Patents

Literature

116results about How to "High accuracy of deviation correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

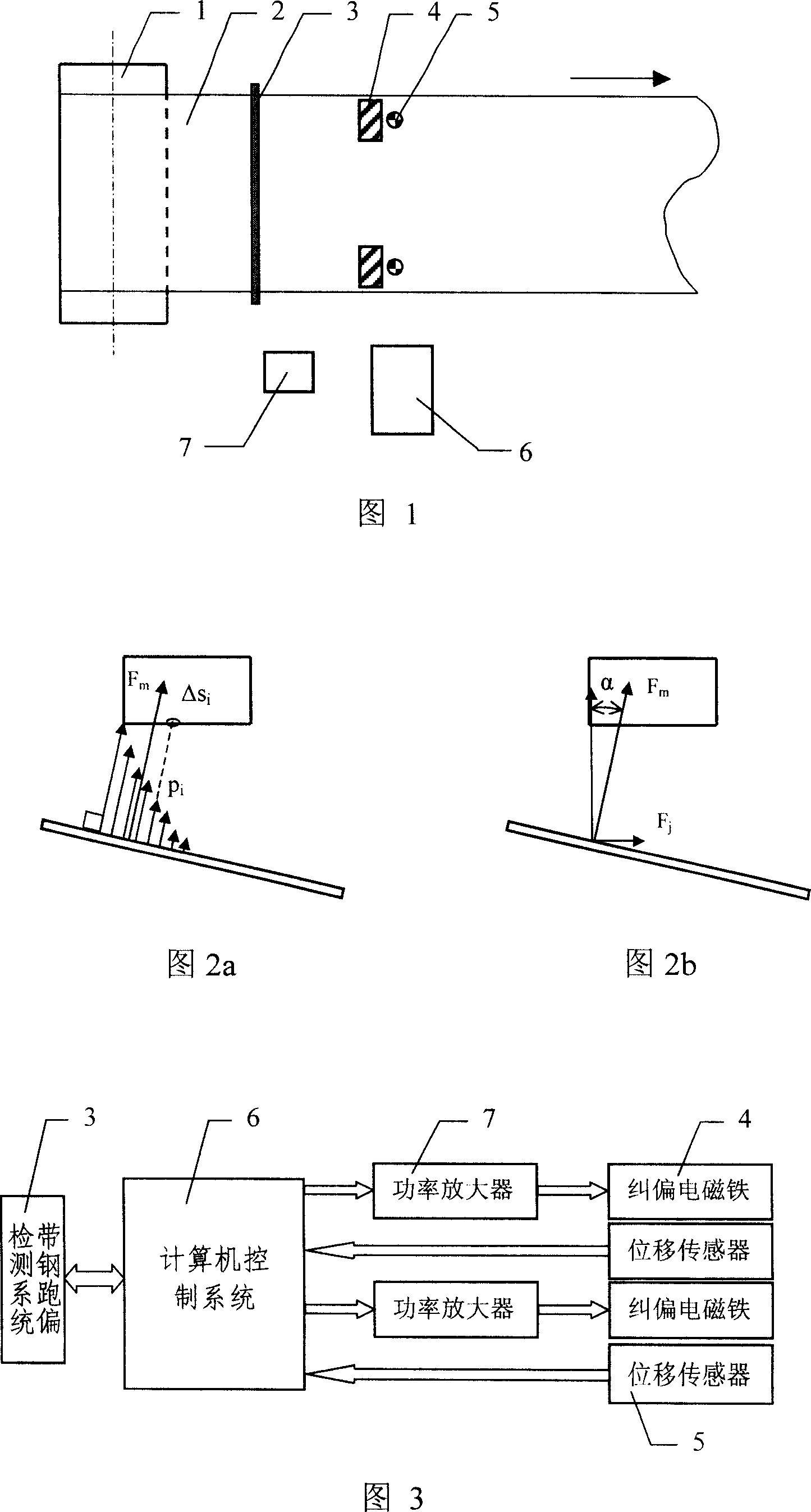

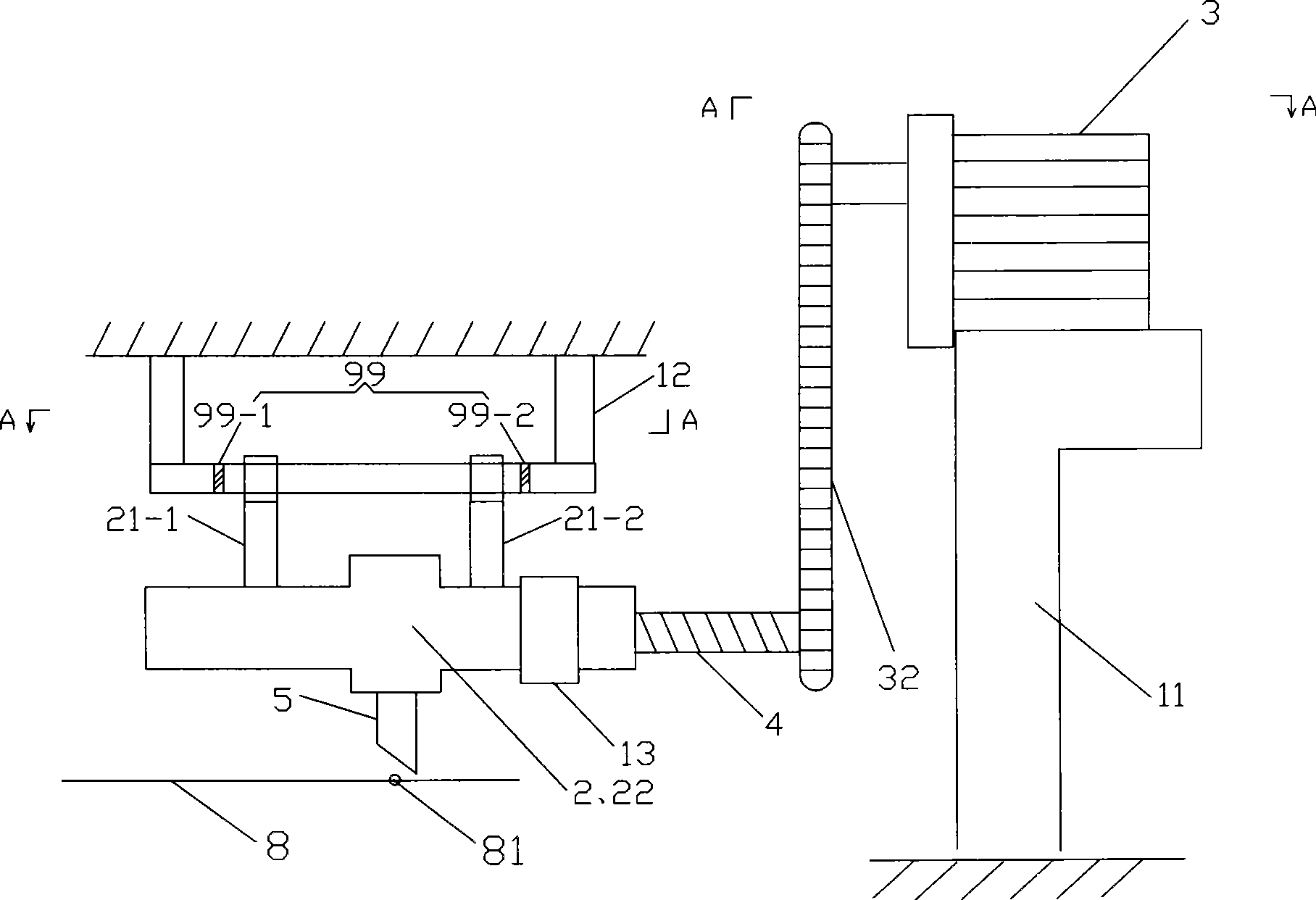

Strip steel non-roller correcting error method and apparatus

ActiveCN101152934AImprove surface qualityEasy to controlControl using feedbackWebs handlingComputer control systemExcitation current

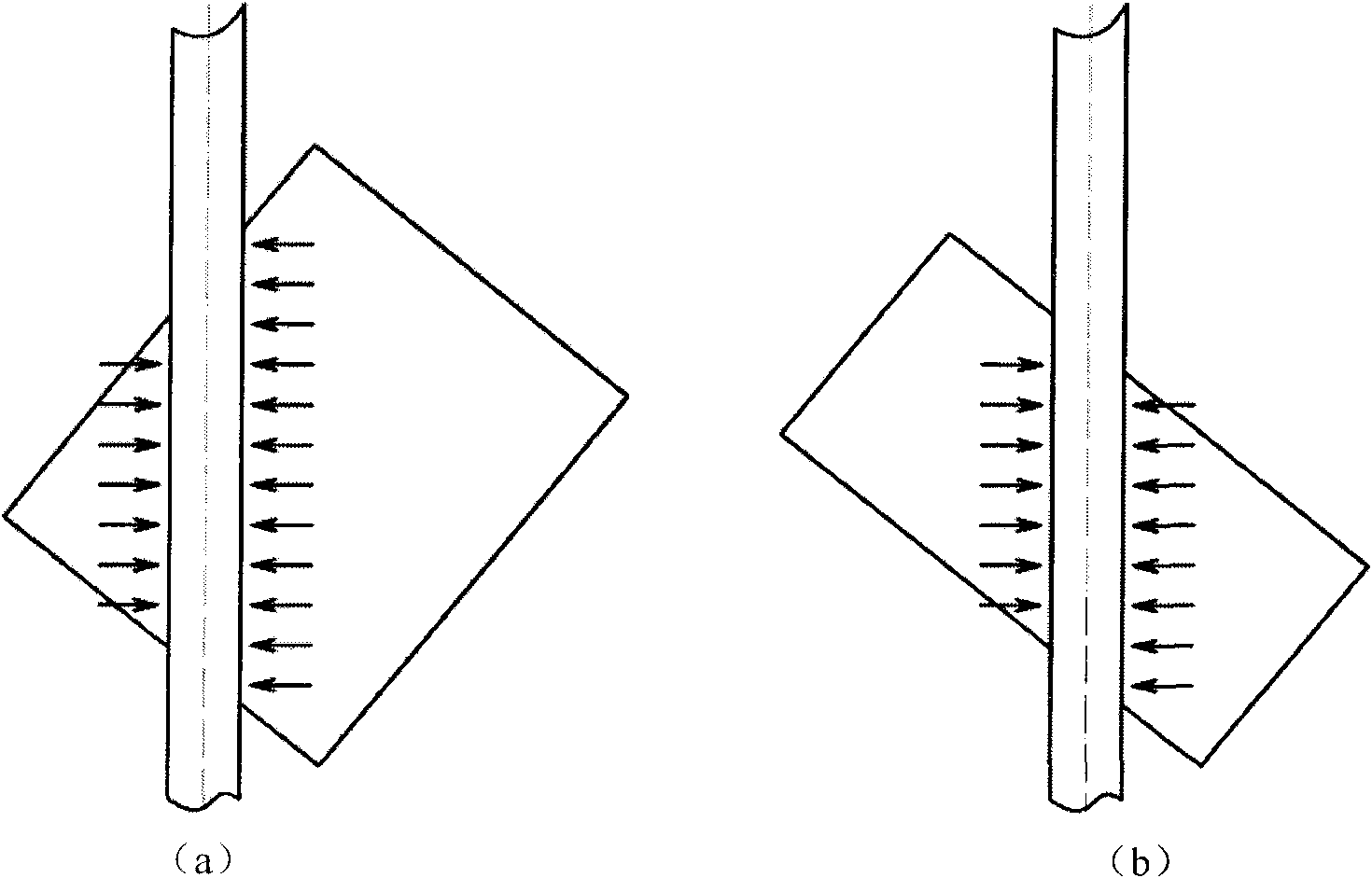

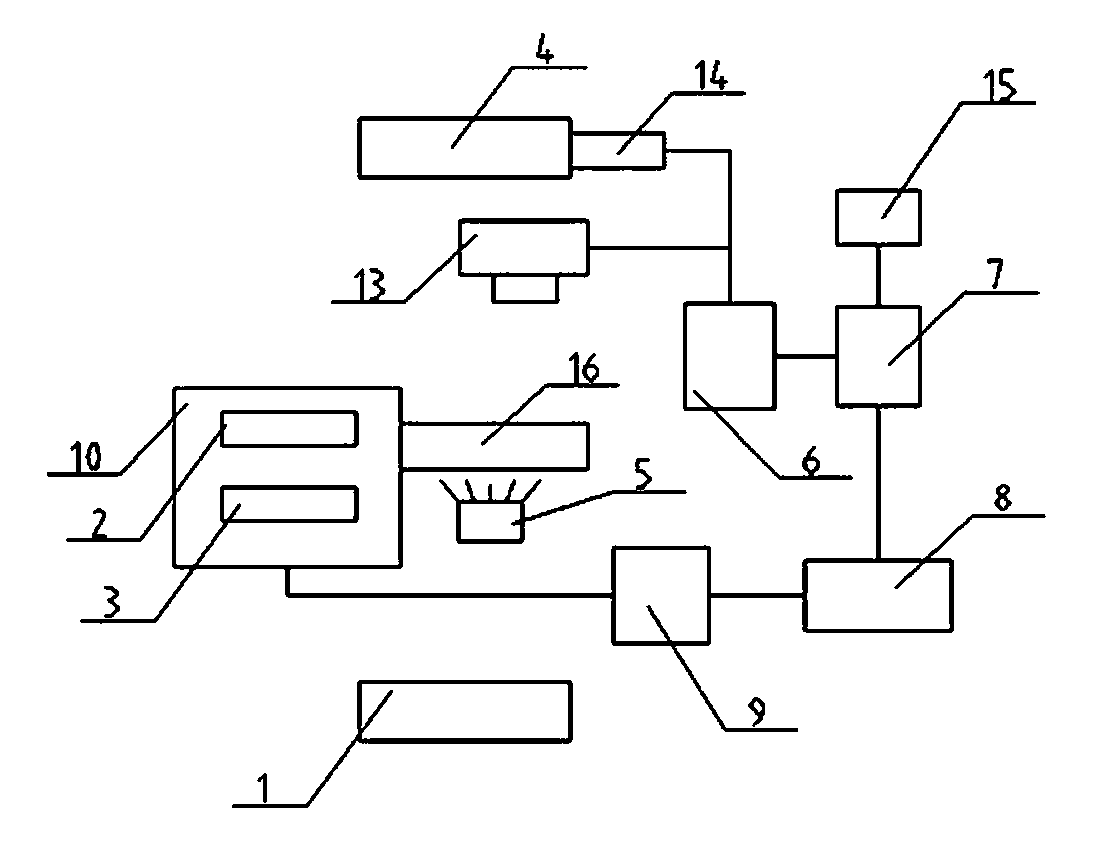

The present invention relates to a strip steel correcting technology, in particular to relate to a non-contacting strip steel correcting technology method and a device. A no-roll strip steel correcting technology is characterized in that a couple of electromagnets are arranged above two sides of the strip steel in a place where the strip steel is easy to deviate or has requirements to the deviating quantity. When a strip steel deviating quantity detecting system detects the deviation of the strip steel, a detected signal is changed into an electric signal; the deviating quantity and deviating direction is gained by gathering and operating the electric signal through a computer; the clearance between the strip steel and the electromagnet is changed by controlling an excitation current of two electromagnets; then the deviation of the strip steel is corrected. At the same time, the distance between the electromagnet and the strip steel is detected by a displacement sensor; then the detected signal is input into a computer controlling system; the excitation current of the electromagnet is controlled by the output signal made by the computer controlling system after operating. The present is simple in structure, high in response rate, precise in deviation correcting and easy to realize the computer controlling.

Owner:BAOSHAN IRON & STEEL CO LTD

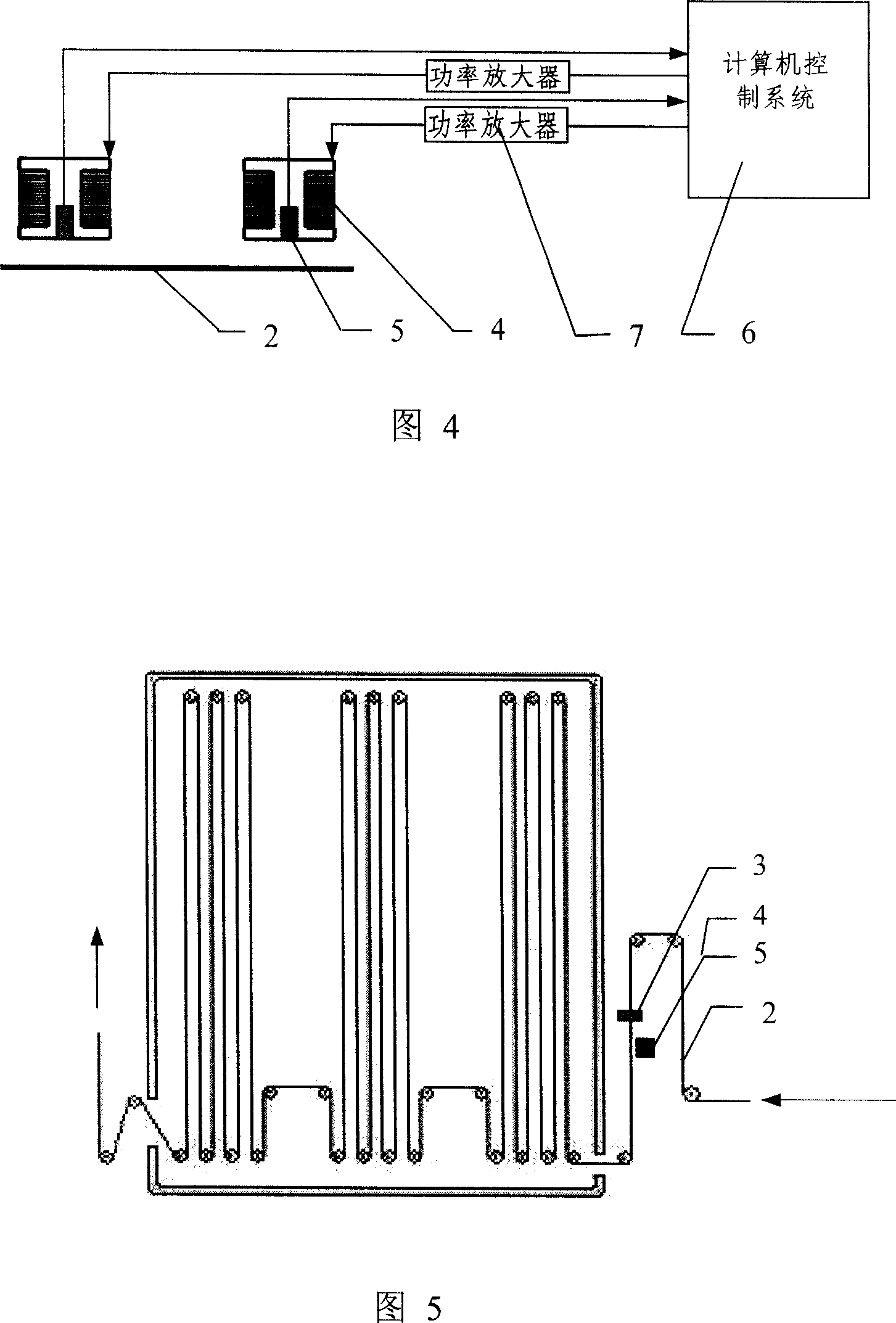

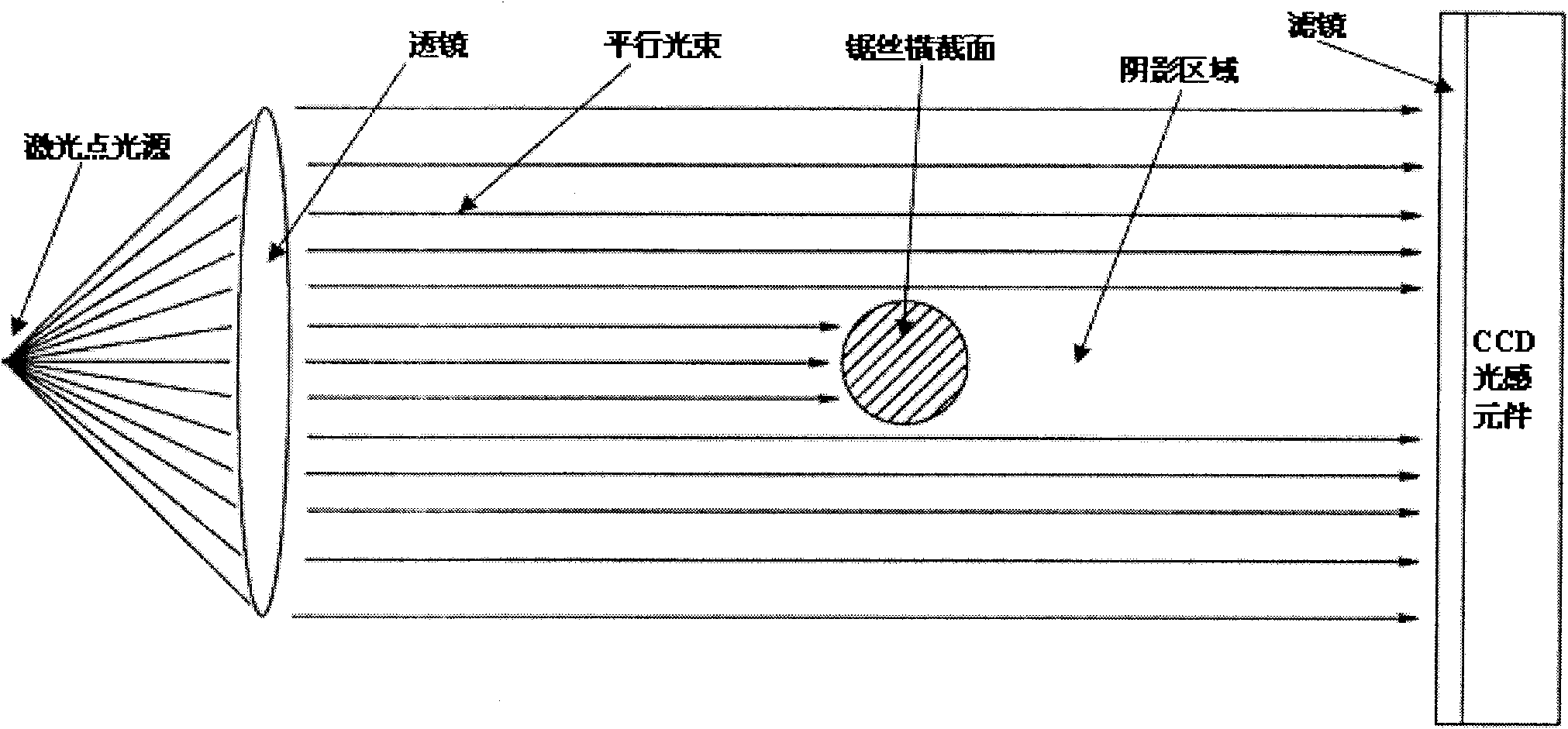

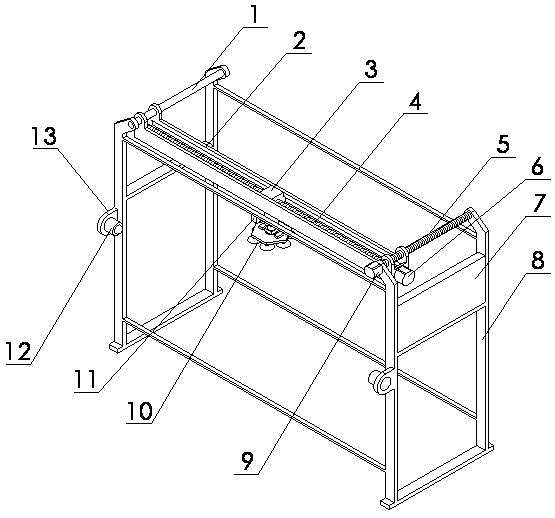

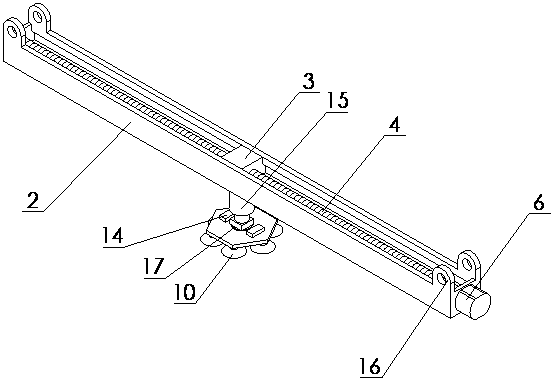

Real-time deviation correcting method for precise cutting process of diamond wire saw

InactiveCN101817209AQuick correctionAvoid wear and tearFine working devicesStone-like material working toolsTime deviationComputer control system

The invention discloses a real-time deviation correcting method for a precise cutting process of a diamond wire saw, which belongs to the technical field of precise cutting and machining of large-size artificial crystal. The method is characterized by comprising the following steps of: detecting the position offset of the diamond wire saw in real time by using a photoelectric position detecting element, and feeding back the position offset to a computer control system to control a workbench to perform corresponding position and angle adjustment so that the wire saw moves towards the direction of reducing the cutting deviation and the cutting deviation correction is realized. The method has the advantages that abrasion brought to contact detection and deviation correction of the wire saw can be avoided by adopting non-contact wire saw position detection and wire saw deviation correcting motion; and in addition, compared with a method for reducing cutting deviation by improving the precision of a machine tool, a deviation feedback-based deviation correcting strategy adopted by the invention has the advantage that: good deviation correcting effect can be achieved for wire saw precision cutting of a large-scale workpiece on the premise of not remarkably improving the manufacturing cost of a wire saw cutting system. Theoretically, the method can obtain highest deviation correcting precision of 17 microns.

