Patents

Literature

32results about How to "Reduce the difficulty of correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

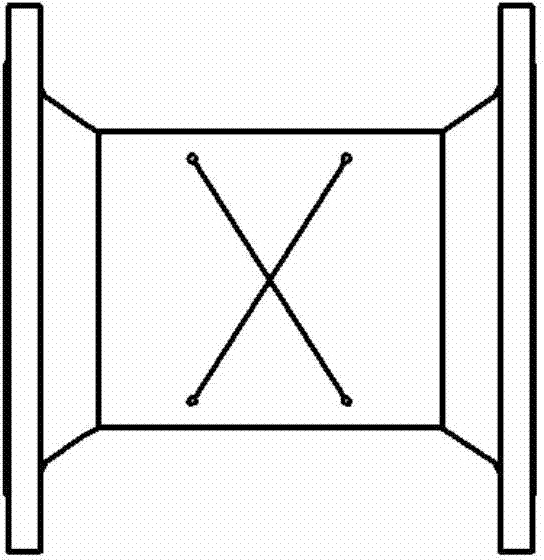

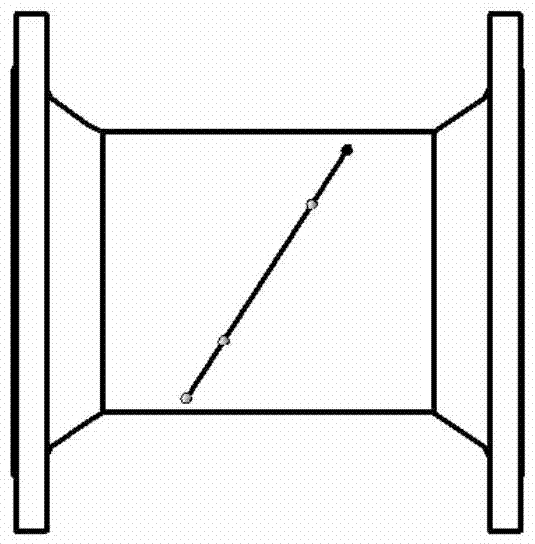

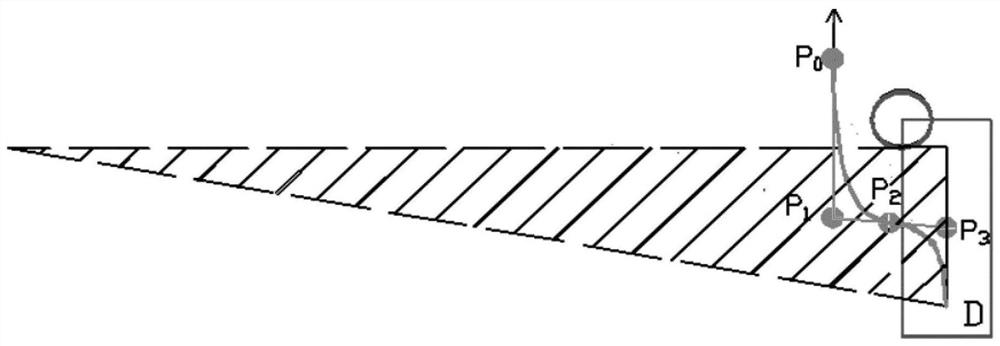

Automatic parallel parking path planning method based on two sections of second-order Bezier curves

ActiveCN110949374AReduced starting pose requirementsReduce the difficulty of correctionControl devicesSimulationObstacle avoidance

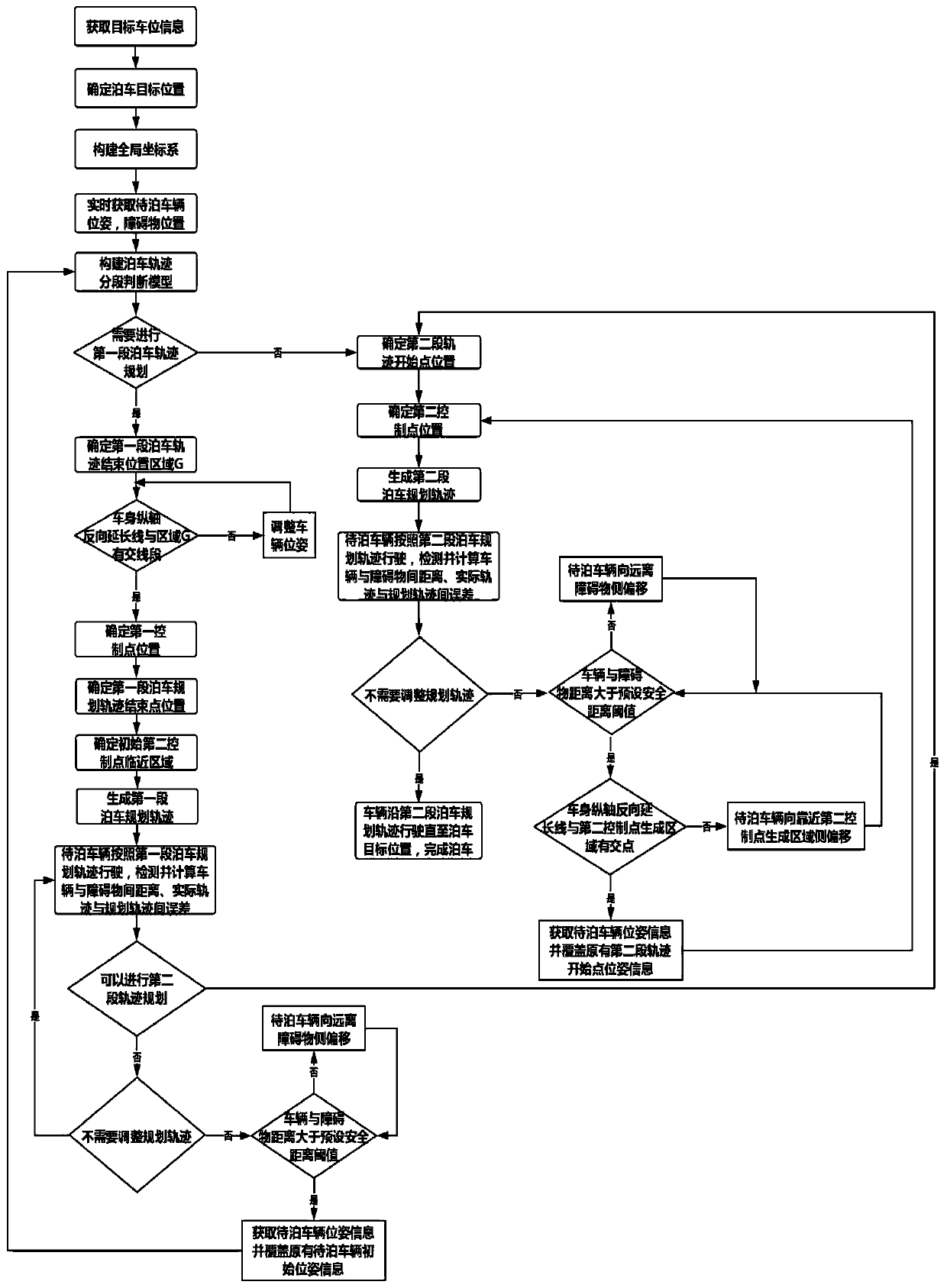

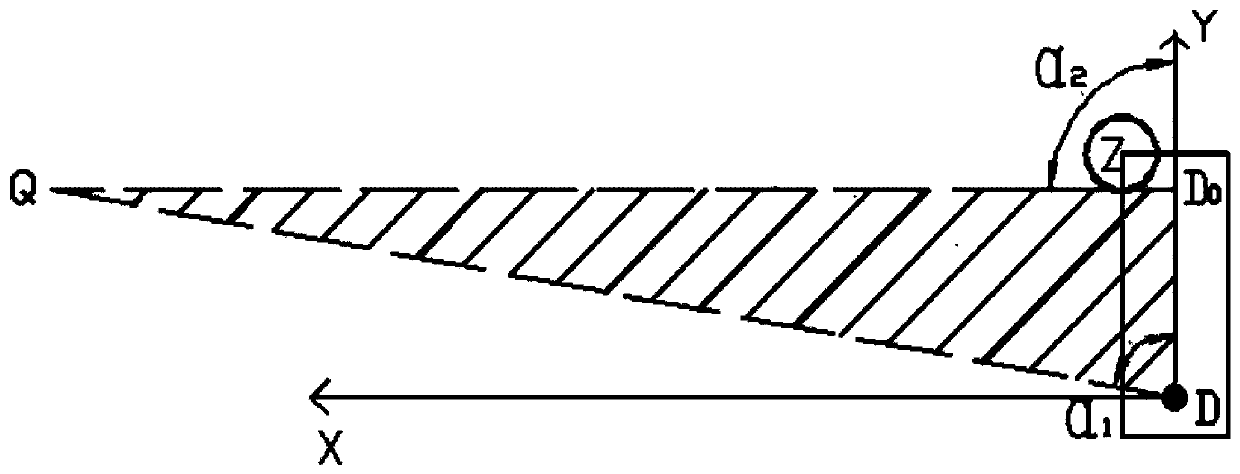

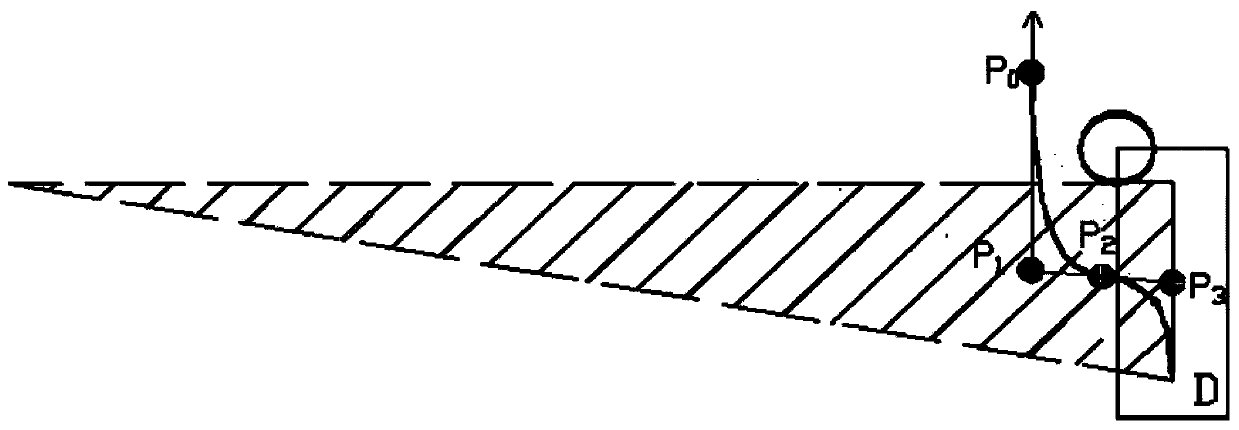

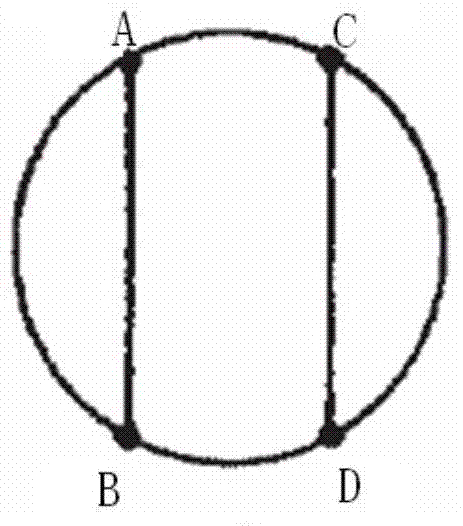

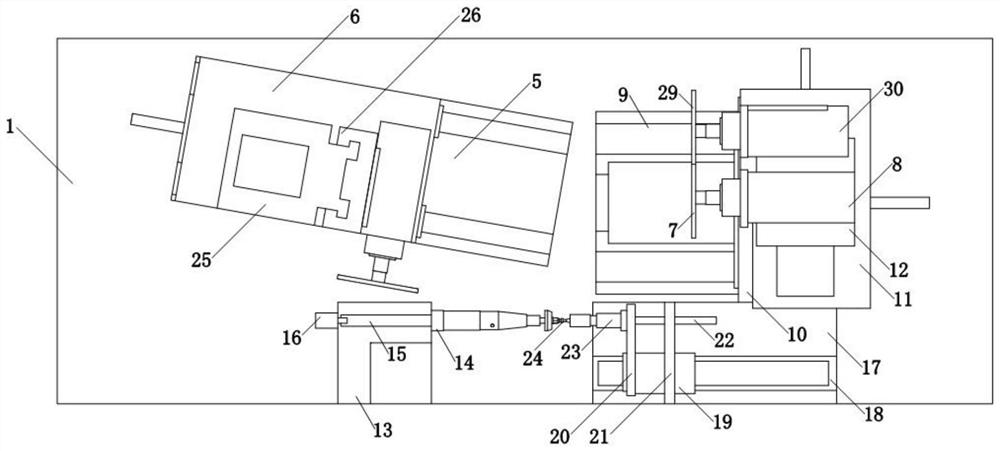

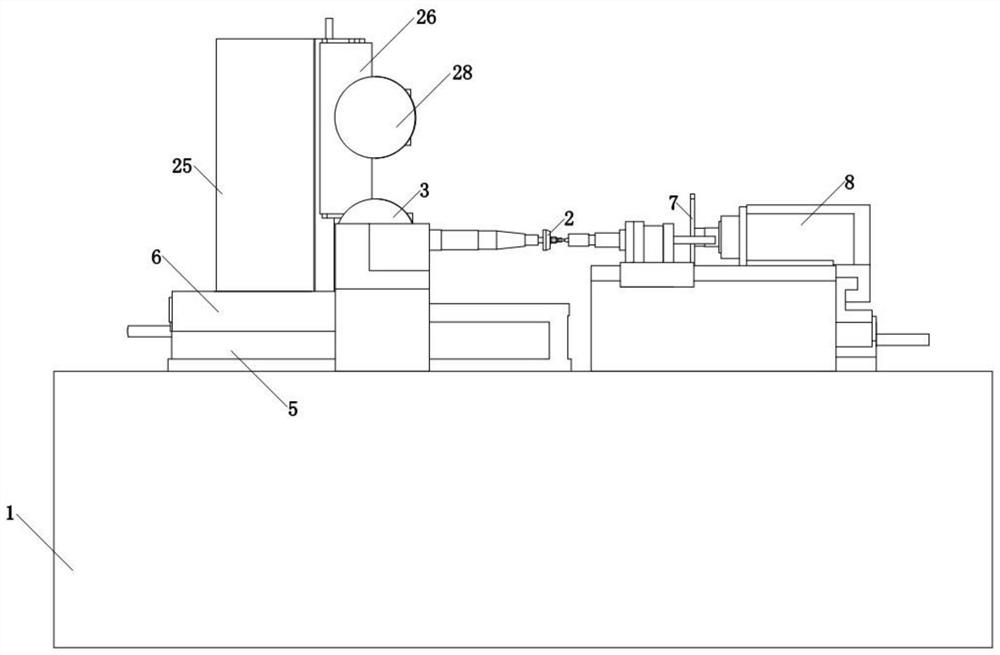

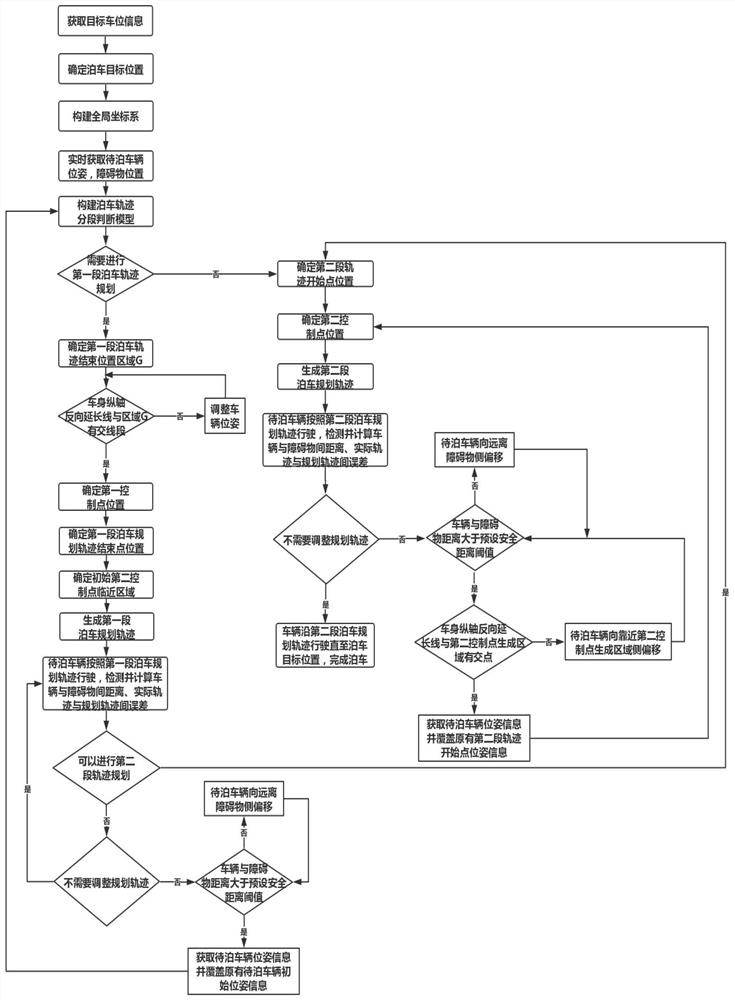

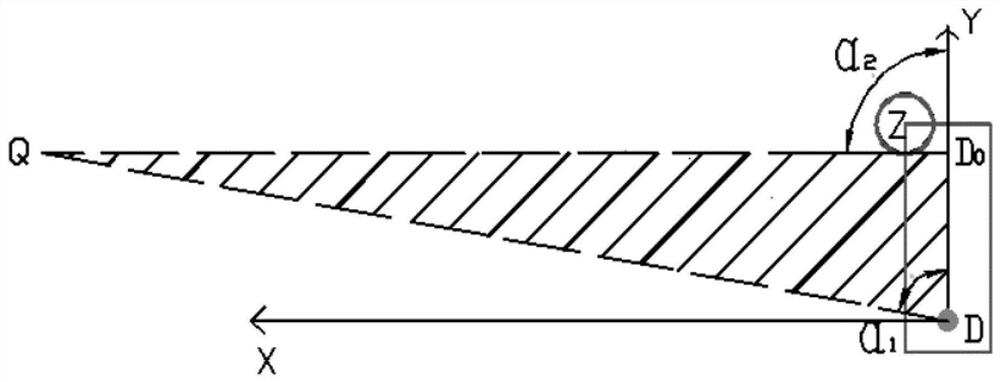

The invention discloses an automatic parallel parking path planning method based on two sections of second-order Bezier curves. The method comprises the steps of obtaining target parking space information to determine a parking target position and establishing a global coordinate system by taking the parking target position as an original point; constructing a parking trajectory segmentation judgment model to determine the number of planned trajectory segments, planning the end position range of the first section of trajectory, determining the start point, the end point and the control point of each section of planned trajectory, performing path planning by using a second-order Bezier curve, performing monitoring at set intervals, and adjusting the planned trajectory by using a dynamic adjustment planning trajectory method. According to the method, the requirement for the initial pose of the to-be-parked vehicle is lowered, and the environmental adaptability of the path planning methodis improved; the vehicle can be driven into the planned area manually through simple adjustment, so that the cost is reduced, and the method can be applied to medium and low-grade vehicles; control points of parking trajectory planning are easy to determine, a trajectory generation algorithm is simple, and the path curvature is continuous. The correction difficulty of the track error is reduced,and the obstacle avoidance performance and parking efficiency of the vehicle are improved.

