Patents

Literature

140results about How to "Guaranteed normal winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

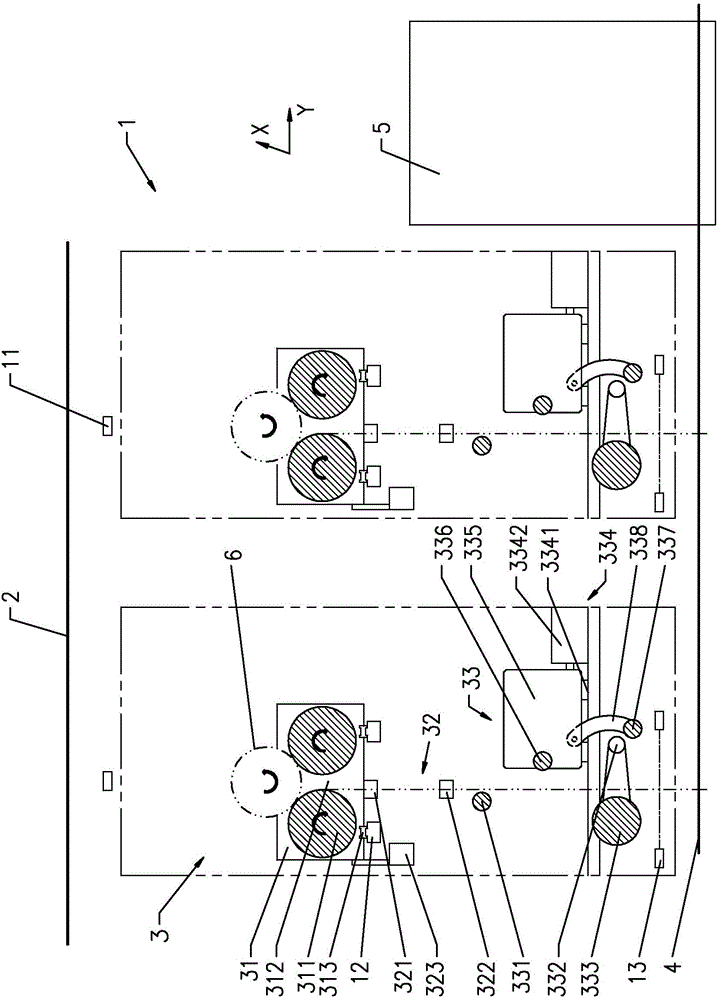

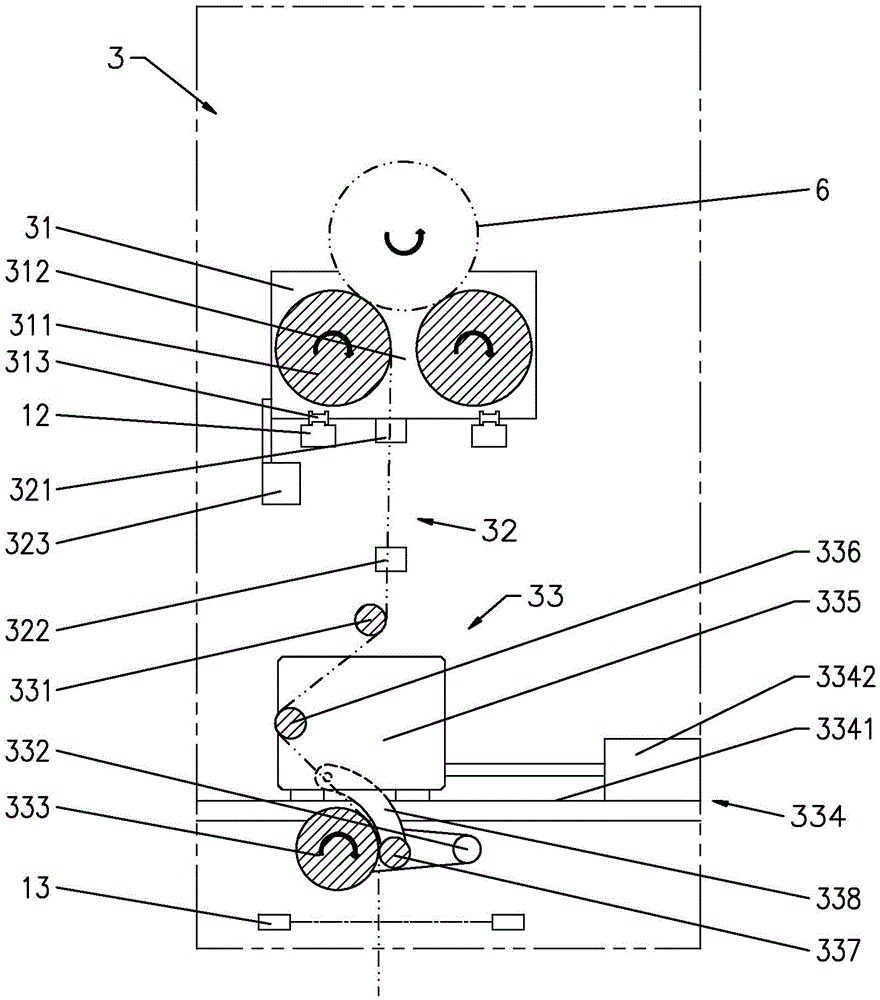

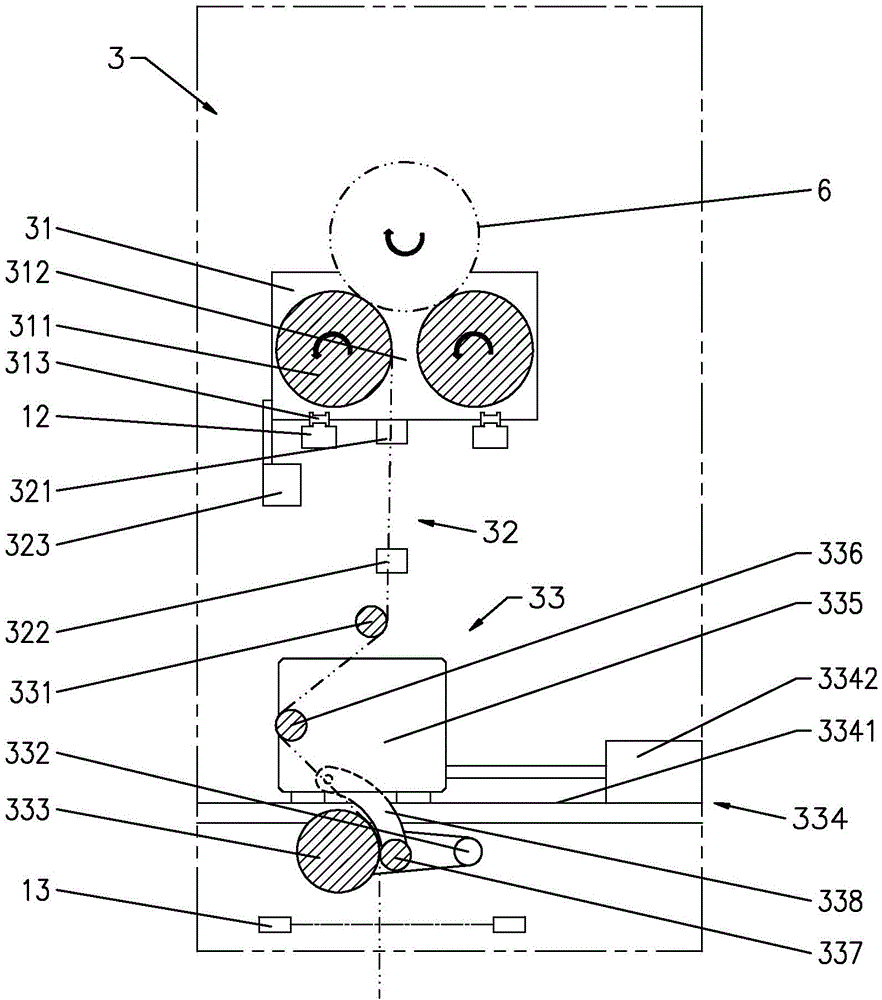

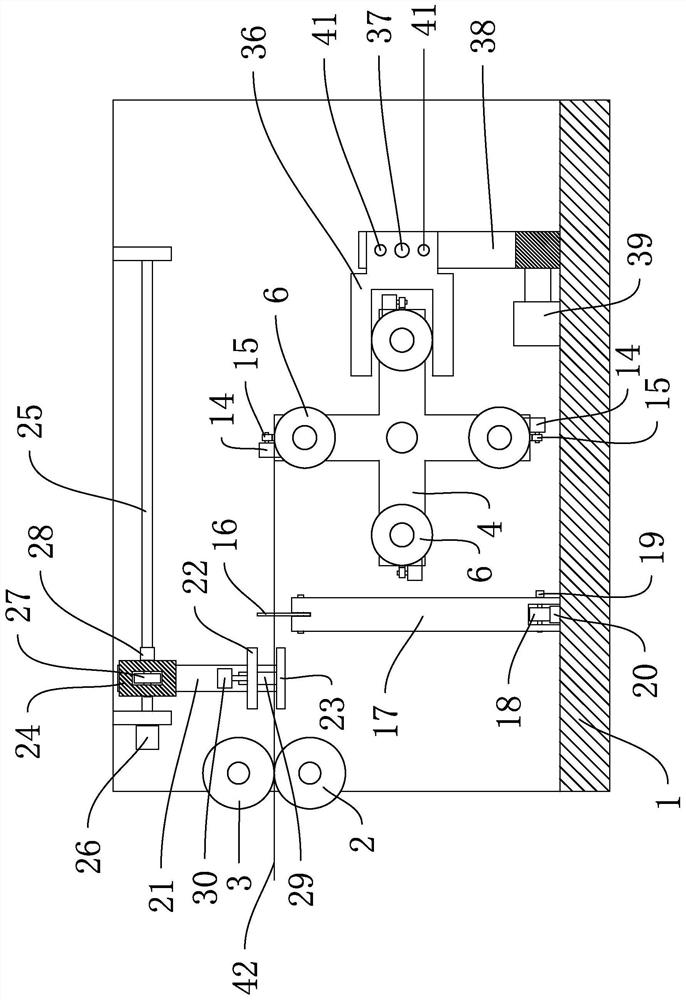

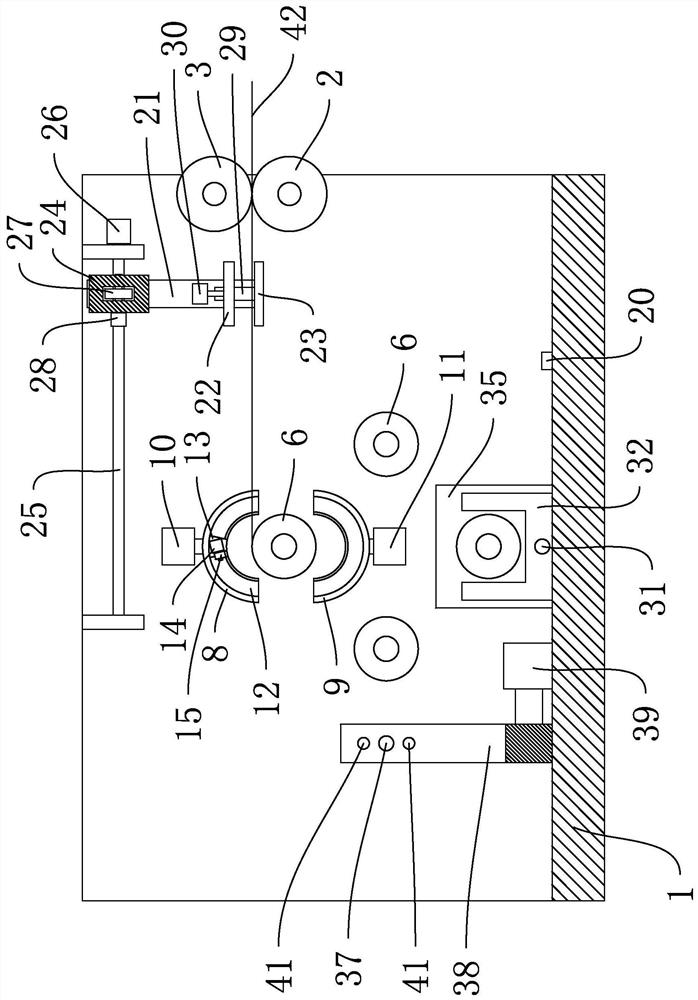

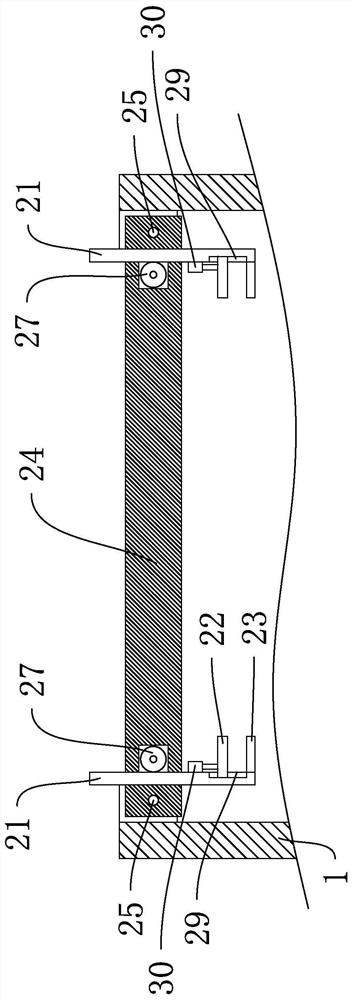

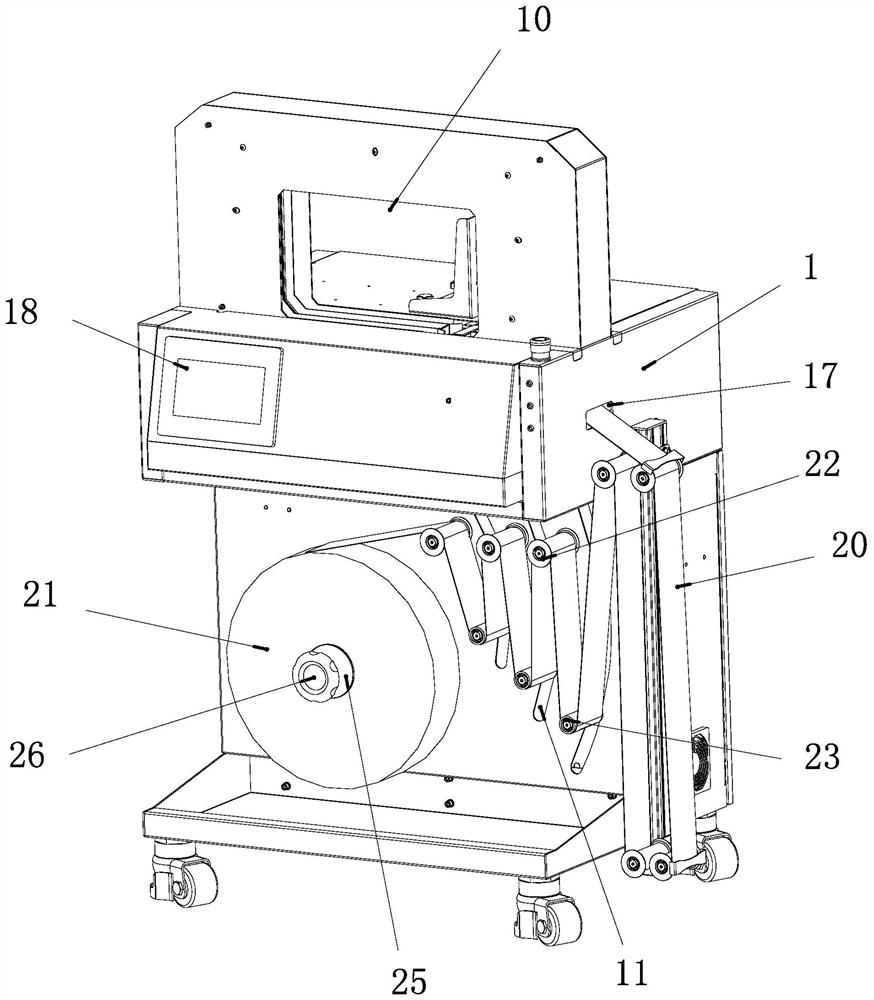

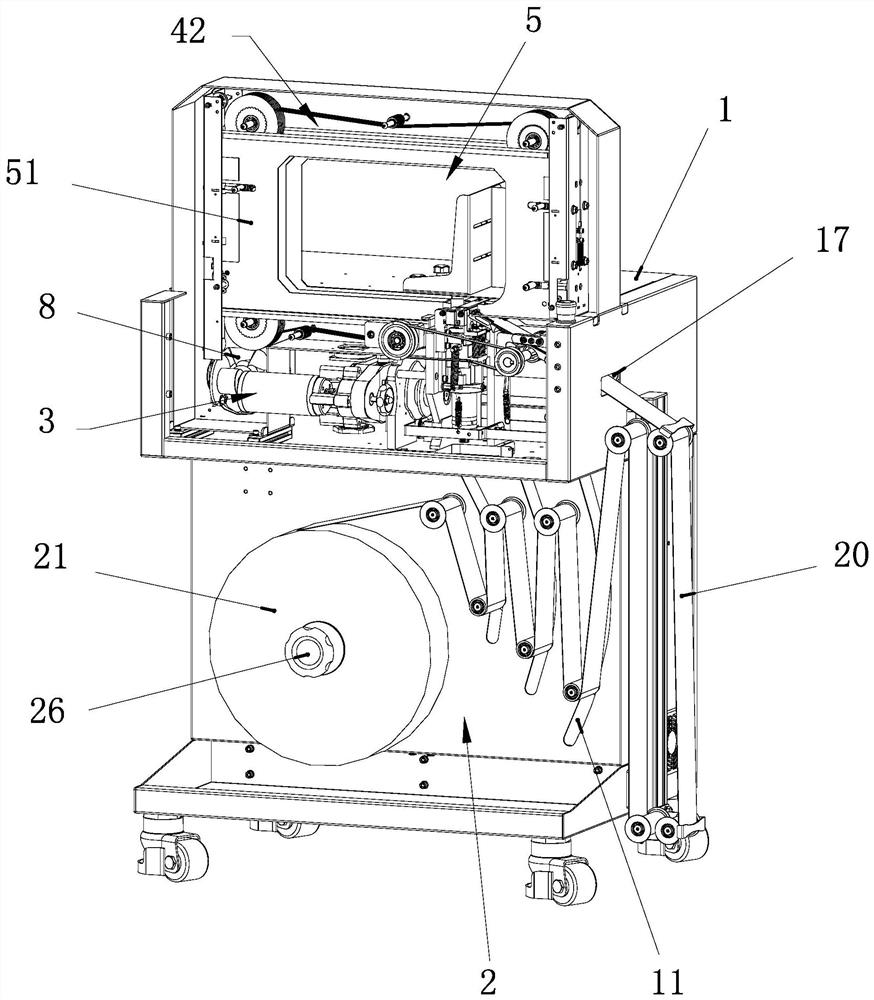

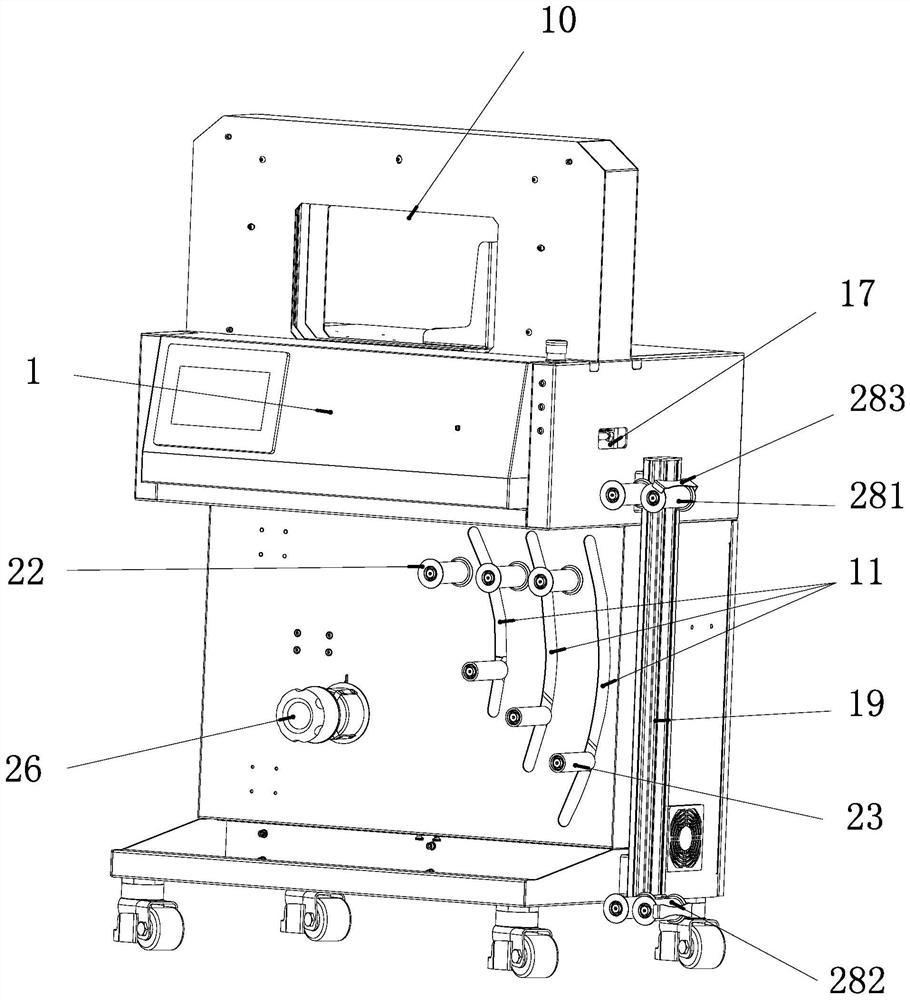

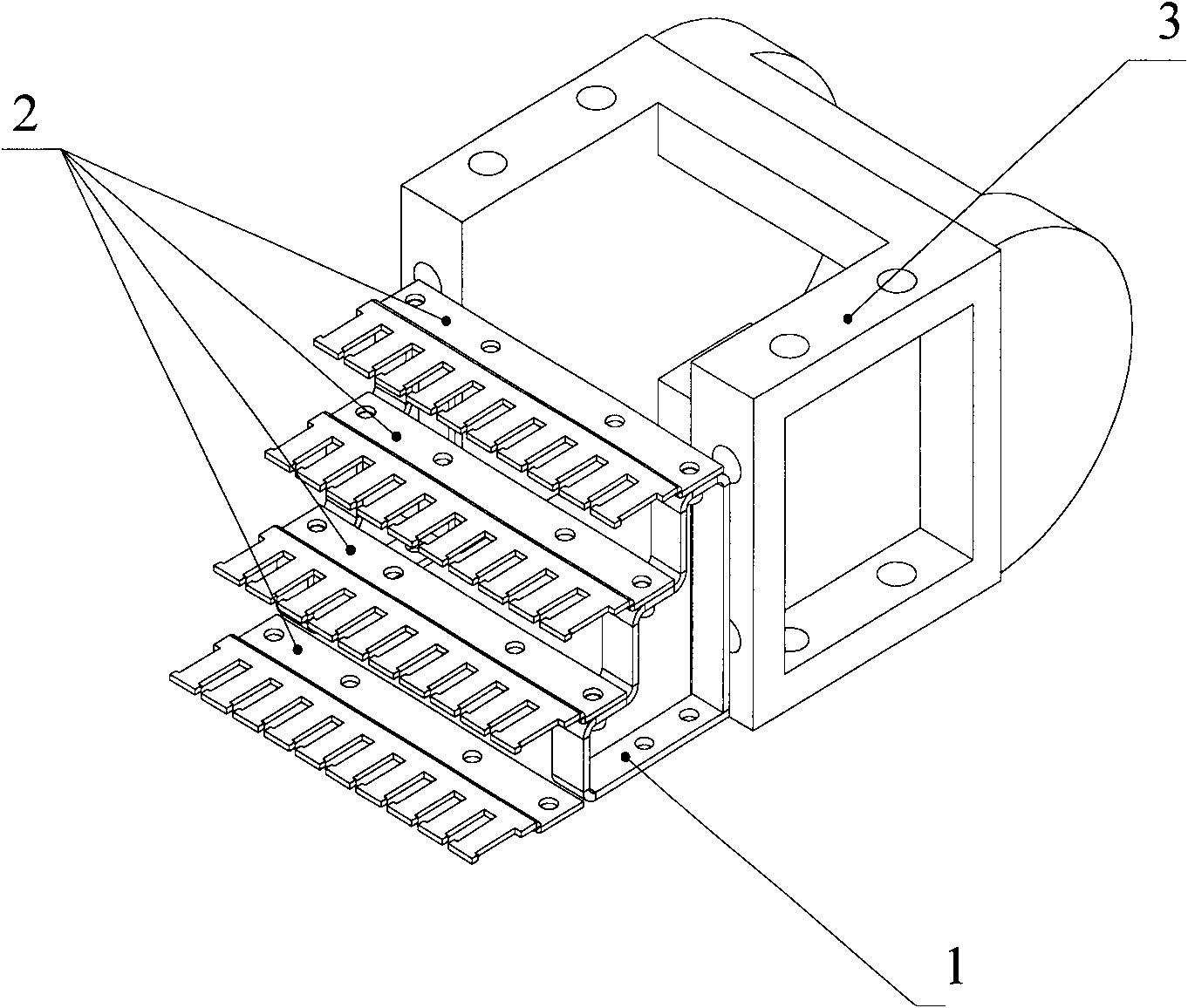

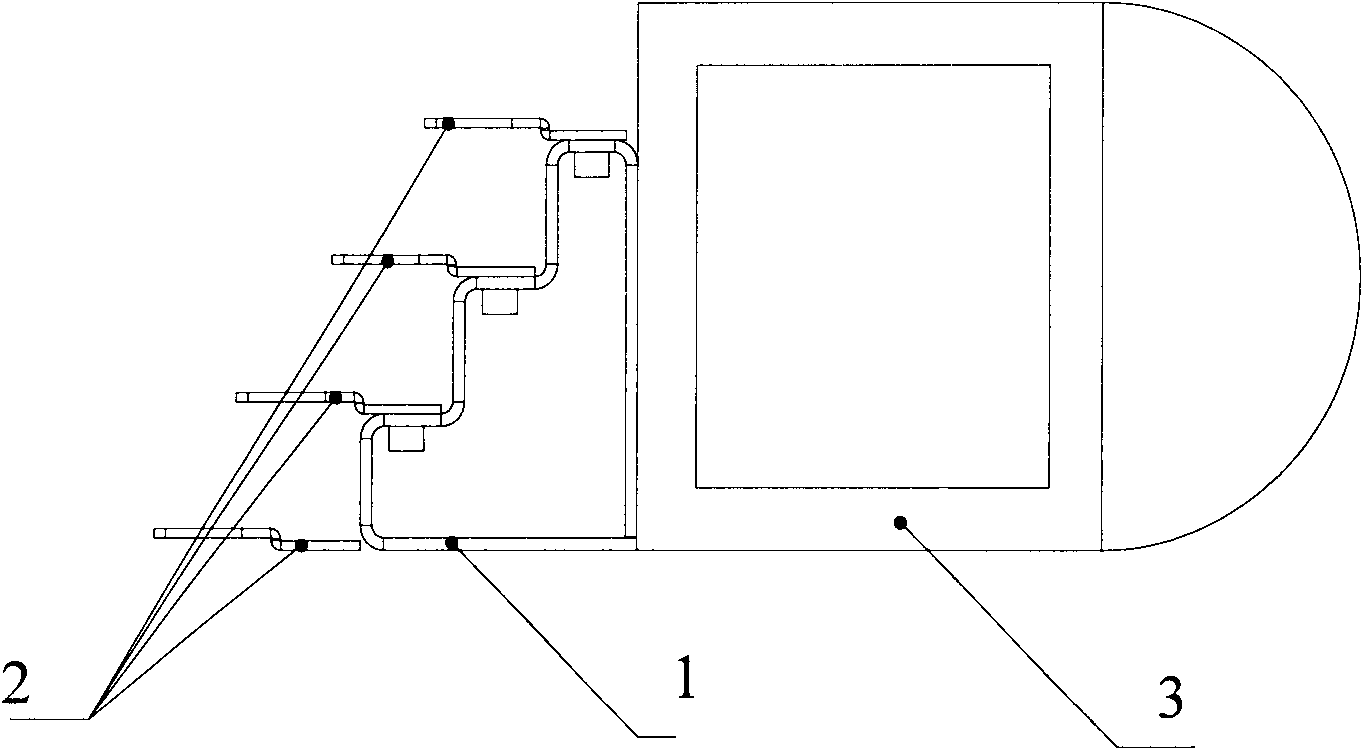

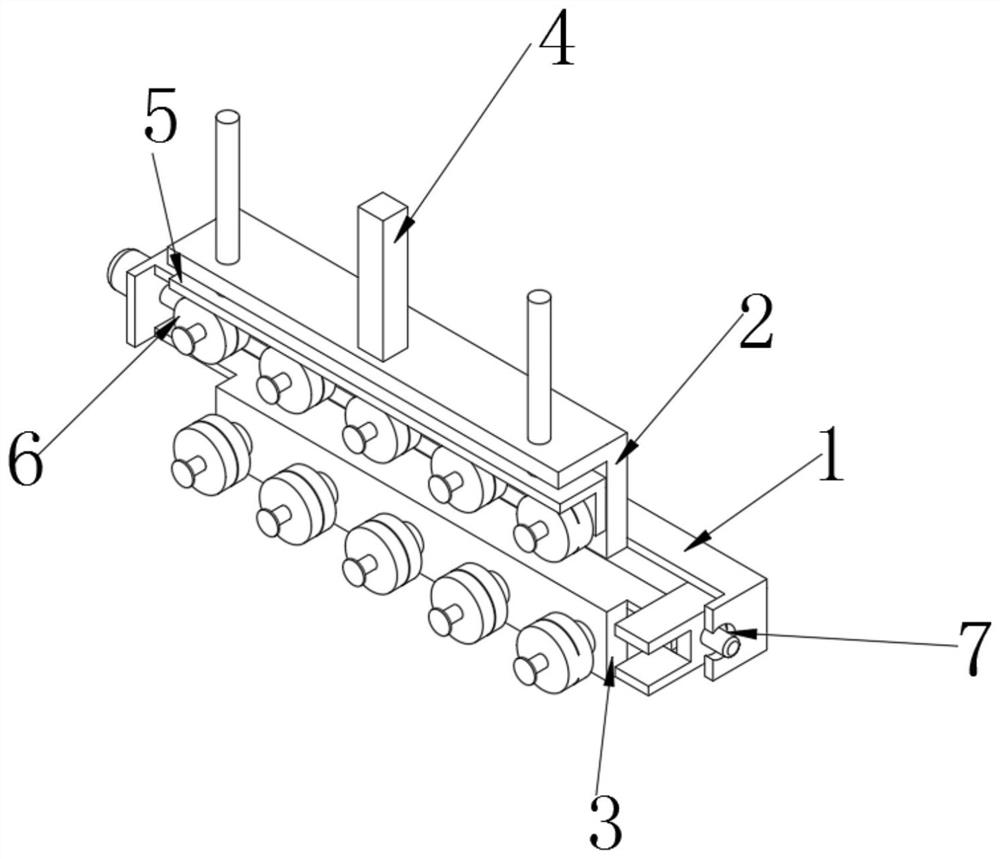

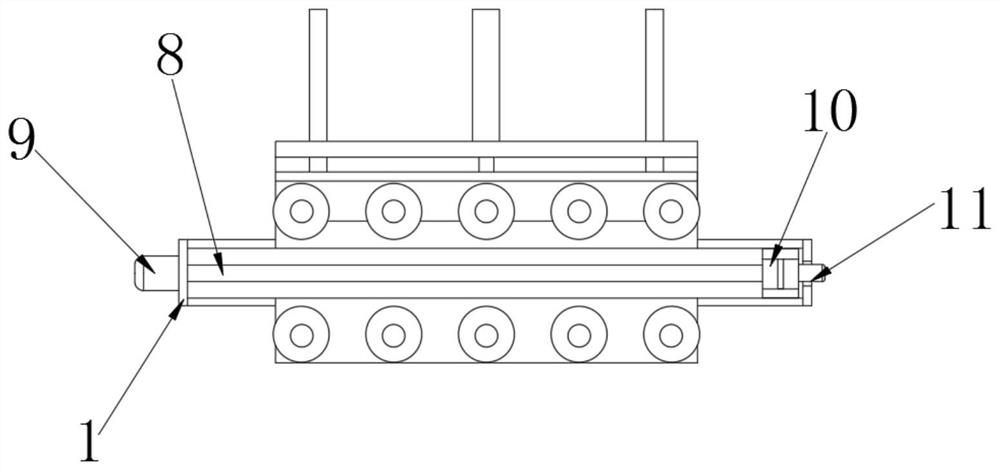

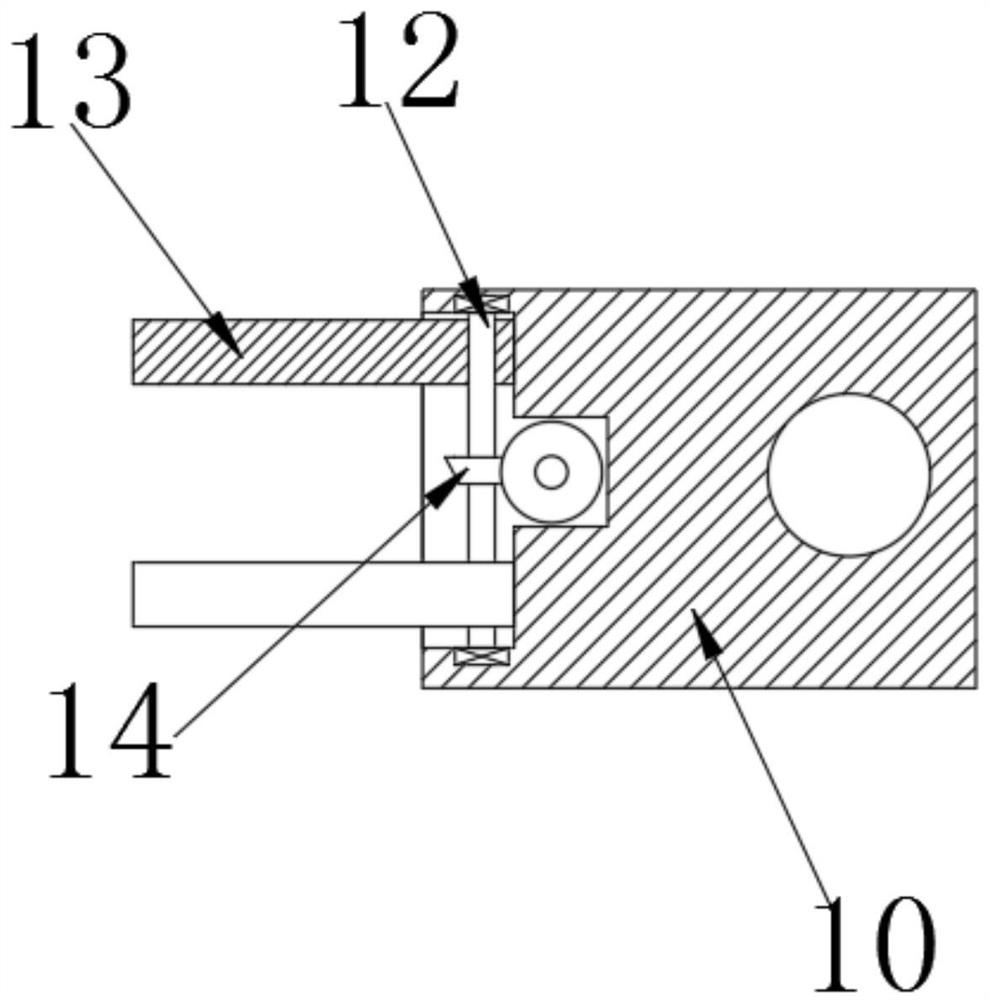

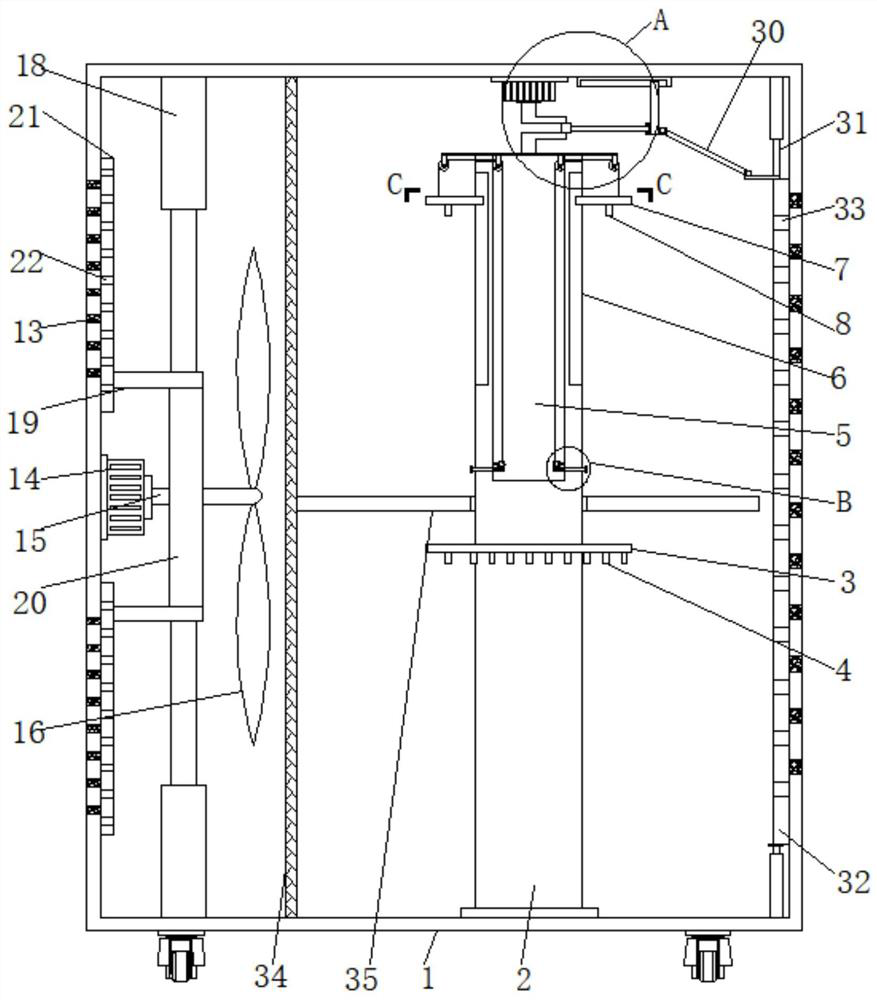

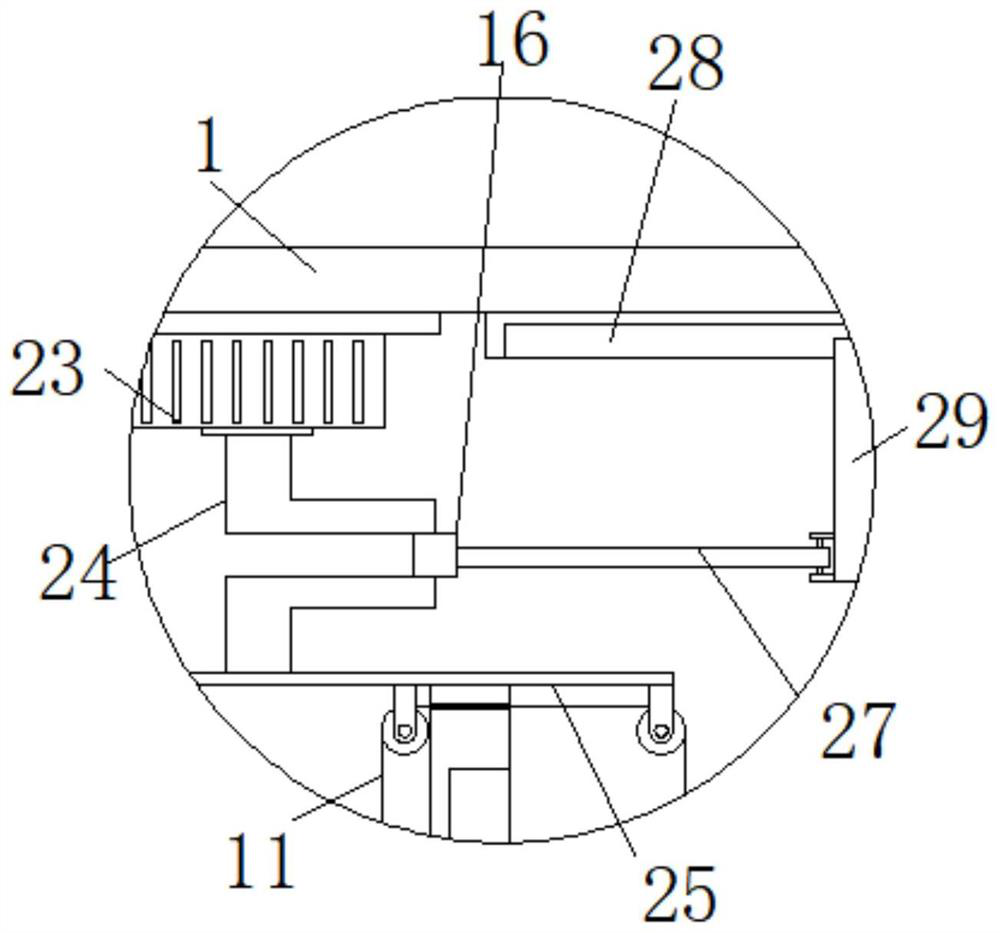

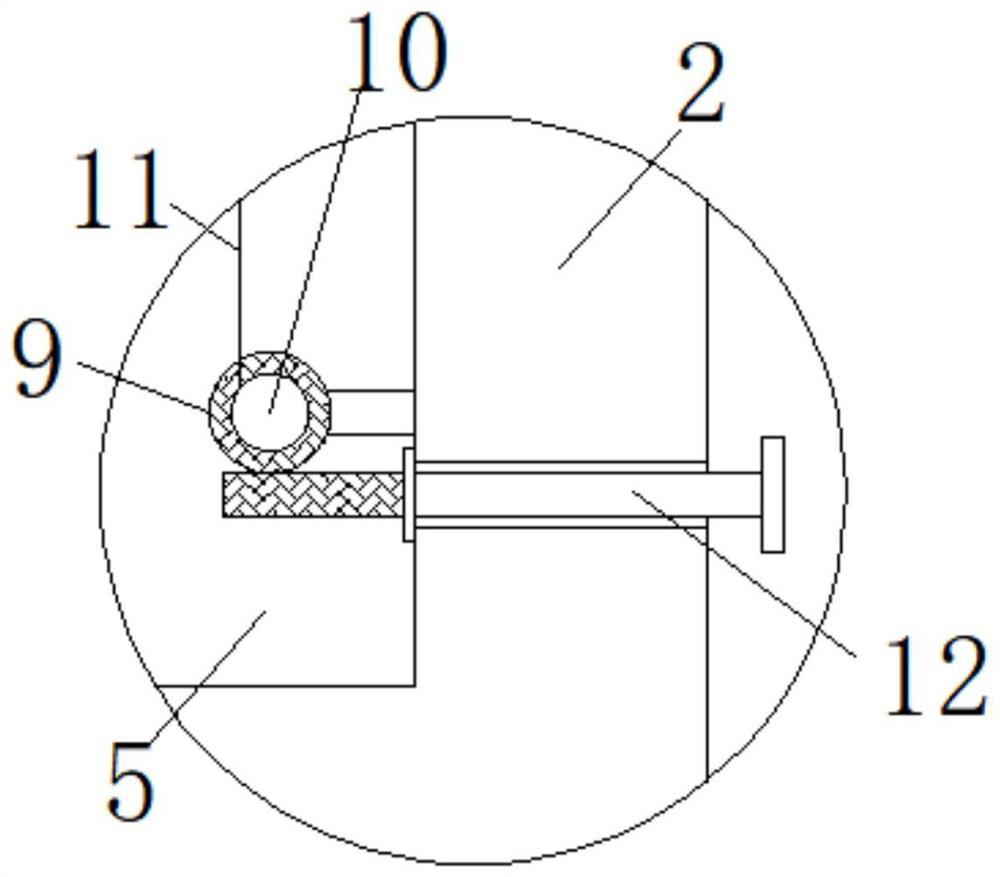

Flexible material processing and production equipment

The invention discloses flexible material processing and production equipment, which comprises a machine frame, wherein the machine frame is provided with a material input mechanism, a plurality of discharging and collection mechanisms, a material output mechanism and processing equipment, wherein each discharging and collection mechanism comprises two power rolls and a tension mechanism, each tension mechanism comprises at least one fixing roll, a traction roll, a second movement frame, at least one movement roll and a press roll, each traction roll is driven by a second power device, each second movement frame is driven by a Y-axis movement mechanism, and each movement roll and each fixing roll are vertically staggered. The flexible material processing and production equipment has the advantages that the structure is compact, and the space is saved; a material coil can be conveniently and rapidly charged; the flexible material is discharged and collected according to requirements, and a plurality of coils of flexible material can be flexibly and quickly replaced according to requirements.