Owner:DALIAN UNIV OF TECH

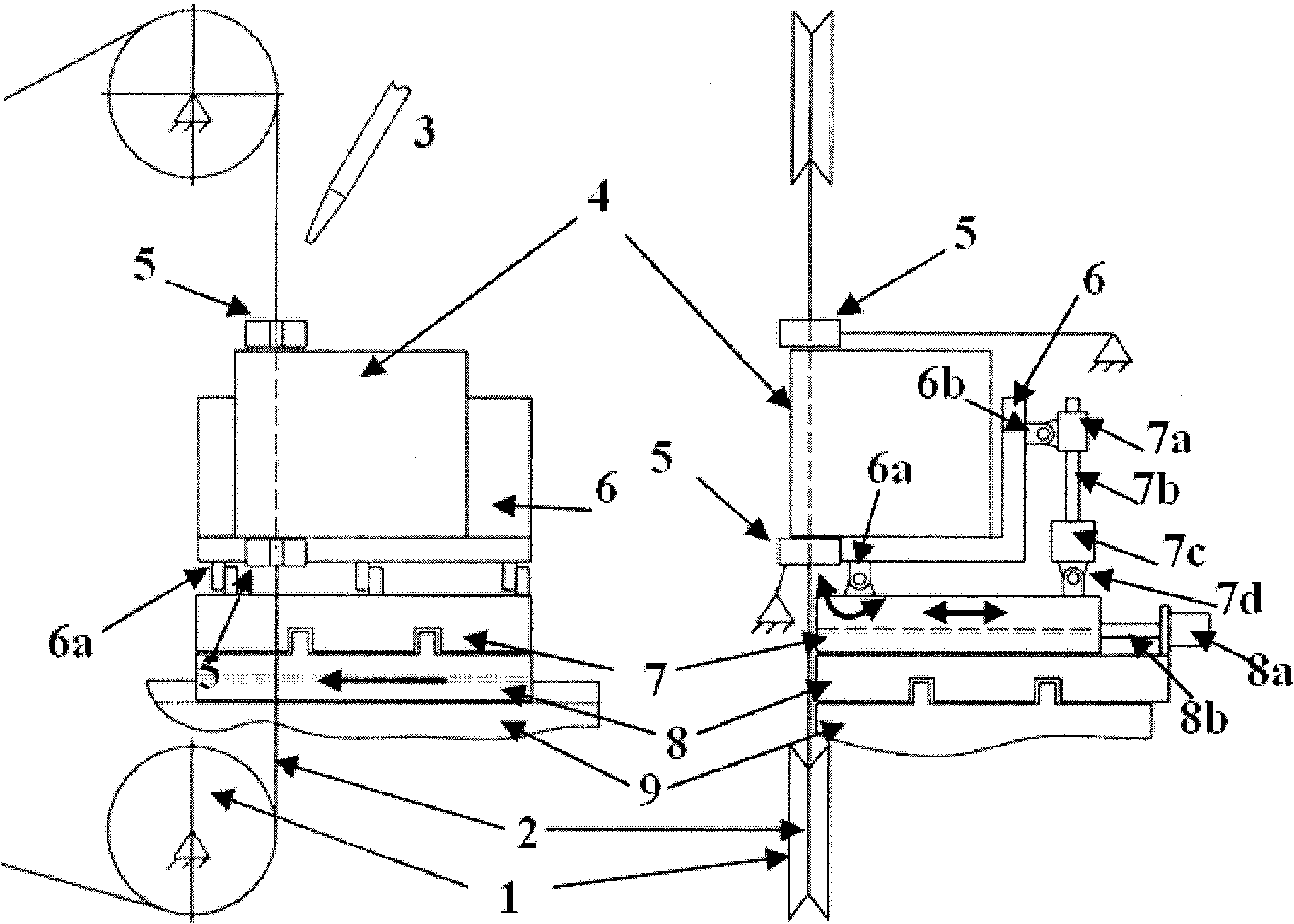

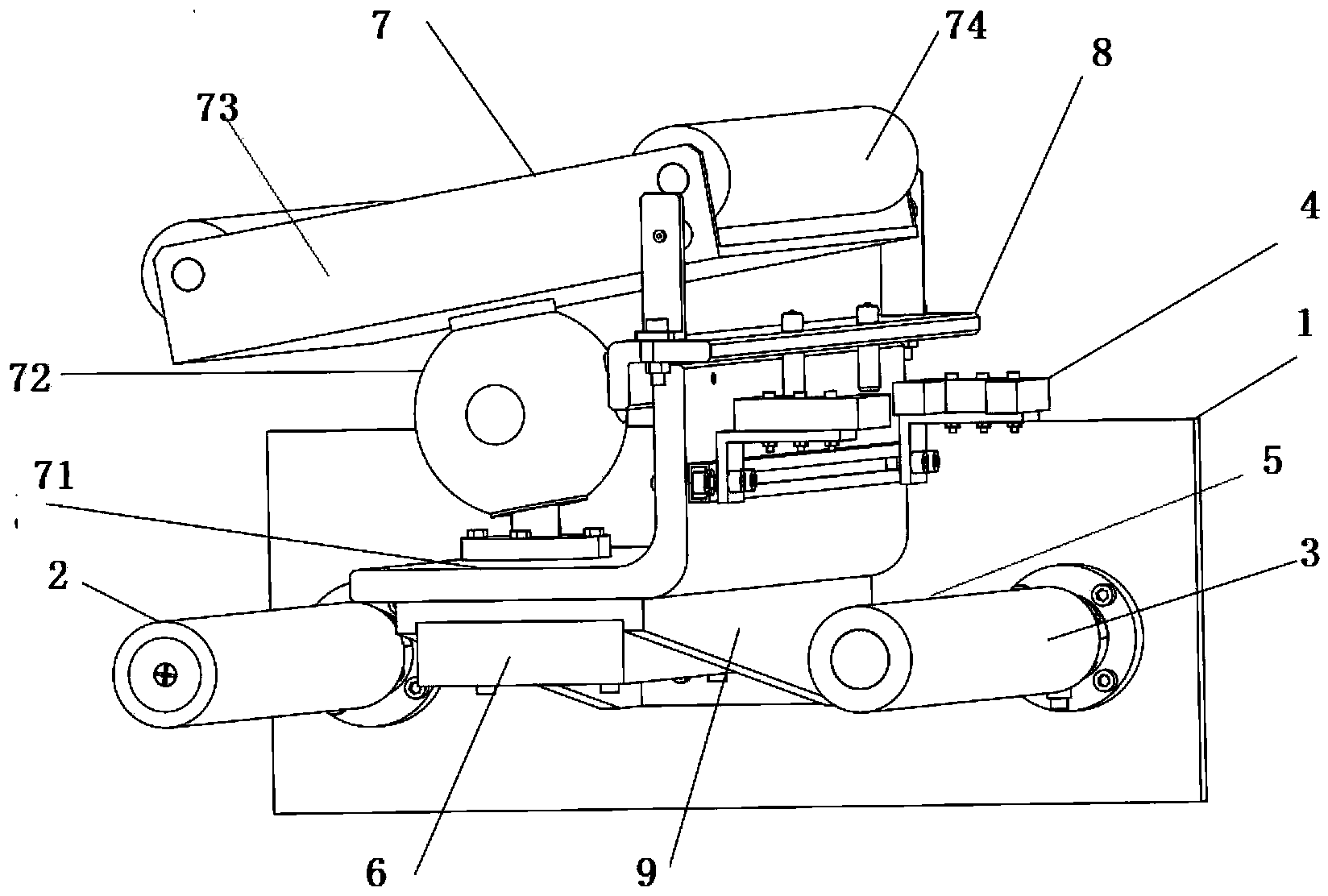

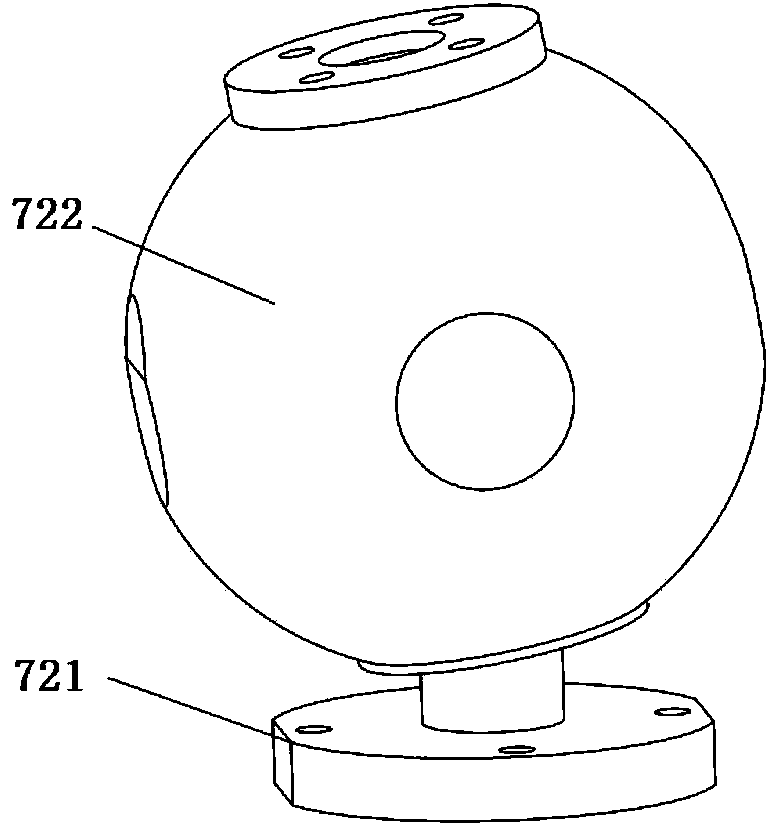

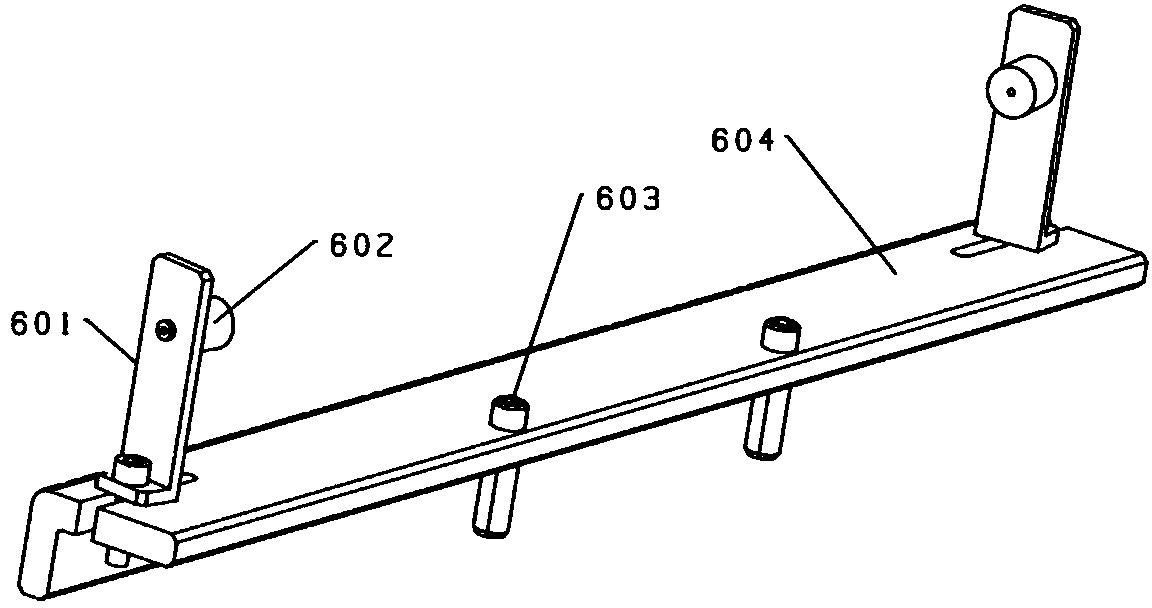

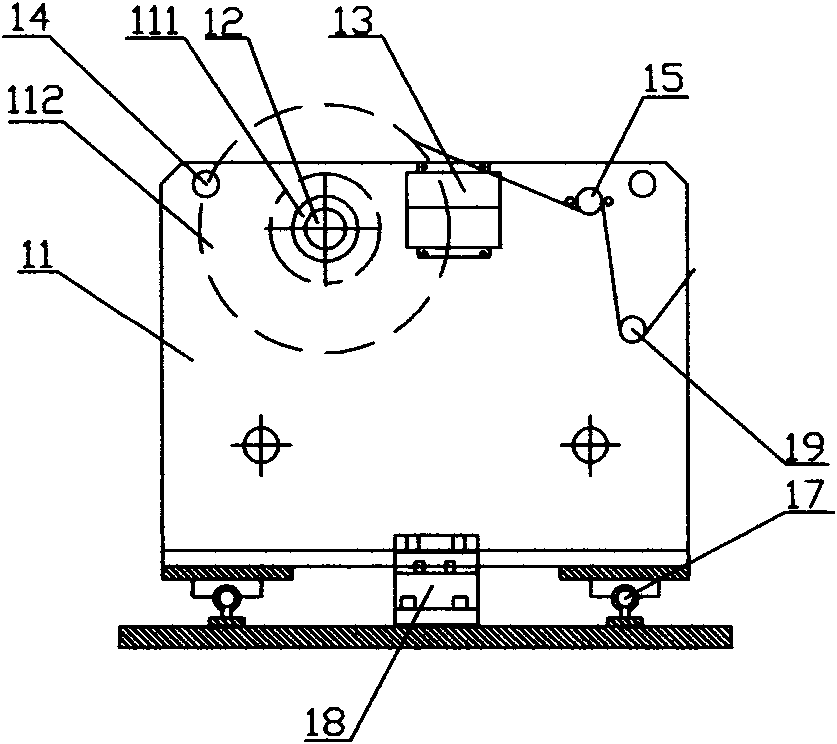

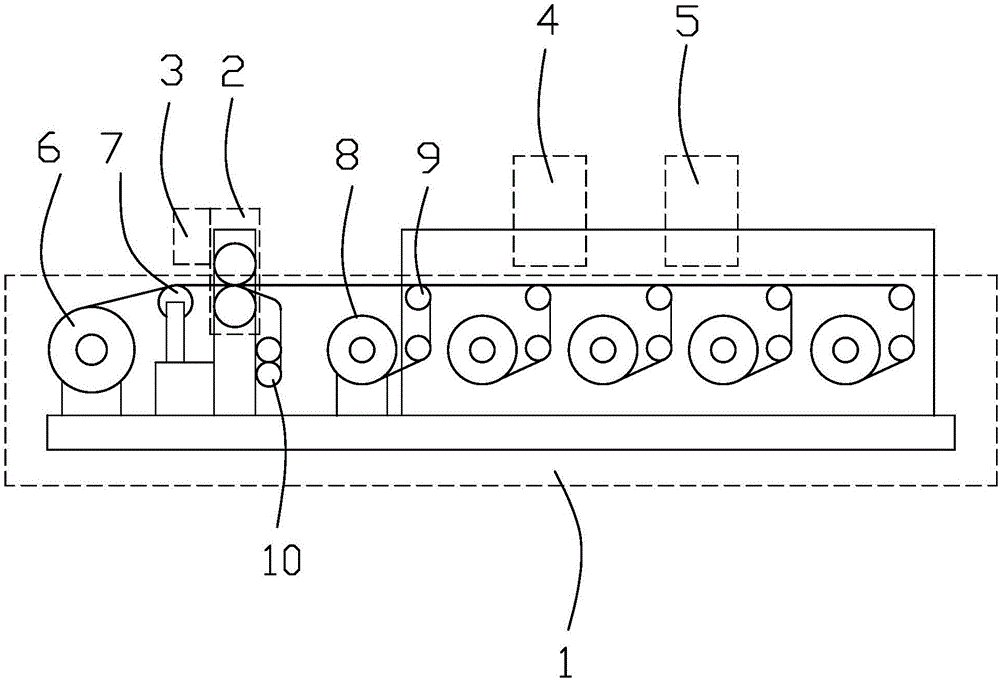

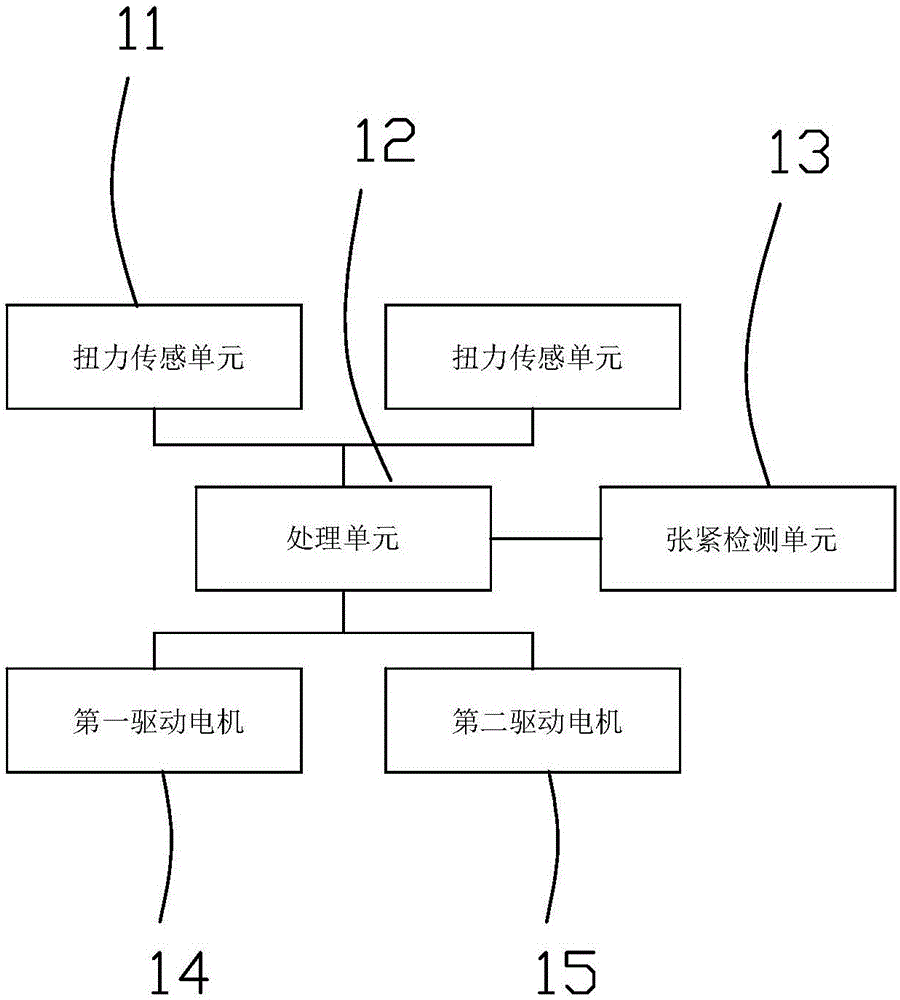

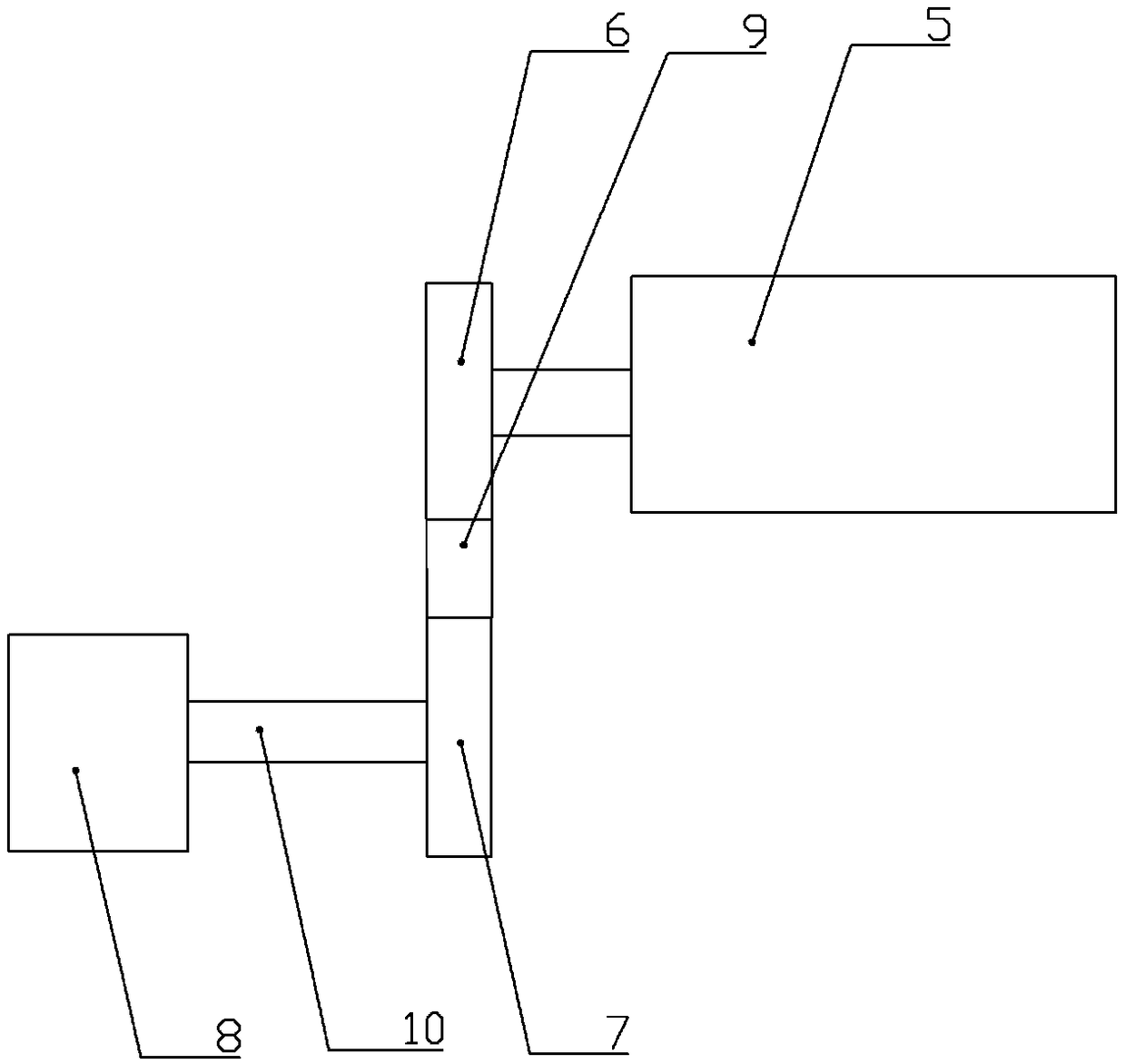

Film conveying deviation-rectifying device combining tension control

The invention provide a film conveying deviation-rectifying device combining the tension control, which comprises a film input guiding roller, an output guiding roller, a deflection detecting mechanism, a tension detecting mechanism, a controller and a deviation-rectifying actuating mechanism, wherein the film input guiding roller and the output guiding roller are used for inputting a film guide into the deviation-rectifying actuating mechanism and outputting the film guide from the deviation-rectifying actuating mechanism; the deflection detecting mechanism is used for detecting whether the film deflects or not; the tension detecting mechanism is used for detecting the film tension; the controller is used for generating deviation-rectification or / and tension control instruction as per the detection information; the deviation-rectifying actuating mechanism comprises a spherical motor, a deflection frame and a deviation-rectification roller; a runner of the spherical motor drives the deflection frame to rotate on a feeding surface of the film; the friction between the rectification roller and the film drives the inverse rotation of the film to realize the deviation-rectification; meanwhile, the runner of the spherical motor drives the deflection frame to rotate on the surface vertical to the feeding surface of the film, so as to tighten or loose the film to realize the tension control. According to the invention, the deviation-rectification and the tension control of the film can be realized simultaneously, the influence of the tension variation on the deviation-rectification is greatly reduced, the structure is simple, and the deviation-rectifying precision is high.

Owner:HUAZHONG UNIV OF SCI & TECH

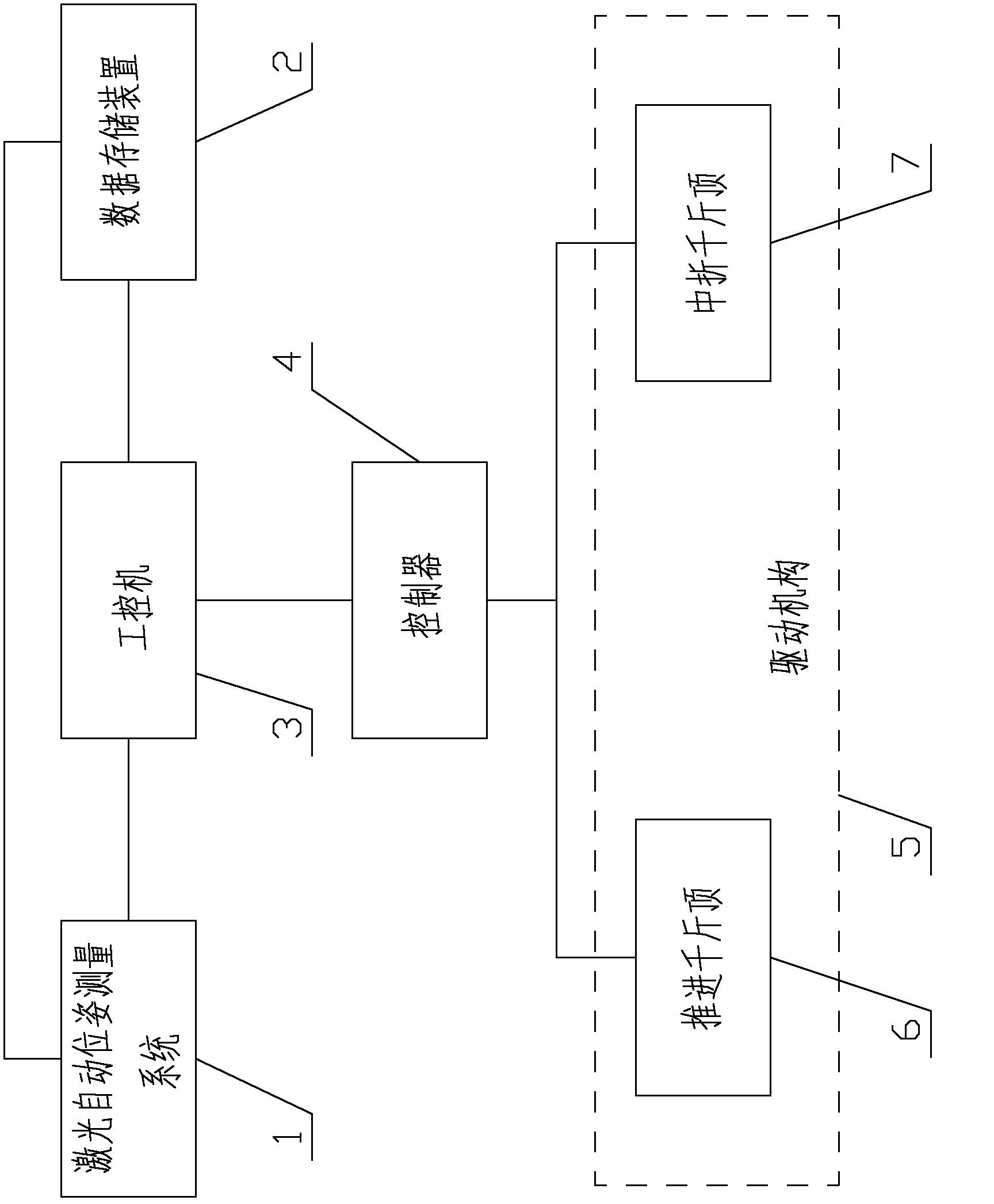

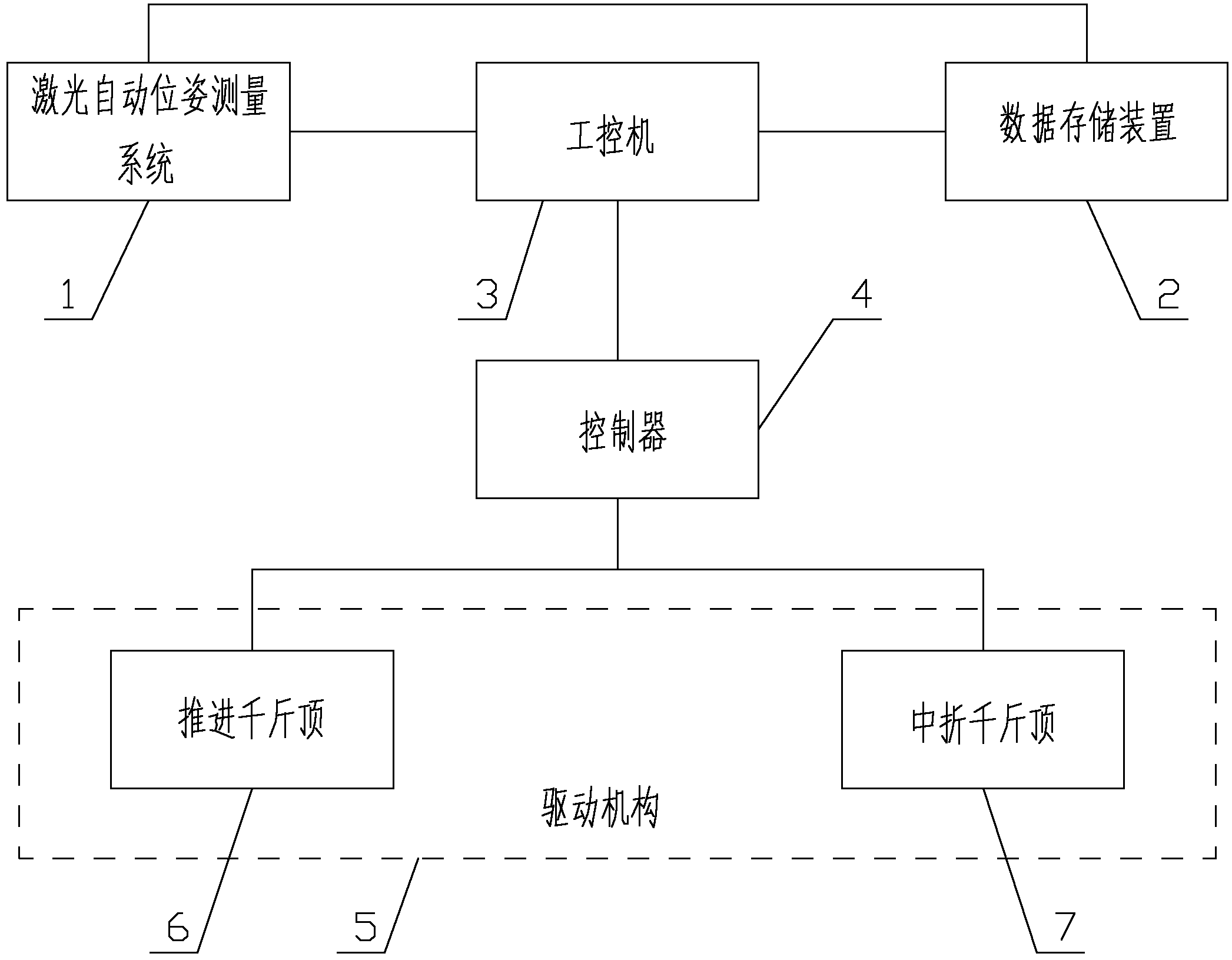

Automatic deviation rectifying system for shield machine and operating method of automatic deviation rectifying system

The invention discloses an automatic deviation rectifying system for a shield machine and an operating method of the automatic deviation rectifying system. The automatic deviation rectifying system comprises an automatic laser position and posture measuring system, a data storage device, an industrial personal computer, a controller and a driving mechanism, wherein the automatic laser position and posture measuring system is used for monitoring the position and the posture of the shield machine in real time, the data storage device is used for storing correct and real-time position and posture data of the shield machine, the industrial personal computer is used for comparing the correct and real-time position and posture data of the shield machine and transmitting deviation rectifying control signals, the controller is used for controlling the driving mechanism to start, and the driving mechanism is used for rectifying deviation of the shield machine. The automatic deviation rectifying system for the shield machine and the operating method of the automatic deviation rectifying system can be used for automatically rectifying the running track of the shield machine, and has the advantages of high precision, high efficiency and the like. Besides, manual intervention in deviation rectifying is decreased, and constructional safety is improved.

Owner:DUNJIAN HEAVY IND MFG

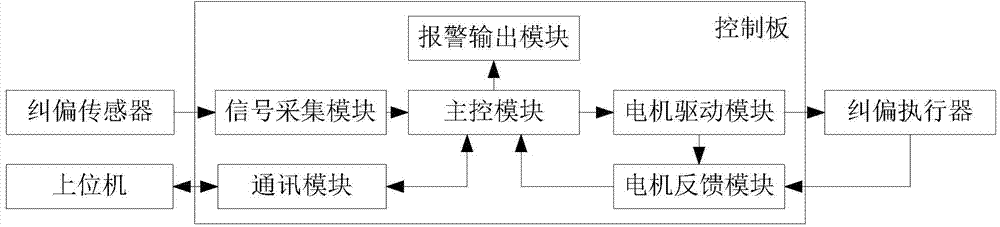

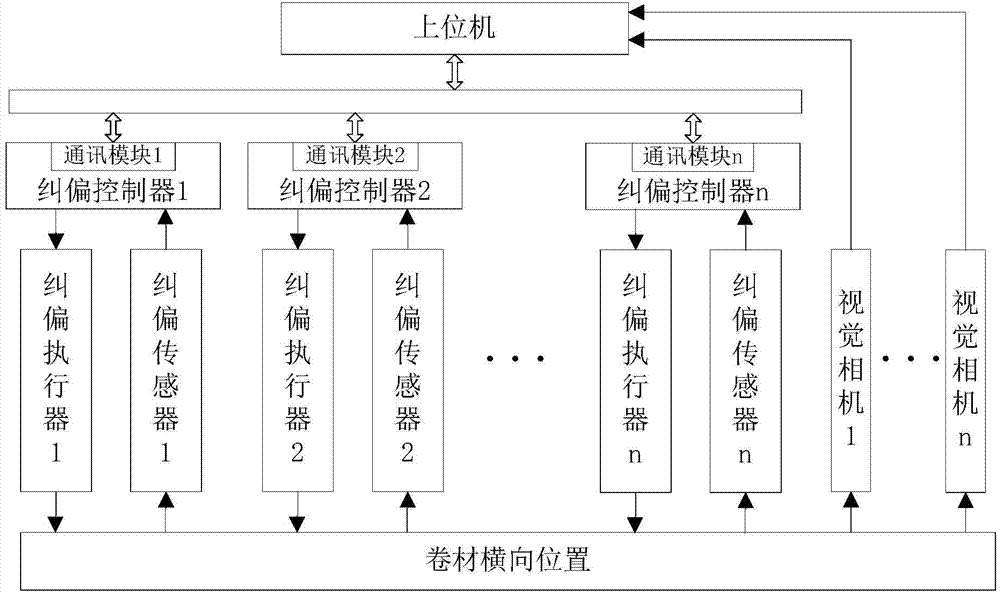

Deviation rectification control system for flexible film conveying

ActiveCN104773573ARealize alignment correction methodGood correction effectWebs handlingMotor driveControl system

The invention discloses a deviation rectification control system for flexible film conveying. The deviation rectification control system comprises a plurality of deviation rectification controllers, an upper computer, a communication module and the like, wherein each deviation rectification controller comprises a deviation rectification sensor, a signal acquiring module with double input channels, a main control module, a motor driving module and a motor feedback module respectively; the signal acquiring modules are used for acquiring analog signals output by the deviation rectification sensors, and outputting the acquired analog signals to the main control module; the main control modules are used for performing comparative calculation on the analog signals and a set value to obtain PWM (Pulse-Width Modulation) waves, outputting the PWM waves to the motor driving modules, and controlling a deviation rectification executor to work by using the PWM waves; and the motor feedback modules are used for feeding information to the main control modules to finish a closed loop control process. Moreover, a deviation rectification control mode and the internal circuit structures of the motor driving module and the signal acquiring modules serving as key components are designed. The deviation rectification control system can be suitable for deviation rectification executors of various types, and has high control accuracy; and a plurality of deviation rectification control schemes can be provided.