Owner:JIANGSU UNIV

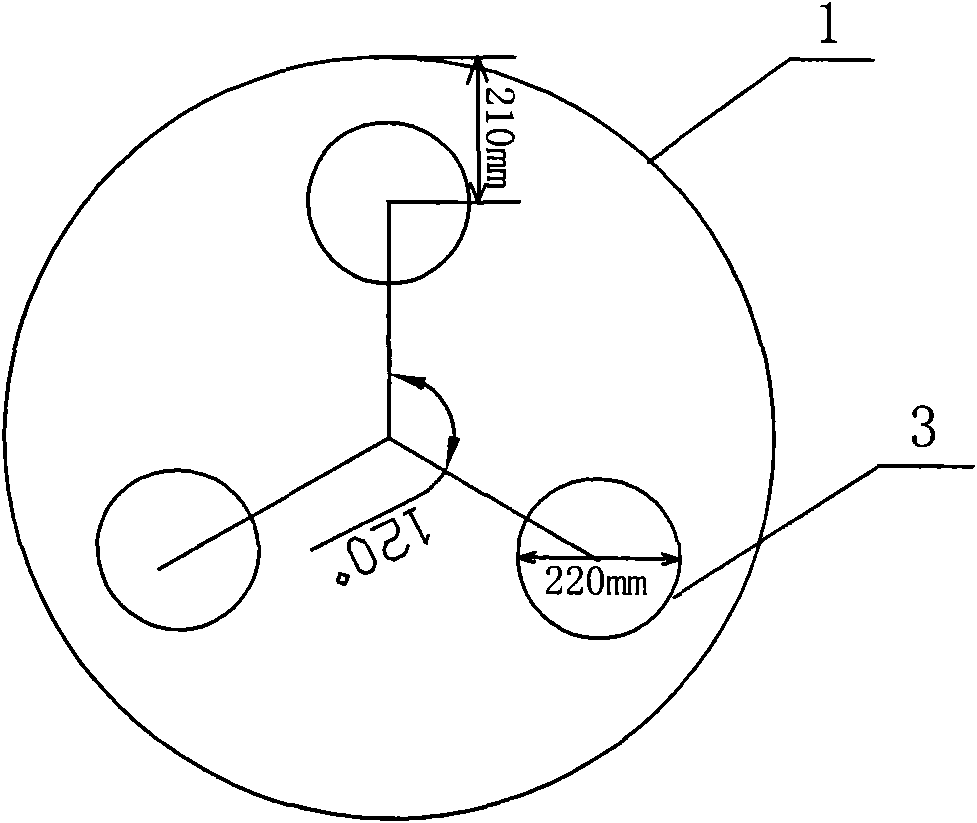

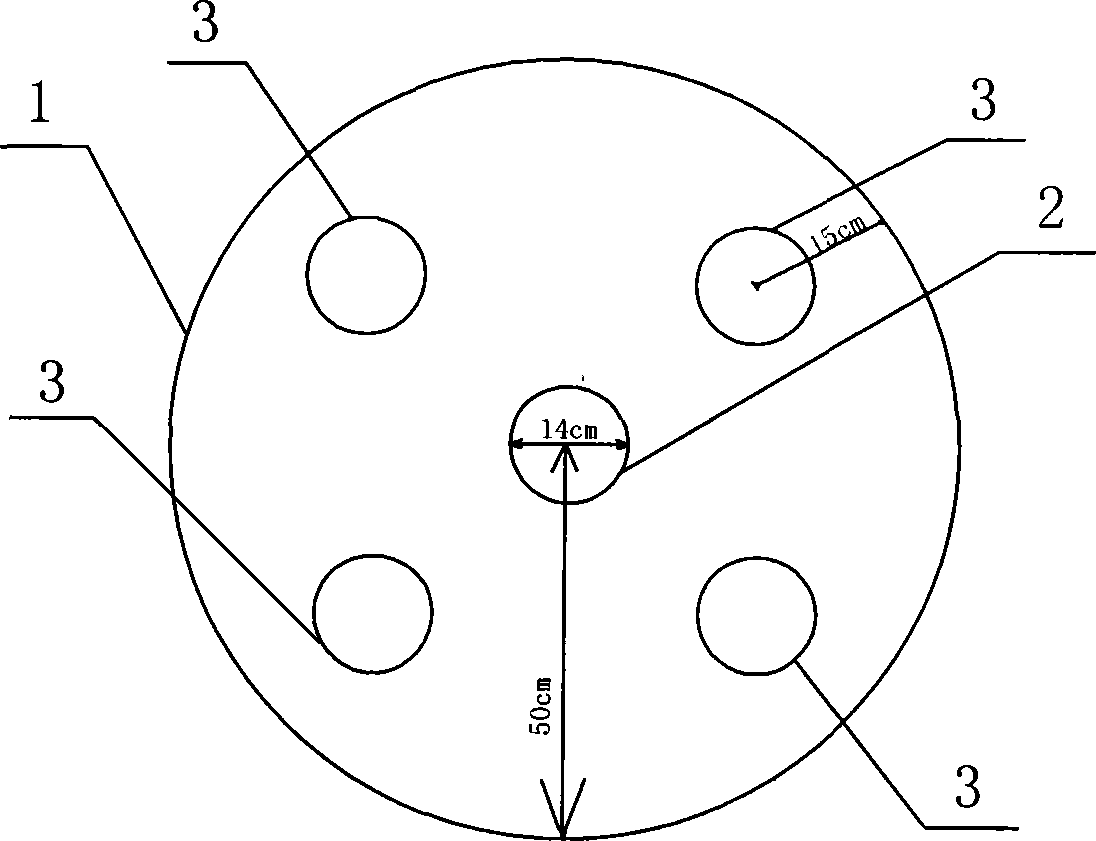

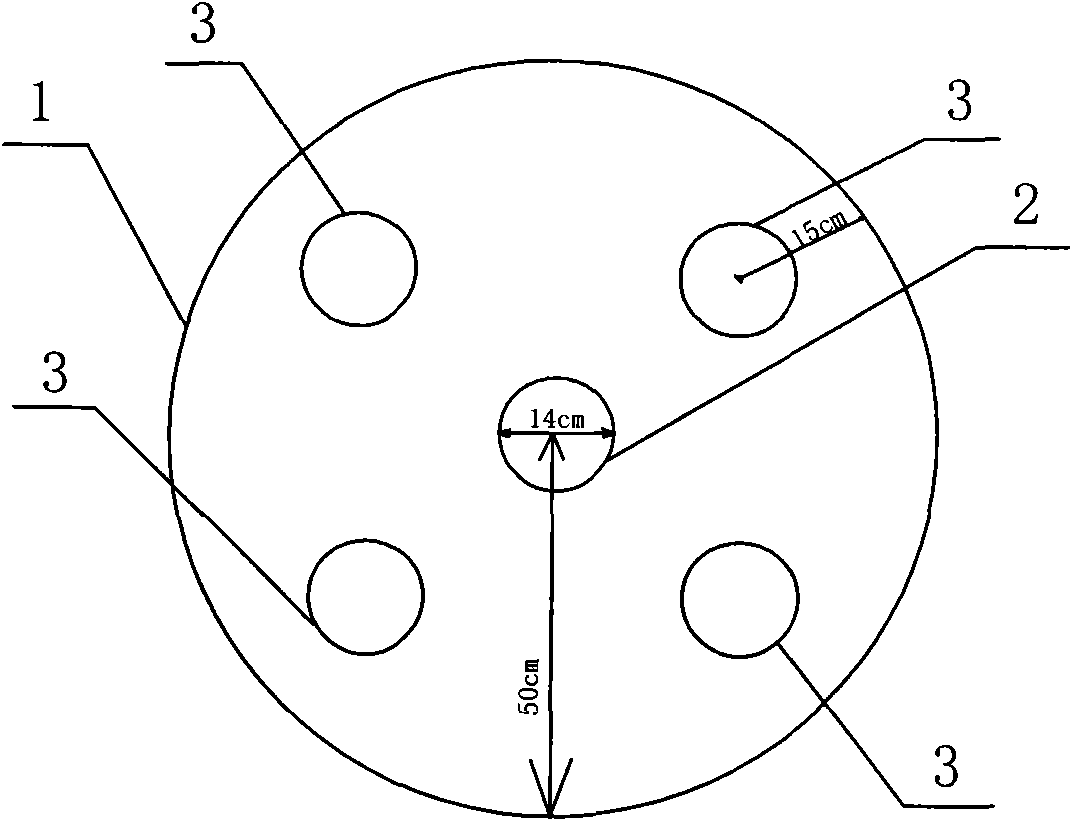

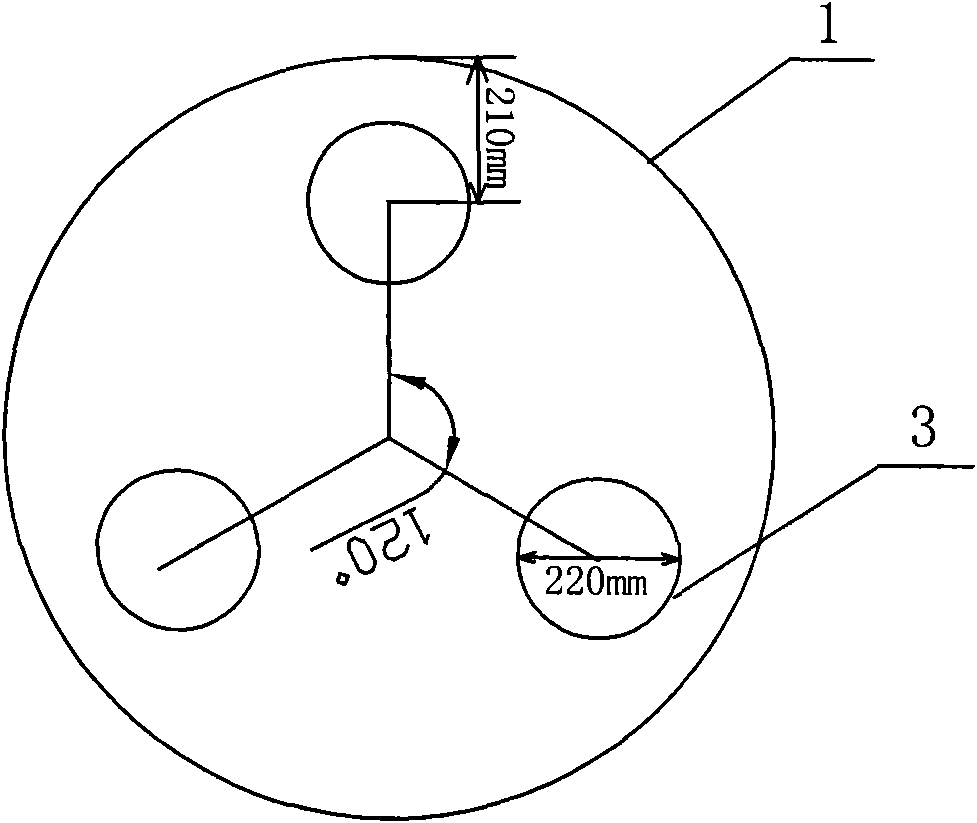

Rock mass pile foundation pore-forming preboring construction method

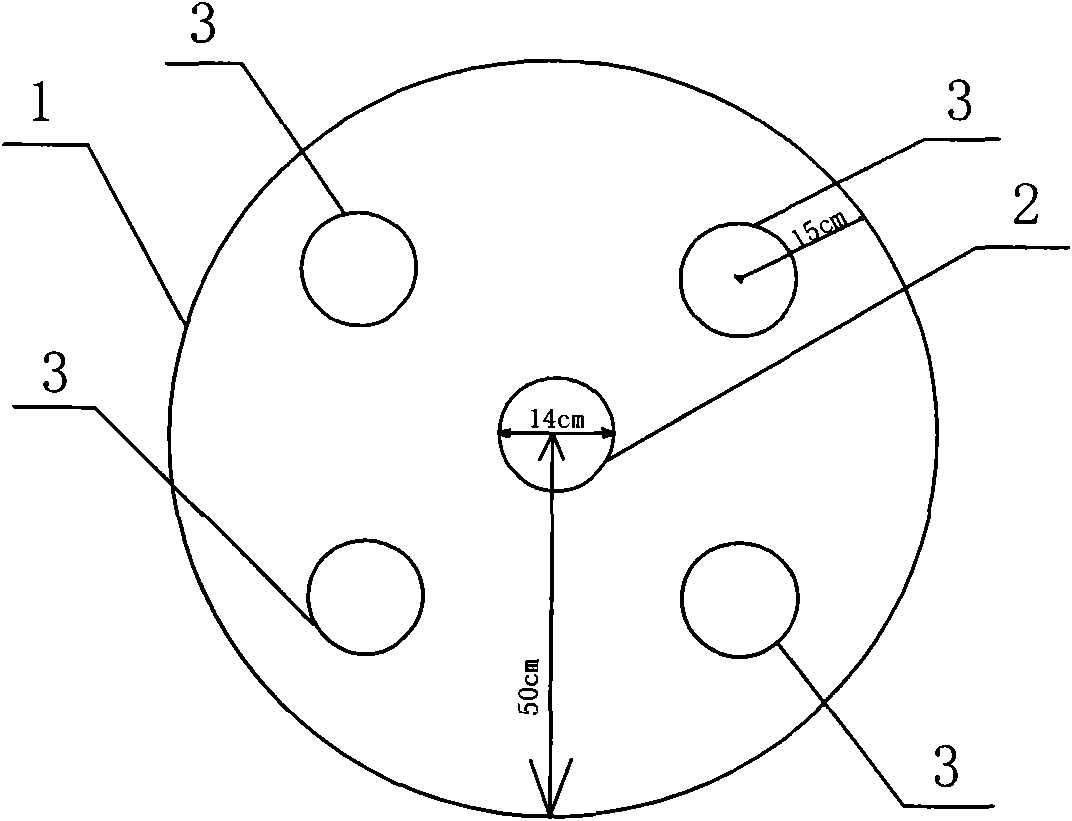

ActiveCN101570971AReduce the difficulty of correctionImprove pore forming efficiencyReciprocating drilling machinesFoundation engineeringPunchingModel Number

The invention relates to a rock mass pile foundation pore-forming preboring construction method, including: five hole sites are arranged at a drilled pile site, a center hole sit is arranged in the center of the drilled pile site, four surrounding hole sites are evenly distributed outside the center hole site, the distance between the center of each surrounding hole and the margin of the drilled hole site is equal, and an in-the-hole drill with a drill model number of Phi 140mm is used for drilling on the center hole site and the surrounding hole site. Another hole distribution mode includes: three hole sites are arranged at the drilled pile site, the distance between the center of each hole site and the center of the drilled hole pile site is equal and the connection lines of two adjacent hole site and the center form a 120 degrees angle, the distance between the center of the hole site and the margin of the drilled hole pile site is equal, and an in-the-hole drill with the model number of Phi 220mm is used for punching on the hole site. The method of the invention realizes that pore-forming efficiency of a punching drill is high, slant rock correction difficulty is reduced, construction quality is high, construction period is short and construction cost is low when rock bearing capacity at the foundation pile site of a bridge pile is more than 1000kPa or a slant rock is existed.

