Deviation rectification control method of nuclear waste intelligent bridge crane

A technology for bridge cranes and control methods, which is applied to traveling bridge cranes, hoists, and traveling mechanisms, etc., can solve the problems of large running deviation at both ends of the crane cart, excessive wear of wheel flanges, and increased maintenance costs, etc., to achieve The best running effect, high accuracy of deviation correction, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

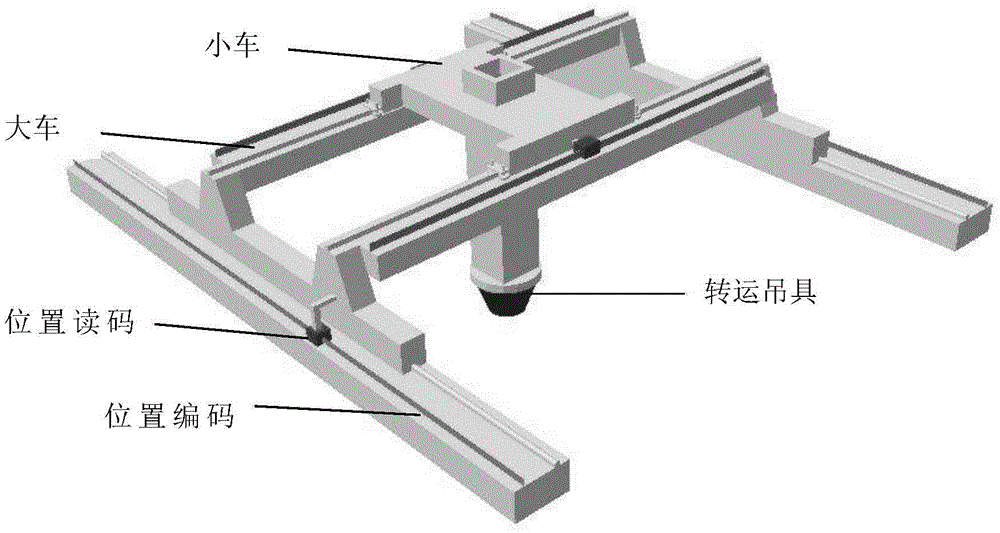

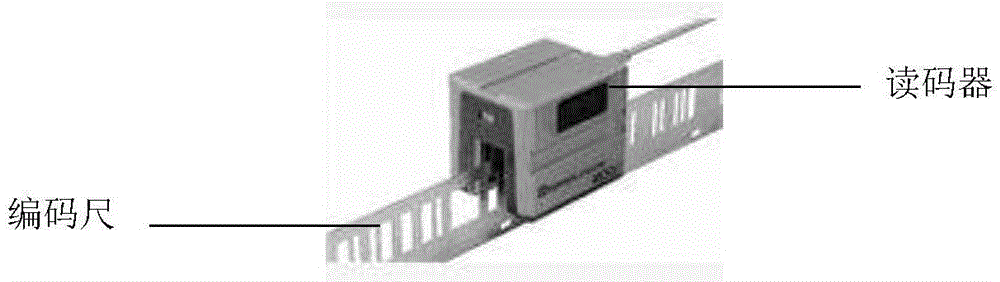

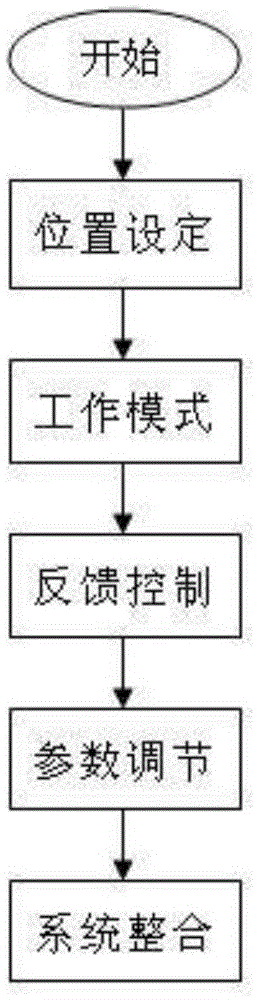

[0022] The basic idea of the present invention is: the bridge crane travels to deviate and needs to be corrected. The main factor of the deviation is rail gnawing, and the key to avoid rail gnawing is to correct the deviation of the crane cart to make the two ends of the cart walk synchronously. From the perspective of control strategy, if the non-master-slave mode is used to correct the deviation of the nuclear waste intelligent bridge crane, it will be due to the processing error of the mechanical structure at both ends of the cart, the error of the code ruler itself, the error of data transmission efficiency, and other uncertain factors. The accumulative error of the cart makes the walking state sometimes stable and sometimes oscillating violently when the cart is cyclically walking back and forth, and the deviation value is obviously not within a fixed range, and the fluctuation is too large. Consider changing the working mode of the deviation correction control strategy,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com