Owner:HUAZHONG UNIV OF SCI & TECH

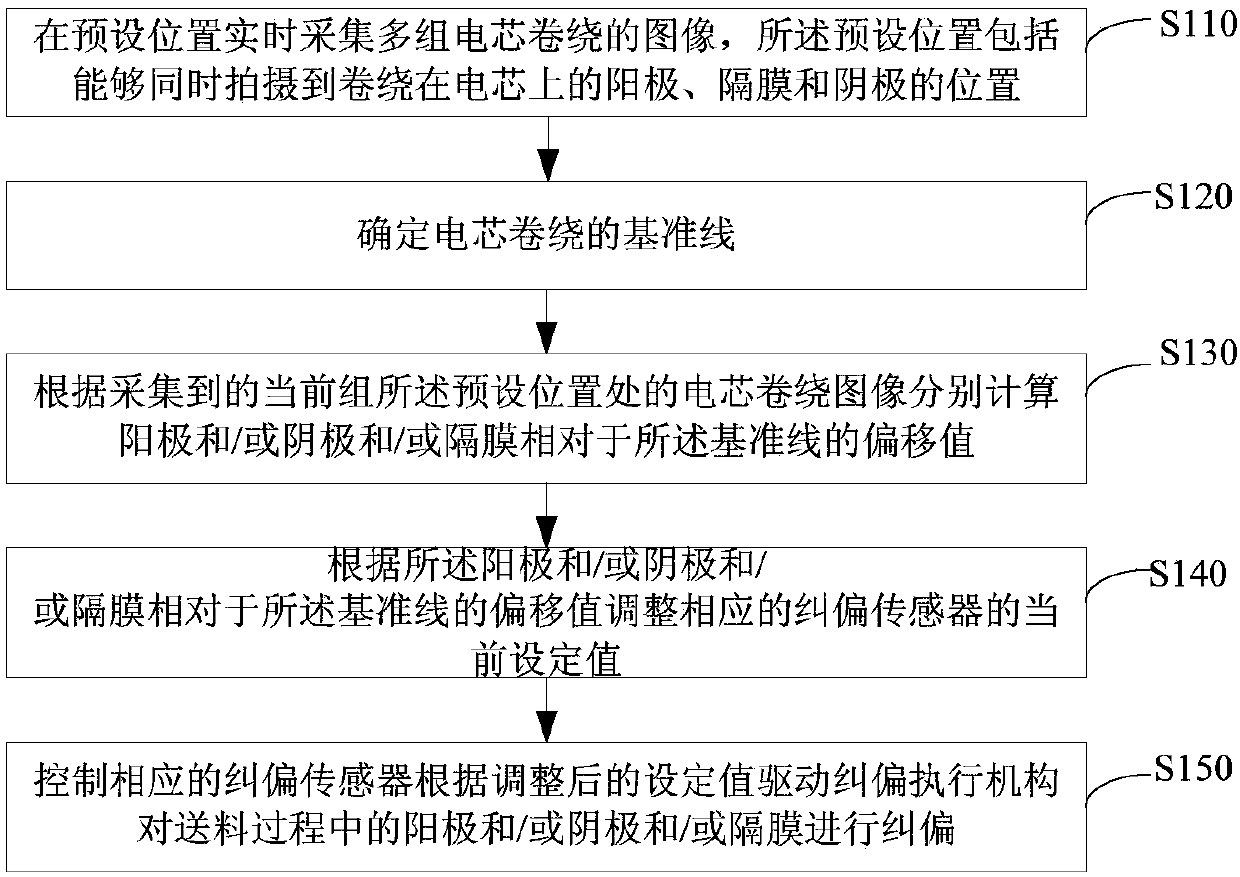

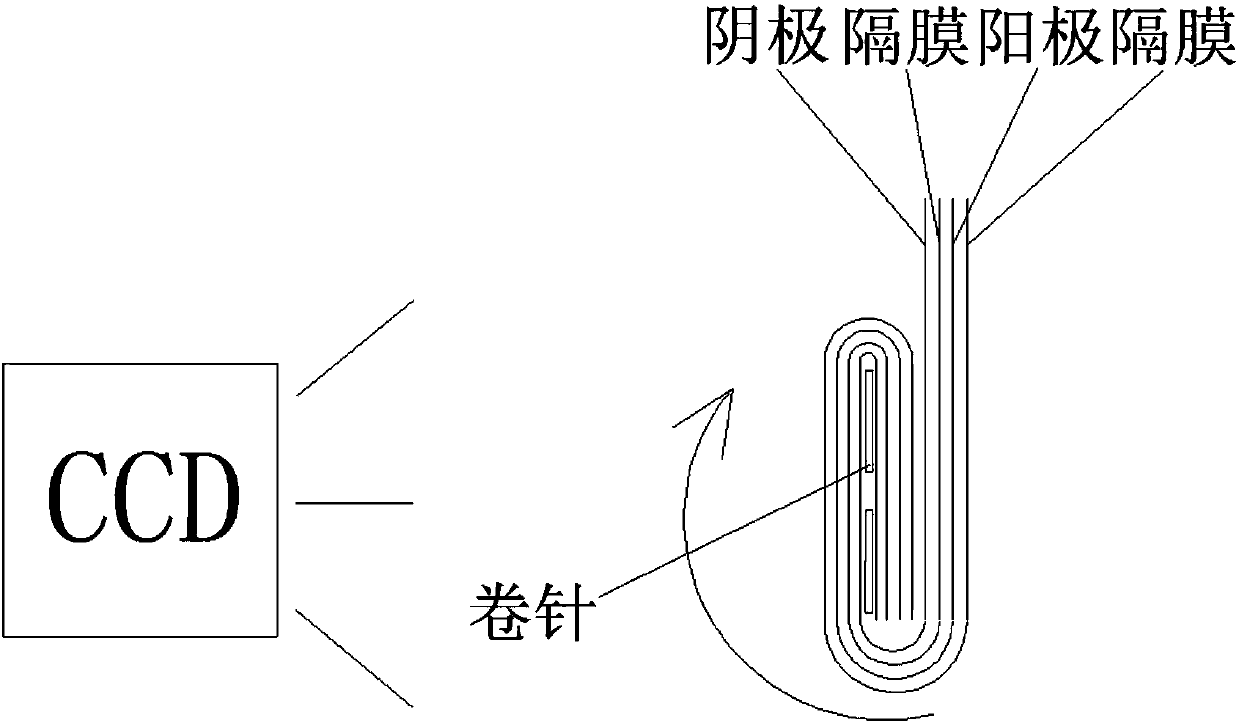

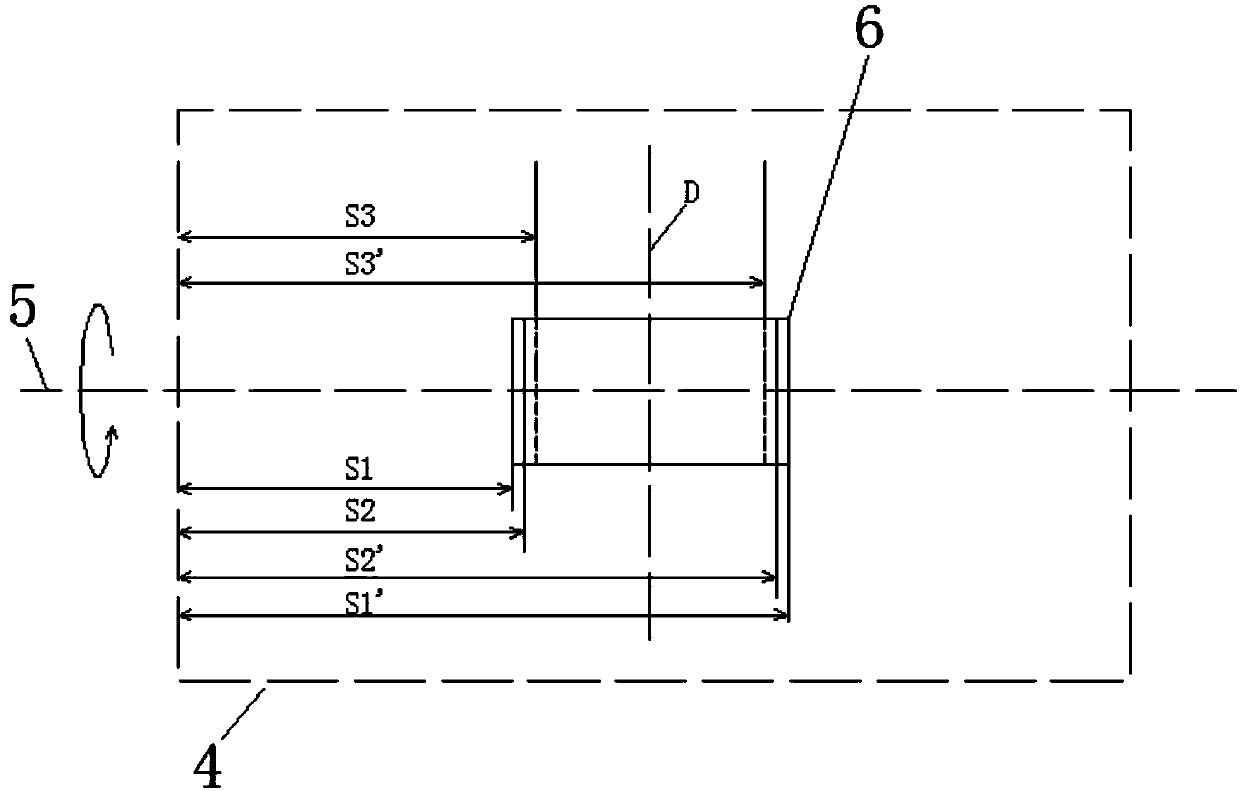

Charge coupled device (CCD) feedback correction closed-loop control method, control device and control system

ActiveCN107681202AHigh accuracy of deviation correctionFinal product manufactureSecondary cells manufactureLoop controlAnode

The invention discloses a charge coupled device (CCD) feedback correction closed-loop control method. The CCD coupled device (CCD) feedback correction closed-loop control method comprises the steps ofacquiring winding images of multiple groups of battery cells at a preset position, wherein the preset position comprises positions, at which the battery cell winding position can be shot, of a positive electrode, a separator and a negative electrode; determining a reference line of battery cell winding; respectively calculating a deviation value of the positive electrode and / or the negative electrode and / or the separator relative to the reference line according to the acquired winding images of current groups of battery cells at the preset position; adjusting a current setting value of a corresponding correction sensor according to the deviation value of the positive electrode and / or the negative electrode and / or the separator relative to the reference line; and controlling the corresponding correction sensor to drive a correction execution mechanism so as to correct the positive electrode and / or the negative electrode and / or the separator during the feeding process according to the adjusted setting value. The invention also discloses a CCD feedback correction closed-loop control device and control system. With the CCD feedback correction closed-loop control method provided by theinvention, the correction accuracy is improved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

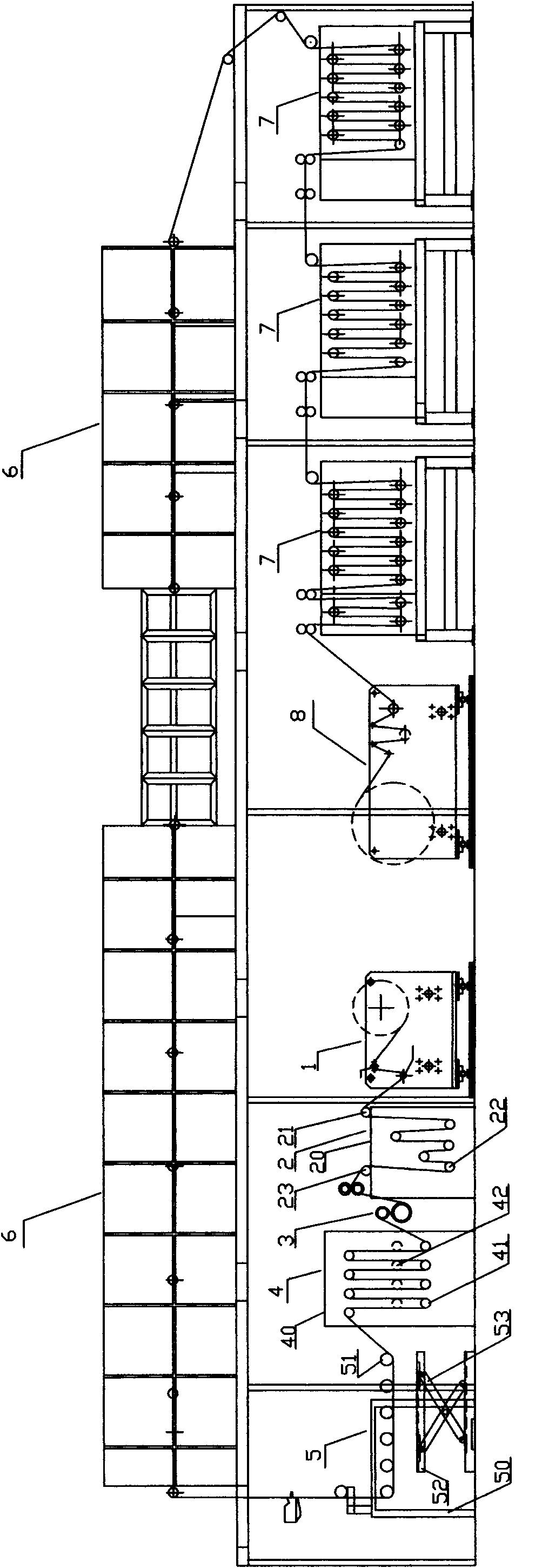

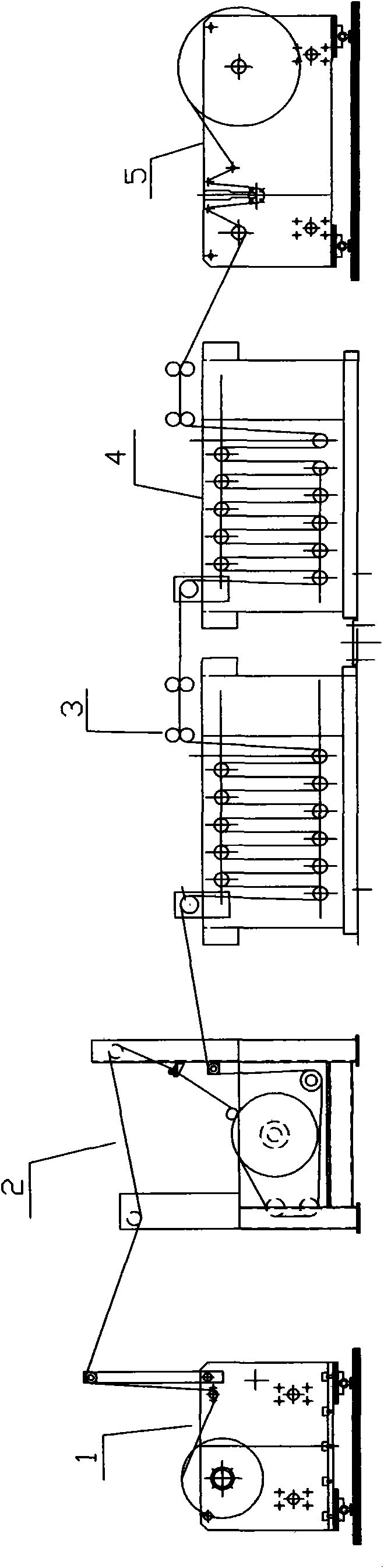

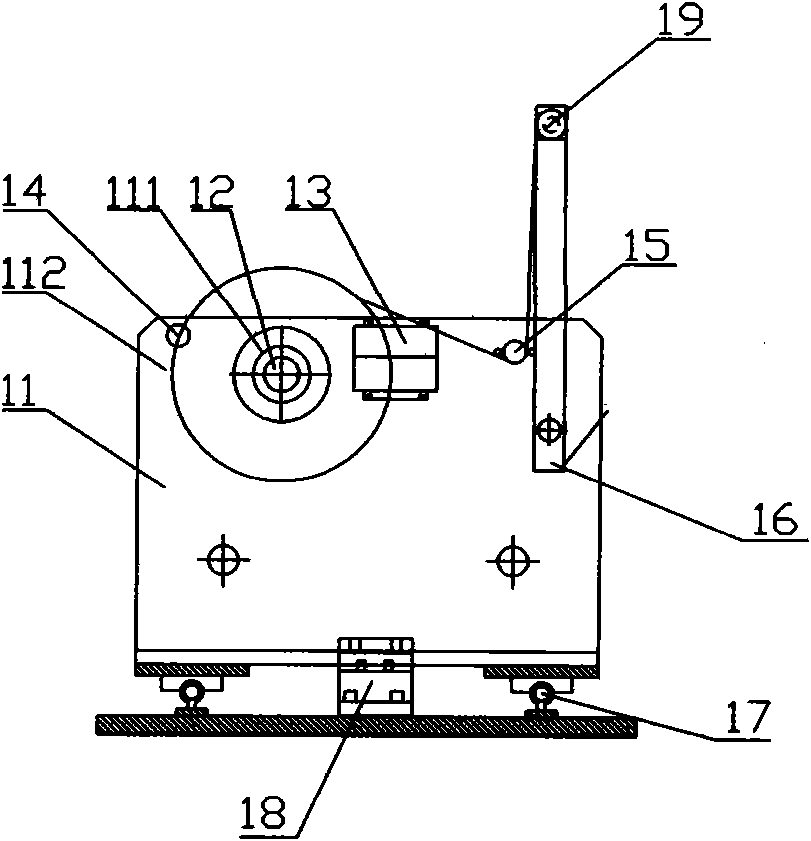

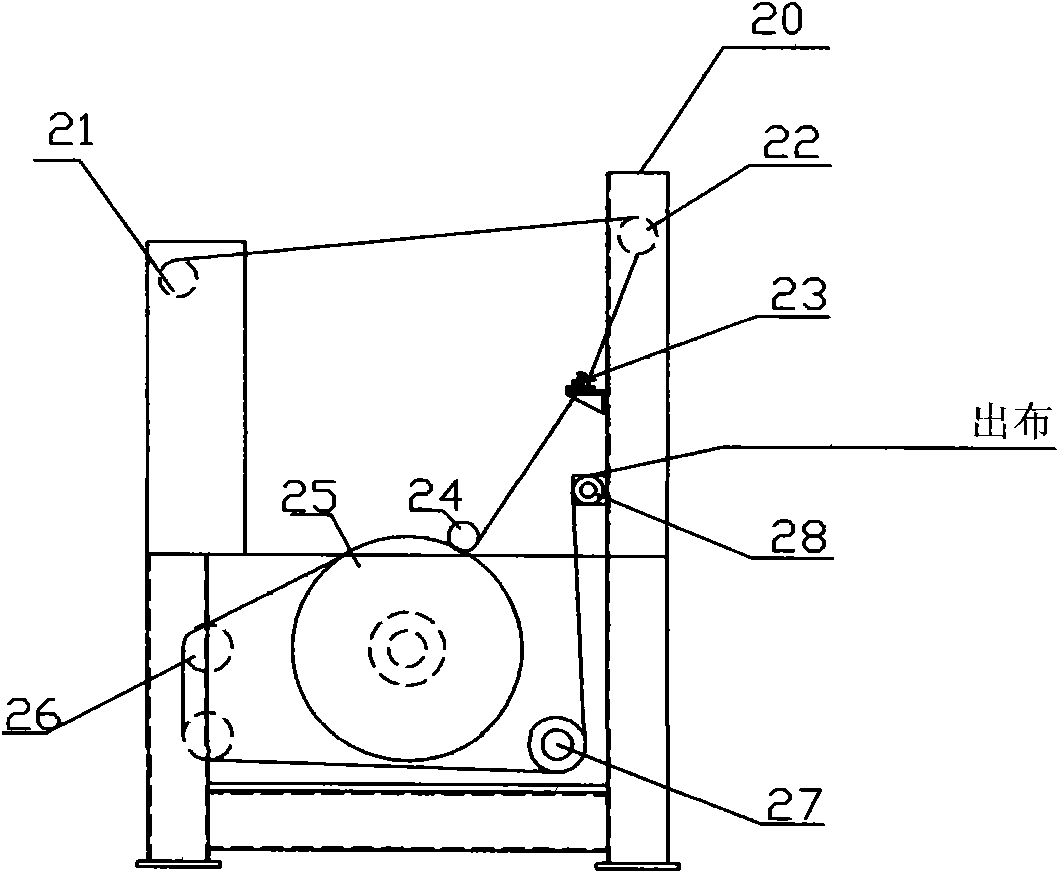

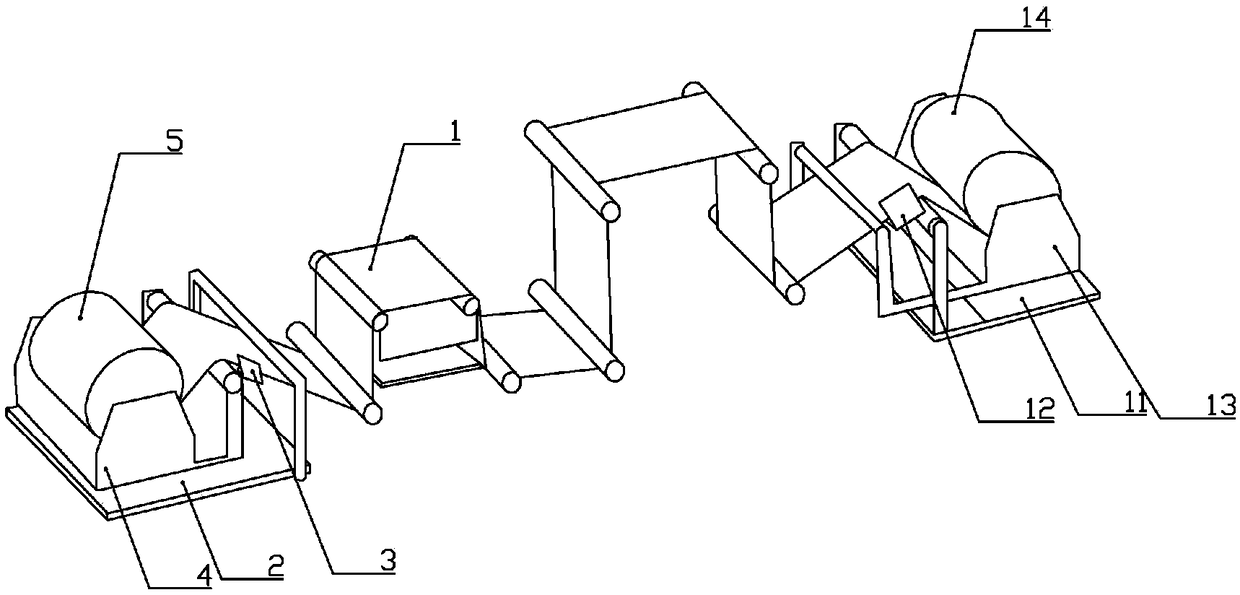

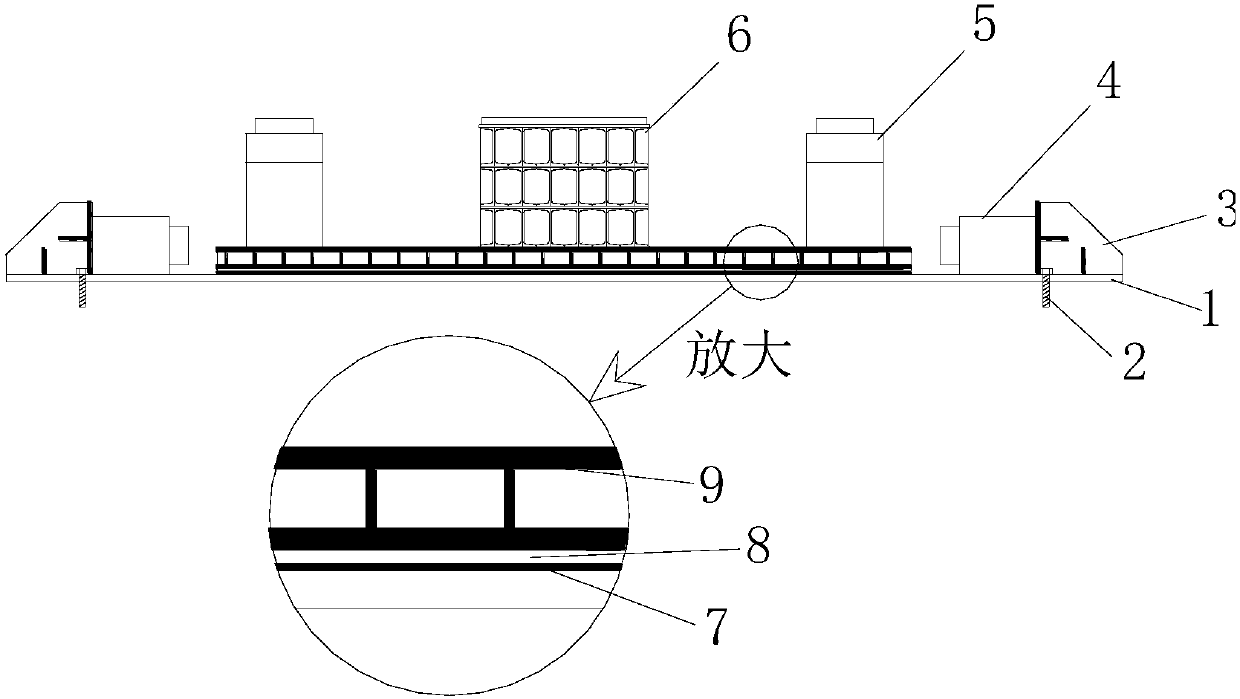

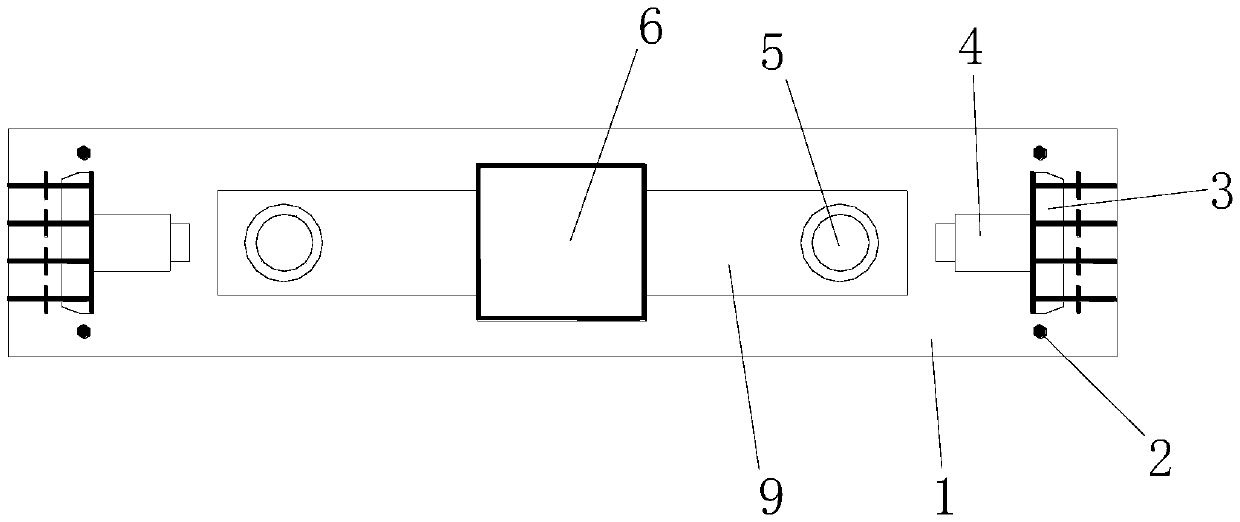

Composite membrane machine for manufacturing flat membrane

InactiveCN102002835ARealize streamlined productionReasonable structureSemi-permeable membranesLiquid/gas/vapor removalEngineeringComposite membrane

The invention discloses a device for manufacturing a flat membrane, in particular a composite membrane machine for manufacturing the flat membrane. The device is characterized by comprising an unfolding cloth charging unit, an immersion unit, a transport unit, a ventilating adjusting unit, a membrane manufacturing unit, a baking unit, a washing unit and a folding cloth discharging unit, wherein the unfolding cloth charging unit, the immersion unit, the transport unit, the ventilating adjusting unit, the membrane manufacturing unit, the baking unit, the washing unit and the folding cloth discharging unit are sequentially arranged in a streamline mode; and the transport unit is arranged on each function unit, and a plurality of groups of cloth guide rollers form a transport rail so that the base cloth can steadily run on the transport rail and is constantly processed by each function unit. The composite membrane machine for manufacturing the flat membrane is reasonable in structure and high in production efficiency, realizes streamline production of the non-woven flat membrane and is applicable to industrial promotion in a large scale.