Owner:GOERTEK INC

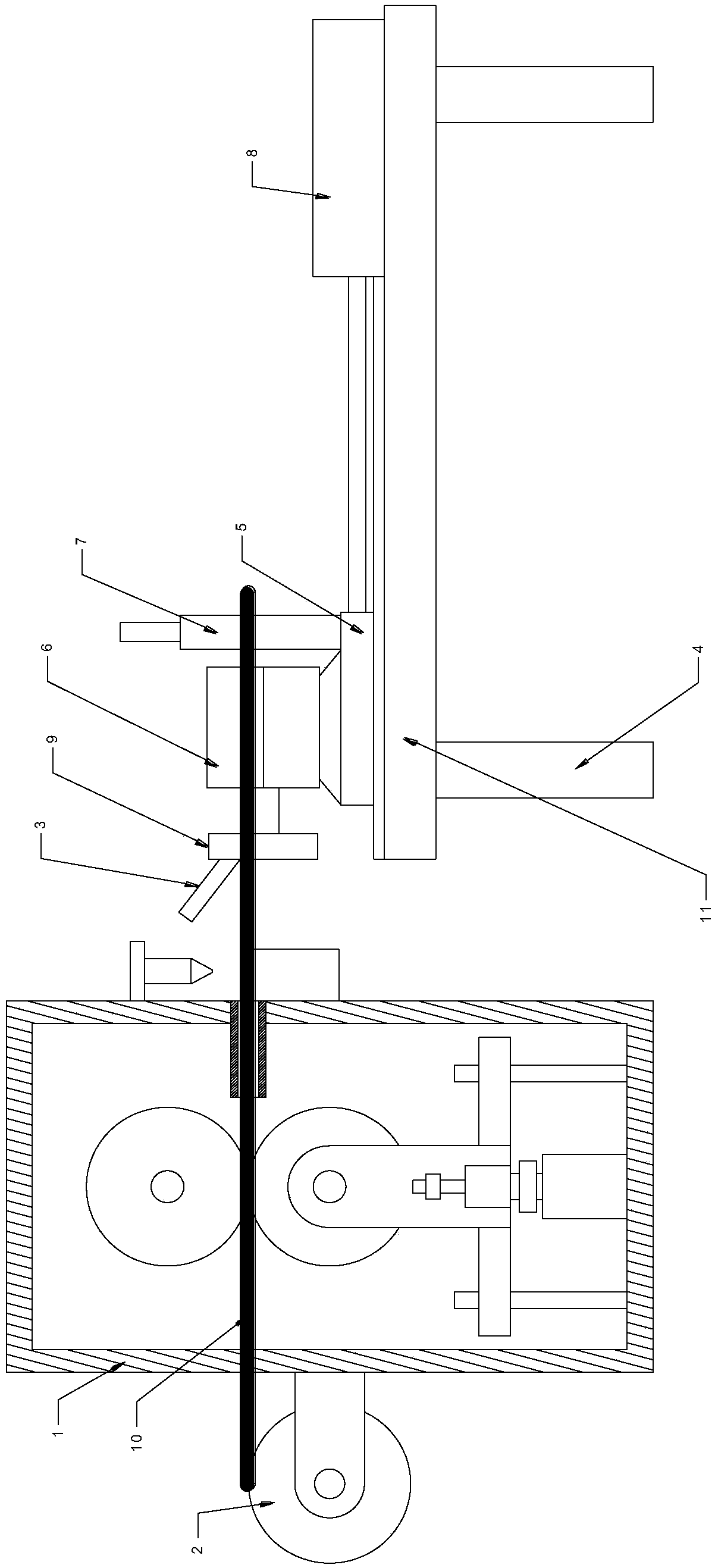

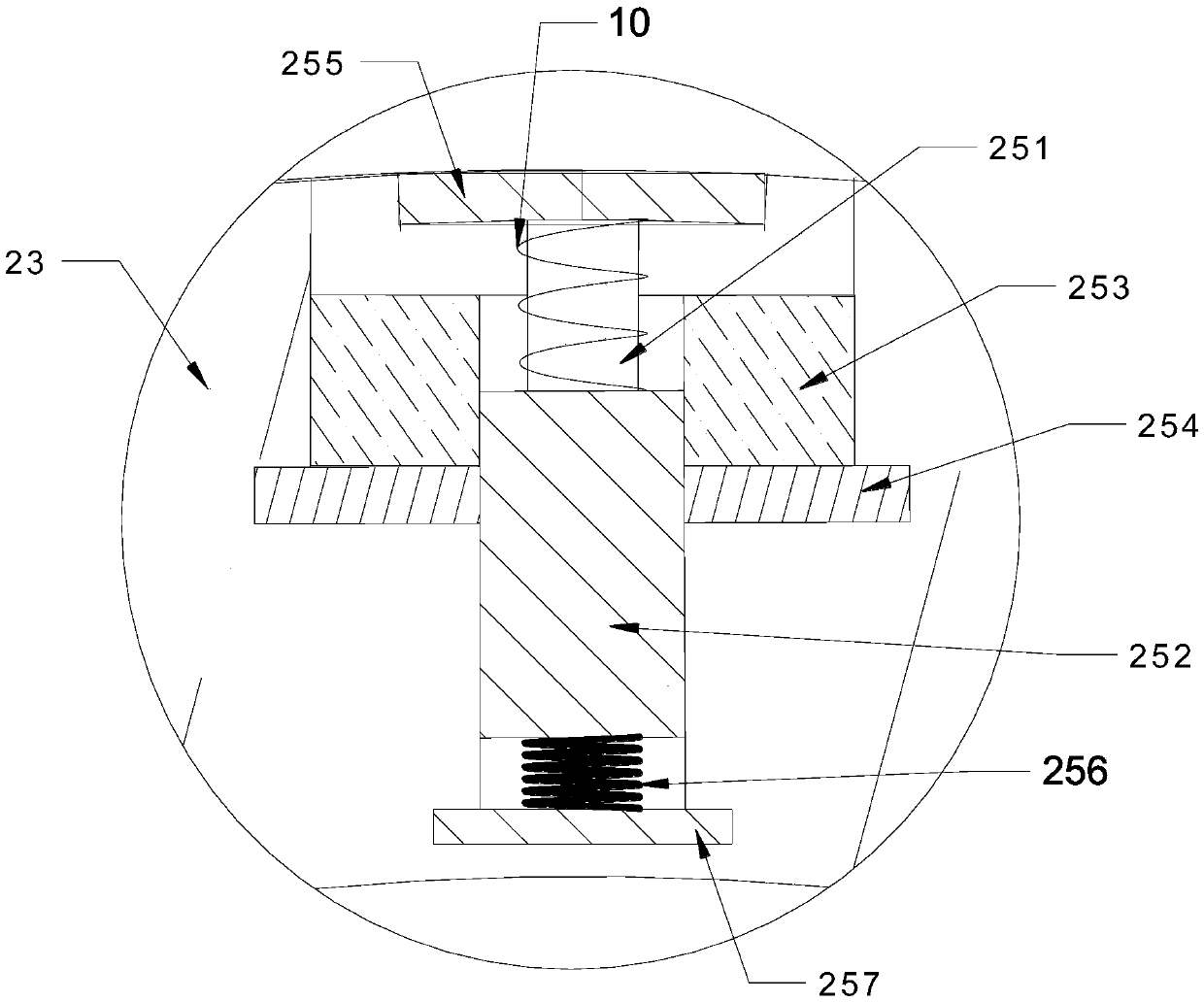

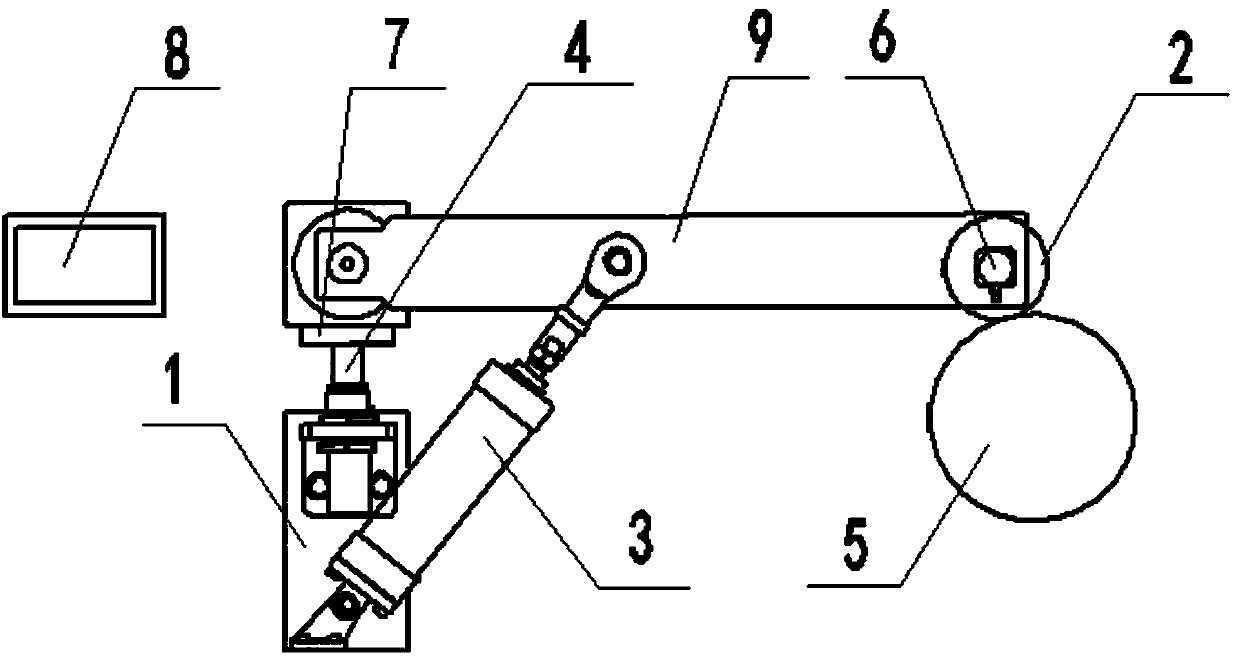

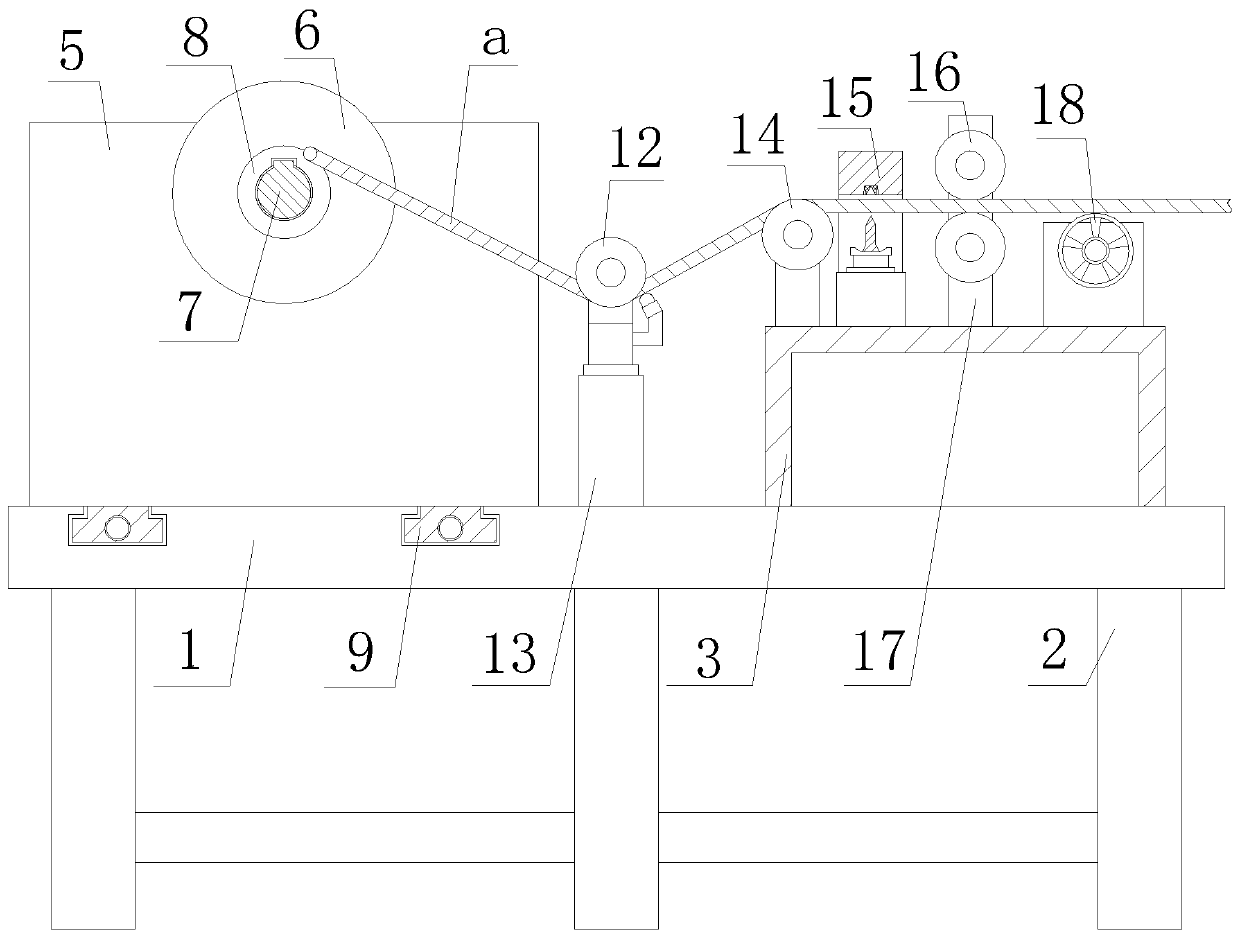

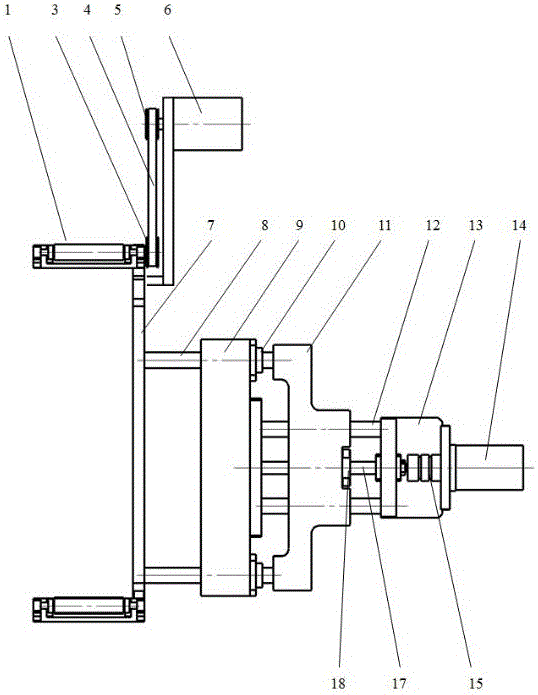

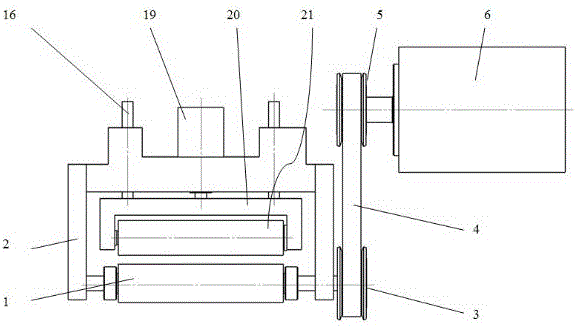

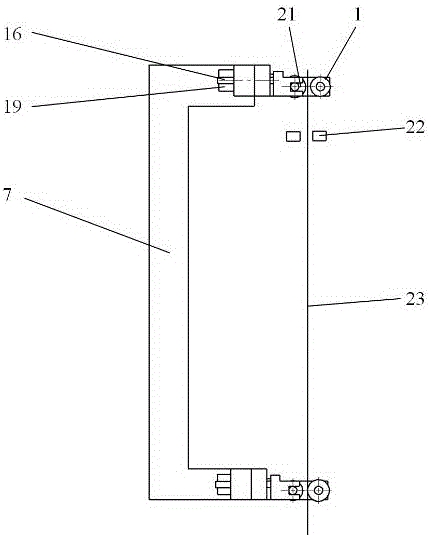

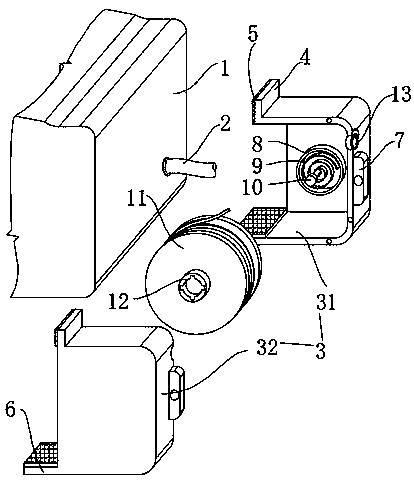

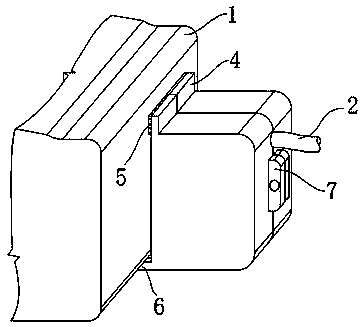

Equipment used for changing grounding wire to be spiral

The invention provides equipment used for changing a grounding wire to be spiral. The equipment comprises a first rack, a convoluting device, a winding rod, a second rack, a sliding seat, a rotary driving device, a clamping device and a horizontal driving device. The convoluting device used for convoluting the grounding wire is mounted on one side of the first rack. A supporting table is mounted on the second rack. The sliding seat capable of sliding is mounted on the supporting table. The rotary driving device is mounted on the sliding seat. The output end of the rotary driving device is connected to a rotary disc. The winding rod is mounted on the rotary disc. The clamping device is mounted on the sliding seat and used for clamping the end, away from the convoluting device, of the grounding wire. The horizontal driving device is mounted on the side, away from the convoluting device, of the sliding seat. By means of the equipment used for changing the grounding wire to be spiral, theproblems that during winding in the prior art, a grounding wire needs to be pulled and moves in the direction parallel to a central line of a wire spool relative to a winding rod, and consequentially,the winding rod and the grounding wire are prone to being damaged are solved.

