ends at the spool holder. The threads to be rewound are drawn overhead from the feed spools, joined and wound into a cross-wound bobbin. The usual gap between the top edge of the thread feed spool holder and the thread guide is considerably increased, so that the thread crosses a free section of more than 600 mm, and is not exposed to any further guidance in this section.

Owner:邓肯多夫德国纺织纤维研究所

Automatic cable winding device

PendingCN106044369AIncrease winding speedImprove processing efficiencyFilament handlingEngineeringProcessing cost

The present invention is an automatic cable coiling device, which includes a bottom frame, a gear box, a motor and a hydraulic machine arranged under the bottom frame, a turntable arranged above the bottom frame, and a movable plate and a rotary drum positioned above the turntable , the center of the chassis and the turntable is provided with a chuck, the center of the chuck is provided with a limit groove, one side of the chassis is connected with a drag bottom, and a limit rod and a hydraulic rod are arranged above the drag bottom, and the upper end of the hydraulic rod is connected with a The lead plate, the rotating cylinder is located in the center of the movable plate, the inside of the rotating cylinder is provided with a mandrel, the lower part of the movable plate is connected with a connecting rod, the lower part of the connecting rod is provided with a clamping rod, and the clamping rod is located in the limiting groove , the motor and the gearbox are connected by a belt, and a rotating shaft is arranged above the gearbox; the automatic cable winding device allows the user to directly wrap the cable, avoiding the use of the winding drum by the user, and effectively It greatly reduces the user's processing cost for the cable, and also facilitates the user's storage and placement of the cable.

Owner:ZHEJIANG LIUHUAN WIRE & CABLE CO LTD

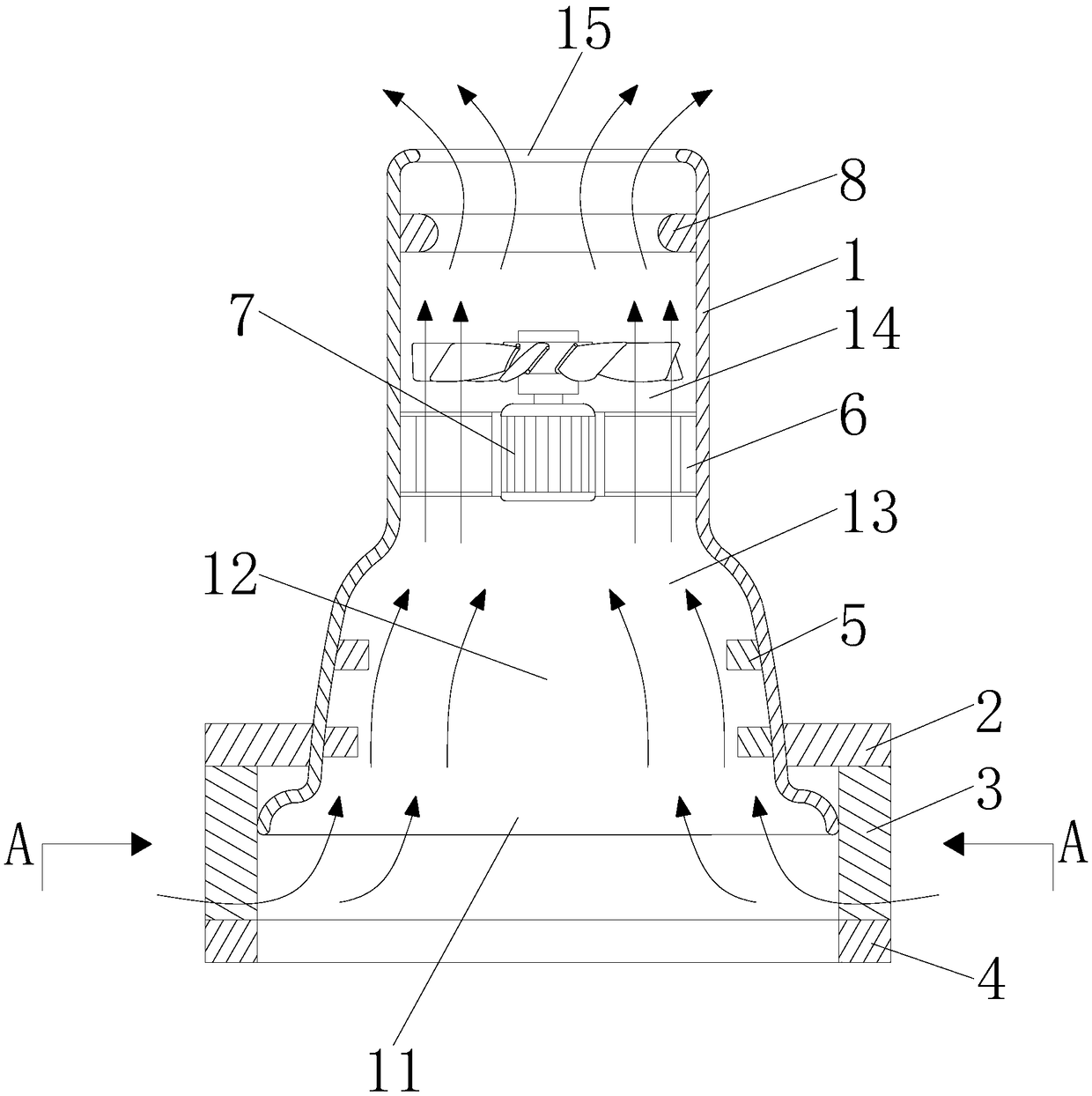

Air duct structure of air purifier

InactiveCN109282379AIncrease the air intakeImprove efficiencyDucting arrangementsMechanical apparatusIndoor airAir purifiers

The invention discloses an air duct structure of an air purifier. The air duct structure of the air purifier comprises a shell body, wherein the shell body comprises an air inlet cavity, a purification cavity, a buffer area, a fan cavity and an air outlet which are sequentially arranged from bottom to top, the opening diameter of the bottom of the air inlet cavity is larger than the opening diameter of the bottom of the purification cavity, the opening diameter of the top of the purification cavity is larger than the opening diameter of the buffer area, the opening diameter of the bottom of the buffer area is larger than the diameter of an inner circle of the fan cavity, the diameter of the inner circle of the fan cavity is larger than the opening diameter of the air outlet, and wall bodies on the two sides of the air outlet are inwards chamfered. According to the air duct structure of the air purifier, the shell body as well as the air inlet cavity, the purification cavity, the bufferarea, the fan cavity and the air outlet of the shell body are arranged and formed so that the air inlet amount of the air purifier can be effectively improved, and the air purification efficiency isimproved; and in addition, the air outlet speed of the air outlet is increased, the circulation speed of indoor air is increased, and the problems that a traditional air duct structure of an air purifier is small in air inlet amount and low in air outlet speed are solved.

Owner:JIAXING MYSKY ELECTRICAL TECH CO LTD

Blow molding machine winding device and method for reducing adhesion of film and roller

The invention relates to the technical field of film winding and discloses a blow molding machine winding device for reducing adhesion of a film and a roller. The blow molding machine winding device comprises a support, a first rotating shaft is fixedly connected to the inner wall of the middle of the support, a measuring mechanism is fixedly connected to the inner wall of the middle of the support, the outer side of the first rotating shaft is sleeved with an inner roller, the outer side of the inner roller is fixedly connected with a winding roller, and the top of the support is fixedly connected with a connecting column. According to the blow molding machine winding device for reducing adhesion of the film and the roller, electromagnets drive fixing bases to move, the fixing bases drive static electricity removing pieces to move, the static electricity removing pieces clamp the film, then the inner roller drives pistons to move, a second magnetic block drives first magnetic blocks to operate, and then the first rotating shaft, a magnetism isolating plate and the first magnetic blocks are used in cooperation with compression cavities, so that the effects of removing static electricity on the film, preventing the film from being bonded and improving the film winding speed are achieved, and compared with traditional equipment, the blow molding machine winding device can effectively guarantee winding of the film.