Owner:ZHEJIANG SHENGSHI MECHANICS

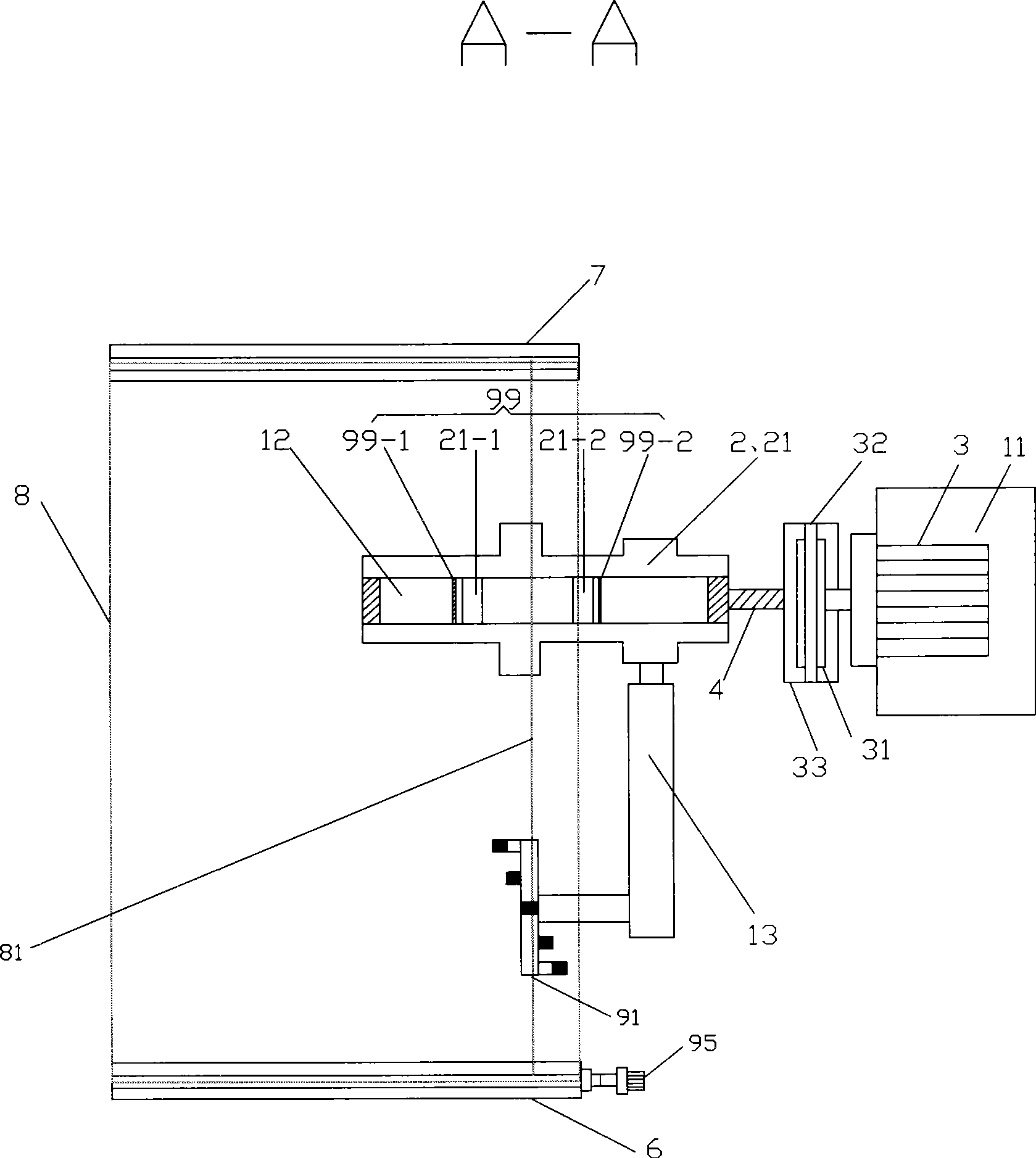

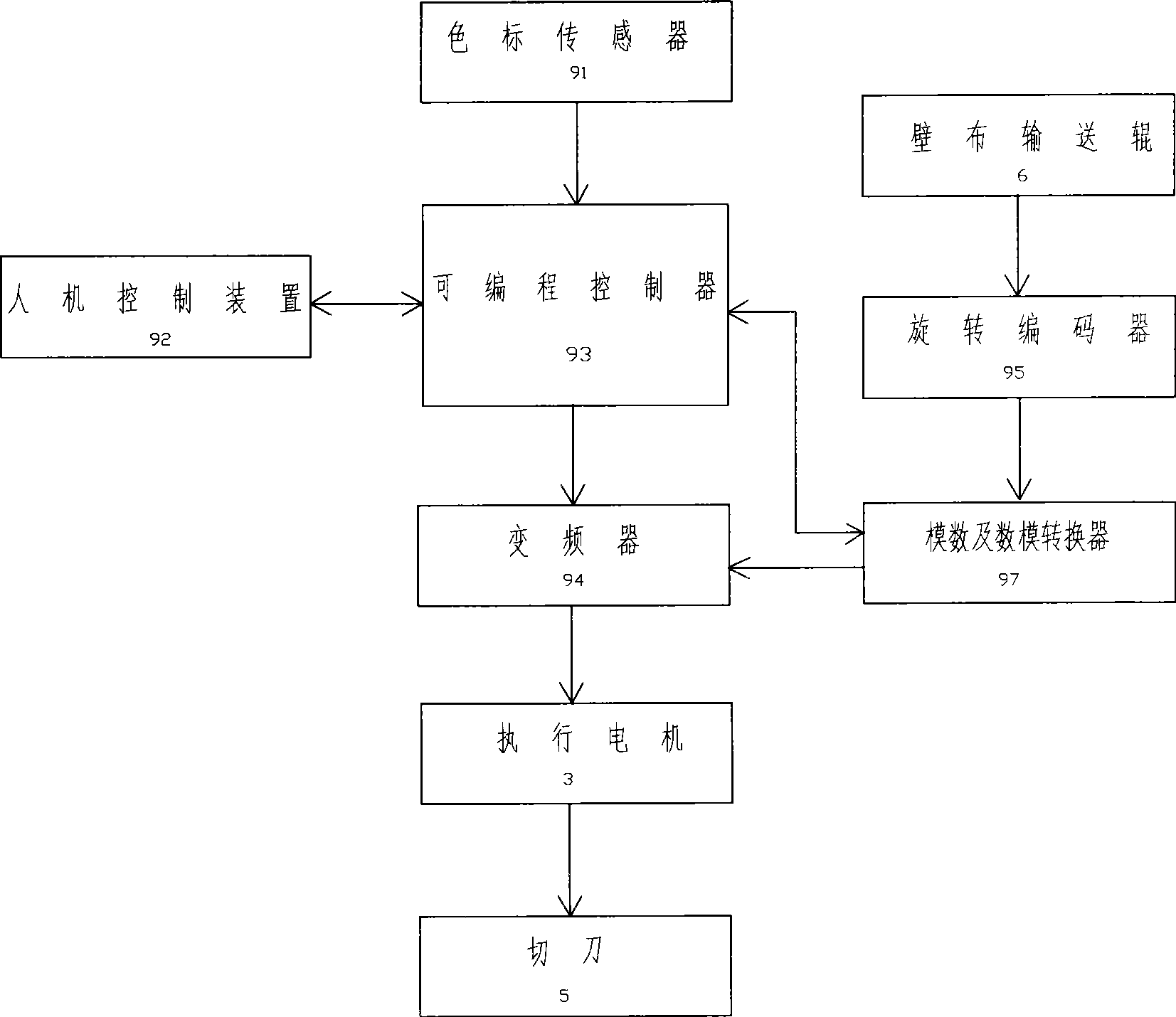

Glass fiber wall cloth edge-cutting electronic error-correcting apparatus

InactiveCN101368327AHigh degree of automationImprove quality and efficiencySevering textilesControl using feedbackColor ScaleGlass fiber

The invention discloses an electronic deviation rectifying device used in glass fiber wallhanging cut trimming, consisting of a control system and an execution system. The control system comprises at least two colour mark sensors, a programmable controller, a transducer, and a revolving coder, and the execution system is composed of an execution motor frame, a slide bar frame, a sensor frame, a cutter saddle, an execution motor, a screw mandrel and a cutter. After any of the colour mark sensors detects color streak which serves as a colour mark inlayed along the edge on the upper surface at one side of the edge to be cut of the wallhanging, the colour mark sensor sends the location information to the programmable controller to control the movement of the cutter so as to rectify deviation. The signals of the colour mark sensors can be used in high speed deviation rectification and low speed deviation rectification. The revolving coder feeds back the detected speed of the threads of the wallhanging to the programmable controller to control the movement speed of the cutter so as to ensure constant ratio of deviation rectification to the speed of the threads of the wallhanging. The electronic deviation rectifying device realizes automated control to deviation rectification and is high in rectification precision, stable in performance, simple in operation and installation and low in making cost.

Owner:常州华碧宝特种新材料有限公司

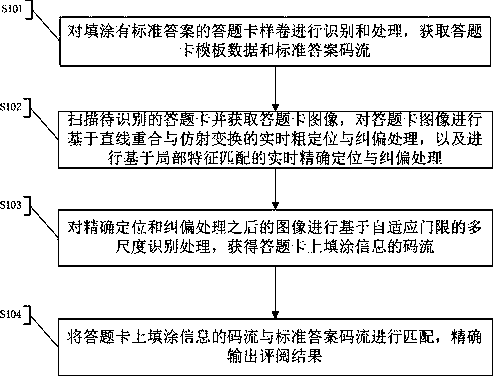

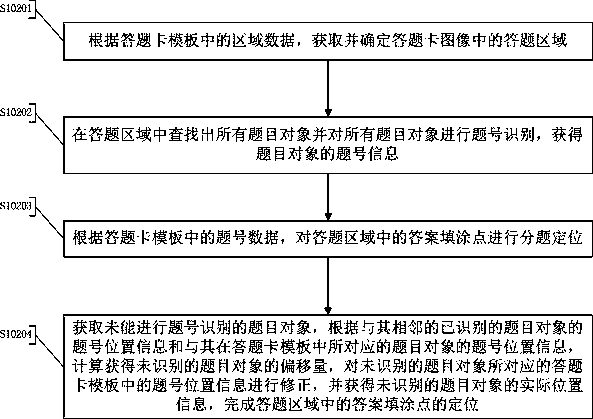

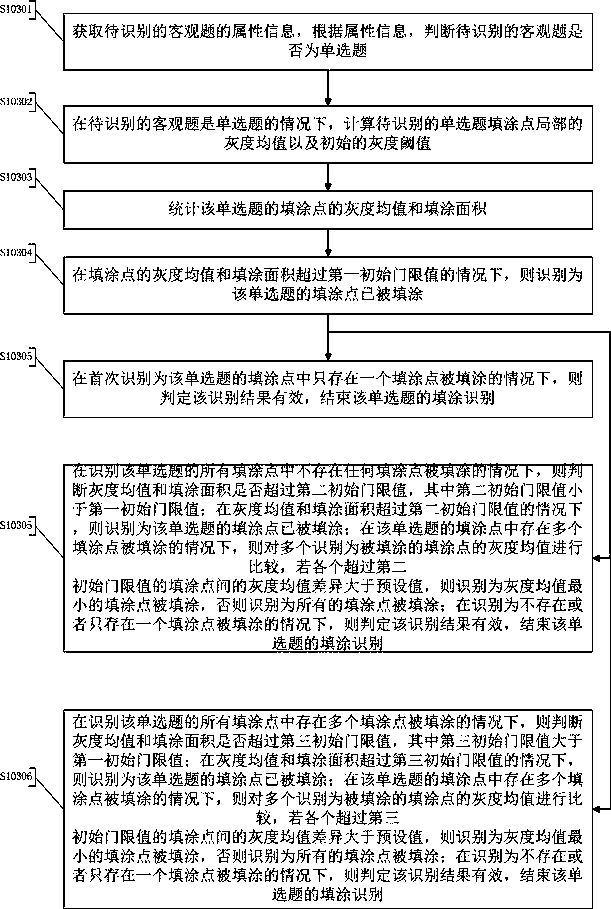

Recognition processing method and device for answer sheet

ActiveCN108537218AAchieve positioningAccurate realizationImage analysisGeometric image transformationPattern recognitionFeature matching

The invention provides a recognition processing method for an answer sheet. The method comprises the following steps: performing recognition and processing on answer sheet sample test paper filled with standard answers, and obtaining answer sheet template data and standard answer code stream; scanning an answer sheet to be scanned and obtaining an answer sheet image, performing real-time coarse positioning based on linear superposition and affine transformation and correction processing on the answer sheet image, and performing real-time accurate positioning based on local feature matching andcorrection processing; performing multi-scale recognition processing based on an adaptive threshold on the image subjected to accurate positioning and correction processing, so as to obtain code stream of filled information on the answer sheet; and matching the code stream of the filled information on the answer sheet with the standard answer code stream, and accurately outputting review results.Correspondingly, the invention further provides a recognition processing device for the answer sheet. The method has the advantages that the answer card can be accurately positioned, single choices,multiple choices and indefinite choices can be recognized and processed, and the recognition precision is high.

Owner:湖南诚壹文化产业有限公司

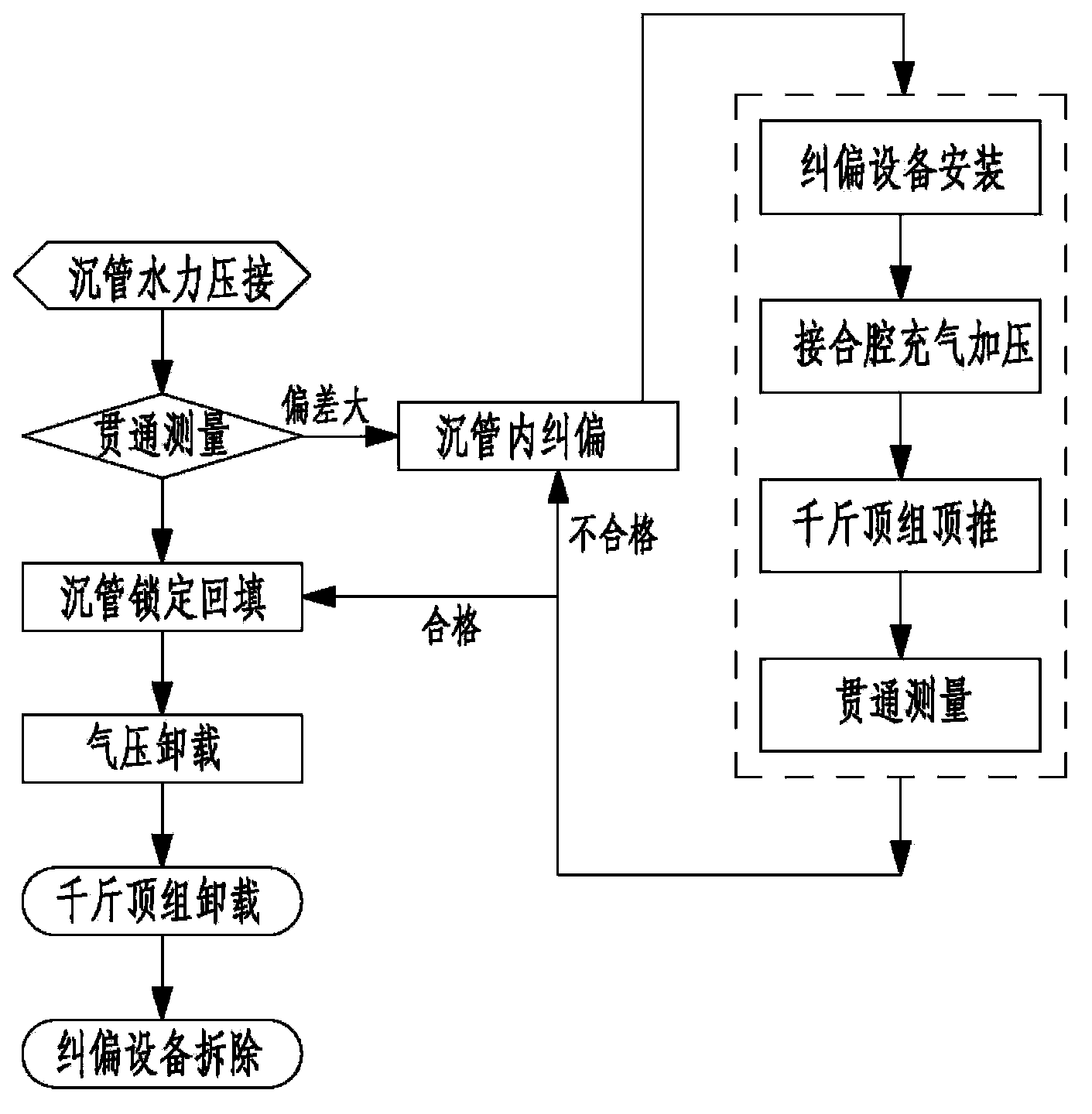

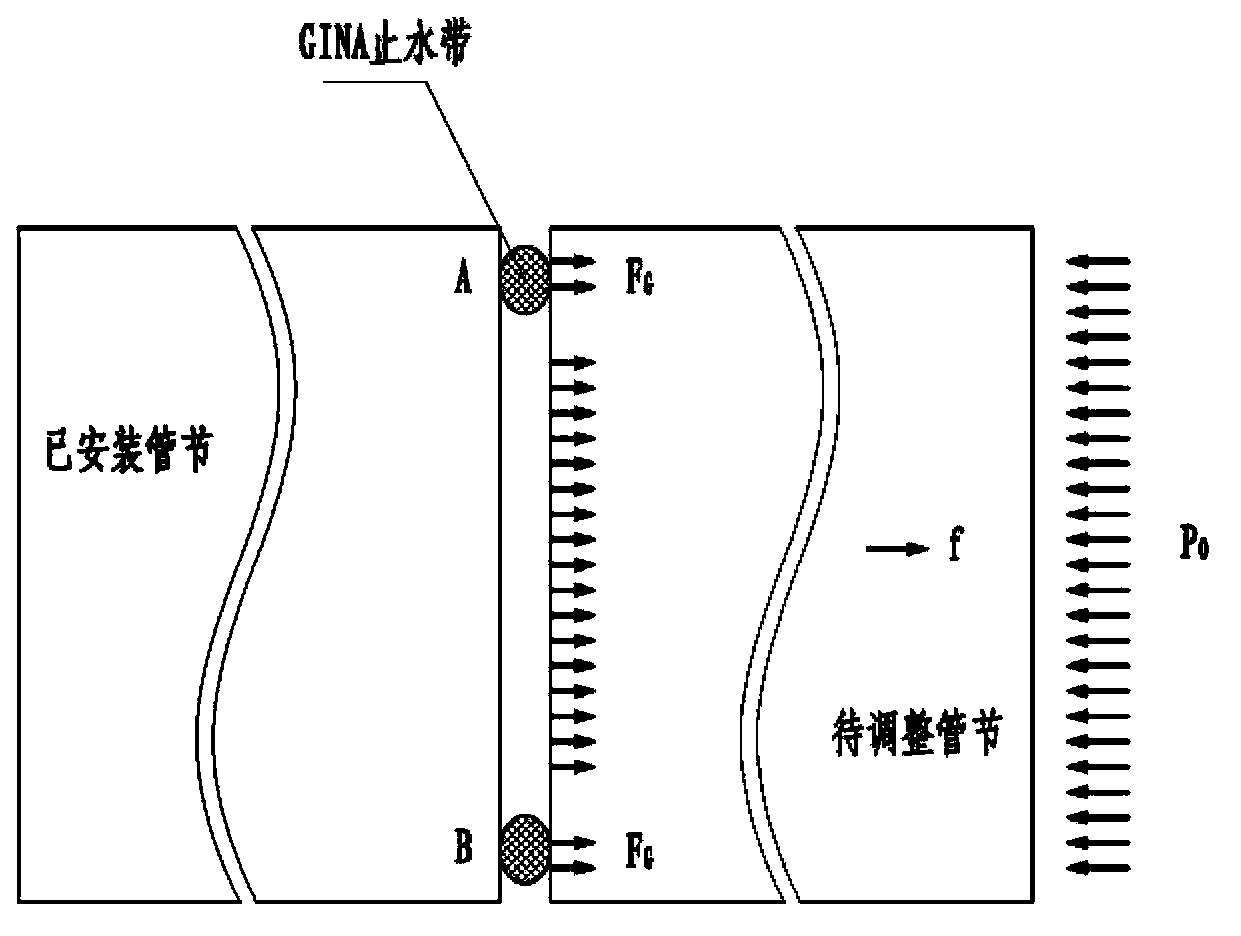

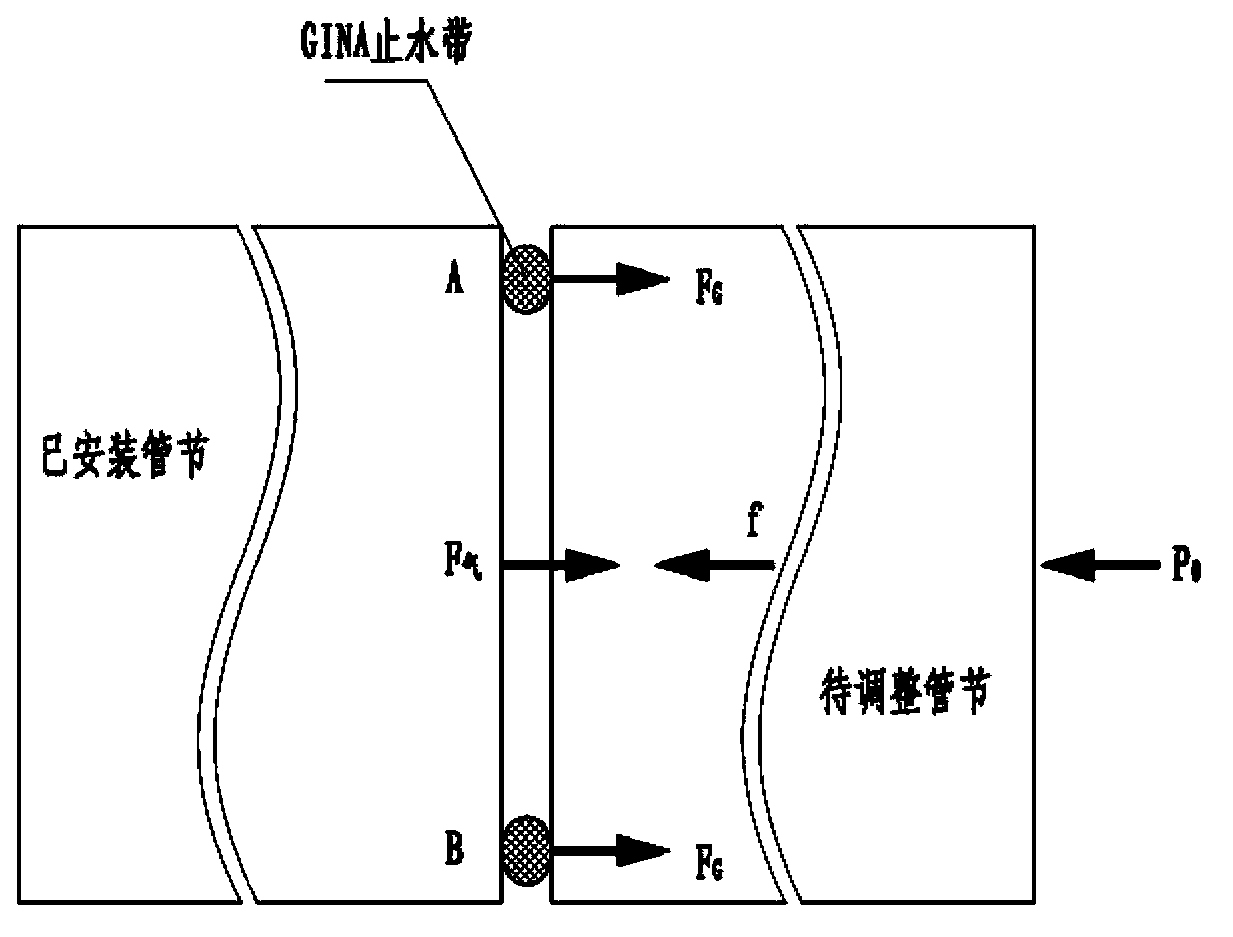

Rectification method for immersed tube tunnel

ActiveCN103912017AReduce the difficulty of correctionSimplify the construction processArtificial islandsUnderwater structuresEngineeringImmersed tube

The invention provides a rectification method for an immersed tube tunnel. The rectification method comprises a step of mounting a jack group in a joint chamber, a step of controlling the jack group to jack up a tube section to be adjusted until completion, a step of backfilling at the two sides of the immersed tube, a step of removing the jacking force of the jack group, and a step of detaching the jack group. Due to the adopted steps, the jack group is mounted in the jointed chamber to perform fine adjustment rectification on the immersed tube in the chamber, and therefore, the rectification difficulty of the immersed tube under water can be reduced, the construction cost can be reduced and the rectification precision can be improved; air can be charged into the jointed chamber so that the total pressure in the joint chamber is basically equal to the sum of water pressure outside the tube section to be adjusted and the frictional force of a foundation bed, and therefore, the tube section to be adjusted is located in a dynamic-static critical state; rectification can be realized by just applying relatively low jacking force to the immersed tube by using the jack group of a relatively small size, and therefore, the size of the jack group is effectively reduced and then the jack group can be matched with the relatively small space of the joint chamber.

Owner:CCCC FIRST HARBOR ENG +1

Plate membrane coating machine

InactiveCN102011282ARealize streamlined productionReasonable structureSemi-permeable membranesLiquid/gas/vapor removal by scrapingBiochemical engineeringAssembly line

The invention discloses production equipment for plate membranes, in particular a plate membrane coating machine. The plate membrane coating machine is characterized by comprising an uncoiling feeding unit, a coating unit, a conveying unit, a washing unit and a coiling folding unit, wherein the uncoiling feeding unit, the coating unit, the washing unit and the coiling folding unit are arranged in turn according to an assembly line; and the conveying unit is arranged on the functional units and mainly comprises a conveying rail consisting of a plurality of groups of cloth guide rollers, so that base fabrics can be treated by each functional unit through the conveying rail uninterruptedly. The plate membrane coating machine is reasonable in structure and high in production efficiency, realizes streamlined production of non-woven plate membranes and is suitable for large-scale industrial popularization.

Owner:ZHEJIANG SHENGSHI MECHANICS

Automatic paper web deviation rectifying device

ActiveCN103569715AAccurate realizationSimple structureWebs handlingPulp and paper industryPosition analysis

The invention discloses an automatic paper web deviation rectifying device which comprises a front paper carrying roll, a front deviation rectifying roll, a rear deviation rectifying roll, a rear paper carrying roll, a light source, an imaging device, a longitudinally cut cursor position analysis and deviation calculation module and a deviation rectifying master control module. A paper web is led in from the front paper carrying roll, sequentially passes the front deviation rectifying roll and the rear deviation rectifying roll and finally is led out from the rear paper carrying roll, the front deviation rectifying roll and the rear deviation rectifying roll tension the paper web, the light source irradiates the surface of the paper web between the rear deviation rectifying roll and the rear paper carrying roll, the imaging device can be used for imaging the paper web irradiated by the light source and messaging the longitudinally cut cursor position analysis and deviation calculation module, the longitudinally cut cursor position analysis and deviation calculation module obtains paper web deviation position information by calculation and comparison and transmits the information to the deviation rectifying master control module, and the deviation rectifying master control module controls the front deviation rectifying roll and the rear deviation rectifying roll to axially and synchronously deflect in a plane perpendicular to the paper web. The automatic paper web deviation rectifying device is simple in structure, high in deviation rectifying precision, smooth in operation and convenient to use, and the motion state of the paper web is conveniently monitored, controlled and adjusted in real time.