Owner:STATE GRID CORP OF CHINA +1

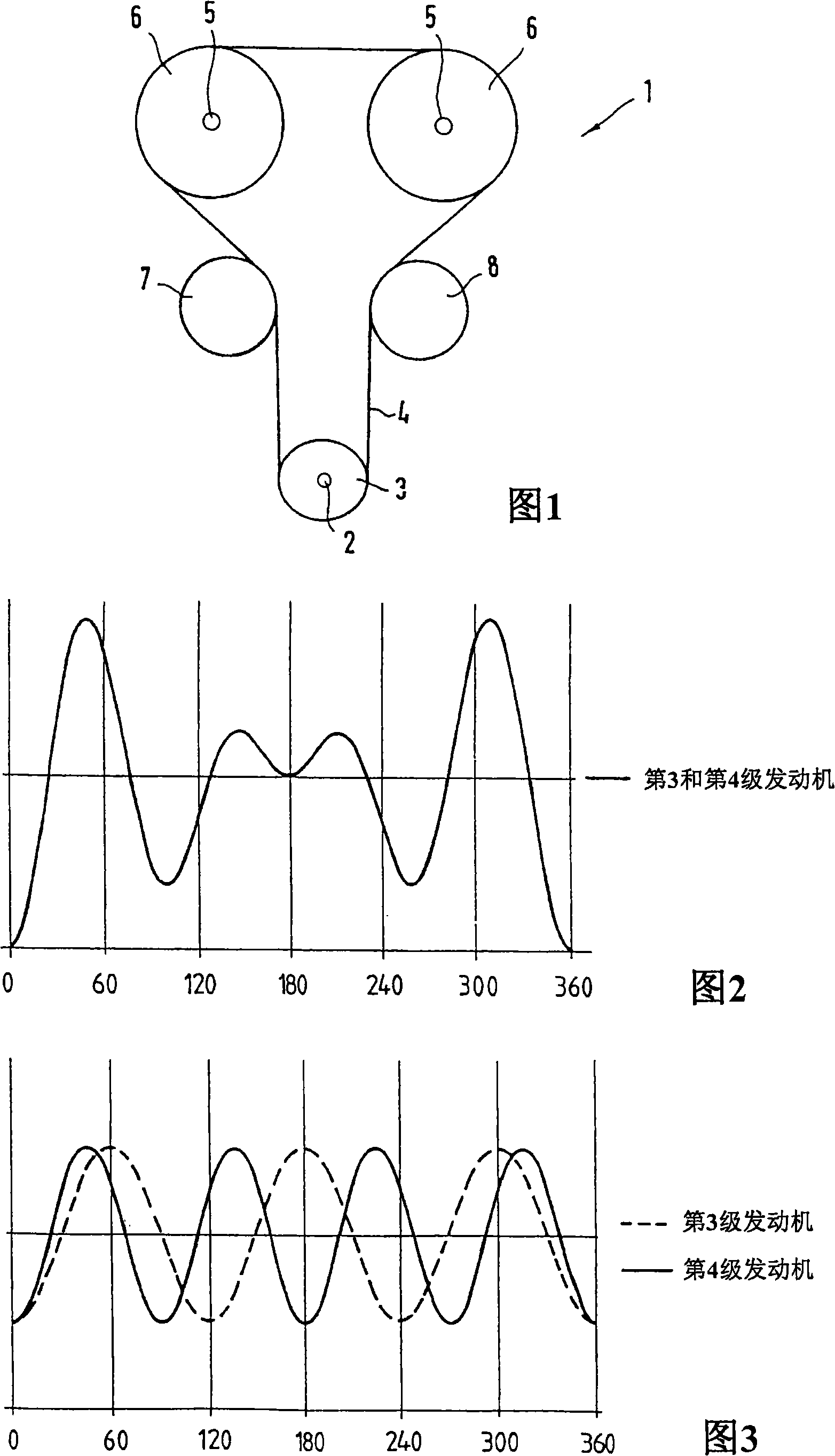

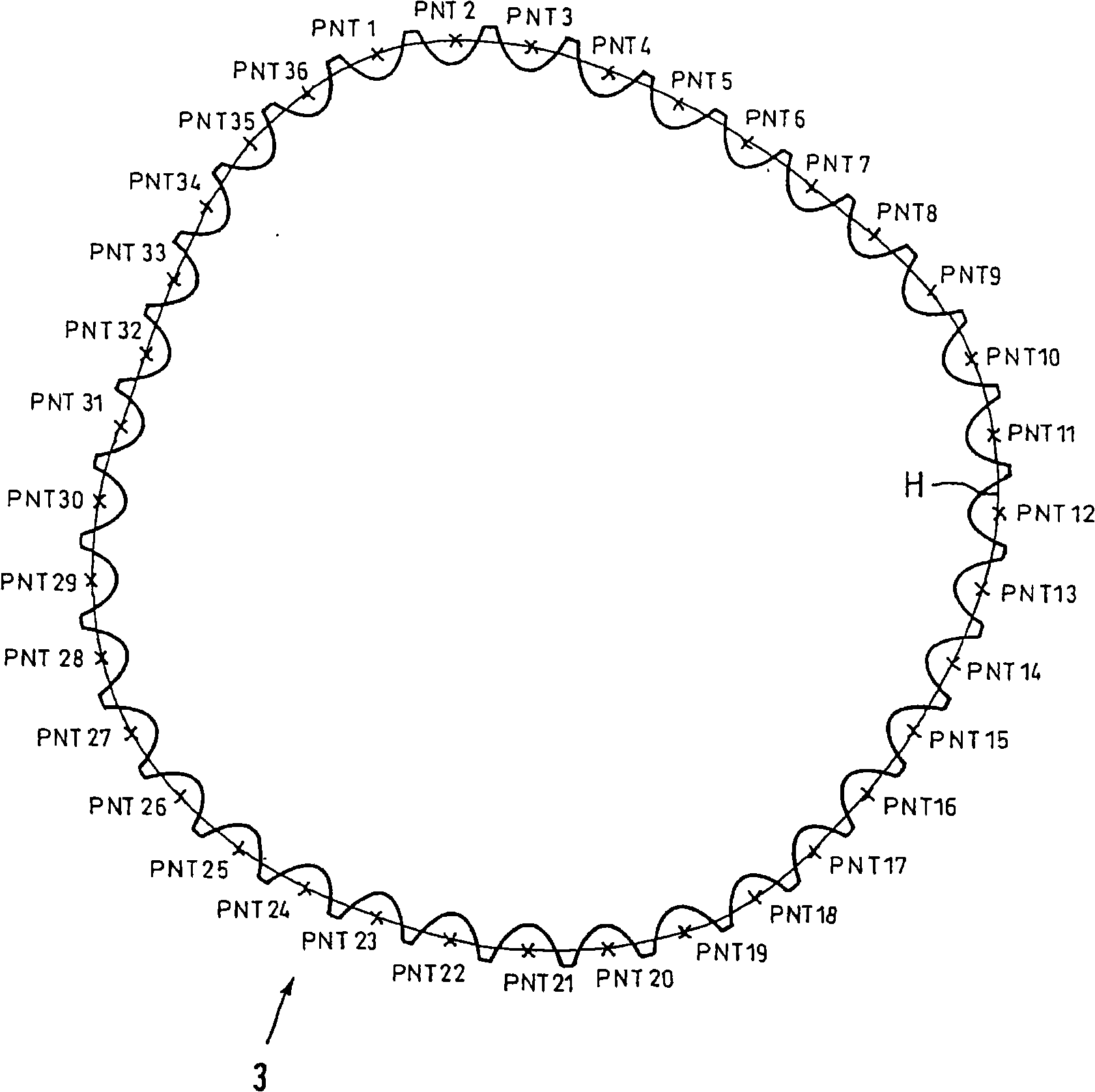

Belt drive

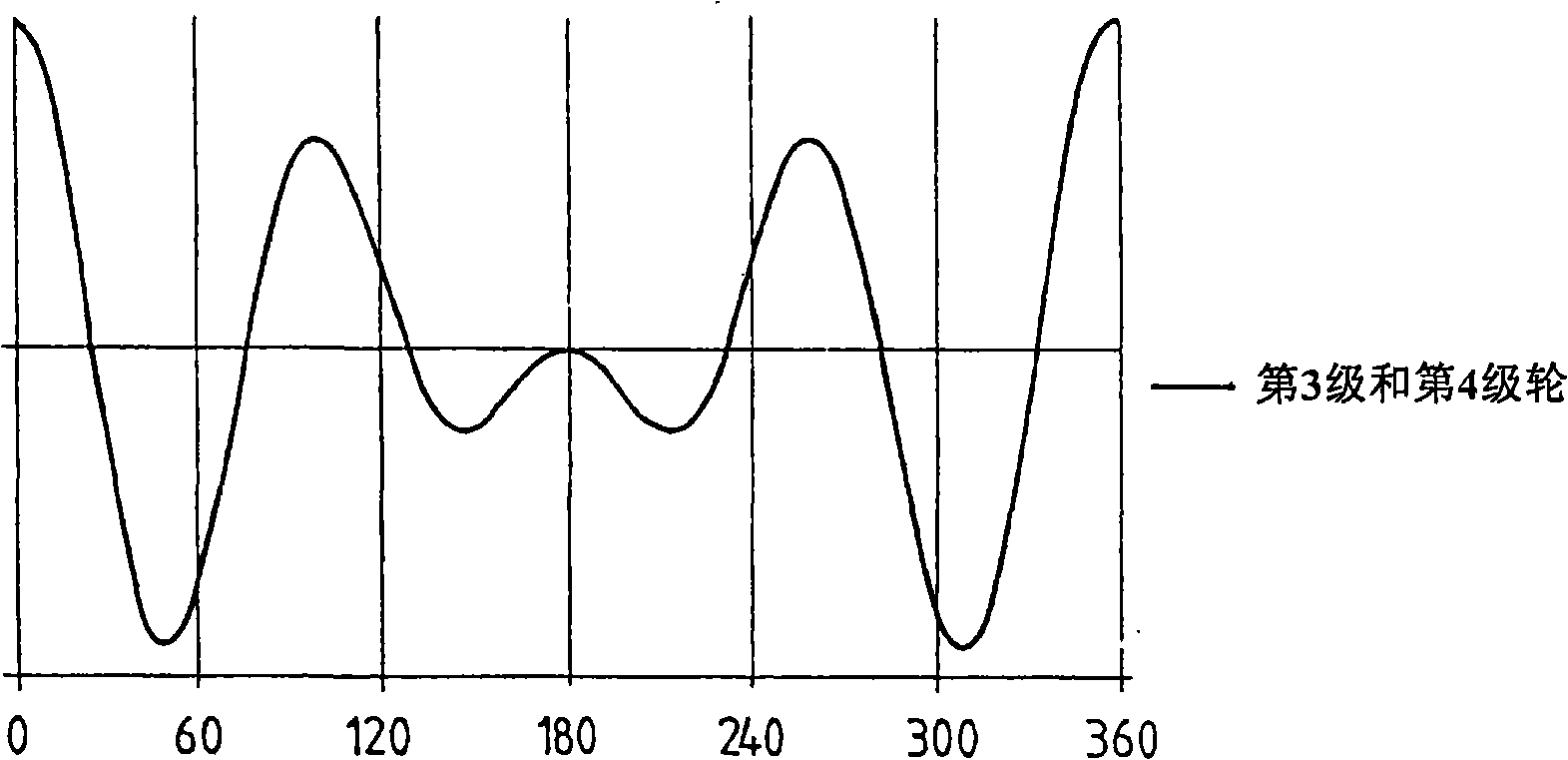

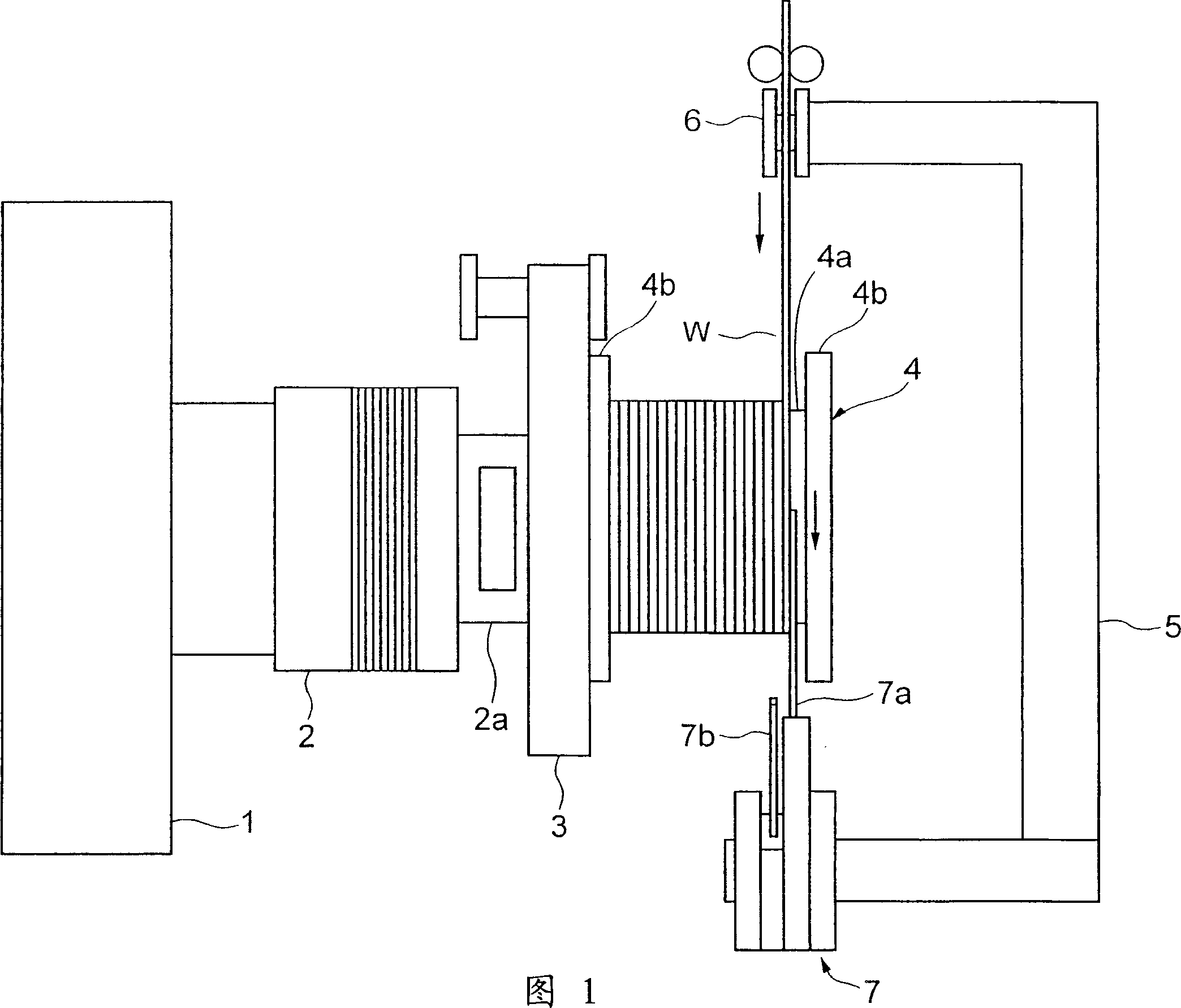

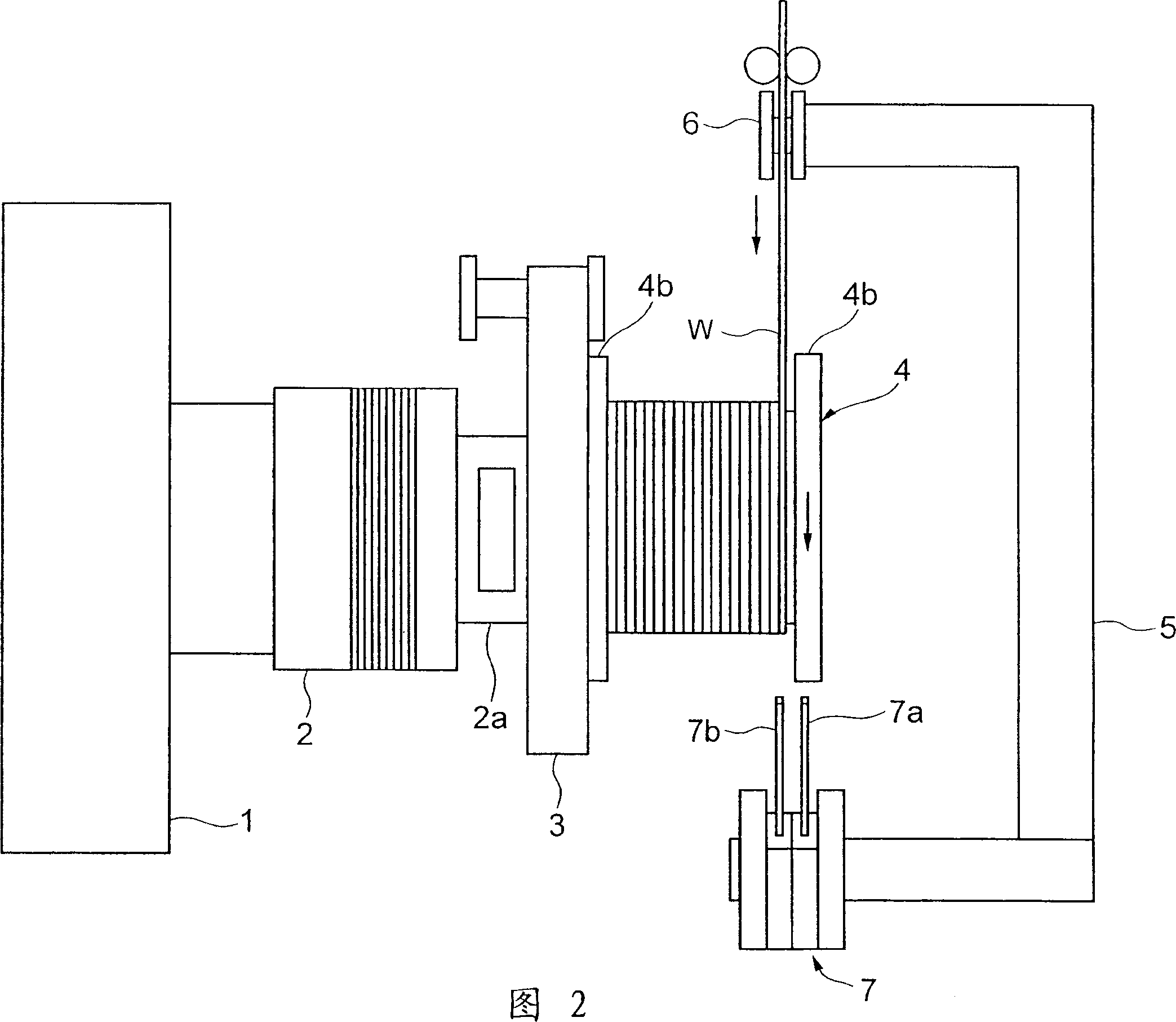

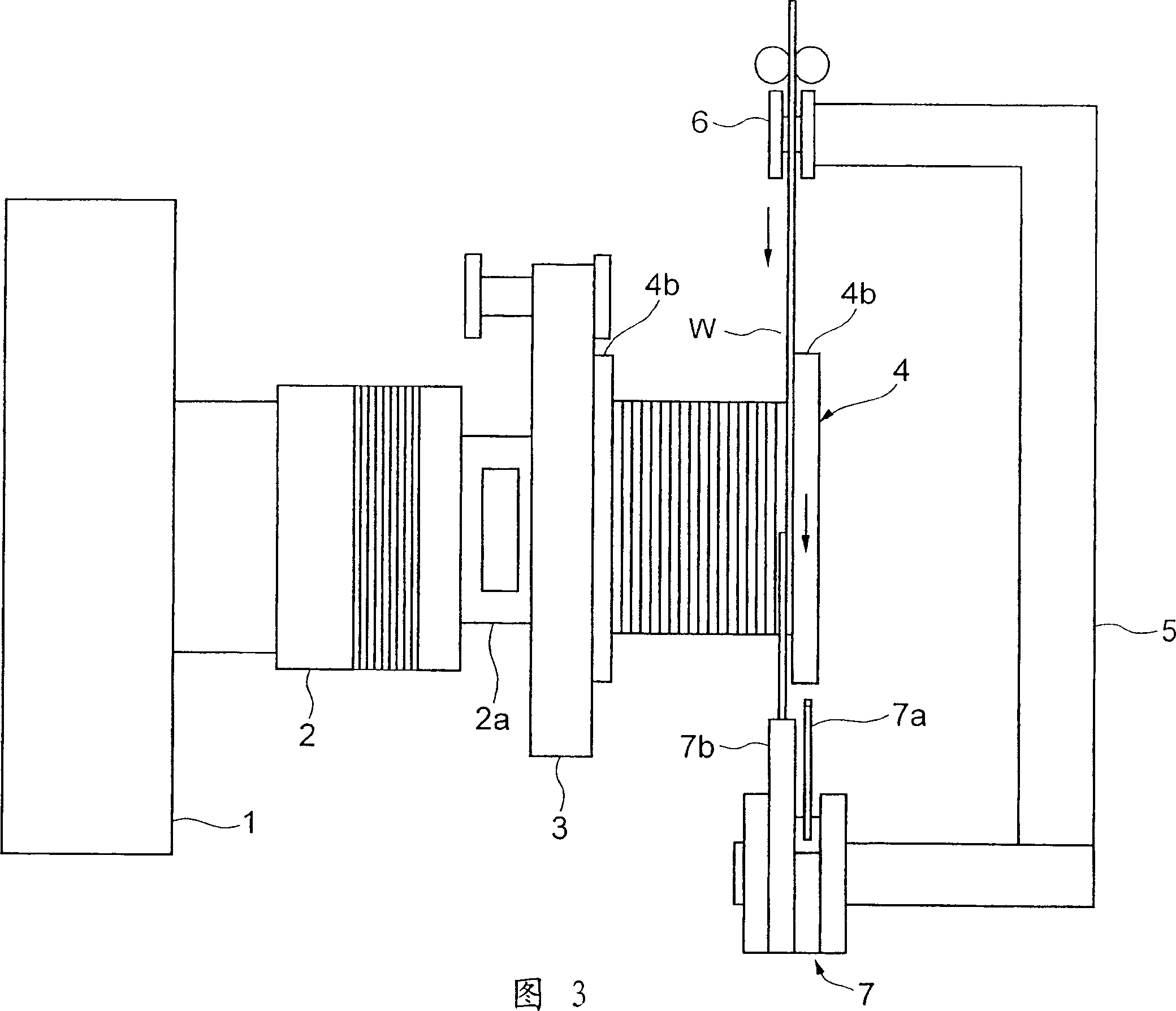

InactiveCN101310128AGuaranteed normal windingBest torque transmissionValve drivesGearingEngineeringParasitic oscillation

The invention relates to a belt drive (1) comprising belt drive means (4) such as a belt or a chain and a plurality of wheels (1, 6, 7, 8), sitting on shafts and integrated into the drive, around which the belt drive is wound, parasitic oscillations being introduced into the belt drive (1) by means of at least one shaft. For the purpose of generating a counter-oscillation, at least one wheel (3) has a noncircular shape. Said noncircular wheel (3) is configured, in terms of its shape, in such a manner that it is adapted to generate a counter-oscillation which compensates at least two different main oscillation orders of the parasitic oscillation.

Owner:SCHAEFFLER TECH AG & CO KG

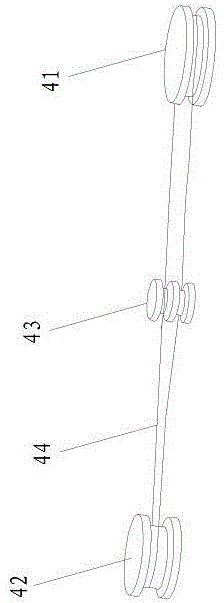

Winding device for wire material with rectangular section

Owner:TANAC CO LTD +1

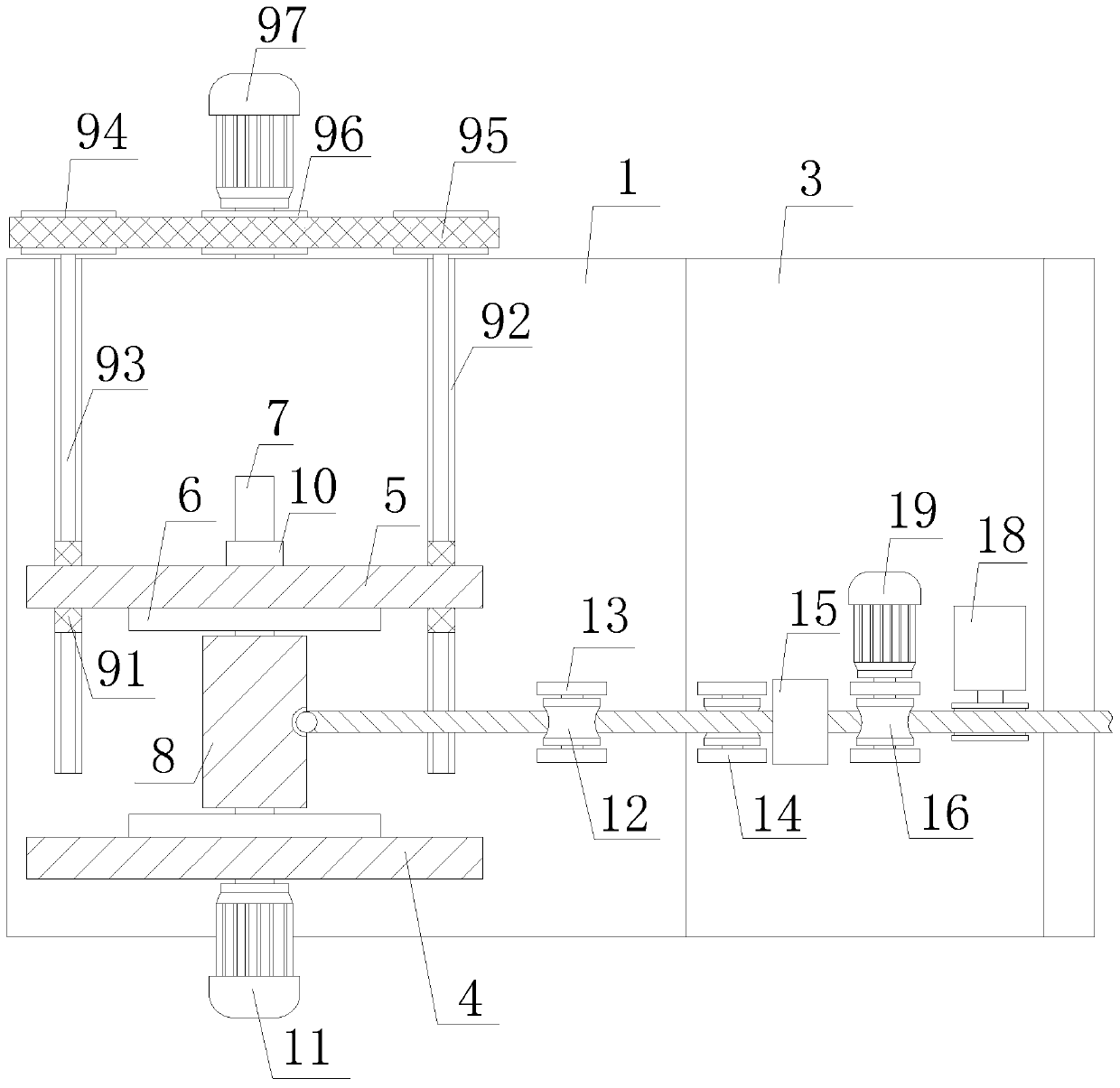

Machining device for textile production

InactiveCN112960436AGuaranteed automatic loadingImprove work efficiencyWebs handlingTextile productionIndustrial engineering

The invention provides a machining device for textile production, and belongs to the technical field of machinery. The machining device solves the technical problems that existing textiles are inconvenient to wind, low in efficiency and the like. The machining device for textile production comprises a rack, wherein a cutting mechanism for cutting textile fabric is slidably arranged on the rack, a support is rotatably arranged on the rack, a plurality of winding rollers are rotatably arranged on the support, an upper supporting frame and a lower supporting frame used in cooperation with the winding rollers are slidably arranged on the rack, an annular first sliding groove is formed in the upper supporting frame and the lower supporting frame, a sliding block is arranged on the first sliding groove in a sliding mode, fixing mechanisms for fixing the textile fabric are arranged on the winding rollers and the sliding block correspondingly, a moving mechanism capable of moving the textile fabric to a winding mechanism is arranged at the upper end of the rack, a sleeving mechanism for sleeving the winding rollers with winding paper cores is arranged on the rack in a sliding mode, and a discharging mechanism for taking down the wound textile fabric is further arranged on the rack. The machining device has the advantages of being convenient for winding and high in efficiency.

Owner:WUHAN CITY VOCATIONAL COLLEGE

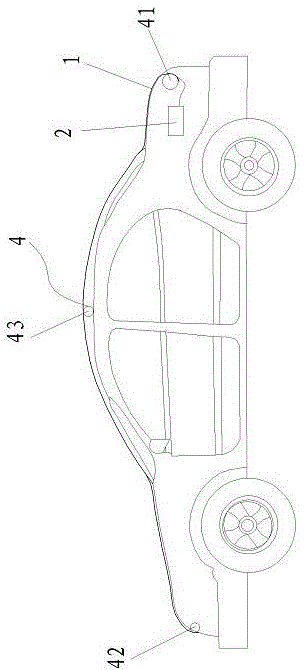

Intelligent regulating system for automobile sunshade

InactiveCN104589981AAvoid displacementGuaranteed effectRemovable external protective coveringsElectric machineryAutomotive engineering

The invention relates to the technical field of intelligent household electrical appliances, and discloses an intelligent regulating system for an automobile sunshade. The intelligent regulating system comprises a flexible solar cell film, an accumulator, a motor and an 8-shaped loop reeling system, wherein the flexible solar cell film is driven by the 8-shaped loop reeling system and the motor to be retracted and spread; the accumulator is electrically connected with the flexible solar cell film and used for storing the solar energy collected by the flexible solar cell film; the intelligent regulating system further comprises a control circuit; the control circuit comprises a wireless communication module; the control circuit is electrically connected with the motor; the wireless communication module is used for receiving wireless signals and further controlling the motor to be turned on and off, so as to realize wireless intelligent control of the sunshade. The brand new solar film is used as a main part of the sunshade; the whole sunshade can be spread to form a solar device; the absorbed solar energy can be stored by the accumulator, so that the intelligent regulating system for the automobile sunshade can realize purely environment-friendly intelligent control.

Owner:JIANGSU WEIHANG AUTOMOBILE COMM TECH CO LTD

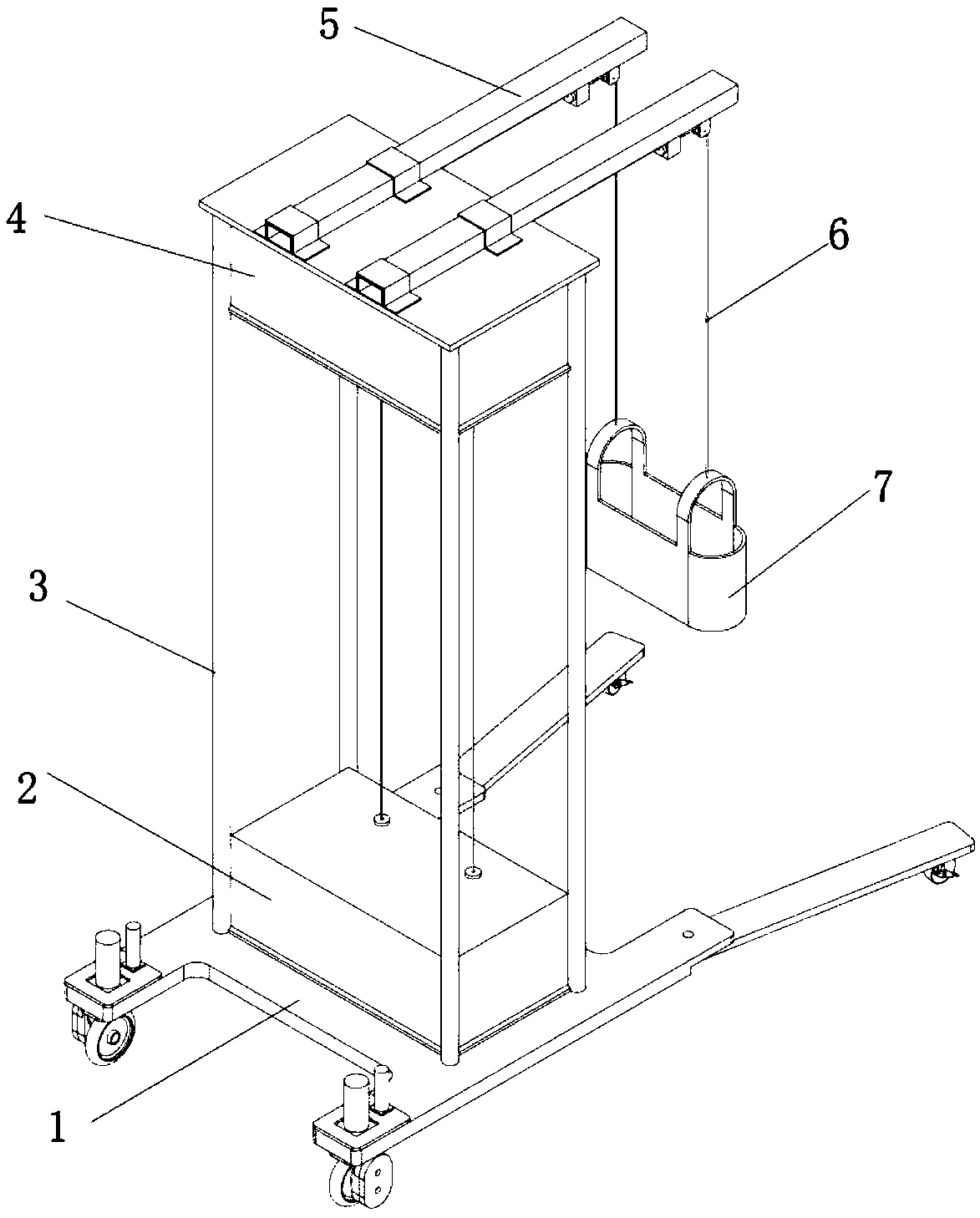

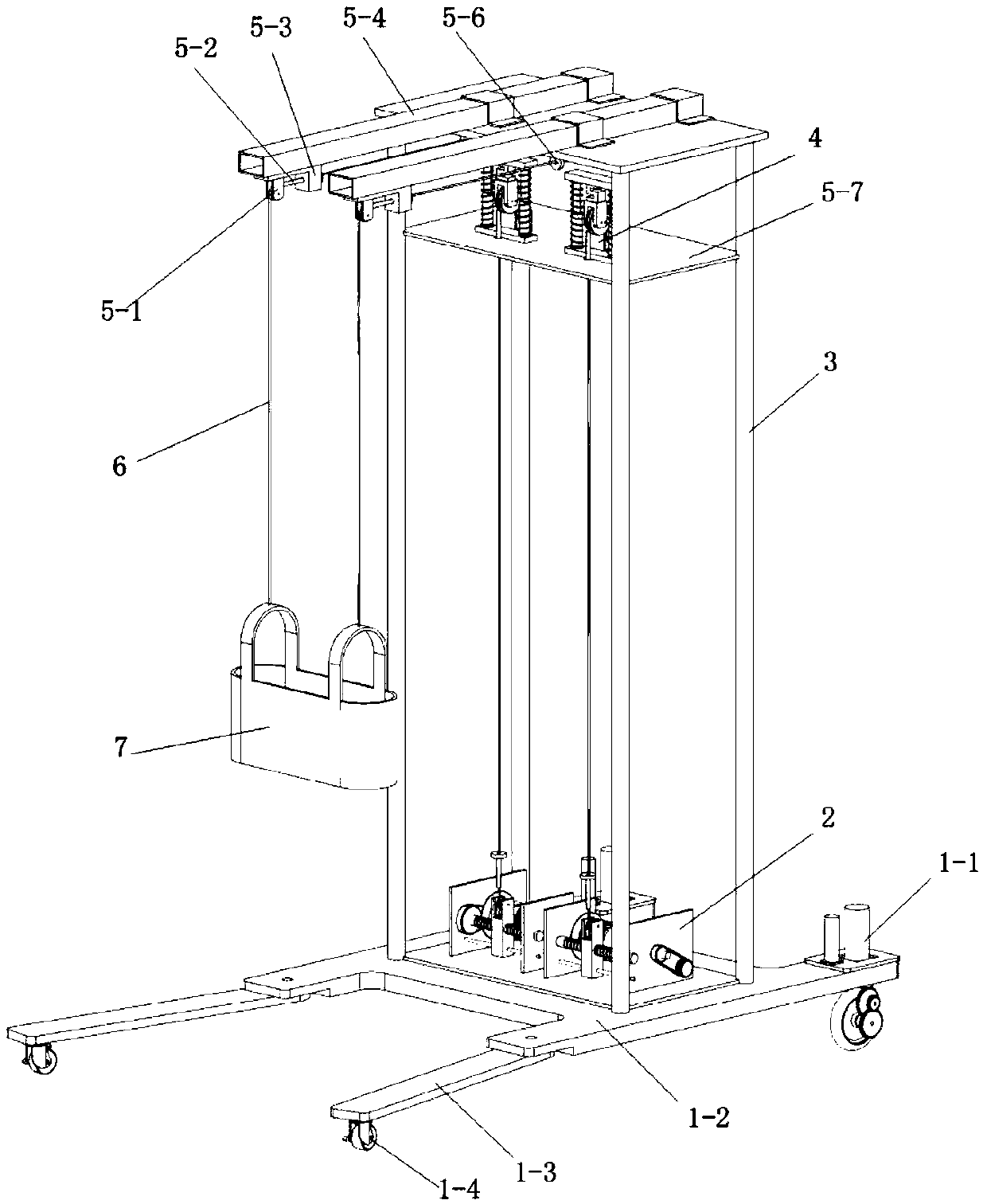

Suspension weight reduction training device

The invention relates to a suspension weight reduction training device which comprises a base, a supporting frame, a wearable device, a rope and a rope winding device. Rollers are arranged on the base, the supporting frame is placed on the base, one end of the rope is connected with the rope winding device and wound on the rope winding device, the other end of the rope is connected with the wearable device, and the rope winding device comprises a rope winding and unwinding device. The suspension weight reduction training device can prevent the problems that ropes are overlapped and winding paths are messy in the winding process.