Owner:许儒连

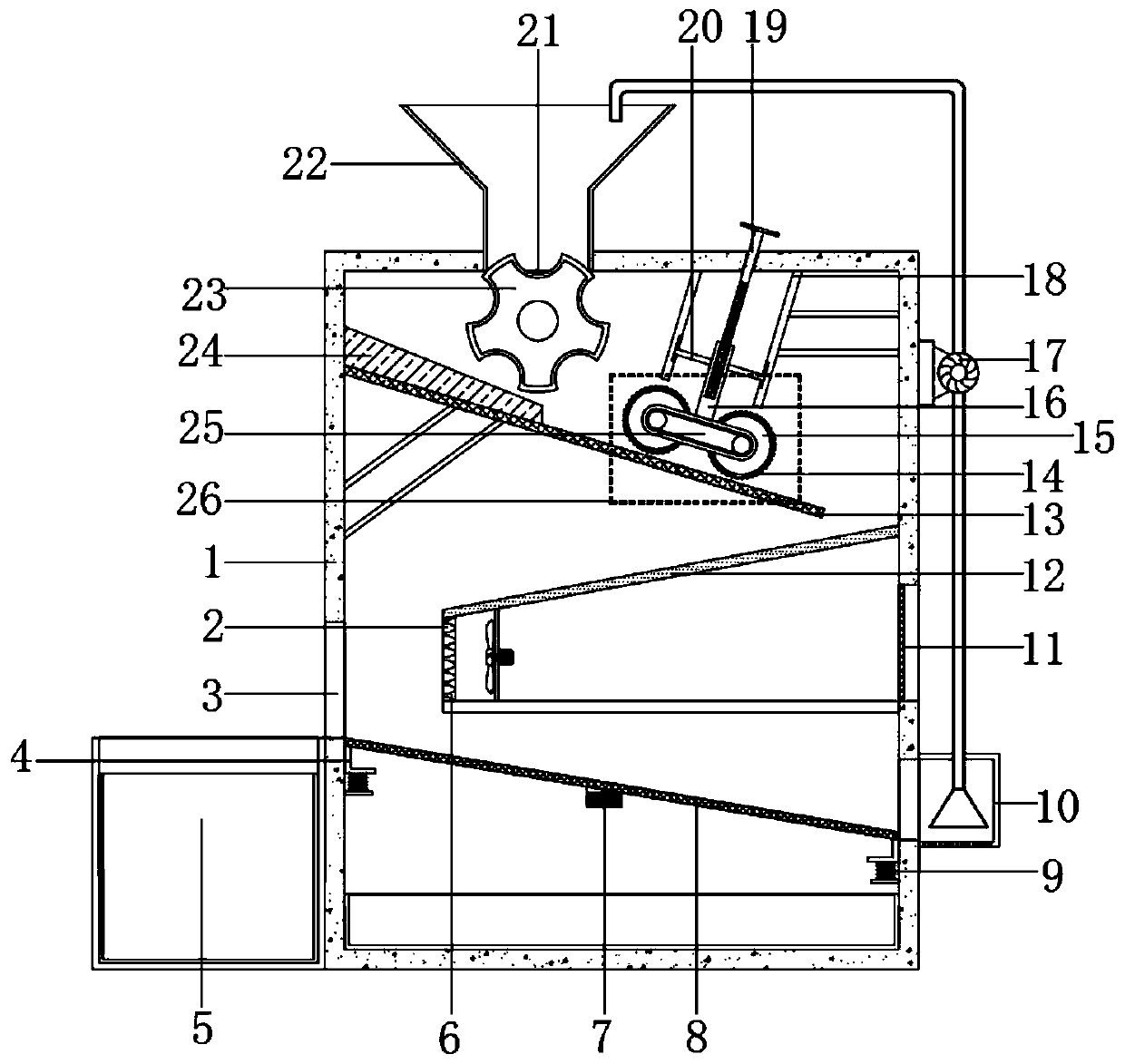

Peanut shelling device for agricultural production

InactiveCN111543648APlay the role of primary shell grindingImprove functionalityGas current separationHuskingAgricultural scienceAgricultural engineering

The invention belongs to the technical field of agricultural production, and in particular, relates to a peanut shelling device for agricultural production. Aiming at the problems that most of traditional peanut shelling devices are simple in structure and poor in shelling effect, the invention provides the peanut shelling device for agricultural production, wherein the device comprises a box bodyand a feeding hopper welded to one side of the top end of the box body. The side, close to the feeding hopper, of the box body is rotationally connected with a discharging roller through a bearing. One end of the discharging roller is connected with a gear motor through a coupler, arc-shaped discharging grooves distributed at equal intervals are formed in the outer wall of the circumference of the discharging roller, an obliquely-arranged discharging plate is welded to the side, close to the discharging roller, of the box body, and triangular strip-shaped plates distributed at equal intervalsare welded to the end of the discharging plate. Uniform-speed discharging treatment is conducted through the arc-shaped discharging grooves, and the subsequent shelling effect is guaranteed; and through the arrangement of grinding blocks and a discharging roller, the rotating discharging roller and an arc-shaped strip can be used in cooperation, the primary shell grinding effect on peanuts is achieved, and the functionality of the discharging roller is improved.