Owner:KUNSHAN BANKNOTE PAPER +1

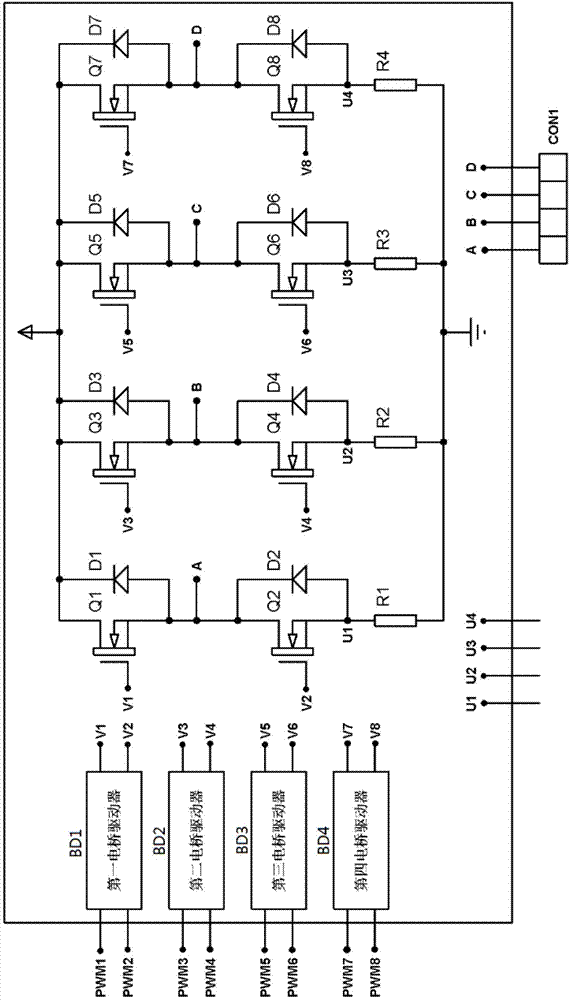

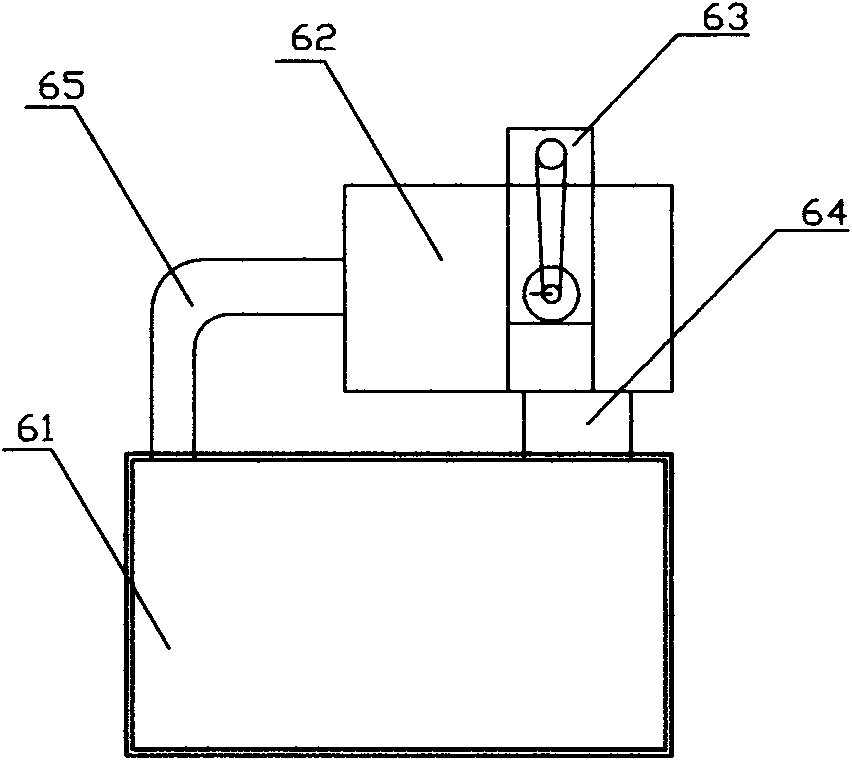

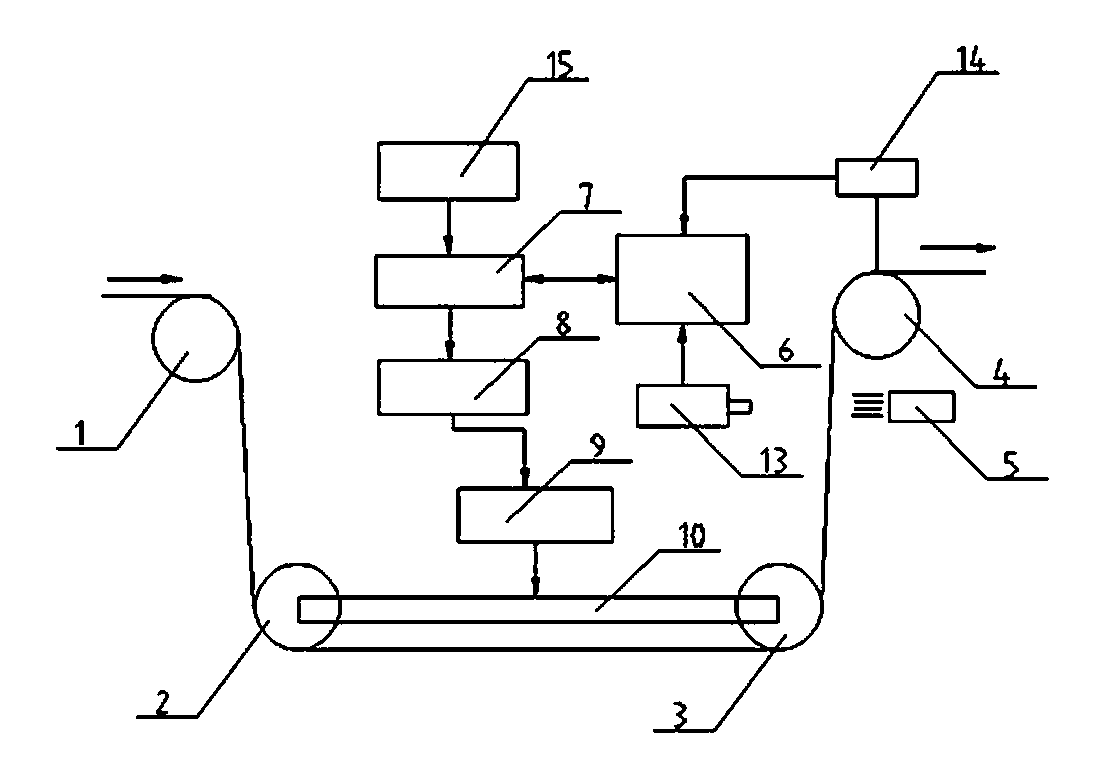

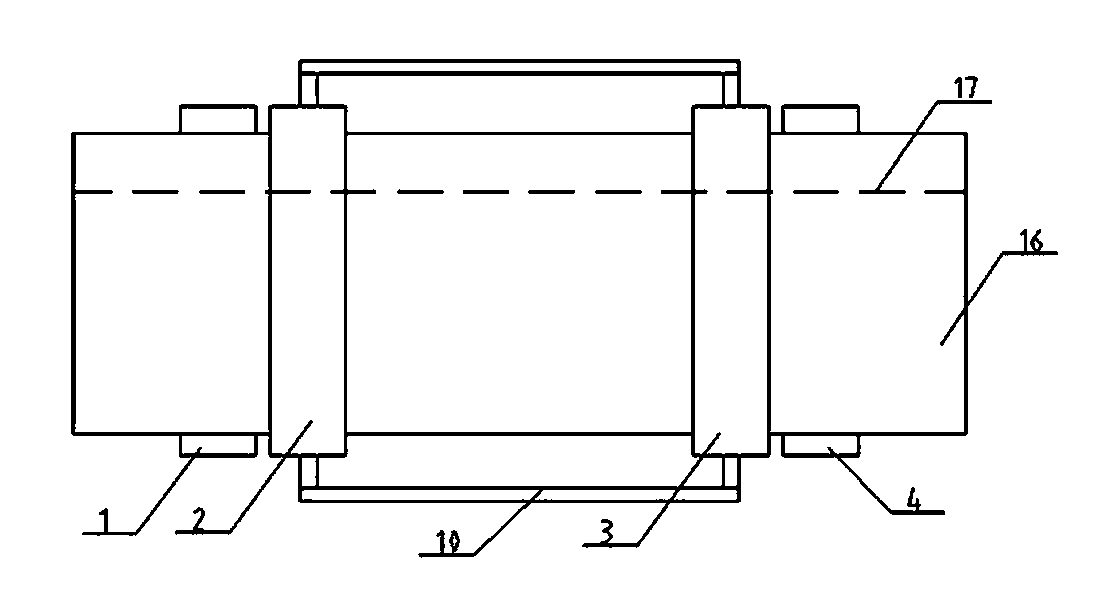

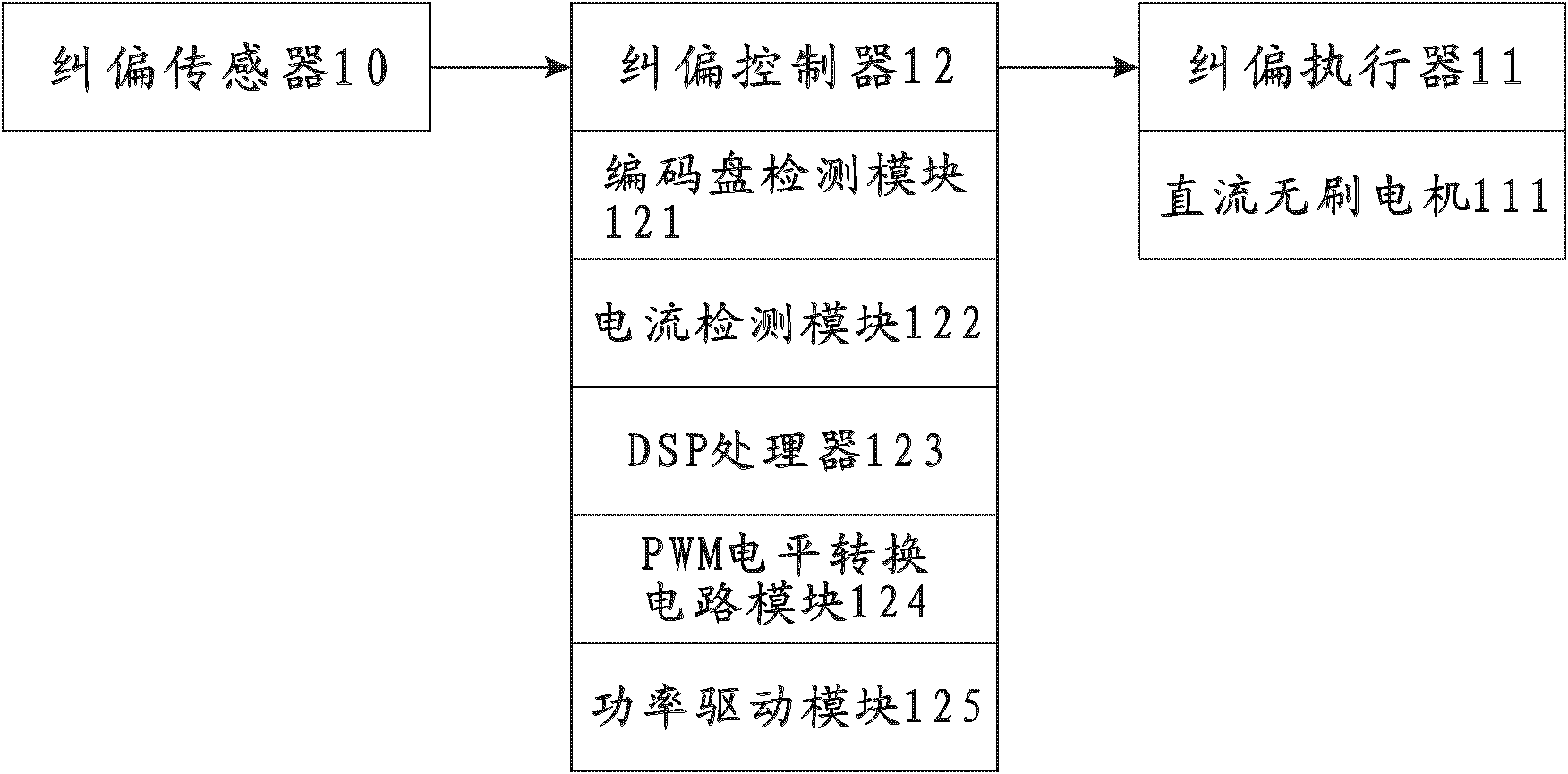

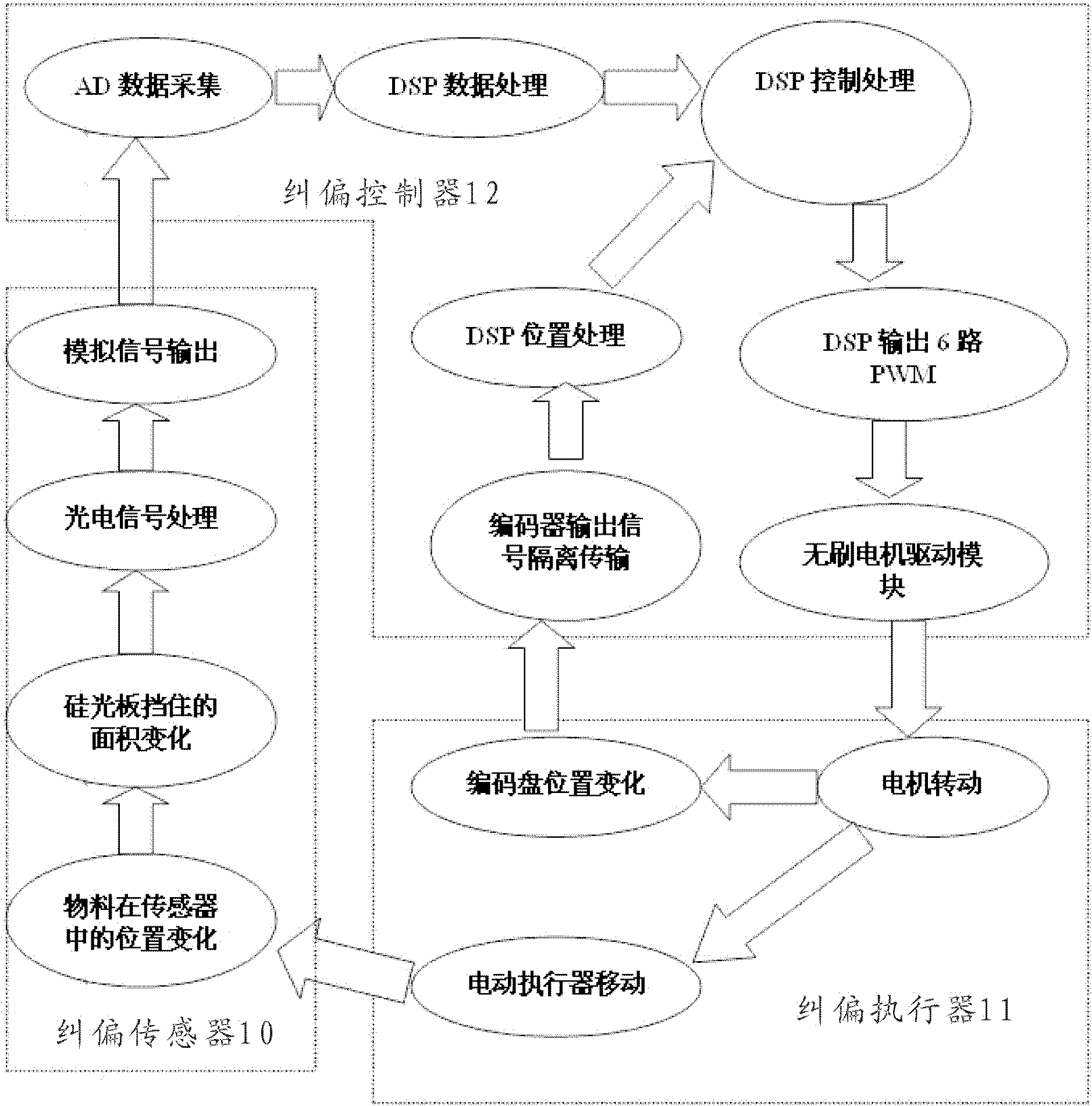

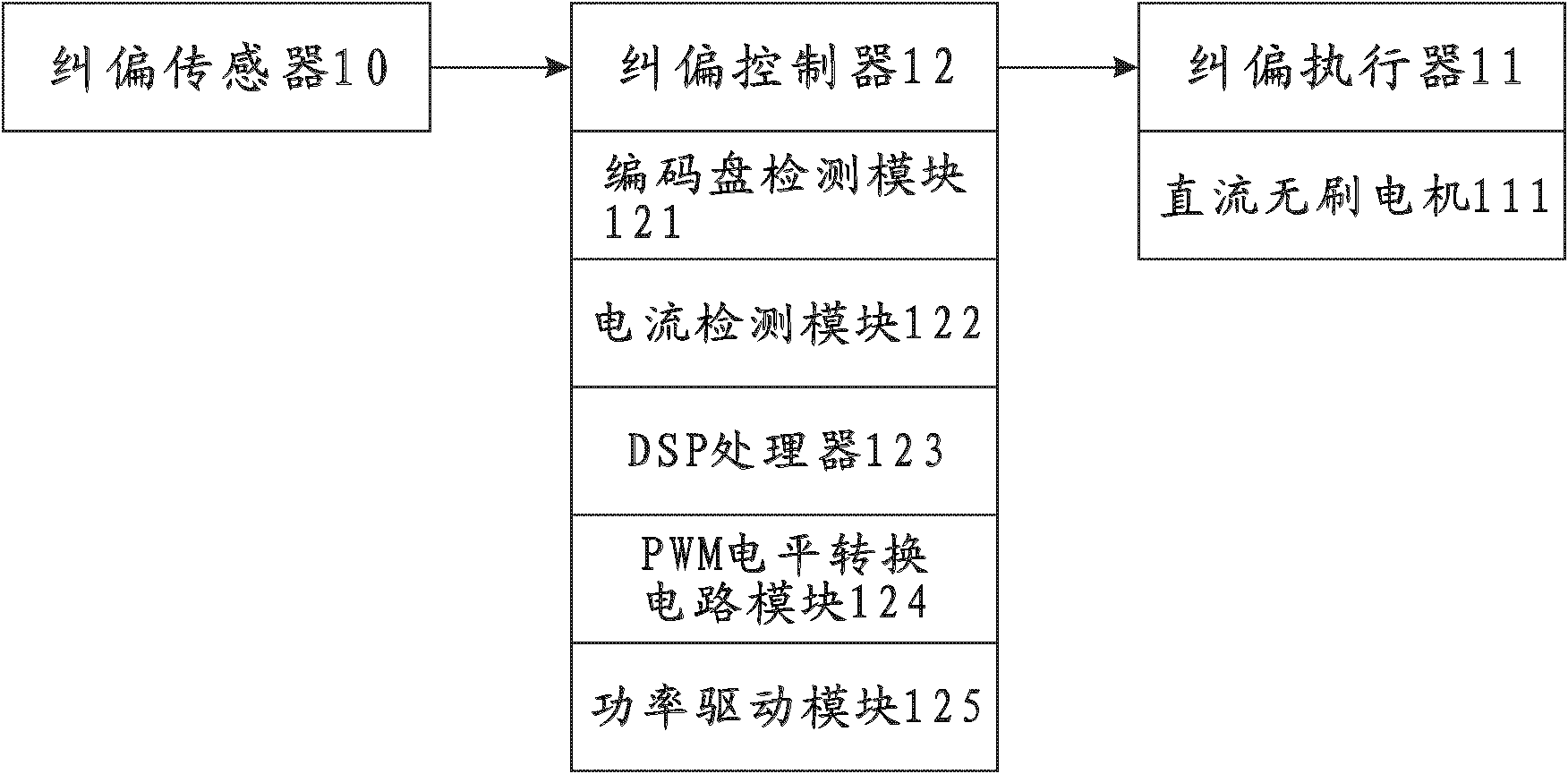

Device and system for controlling deviation correction of brushless direct current (DC) motor

InactiveCN102053630AOvercoming the defects of easy wearHigh accuracy of deviation correctionControl using feedbackClosed loopActuator

The invention discloses a device and system for controlling deviation correction of a brushless direct current (DC) motor. The device comprises a deviation correcting sensor, a deviation correcting controller and a deviation correcting actuator which are connected in sequence, wherein the deviation correcting sensor is used for acquiring the advancing positions of the materials; the deviation correcting controller is used for acquiring the deviation correcting sensor data and controlling the action of the deviation correcting actuator; the deviation correcting actuator is used for pulling the materials back to the normal positions and comprises the brushless DC motor; the deviation correcting controller comprises a coding disc detection module, a current detection module, a digital signal processor (DSP), a pulse width modulation (PWM) level converting circuit module and a power drive module; the DSP drives the deviation correcting actuator to work via the PWM level converting circuit module and the power drive module; and the DSP ensures a coding disc to carry out closed loop switch in various states according to the state of the coding disc of the motor and the rotation speed value of the motor. The device and the system can be accurately positioned through state switching of a coder under the premise of not adopting limit switches and can implement closed loop control along with the rotation speed of the brushless DC motor.

Owner:惠州市爱博智控设备有限公司

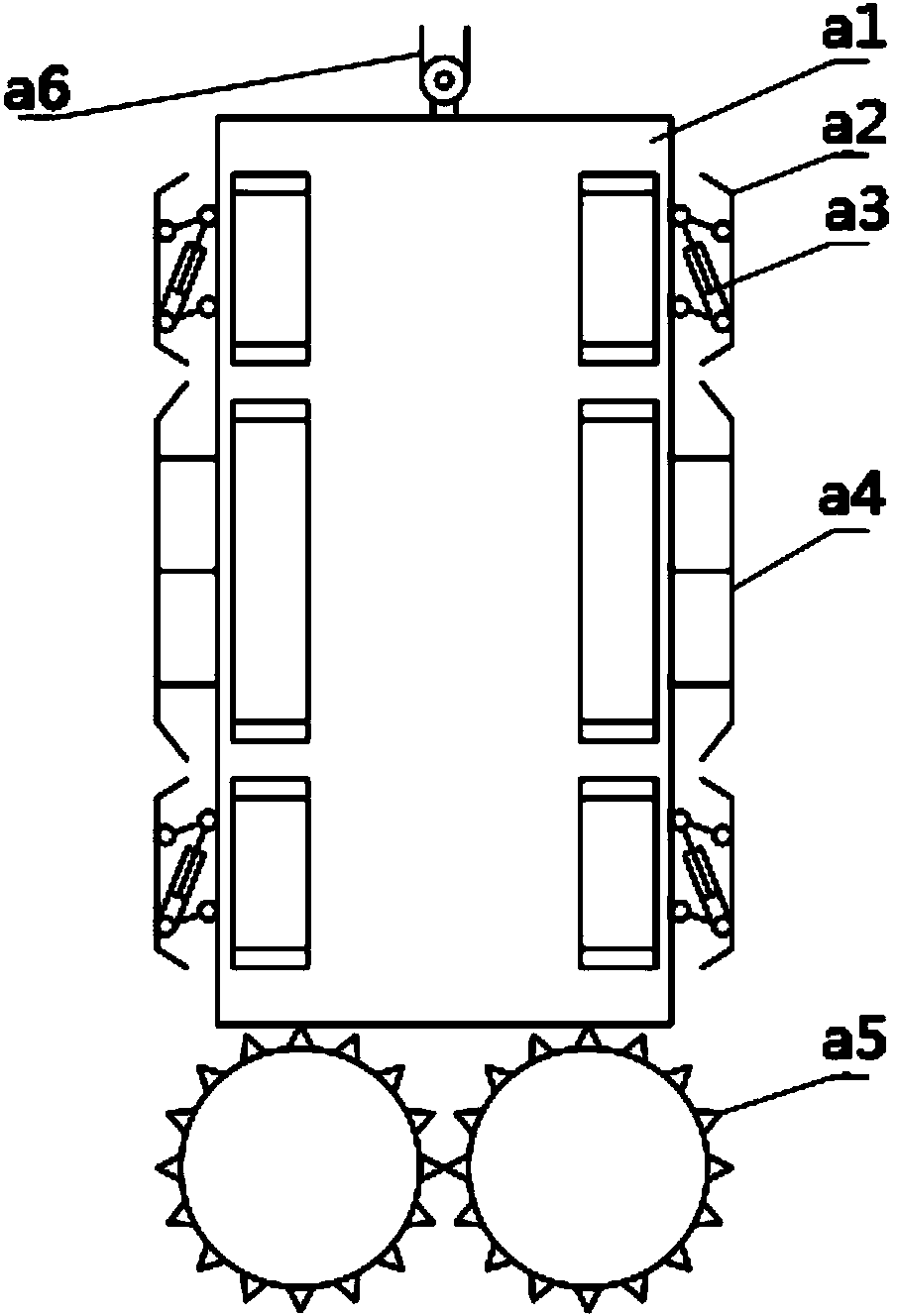

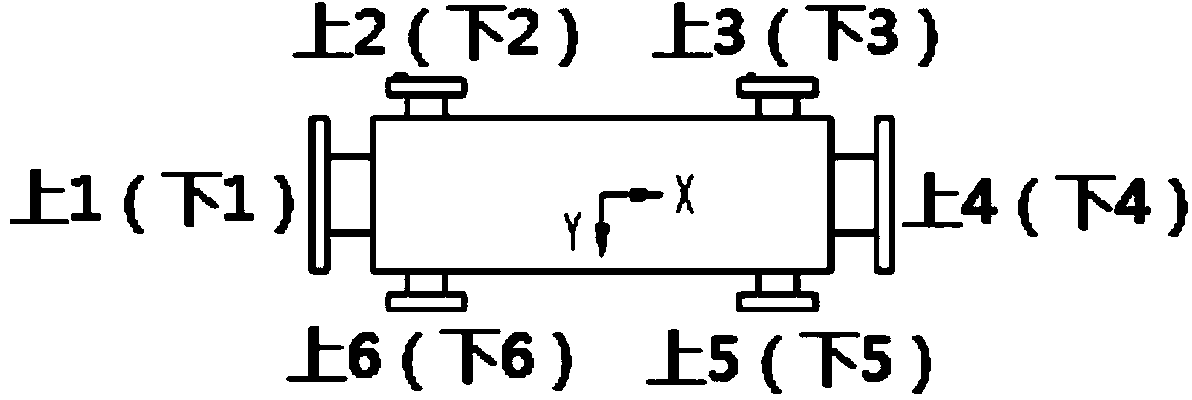

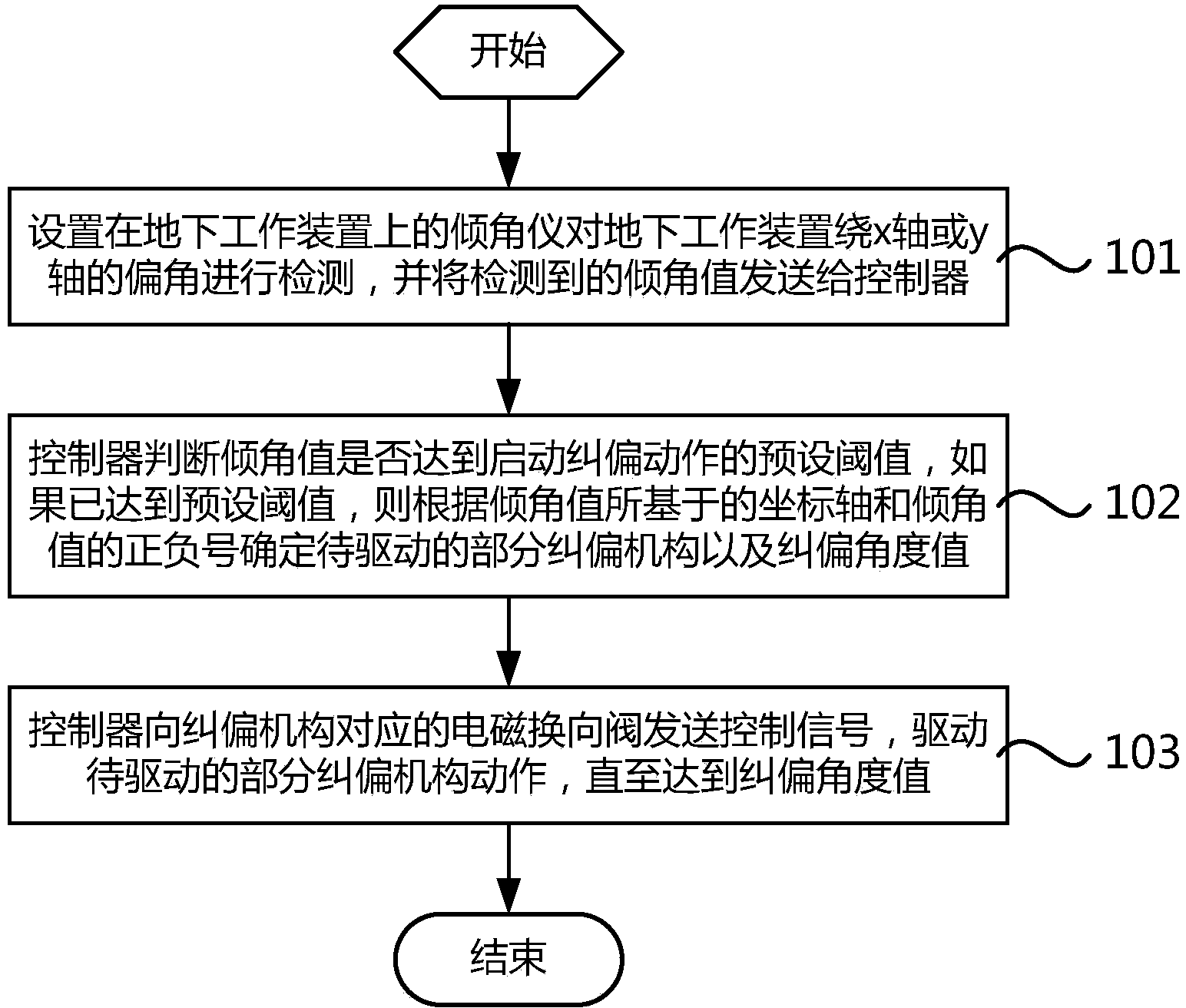

Automatic inclination correcting method and device

ActiveCN103835329AHigh accuracy of deviation correctionImprove groove qualitySoil-shifting machines/dredgersControl signalAngular degrees

The invention relates to an automatic inclination correcting method and device. The method includes the flow of correcting the angle of declination of an underground working device around an x axis or a y axis, and the flow specifically includes the steps that an inclinator is used for detecting the angle of declination of the underground working device around the x axis or the y axis and sending the detected value of the dip angle to a controller; the controller judges whether the value of the dip angle reaches a preset threshold value or not, and if the value of the dip angle reaches the preset threshold value, part of inclination correcting mechanisms to be driven and an inclination correcting angle value are determined according to a coordinate axis on which the value of the dip angle is based and the sign of the value of the dip angle; the controller sends control signals to electromagnetic directional valves corresponding to part of the inclination correcting mechanisms to be driven to drive part of the inclination correcting mechanisms to be driven to move till the inclination correcting angle value is reached. The multiple inclination correcting mechanisms on the underground working device can automatically and properly conduct inclination correcting based on inclination of the underground working device, high inclination correcting accuracy can be achieved without depending on the experience and the state of an operator, and grooving quality is improved.

Owner:XCMG CONSTR MACHINERY

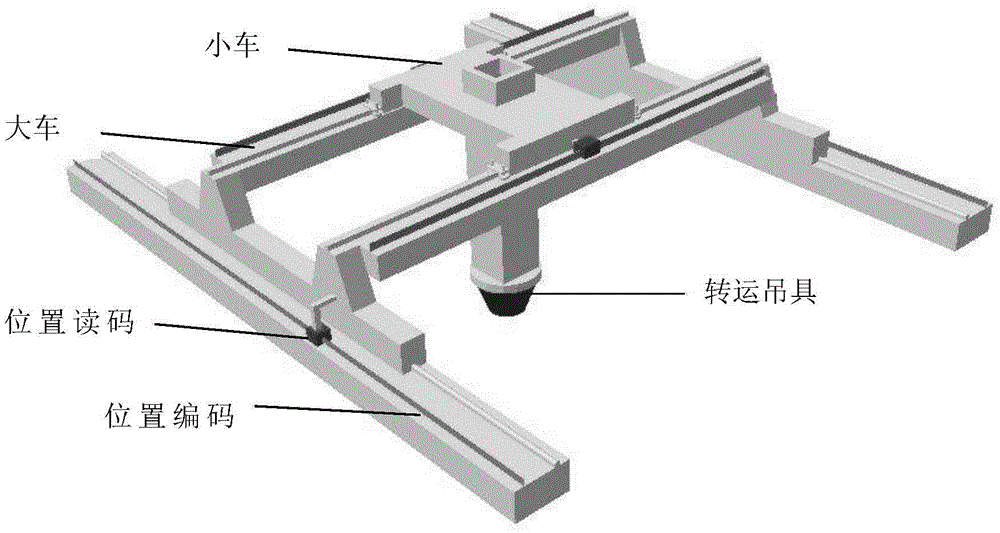

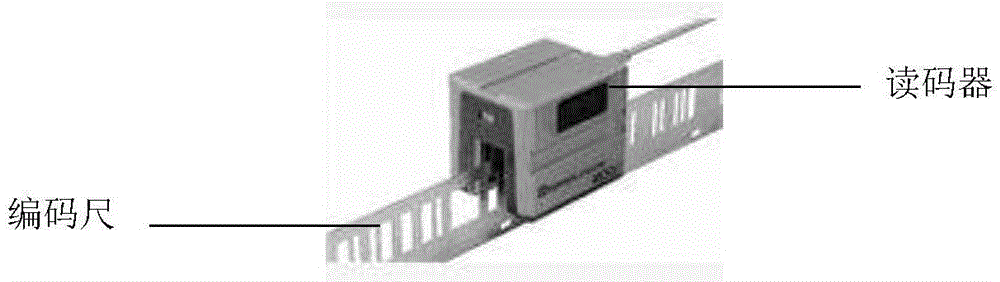

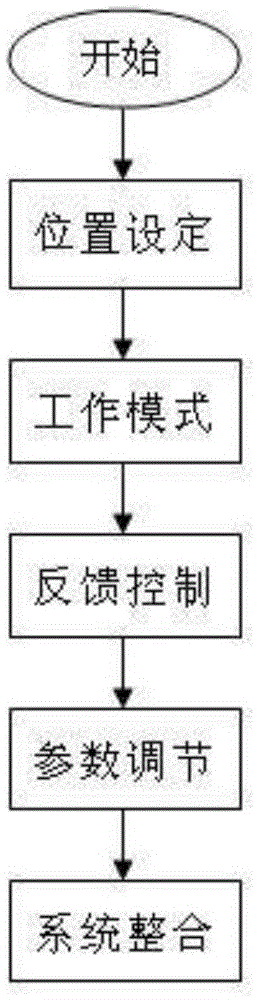

Deviation rectification control method of nuclear waste intelligent bridge crane

InactiveCN105565159AAvoid exposureHigh accuracy of deviation correctionTravelling cranesTravelling gearTime deviationWalking distance

The invention discloses a deviation rectification control method of a nuclear waste intelligent bridge crane, and solves the problem of safe and reliable real-time deviation rectification control of the nuclear waste intelligent bridge crane under the working condition of unattended operation. A control system adopts a master-slave working mode; position encoding systems are respectively mounted on the outer sides of rails at two ends of a cart; and position data is sent to a controller from a code reader through a RS485 interface. The position encoding systems respectively acquire position scale values, actual walking distance values and the like of master-slave two ends of the cart to obtain a deviation value of the master-slave two ends; and a Siemens PLC S7-300 PID feedback control module is used in the controller for real-time deviation rectification control of the cart of the nuclear waste intelligent bridge crane. The method can enable the cart of the nuclear waste intelligent bridge crane to realize real-time synchronous deviation rectification control function, guarantees qualified precision of the control system, is efficient, safe and reliable in system operation, and has important actual use meaning.