Owner:HUBEI UNIV OF ARTS & SCI

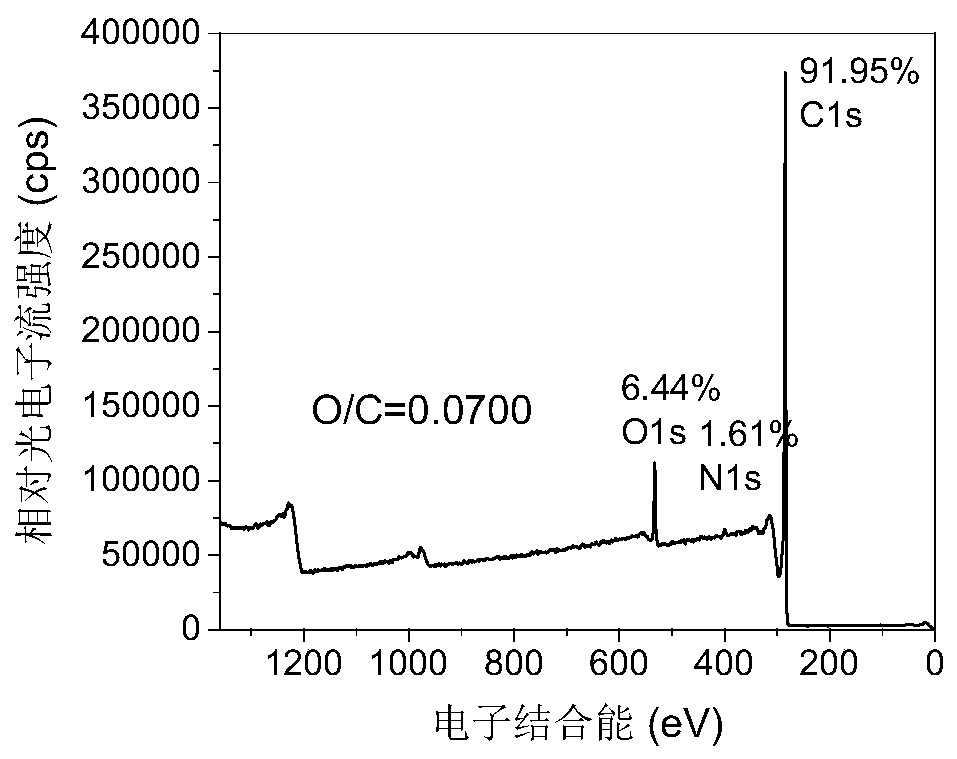

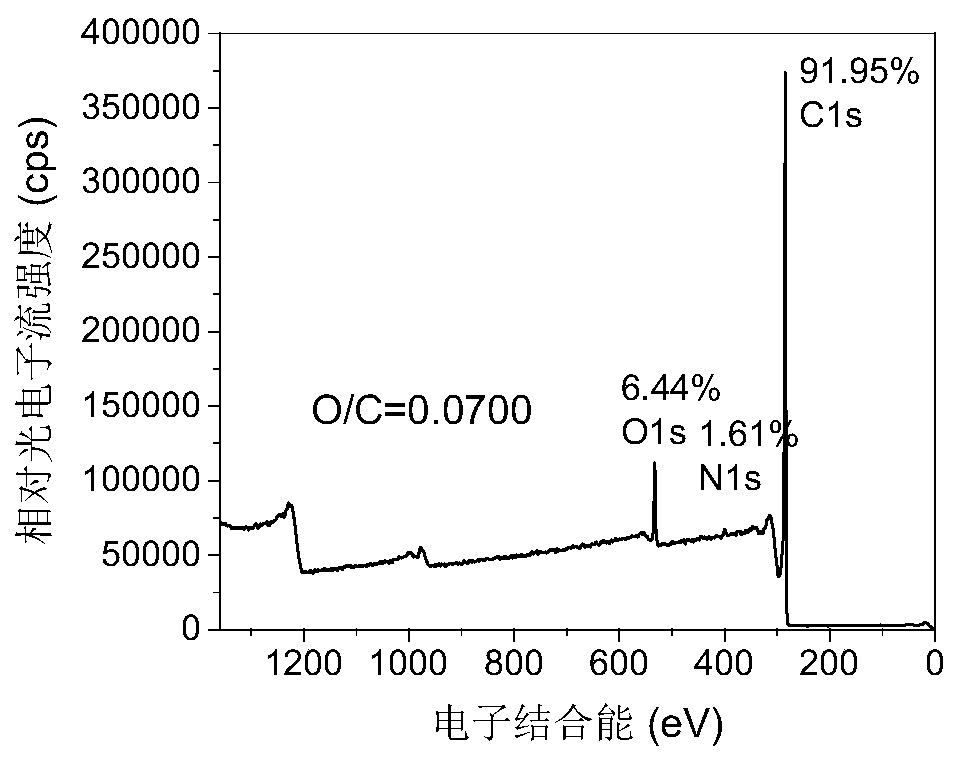

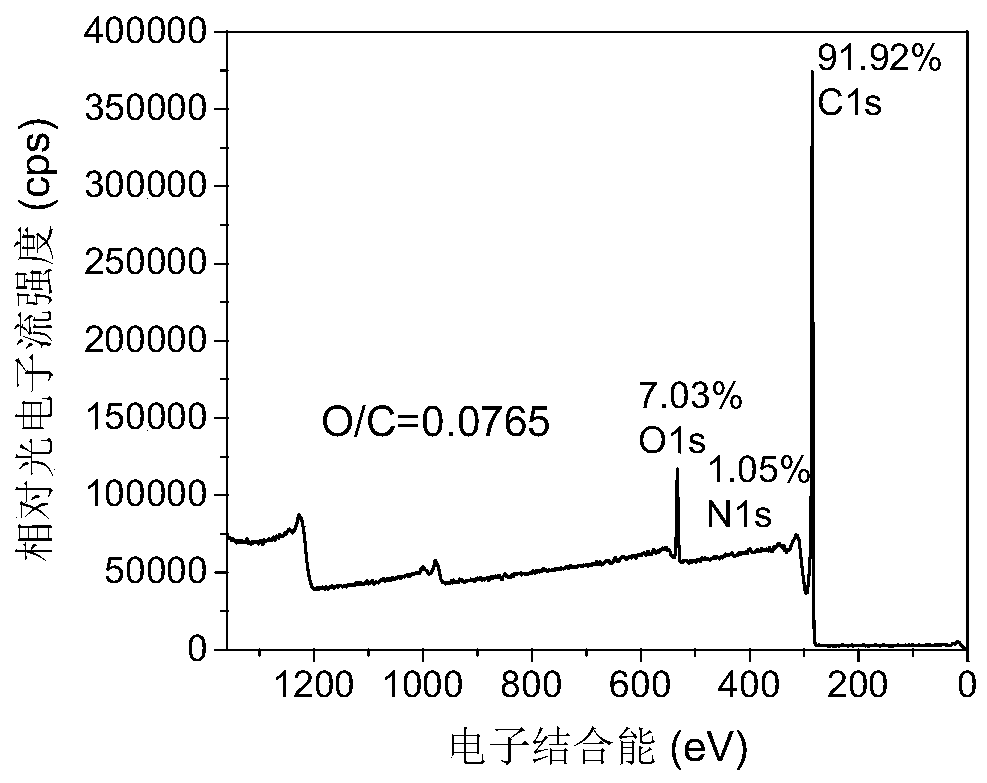

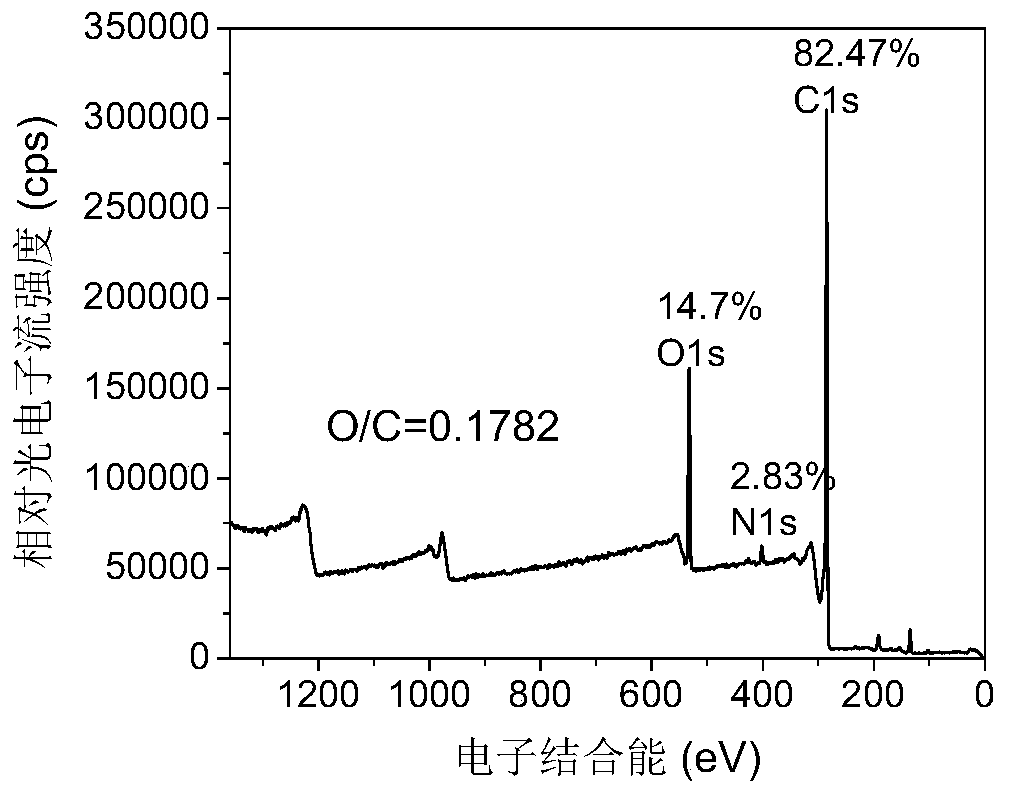

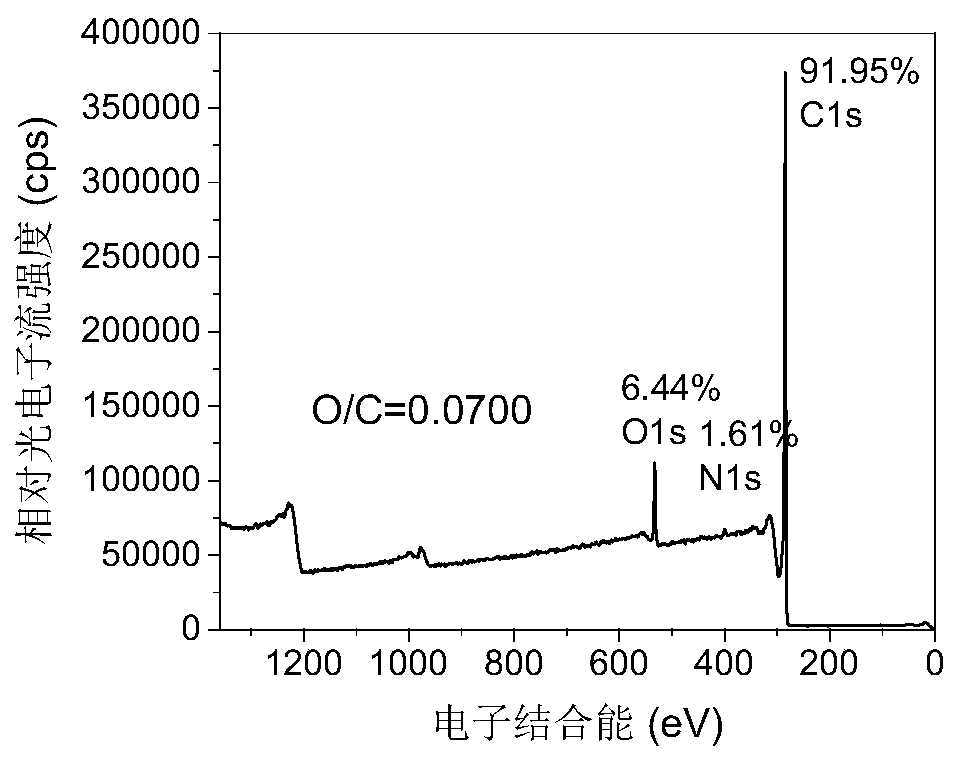

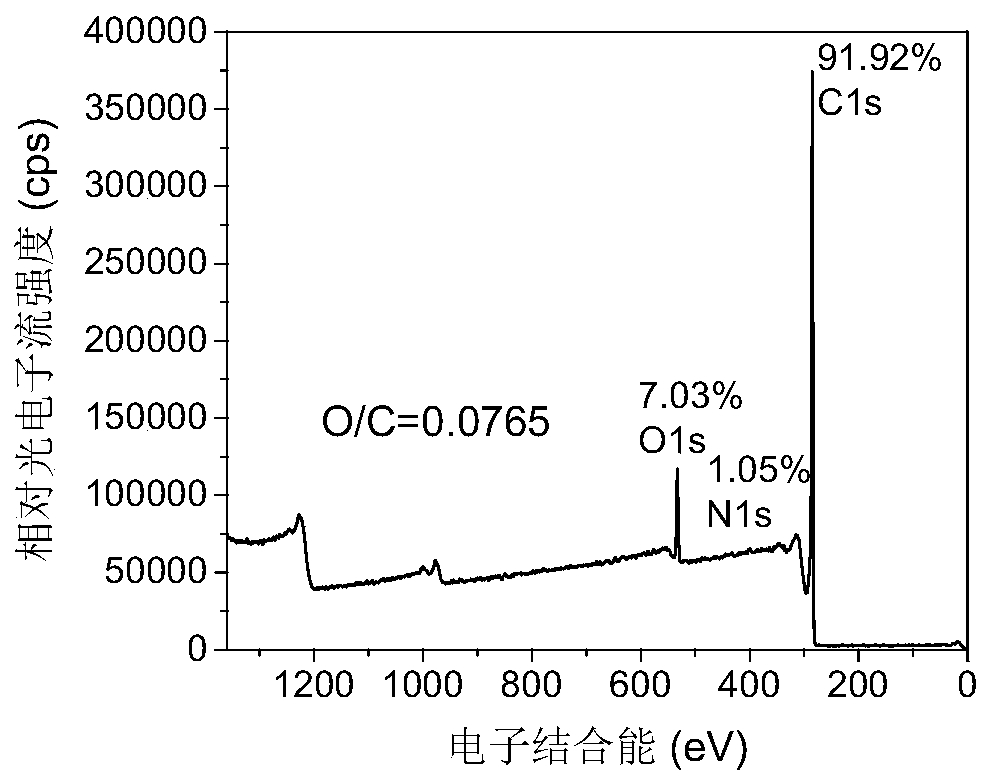

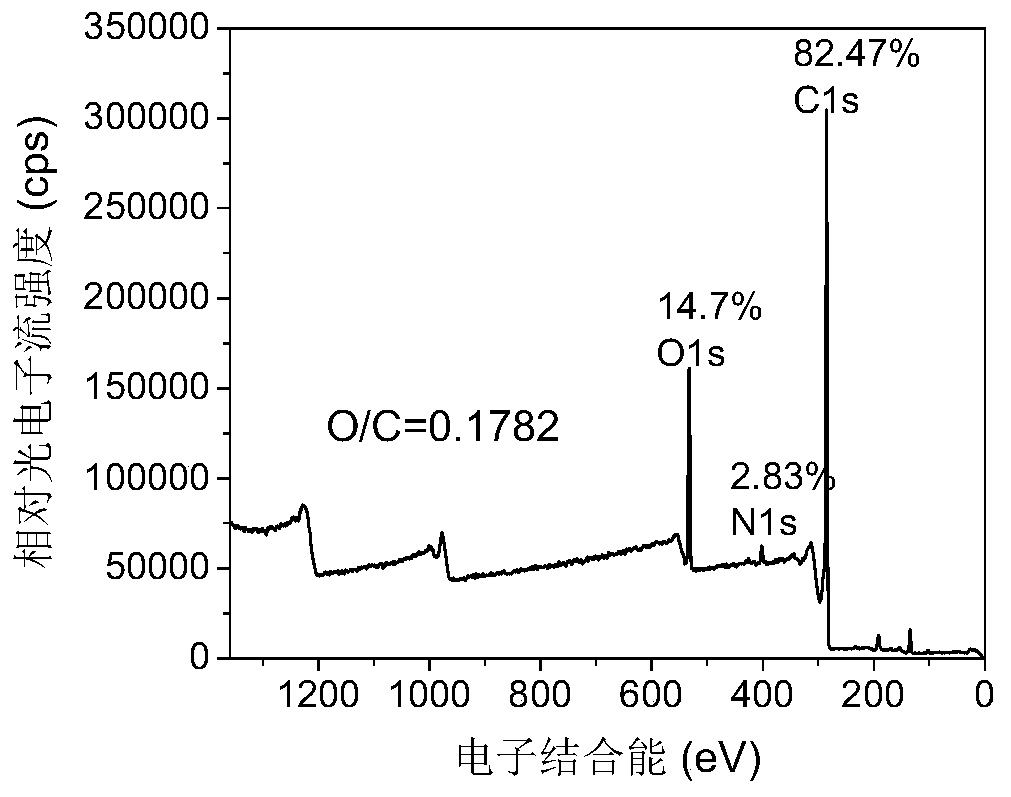

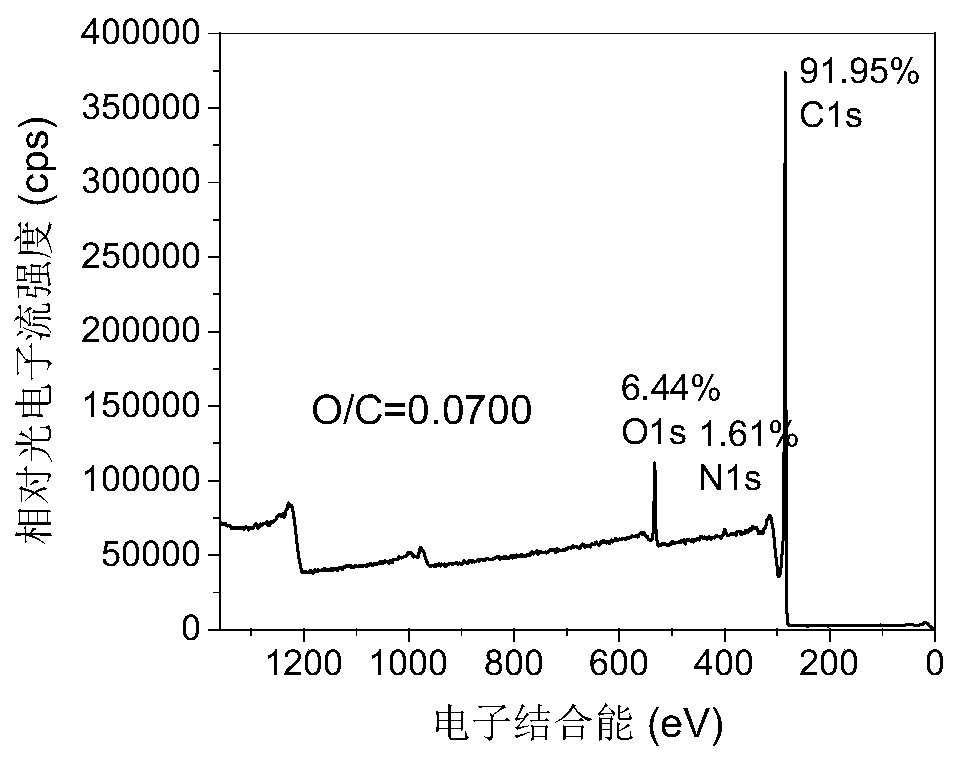

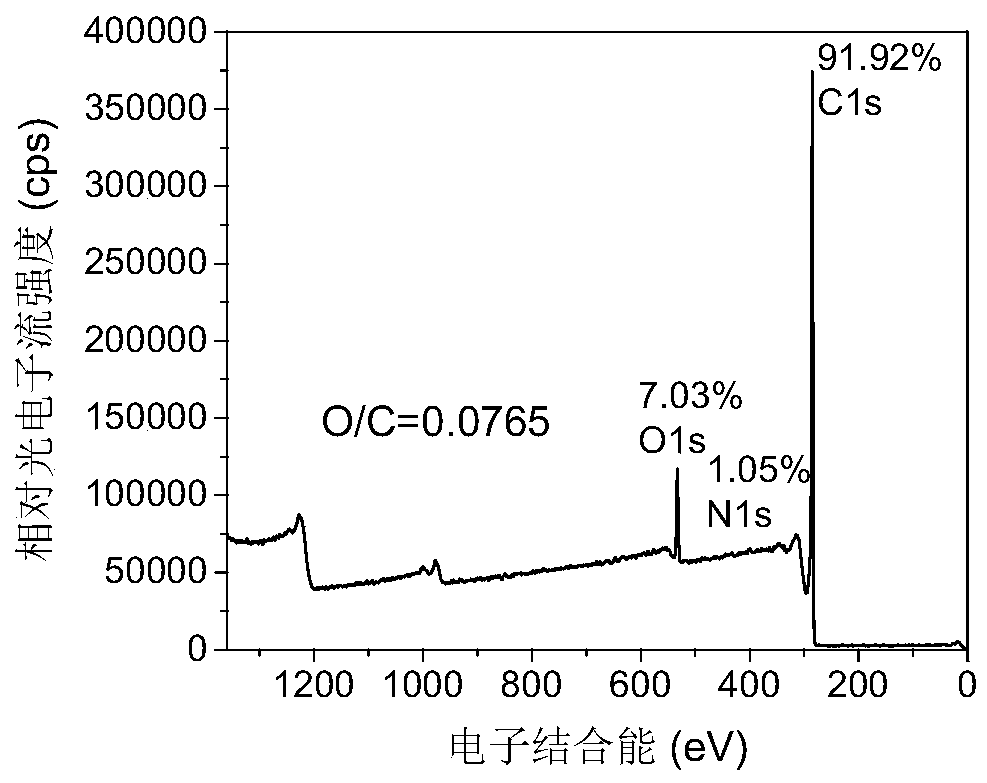

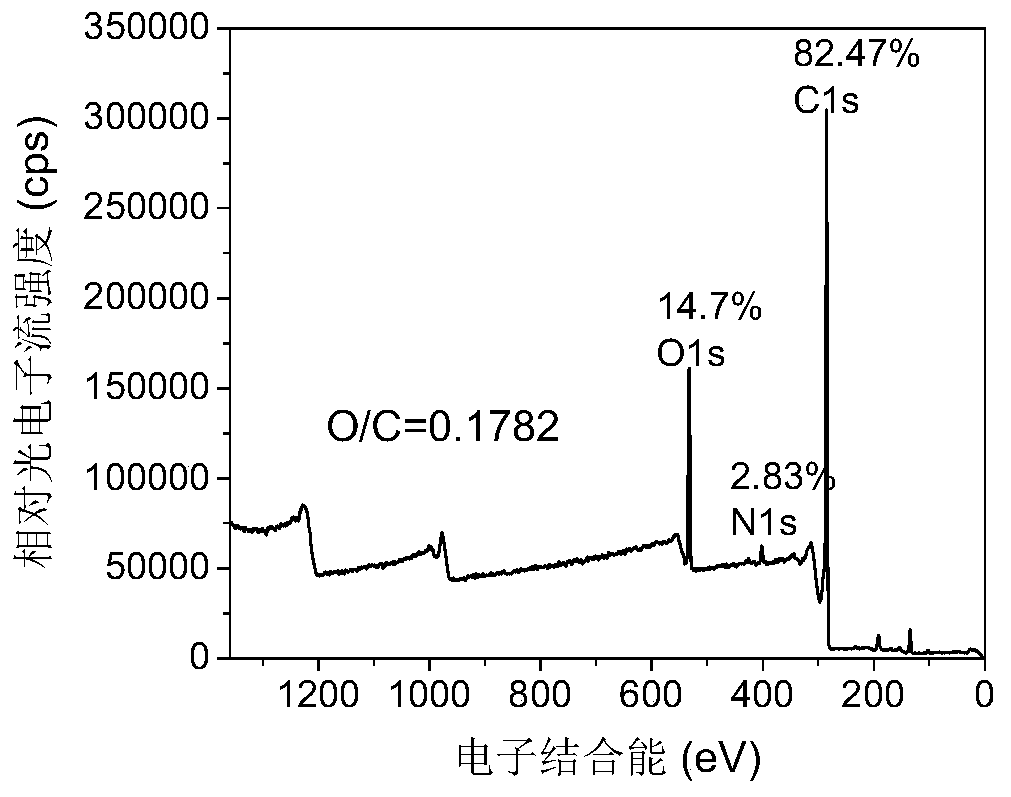

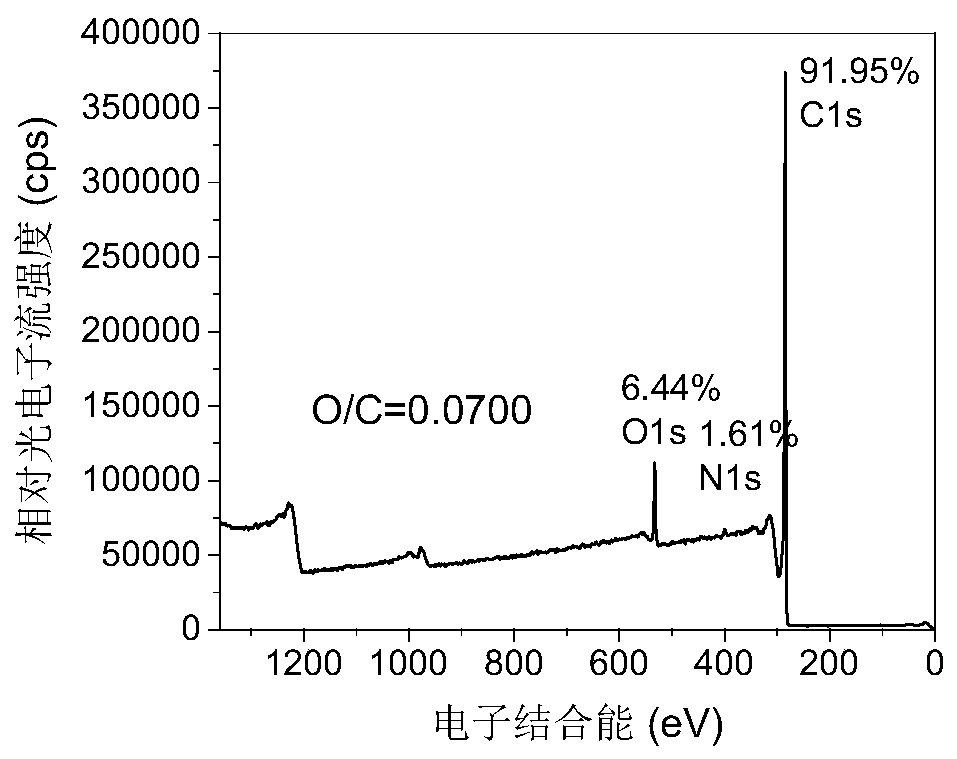

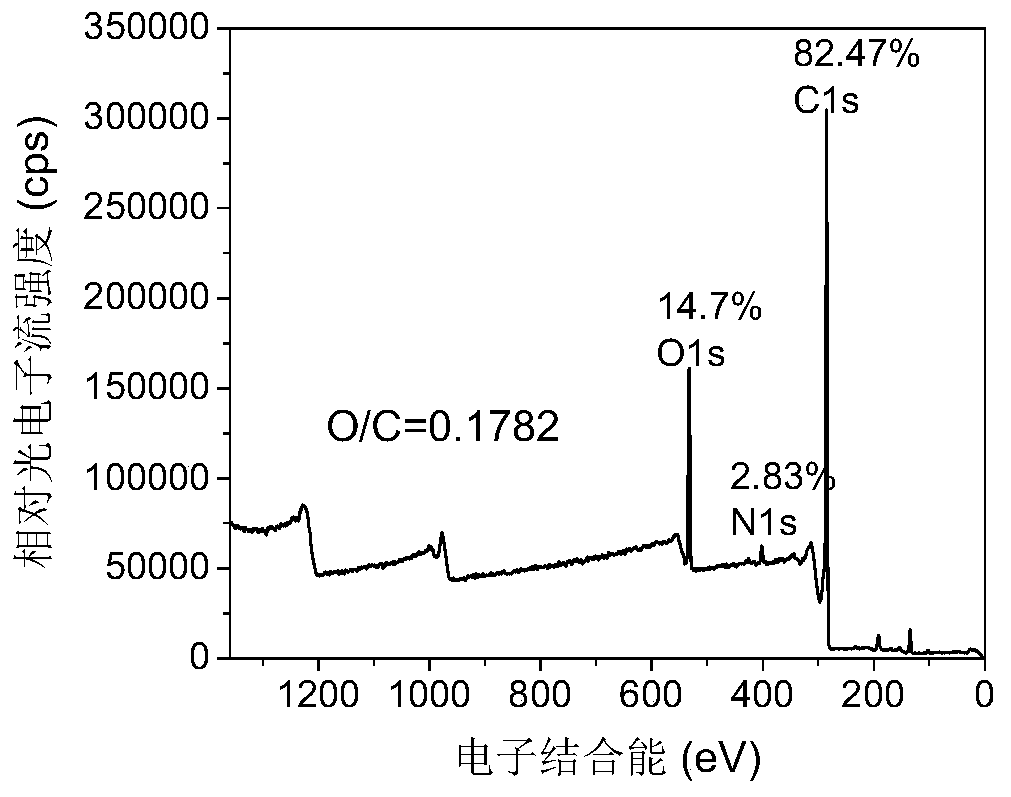

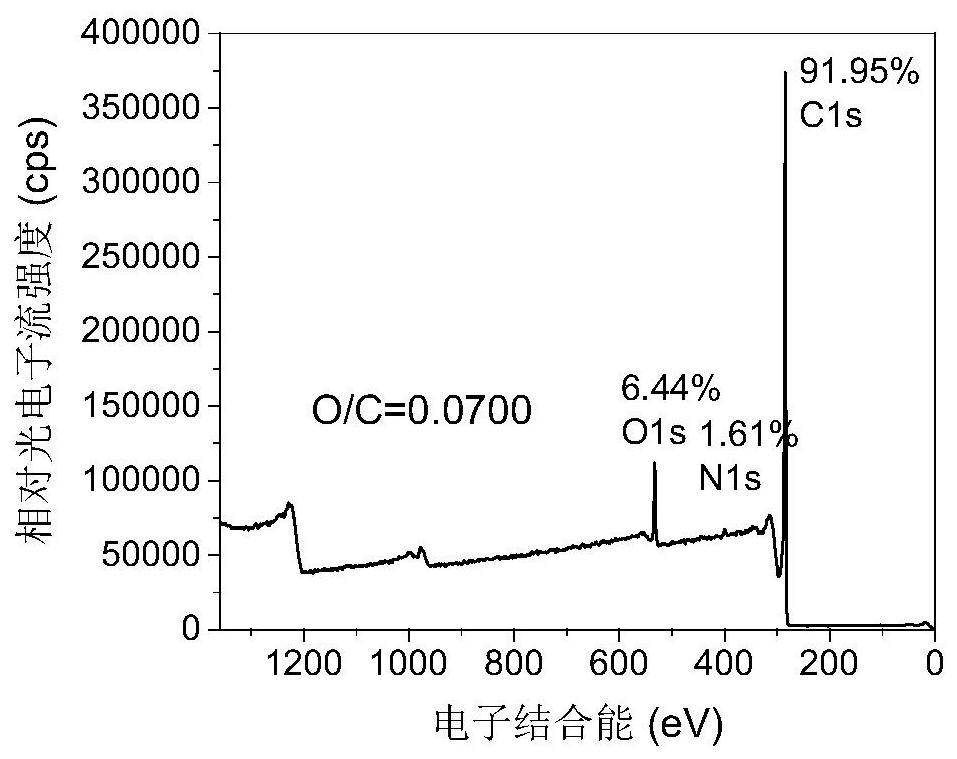

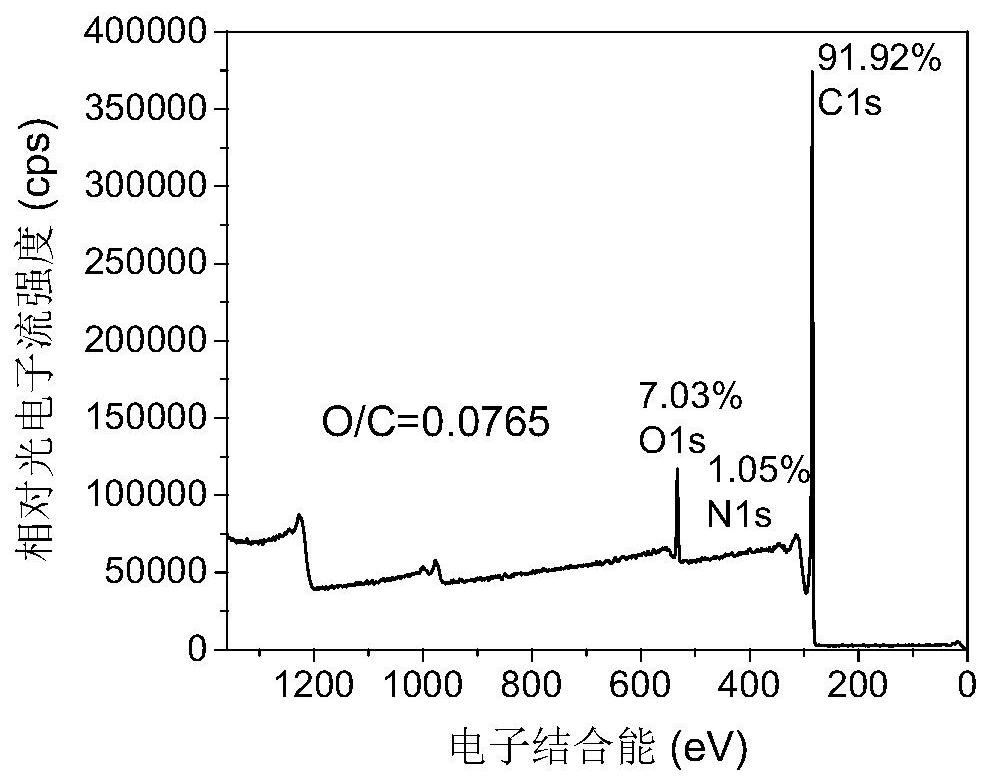

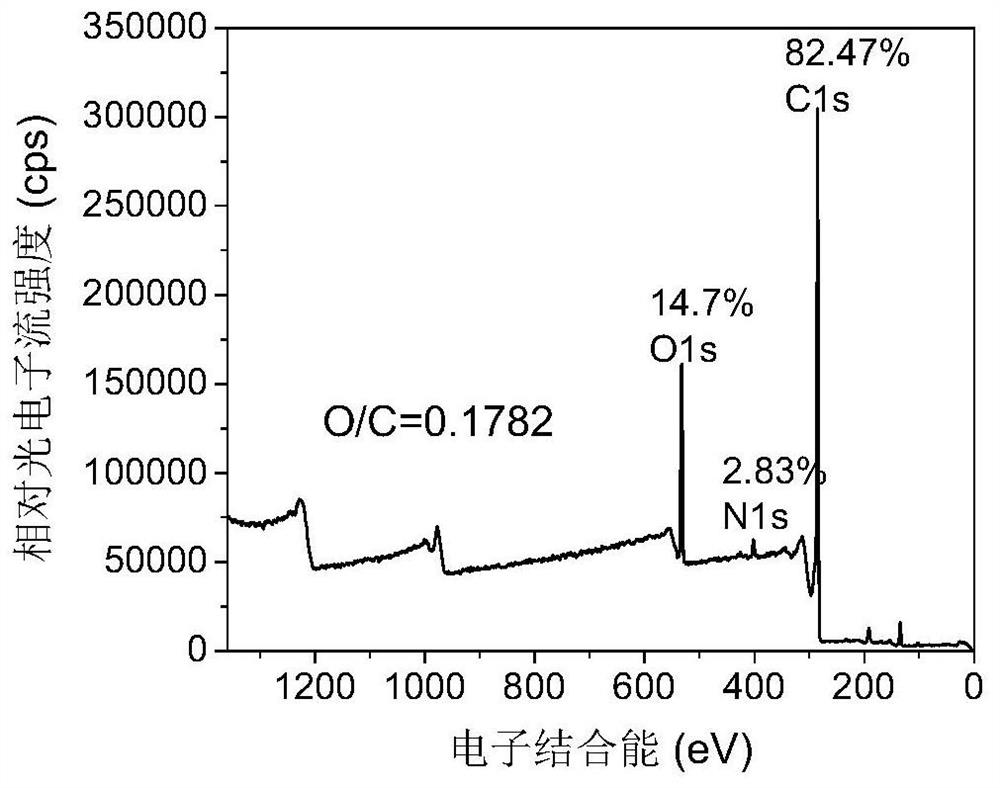

CF/PEEK composite material with chemical bond strong interface and preparation method thereof

The invention relates to a CF / PEEK composite material with a chemical bond strong interface and a preparation method thereof. The method comprises the following steps: (1) carrying out high-temperature decomposition on an original sizing agent on the surface of CF; (2) simultaneously carrying out microwave radiation and ultraviolet irradiation on CF in a saturated water vapor environment, and marking a product as ACF; (3) immersing ACF into the aminated PEEK / dimethylformamide / carbon nanotube suspension, performing heating to enable aminated PEEK to react with ACF, taking out, and drying, so asto obtain sized modified carbon fiber MCF; and (4) laminating and hot-pressing the MCF and the PEEK material, the CF / PEEK composite material with the chemical bond strong interface is obtained. The bending strength of the finally prepared CF / PEEK composite material with the chemical bond strength interface is 900-1100 MPa, the bending modulus of the finally prepared CF / PEEK composite material is57-65 GPa, the interface shear strength of the finally prepared CF / PEEK composite material is 100-120 MPa, and the residual compression strength of the finally prepared CF / PEEK composite material after impact is 210-250 MPa. The method disclosed by the invention has the characteristics of high efficiency, environmental friendliness and capability of realizing large-scale production, and the prepared CF / PEEK composite material can replace metal to be applied to the fields of aerospace, medical treatment, machinery, automobiles, rail transit and the like.

Owner:DONGHUA UNIV

Rolling pressure roller of electrolytic copper foil all-in-one machine

The invention discloses a rolling pressure roller of an electrolytic copper foil all-in-one machine. The rolling pressure roller comprises a base frame and a first gas cylinder arranged on the base frame, wherein a piston rod of the first gas cylinder is connected with one end shaft of a pressure rod arm; the other end shaft of the pressure rod arm is connected with the rolling pressure roller which is in contact with a rolling shaft; piston rods at the two ends of a second gas cylinder are separately connected to the base frame and the pressure rod arm; and a sensor and a meter counter whichare connected to a controller are separately arranged on the first gas cylinder and the rolling pressure roller. According to the rolling pressure roller disclosed by the invention, copper foil related parameters are input to a control panel, so that the pressure roller continuously and constantly gives force of a constant size and a constant angle to the rolled copper foil in a rolling process, and rolling pressure of the copper foil is not changed even a rolling diameter of the copper foil changes, and therefore, the uniform and stable rolling purpose is achieved. The rolling pressure rolleris convenient in setting, can guarantee that the copper foil rolls with relatively great rolling tension in case of gradually reducing an electrolytic copper foil, and avoids the occurrence of a rolling layering condition.

Owner:XIAN TAIJIN NEW ENERGY & MATERIALS SCI TECH CO LTD

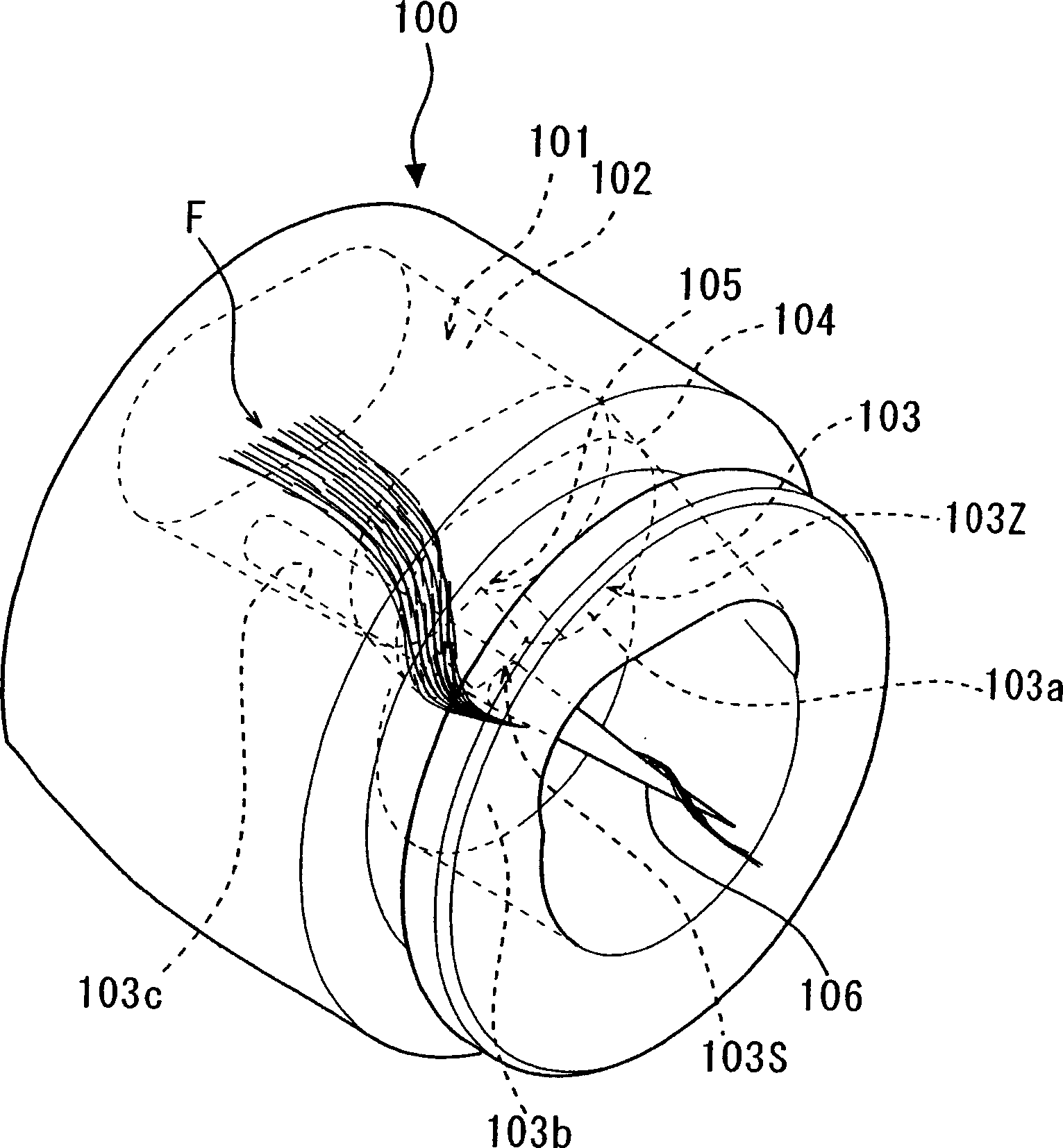

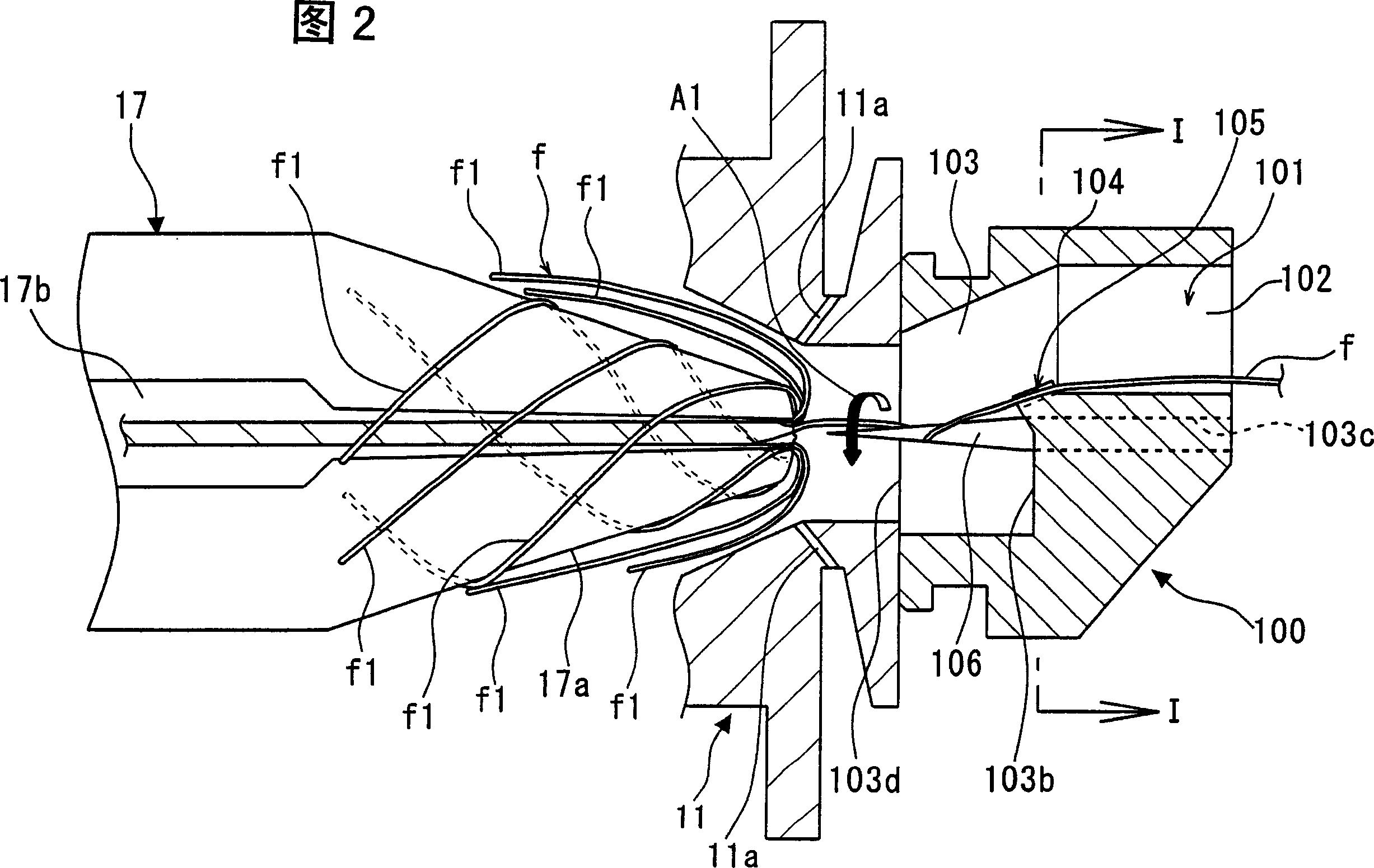

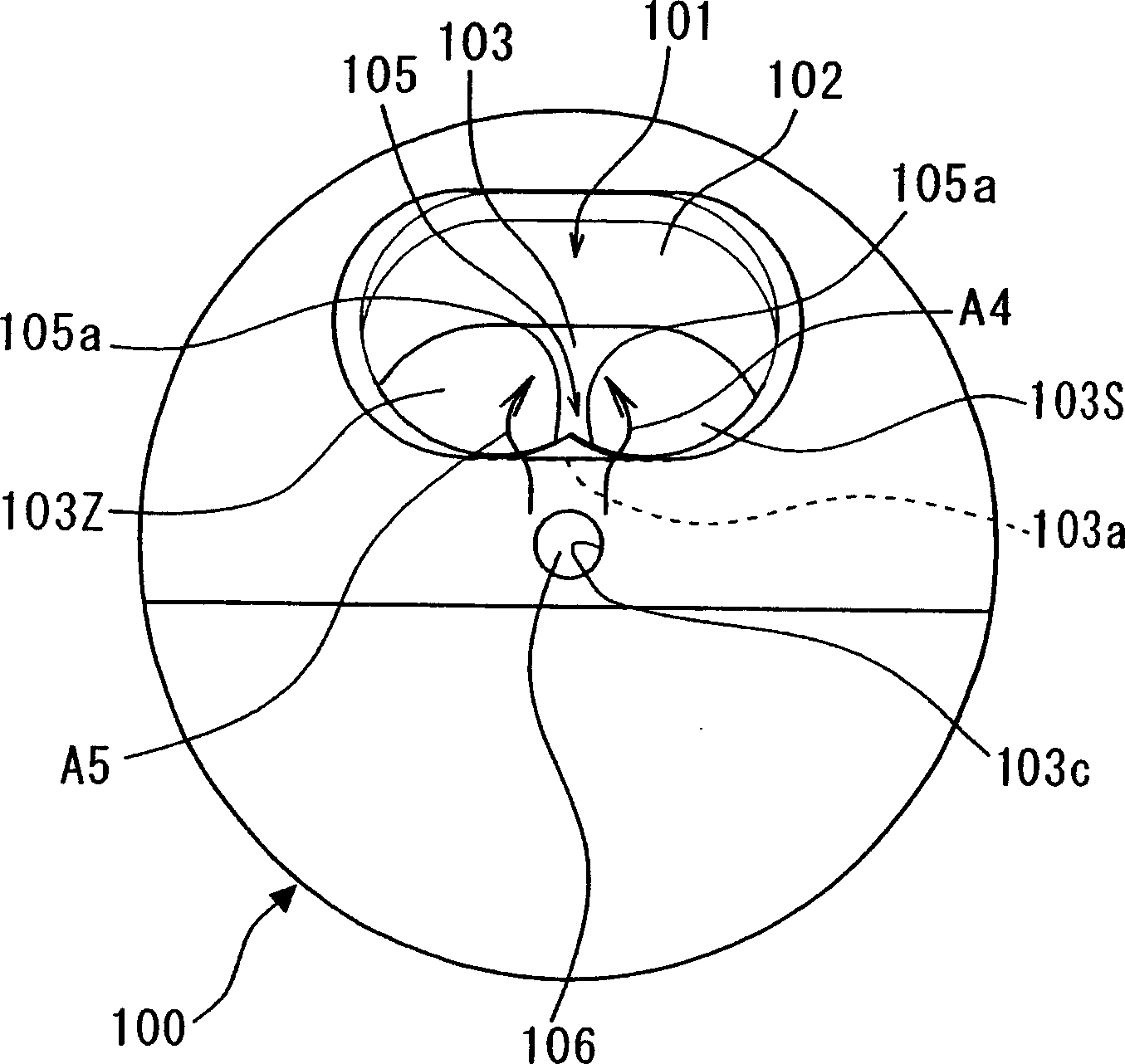

Spinning machine

ActiveCN1603481AImprove operabilitySmooth goingContinuous wound-up machinesOpen-end spinning machinesInjection airFiber

A spinning machine in which a spinning member is disposed, the spinning member having a nozzle block 11 in which air injection holes are drilled, a hollow guide shaft 17, a fiber introduction hole 101 opened at a tip side of the hollow guide shaft 17, and a fiber guide member 106 that guides fibers to the tip of the hollow guide shaft 17, wherein, first, a separating projecting portion 105 is formed in a fiber contact surface of the fiber introduction hole 101 to define a plurality of passages 103S, 103Z having different fiber introduction directions with respect to said fiber guide member 106 (Fig 2).