Owner:任静

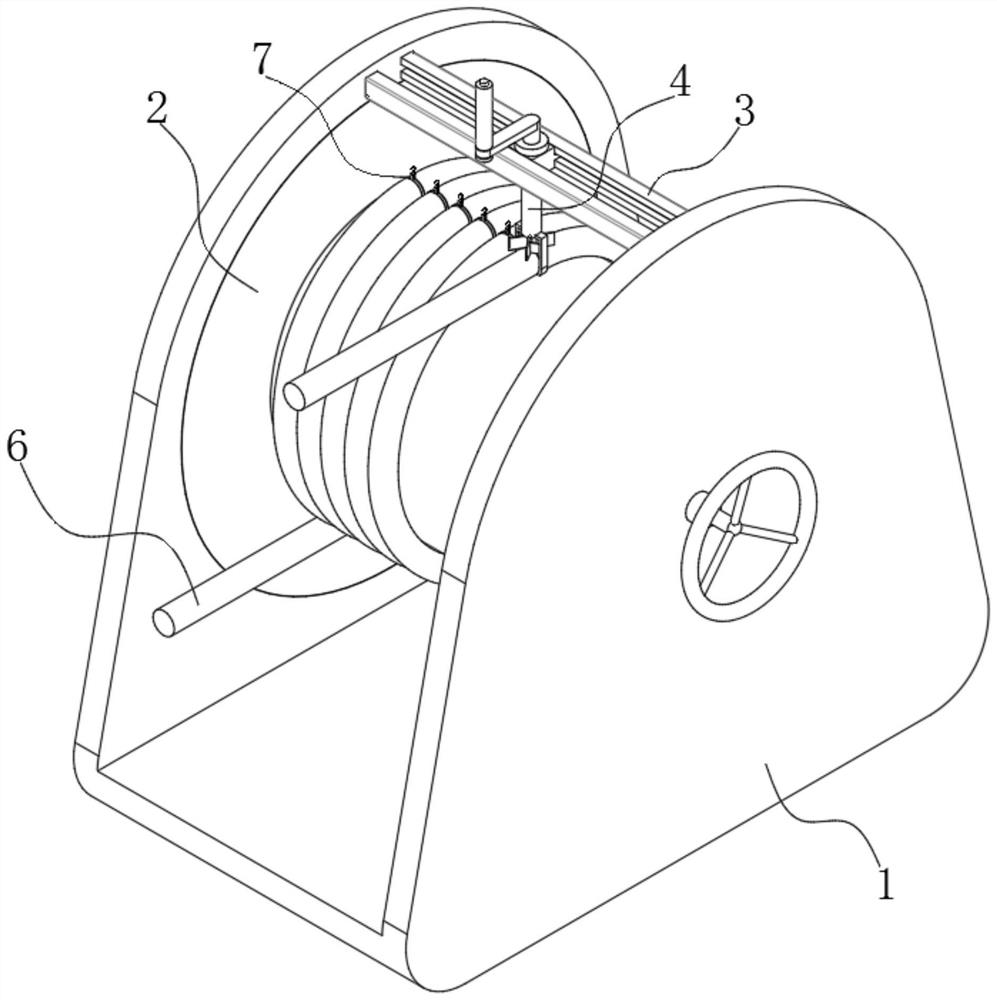

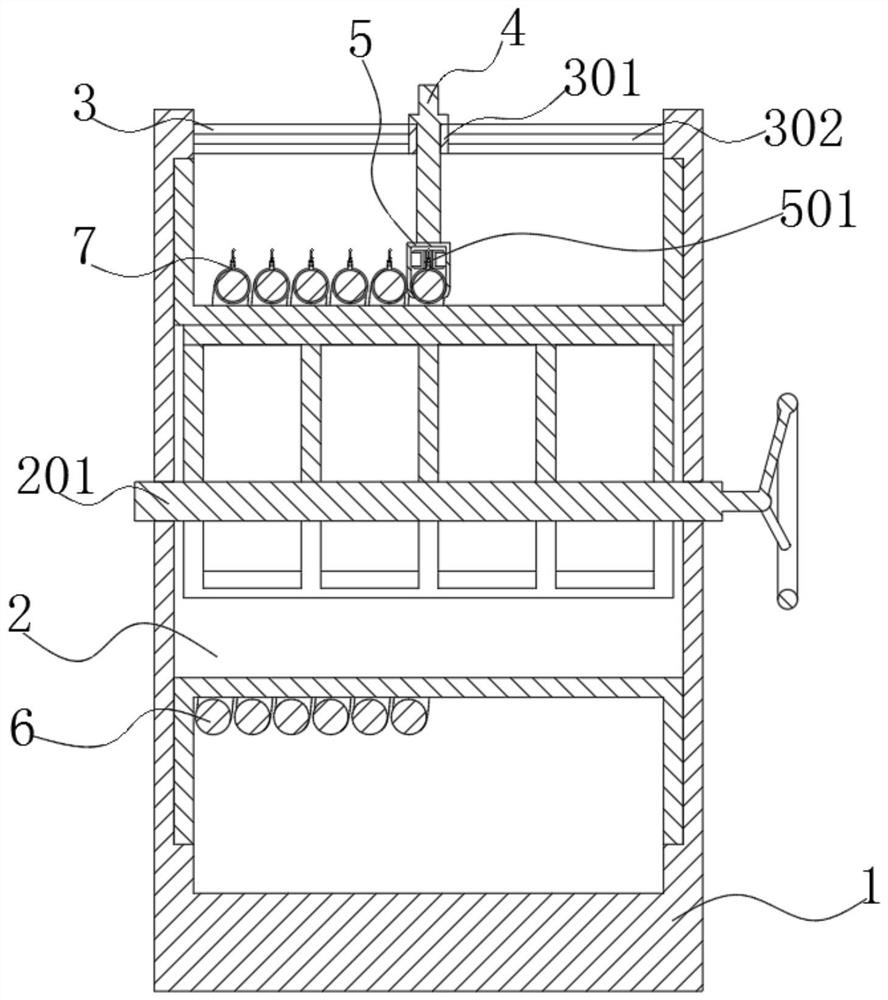

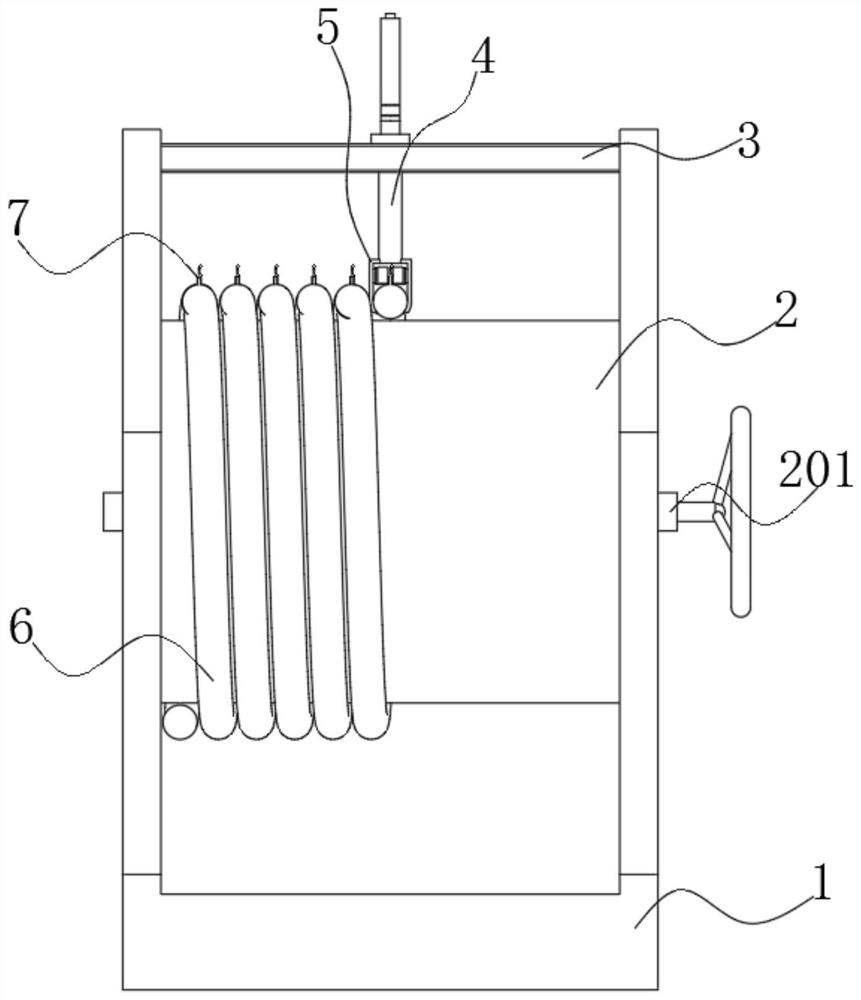

A cable limiting device for new energy vehicles

ActiveCN111731936BConvenient winding workIncrease winding speedFilament handlingNew energyStructural engineering

The invention discloses a cable limiting device for new energy automobiles, and relates to the technical field of automobile cables. The invention comprises a rotating frame, the inner top of the rotating frame is rotatably fitted with a cable reel, and a slide rail is fixed above the rotating frame inside the rotating frame, a sliding block is slidingly fitted in the sliding rail, and a limit rod is set on the sliding block; The bottom end of the limit rod is fixed with a door frame, and the bottom of the door frame is fixed with two opposite guide plates; the cable reel is wound with a cable body, and the cable body is embedded with clamps at intervals, and the top of the clamp is rotated to fit. There is a hook, and the hook cooperates with the guide plate. The present invention ensures orderly and stable winding of the cable body on the cable reel through the cooperation of the limit rod and the door frame, and ensures the efficiency of cable winding; through the cooperation of the door frame and the hoop, the cable body is guaranteed The non-deflection winding of the reel avoids local twisting of the cable and ensures the efficacy and quality of the cable.

Owner:蔡金花

Composite device for air bubble film processing

The invention discloses a composite device for air bubble film processing. The composite device comprises a foundation seat; the top of the foundation seat is fixedly connected with a strong frame; the top of the strong frame is fixedly connected with a composite workbench; the top of the foundation seat is movably provided with an automatic telescopic rod; the front side of the top end of the automatic telescopic rod is fixedly connected with a mounting protection frame; and a composite roller is movably mounted at the bottom of the mounting protection frame. According to the composite device for air bubble film processing, an air bubble film gradually gets close to the composite workbench, at the moment, the resistance value of a photoresistor which is shielded by the air bubble film and is in a dark state is increased, so that an electromagnetic valve in a shielded adsorption hole is in a conducting state, a change cavity in a negative pressure state forms a negative pressure adsorption effect on a drawing through the adsorption hole, and the air bubble film can be conveniently positioned at any position on the composite workbench; and meanwhile, a plurality of air bubble films can be positioned, and the flatness of the air bubble film on the composite workbench can be kept, so that subsequent composite treatment is facilitated, and the composite quality of the air bubble film is better.

Owner:胡翠凤

Automatic tension balancing device

PendingCN109052041AAvoid disorderRealize the function of balancing tensionFilament handlingBobbinEngineering

The invention discloses an automatic tension balancing device. The problems that during operating of traditional paying-off and winding equipment, winding disorder or even cable breaking due to unbalanced tension of a wound cable is prone to occurring frequently, and in addition, because of a lack of balancing measures, a paying-off bobbin is prone to being rotated backwards under centrifugal force during rotating can be solved. The automatic tension balancing device comprises a paying-off frame and a winding frame connected with the paying-off frame. A belt paying-off disc is mounted at the top of the paying-off frame. A tension belt is arranged at the bottom of the belt paying-off disc in a traction mode. A lapping head is mounted on the belt paying-off disc, and a cross-shaped balancingsupport is mounted on one side of the belt paying-off disc. A second balancing weight and a third balancing weight are mounted at the tops of the adjacent two ends of the cross-shaped balancing support correspondingly. When the device works, the situation that the distances between guide rollers and a turning roller are excessively long, the cable is loosened, and consequentially, wound cable disorder is caused can be prevented, in addition, the weight of the three balance weights on the cross-shaped balancing support is equal to the weight of the guide rollers, and therefore, the lapping head can be prevented from being rotated backwards during rotating.

Owner:HEFEI SMARTER TECH GROUP CORP

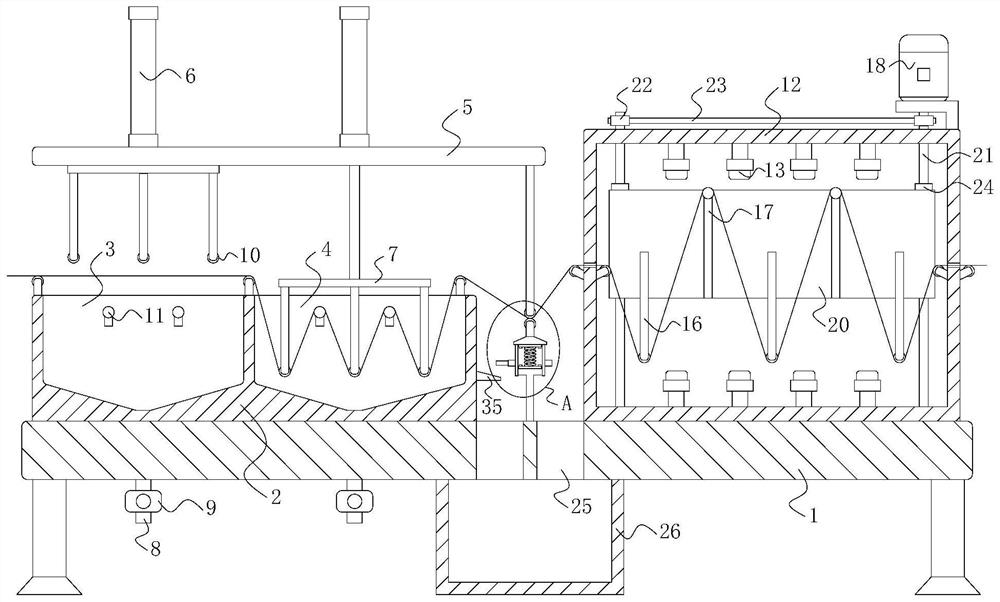

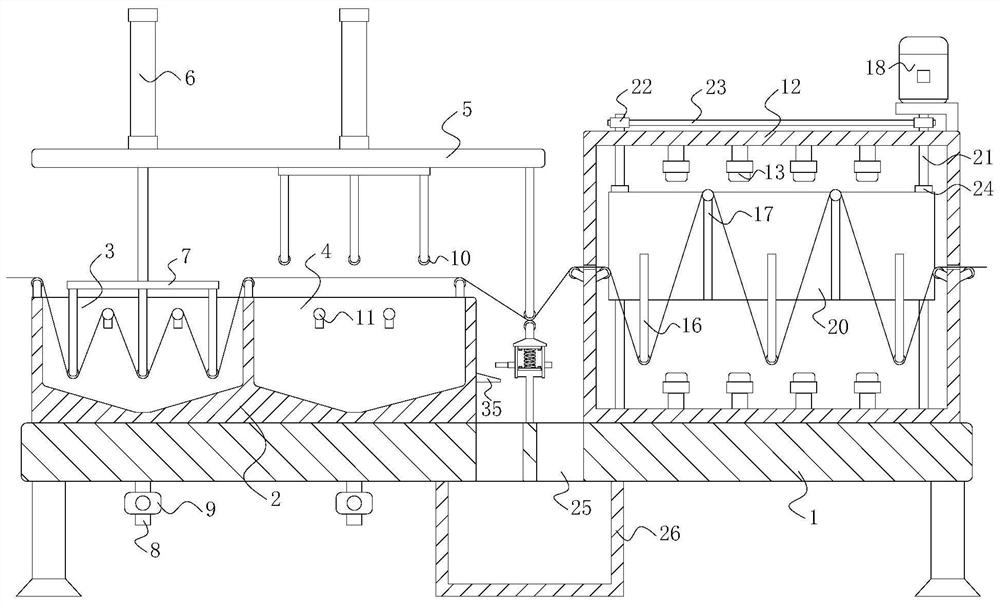

Dyeing machine for chemical fiber textiles

PendingCN113417095AReduce manufacturing costReduce use costLiquid/gas/vapor removal by squeezing rollersDrying machines with progressive movementsFiberProcess engineering

The invention relates to the technical field of textile equipment, in particular to a dyeing machine for chemical fiber textiles. The dyeing machine comprises a textile fabric and a dyeing machine body matched with the textile fabric, the dyeing machine body comprises a machine frame, a dyeing box is fixedly mounted on the top wall of one end of the machine frame, and a first dyeing tank and a second dyeing tank which are mutually independent are arranged in the dyeing box; and a top plate is mounted at the top end of the machine frame, two air cylinders are symmetrically mounted at the top wall of the top plate, mounting plates are fixedly connected with the output ends of the two air cylinders, and the two mounting plates are correspondingly located on the upper sides of the first dyeing tank and the second dyeing tank. Dyeing liquid in the dyeing tanks can be replaced by alternately pressing the textile fabric into the first dyeing tank and the second dyeing tank, the structure is simple, operation is convenient, the manufacturing and using cost of the dyeing machine is reduced, and the processing rate of the dyeing machine is remarkably increased due to the fact that the dyeing process does not need to be stopped when the dyeing liquid is replaced, so that the dyeing machine for the chemical fiber textiles is suitable for large-batch cloth dyeing.