Owner:SOUTHWEST JIAOTONG UNIV

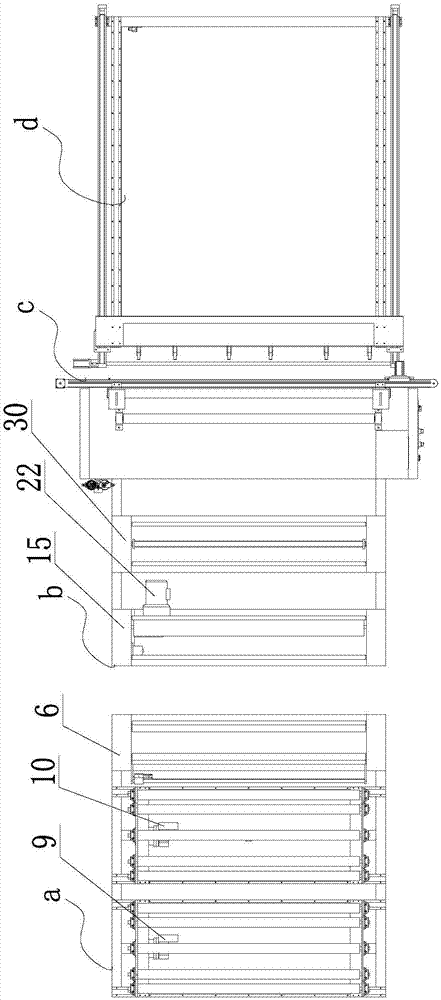

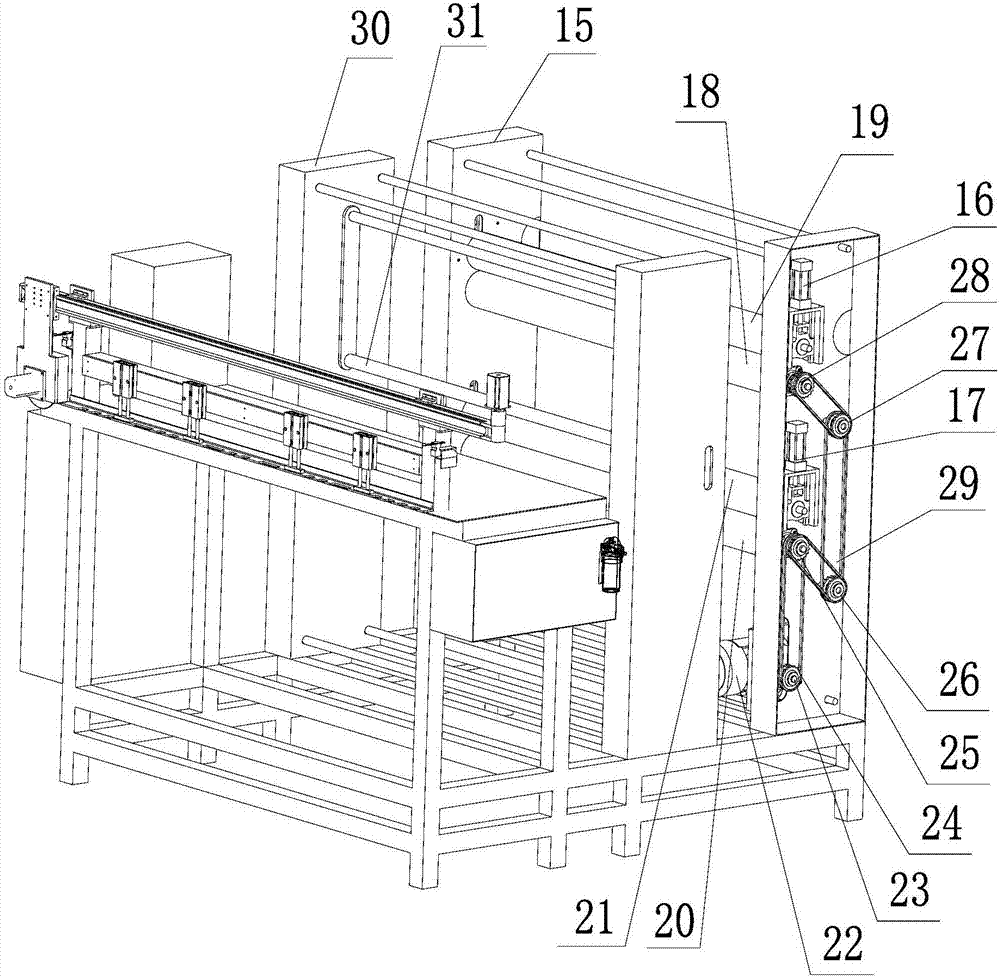

Double-layer sheet transverse cutting machine

InactiveCN107953395AHigh accuracy of deviation correctionImprove work efficiencyLamination ancillary operationsLaminationCross cutEngineering

The invention discloses a double-layer sheet cross-cutting machine. According to the conveying direction of the sheet, a discharging mechanism, a traction mechanism, a cutting mechanism and a receiving hopper are sequentially arranged on a support; the cutting mechanism includes a front clamping assembly, a rear clamping assembly, a transverse The cutting guide assembly and the circular knife assembly, the front clamp assembly is installed on the bracket, the rear clamp assembly is installed on the receiving hopper and moves reciprocally on the receiving hopper along the sheet conveying direction, the cross cutting guide assembly is arranged above the front clamp assembly, The circular knife assembly is arranged on the cross-cut guide assembly and moves back and forth along the cross-cut guide assembly. This double-layer sheet cross-cutting machine can realize the synchronous and stable conveying and cutting of corrugated paper and bubble paper on the same equipment, filling the gap in the market, reducing manual operations, and effectively improving the work efficiency of the cross-cutting machine; It avoids the inconsistent size of corrugated paper and bubble paper, reduces subsequent trimming work, and effectively controls and improves the packaging efficiency of distribution boxes.

Owner:昇辉控股有限公司

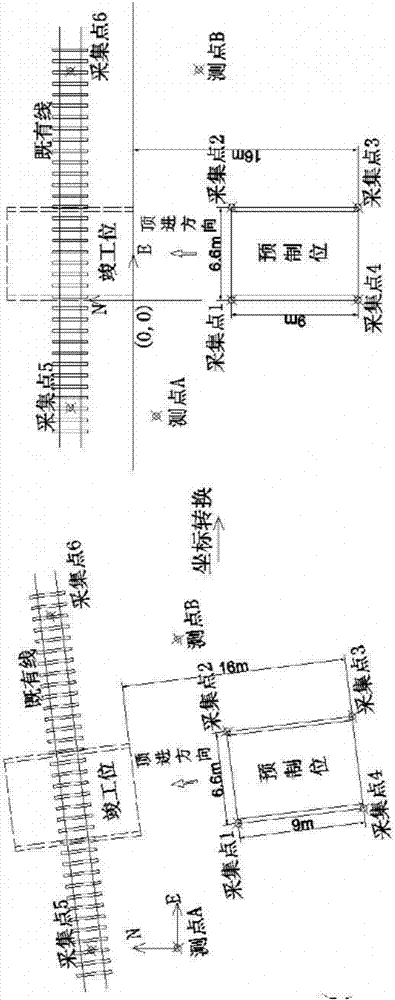

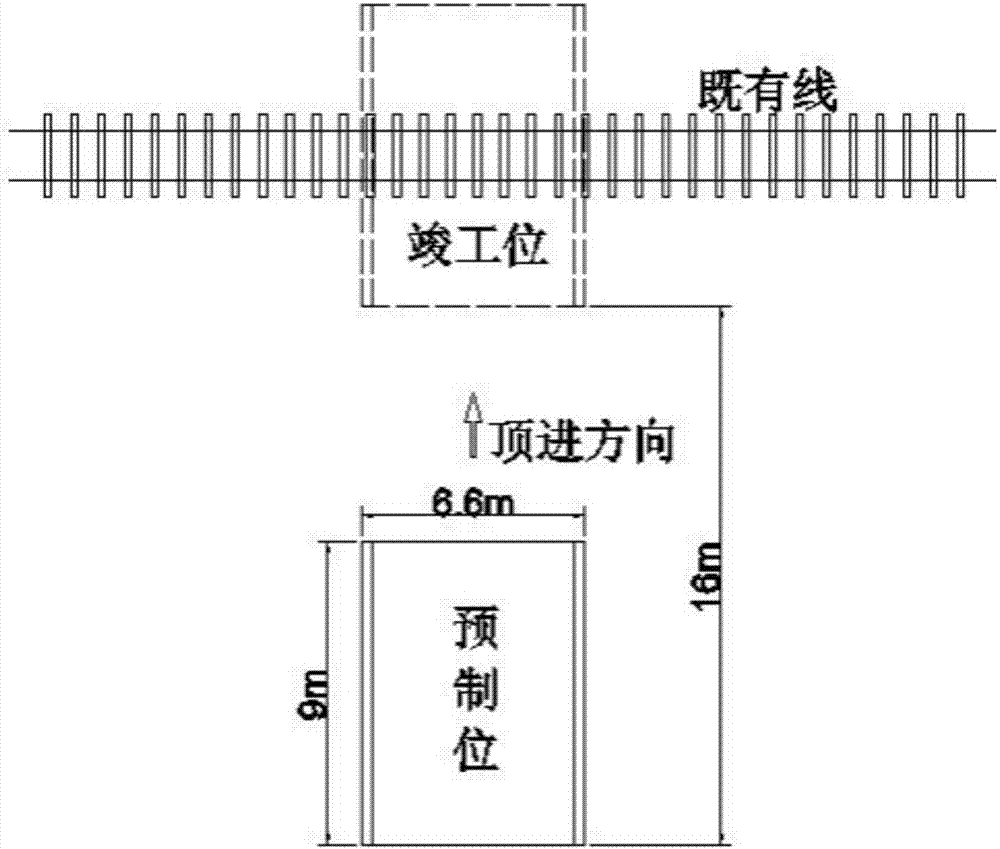

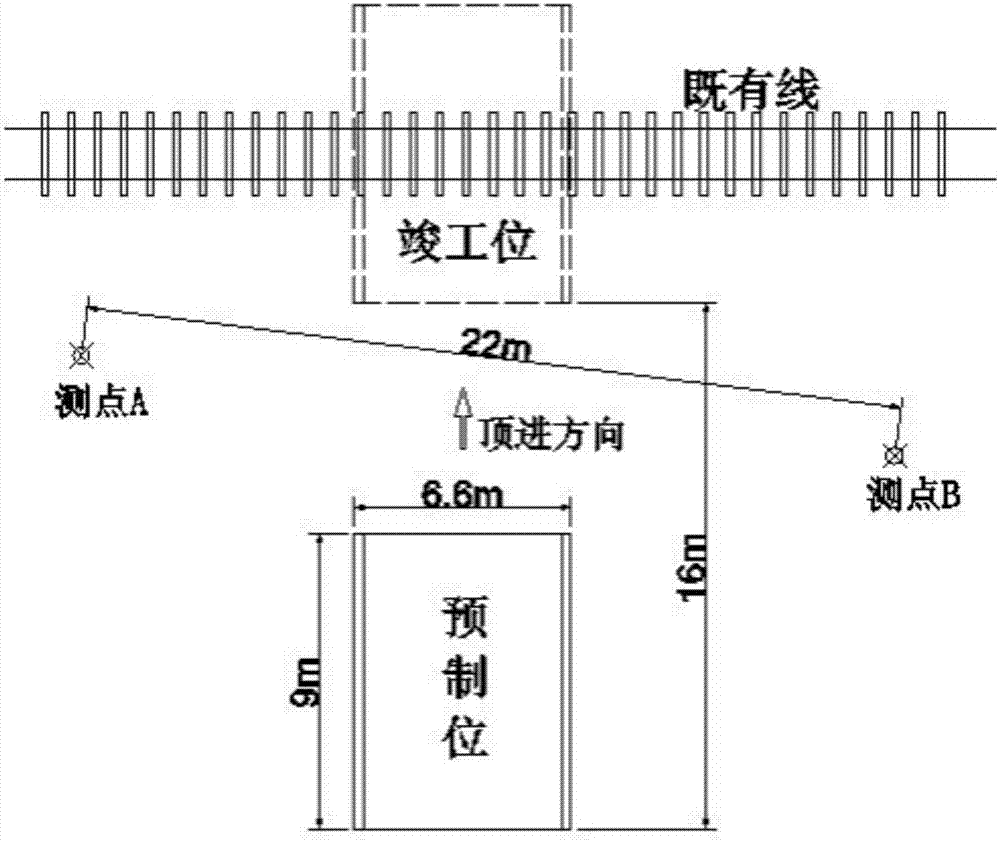

Monitoring and measuring method of culvert jacking deviation rectification

ActiveCN107421519AHigh accuracy of deviation correctionSimple and fast operationSurveying instrumentsHeight/levelling measurementAngular pointTotal station

The invention discloses a monitoring and measuring method of culvert jacking deviation rectification. The method comprises the steps as follows: (1) a measuring point A and a measuring point B are arranged on two sides of a prefabricated culvert; (2) the distance between the two measuring points is measured with a total station instrument; (3) a coordinate system is established by use of the measuring point A and the measuring point B; (4) the total station instrument is set up to collect coordinates of four angular points of the prefabricated culvert and the central point of an existing route, a field plane graph is drawn by CAD cartographic software, and the position of the completed culvert is determined; (5) the established coordinate system is converted into a coordinate system with the angular points of completed culvert as the original points by use of the CAD cartographic software; (6) new coordinates of the measuring point A and the measuring point B are calculated; (7) the elevations of the measuring point A and the measuring point B are measured, a plane coordinate system is transformed into a 3D coordinate system, the coordinates of the measuring point A and the measuring point B are back viewed by the aid of rear intersection of the total station instrument, a survey station is established, coordinate values of any point of the culvert are collected in real time during jacking and compared with coordinate values of the in-place culvert, and required deviation rectification data are obtained.

Owner:CHINA RAILWAY NO 10 ENG GRP NO 1 ENG CO LTD

Solar cell cutting system

ActiveCN106558636APinpoint local defectsReduce workloadSemiconductor/solid-state device testing/measurementFinal product manufactureDual modeEngineering

The invention relates to a solar cell cutting system, and solves problems of easy short circuit of cells of a solar cell cutting device, failure of qualification detection of the cut cells in time, and lack of deviation correction of the solar cells in the prior art. The system comprises a conveying device for conveying flexible cell rolls in a roll-to-roll manner, a cutting device comprising an upper cutter and a lower cutter capable of integrally dismounted and fit in the vertical manner, an intelligent dual-mode deviation correction device, a voltage test device and a surface test device. The system is advantageous in that functions of voltage tests and surface tests are integrated, product qualification tests of the cell rolls are conducted after cutting, problems can be discovered in time after the cutting of the cell rolls, the workload is reduced, the production efficiency is improved, automatic deviation correction of the positions of the cell rolls before and after printing can be performed, the precision of deviation correction is high, the reliability is high, the error is small, the cell rolls can operate in correct positions, and the cutting precision of the cell rolls is guaranteed.

Owner:浙江尚越新能源开发有限公司

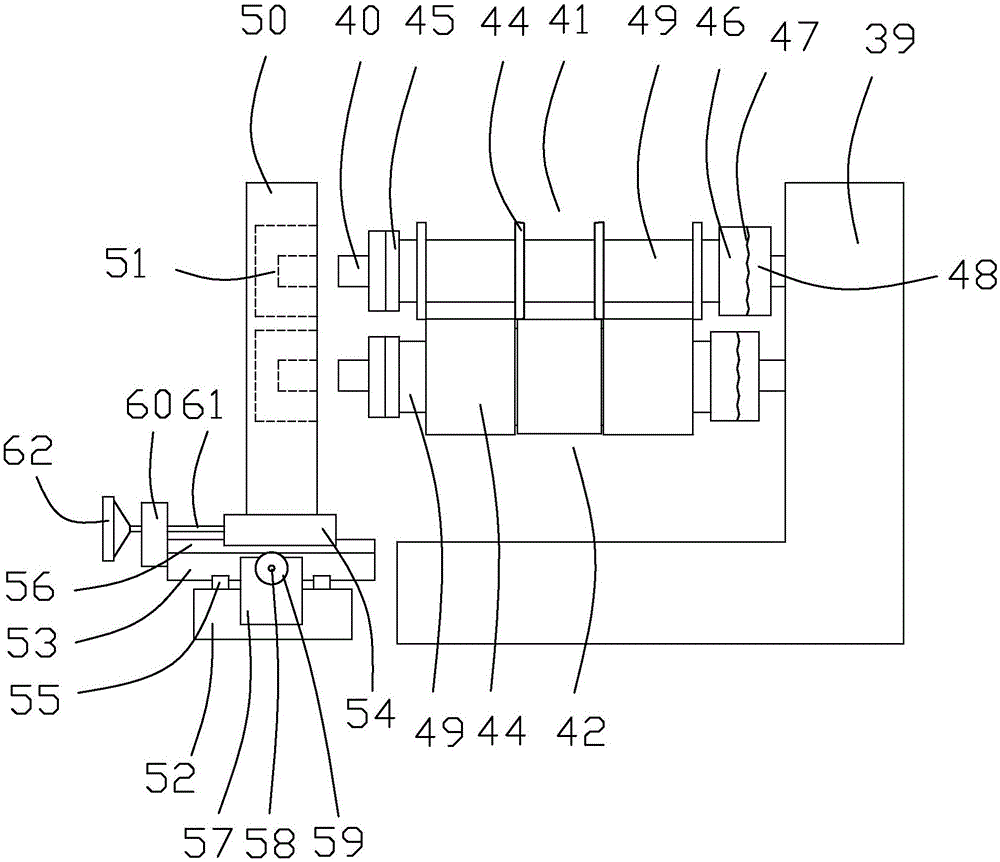

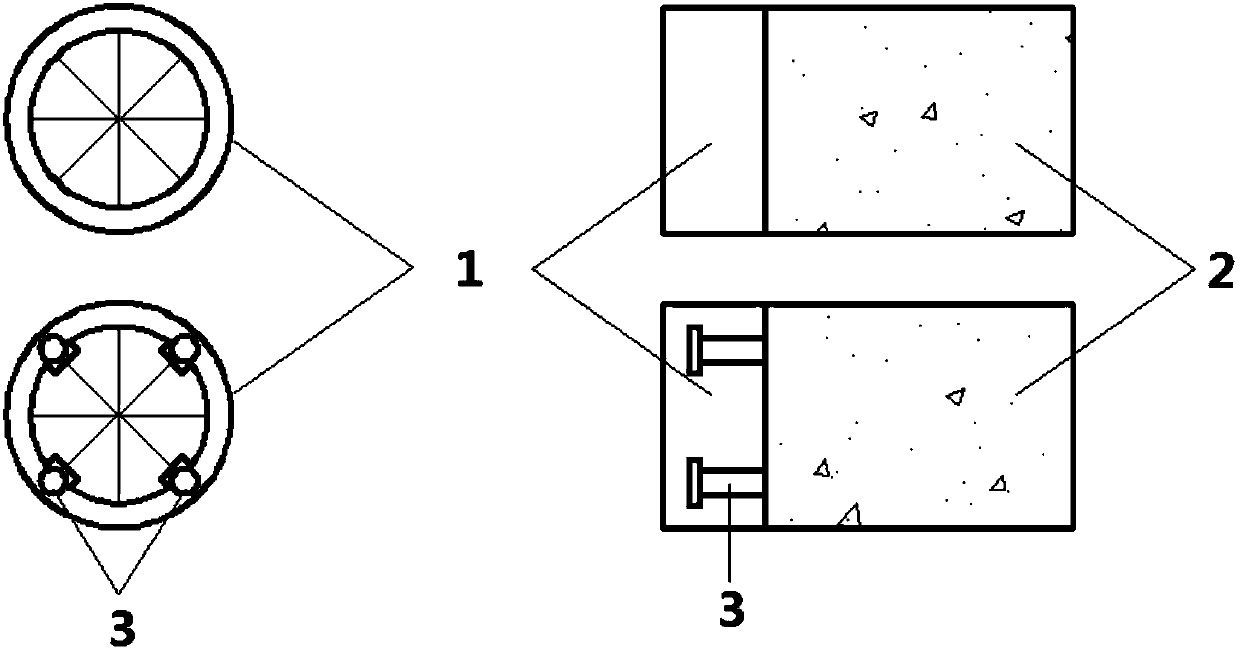

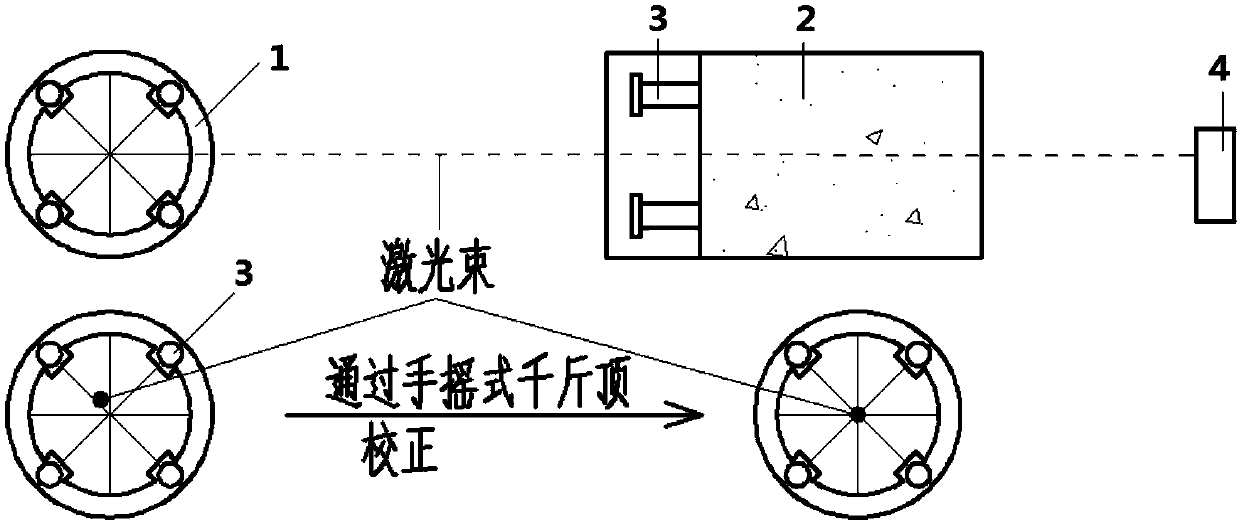

Device and method for correcting cutterhead jacking direction in real time during manual pipe jacking construction

InactiveCN107725892AReduce the difficulty of correctionRealize integrationPipe laying and repairEngineeringBuilding construction

The invention discloses a device and method for correcting the cutterhead jacking direction in real time during manual pipe jacking construction, and relates to the field of municipal road drain pipeline construction. The method comprises the following steps that four hand-operated jacks are uniformly arranged and fixed to the inner side of the circumference of a cutterhead, a protection barrel ofthe cutterhead extends to cover the four hand-operated jacks, and the cutterhead is connected with a pipeline through the four hand-operated jacks; and when the cutterhead is jacked into a first pipeline section, in the deviation correcting process, the center line and the elevation are measured every time the cutterhead is jacked in by 20-30 cm, the hand-operated jacks are operated manually to slightly adjust the angle of the cutterhead according to the measurement results so that the pipeline jacking direction can be corrected. Through the device and method for correcting the cutterhead jacking direction in real time during manual pipe jacking construction, the constructed pipeline can be precisely positioned, the underground extending deviation of the pipeline is corrected in real time, and the jacking direction in the whole pipeline jacking process is effectively controlled.

Owner:WUHAN HANYANG MUNICIPAL CONSTR GRP CO LTD

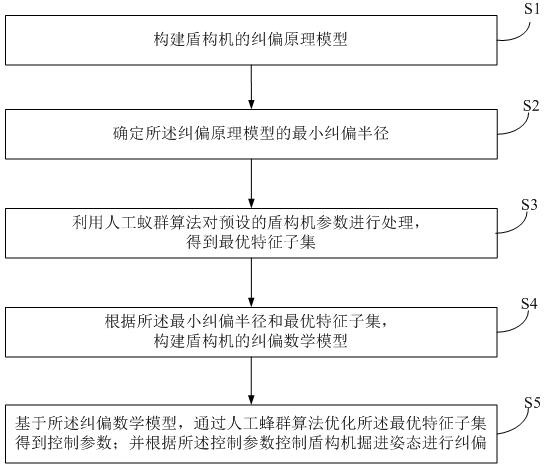

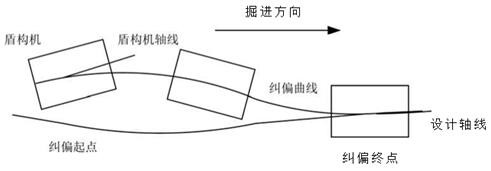

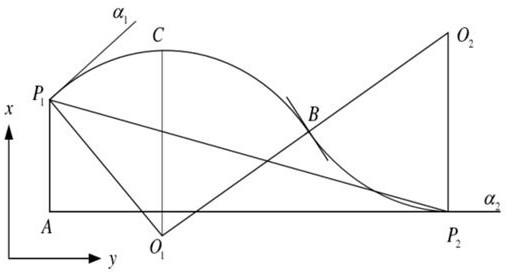

Deviation rectification control method and device for shield tunneling postures

ActiveCN112682049AImprove solution qualityHigh accuracy of deviation correctionMining devicesTunnelsArtificial AntsMathematical model

The invention belongs to the technical field of general control or adjustment systems, and particularly relates to a deviation rectification control method and device for shield tunneling postures. The deviation rectification control method comprises the steps that a deviation rectification principle model of a shield tunneling machine is constructed; the deviation rectification principle model comprises a deviation rectification track curve; the minimum deviation rectification radius of the deviation rectification principle model is determined; the minimum deviation rectification radius of the deviation rectification principle model is the curvature radius of the deviation rectification track curve; preset shield tunneling machine parameters are processed by using an artificial ant colony algorithm to obtain an optimal feature subset; according to the minimum deviation rectification radius and the optimal feature subset, a deviation rectification mathematical model of the shield tunneling machine is constructed; based on the deviation rectification mathematical model, the optimal feature subset is optimized through an artificial bee colony algorithm to obtain control parameters; and a tunneling posture of the shield tunneling machine is controlled to rectify deviation according to the control parameters. The optimal feature subset can be screened out by introducing the ant colony algorithm, and the optimal feature subset is used as an initial population of the artificial bee colony algorithm, so that the solving quality can be improved, the deviation rectification precision can be improved, and a better deviation rectification effect can be achieved.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY NO 9 GRP

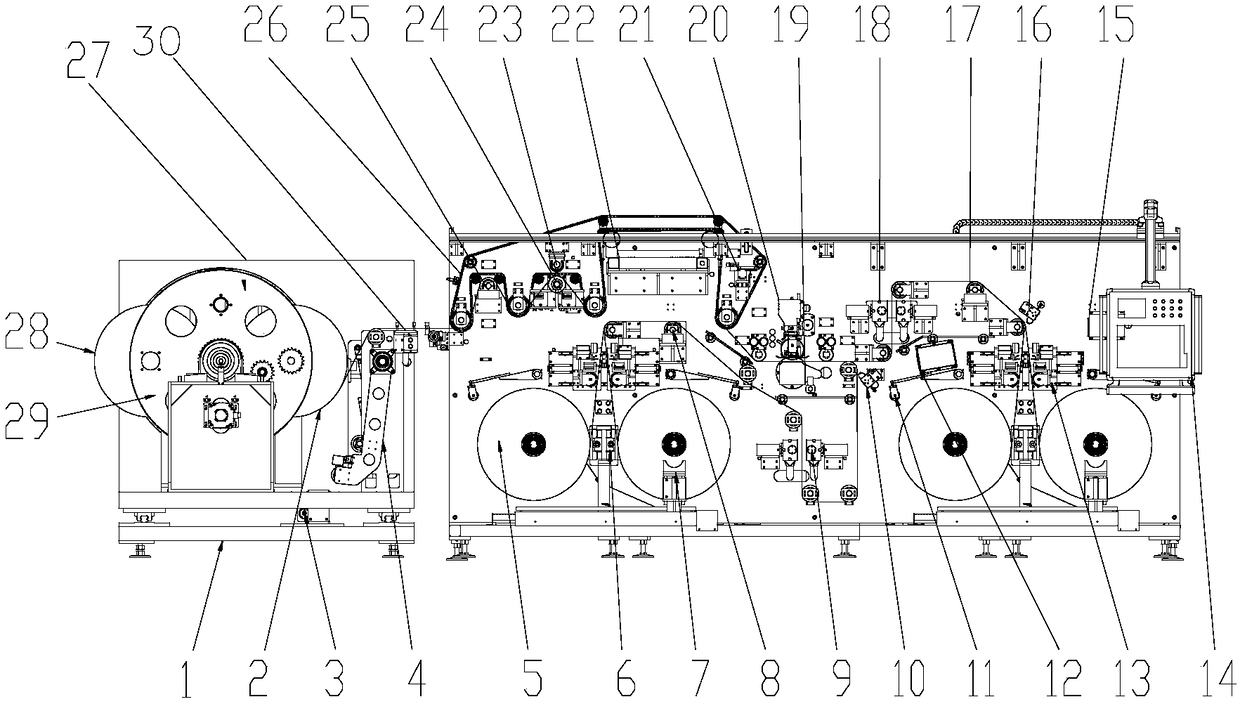

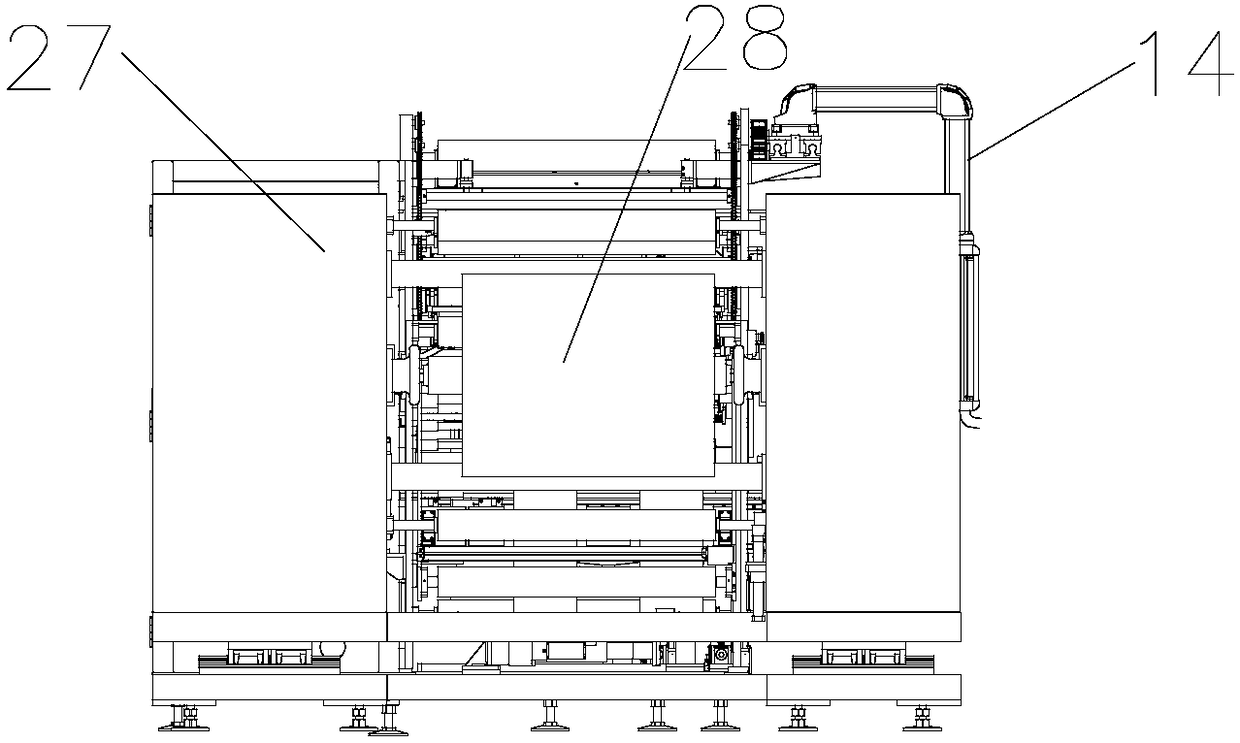

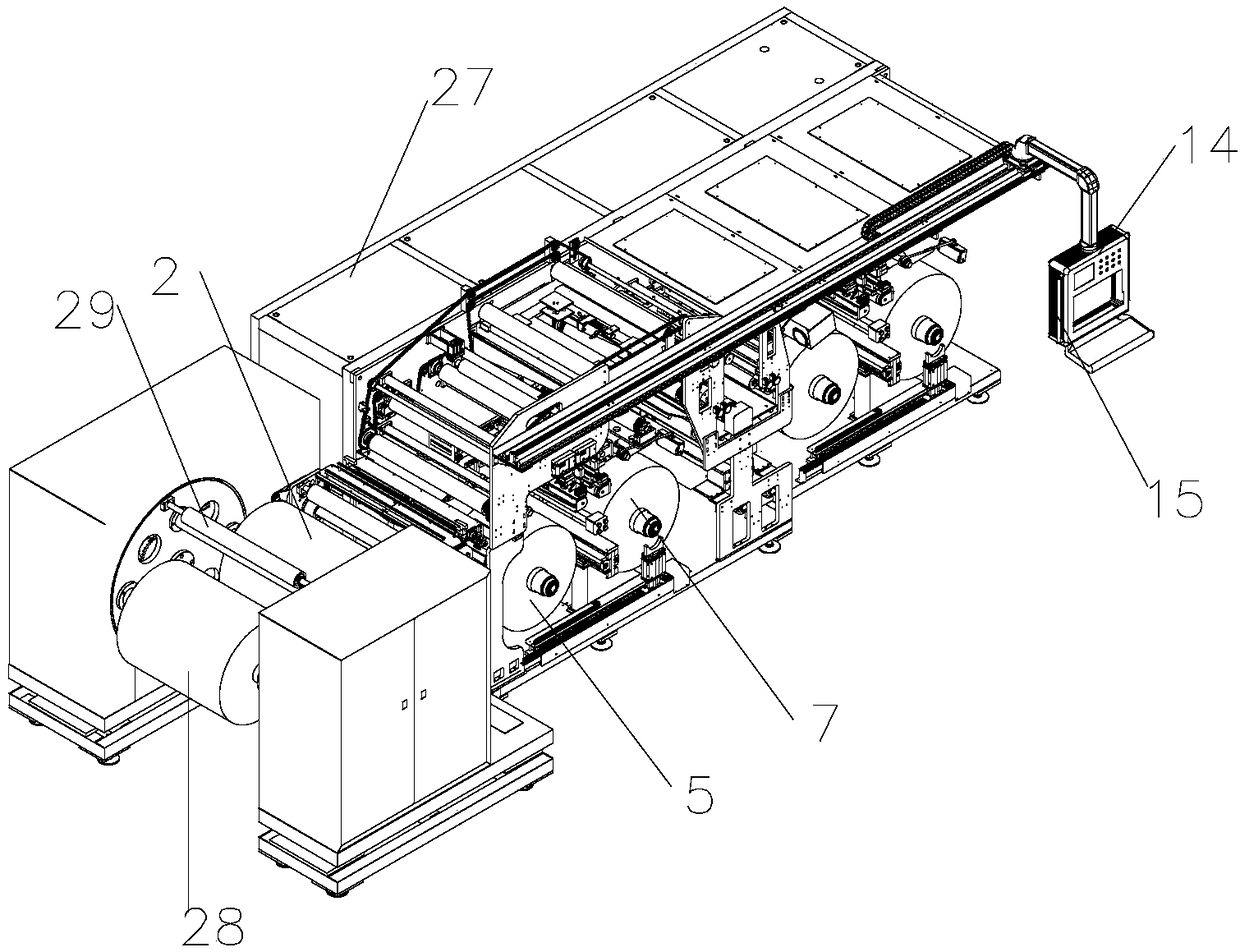

Full-automatic high-speed pre-splitting machine

InactiveCN108263896AGuaranteed cleanlinessAvoid breakingArticle deliveryWebs handlingEngineeringConductor Coil

The invention relates to a full-automatic high-speed pre-splitting machine which comprises an unwinding part, a to-be-split complete roll, an unwinding correction device, an electronic cutter device,a before-splitting correction detection device, an automatic tape threading device, a manual splicing tape workbench, a standby to-be-split roll, a rotating material rack device and a workbench; the to-be-split complete roll, the standby to-be-split roll, an automatic pushing-out device, a winding auxiliary supporting device, a front winding tension device, a front winding dust removing device, afront detection light source device, a winding pressing wheel device, a front width measurement device and a winding and automatic tape splicing device are fixed to the workbench from left to right sequentially; and a rear detection light source device, a rear winding tension device, a rear winding dust removing device, a splitting and cutting device, the electronic cutter device, the before-splitting correction detection device, a before-splitting correction device, a driving pressing roller device, a driving roller device, an unwinding tension device and the automatic tape threading device are fixed to the workbench sequentially. The full-automatic high-speed pre-splitting machine is good in splitting effect and high in automation degree, facilitates dust removal and has multiple functions.