Owner:MURATA MASCH LTD

String binding machine

ActiveCN112278965AEasy to transportImprove work efficiencyFinal product manufactureArticle deliveryEngineeringMachine

The invention belongs to the technical field of packing string packing machines, and particularly relates to a string binding machine which comprises a rack, and a string storage mechanism, a loopingmechanism, a tightening mechanism, a fusion welding mechanism and a string shearing mechanism are arranged on the rack. The looping mechanism comprises a plurality of transmission wheels, a belt assembly and a vacuum device, the belt assembly is wound among the transmission wheels and can transfer a binding string, and the vacuum device adsorbs the string on the surface of the belt assembly. The looping mechanism comprises a string guide frame assembly, the string guide frame assembly at least comprises a movable covering part, the covering part has a working position and an opening position,and in the forward conveying process of the string, the covering part is located at the working position and at least covers part of a rail. In the backward tightening process of the string, the covering part is located at the opening position and does not cover the rail so that the string can be separated from the rail. According to the string binding machine, string storage, looping, fusion welding and string cutting are integrated, adaptive adjustment and mechanical control can be carried out on a string conveying channel, the working efficiency is high, the labor cost is reduced, and safety and convenience are achieved.

Owner:TAIZHOU XUTIAN PACKAGING MACHINERY

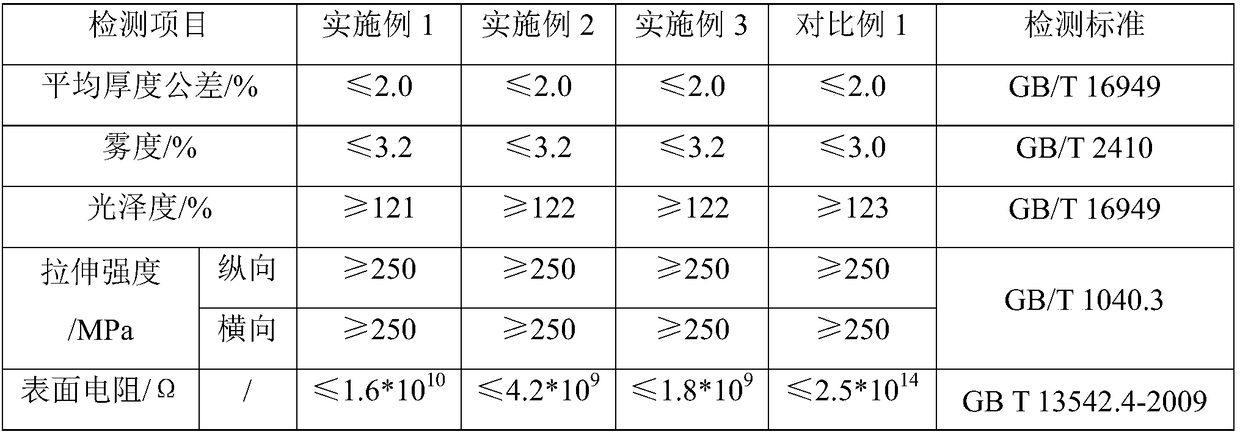

Biaxially-oriented polyester film and preparation method thereof

InactiveCN109016768AImprove antistatic performanceGuaranteed normal windingSynthetic resin layered productsDomestic articlesPolyesterMasterbatch

The invention discloses a biaxially-oriented polyester film, which is composed of an upper surface layer, a core layer and a lower surface layer, wherein the middle core layer is composed of polyesterchips; the upper surface layer is an anti-stick layer, and is composed of a glass microbead anti-stick masterbatch and the polyester chips; the lower surface layer is an antistatic layer composed ofan antistatic masterbatch and the polyester chips. The biaxially-oriented polyester film adopts single-sided antistatic treatment, compared with a conventional film coated with a surface antistatic layer, the biaxially-oriented polyester film is less affected by environmental humidity and has a long antistatic effect; in addition, the small particle size glass microbead anti-stick masterbatch is used to reduce the haze of the film and improve the optical properties of the film under the condition of ensuring the normal winding of the film.

Owner:ANHUI GUOFENG PLASTIC

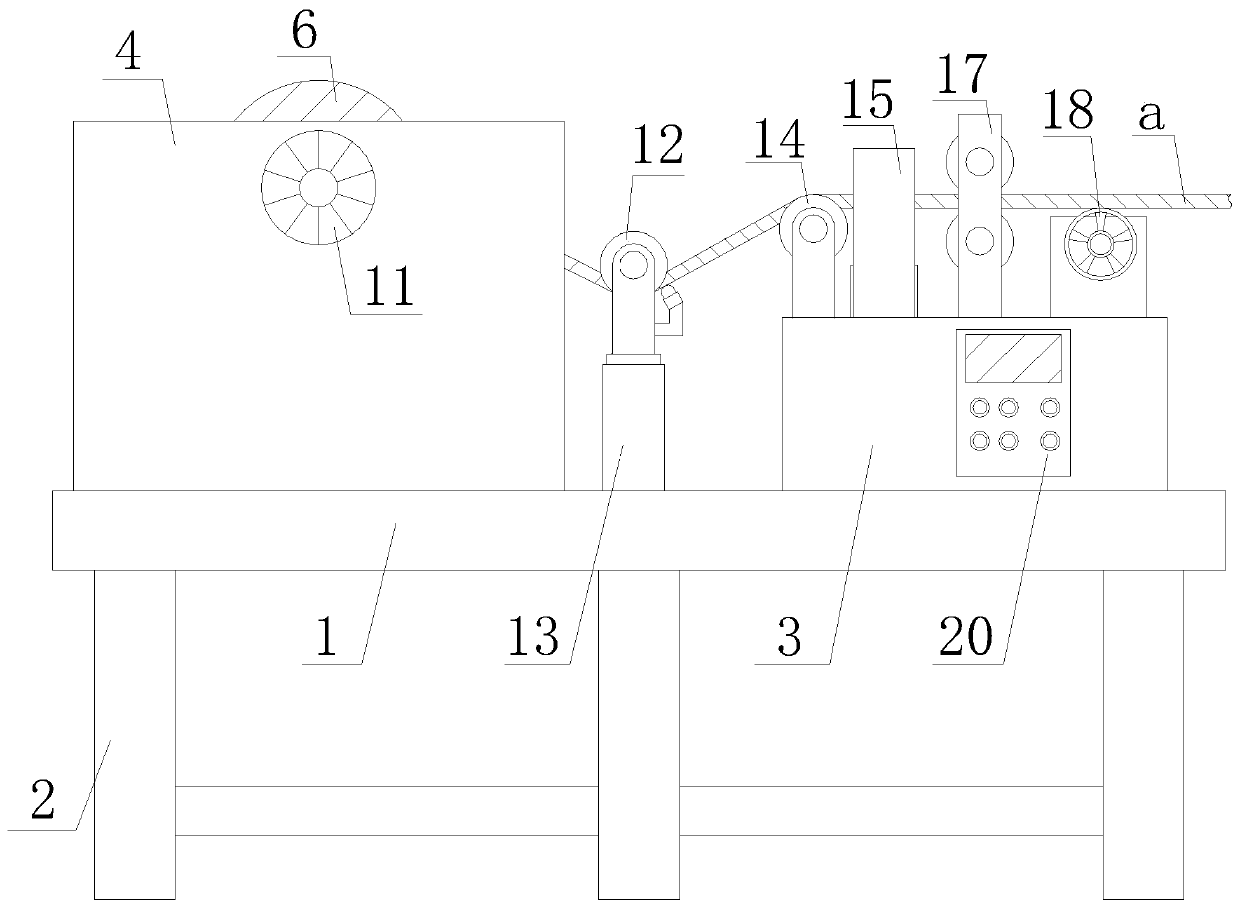

Traction coiling device for cable processing

The invention relates to the cable processing device technology field, and provides a traction coiling device for cable processing. The traction coiling device for the cable processing aims at solvingthe problems that 1) the standard coiled length of a cable cannot be accurately controlled; 2) in the coiling process of the cable, processing personnel need to pay attention to coiling progress at any moment, and a labor load is huge; and 3) after cable coiling is completed, the cable is inconvenient to fetch from the device, and coiling efficiency of the cable is influenced in a traditional electric coiling device. The traction coiling device for the cable processing comprises a processing platform and a plurality of support feet installed at the lower end of the processing platform, and further comprises a cable bundling cylinder, a tensioning assembly and a length counter, wherein a coiling shaft is inserted into the middle of the cable bundling cylinder, the front end of the coilingshaft runs through the side wall of a fixed plate and is installed at an output end of a first drive motor, the rear end of the coiling shaft is inserted into the side wall of a moving plate, and a cable dismounting mechanism is installed at the lower end of the moving plate. The traction coiling device for the cable processing is particularly suitable for semi-automatic coiling in the coil processing, and has high social use value and wide application prospects.