Owner:孙冶

A kind of non-woven fabric production anti-deviation release cloth receiving equipment

ActiveCN109516256BIncrease winding speedEasy to useWebs handlingStructural engineeringNonwoven fabric

The invention discloses anti-deviation cloth unwinding and winding equipment for non-woven fabric production. The anti-deviation cloth unwinding and winding equipment comprises a workbench, a first roller shaft, a second roller shaft, a third roller shaft, a fourth roller shaft, a winding drum and fixing strips. First roller shaft seats are arranged at the upper end of the workbench. Second rollershaft seats are arranged inside the first roller shaft seats. Third roller shaft seats are arranged inside the second roller shaft seats. A main mandrel is arranged inside the winding drum. Fixing sleeves are fixed around the main mandrel. Sliding rails are correspondingly arranged inside the two ends of the winding drum. The top ends of the fixing strips are connected with the winding drum through folding shafts. According to the anti-deviation cloth unwinding and winding equipment, due to the arrangement of the multiple groups of roller shaft seats and the different heights of each group ofroller shaft seats, the heights of each group of roller shafts are different, so that the non-woven fabrics can be conveniently wound and unwound, and the situation that the non-woven fabrics are mutually wound in the unwinding and winding processes is avoided; and a winding method is simple, easy to implement, low in cost and generally applicable to a large number of manufacturers.

Owner:苏州长晟无纺科技有限公司

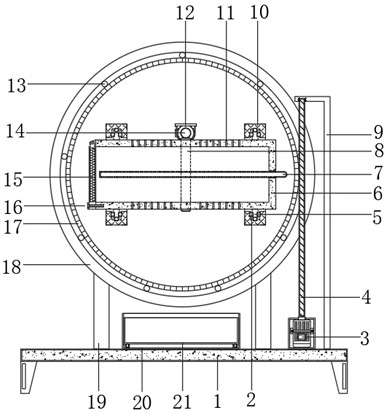

A drum type drying device for processing dendrobium candidum

ActiveCN110906711BGuaranteed uniformityStable supportDrying gas arrangementsDrying chambers/containersStructural engineeringMechanical engineering

The invention belongs to the technical field of dendrobium processing, in particular to a drum-type drying device for dendrobium officinale processing. Aiming at the problems that the drying uniformity of a traditional dendrobium drying device is poor and the subsequent drying quality is influenced, the drum-type drying device for the dendrobium officinale processing comprises a rotary drum; a drying tank and bases with support legs welded at four corners at the bottom; two sides of the outer wall of one side of the rotary drum are vertically welded with fixed plates; one sides of the two fixed plates are respectively provided with mounting circular grooves used for mounting the drying tank; two ends of the rotary drum are respectively welded with fixed rings; and one sides, opposite to the mounting circular grooves, of the fixed rings are respectively provided with first annular grooves. According to the drum-type drying device for the dendrobium officinale processing, a second driving mechanism is arranged, the rotary drum can be driven to stably rotate through a second worm and a worm gear tooth ring, so that the drying tank is driven to overturn, due to the fact that a rise angle of the second worm and the worm gear tooth ring is smaller than a friction angle, the drying device has good self-locking property, stable overturning of the drying tank is realized, and the advantages of convenient loading and unloading are achieved.

Owner:花垣县大峡谷生态农业发展有限公司

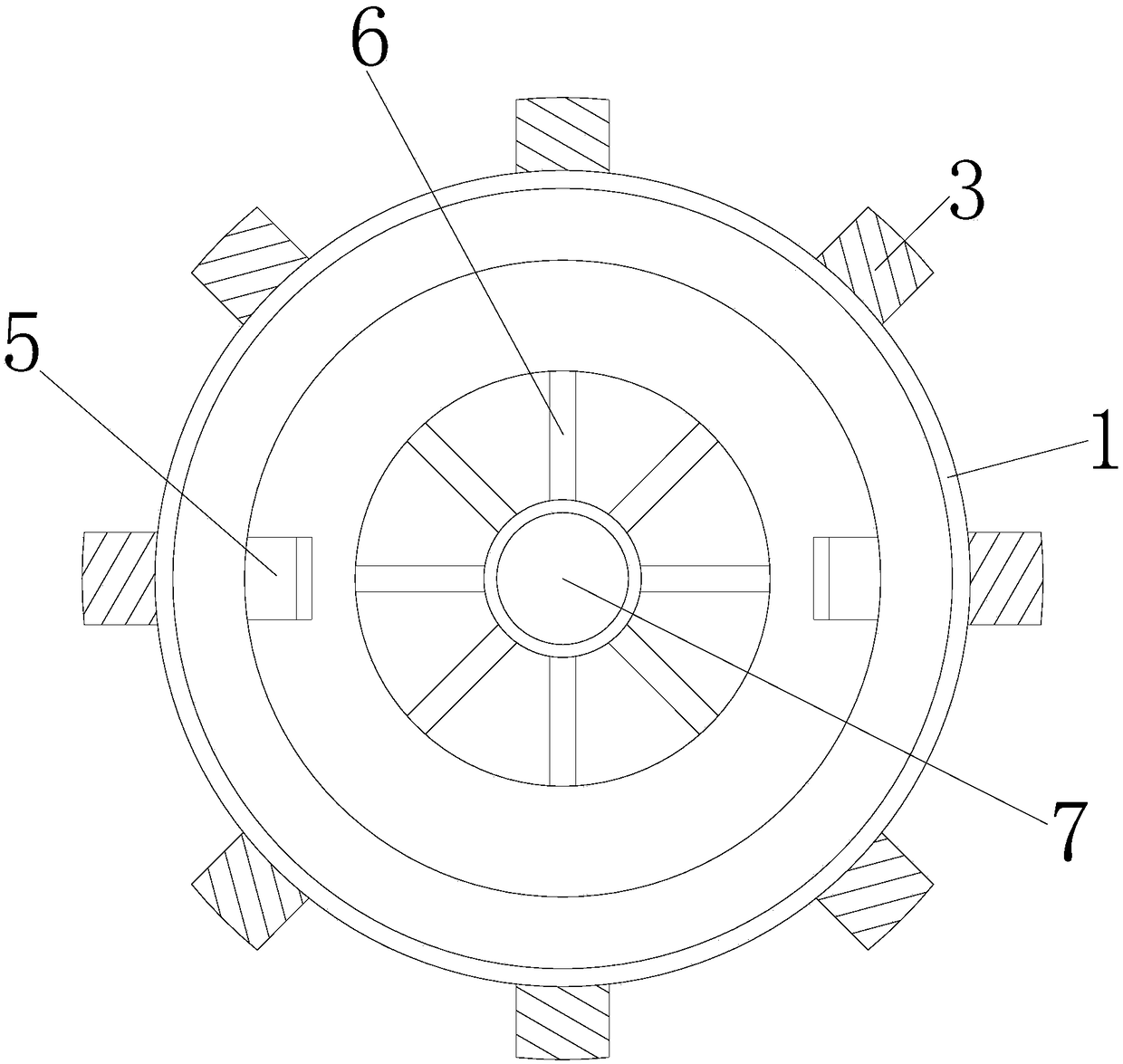

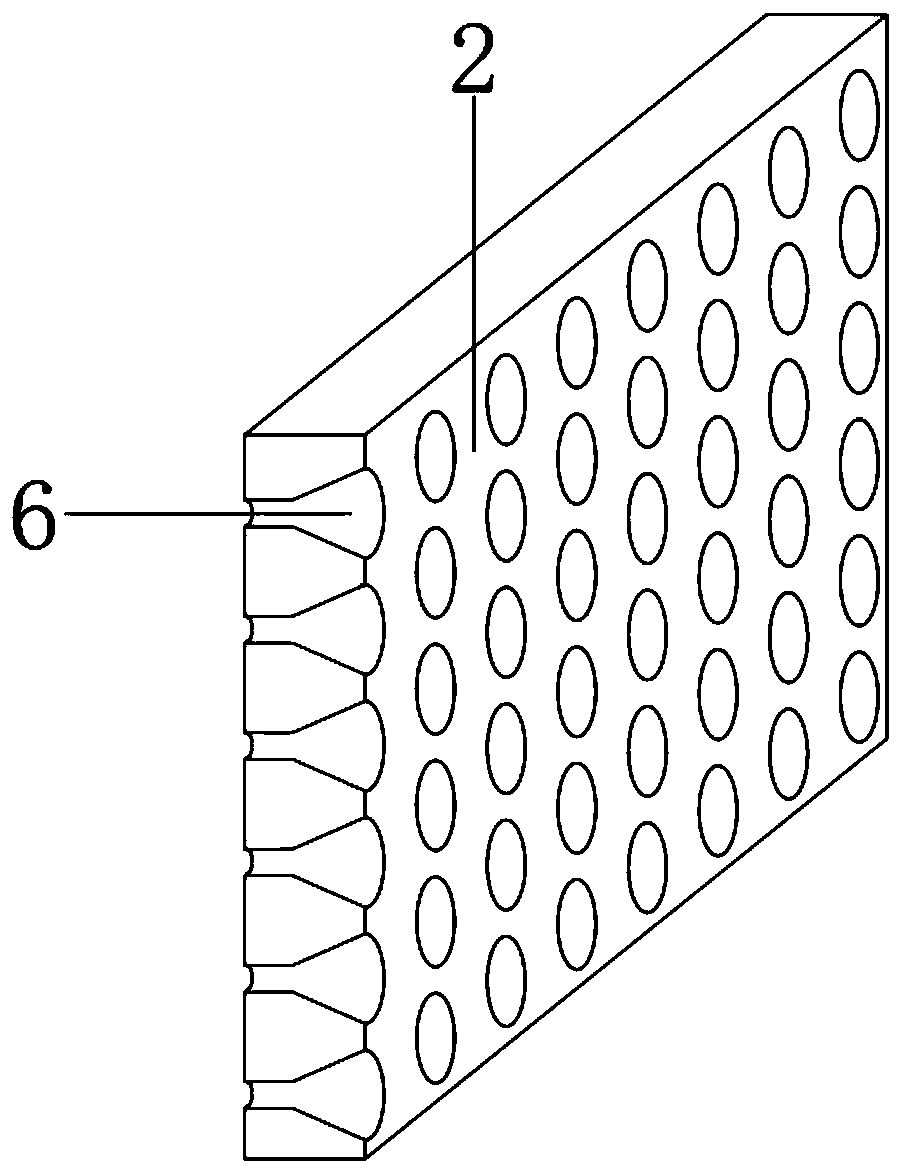

Copper strip machining process

ActiveCN111438224AGood limit effectSave operating timeFouling preventionBar pressingMachining process