Owner:SINOHYDRO ENG BUREAU 4 +1

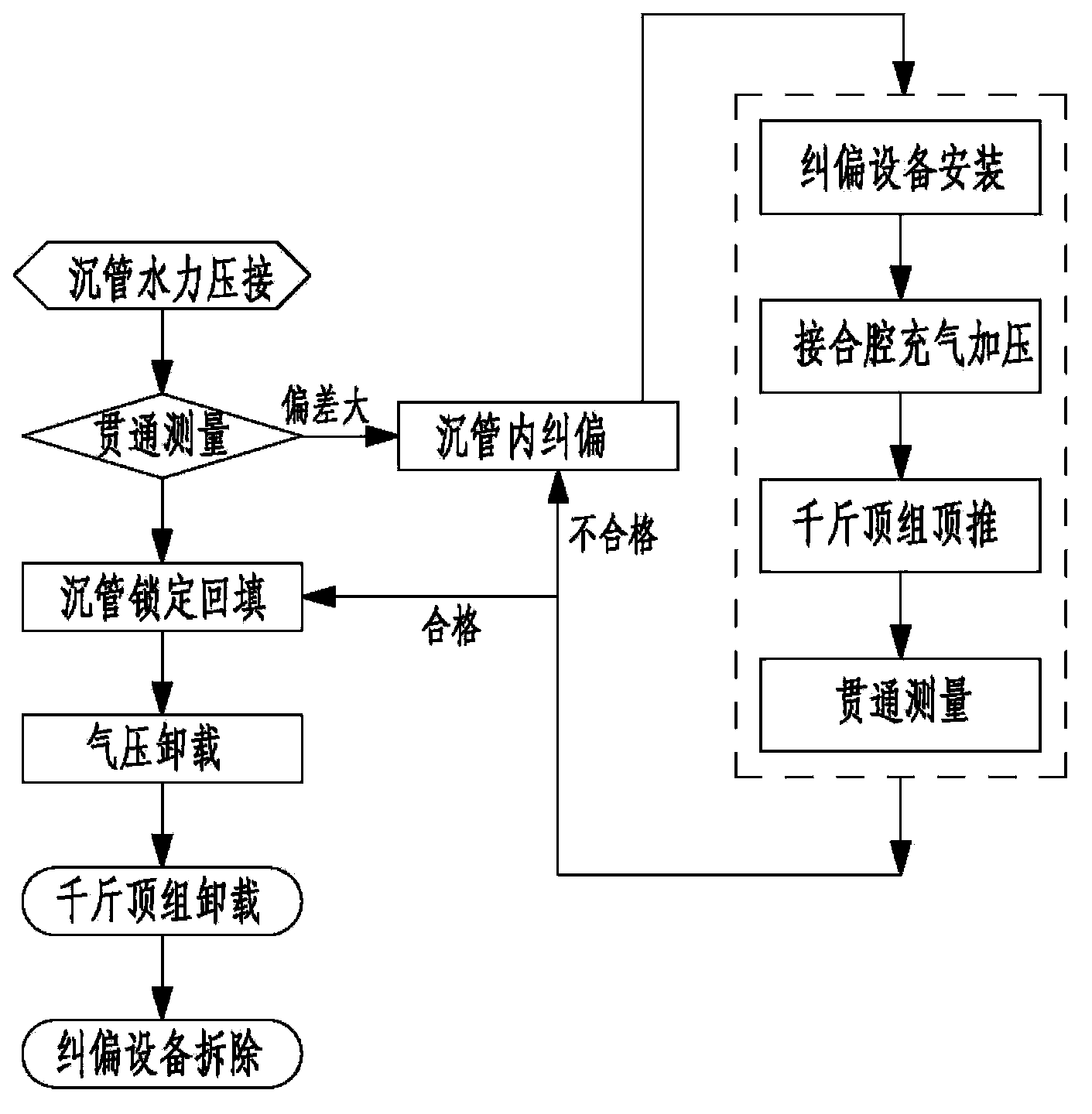

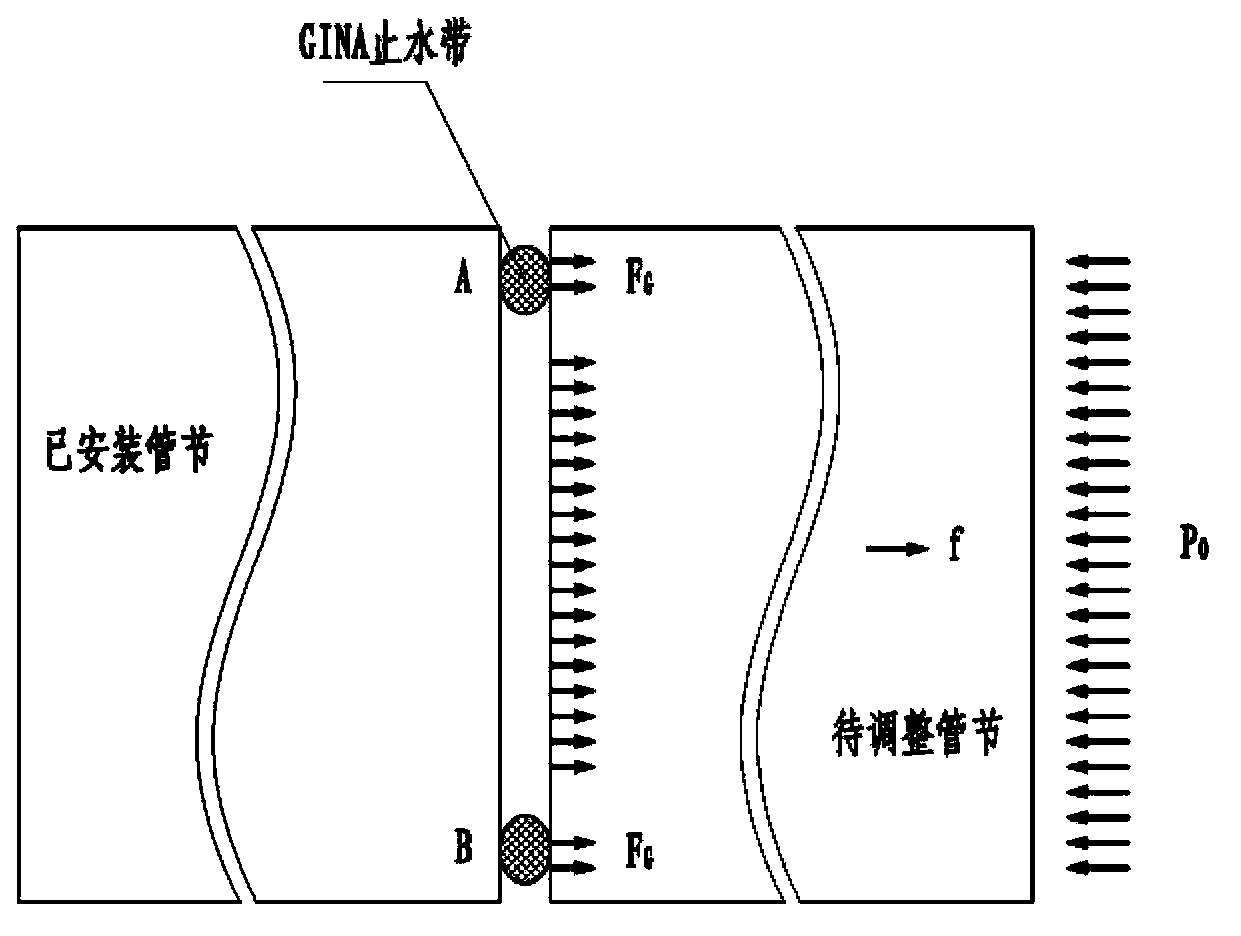

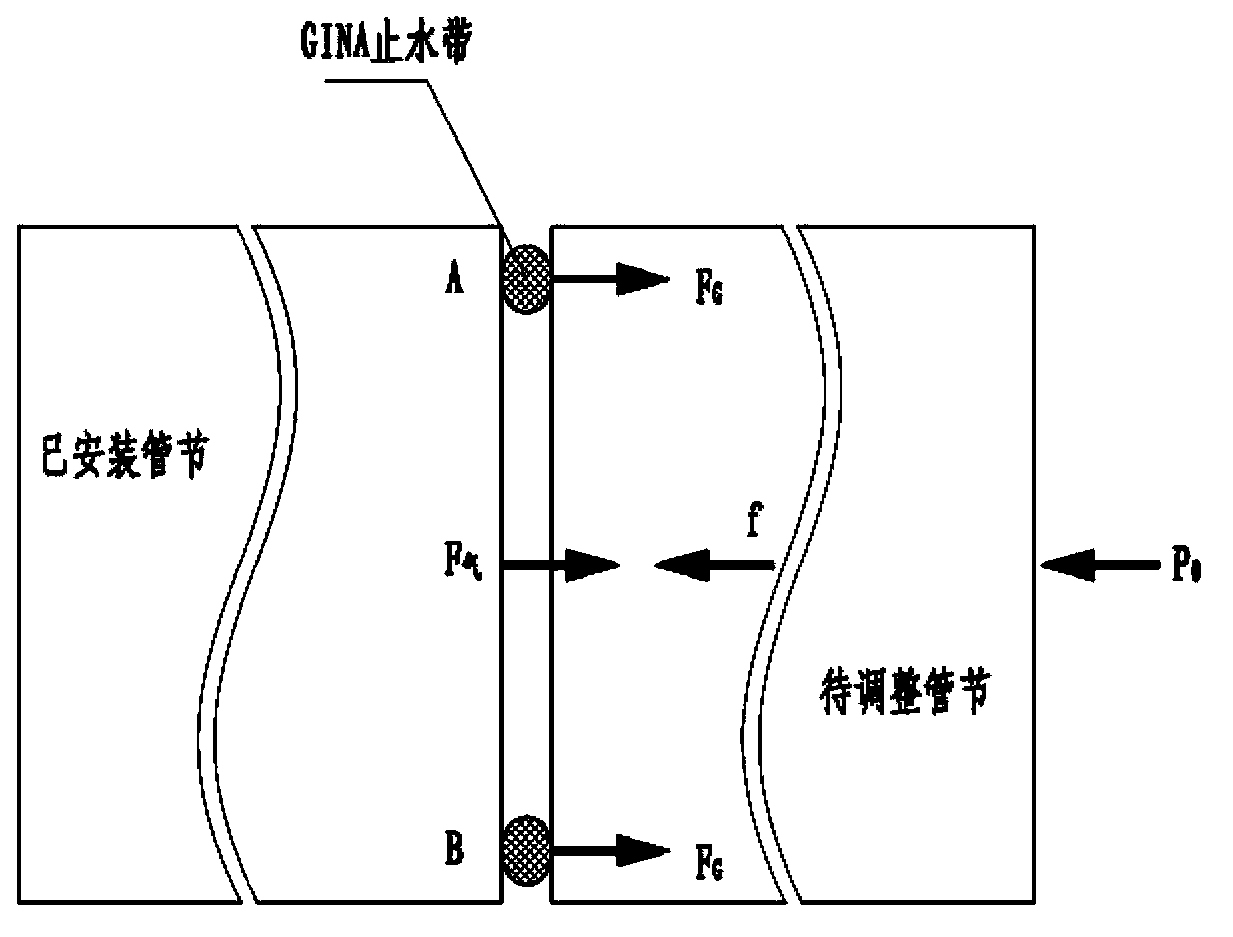

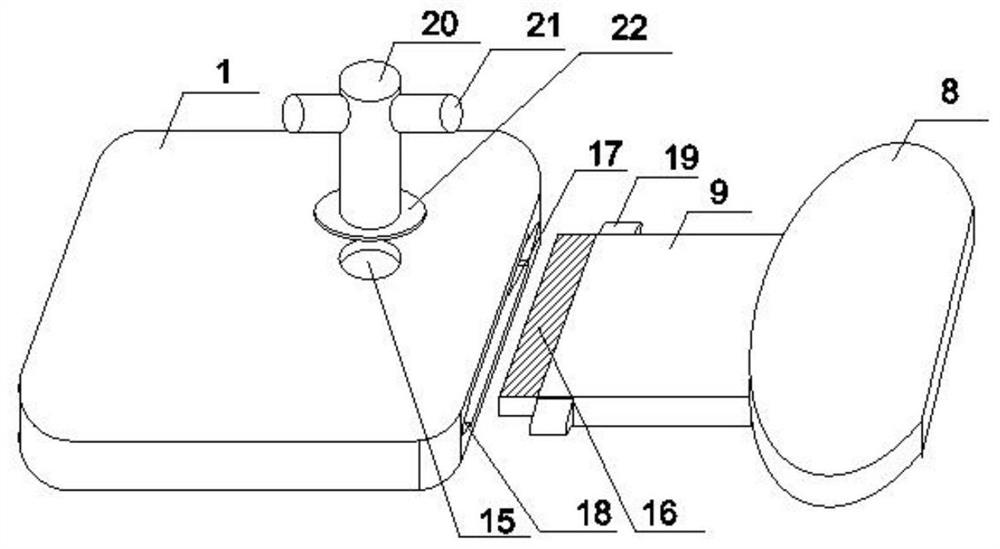

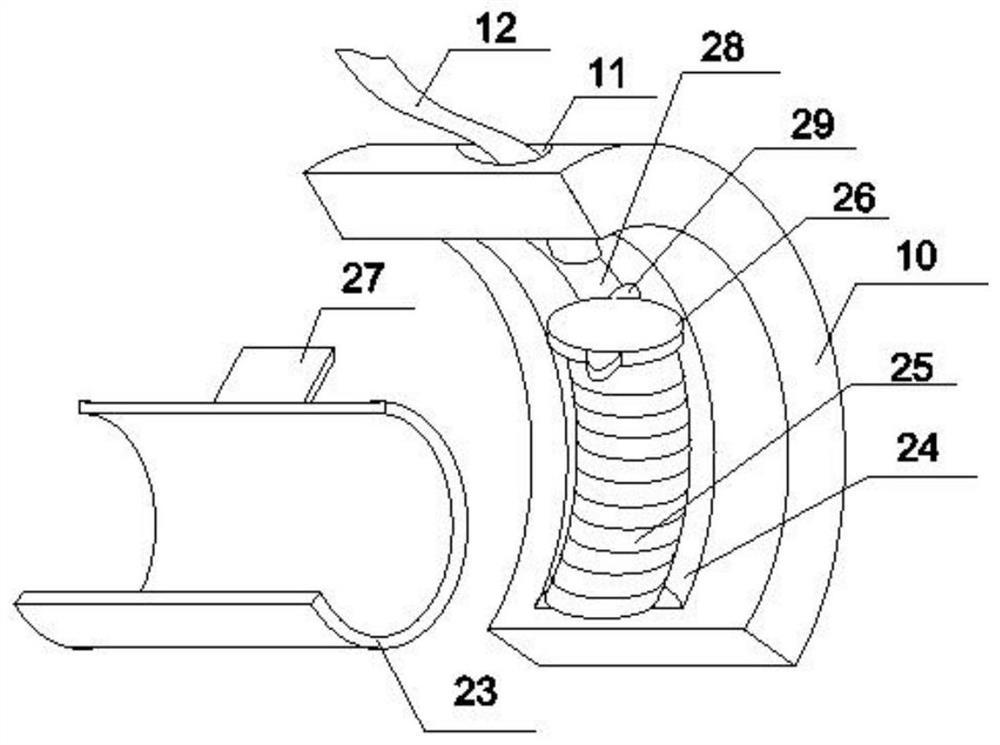

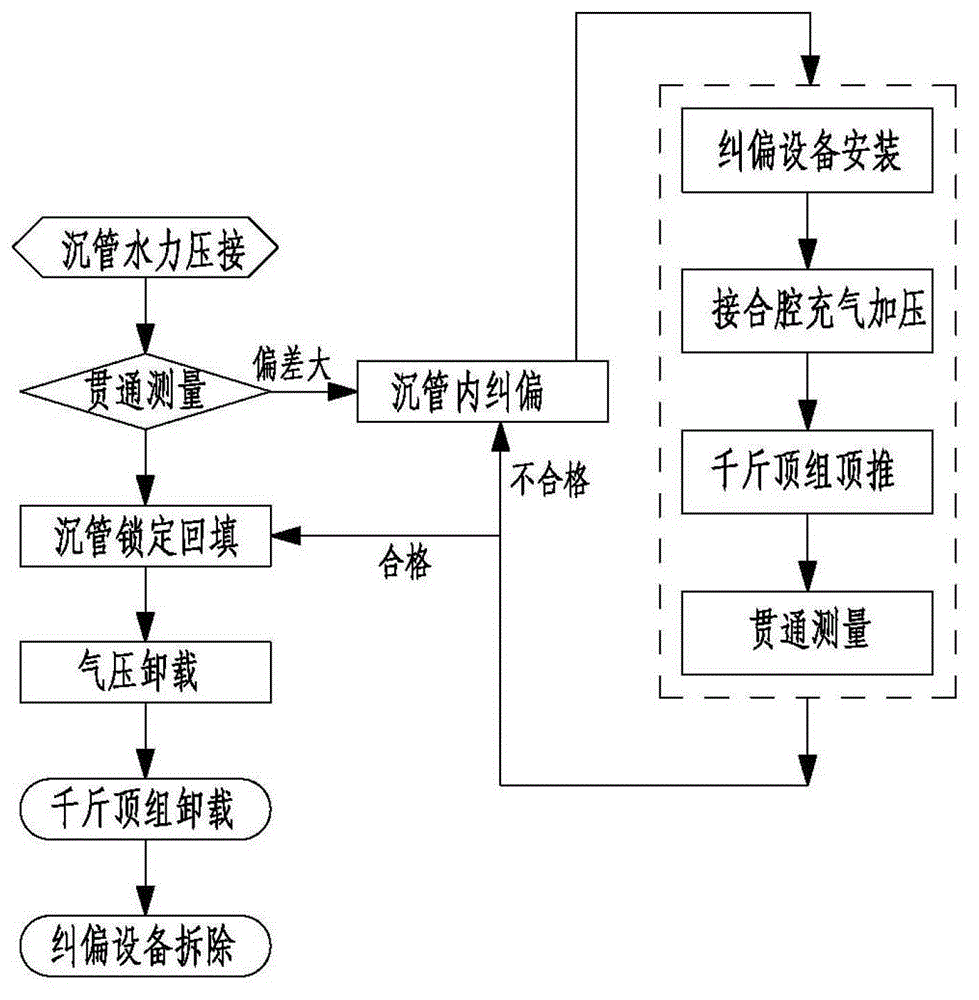

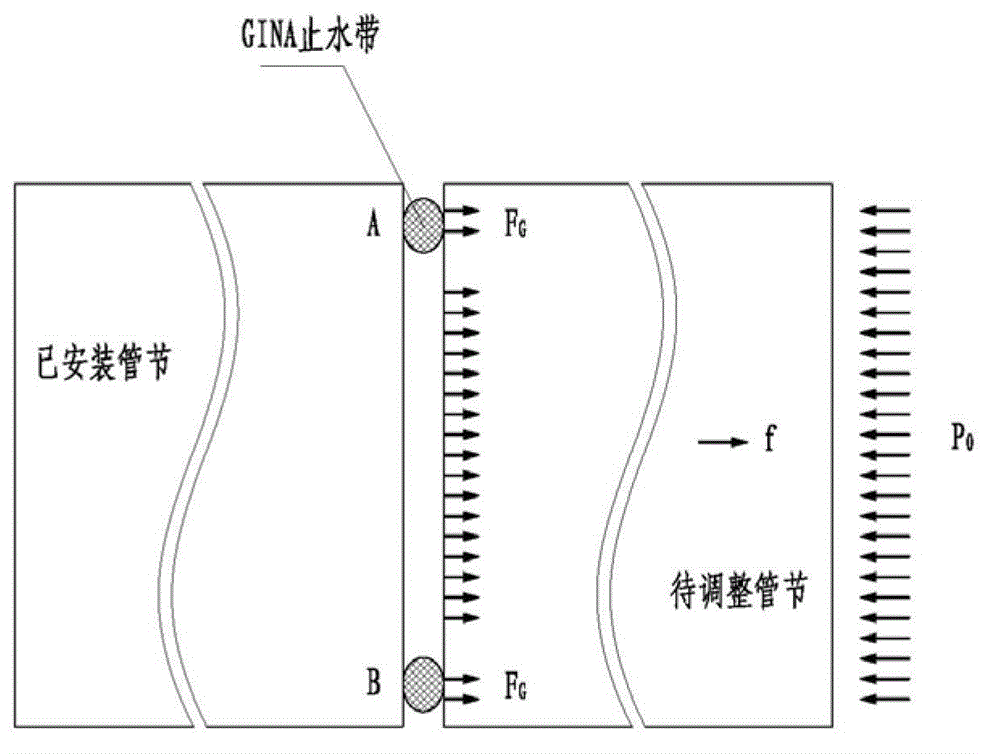

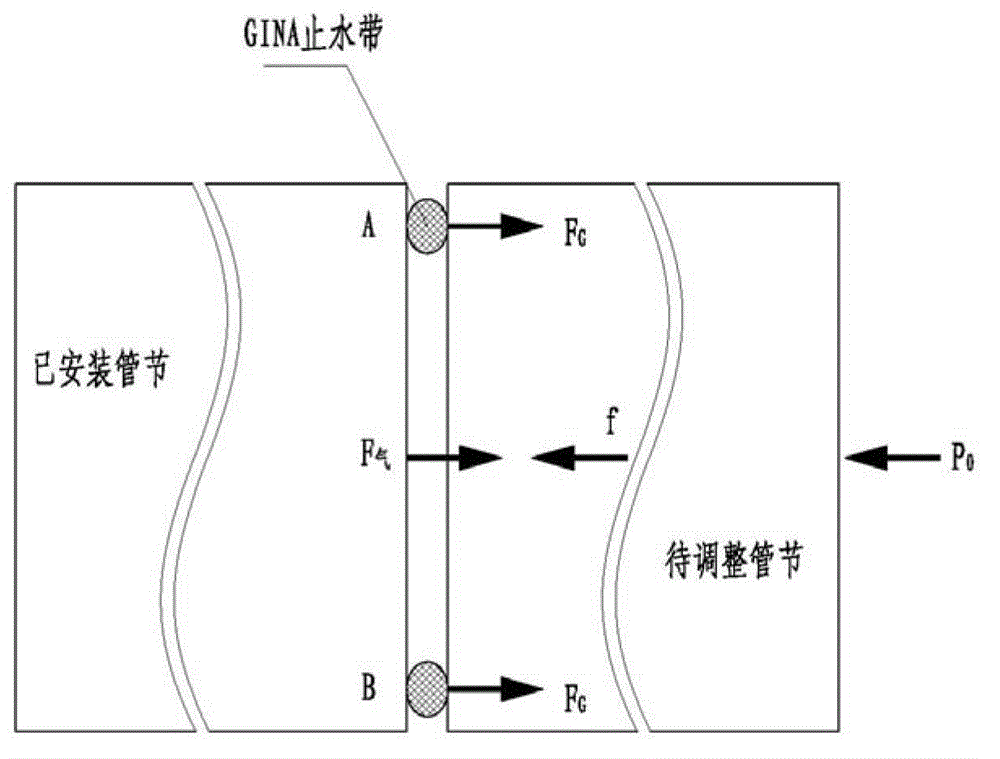

Rectification method for immersed tube tunnel

ActiveCN103912017AReduce the difficulty of correctionSimplify the construction processArtificial islandsUnderwater structuresEngineeringImmersed tube

The invention provides a rectification method for an immersed tube tunnel. The rectification method comprises a step of mounting a jack group in a joint chamber, a step of controlling the jack group to jack up a tube section to be adjusted until completion, a step of backfilling at the two sides of the immersed tube, a step of removing the jacking force of the jack group, and a step of detaching the jack group. Due to the adopted steps, the jack group is mounted in the jointed chamber to perform fine adjustment rectification on the immersed tube in the chamber, and therefore, the rectification difficulty of the immersed tube under water can be reduced, the construction cost can be reduced and the rectification precision can be improved; air can be charged into the jointed chamber so that the total pressure in the joint chamber is basically equal to the sum of water pressure outside the tube section to be adjusted and the frictional force of a foundation bed, and therefore, the tube section to be adjusted is located in a dynamic-static critical state; rectification can be realized by just applying relatively low jacking force to the immersed tube by using the jack group of a relatively small size, and therefore, the size of the jack group is effectively reduced and then the jack group can be matched with the relatively small space of the joint chamber.

