Automatic deviation correction device

An automatic deviation correction device and a deviation correction technology, applied in the field of deviation correction devices, can solve the problems of reducing the stability of battery winding performance, etc., and achieve the effects of low processing and manufacturing costs, guaranteed stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

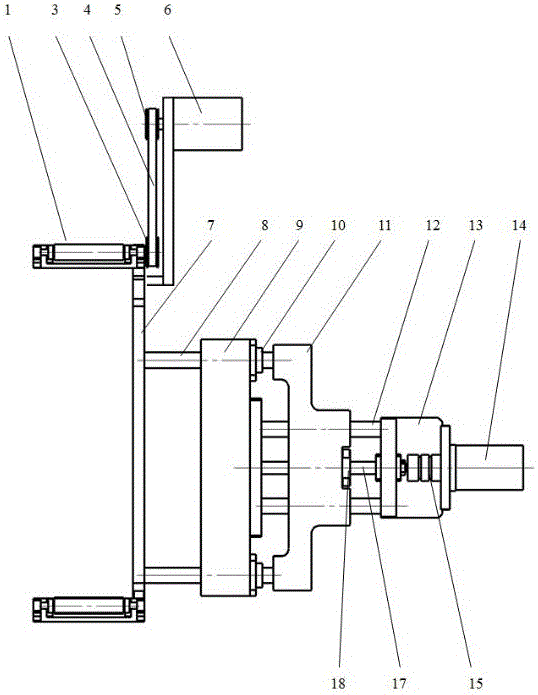

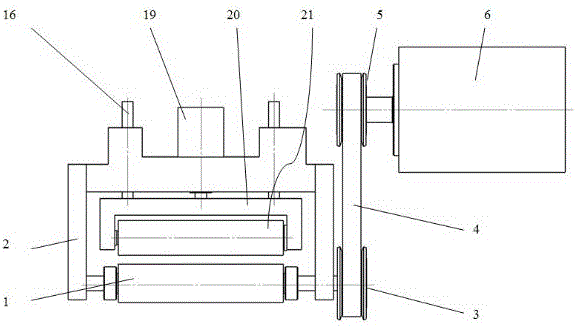

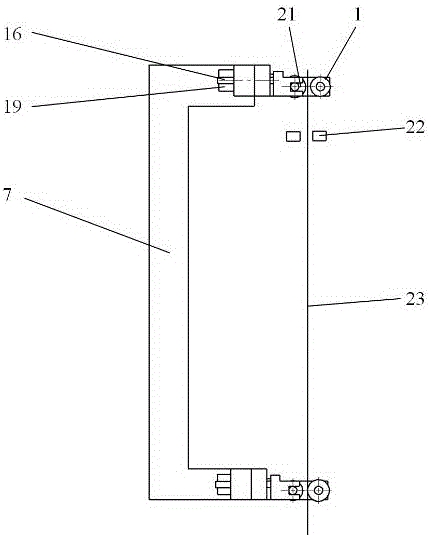

[0018] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are schematic and are intended to explain the present invention and not to limit the present invention.

[0019] Refer below Figure 1-Figure 3 The protection tape clip feeding and pressing device of the embodiment of the present invention will be described.

[0020] An automatic deviation correction device, comprising a fixed seat 9, a deviation correction sensor 22, a deviation correction drive mechanism, a first deviation correction roller mechanism, a second deviation correction roller mechanism, and a deviation correction roller driving mechanism.

[0021] Described correction driving mechanism comprises correction roller bracket 7, forward and backward movement mechanism, and described front and rear movement mechanism comprises guide shaft 8, fixed seat 9, nut support 11, screw man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com