Owner:GUANGZHOU EHOLLY MACHINERY CO LTD

Pole piece detection device

PendingCN111322945AHigh accuracy of deviation correctionAvoid image blurOptically investigating flaws/contaminationUsing optical meansEngineeringPole piece

The invention provides a pole piece detection device. The pole piece detection device comprises a bottom plate, a light source and an image acquisition device. A groove is arranged in a surface of oneside of the bottom plate, a cover plate covers an opening of the groove, and the cover plate is used for supporting a pole piece; the light source is arranged in the groove and used for irradiating apositioning detection area; light emitted by the light source can penetrate through the cover plate; and the image acquisition device is arranged on one side, away from the light source, of the coverplate and used for acquiring image information of the pole piece located in the positioning detection area by receiving the light penetrating through the cover plate. The pole piece detection devicecan effectively avoid a problem of blurred imaging at an edge of the pole piece so that accuracy of the acquired image information of the pole piece can be effectively improved, and deviation rectification precision of the pole piece can be greatly increased.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

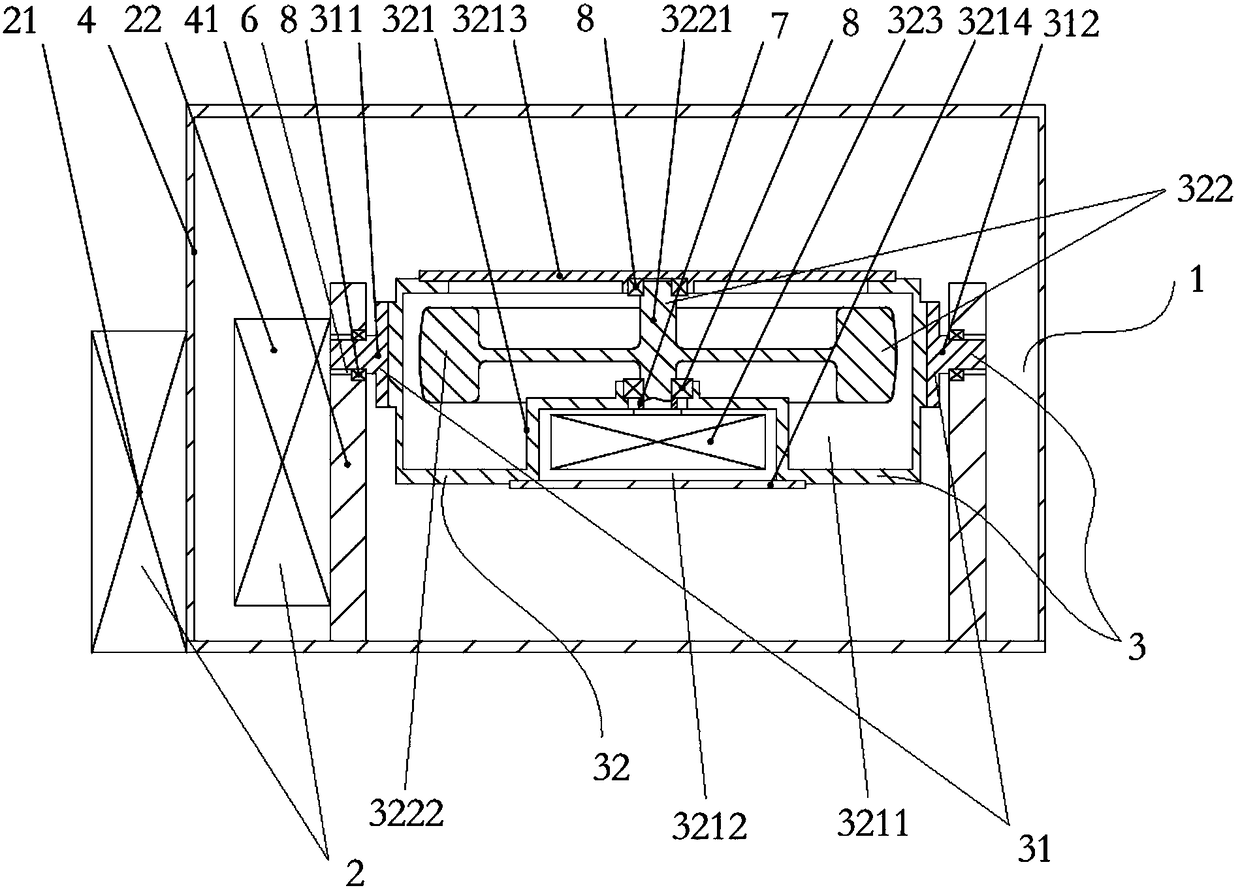

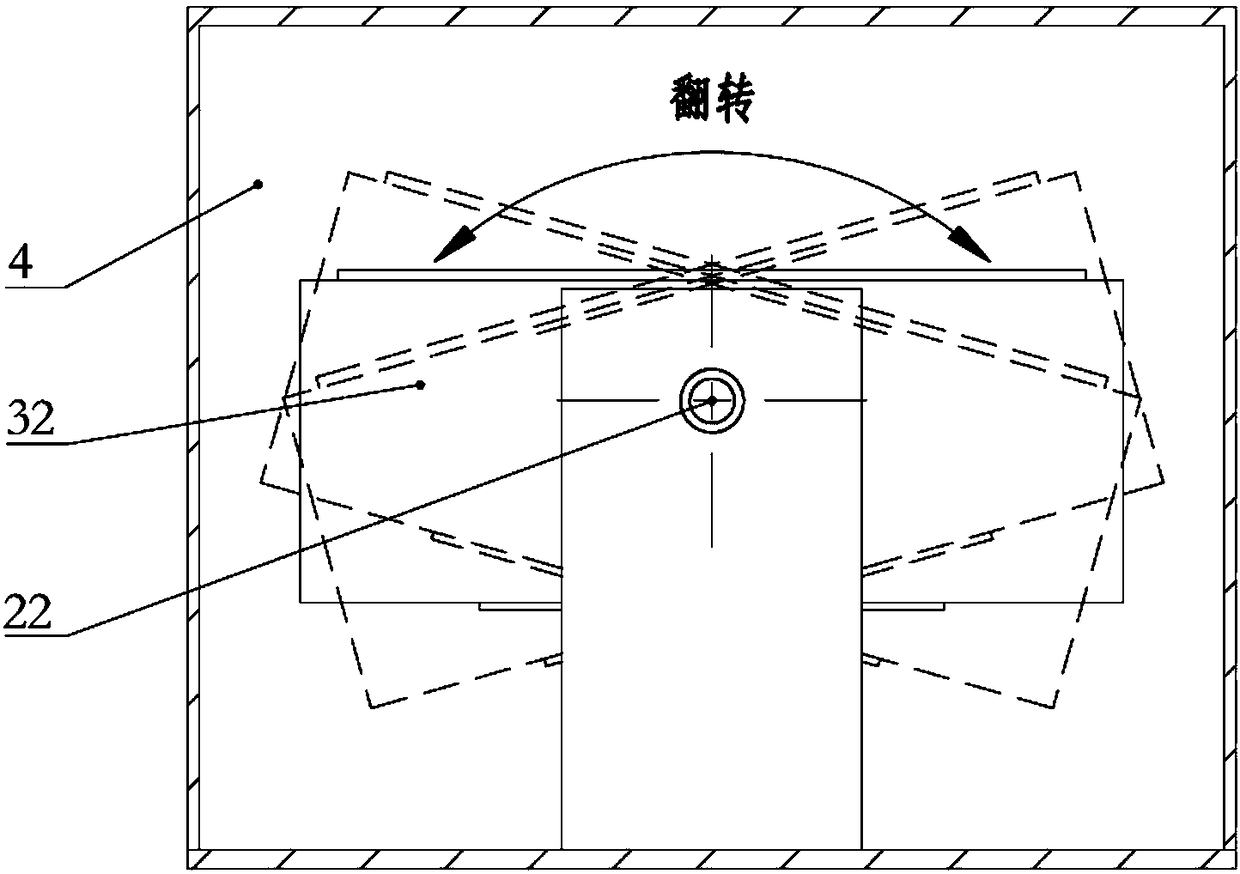

Attitude detection system and method of coiled material under motion state

InactiveCN109230729AEliminates the possibility of driftReduce scrap rateWebs handlingProcess deviationsEngineering

The invention relates to the technical field of coiled material deviation rectification, and discloses an attitude detection system and method of the coiled material under a motion state. The system comprises an unreeling deviation rectification mechanism, a winding deviation rectification mechanism and a process deviation rectification mechanism, wherein the process deviation rectification mechanism comprises a process deviation rectification controller and a process deviation rectification sensor, a process deviation rectification guide mechanism and a process deviation rectification transmission mechanism, the process rectification guide mechanism comprises a base, two mounting plates and a guide roller, wherein two ends of the guide roller are rotatably connected with the inner walls of the two mounting plates respectively; the process deviation rectification transmission mechanism comprises a transmission box which is arranged below the base, a supporting rod is fixedly connectedon the transmission box, in a feeding direction, a first through groove is formed in the transmission box, in a discharging direction, a shell is arranged in the transmission box, and the shell is rotatably connected with the upper part and bottom part of the transmission box. According to the invention, the deviation rectification is carried out during the unwinding, winding and conveying processes of the coiled material, and the transverse displacement of the coiled material is reduced.

Owner:CHONGQING DONGDENG TECH

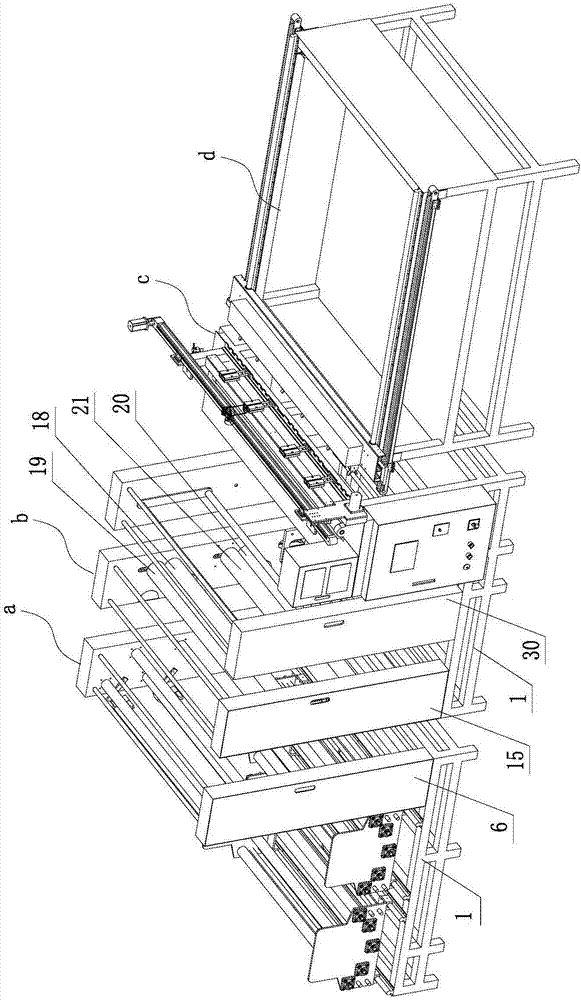

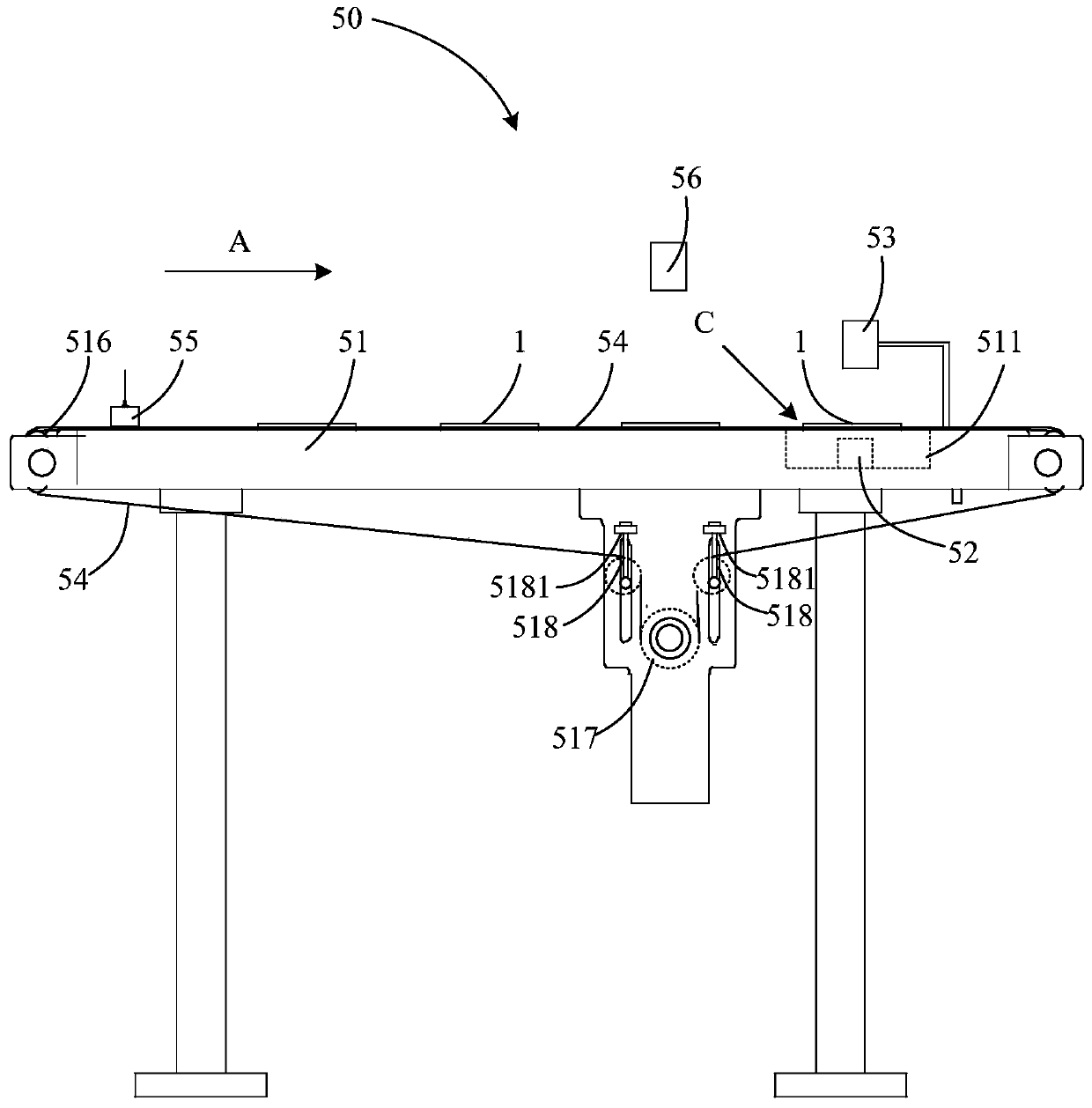

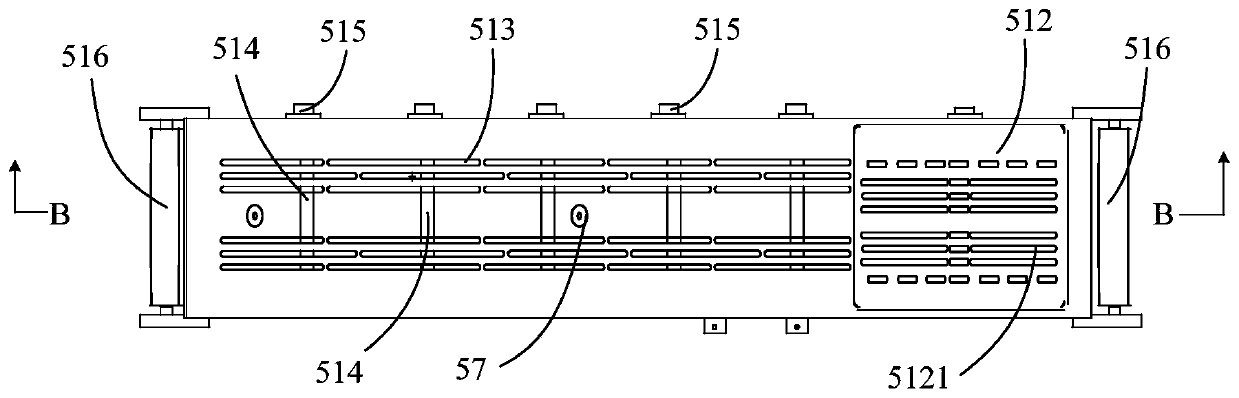

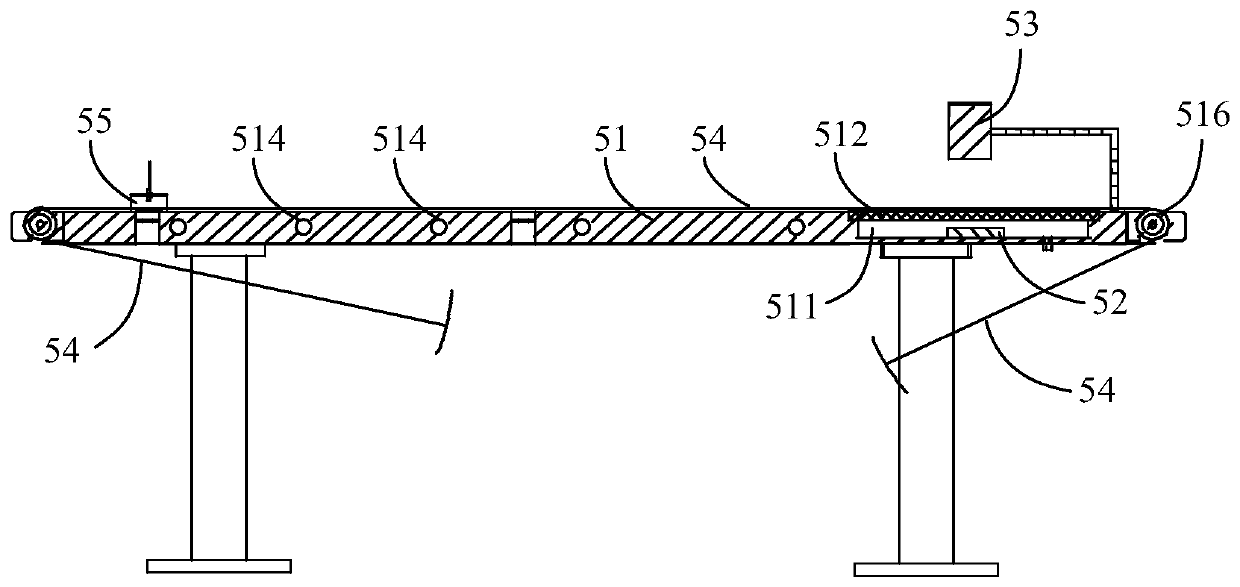

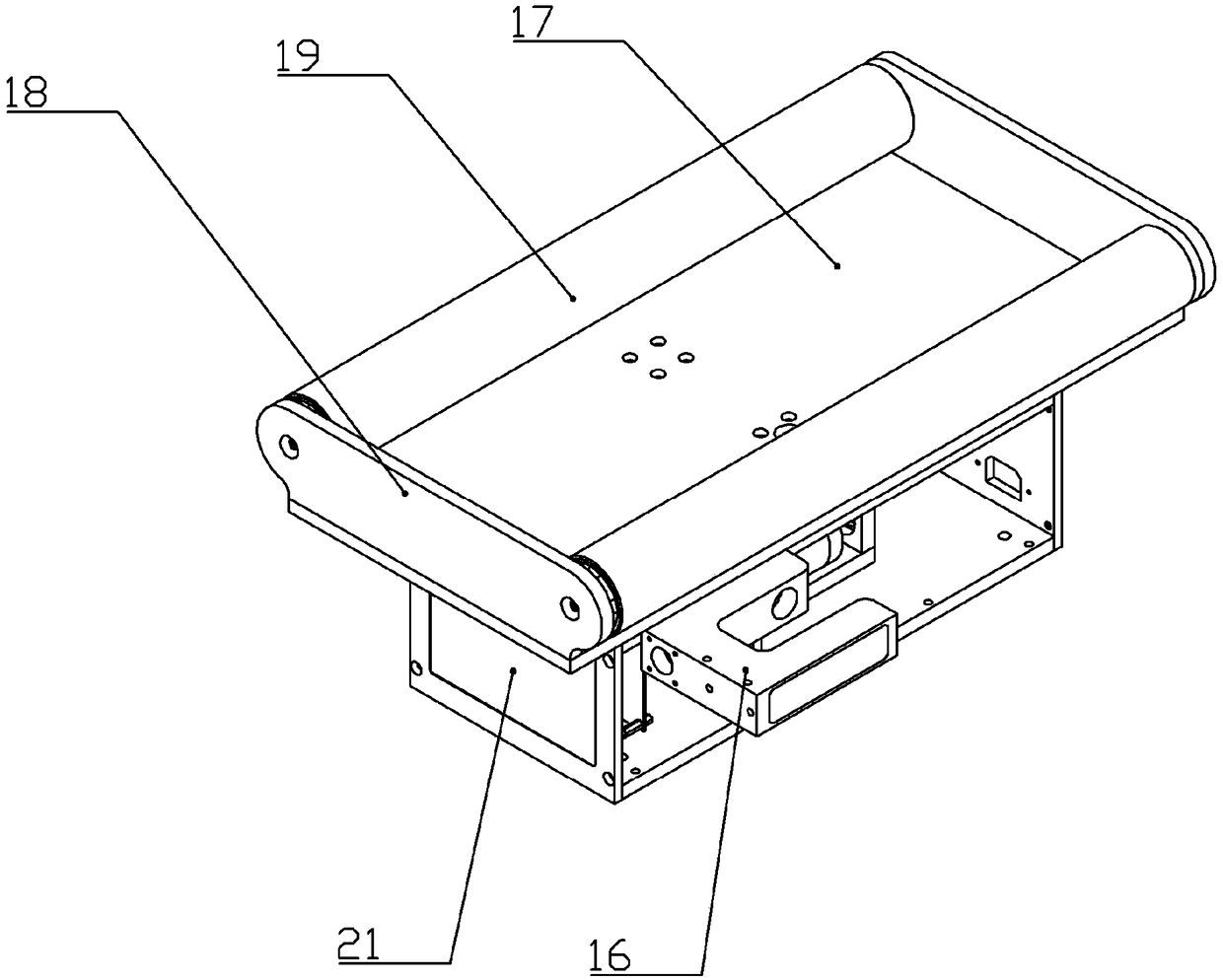

Product conveying and arranging device of intelligent production line

ActiveCN110540035AHigh accuracy of deviation correctionIncreased adjustment accuracy and stabilityConveyor partsMotor shaftEngineering

The invention discloses a product conveying and arranging device of an intelligent production line. According to the product conveying and arranging device, the position and the angle of a product canbe adjusted, and the product and a conveying belt can be kept at the same speed to achieve relative static stopping when the product is put down, and the product can be prevented from swinging due tothe accelerated speed of the conveying belt when being put down. The product conveying and arranging device is characterized in that a sliding rod is arranged at the top of one end of a support, thetwo ends of the sliding rod are fixedly connected with the support correspondingly, a second screw rod is arranged at the top of the other end of the support, and the second screw rod and the slidingrod are symmetrical with respect to the support; the two ends of the second screw rod are fixedly connected with the support through bearings correspondingly, a second motor is arranged on the support, and a motor shaft of the second motor is connected with one end of the second screw rod; a sliding frame is arranged between the sliding rod and the second screw rod, two connecting lugs are arranged at one end of the sliding frame, and the two connecting lugs can slide on the sliding rod in a sliding mode; two connecting lugs are arranged at the other end of the sliding frame, and the two connecting lugs are in threaded connection with the second screw rod; and a sliding groove is formed in the sliding frame.

Owner:徐州柚创谷智能科技有限公司

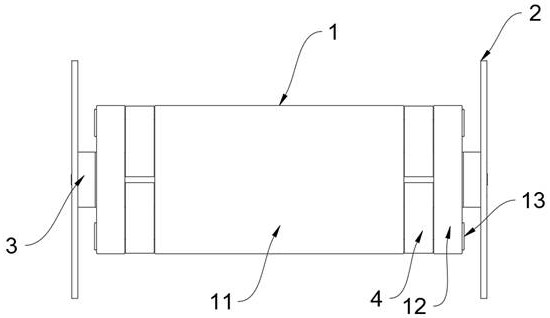

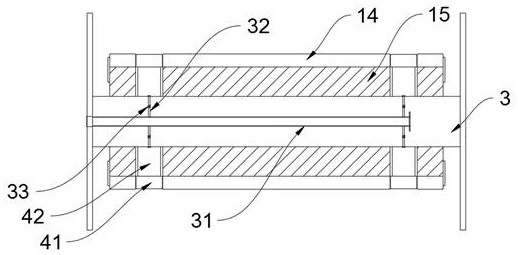

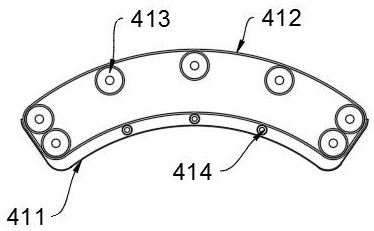

Deviation rectifying method and equipment for amorphous strip processing device

ActiveCN113184595AEasy to rewindSimple structureWebs handlingMechanical engineeringElectrical and Electronics engineering

The invention relates to a deviation rectifying method and equipment for an amorphous strip processing device. According to the deviation rectifying method for the amorphous strip processing device, a sensor for monitoring deviation of the amorphous strip and a deviation rectifying roller are included; the deviation rectifying roller is arranged above or below the amorphous strip; two sets of deviation rectifying assemblies are arranged in the deviation rectifying roller and are close to the two sides of the amorphous strip respectively; the deviation rectifying assemblies can press down or jack up the amorphous strip; after the sensor monitors that the amorphous strip deflects, the deviation rectifying assembly in the deviation direction presses down or jacks up the amorphous strip; and after the amorphous strip is reset again, the deviation rectifying assembly is reset. The deviation rectifying method and equipment for the amorphous strip processing device are simple in structure, ingenious in design, convenient to operate, very suitable for deviation rectifying in amorphous strip processing and convenient to popularize and use in the industry.