Owner:CCCC FIRST HARBOR ENG +1

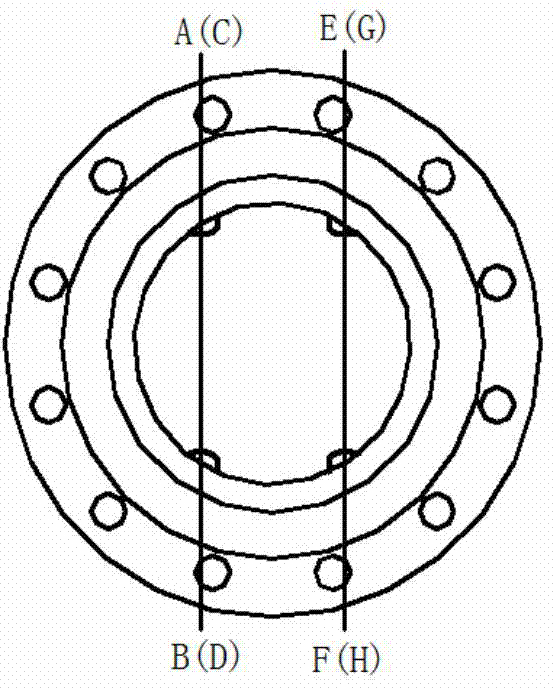

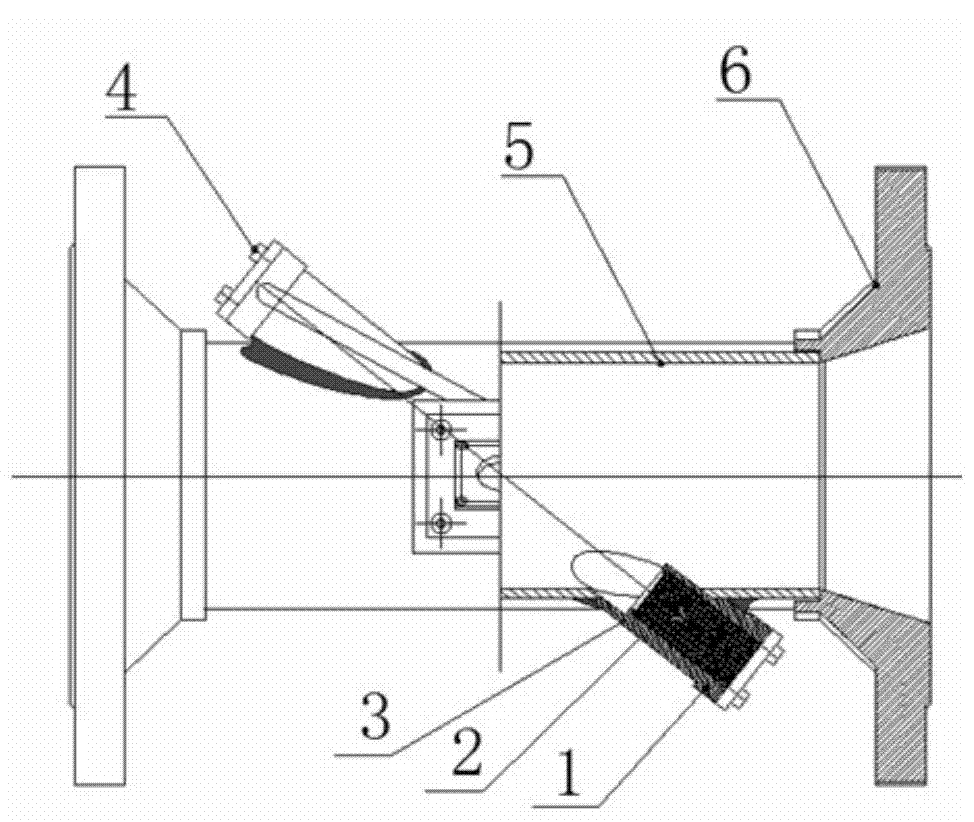

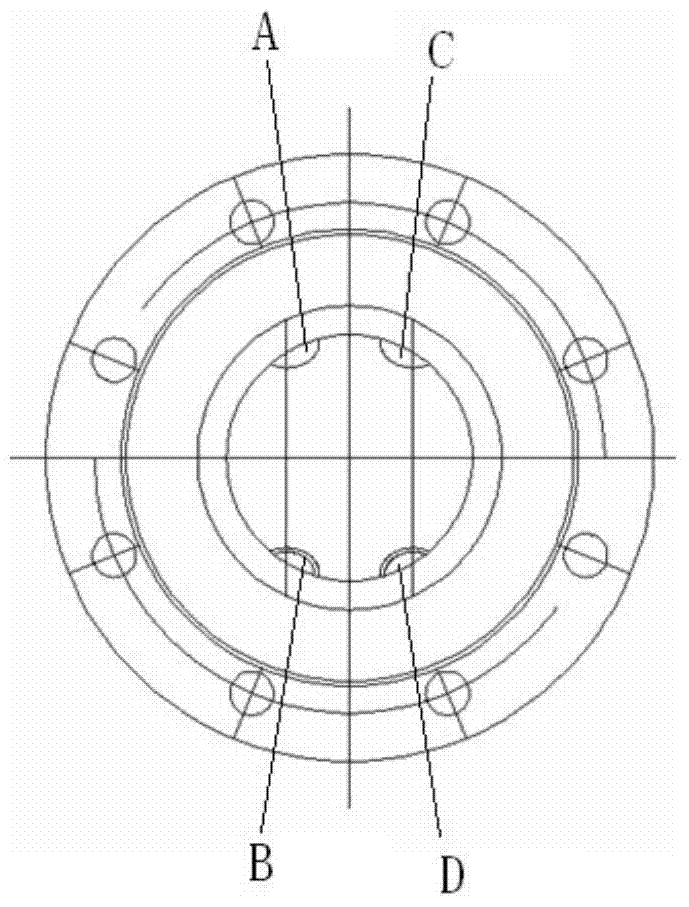

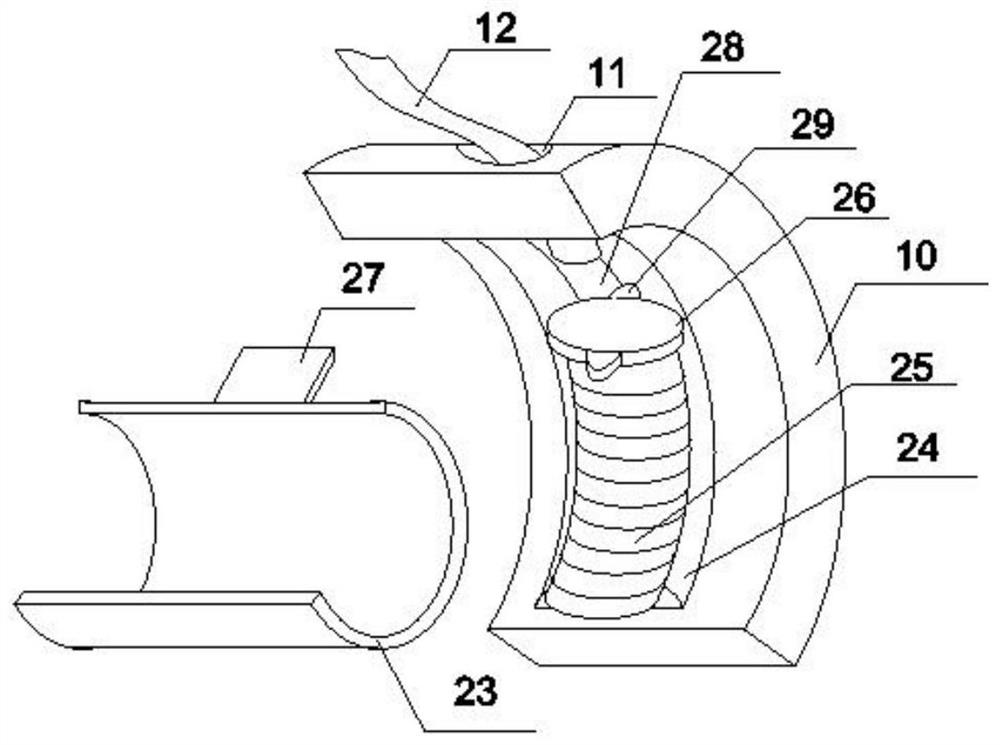

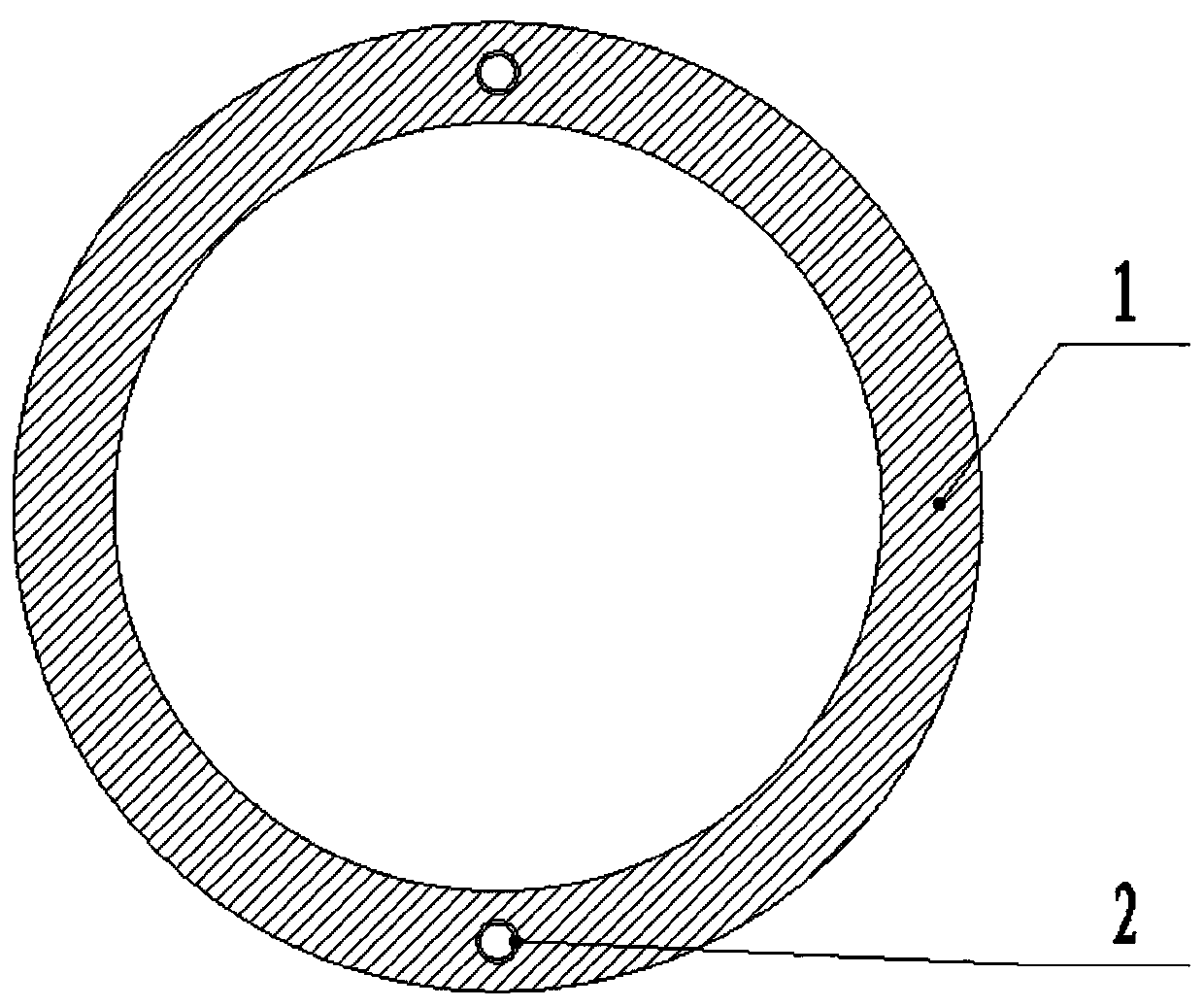

Quadraphonic ultrasonic heat meter

InactiveCN103698058AReduce the difficulty of correctionImprove reliabilityVolume/mass flow measurementFluid speed measurementObservational errorTransducer

The invention discloses a quadraphonic ultrasonic heat meter. The meter comprises a pipe body, wherein the wall of the pipe body is provided with eight mounting ports, each mounting port is respectively provided with an ultrasonic transducer, four sound tracks are formed by the eight ultrasonic transducers which are opposite in pairs, the axes of every two sound tracks in the four tracks are parallel to each other, are equal in length and are symmetrically distributed at the two sides of the axis of the pipe body, and the distances between the axes of the two sound tracks and the axis of the pipe body are equal. The transducers are distributed on a section according with the velocity distribution rule of a flow field, so that the correction difficulty of measuring errors caused by a computing instrument matched with a flowmeter can be greatly reduced, and a final measuring result is more accurate; the adaptability and the stability of the ultrasonic heat meter on different incoming flows can be improved, and the installation requirements can be reduced.

