Dyeing machine for chemical fiber textiles

A chemical fiber and printing and dyeing machine technology, which is applied in textiles and papermaking, textile material processing, and textile material carrier processing. It can solve the problems of difficult cloth dyeing, increase the cost of printing and dyeing machine manufacturing and use, and the size and weight of the dyeing box. , to achieve the effect of increasing the winding speed, improving the drying effect and reducing the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

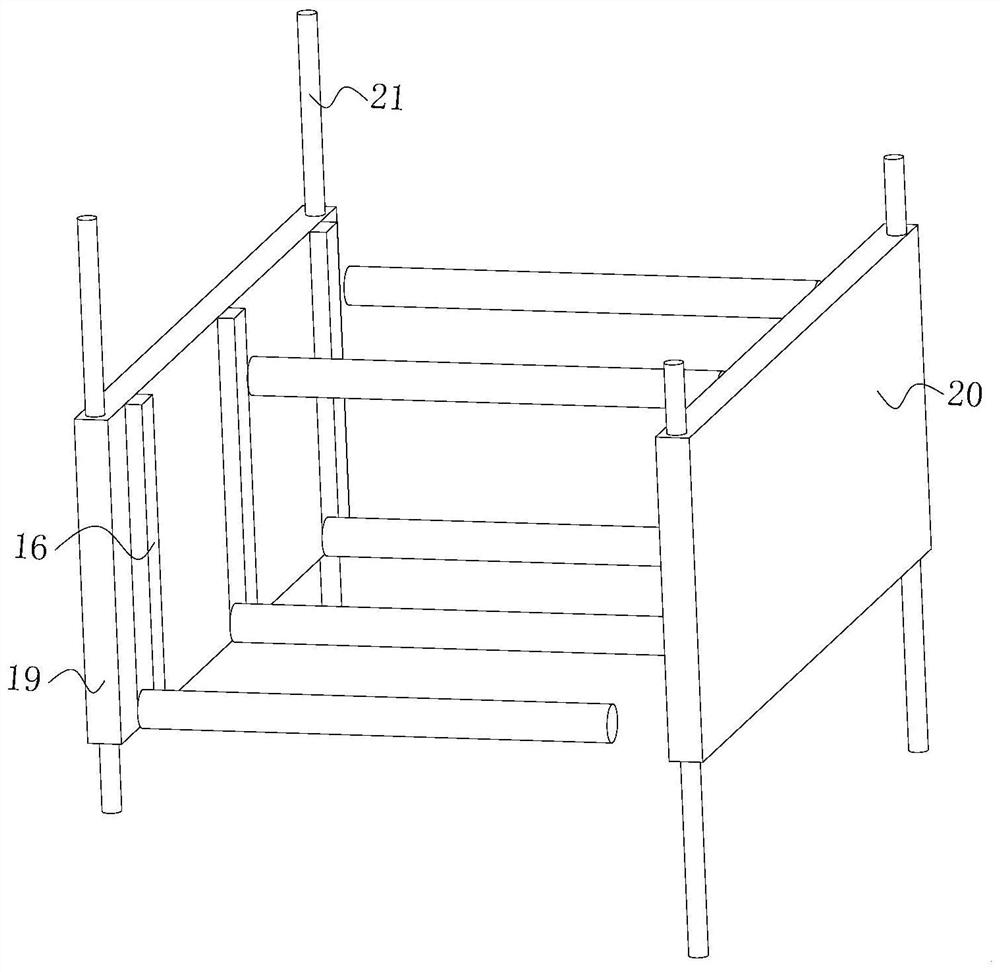

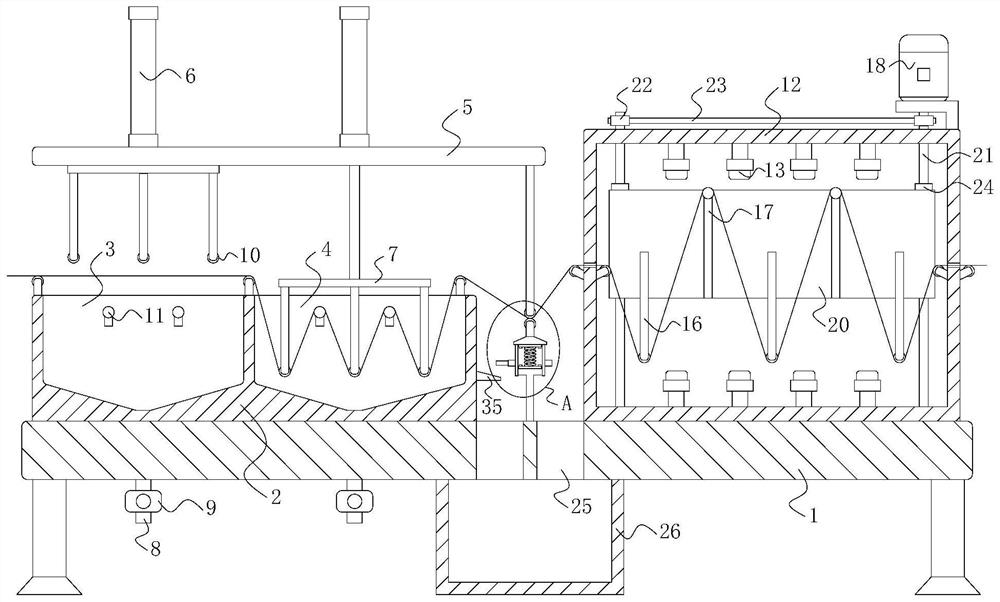

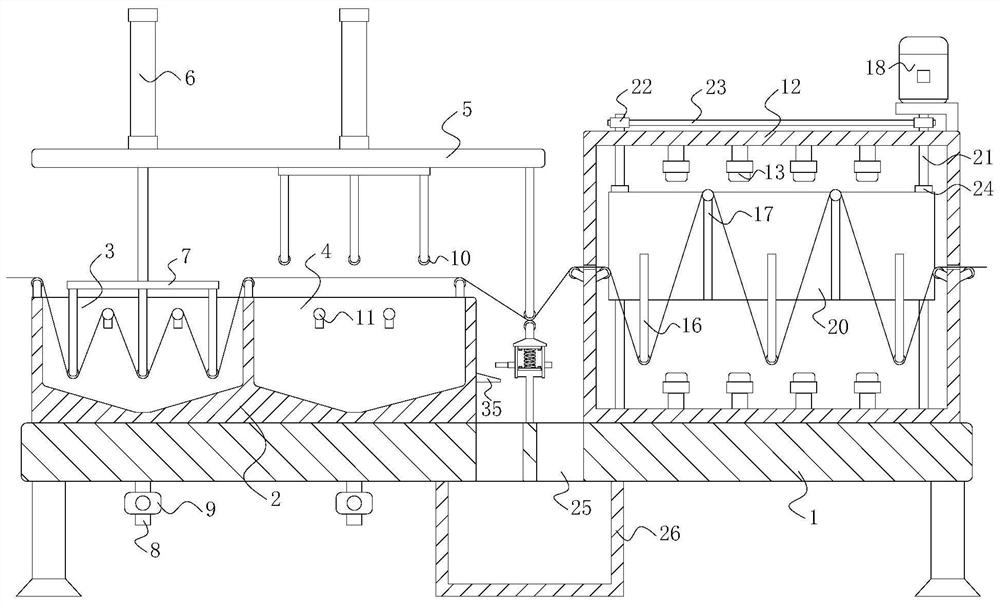

[0045] As an embodiment of the present invention, refer to figure 2 and Figure 8 , the squeeze assembly includes a top roller 27 fixedly mounted on the bottom of the top plate 5, and the top roller 27 is located between the dyeing box 2 and the oven 12, a mounting frame 28 is installed on the top wall of the frame 1, and the top of the mounting frame 28 is provided with Mounting seat 29, the top of mounting seat 29 is rotatably installed with the bottom roller 30 that cooperates with top roller 27, is connected with spring 31 between mounting frame 28 and mounting seat 29, is threaded with spring 31 on the bottom wall of mounting seat 29 The annular cover 32 that cooperates with each other, and the bottom end of the annular cover 32 is sleeved on the outside of the mounting frame 28 can prevent the spring 31 from directly contacting the dyeing solution and getting rusty. The elastically deformable spring 31 can be easily replaced, and the annular cover 32 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com