Owner:江苏知行科技有限公司

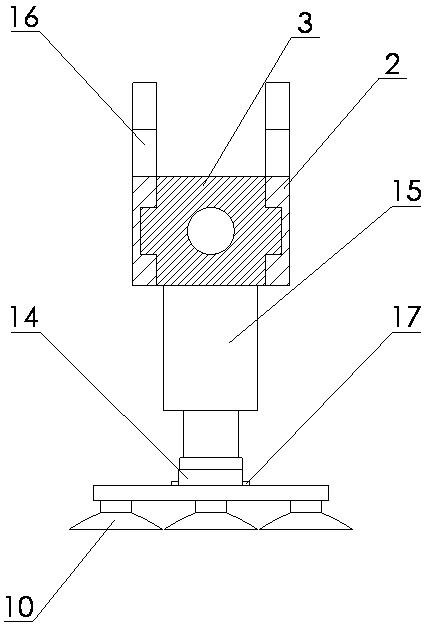

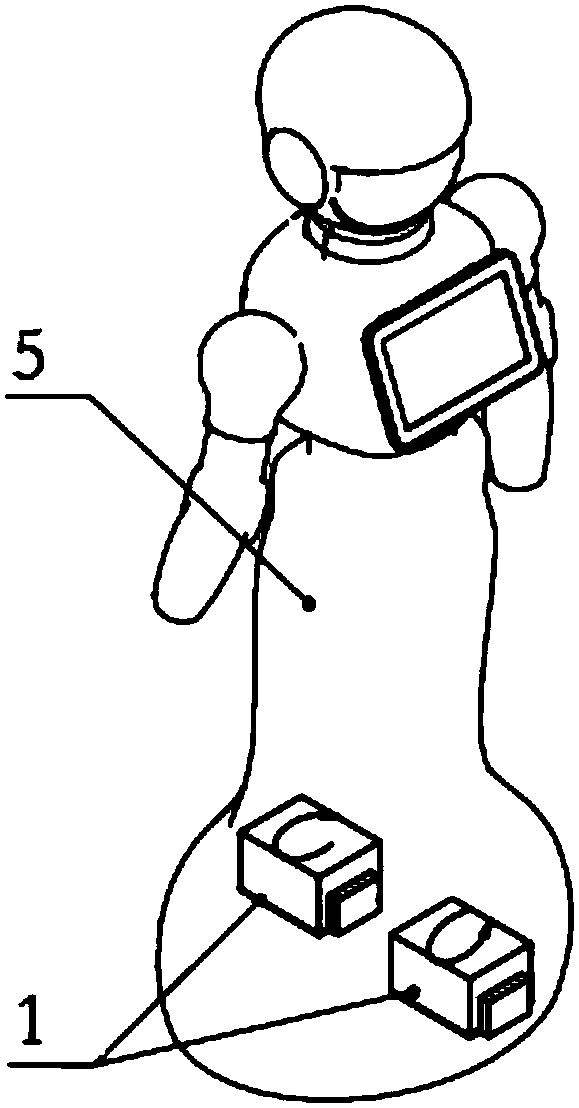

Bio-robot stabilizing device and system

InactiveCN108145749ADoes not affect appearanceHigh accuracy of deviation correctionManipulatorControl theoryAcceleration Unit

The invention discloses a bio-robot stabilizing device comprising a detection control device and a gyro mechanism; the gyro mechanism comprises rotating shafts and a rotating piece; the detection control device is used for performing the following operation that the motion deviation of a main body is detected; if the motion deviation of the main body is detected, the rotation shafts are controlledto rotate; and the first gyro torque is generated by rotating of the rotating piece by rotating the rotating shafts, and the first gyro torque is used for correcting the motion deviation. The bio-robot stabilizing device solves the problem that the application effect is not good, the limitation is big, the traffic ability characteristic of a robot is influenced, the ability of rectifying a deviation is weak; the error correction precision is improved greatly; and when any angle or acceleration occurs, rectification is continued, and the ability to rectify deviation is strengthened. The systemcomprises a robot main body and at least two bio-robot stabilizing devices. The system comprises the beneficial effects that through multiple sets of stabilizing devices, the robot can maintain stability in any direction, and the ability of rectifying the deviation when the robot is running is greatly improved.

Owner:北京理工华汇智能科技有限公司

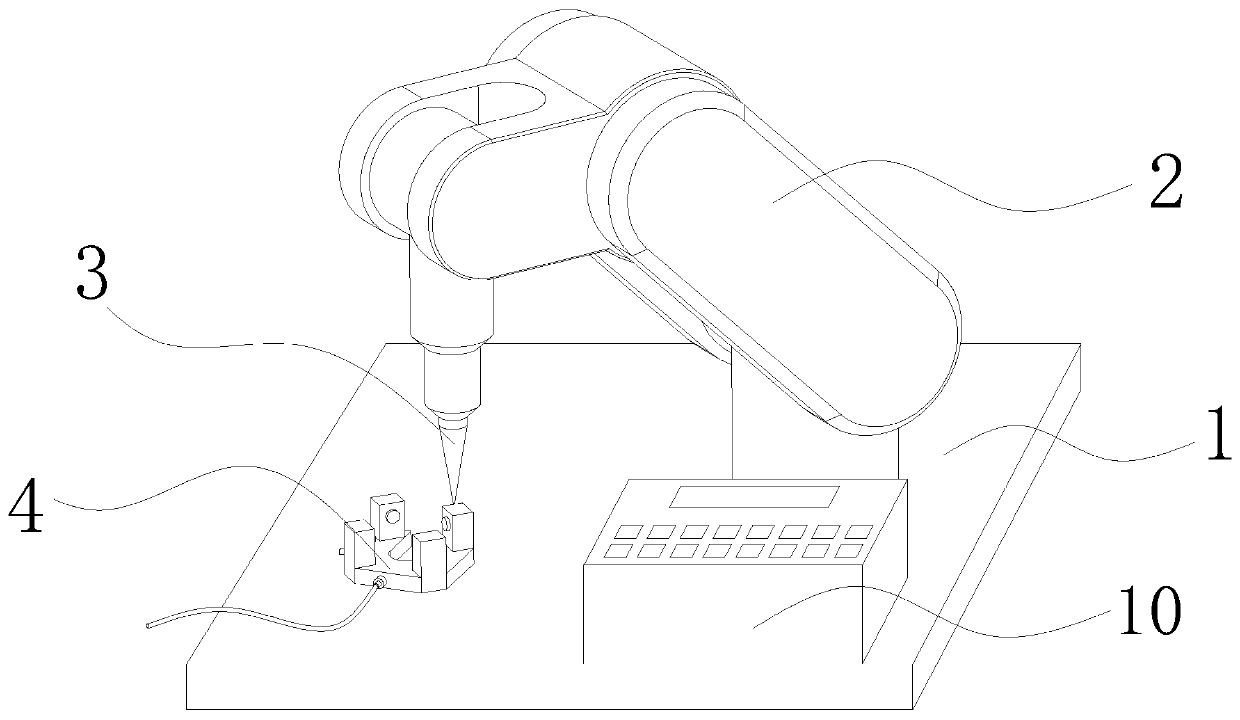

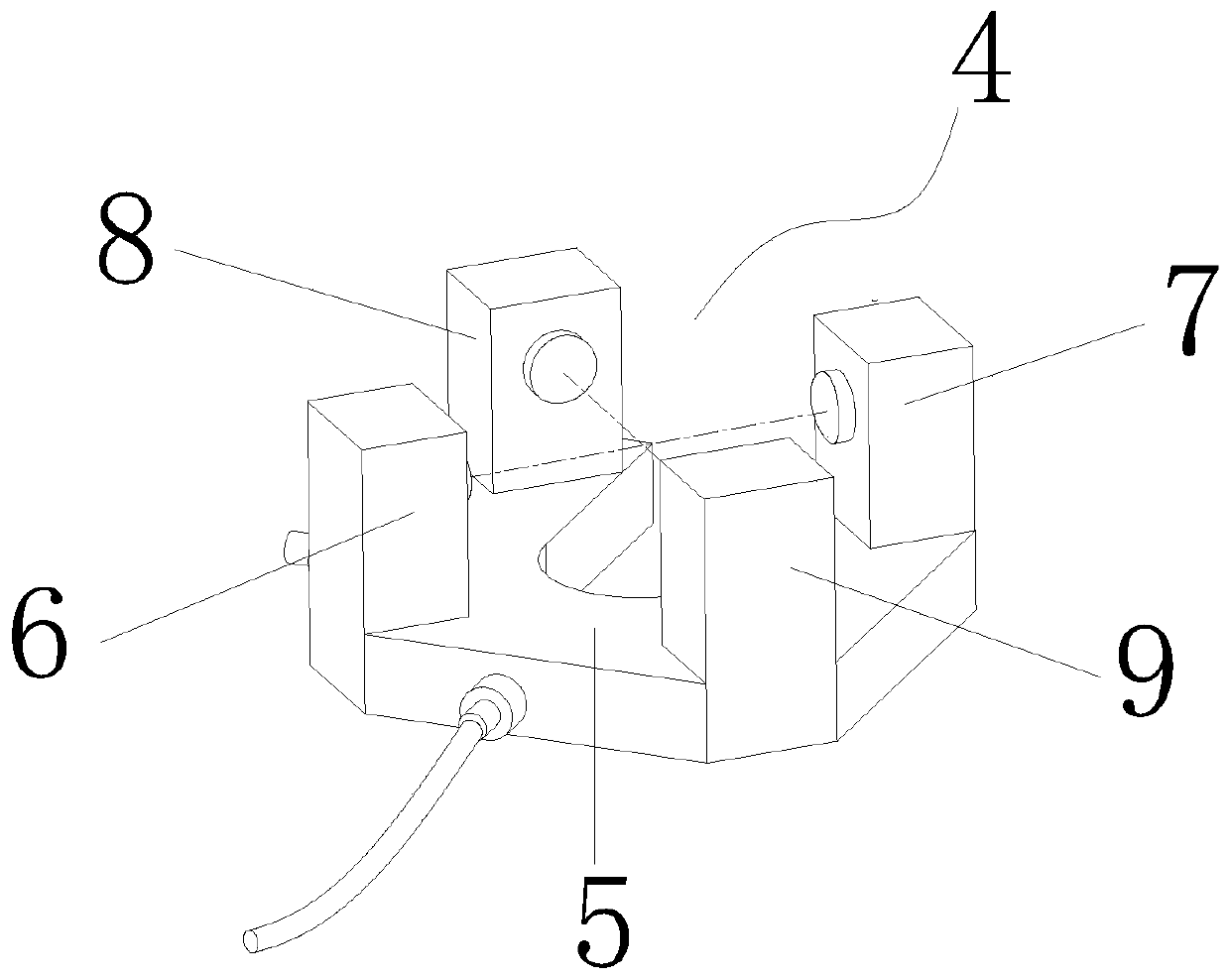

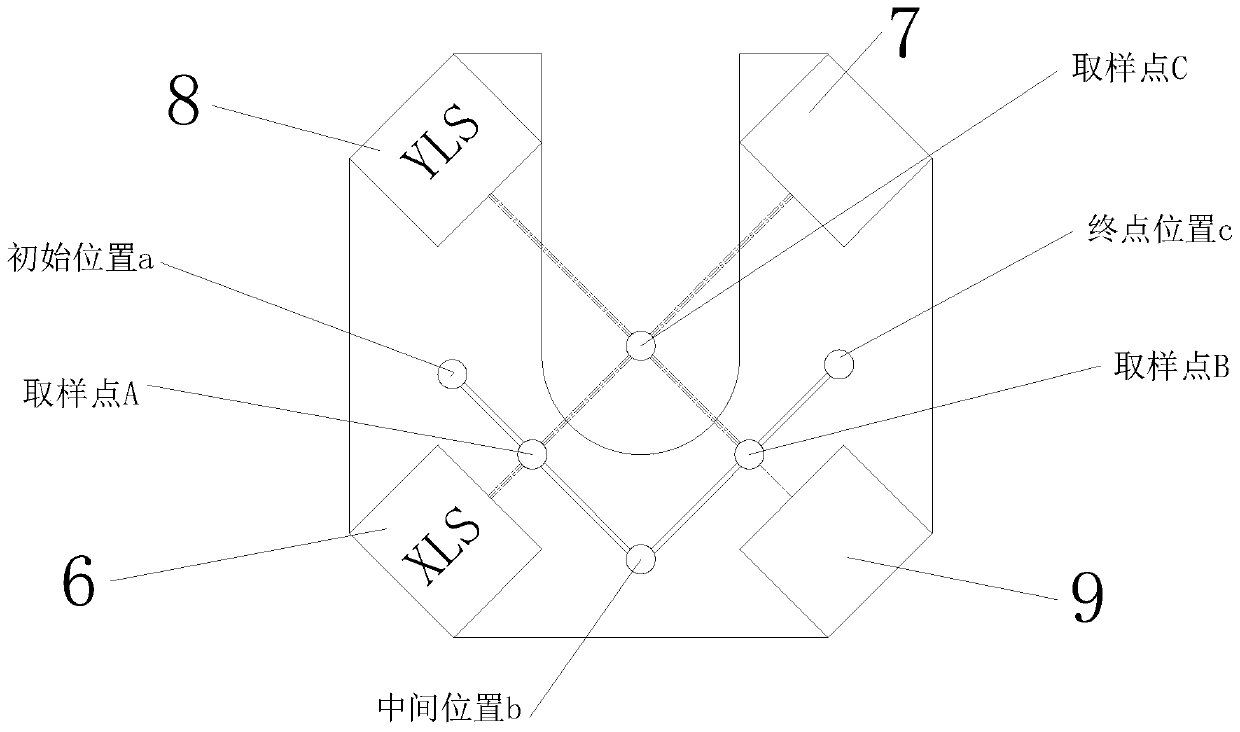

TCP robot tool tail end 3D and 5D error correction system and error correction method thereof

ActiveCN111421541AHigh accuracy of deviation correctionCorrection speed is fastProgramme-controlled manipulatorRobotic armLight beam

The invention belongs to the technical field of TCP robot control, and particularly relates to a TCP robot tool tail end 3D and 5D error correction system and an error correction method thereof. The TCP robot tool tail end 3D and 5D error correction system comprises a reference platform, a mechanical arm, a cross sensor and a computing controller, wherein the mechanical arm is arranged above the reference platform, and a guide needle is installed at a movable end of the mechanical arm; the cross sensor is fixedly installed on a plane of the reference platform, and the movable end of the mechanical arm is located above the cross sensor; the cross sensor comprises a set of first laser transmitting ends and first laser receiving ends which are opposite in position and another set of second laser transmitting ends and second laser receiving ends which are opposite in position, and the first laser transmitting ends transmit light beams XLS to point to the first laser receiving ends. The error correction precision is high, and the error can be controlled to be 2-6 decimillimetres after automatic adjustment; compared with manual adjustment, the error correction precision is improved to the decimillimetre level from the millimeter level, and is close to the 3D vision detection precision, the error correction speed is high, data is written into a file in a binary mode, and the data read-write processing speed is high.

Owner:无锡市创凯电气控制设备有限公司

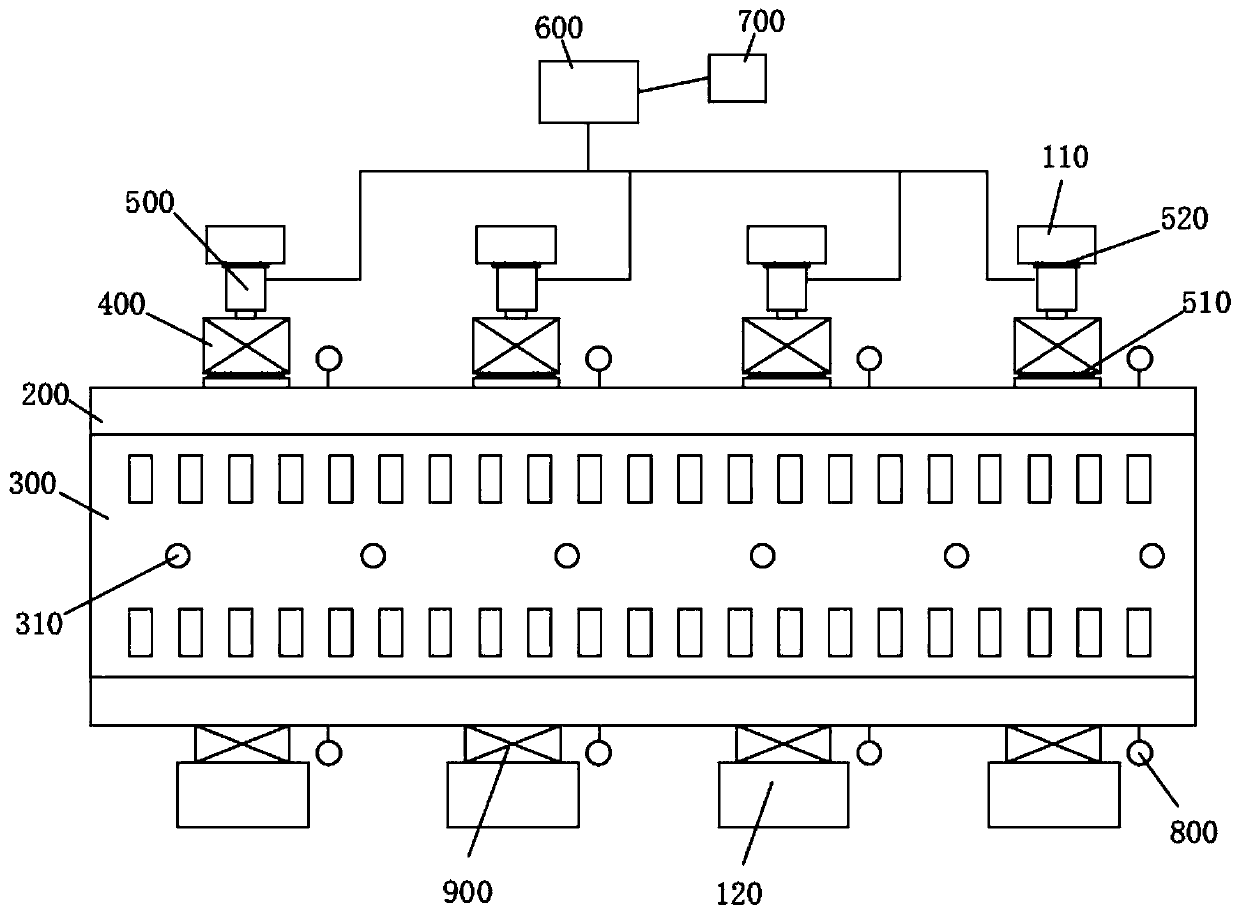

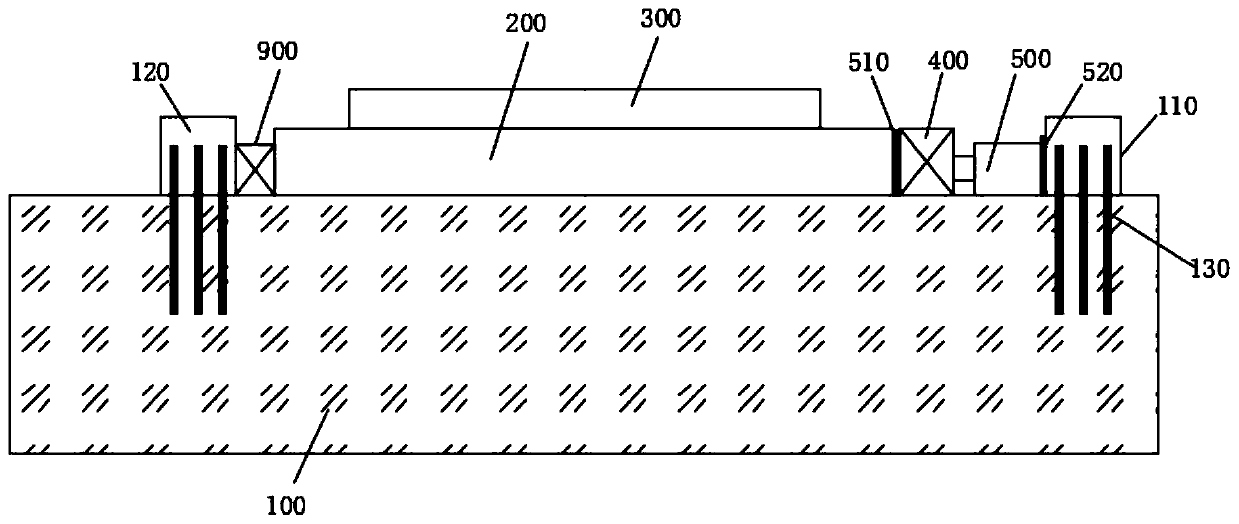

Ballastless track deviation rectifying system and pushing device

PendingCN111441194ARealize large correction processingReasonable layoutBallastwayTrack superstructureTrackwayControl theory

The invention discloses a ballastless track deviation rectifying system. A ballastless track comprises a supporting layer and a ballastless track plate. The ballastless track plate is laid on the supporting layer. The supporting layer is laid on a roadbed. The deviation rectifying system comprises a pushing device; the pushing device is arranged on one side of the supporting layer; the pushing direction of the pushing device is consistent with the width of the supporting layer, a displacement sensor is arranged on the supporting layer, and the pushing device and the displacement sensor are connected with the controller. The ballastless track deviation rectifying system is reasonable in layout, stable in operation, capable of achieving large deviation rectifying treatment on a ballastless track, high in deviation rectifying precision, capable of saving time and labor and capable of meeting the existing use requirements.

Owner:湖北木之君工程材料有限公司

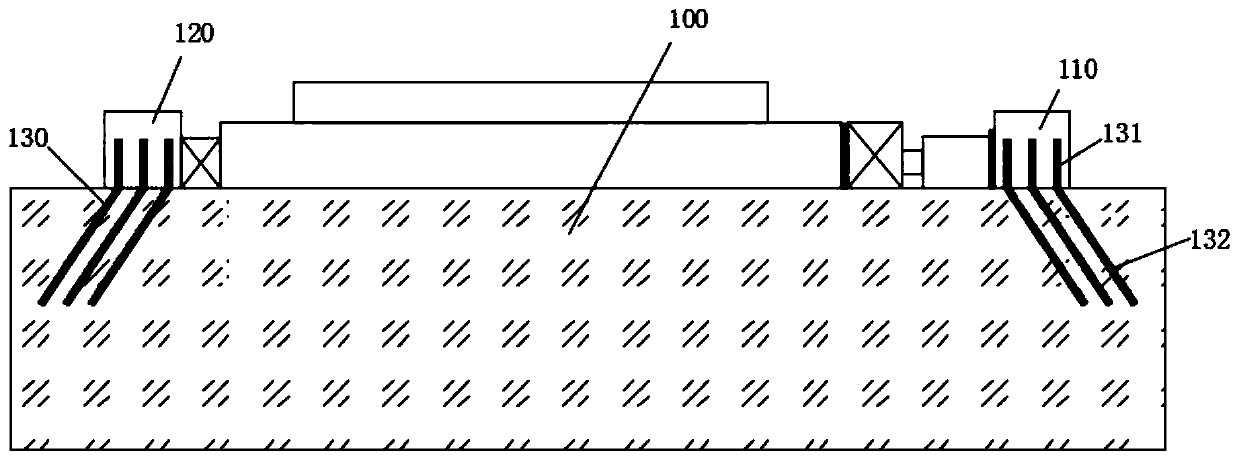

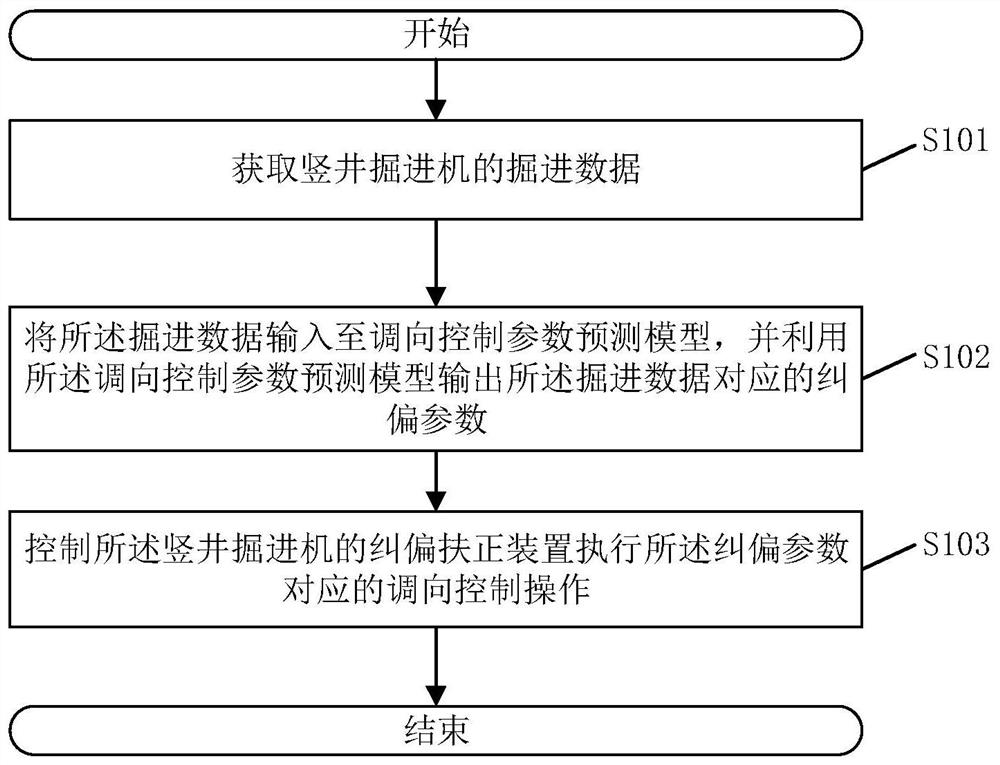

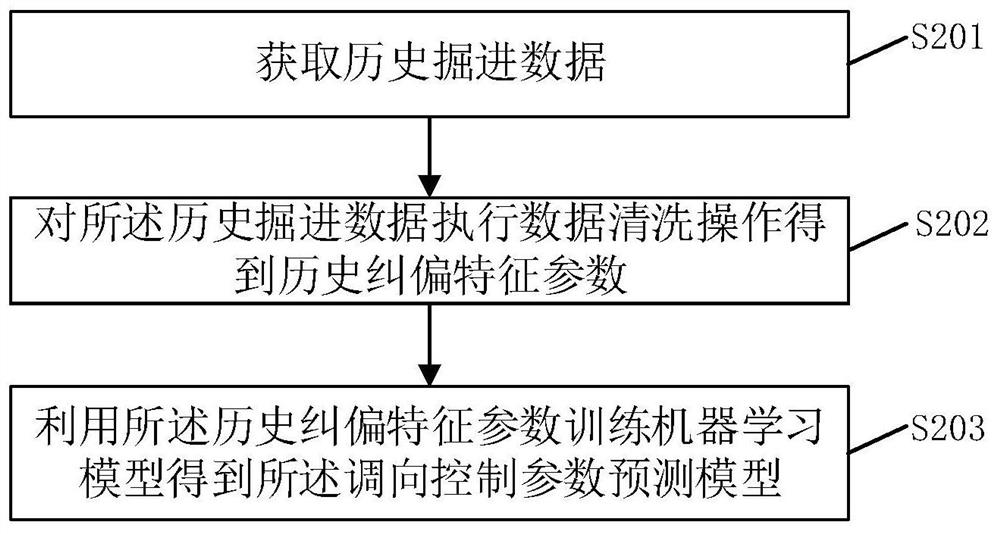

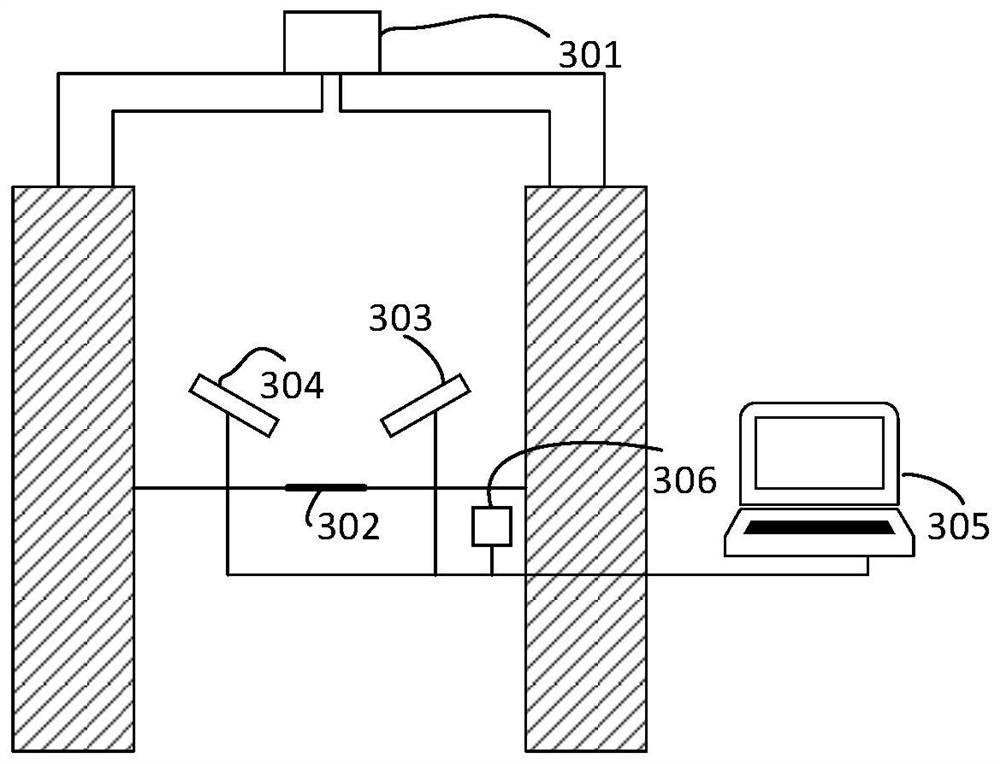

Direction adjusting control method and system for vertical shaft heading machine, vertical shaft heading machine and storage medium

InactiveCN111622763AHigh accuracy of deviation correctionImprove well completion qualityCharacter and pattern recognitionShaft sinkingRolling angleControl parameters

The invention discloses a direction adjusting control method for a vertical shaft heading machine. The direction adjusting control method comprises the following steps that heading data of the vertical shaft heading machine are acquired, wherein the heading data comprise an excavation diameter, horizontal deviation information, a heading machine pitch angle, a heading machine rolling angle, cutterhead rotating speed, cutter head torque, penetration degree and advance speed; the heading data are input into a direction adjusting control parameter prediction model, and deviation rectifying parameters corresponding to the heading data are output by using the direction adjusting control parameter prediction model; and a deviation rectifying and righting device of the vertical shaft heading machine is controlled to execute a direction adjusting control operation corresponding to the deviation rectifying parameters. According to the direction adjusting control method for the vertical shaft heading machine, the deviation rectifying precision of direction adjusting control of the vertical shaft heading machine can be improved, and the shaft forming quality is improved. The invention further discloses a direction adjusting control system for the vertical shaft heading machine, a storage medium and the vertical shaft heading machine with the beneficial effects.

Owner:CHINA RAILWAY CONSTR HEAVY IND

One-way all-cantilever steel truss arch bridge correcting device and use method thereof

PendingCN108035259ASimple structureEasy to operateBridge erection/assemblyArch-type bridgeArchitectural engineeringArch bridge

The invention discloses a one-way all-cantilever steel truss arch bridge correcting device and a use method. The correcting device comprises a base. The two ends of the base are each provided with a counter-force base for transversely limiting a steel beam in the construction process and providing stand counter-force during transverse correcting. The two counter-force bases are each connected witha horizontal jack I. The two jacks I are oppositely arranged and used for transverse correcting adjustment of the steel beam in the construction process. A temporary stand is arranged in the middle of the base and used for temporarily supporting a force point of the steel beam. A vertical jack II is arranged between the temporary stand and each jack I. The force exerting end of each jack II facesupward, and the jacks II are used for vertical correcting adjustment of the steel beam in the construction process.

Owner:SHANDONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com