The invention belongs to the technical field of copper strip machining, and particularly relates to a copper strip machining process. The process comprises a machine body; a turn table is arranged onthe surface of one side of the machine body; a central shaft is arranged at the center of the surface of one side of the turn table; four fan-shaped bracing plates are arranged on the surface of one side of the turn table; and two pressing rods are arranged in symmetry on one side of the turn table. When a copper strip disc is sleeved on the surfaces of the fan-shaped bracing plates, the two pressing rods are sleeved on the surfaces of two random symmetrical fan-shaped bracing plates, and the pressing rods are then pushed to one side of the copper strip disc and compact the copper strip disc via a squeezing plate, so the copper strip disc can be limited. When the copper strip disc that rolls up a cooper strip is required to be taken down afterwards, the copper strip disc can be successfully taken down by upwardly lifting a lifting rod from the inside of a rectangular gap and taking down the pressing rods. The whole process is simple and convenient, and good effect of limiting the copper strip disc can be realized. Compared with complicated operation of an original device, the process can save the operation time of an operator by a large percentage.

Owner:ZHAOQING CITY ZHONGNANTIAN IND CO LTD

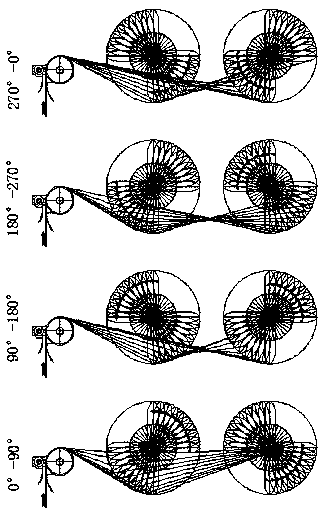

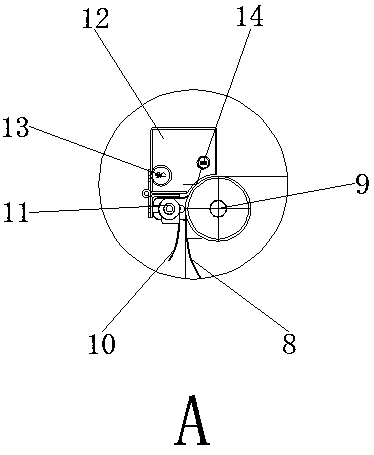

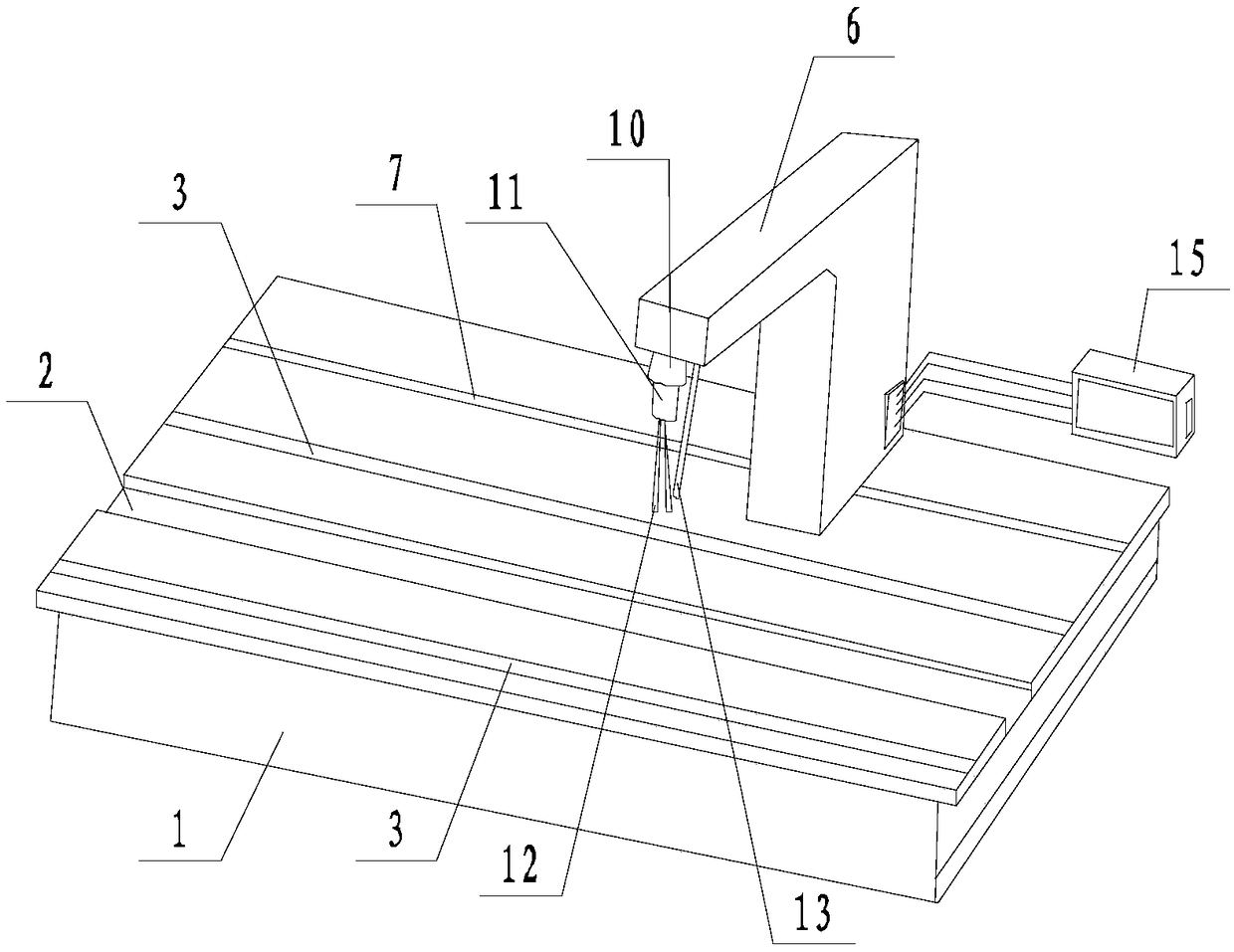

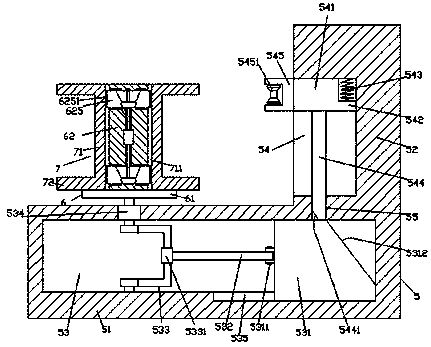

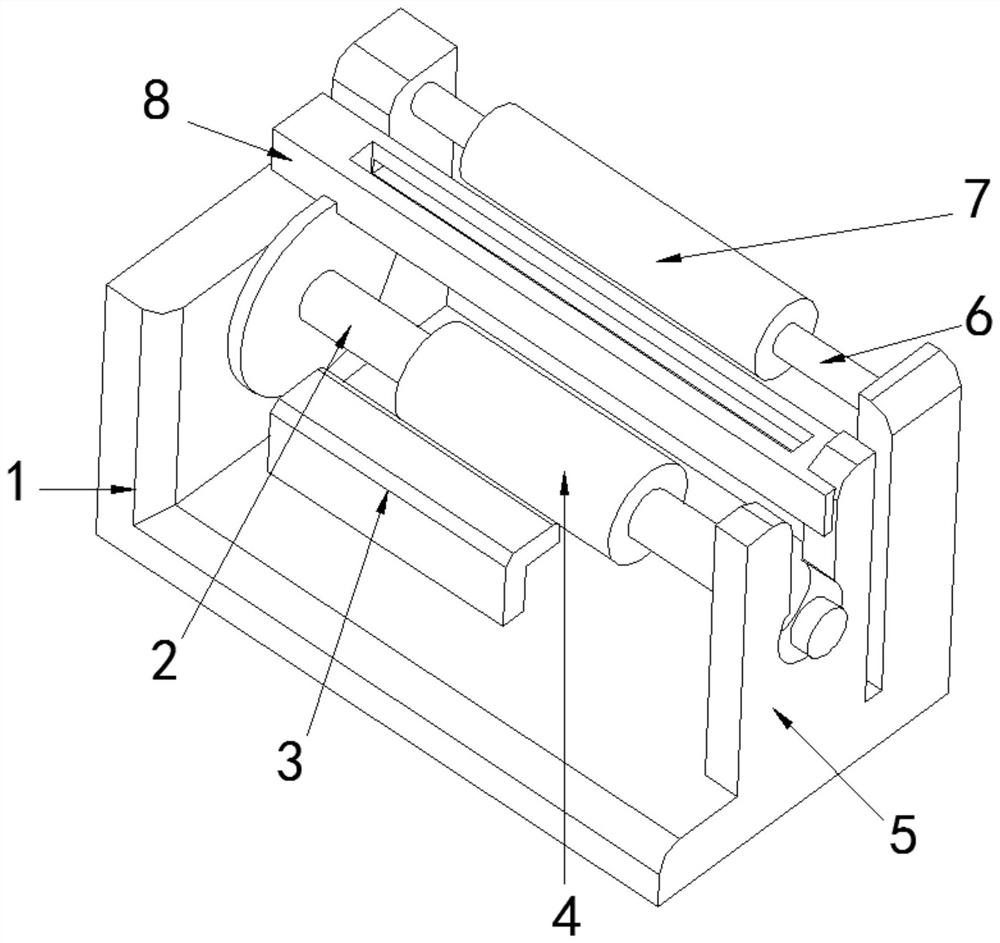

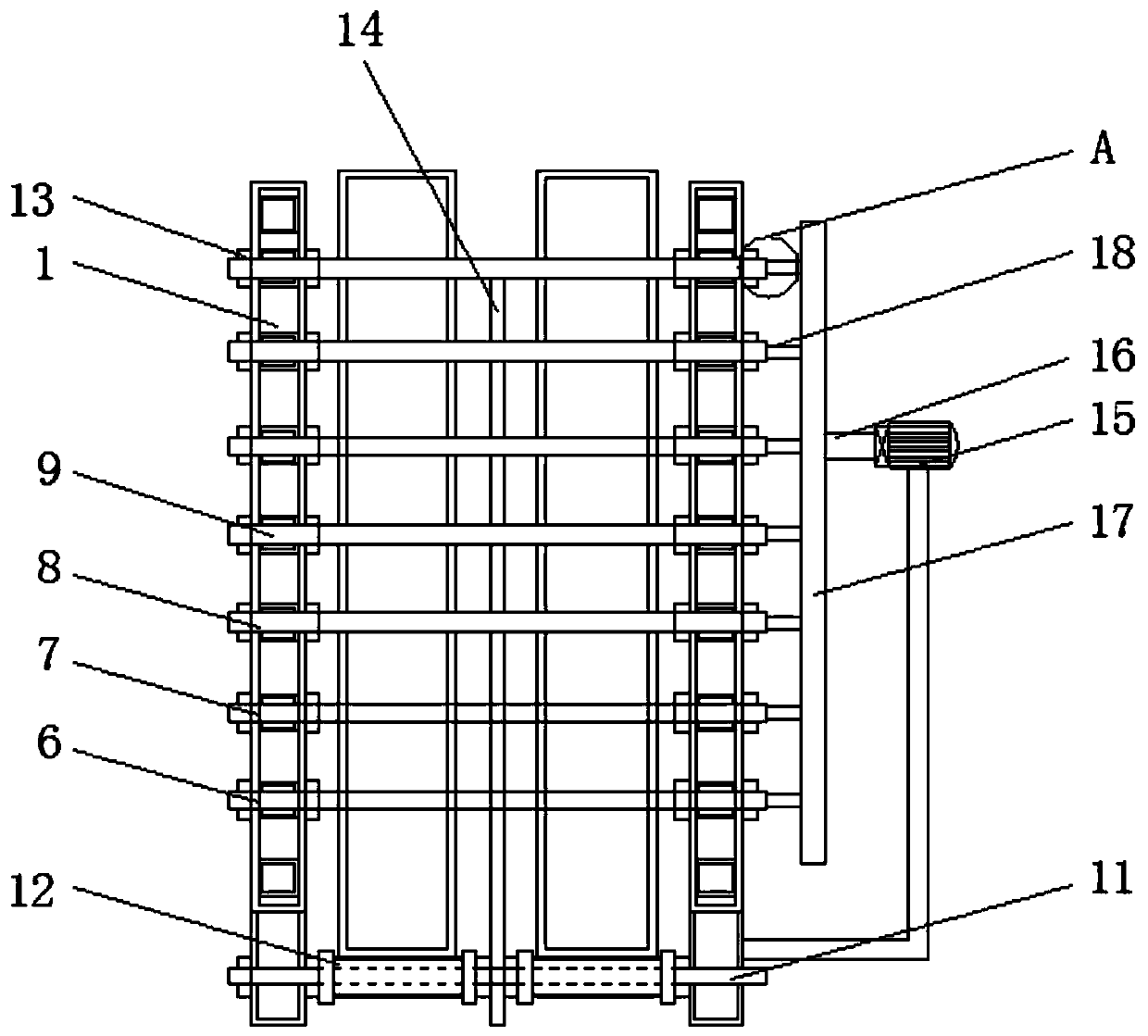

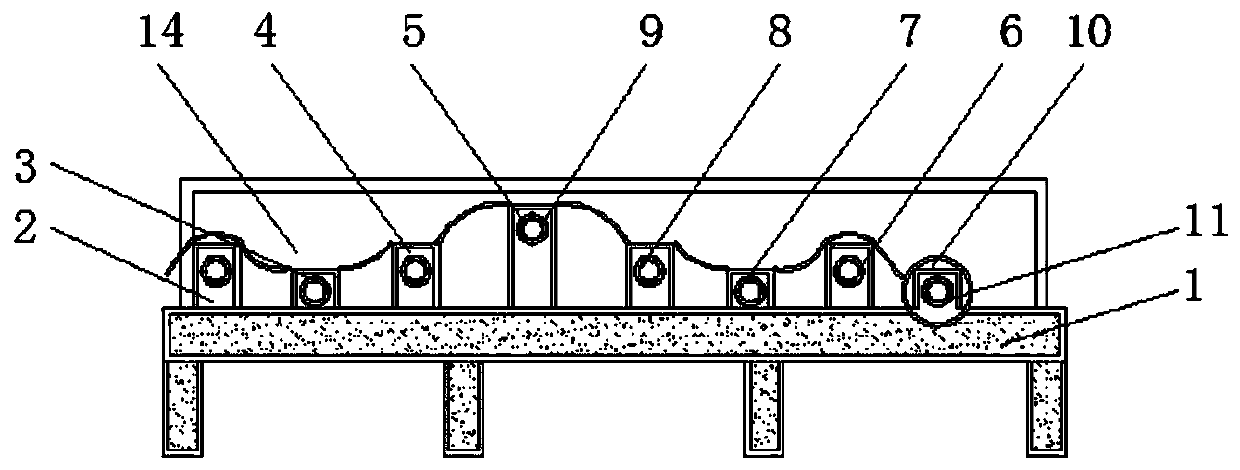

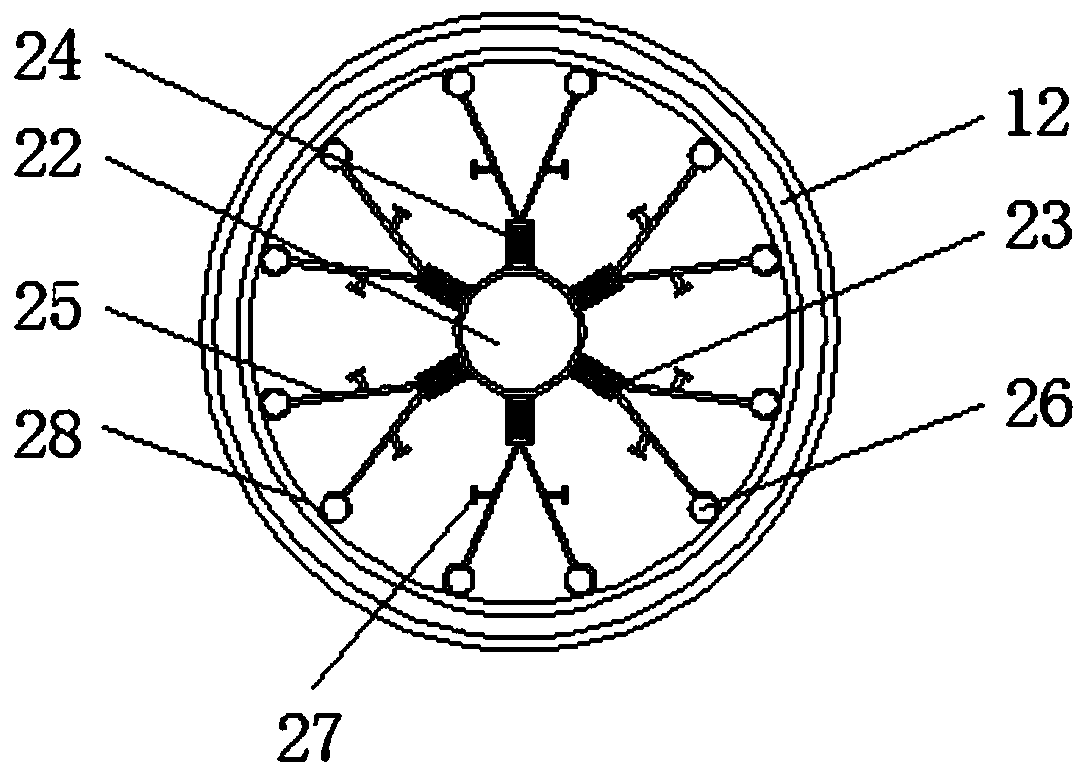

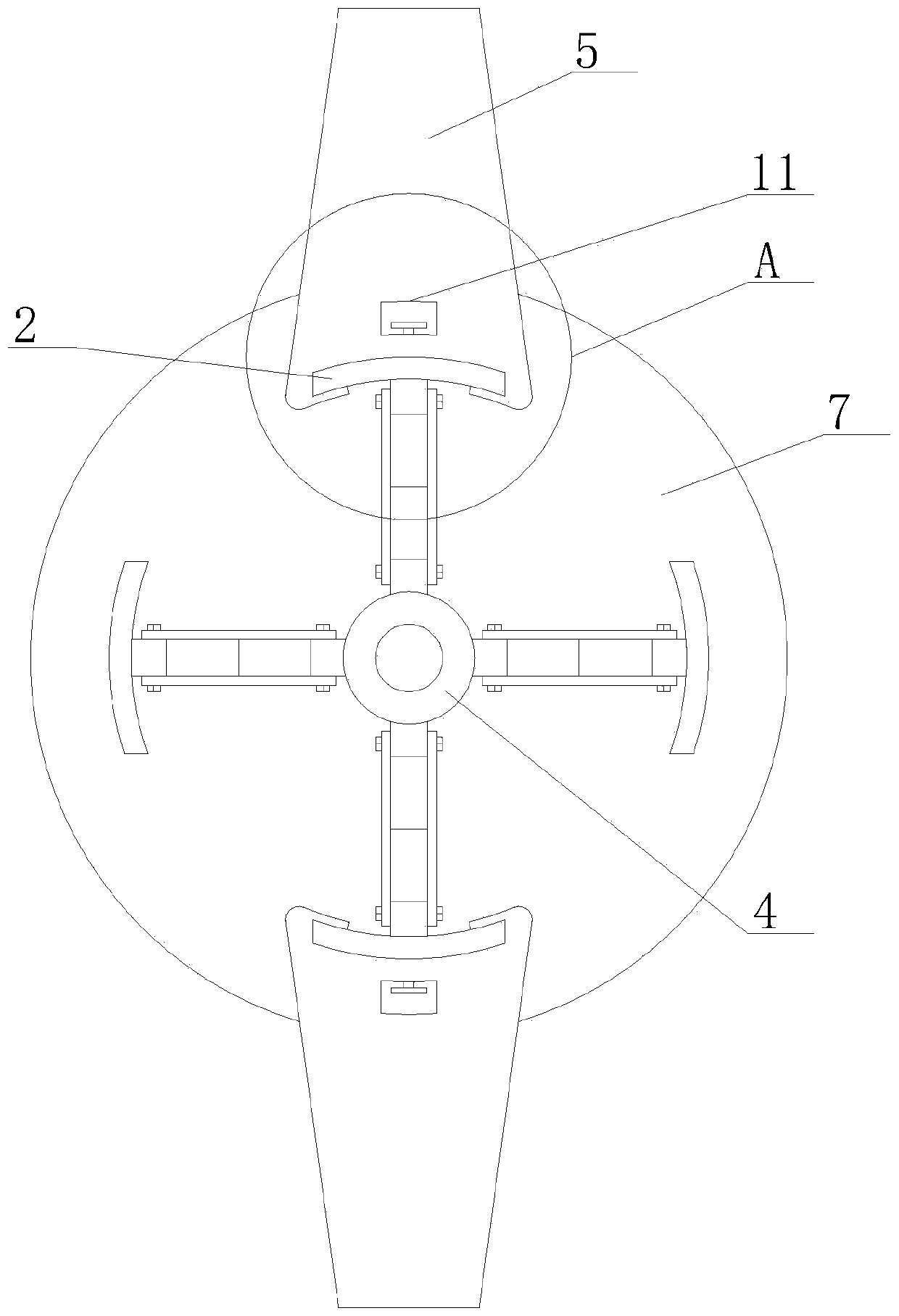

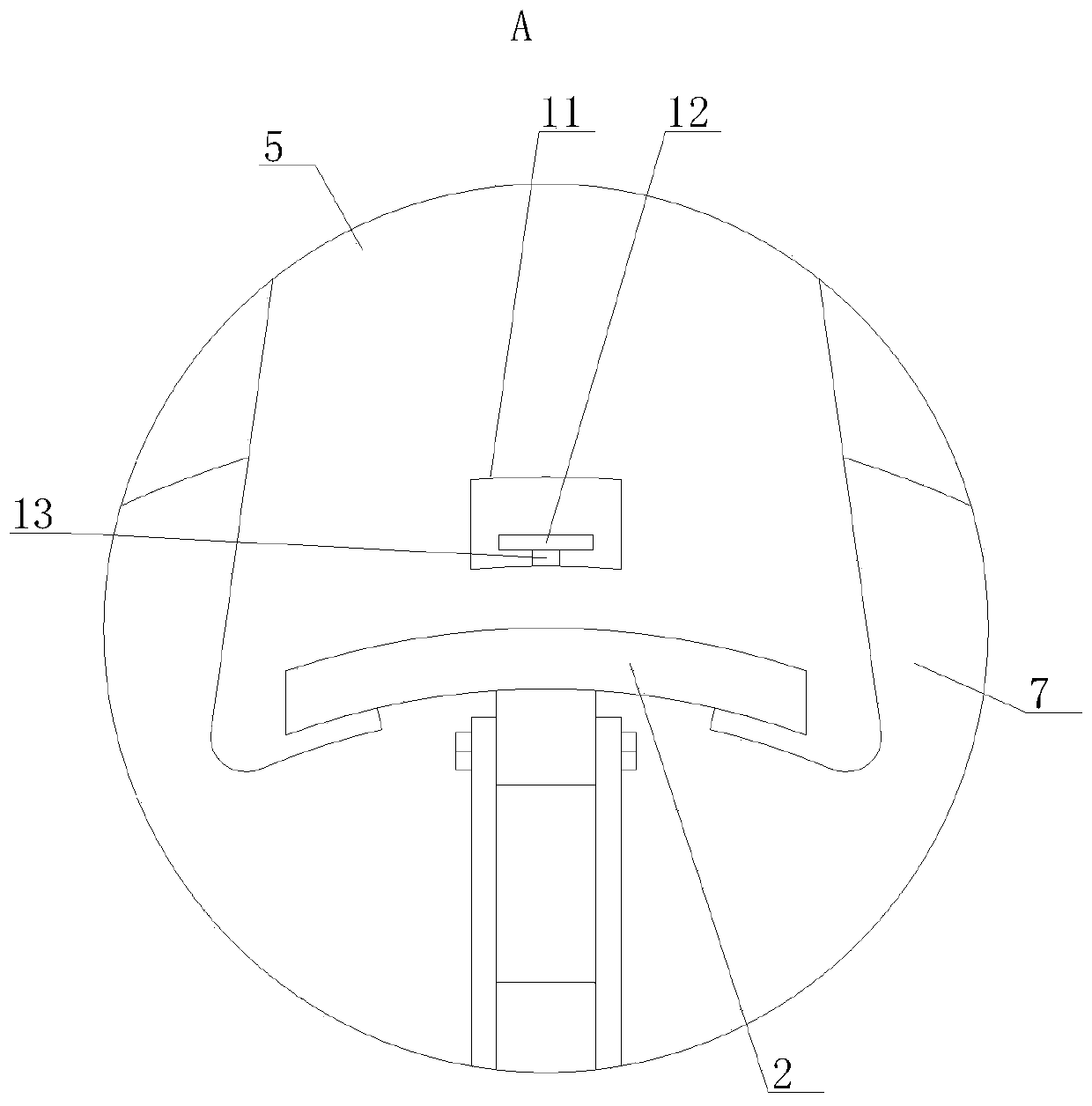

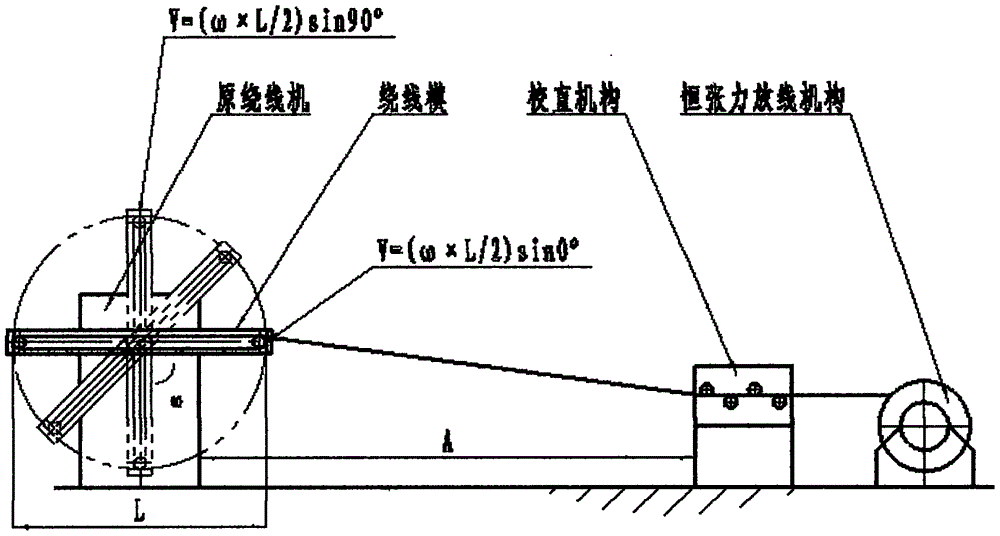

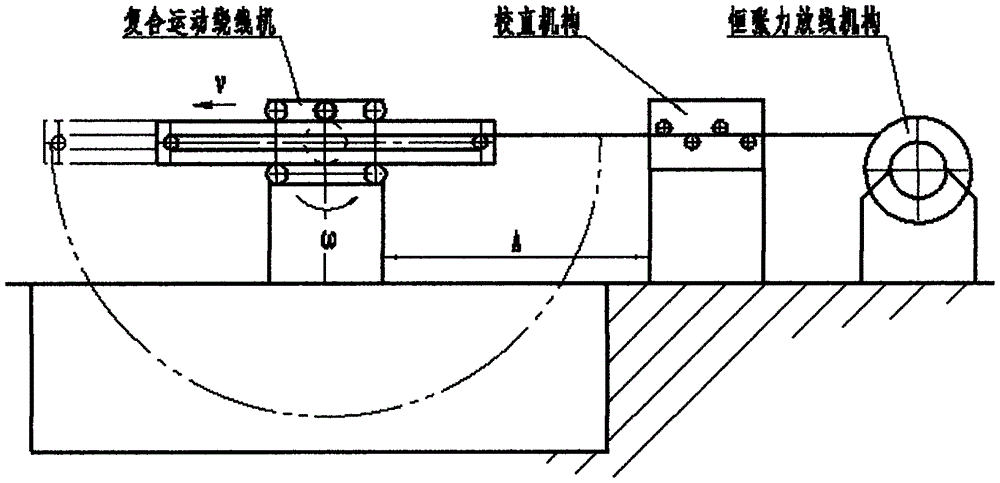

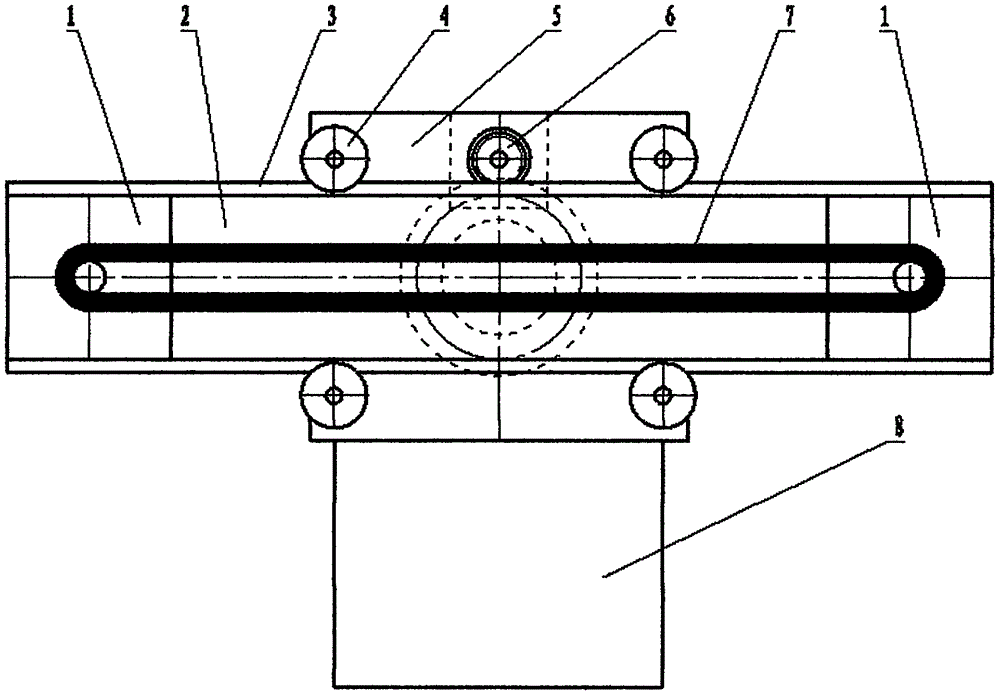

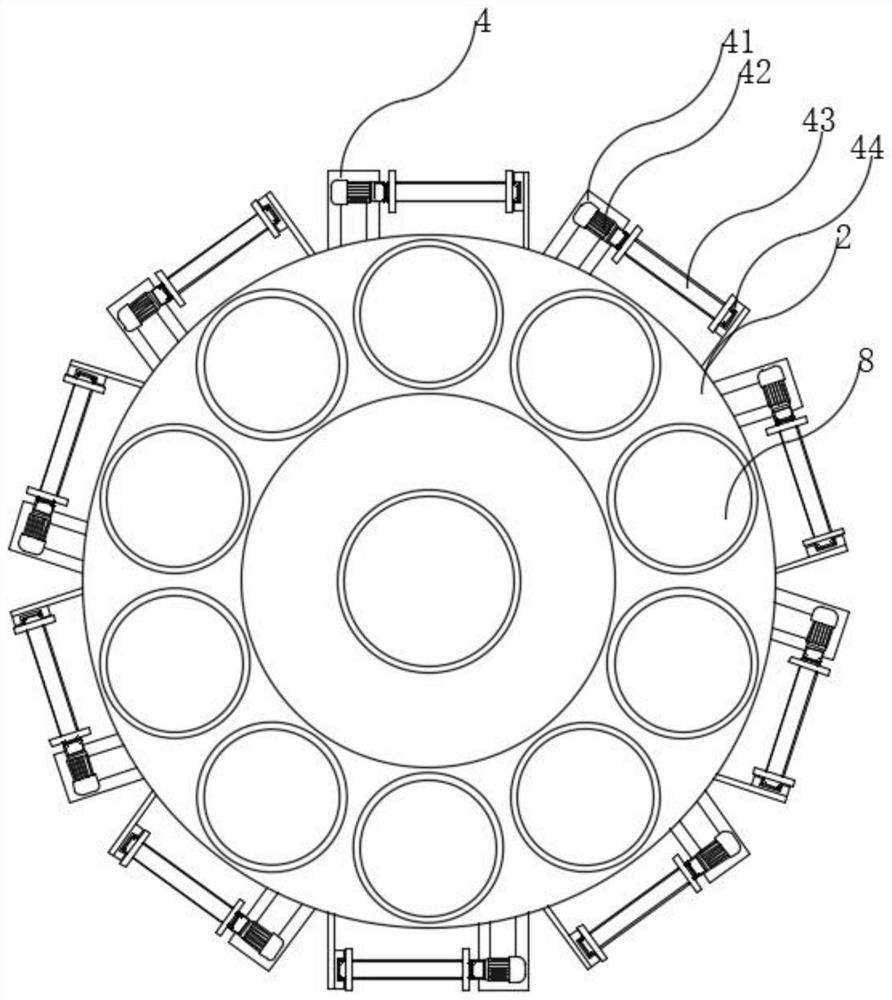

Compound movement winding machine for large-and-middle-scale motor coil

ActiveCN106787517AIncrease winding speedSmall footprintManufacturing dynamo-electric machinesCoils manufactureWinding machineEngineering