Owner:RUINA INTELLIGENT EQUIP CO LTD

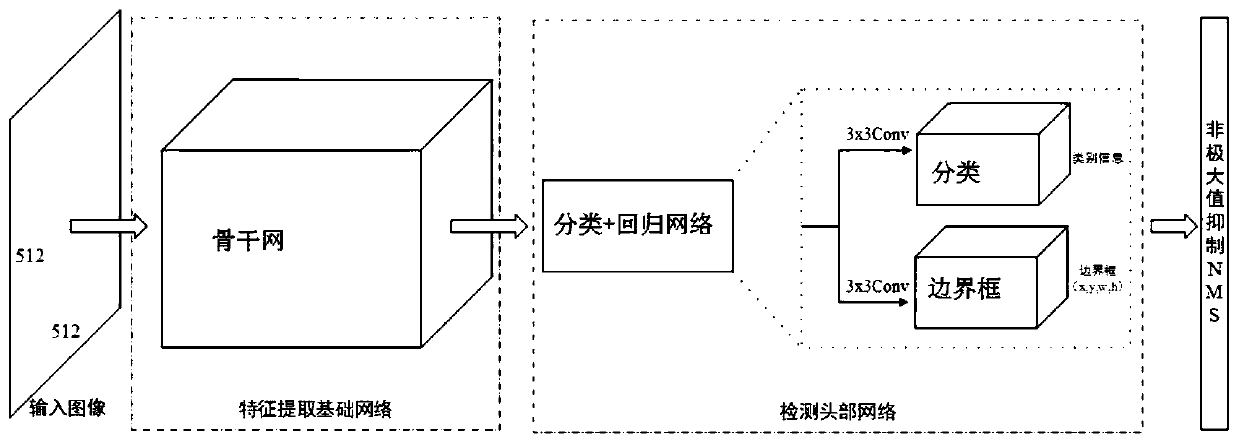

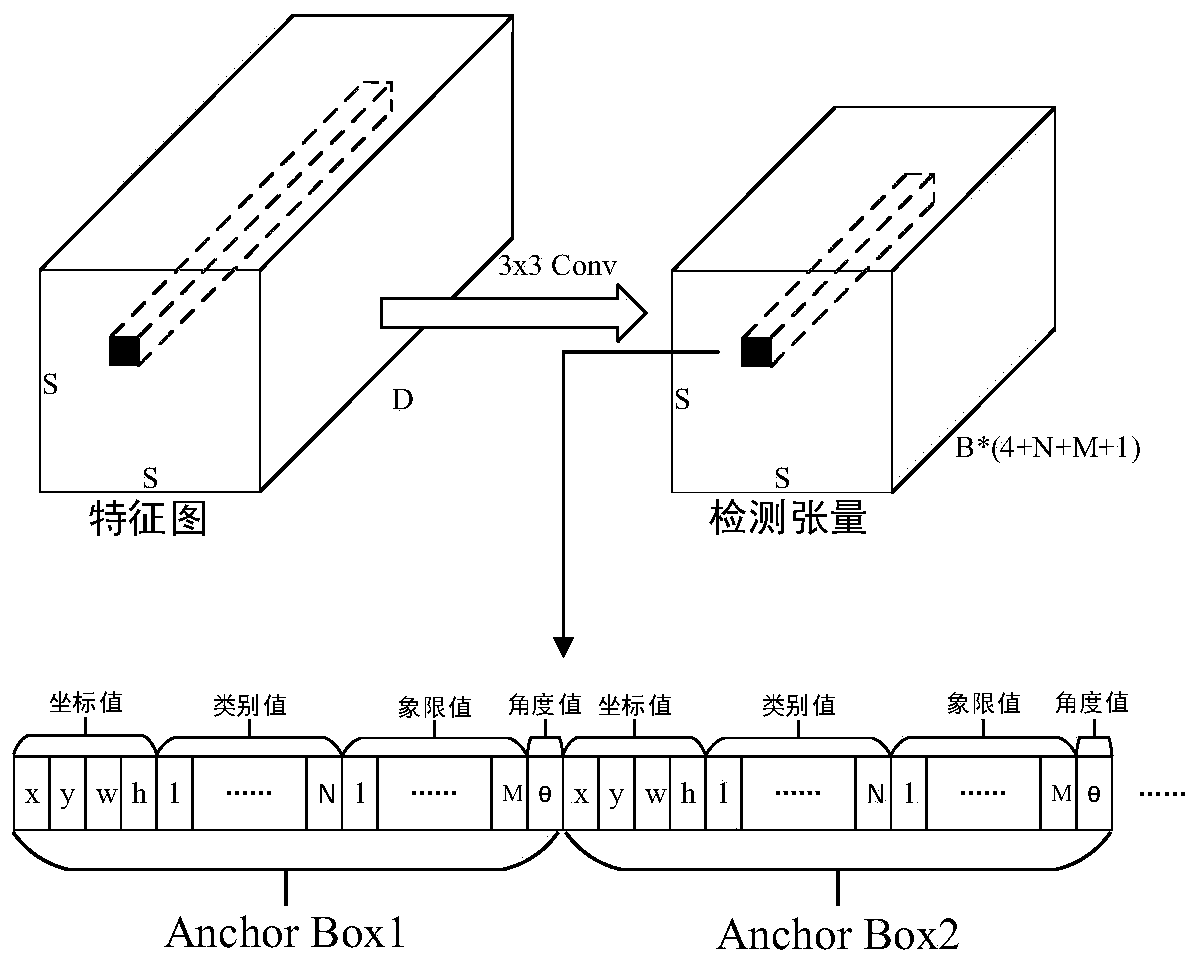

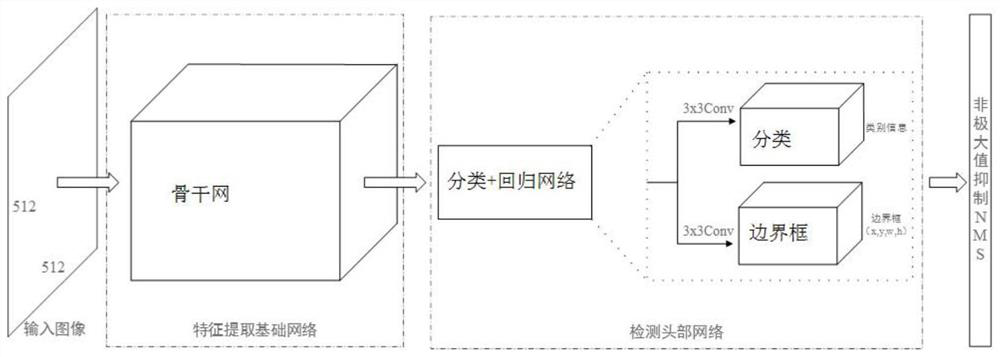

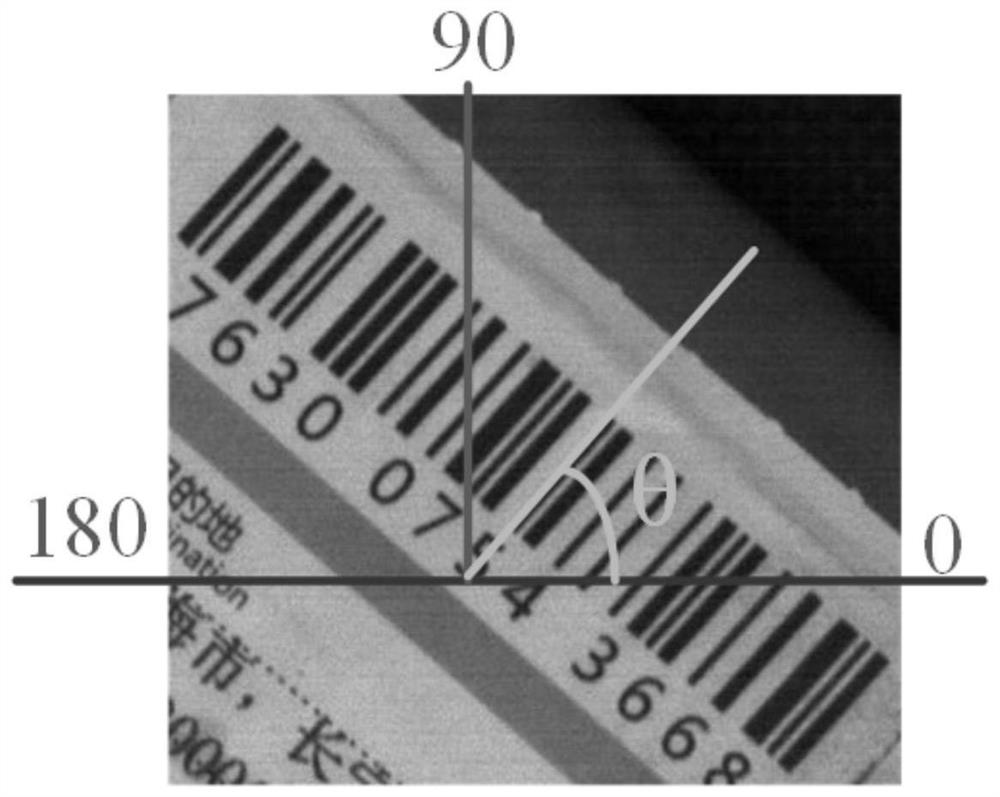

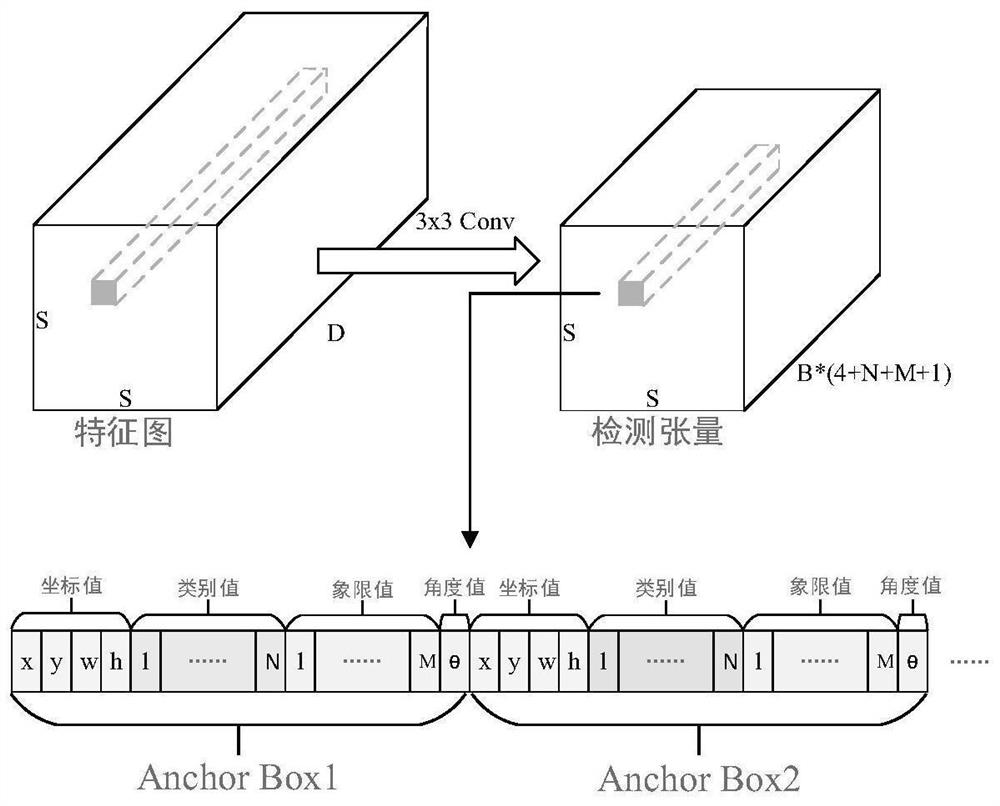

Bar code inclination correction method based on multi-task target detection

ActiveCN110046530AReduce the difficulty of correctionImprove accuracySensing by electromagnetic radiationCorrection methodFeature extraction

The invention discloses a bar code inclination correction method based on multi-task target detection, and the method comprises the steps: building a single-stage target detector which comprises a feature extraction basic network and a detection head network which are connected in sequence; inputting the bar code image into the feature extraction basic network, and extracting to obtain a feature map; and inputting the feature map into a detection head network, and carrying out classification and position regression on the feature map to obtain a correction result. According to the method, theinclination degree of the bar code is firstly classified, then angle regression is carried out, the bar code correction difficulty is effectively reduced, the bar code is fused with a single-stage target detector to form a multi-task target detection model, the detection and correction efficiency is improved in parallel, and the decoding accuracy and speed are well improved.

Owner:WAYZIM TECH CO LTD

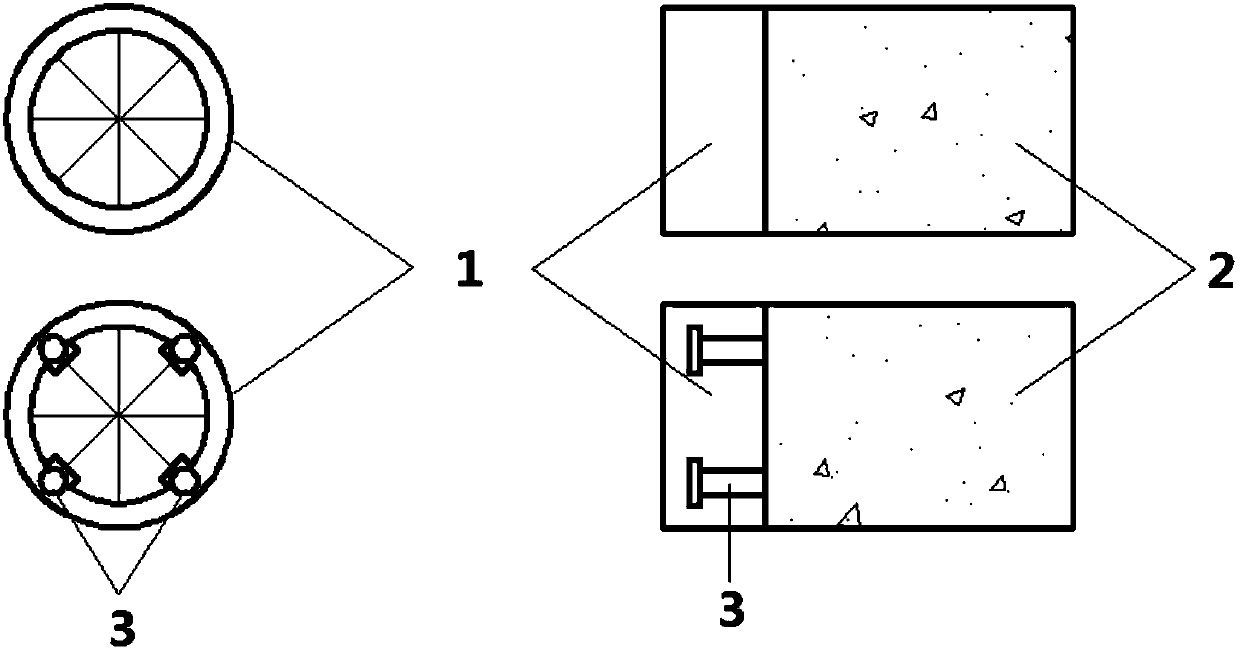

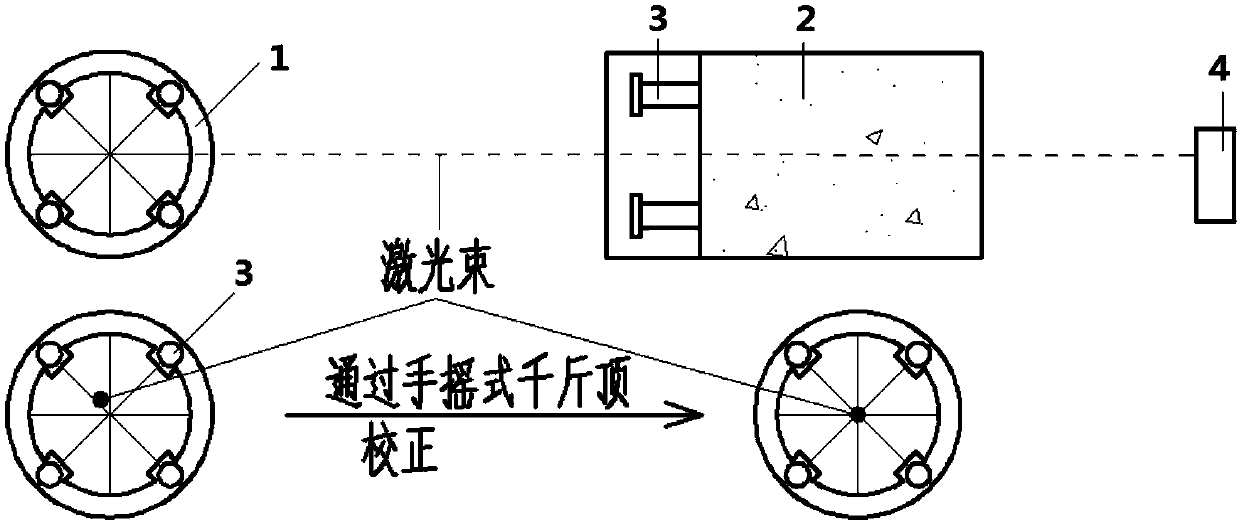

Device and method for correcting cutterhead jacking direction in real time during manual pipe jacking construction

InactiveCN107725892AReduce the difficulty of correctionRealize integrationPipe laying and repairEngineeringBuilding construction

The invention discloses a device and method for correcting the cutterhead jacking direction in real time during manual pipe jacking construction, and relates to the field of municipal road drain pipeline construction. The method comprises the following steps that four hand-operated jacks are uniformly arranged and fixed to the inner side of the circumference of a cutterhead, a protection barrel ofthe cutterhead extends to cover the four hand-operated jacks, and the cutterhead is connected with a pipeline through the four hand-operated jacks; and when the cutterhead is jacked into a first pipeline section, in the deviation correcting process, the center line and the elevation are measured every time the cutterhead is jacked in by 20-30 cm, the hand-operated jacks are operated manually to slightly adjust the angle of the cutterhead according to the measurement results so that the pipeline jacking direction can be corrected. Through the device and method for correcting the cutterhead jacking direction in real time during manual pipe jacking construction, the constructed pipeline can be precisely positioned, the underground extending deviation of the pipeline is corrected in real time, and the jacking direction in the whole pipeline jacking process is effectively controlled.