Owner:ANHUI CABLE

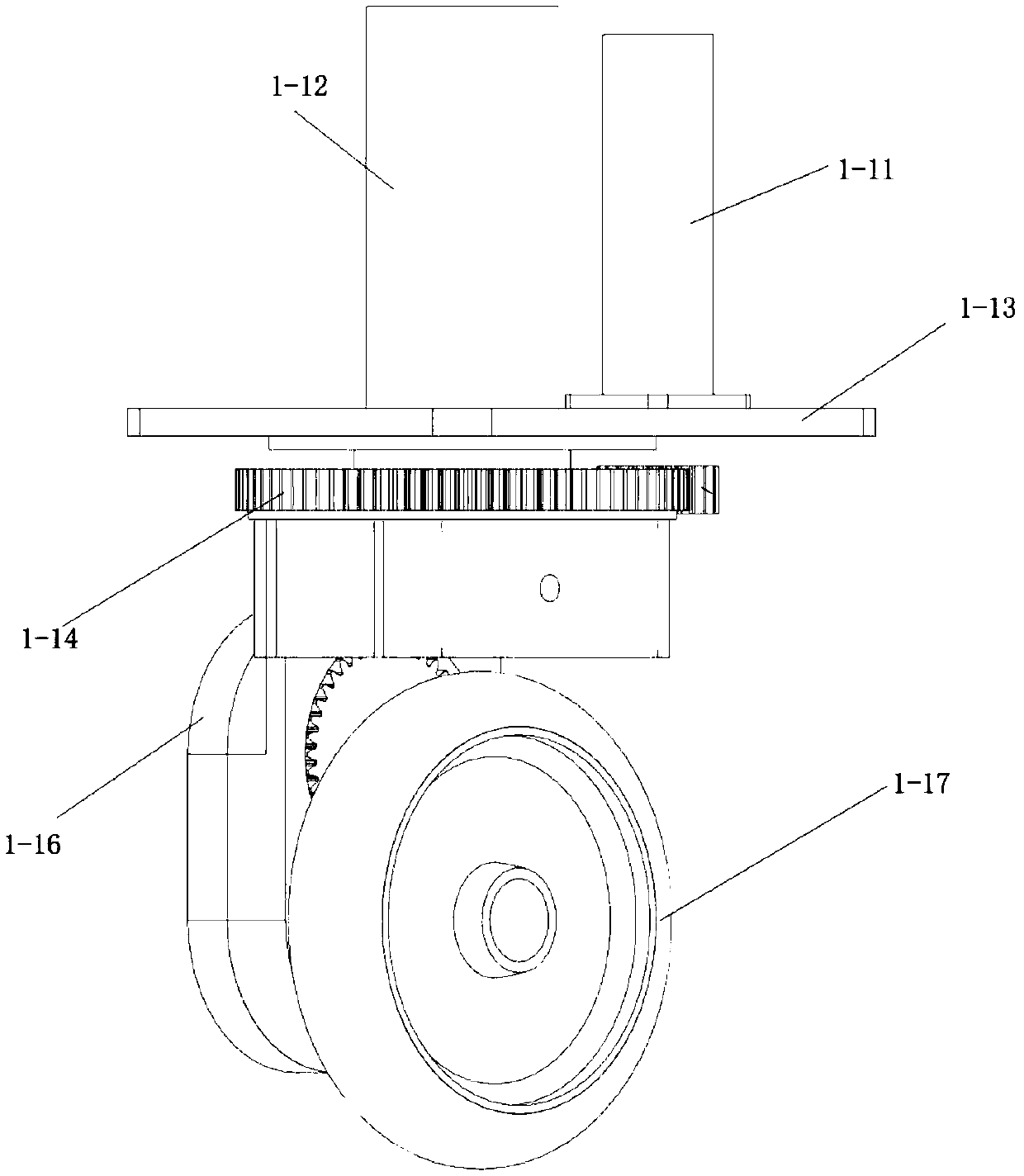

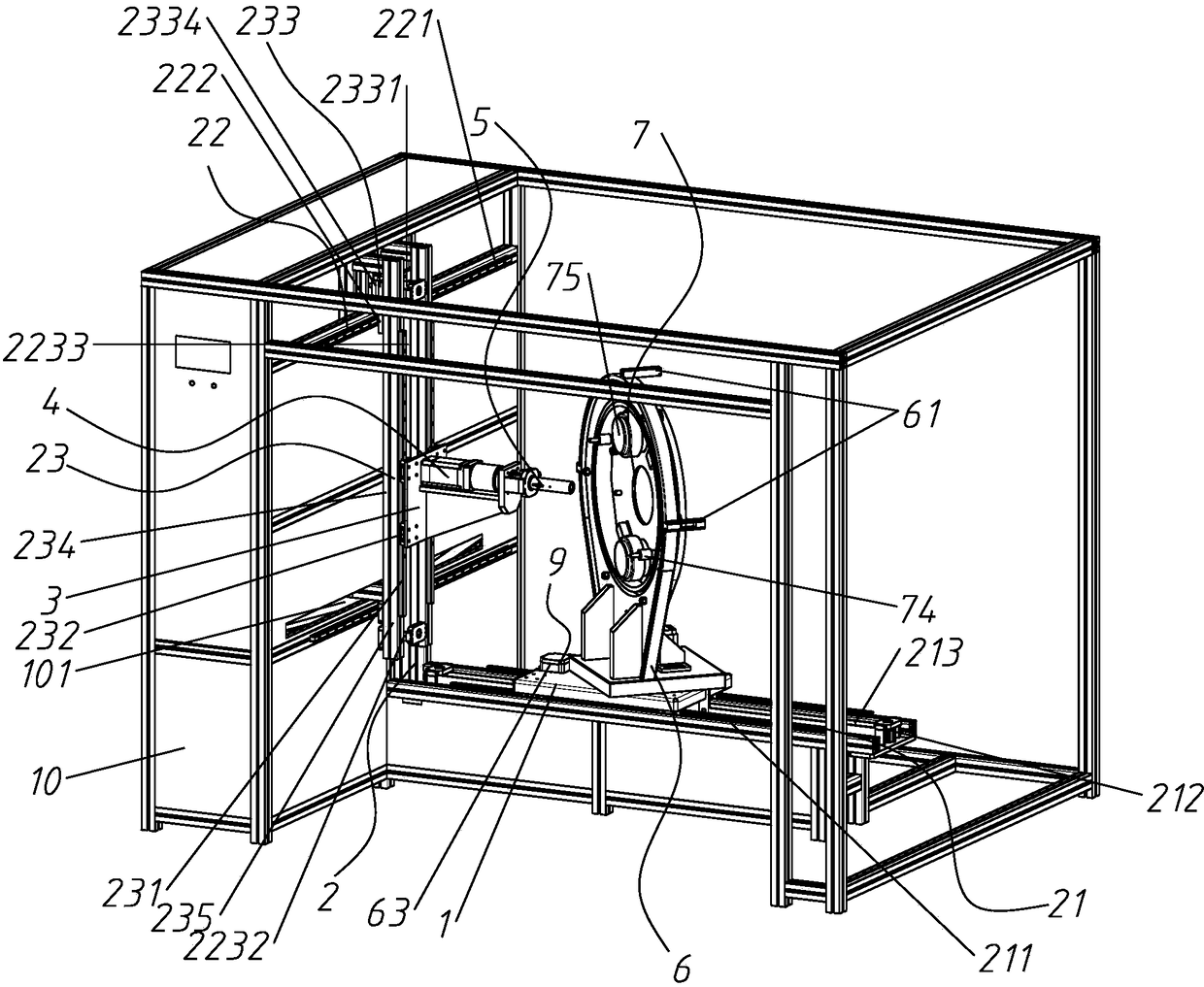

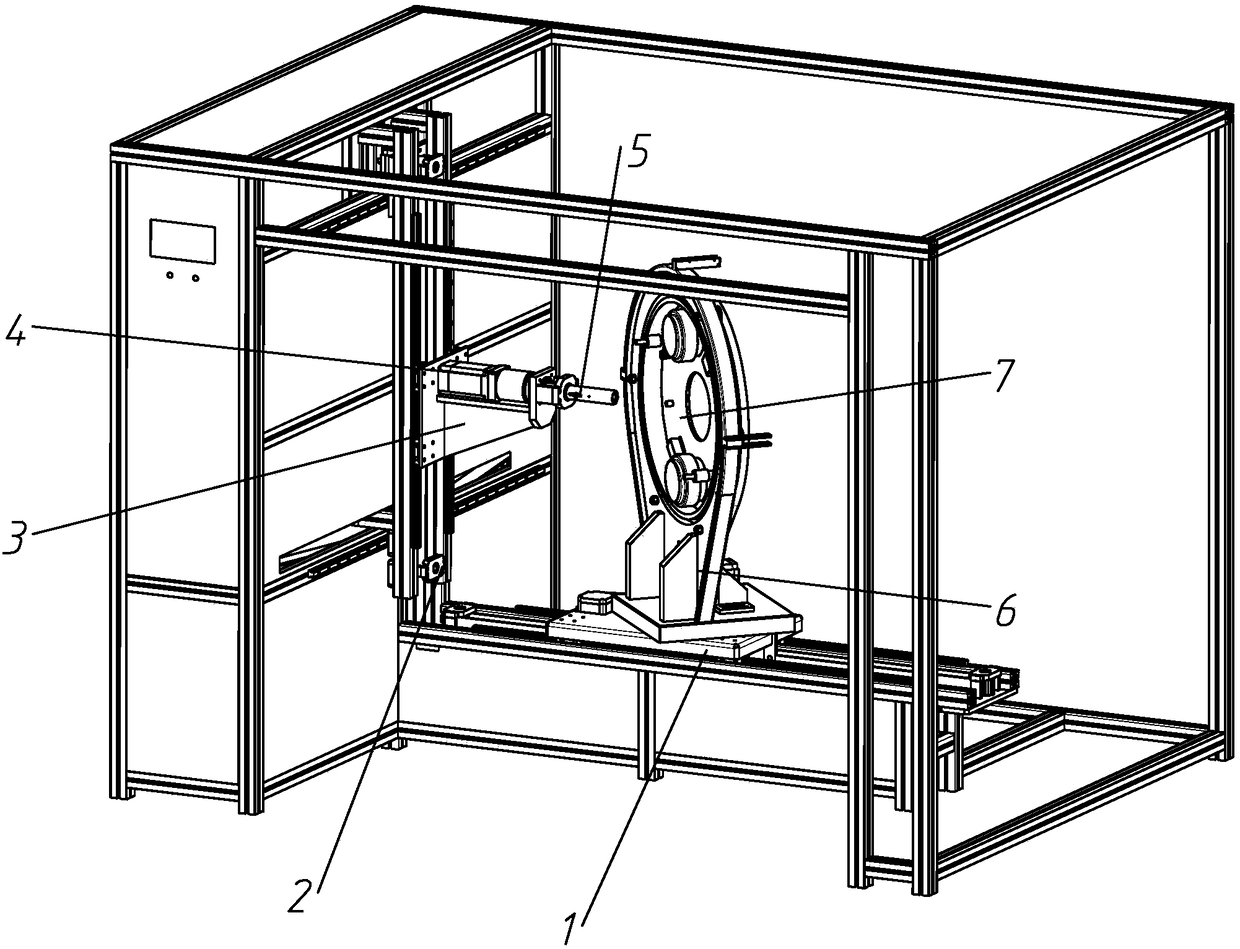

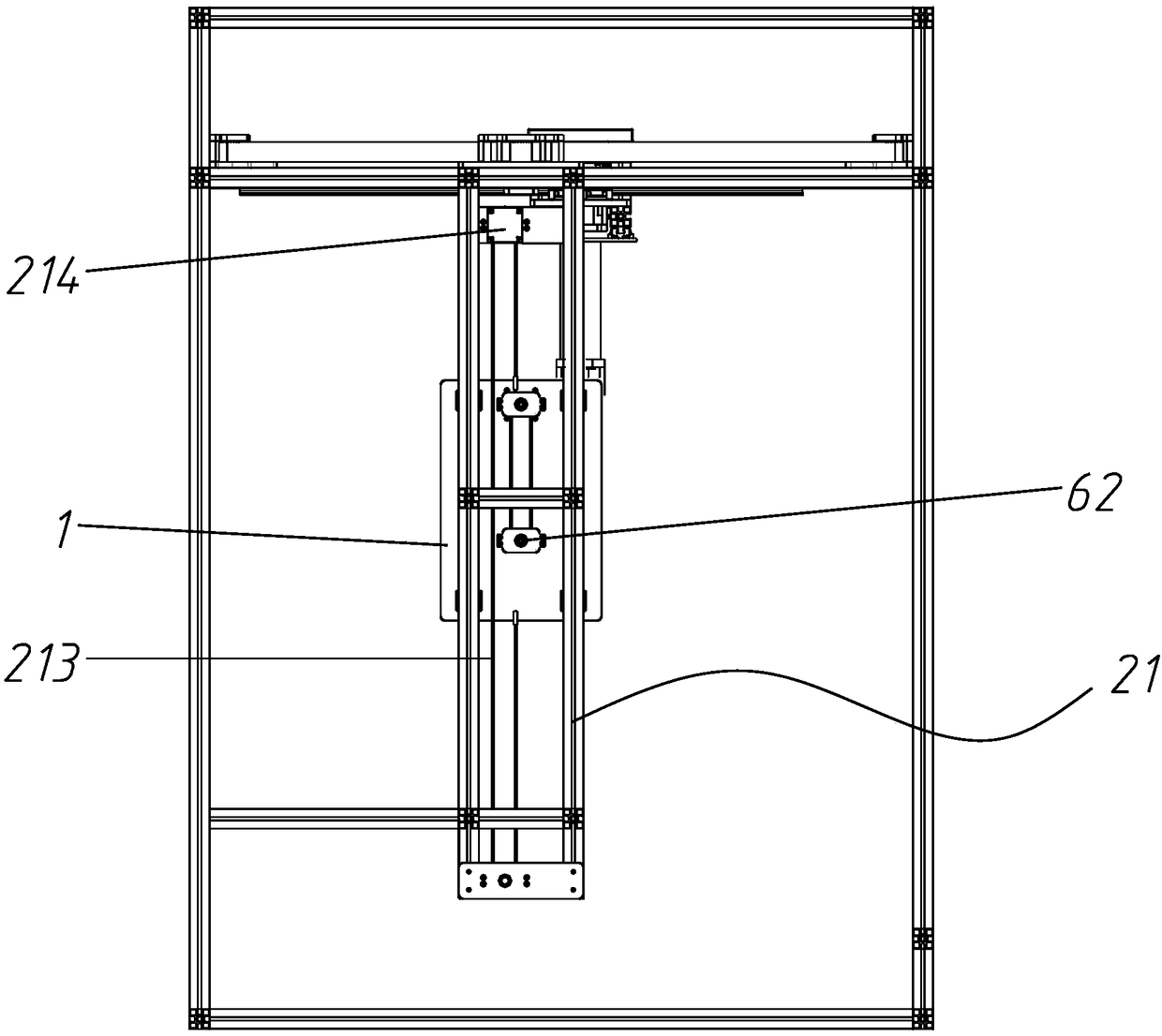

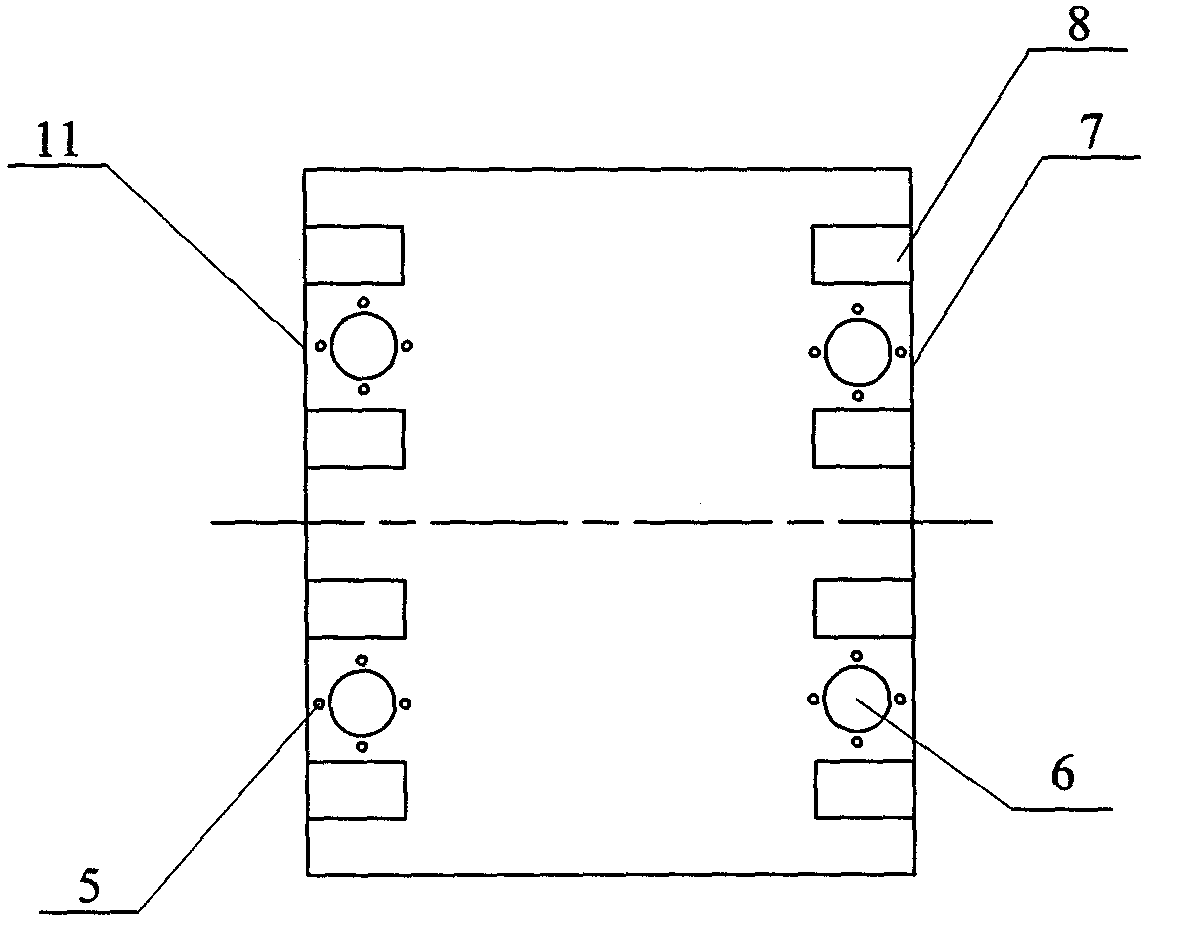

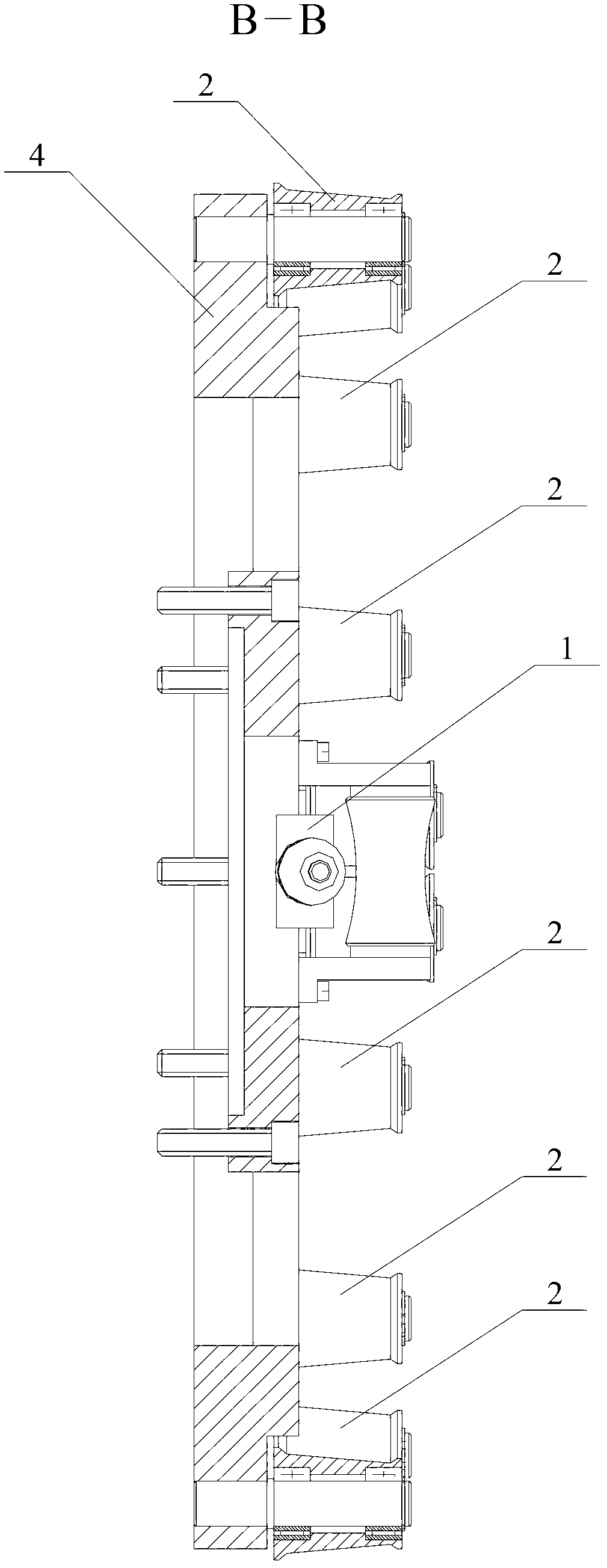

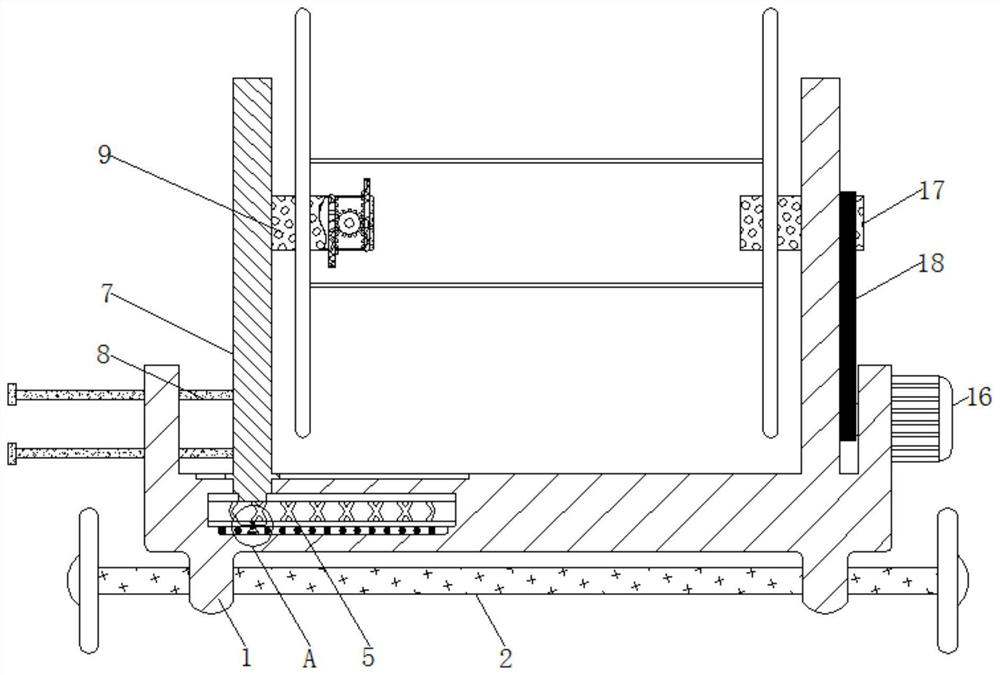

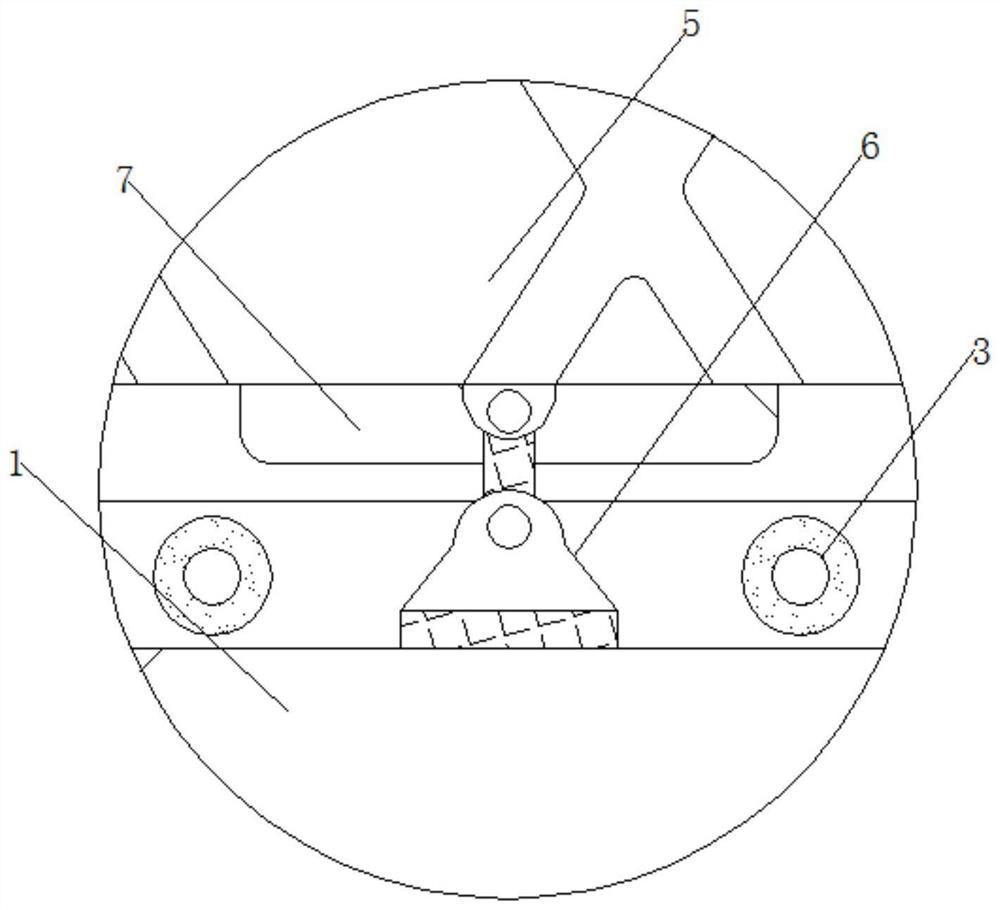

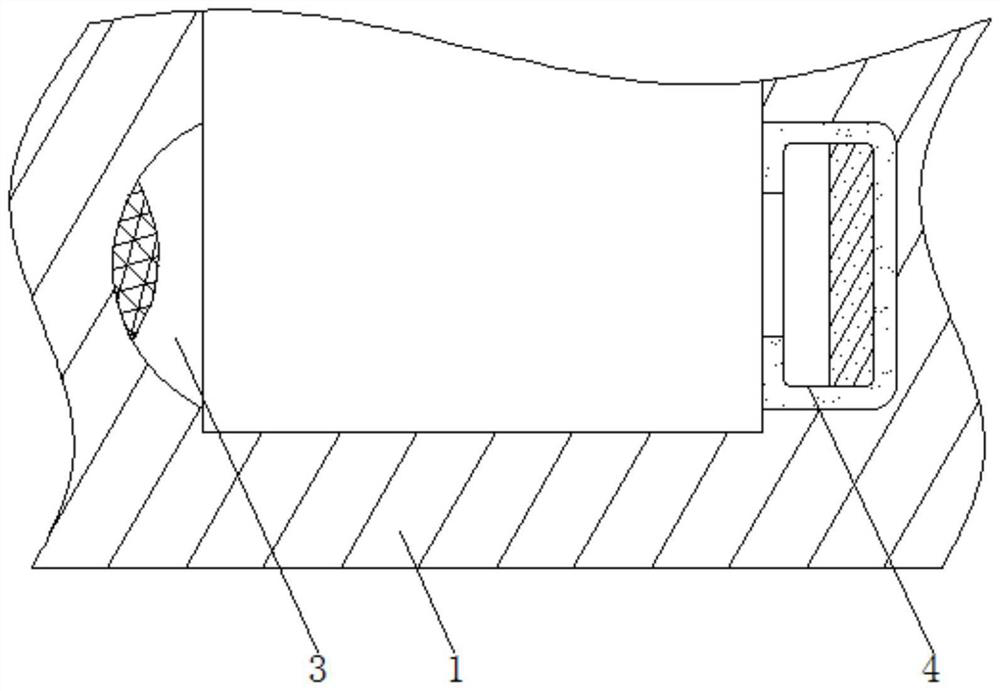

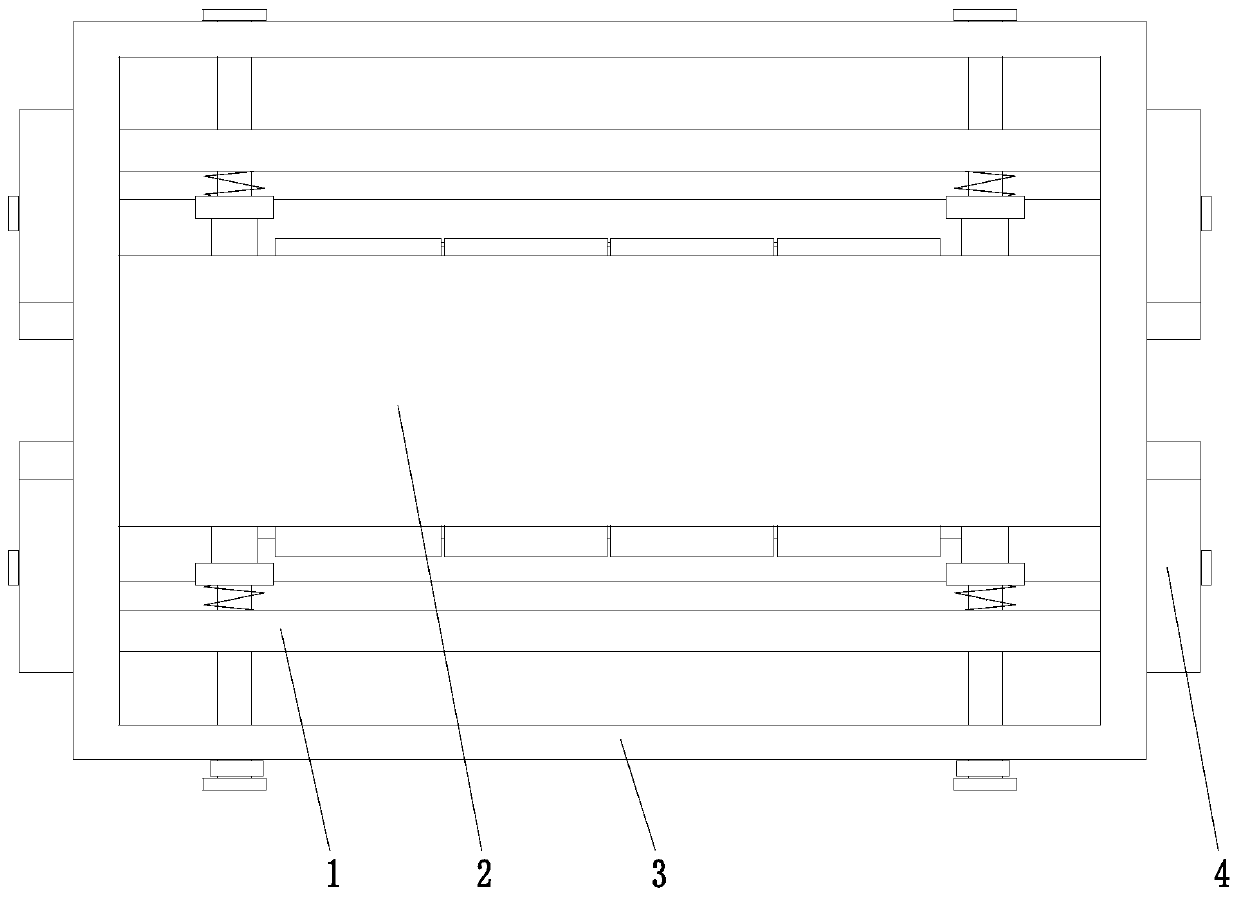

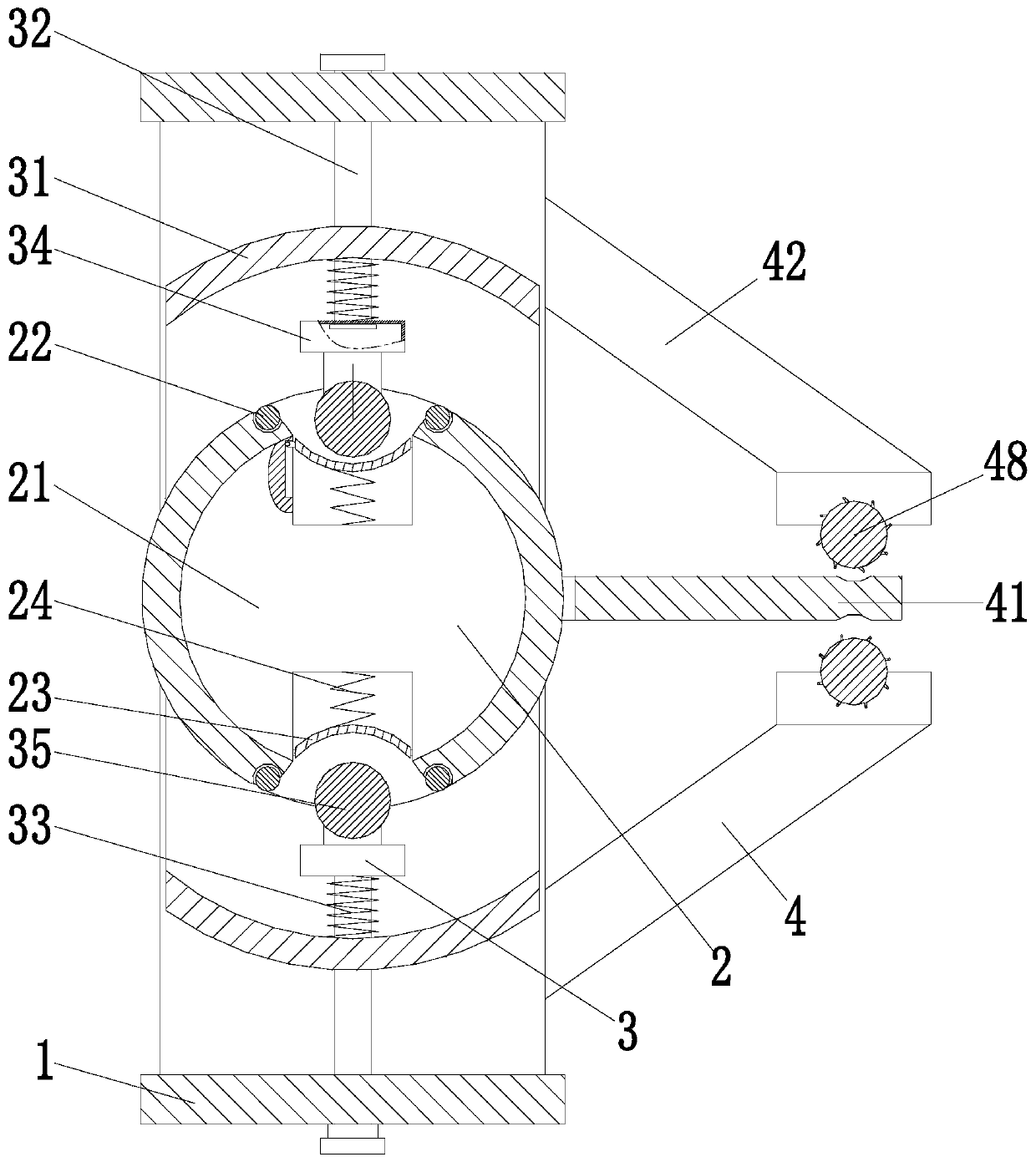

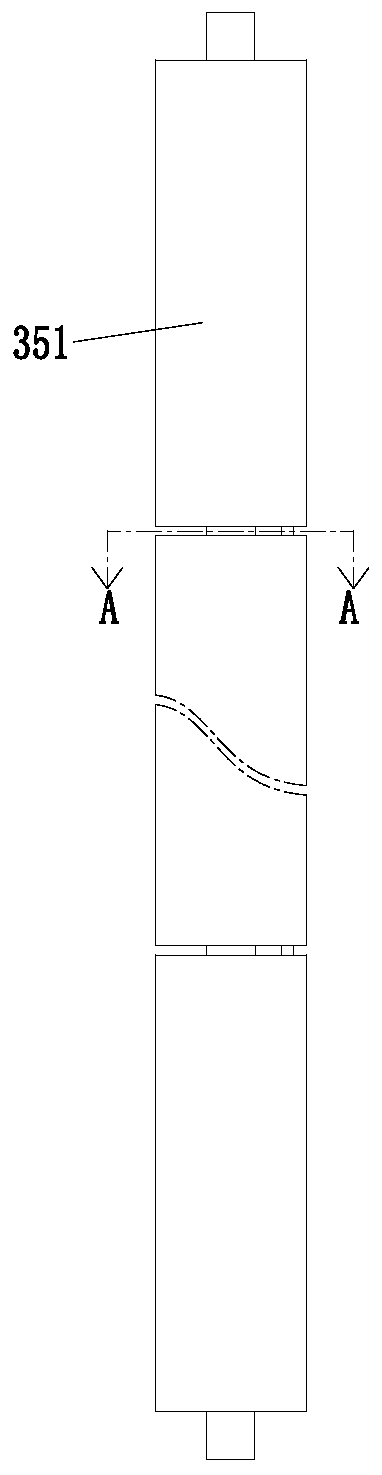

Multi-axis linkage winding machine for wrapping irregular pipe body

ActiveCN108423220AGuaranteed normal windingGuaranteed wrappingWrapping with article rotationWinding machineMulti axis

The invention belongs to the technical field of a winding machine, and provides a multi-axis linkage winding machine for wrapping an irregular pipe body. The multi-shaft linked winding machine comprises a foundation support, wherein the foundation support is connected with a clamping support by virtue of a moving apparatus, the clamping support makes the translation movement in a three-dimensionalspace relative to the foundation support by virtue of the moving apparatus, the clamping support is provided with a clamping portion in a rotating manner by virtue of a rotating apparatus I, the foundation support is provided with a winding frame in a rotating manner by virtue of a rotating apparatus II, a rotating shaft of the winding frame is perpendicular to a rotating shaft of the clamping support, the winding frame is provided with a winding disc in a rotating manner, and the winding disc is provided with a supporting apparatus for supporting a wound strip coil. By virtue of the technical scheme, the technical problems in the prior art that no winding machine for winding the irregular tubular article is provided can be solved.