The invention discloses a compound movement winding machine for a large-and-middle-scale motor coil, belongs to the technical field of the large-and-middle-scale motor coil winding machine, and mainly overcomes the shortcoming of drastic fluctuation of winding speed of the original large-and-middle-scale motor coil winding machine. A pure rotation winding way of the original large-and-middle-scale motor coil winding machine is replaced by a compound movement winding way which comprises movement and rotation; the biggest characteristic of the compound movement winding machine is that the problem of the drastic fluctuation of winding speed of the original winding machine is fundamentally solved; in addition, the winding machine is also simple in structure, practical, and reliable; and the compound movement winding machine is mainly used for a winding procedure of the large-and-middle-scale motor coil.

Owner:广东工商职业技术大学

Automatic winding machine for transformer production

InactiveCN114512330AConvenient winding workConducive to later preservationCoils manufactureWinding machineTransformer

The automatic winding machine comprises a main rod frame, a lower cylinder and an upper cylinder are fixedly installed at the upper end and the lower end of the outer ring of the main rod frame respectively, a winding mechanism is arranged on the outer wall of the lower cylinder, a frame body is fixedly connected with the outer wall of the lower cylinder, a buffer strip is fixedly connected to the tail end of a sliding block, and the buffer strip is fixedly connected to the tail end of the sliding block. The tail end of the buffer strip is fixedly connected with a telescopic spring, the tail end of the telescopic spring is fixedly connected with a clamping strip, a wiping mechanism is installed on the upper portion of the interior of the wire inlet pipe, and a balance cylinder is fixedly connected between the lower cylinder and the upper cylinder. According to the automatic winding machine for transformer production, the multiple sets of winding mechanisms can wind wires of multiple sets of transformers, the winding speed is increased, the automatic winding machine is