Owner:WUHAN HANYANG MUNICIPAL CONSTR GRP CO LTD

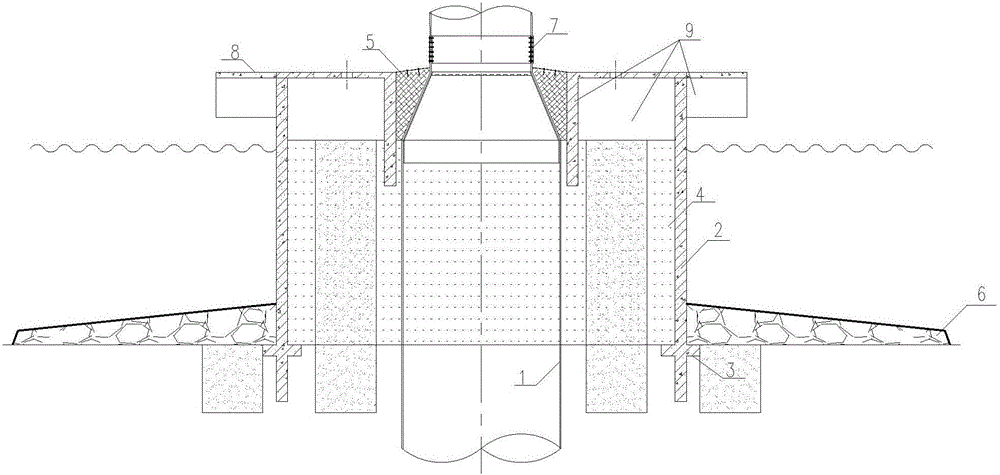

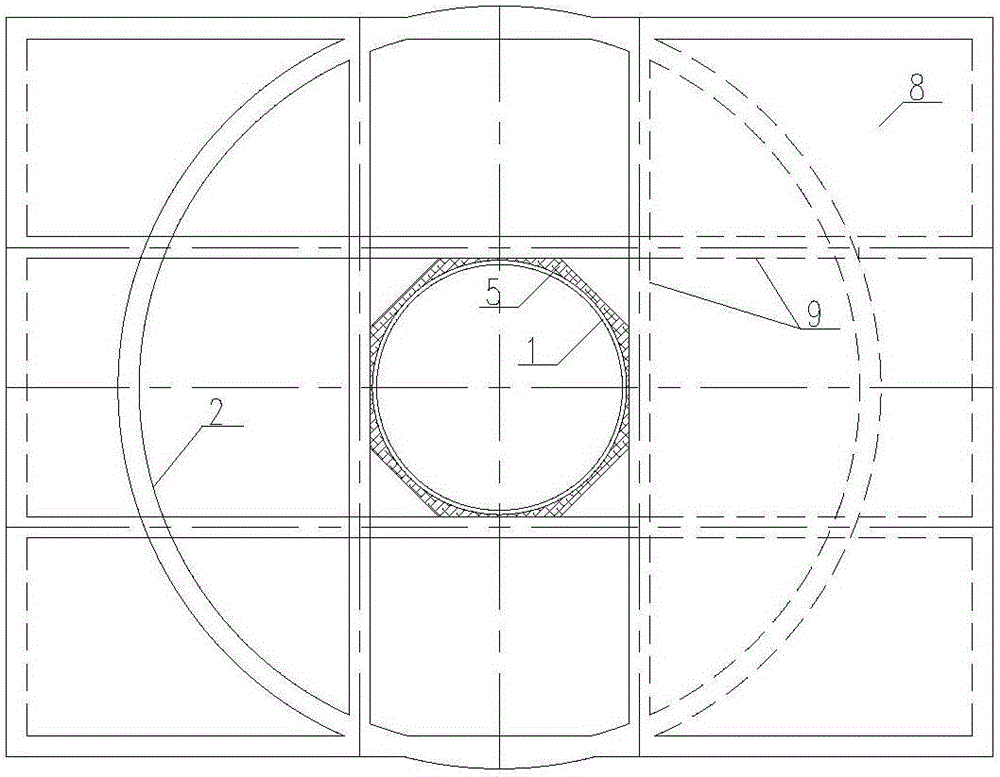

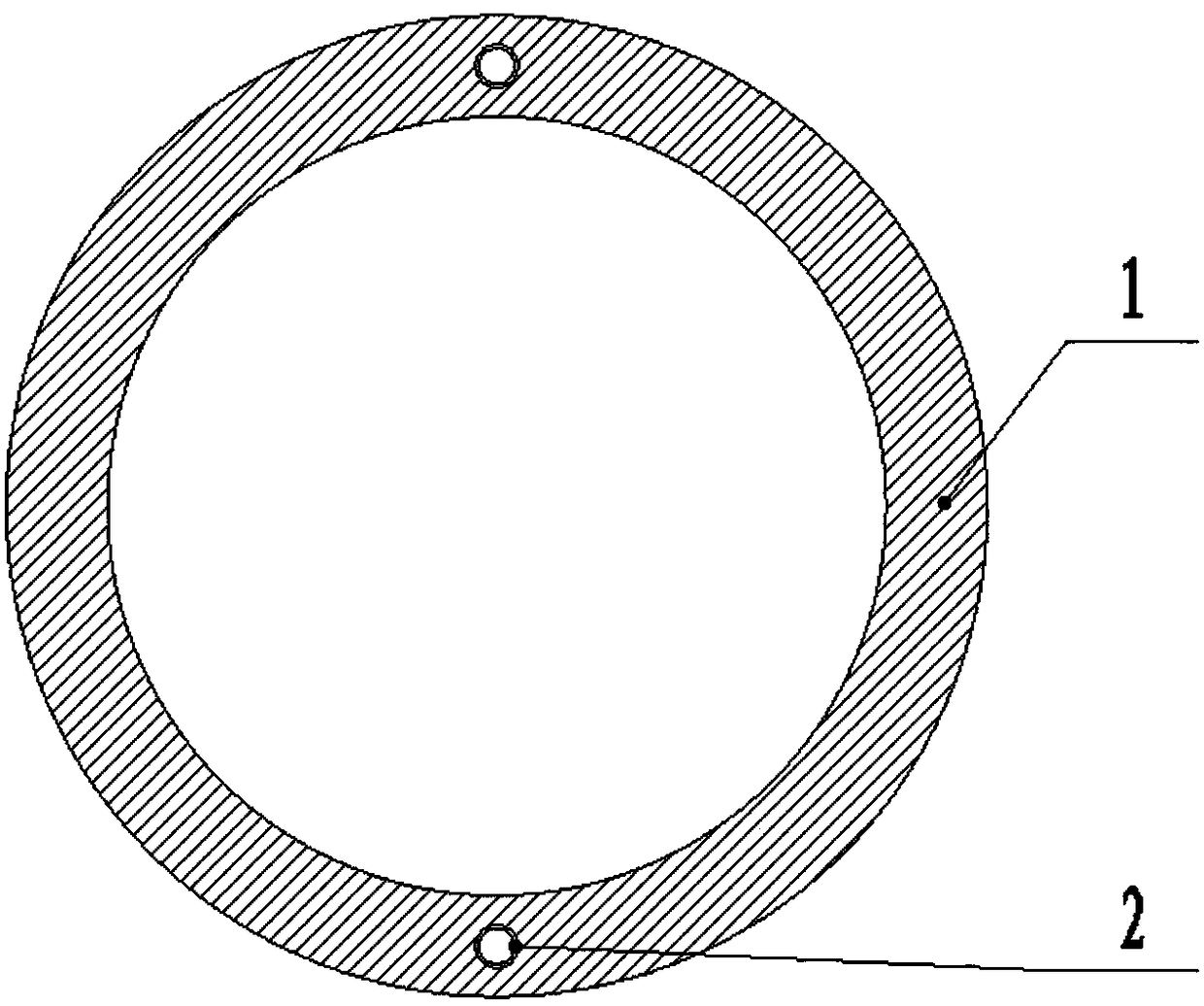

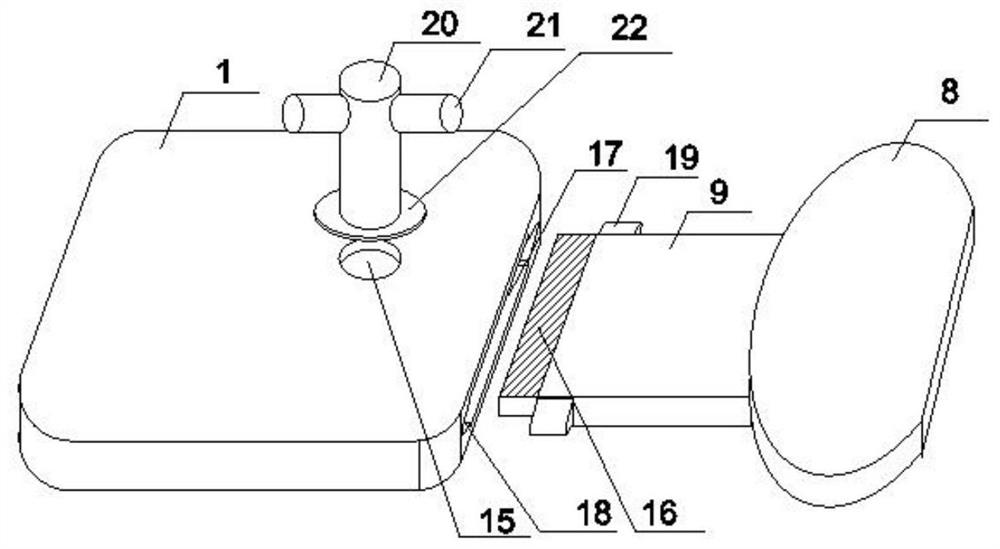

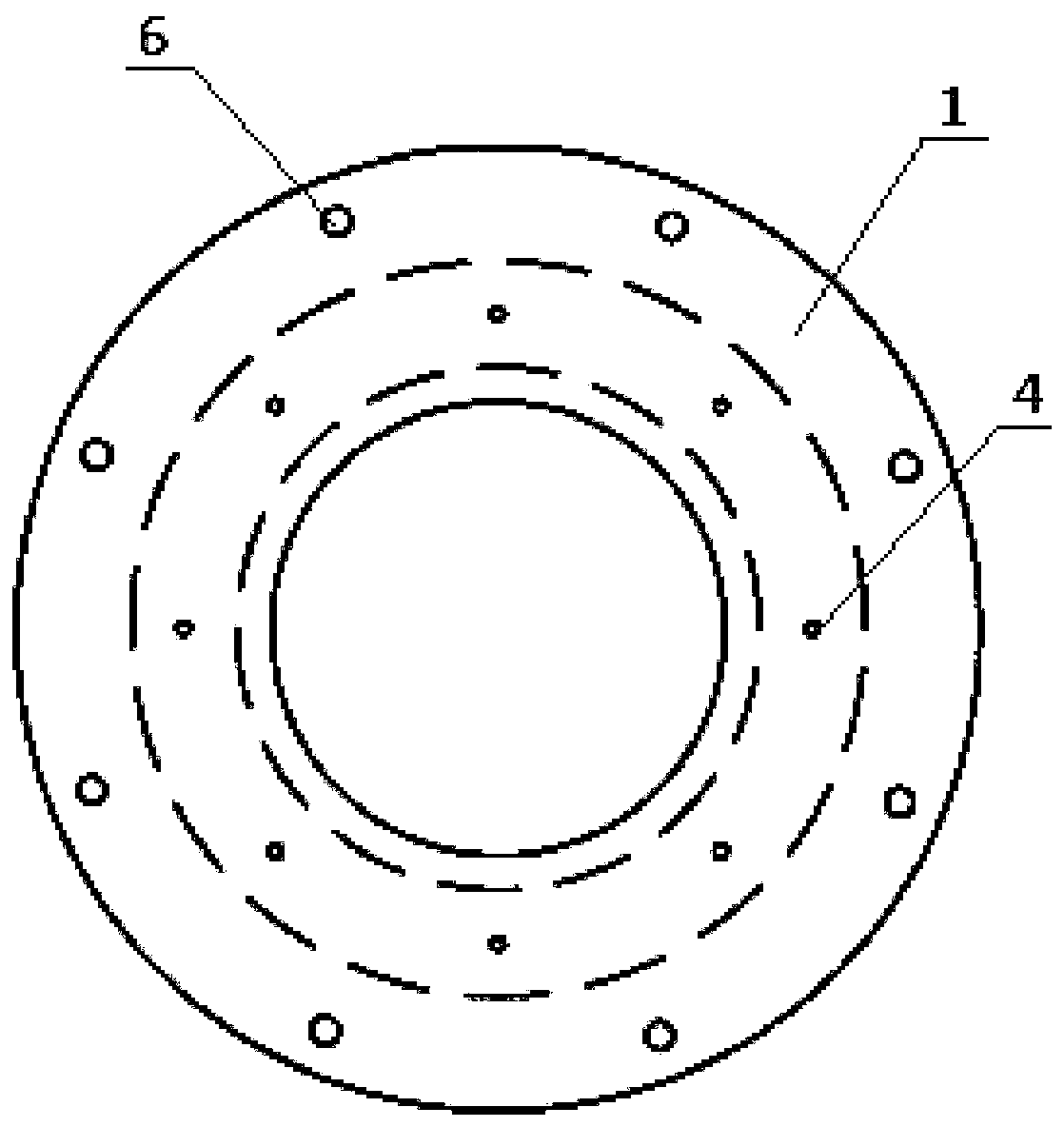

Offshore wind turbine barrel-in-barrel foundation

InactiveCN105155573AFoundation depth reductionReduce the difficulty of correctionFoundation engineeringReinforced concreteEngineering

The invention discloses an offshore wind turbine barrel-in-barrel foundation. The offshore wind turbine barrel-in-barrel foundation comprises an inner steel barrel (1), an outer steel reinforced concrete barrel (2), an outer barrel bottom plate (3), reinforcing filled soil (4), inter-barrel damping materials (5) and pressing stones (6). The outer steel reinforced concrete barrel (2) is located on the periphery of the inner steel barrel (1). The outer barrel bottom plate (3) is supported on the lower portion of the outer steel reinforced concrete barrel (2). The reinforcing filled soil (4) and the inter-barrel damping materials (5) are located between the inner steel barrel (1) and the outer steel reinforced concrete barrel (2). The pressing stones (6) are located on the outer barrel bottom plate (3). A steel barrel flange (7) is connected to the upper portion of the inner steel barrel (1). A construction and maintenance platform (8) for construction installation and routine maintenance is installed on the top of the outer steel reinforced concrete barrel (2). The offshore wind turbine barrel-in-barrel foundation is reasonable in structural design and convenient to install and construct; the embedded depth of the foundation can be reduced greatly, deviation rectifying difficulty is lowered, and manufacturing cost is low; cost of a large floating crane can be saved, and maintenance is convenient.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD +1

Double-sound-track ultrasonic heat meter

InactiveCN103616095AReduce the difficulty of correctionMeet the precision requirementsCalorimeterObservational errorWater velocity

The invention discloses a double-sound-track ultrasonic heat meter. The ultrasonic heat meter comprises a tube body, four installing ports are formed in the wall of the tube body, an ultrasonic transducer is installed on each installing port, the four ultrasonic transducers are arranged opposite in pairs, each two opposite ultrasonic transducers form a sound track, the two sound tracks with axes mutually parallel and lengths equal are symmetrically distributed on the two sides of the axis of the tube body, and the distances between the axes of the two sound tracks and the axis of the tube body are equal. In this way, the ultrasonic transducers are basically arranged in the positions where a flow field velocity is very close to mean flow velocity of the water velocity on the cross section in a tube, correction difficulty of measurement errors by a computer matched with a flowmeter can be greatly reduced, and therefore a final measurement result is accurate.