Owner:河北海赞自动化科技有限公司

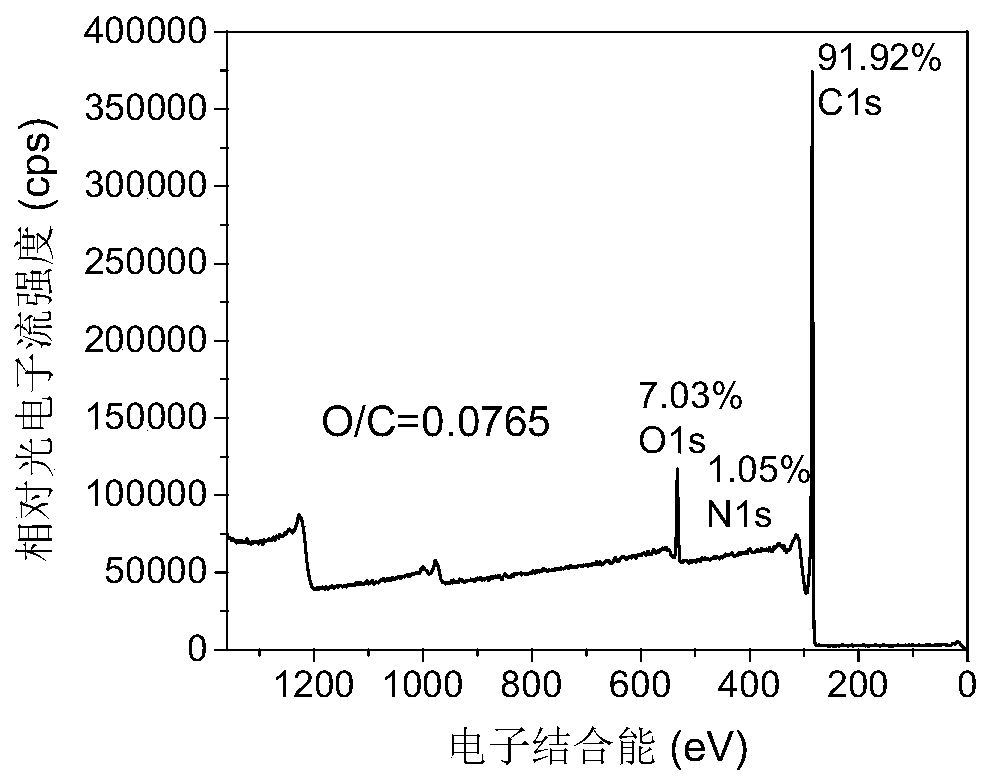

CF/PEEK composite material with excellent high-temperature mechanical properties and preparation method thereof

ActiveCN111410759APossibility of industrial scale productionGuaranteed normal windingMeth-Flexural modulus

The invention relates to a CF / PEEK composite material with excellent high-temperature mechanical properties and a preparation method of the CF / PEEK composite material. The preparation method comprisesthe following steps: (1) carrying out high-temperature decomposition on an original sizing agent on the surface of CF; (2) simultaneously carrying out microwave radiation and ultraviolet irradiationon CF in a saturated water vapor environment, and marking a product as ACF; (3) immersing ACF into the polyamic acid / N-methyl-2-pyrrolidone / carbon nanotube suspension, taking out, drying, and carryingout two-stage heat treatment to obtain sized modified carbon fiber MCF; (4) laminating and hot-pressing the MCF and the PEEK material; wherein the bending strength of the CF / PEEK composite material at 25 DEG C is 780-950 MPa, the bending modulus of the CF / PEEK composite material at 25 DEG C is 55-65 GPa, and the interlayer shear strength of the CF / PEEK composite material at 25 DEG C is 80-93 MPa;the bending strength at 200 DEG C is 550 to 650 MPa, the bending modulus is 40 to 50 GPa, and the interlaminar shear strength is 60 to 75 MPa. The method disclosed by the invention has the characteristics of high efficiency, environmental friendliness and capability of realizing large-scale production, and the prepared composite material can replace metal to be applied to the fields of aerospace,medical treatment, machinery, automobiles and the like.

Owner:常州君航高性能复合材料有限公司

Automatic deviation correction device

InactiveCN105947758AImprove stabilityHigh accuracy of deviation correctionFunction indicatorsWebs handlingMechanical engineeringEngineering

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Device for preventing redundant robot wiring from winding and extruding

InactiveCN101633174AGuaranteed normal windingGuaranteed SqueezeManipulatorConductor CoilCable carrier

The invention discloses a device for preventing redundant robot wiring from winding and extruding, which comprises a partition bracket, a plurality of distressing pieces and a dragging chain bracket, wherein the distressing pieces are connected with the partition bracket; the partition bracket is connected with the dragging chain bracket; and the dragging chain bracket and a cable dragging chain are separately installed. The distressing pieces form a multilayer wiring guide device so that the wiring of a plurality of cables prevents mutual winding and extrusion; and the invention has simple structure and high applicability and can be matched with the dragging chain to ensure the smooth motion of the cables.

Owner:TSINGHUA UNIV +1

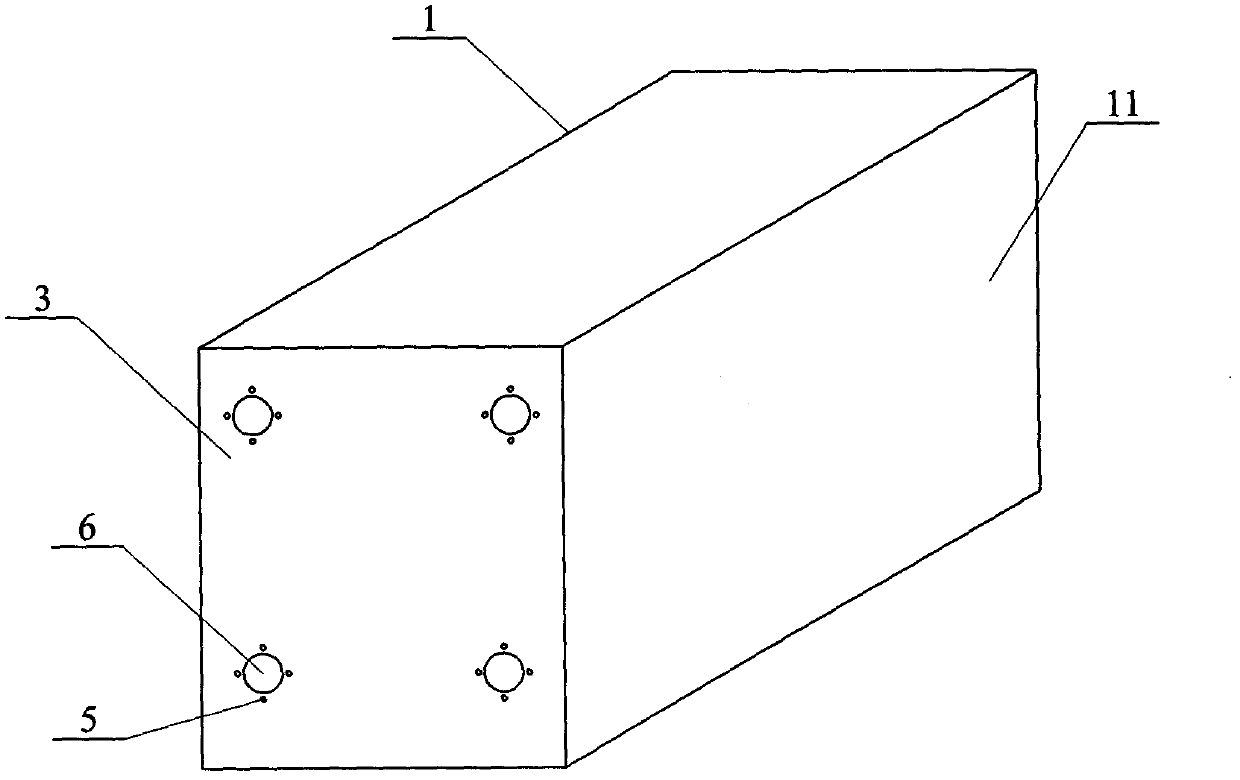

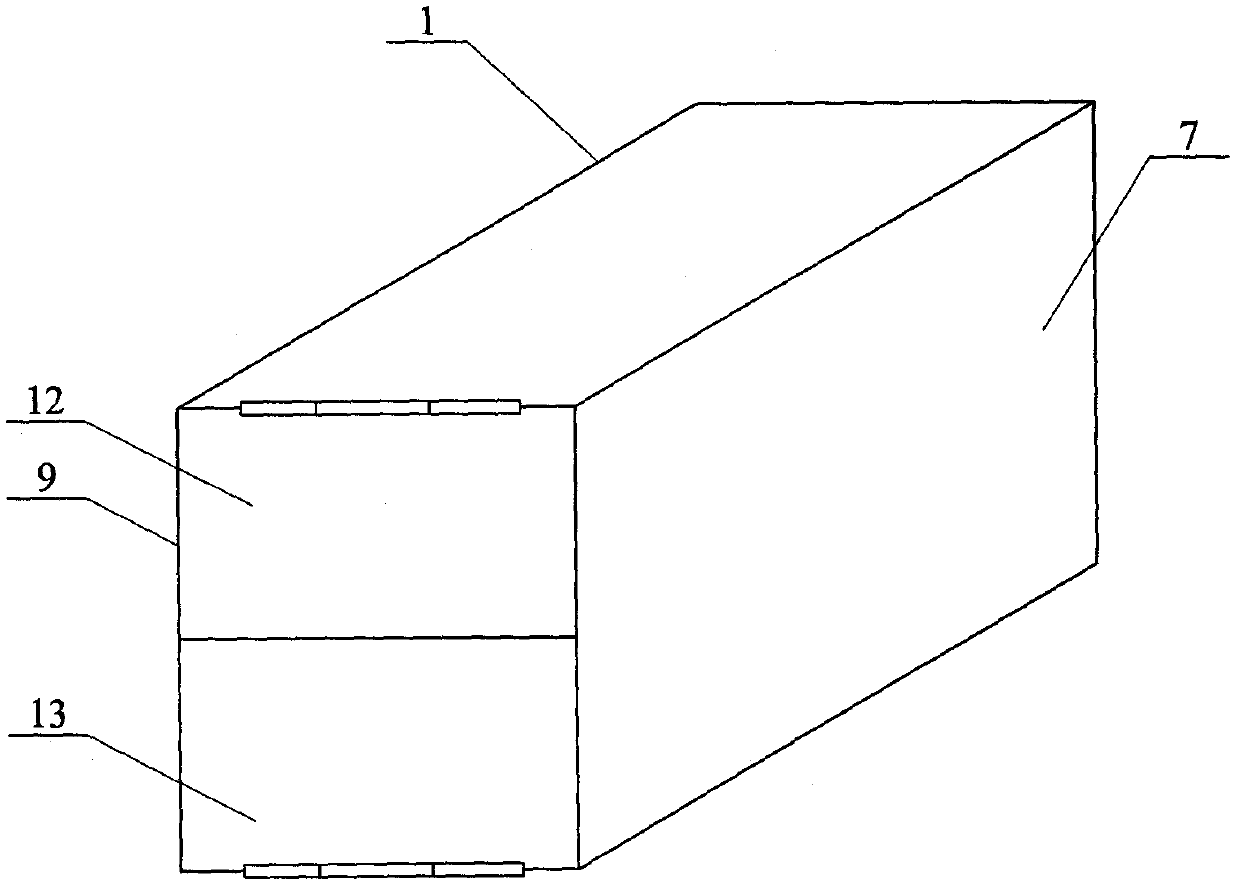

Unfolding control device for three-dimensional inflatable unfolding truss structure

InactiveCN102381491AGuaranteed non-interferenceGuaranteed normal windingArtificial satellitesLeaf springCivil engineering

The invention provides an unfolding control device for a three-dimensional inflatable unfolding truss structure, which relates to the unfolding control device for a three-dimensional truss structure and solves the problem that no unfolding control device for the three-dimensional truss structure exists so far. A back sidewall of a folding loading box is a fixed end of an inflatable unfolding truss; four columns of leaf spring arrays are mounted on the inside surface of a left sidewall of the folding loading box and the inside surface of a right sidewall of the folding loading box respectively; each column of the leaf spring arrays consists of a plurality of rectangular leaf springs; both the rectangular leaf springs of the four columns of the leaf spring arrays mounted on the inside surface of the left sidewall of the folding loading box and the rectangular leaf springs of the four columns of the leaf spring arrays mounted on the inside surface of the right sidewall are respectively distributed along an unfolding direction of the folding loading box; intervals are retained between the rectangular leaf springs in each column of the leaf spring arrays which are adjacent to a box cover of the folding loading box and the box cover of the folding loading box; and an upper-section box cover and a lower-section box cover are hinged with the upper end face and the lower end face of the folding loading box. The unfolding control device is used for controlling the three-dimensional inflatable unfolding truss structure to orderly unfold.

Owner:HARBIN INST OF TECH

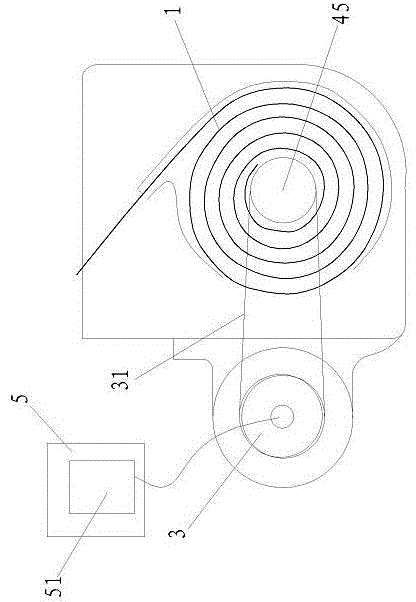

Selectable electronic product wire arrangement device

InactiveCN108675059ARealize disassemblyGuaranteed normal windingEngineeringElectrical and Electronics engineering

The invention discloses a selectable electronic product wire arrangement device. The device comprises a product body and an electric wire; the electric wire is fixedly positioned on the product body;a wire arrangement device is movably installed on a body outside the wire; the wire arrangement device comprises a first wire arrangement device housing and a second wire arrangement device housing; the inner ends of the first wire arrangement device housing and the second wire arrangement device housing are fixedly installed on a housing of the product body. When the device is used, the first wire arrangement device housing is first fixed, and the electric wire is wound on a reel; the second wire arrangement housing is then attached to the product body in the same manner; when the wire needsto be stretched, pulling the wire straight out. When the wire is pulled out, the reel is rotated to tighten the scroll spring. The outer end of the wire is clamped between a card board and the inner ring of the line card to prevent the length from being stretched and then retracted. When the wire needs to be shortened, the card plate is directly pulled up, and the wire reel is driven to rotate inthe opposite direction under the action of the spring force of the scroll spring, thereby winding the wire.

Owner:MINNAN INST OF SCI & TECH

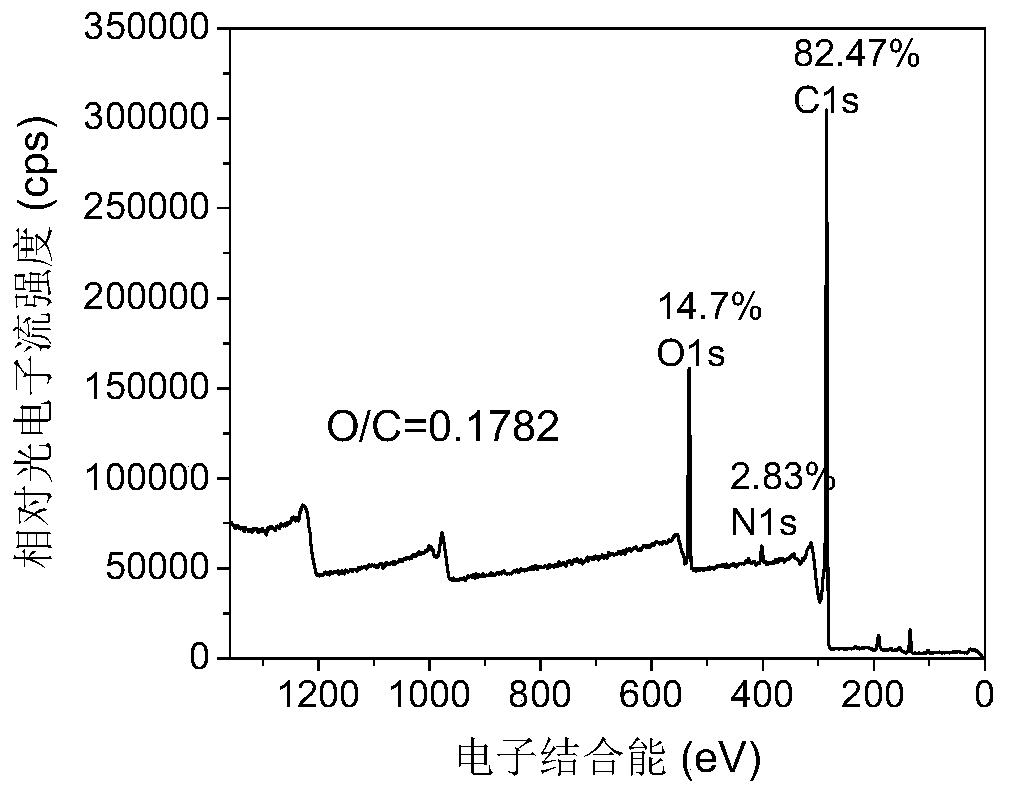

High-impact interface modified CF/PEEK composite material and preparation method thereof

The invention relates to a high-impact interface modified CF / PEEK composite material and a preparation method thereof. The preparation method comprises the following steps: (1) carrying out high-temperature decomposition on an original sizing agent on the surface of CF; (2) simultaneously carrying out microwave radiation and ultraviolet irradiation on CF in a saturated water vapor environment, andmarking a product as ACF; (3) immersing ACF into a polyarylsulfone (PSF) / N, N-dimethylacetamide solution, taking out, and drying to obtain sized modified carbon fiber MCF; (4) laminating and hot-pressing the MCF and the PEEK material to obtain the high-impact-resistance interface modified CF / PEEK composite material. The bending strength of the high-impact interface modified CF / PEEK composite material ranges from 700 MPa to 950 MPa, the bending modulus ranges from 50 GPa to 65 GPa, the interlaminar shear strength (ILSS) ranges from 75 MPa to 90 MPa, and the residual compression strength (CAI)of the high-impact interface modified CF / PEEK composite material after impact reflecting the impact resistance ranges from 260 MPa to 310 MPa. The method disclosed by the invention has the characteristics of high efficiency, environmental friendliness and capability of realizing large-scale production, and the prepared composite material can replace metal to be applied to the fields of aerospace,medical treatment, machinery, automobiles, rail transit, petroleum transportation and the like.

Owner:DONGHUA UNIV

Machine head clamp for automatic threading machine for producing network transformer magnet iron core coil

ActiveCN111653423APlay a guiding roleGuaranteed normal windingCoils manufactureCopper wireTransformer

The invention relates to a machine head clamp for an automatic threading machine for producing a magnetic iron core coil of a network transformer. The machine head clamp comprises a transverse frame,a top seat, a base and guide assemblies, wherein the top seat is installed at the top of one side of the transverse frame, the base is installed at the top of one side of the transverse frame, an airpressure rod is installed in the middle of the top side of the top seat, and a lifting seat is installed at the telescopic end of the air pressure rod and located below the top seat. According to theinvention, one end of a copper wire is placed between two movable clamping blocks, copper wires with different wire diameters are clamped and fixed through the work of a second servo motor, at the moment, a first servo motor drives a first threaded rod in a first sliding groove to rotate, a sliding seat is driven to move along the first threaded rod, the copper wire penetrates through the space between the top seat and the base, then the air pressure rod on the top seat extends to drive the lifting seat to descend, and the copper wire is limited between the guide assemblies of the top seat andthe base, so that the copper wire can be guided in the subsequent magnet core coil machining process, and it is guaranteed that the copper wire is regularly wound on the magnet core coil.

Owner:GUANGAN HUAXUN ELECTRONICS CO LTD

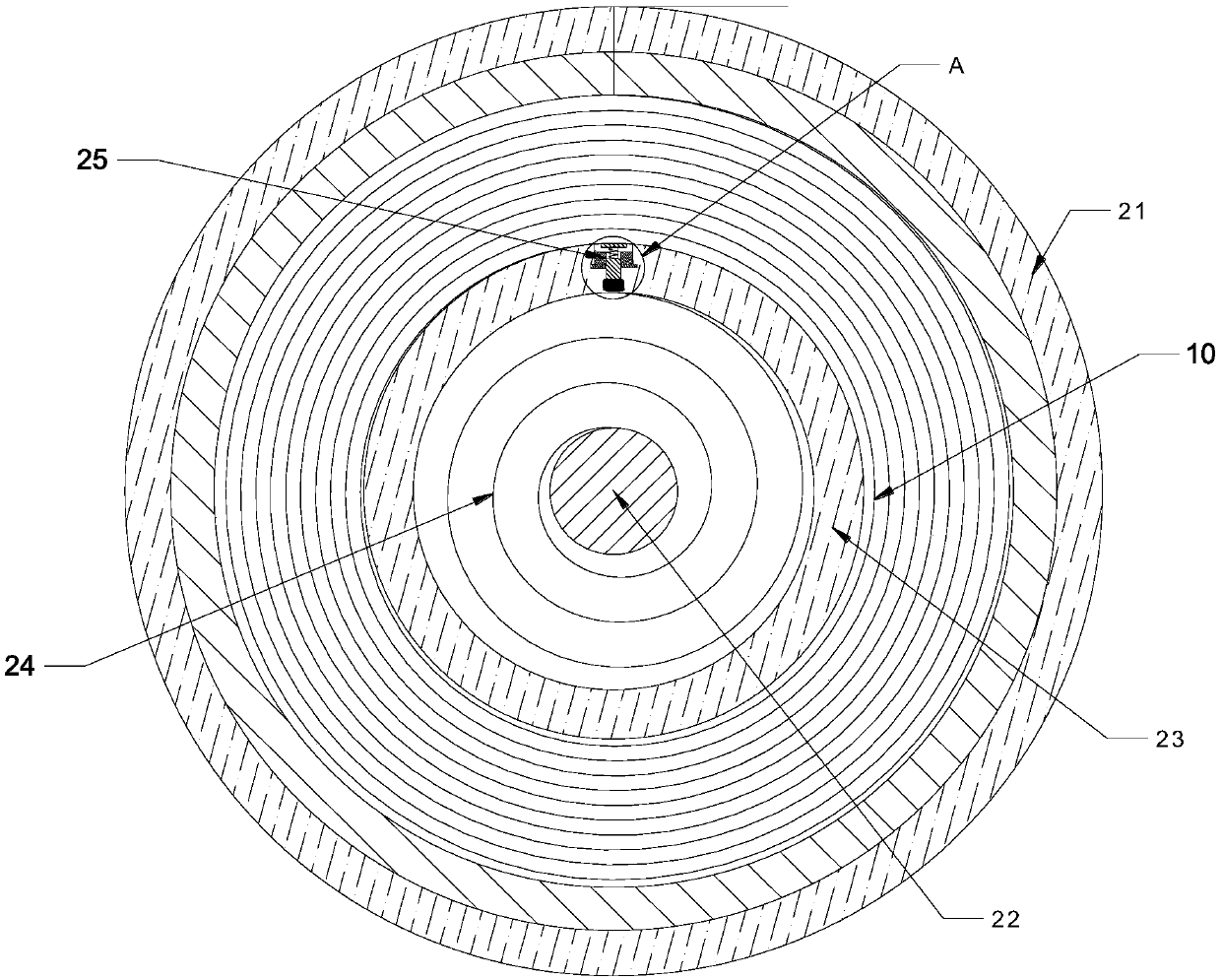

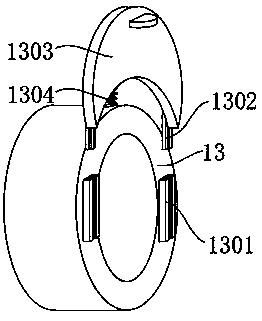

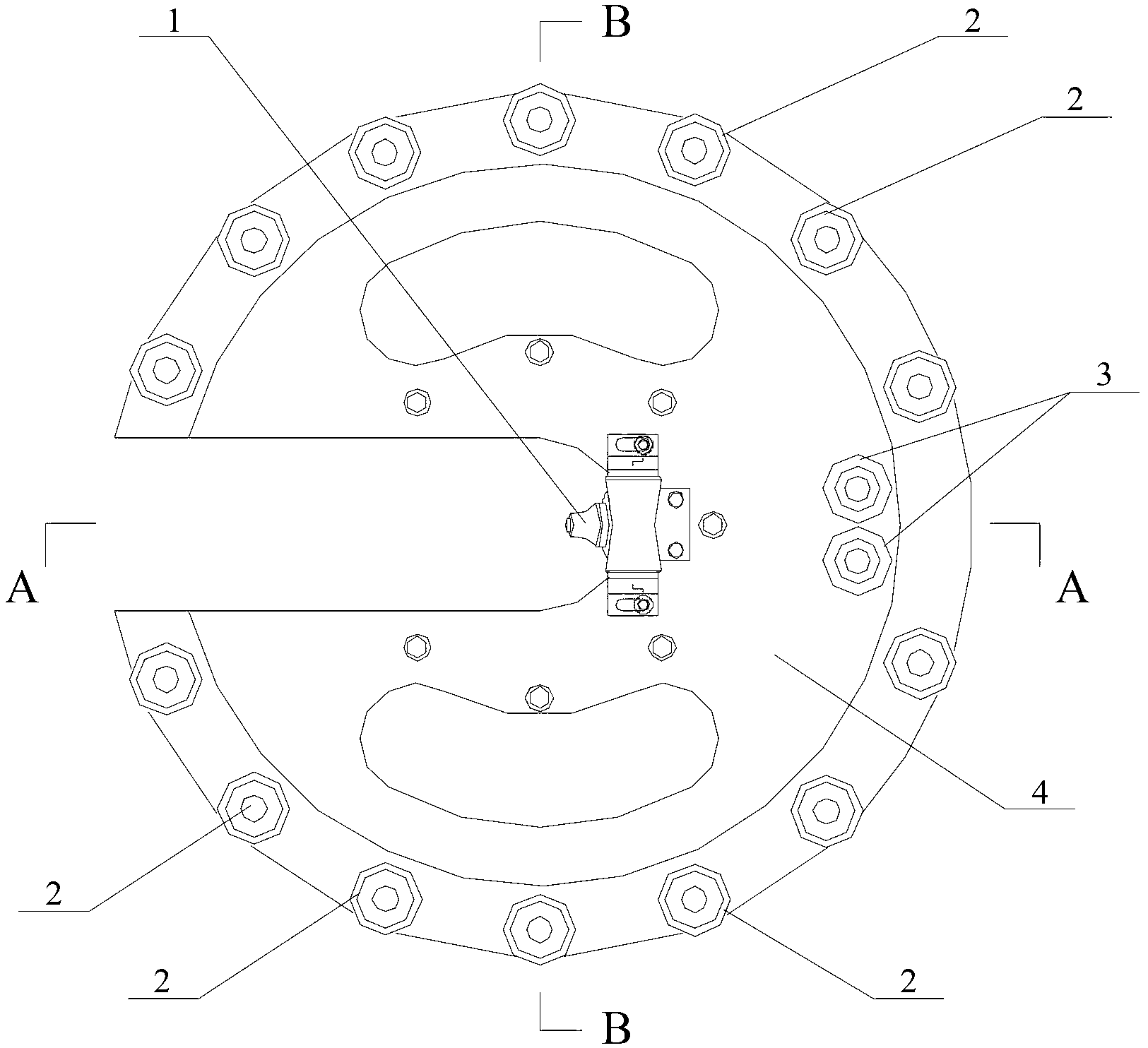

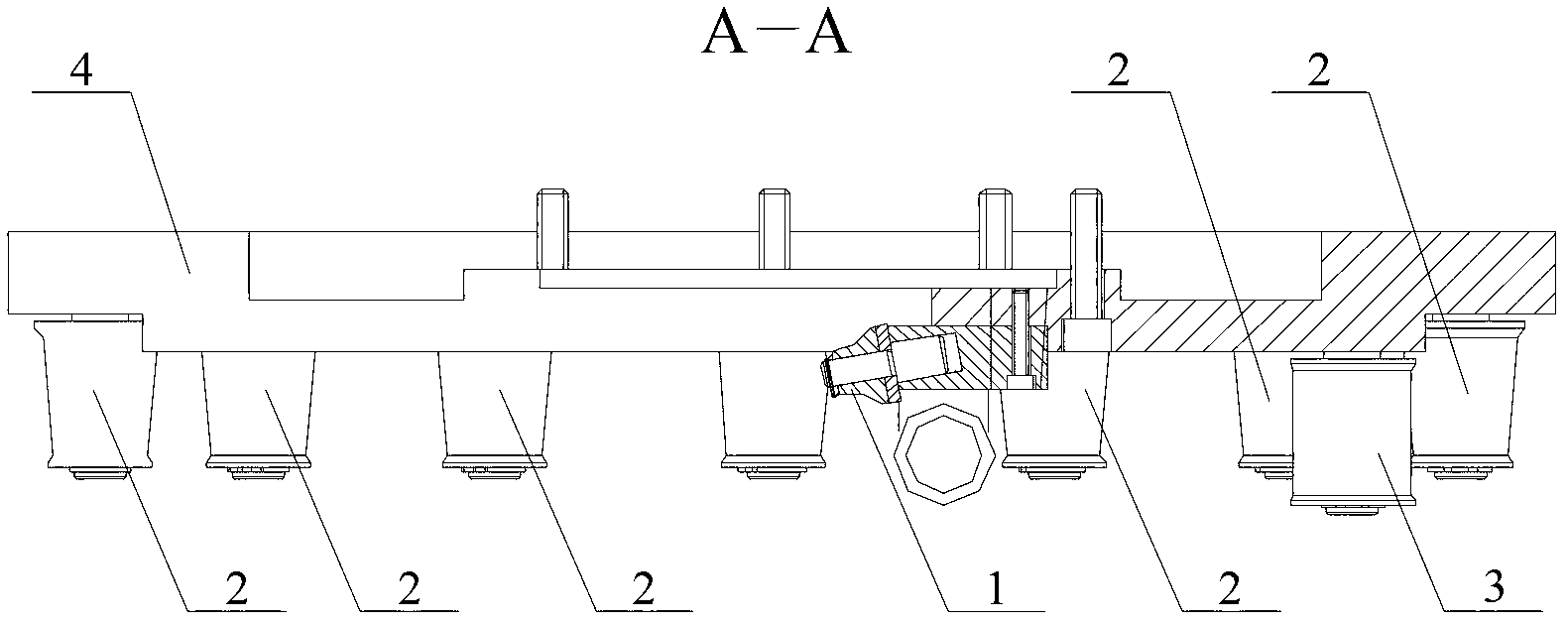

Wire winding disk of aviation tire bead ring winding machine

The invention provides a wire winding disk of an aviation tire bead ring winding machine, belonging to the technical field of bead ring winding disks. The wire winding disk comprises a wire nozzle, winding displacement rolls, two wire guide rolls and a wire winding disk, wherein the wire nozzle is fixed on the center of the wire winding disk, the winding displacement rolls are fixed on the periphery of the wire winding disk, and the two wire guide rolls are fixed on the wire winding disk. The wire winding disk has the beneficial effects that 1, the winding of a large-diameter steel wire can be ensured, the process difficulty of the large-diameter steel wire is overcome; 2, the bending of the large-diameter steel wire is reduced, the plastic deformation of the steel wire is avoided, and thus the guarantee is provided for realizing the high-efficiency winding; and 3, due to the reasonable winding displacement rolls design and the reasonable wire guide roll layout, the process difficulties of few fed wires, multiple supplied wires and large passive pulling tensile force in the process of winding the steel wire are solved, and due to the reasonable design of the wire nozzle, the guide function of spirally winding the steel wire is skillfully realized, and the reverse guide function in the process of winding the steel wire is realized with the positive rotation and the negative rotation of the wire winding disk.