suitable for batch production of cables of the transformers, meanwhile, the sliding grooves, the sliding blocks and the clamping strips are arranged, stable rotation of the winding rollers can be kept, meanwhile, stable supporting force can be provided for rotation of the winding rollers, and the winding efficiency is improved. And the winding work of the cable of the transformer is facilitated.

Owner:连云港顺时针电气有限公司

A cable winding device

ActiveCN110894024BImprove convenienceImprove applicabilityFilament handlingElectric machineryFlywheel

The invention discloses a cable winding device, comprising a pair of main brackets, a pair of auxiliary brackets, a sliding block, a winding wheel and a base. Two ends of the top of the base are symmetrically fixed with a pair of main brackets, and a pair of auxiliary brackets. The bracket is symmetrically fixed on the inner side of a pair of main brackets, a sliding rod is laterally fixed at the upper end between a pair of the auxiliary brackets, a sliding block 1 is slid on one end of the sliding rod, and a pair of auxiliary brackets below the sliding rod are respectively fixed with The second one-way bearing and the third one-way bearing are provided with a screw rod passing through between the second one-way bearing, the first sliding block and the third one-way bearing. The cable winding device provided by the invention can effectively realize the purpose of driving the whole device by one motor through the cooperation of four one-way bearings and the trapezoidal flywheel group, simplify the device structure, and reduce the production and maintenance costs of the device. , Improve the winding speed, make the length of the cable winding meet the actual winding length of the winding wheel, avoid the phenomenon of hollowing and unevenness of the coil, and improve the overall appearance of the coil.

Owner:JINAN SHENGTONG POWER CABLE

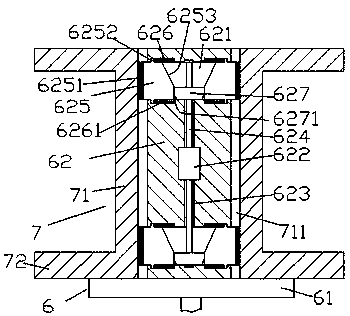

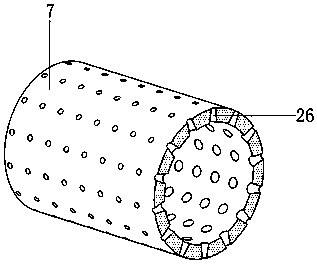

Full-drawn spinning system and technology based on porous ultrafine denier yarn

ActiveCN113279073BAvoid offsetEasy to unloadNew-spun product collectionArtificial thread manufacturing machinesYarnSpinning