Owner:RUINA INTELLIGENT EQUIP CO LTD

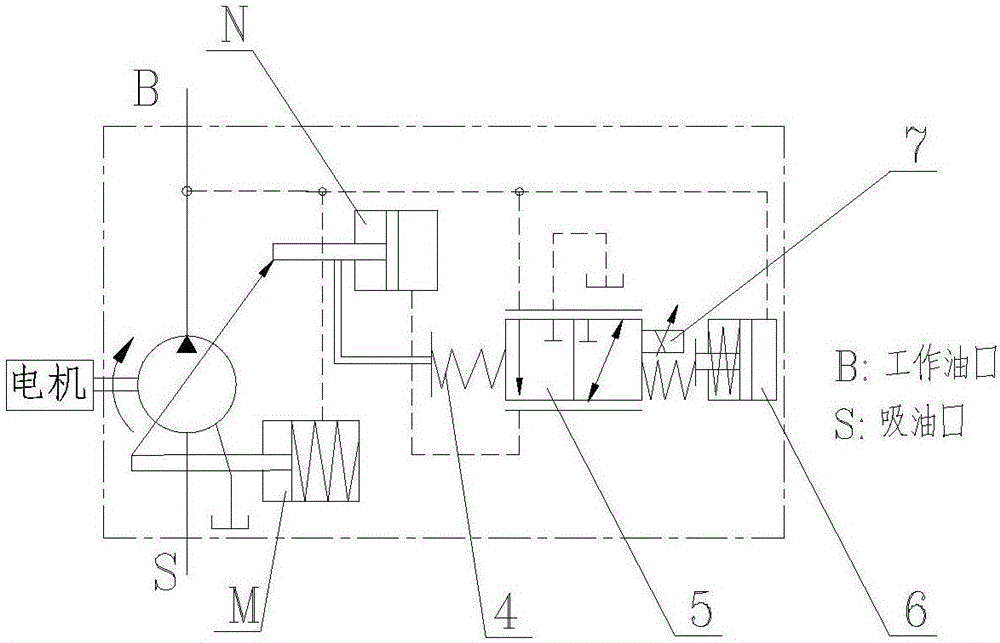

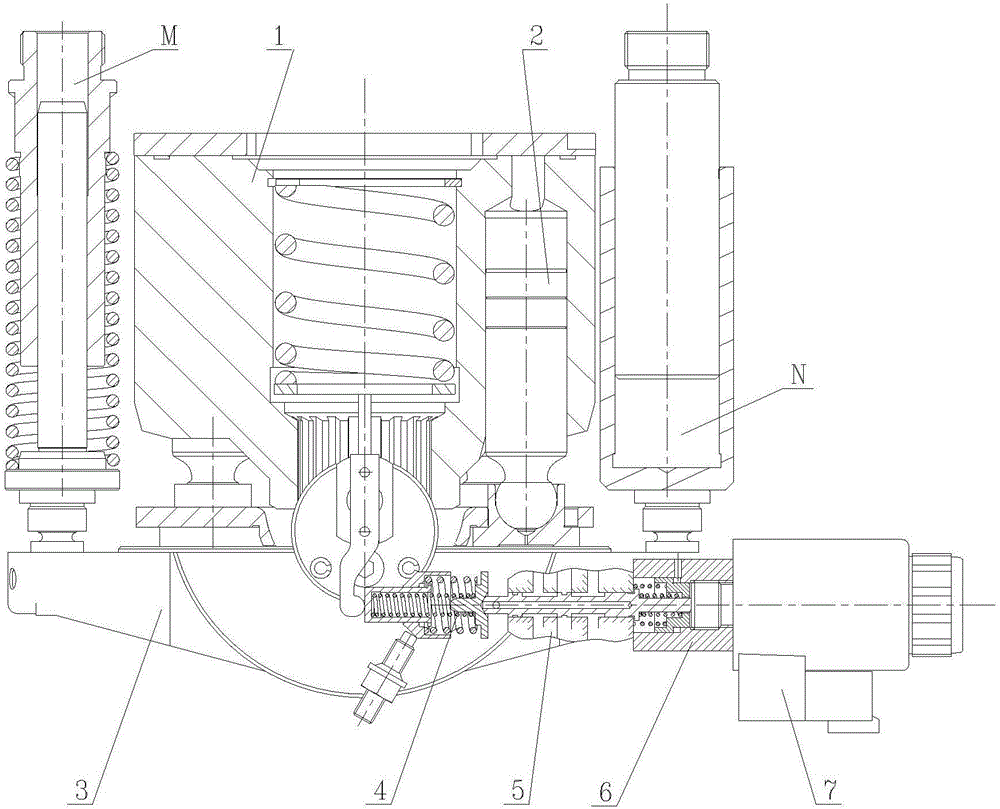

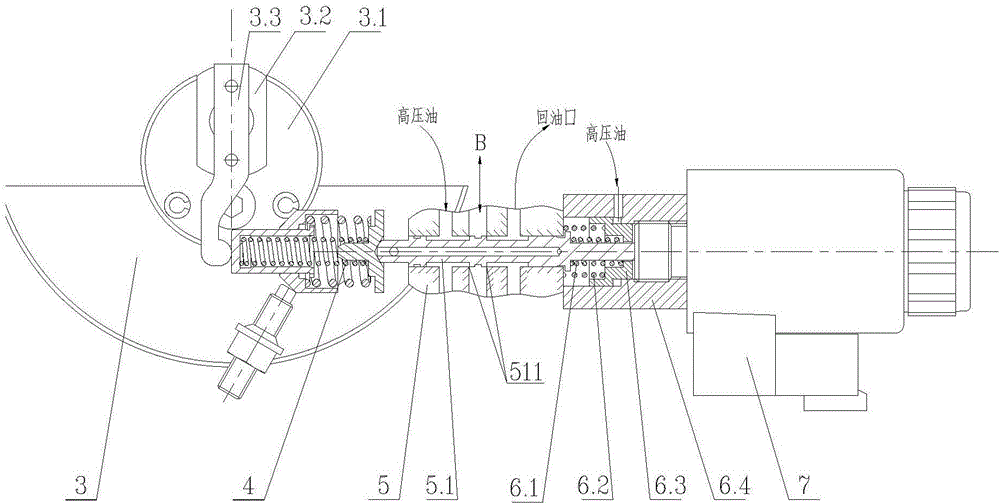

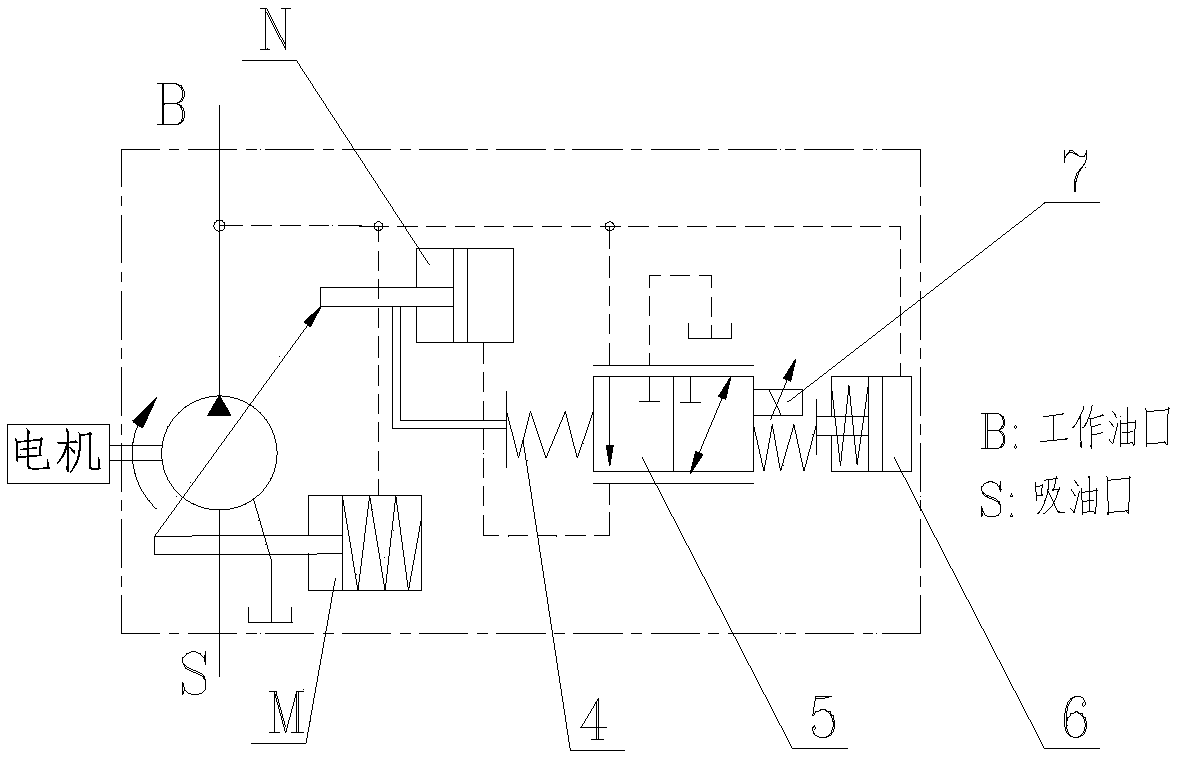

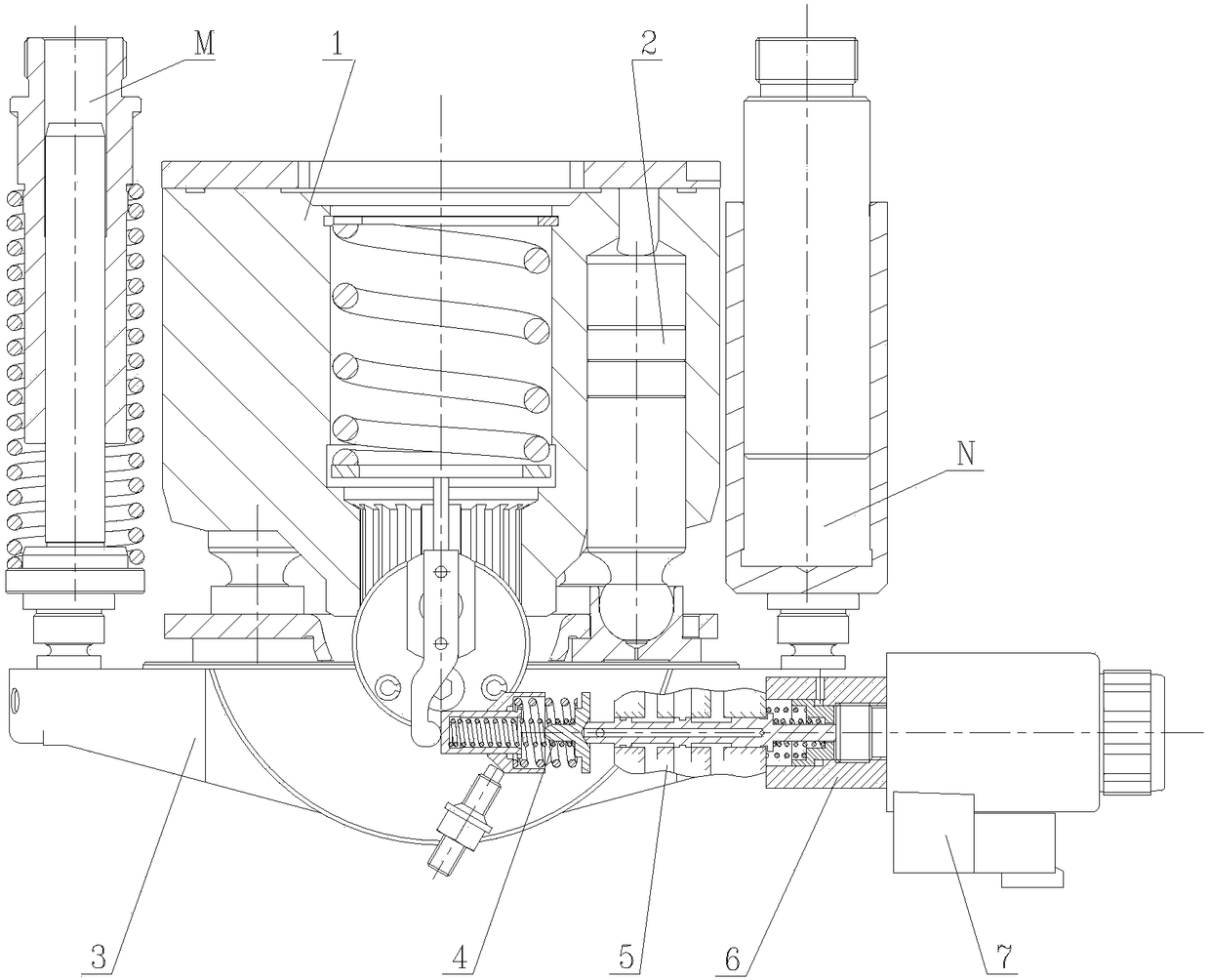

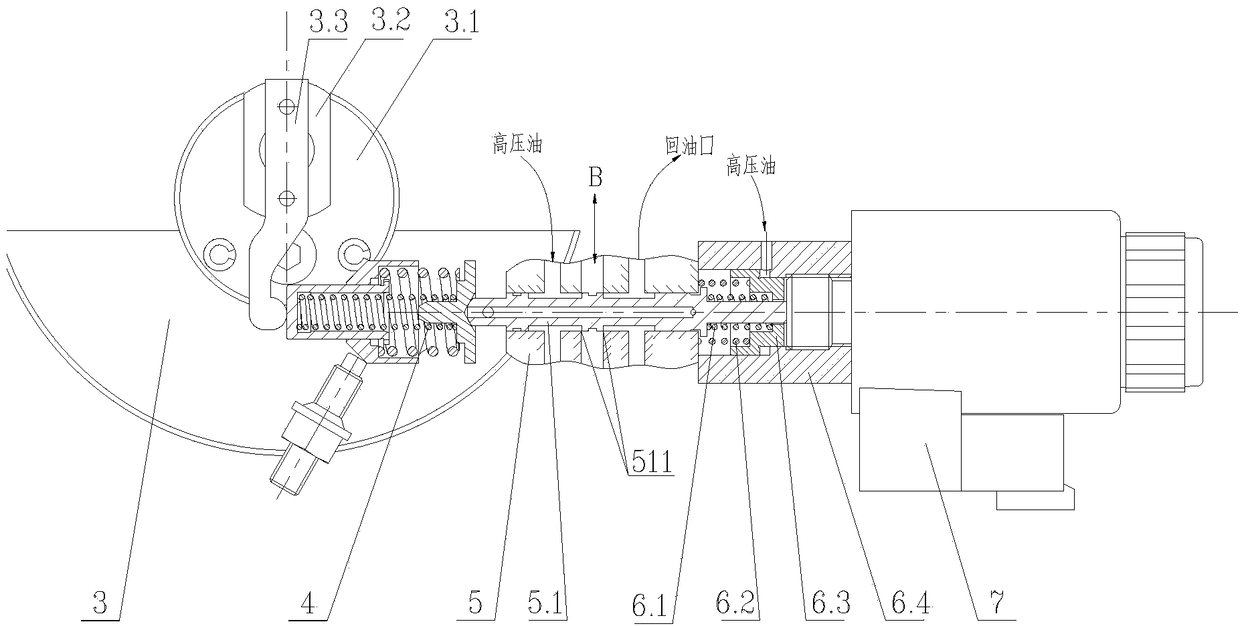

Flow compensation method and flow compensation device for proportional control pump

ActiveCN106438527AImproved output scaling characteristicsReduce the difficulty of correctionServomotor componentsServomotorsProportional controlControl theory

The invention discloses a flow compensation method of a proportional control pump. When outlet pressure of the proportional control pump changes, by carrying out pressure compensation on the valve element end of a proportional control valve, compensation acting force generates a tilting tray angle increment value, and a proportional control pump output flow increment value generated by the tilting tray angle increment value compensates for a flow value lost due to the outlet pressure; a flow compensation device comprises an electric proportional control valve and a main pump provided with an oil absorbing opening and a working oil opening, the variable cylinder small end and the variable cylinder large end of the main pump are connected with the electric proportional control valve, and a pressure compensation valve is arranged at the tail end of the electric proportional control valve. By means of compensation, the influence on flow output by the main pump from pressure change is avoided, the load speed can be controlled stably, and accuracy is ensured.

Owner:AVIC LIYUAN HYDRAULIC

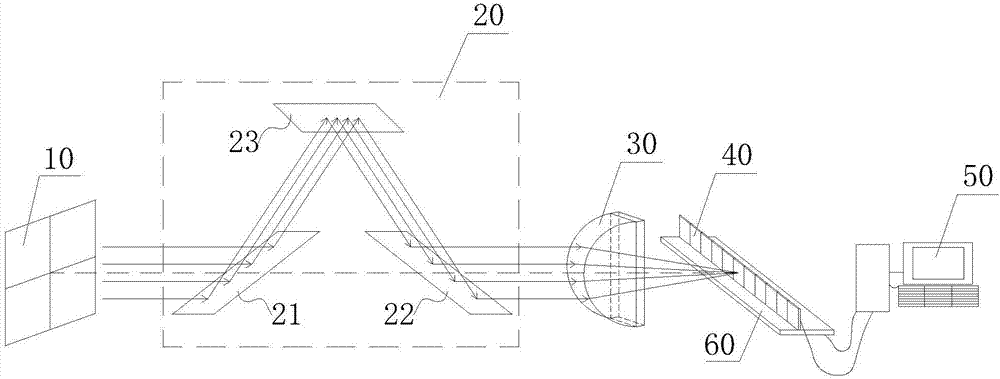

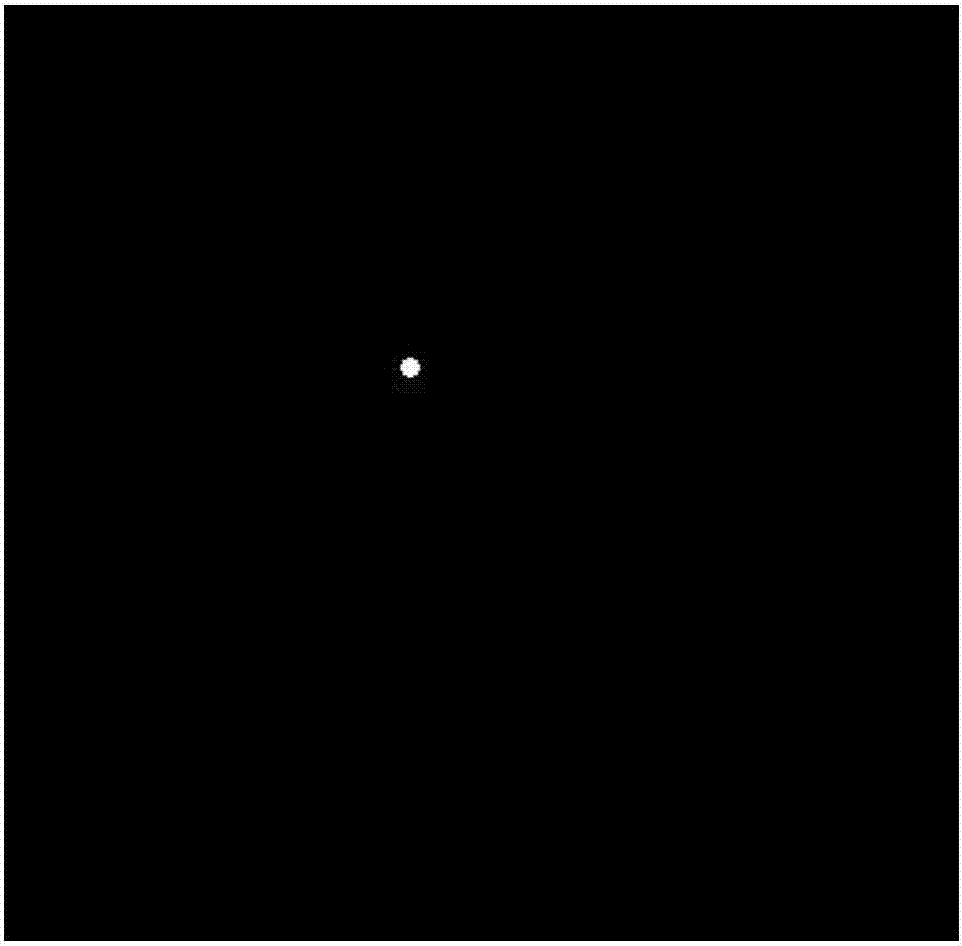

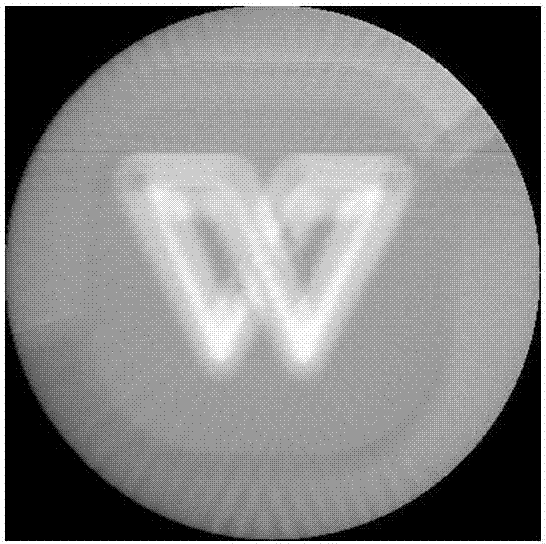

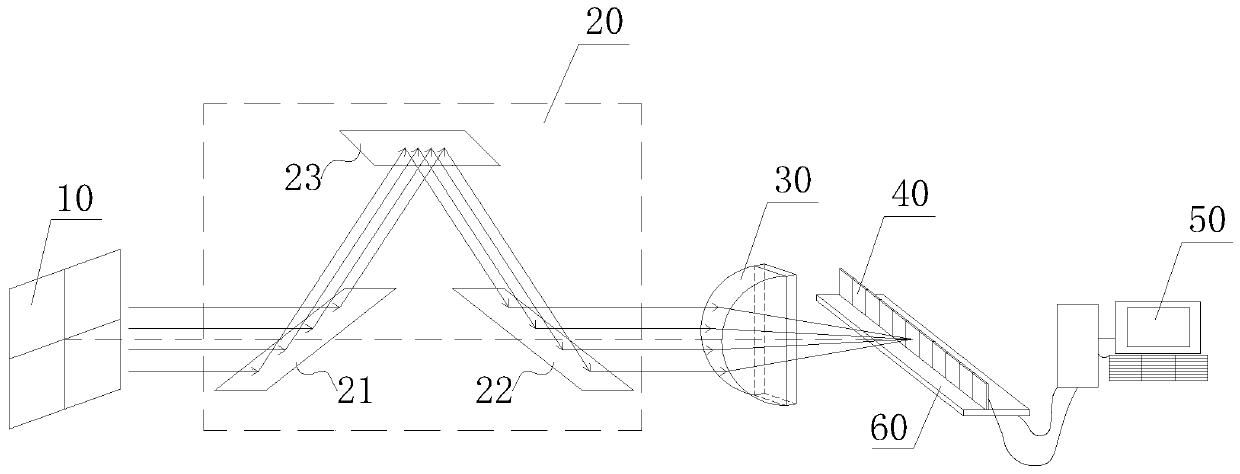

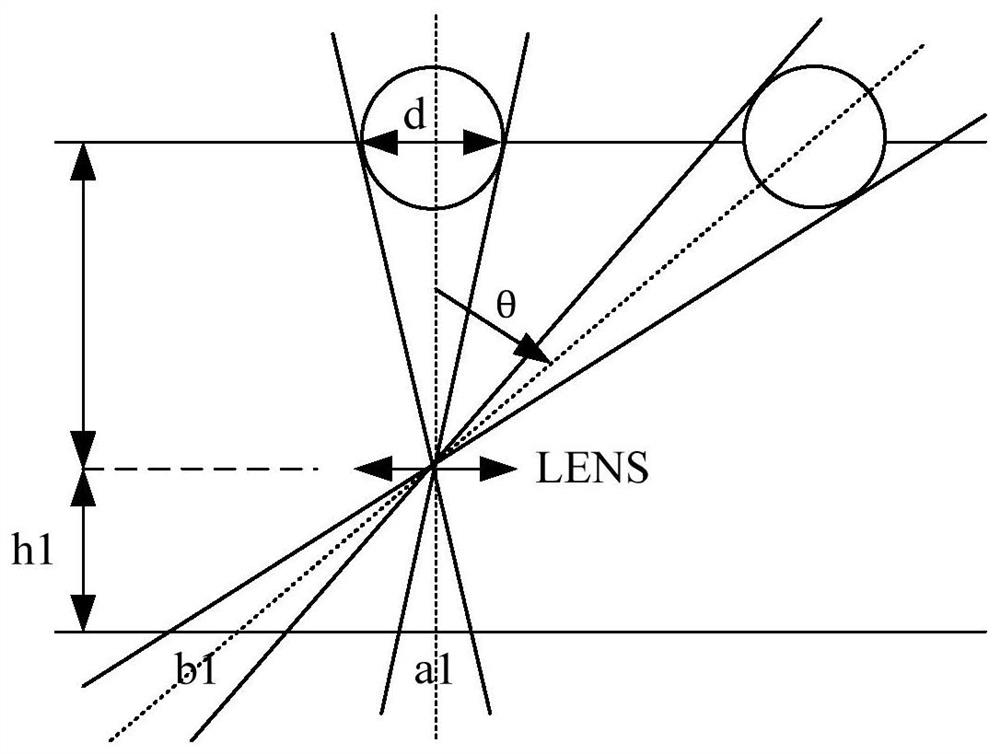

Rotating type optical tomography system and method based on linear array detector

ActiveCN107091810AReduce the difficulty of correctionImaging RealizationMaterial analysis by optical meansConical scanningOptical tomography

The invention belongs to the field of optical imaging, and particularly relates to a rotating type optical tomography system based on a linear array detector. The system comprises a reflector set, a cylindrical mirror and a linear array detector which are sequentially arranged in the front-face direction of the to-be-tested face of a to-be-tested object. The linear array detector is connected with a computer. The invention correspondingly provides a method utilizing the rotating type optical tomography system for imaging. By means of the rotating type optical tomography technology based on the linear array detector, meanwhile, the rotating type optical system is adopted, the single rotating device is arranged, the structure is simple, the rotating eccentric effect and the optical system off-focus effect during conical scanning are overcome, the algorithm correction difficulty during later period algorithm reconstruction is lowered, and the system stability is improved.