Owner:哈尔滨工大宏图橡塑科技有限公司

Wire and cable winding device based on light sensation control

The invention relates to the technical field of cable installation, and discloses a wire and cable winding device based on light sensation control. The wire and cable winding device comprises a base,the bottom of the base is movably connected with rotating assemblies, the interior of the base is movably connected with lamp beads, the interior of the base is movably connected with photosensitive assemblies, the interior of the base is movably connected with a lead screw, the exterior of the lead screw is movably connected with a connecting rod, the exterior of the connecting rod is movably connected with a sliding plate, and the exterior of the sliding plate is fixedly connected with a limiting rod. Under the mutual effect of the base, the rotating assemblies, the lamp beads, the photosensitive assemblies, the lead screw, the connecting rod, the sliding plate and the limiting rod, the device can control the motion of the sliding plate by controlling the lamp beads corresponding to different specifications of winding reels to light, thus, the device can transversely fix the different specifications of winding reels, and then the device has universal applicability for cable winding;and besides, the arrangement of the rotating assemblies can facilitate the movement of the device.

Owner:GUANGZHOU KAIXIE TECH CO LTD

CF/PPS composite material with high impact toughness and preparation method thereof

The invention relates to a CF / PPS composite material with high impact toughness and a preparation method of the CF / PPS composite material. The preparation method comprises the following steps: (1) carrying out high-temperature decomposition on an original sizing agent on the surface of CF; (2) simultaneously carrying out microwave radiation and ultraviolet irradiation on CF in a saturated water vapor environment, and marking a product as ACF; (3) immersing the ACF into polyether sulfone / dimethylformamide, and drying to obtain sized carbon fiber MCF; (4) laminating and hot-pressing the MCF anda PPS material; (5) cooling to a certain temperature at a rate of 50-70 DEG C / min after hot pressing is finished, applying a certain pressure, maintaining the pressure for a period of time, and then relieving the pressure to obtain the CF / PPS composite material with high impact toughness. The tensile strength of the composite material is 650-820 MPa, the tensile modulus of the composite material is 50-63 GPa, the interlaminar shear strength of the composite material is 60-80 MPa, and the residual compression strength of the composite material after impact is 260-300 MPa. The method disclosed by the invention has the characteristics of high efficiency, environmental friendliness and capability of realizing large-scale production, and the prepared composite material can replace metal to be applied to the fields of aerospace, machinery, automobiles, rail transit, petroleum transportation and the like.

Owner:合肥东华复材科技有限公司

Stainless steel cloth guide roller of dyeing and finishing mechanism

ActiveCN110255250AGuaranteed winding and smoothingKeep tightWebs handlingDyeingMechanical engineering

The invention provides a stainless steel cloth guide roller of a dyeing and finishing mechanism. The stainless steel cloth guide roller comprises an outer frame, an assisting unit, flattening units and a tensioning unit, wherein the assisting unit is arranged in the middle part of the outer frame; the flattening units are symmetrically arranged at the inner top and bottom of the outer frame; and the tensioning unit is arranged on the outer wall of the rear end of the outer frame. The stainless steel cloth guide roller of the dyeing and finishing mechanism solves the problems such as that a cloth bears different transverse power under the effect of a pulling coiling device while an existing cloth guide roller is used for conveying and flattening the cloth, thus the clothes passing through two sides of the cloth guide roller are deviated, and the cloth is staggered in later dyeing and finishing process, and as a result, uniform dyeing and finishing cannot be realized, and staggering occurs in the coiling process; the cloth at the lower end of a cloth pressing roller bears different extruding pressure under the effect of the coiling device while being rolled and pressed through the cloth guide roller, thus the cloth is blocked, and the cloth is folded and rolled in case of serious blocking, and even the normal conveying of the cloth is influenced.

Owner:海宁鑫港源纺织品有限公司

CF/PEEK with high interlaminar shear strength and bending strength and preparation method of CF/PEEK

ActiveCN111423695AGuaranteed normal windingMake up or offset the lossFlexural modulusCarbon nanotube

The invention relates to CF / PEEK with high interlaminar shear strength and bending strength and a preparation method of the CF / PEEK. The preparation method comprises the following steps: (1) carryingout high-temperature decomposition on an original sizing agent on the surface of CF; (2) simultaneously carrying out microwave radiation and ultraviolet irradiation on CF in a saturated water vapor environment, and marking a product as ACF; (3) immersing ACF into a sulfonated polyetheretherketone / dimethyl sulfoxide / carbon nanotube suspension, taking out, and drying to obtain sized modified carbonfiber MCF; (4) laminating and hot-pressing the MCF and a PEEK material; and thus obtaining the CF / PEEK with high interlaminar shear strength and bending strength. The bending strength of the finally prepared product is 850-1100 MPa, the bending modulus of the finally prepared product is 55-65 GPa, the interlayer shear strength of the finally prepared product is 95-110 MPa, and the residual compression strength of the finally prepared product after impact is 220-260 MPa. The method disclosed by the invention has the characteristics of high efficiency, environmental friendliness and capability of realizing large-scale production, and the prepared product can replace metal to be applied to the fields of aerospace, medical treatment, machinery, automobiles, rail transit, petroleum transportation and the like.

Owner:DONGHUA UNIV

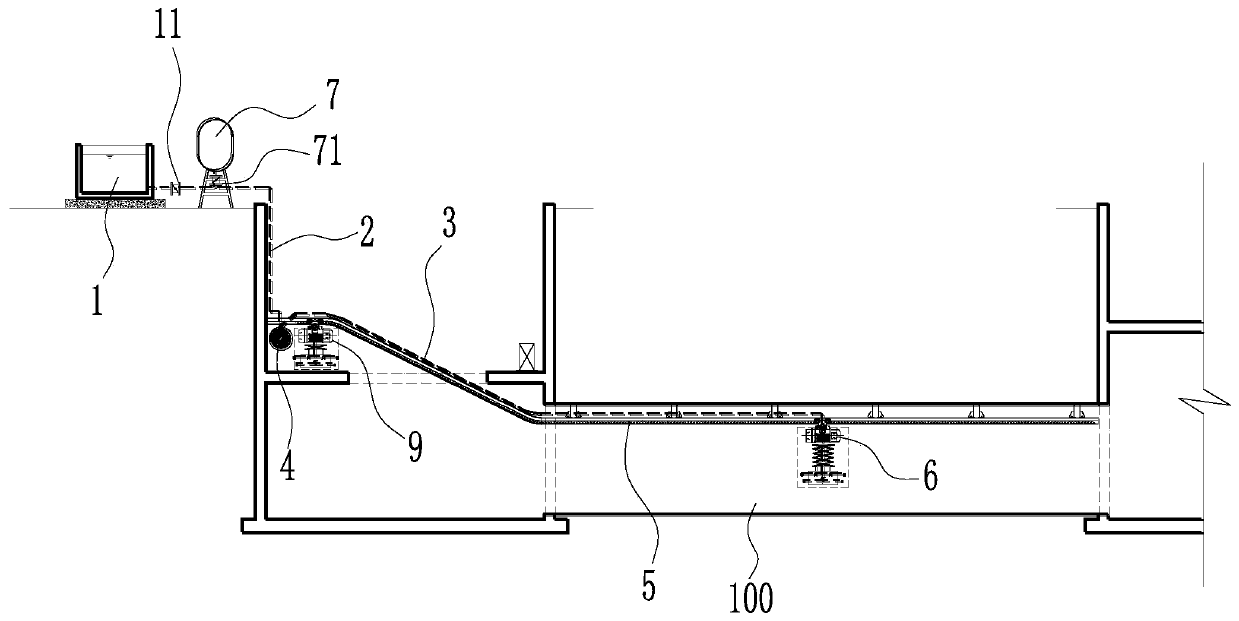

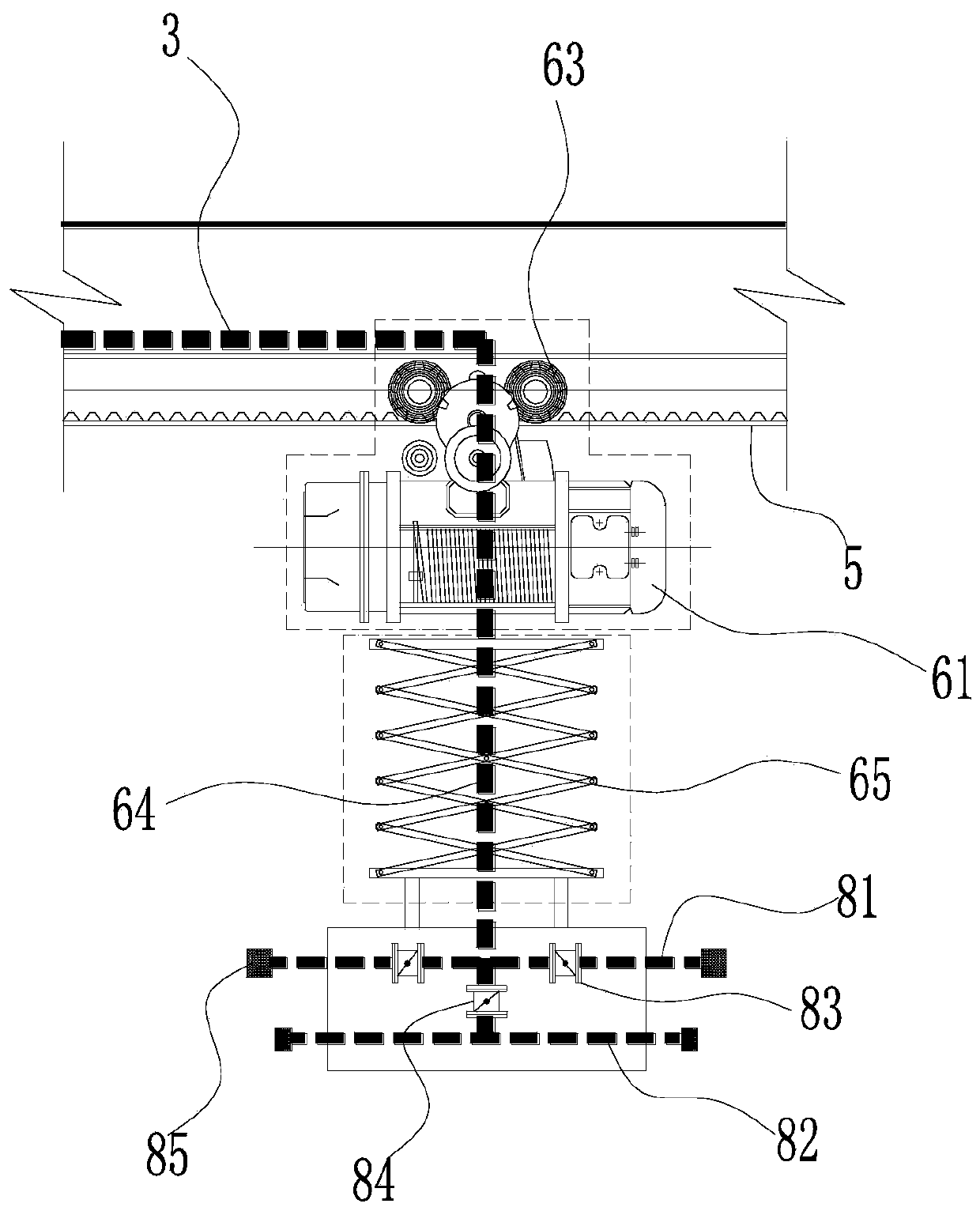

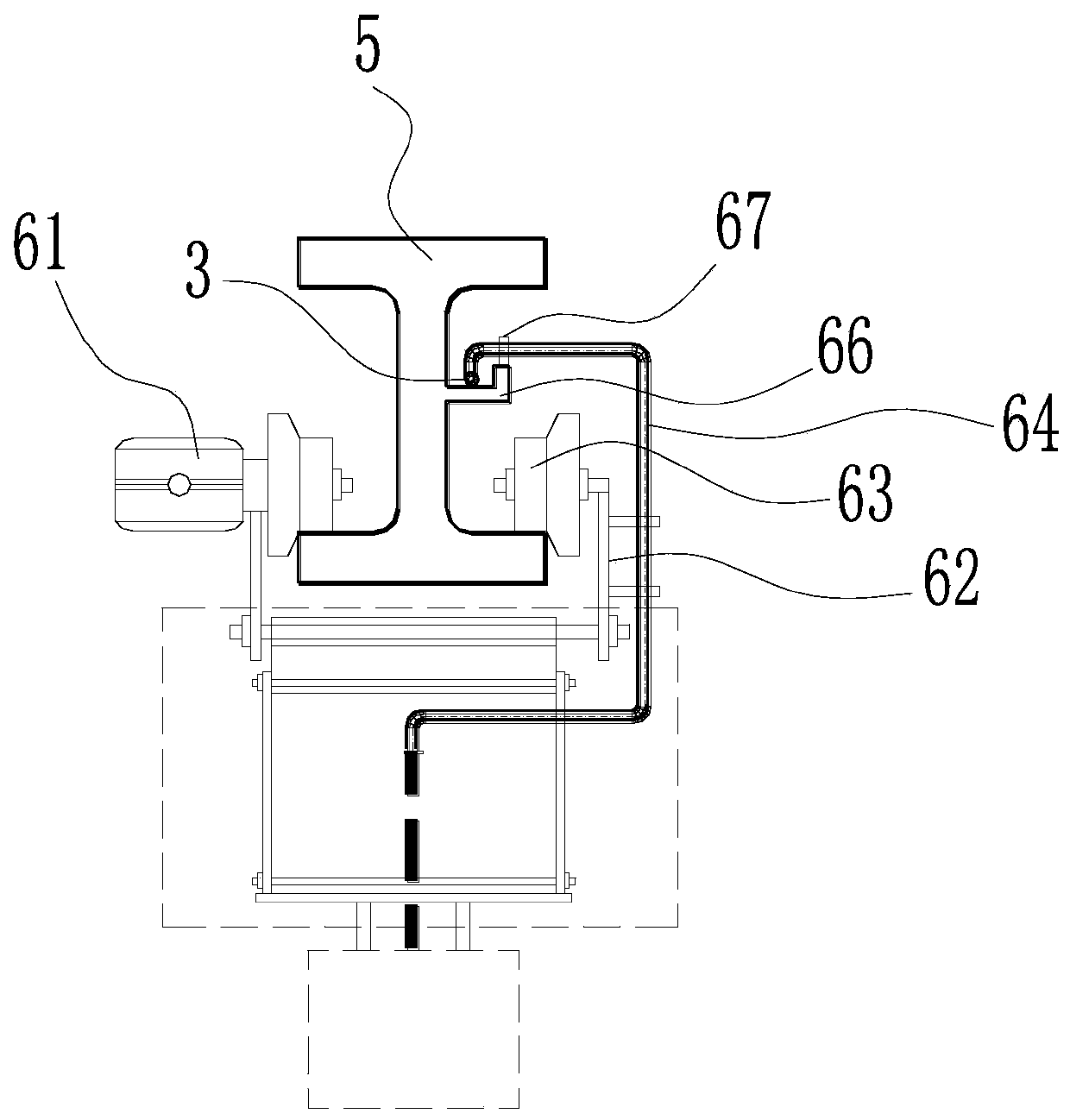

Track type automatic flushing device for deep tunnel

The invention discloses a track type automatic flushing device for a deep tunnel. The device comprises a water pool, a flushing main pipe, a flushing hose, an automatic telescopic pipe winder, a trackand a moving mechanism. The flushing main pipe is connected with the water pool, the automatic telescopic pipe winder is wound by the flushing hose, one end of the flushing hose is connected with theflushing main pipe, the other end of the flushing hose is connected with a water spraying mechanism, the track is arranged in the deep tunnel, the moving mechanism is arranged on the track, and the water spraying mechanism is fixedly arranged on the moving mechanism. At ordinary times, the flushing hose is wound on the automatic telescopic pipe winder, during flushing, the moving mechanism drivesthe water spraying mechanism to move, the automatic telescopic pipe winder automatically unwinds the flushing hose, the flushing hose moves synchronously along with the water spraying mechanism, andthe supply of flushing water is guaranteed. After flushing is finished, the automatic telescopic pipe winder automatically winds the flushing hose, use is very convenient, and the flushing hose can beprevented from being twisted, wound and the like.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Clothes storage device for garment processing

The invention relates to the technical field of garment processing, and discloses a clothes storage device for garment processing. The clothes storage device comprises a storage box, wherein a rotating column is rotatably connected to the inner bottom wall of the storage box through a bearing; an annular plate is fixedly connected to the outer surface of the rotating column; a plurality of first clamps are fixedly connected to the lower surface of the annular plate; a mounting cavity is formed in the rotating column; a plurality of sliding grooves are formed in the outer surface of the rotating column; sliding plates are slidably connected into the sliding grooves; and second clamps are fixedly connected to the lower surfaces of the sliding plates. The clothes storage device for garment processing is reasonable in space distribution, the second clamps at the high position can move up and down, a user can hang clothes conveniently, peculiar smell on the clothes can be removed through ventilation, the rotating column drives the clothes to rotate during ventilation, the ventilation effect is guaranteed, and working dead corners are avoided; and when ventilation is not conducted, ventilation holes are in a closed state, the clothes are not polluted by dust in air, and the cleanliness degree of the clothes is improved.

Owner:太湖新时代服饰股份有限公司

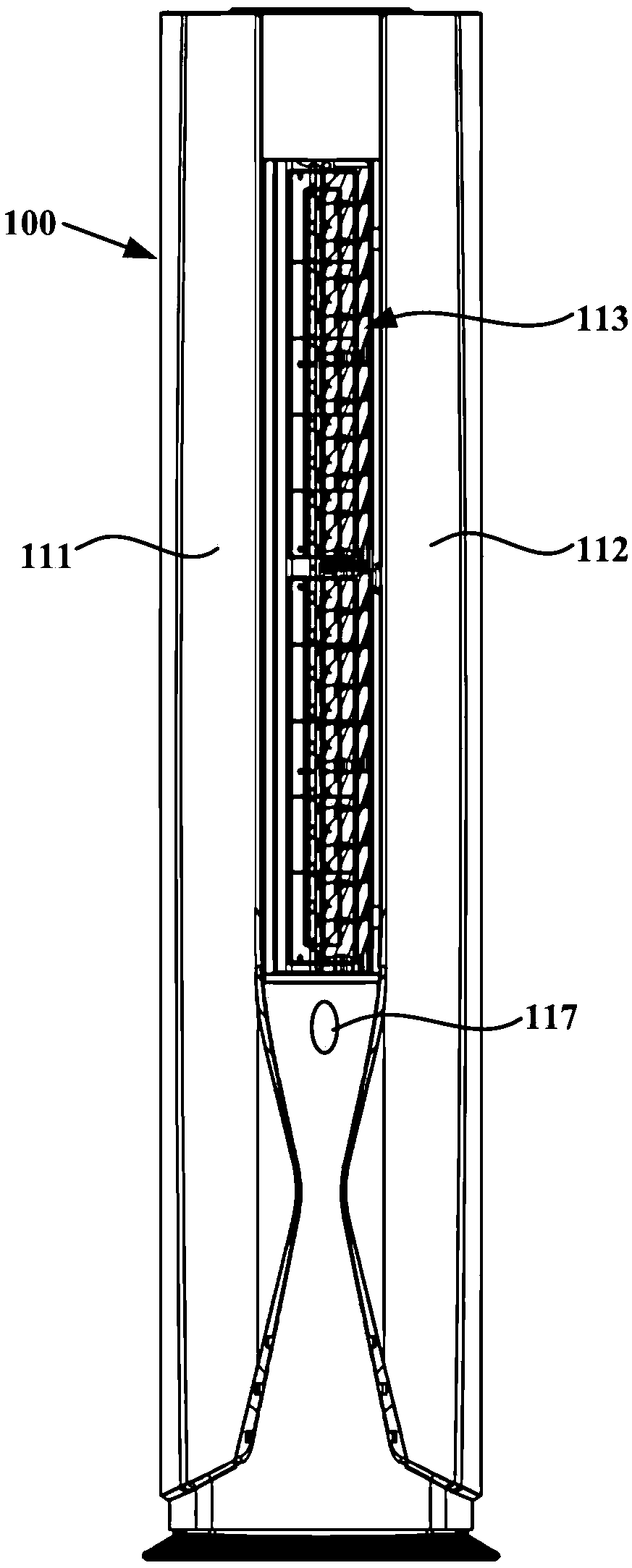

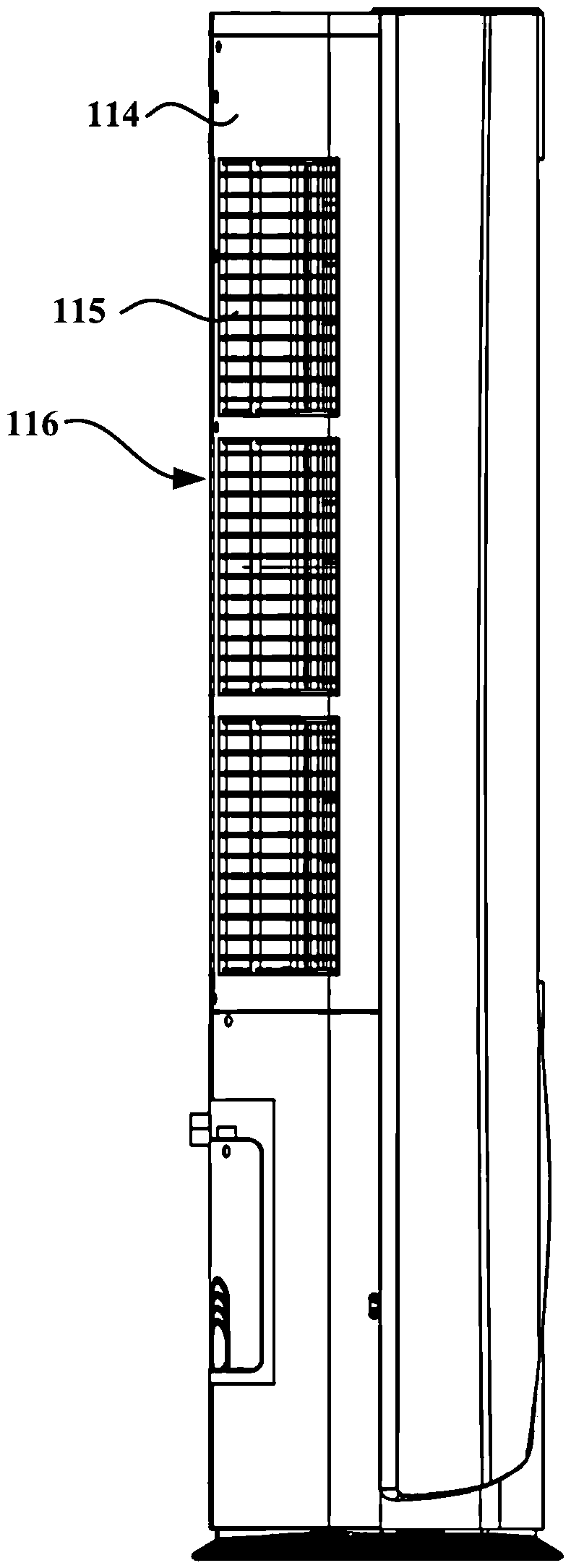

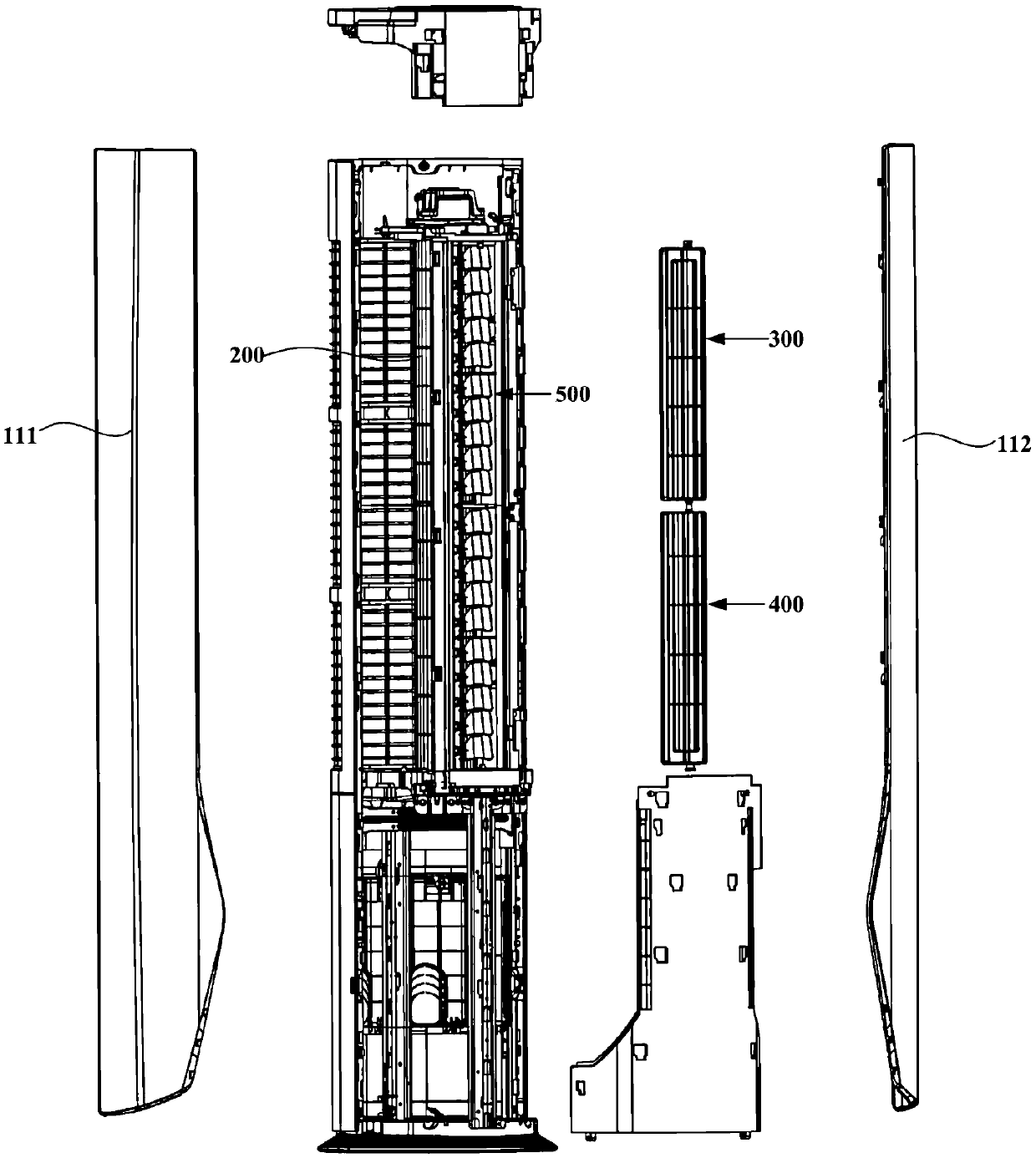

Air supply control method of air conditioner and air conditioner

InactiveCN110779088AAvoid symptomsGuaranteed normal windingMechanical apparatusLighting and heating apparatusAir volumeEngineering

The invention provides an air supply control method of an air conditioner and the air conditioner. The air supply control method of the air conditioner comprises the following steps of detecting a preset range in front of the air conditioner by using an infrared sensor arranged at the front part of a shell; judging whether a user appears in the preset range according to the detection result of theinfrared sensor; and if yes, driving a transverse swing blade assembly and a second vertical swing blade assembly to act. According to the air supply control method of the air conditioner, a first vertical swing blade assembly and the second vertical swing blade assembly of the air conditioner can be correspondingly controlled, and the air conditioner can supply air in different directions at thesame time. According to the air conditioner, the refrigeration effect of the air conditioner is taken into consideration while the air conditioner achieves the wind-free feeling effect, the normal air outlet of each swing blade assembly is ensured, and the air volume loss caused by the pursuit of the wind-free feeling is avoided. On the basis of meeting the requirements of the user on the cold air, the user has the wind-free feeling, and various discomfort symptoms of the user caused by direct air blowing of the air conditioner are avoided.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

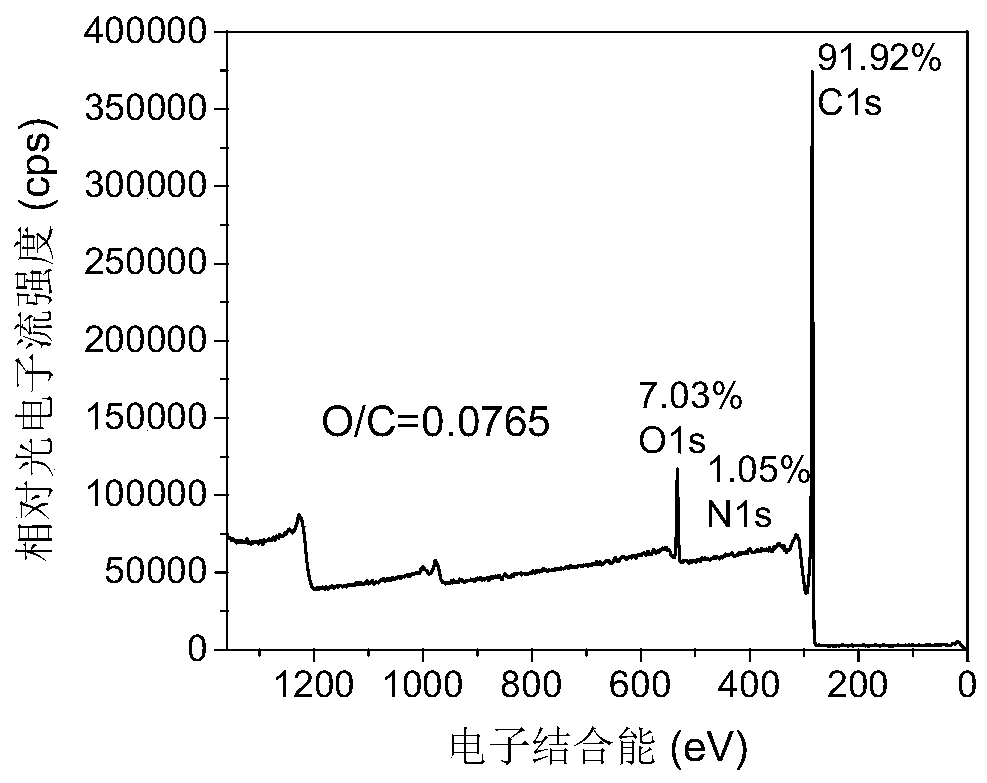

CF/peek composite material with strong chemical bond interface and preparation method thereof

The invention relates to a CF / PEEK composite material with a strong chemical bond interface and a preparation method thereof. The method comprises the following steps: (1) pyrolyzing the original sizing agent on the CF surface; (2) in a saturated water vapor environment, to CF was irradiated with microwave and ultraviolet light at the same time, and the product was recorded as ACF; (3) ACF was immersed in the aminated PEEK / dimethylformamide / carbon nanotube suspension and heated to make the aminated PEEK and ACF react, and after taking it out Dry to obtain sizing modified carbon fiber MCF; (4) MCF and PEEK material lamination hot pressing; promptly get the CF / PEEK composite material with chemical bond strength interface; the final obtained CF / PEEK composite material with chemical bond strength interface The flexural strength is 900‑1100MPa, the flexural modulus is 57‑65GPa, the interfacial shear strength is 100‑120MPa, and the residual compressive strength after impact is 210‑250MPa. The method of the present invention is characterized by high efficiency, environmental protection, and large-scale production, and the prepared CF / PEEK composite material can replace metals and be used in fields such as aerospace, medical treatment, machinery, automobiles, and rail transit.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com