The invention discloses a full-stretched silk spinning system based on porous ultrafine denier yarn and its technology, which includes an outer support, the bottom of the outer support is fixedly connected with a base, and the top of the outer support is fixedly connected with a support plate. The rear side of the support plate is fixedly connected with a transmission box, the left side of the top of the support plate is provided with a finishing box, the inside of the finishing box is provided with a finishing mechanism, and a winding mechanism is provided between the opposite sides of the support plate. It relates to the technical field of spinning processing. Based on the porous ultra-fine yarn full-drawn spinning system and its technology, a winding mechanism is provided, and the drive motor in the transmission unit is used to drive the rotation of the drive shaft, and the winding roller is driven to rotate and wind. Cooperate with the first The block slides out completely from the slot, not only can the winding work be carried out accurately, but also can prevent the deviation of the ultra-fine denier yarn during winding, and at the same time, it can be more convenient to unload the material, thus speeding up the winding process work efficiency.

Owner:杭州辰泽新材料有限公司

Network transformer pin automatic winding lead wire equipment and winding method thereof

InactiveCN108987101BSolve the problem of low winding efficiencyReduce labor intensityInductances/transformers/magnets manufactureTransformerProcess engineering

The invention discloses a network transformer pin automatic winding lead wire device and a winding method thereof, high automation level, greatly reducing the labor intensity of workers, and solves the problem of low winding efficiency of network transformer pins in the prior art, At the same time, the problem of unstable winding quality and high scrap rate is solved, and the purpose of increasingwinding speed, improving winding quality stability and reducing product scrap rate is realized, compared with the traditional process that manual operation depends on worker's skill and proficiency.

Owner:张洪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com