Owner:HEFEI UNIV OF TECH

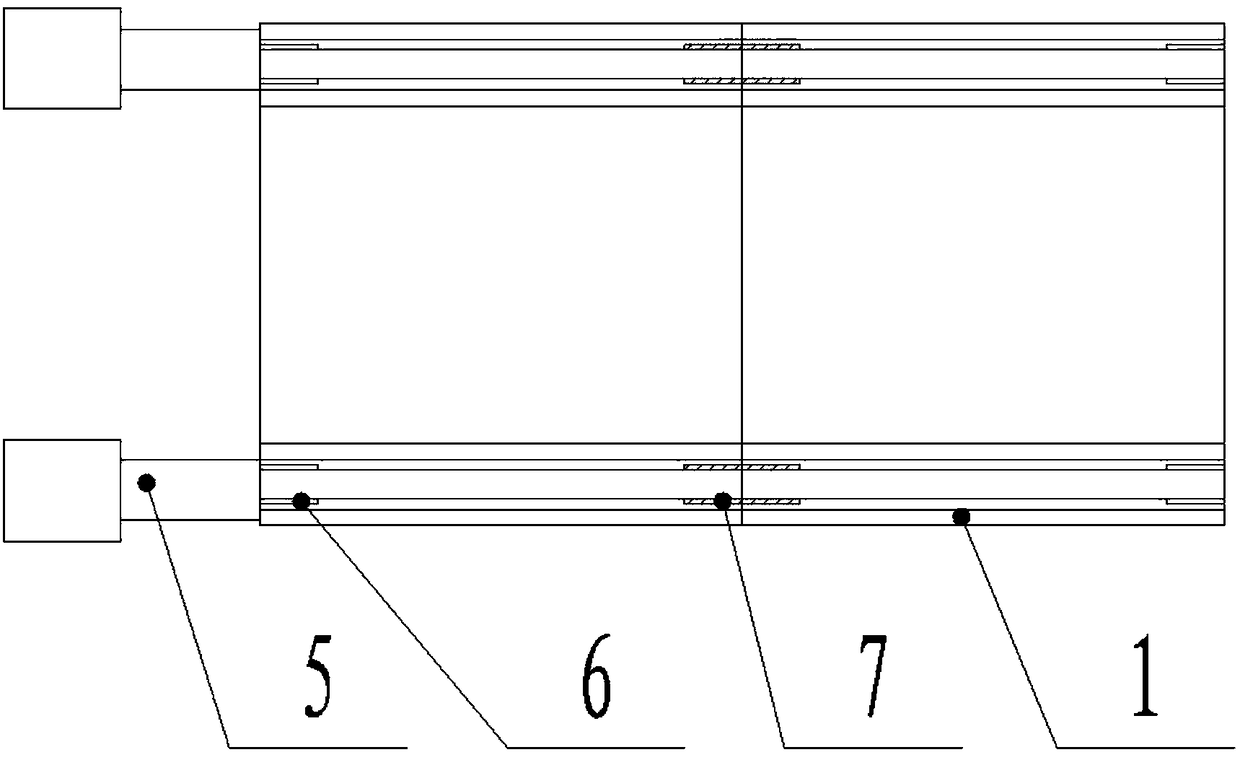

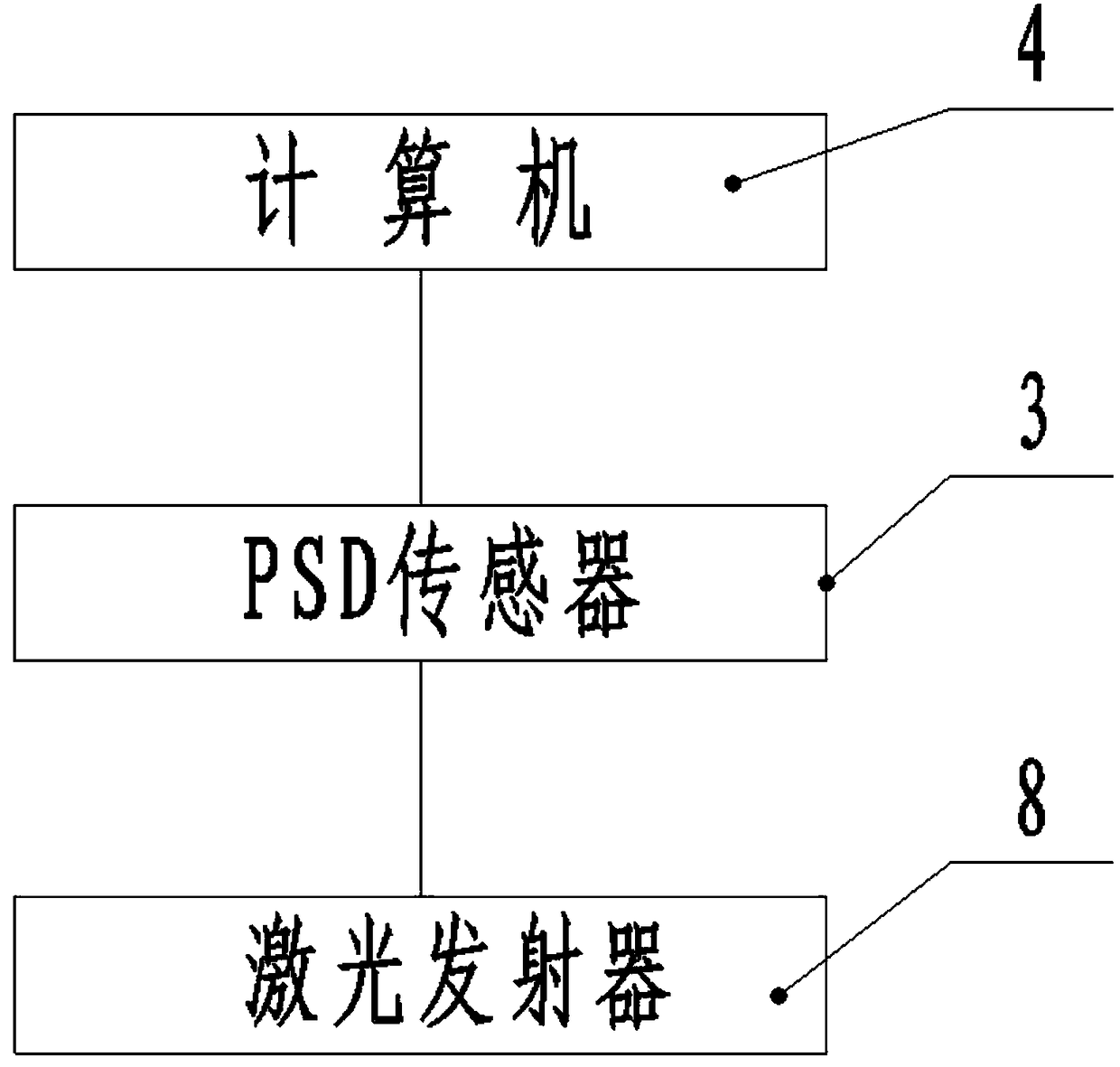

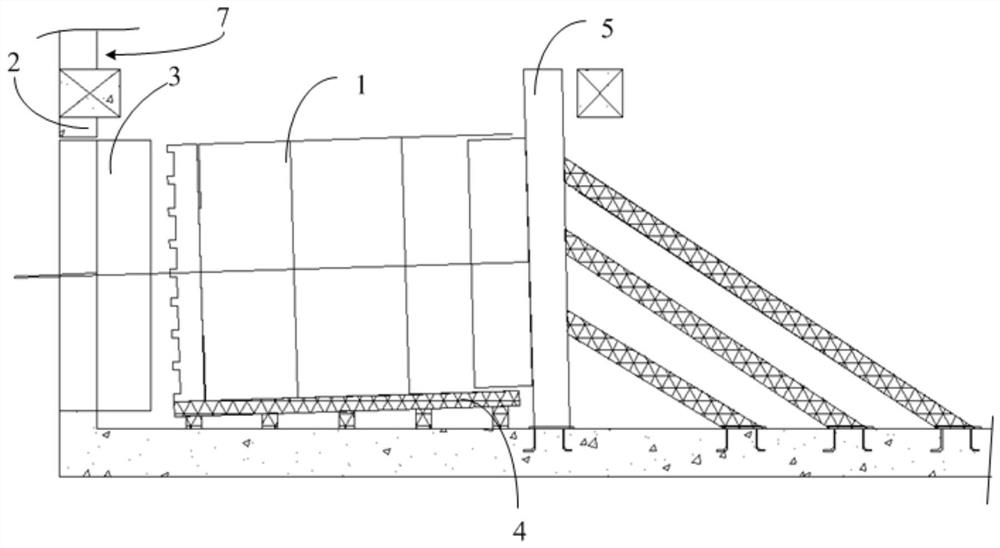

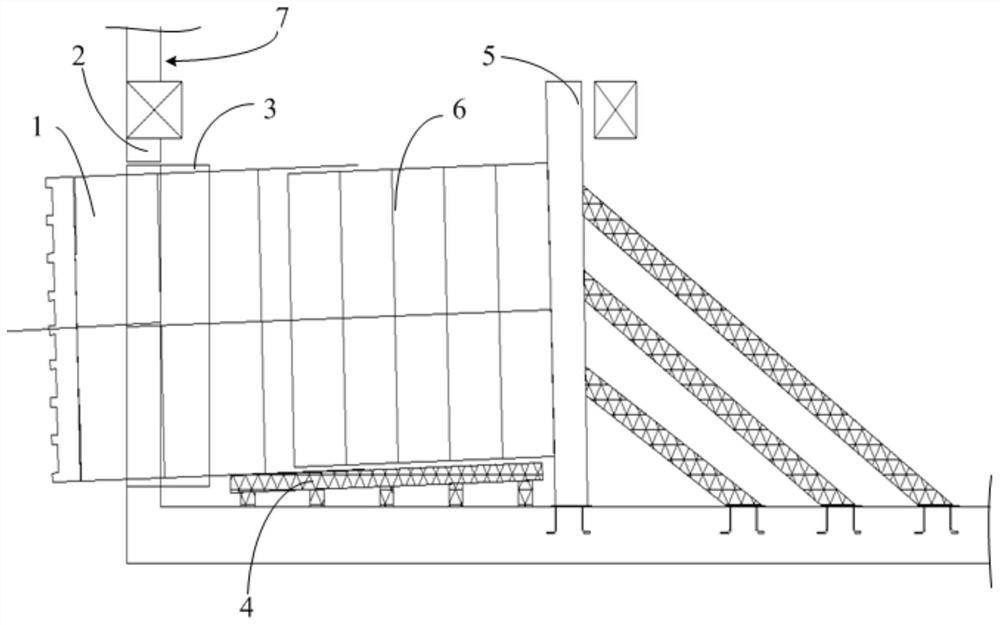

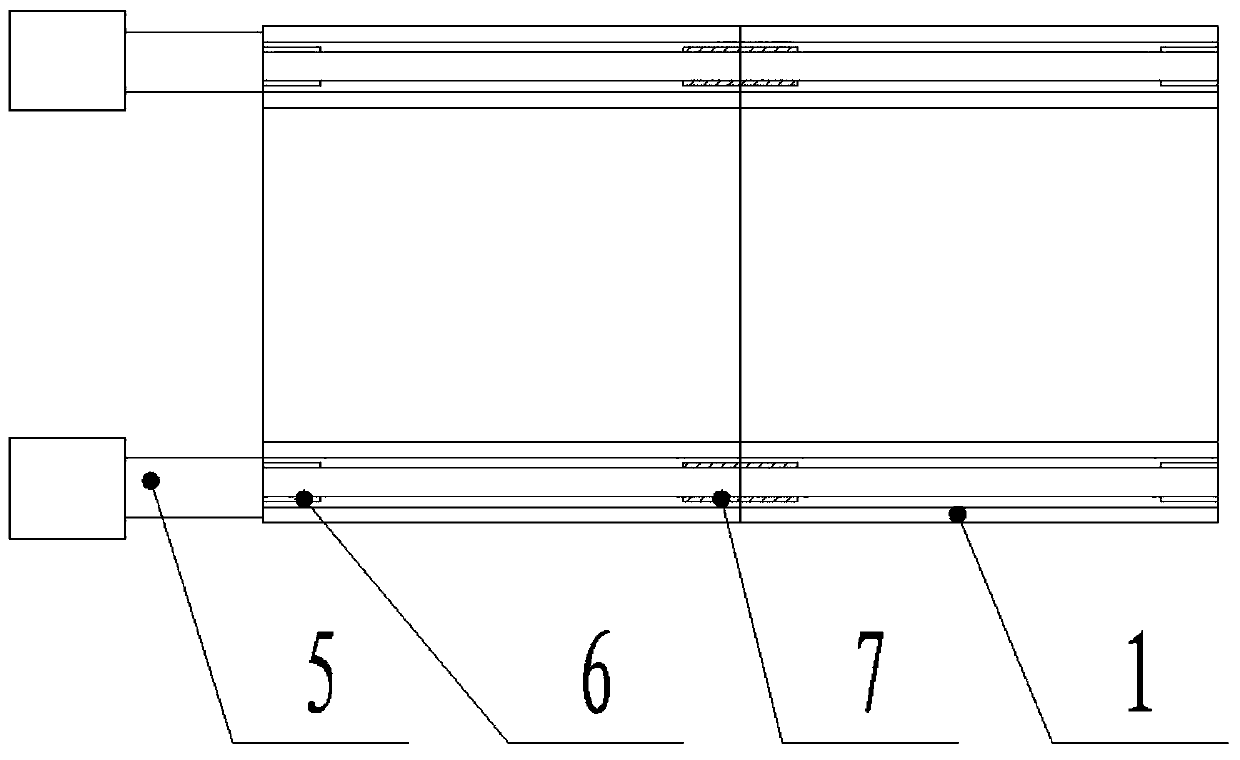

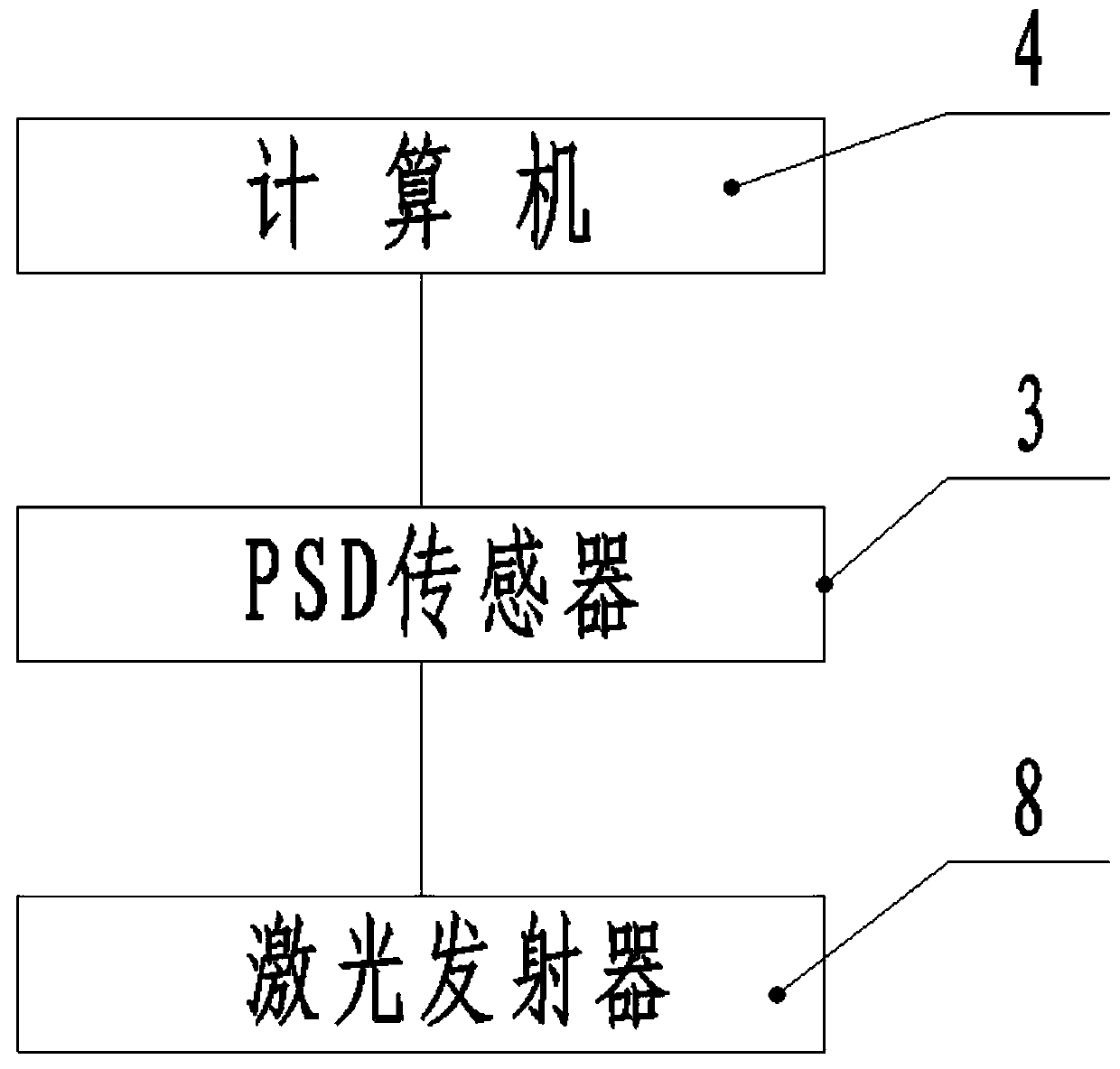

Manual jacking pipe control method and control system

ActiveCN108458164AImprove securityReduce difficultyPipe laying and repairUsing optical meansLaser transmitterStructural engineering

The invention discloses a manual l jacking pipe control method and control system. Two laser detection pipes are symmetrically arranged in the wall of each cement concrete pipe, a PSD sensor is arranged at the position, on the front end of a jacking pipe, in each laser detection pipe of each cement concrete pipe, a computer connected with the PSD sensors are arranged outside each cement concrete pipe, and laser emitters are arranged at the position, on the outer end of the jacking pipe, in the laser detection pipes of one cement concrete pipe, laser emitted by the laser emitters is irradiatedon the PSD sensors to form light spots, the PSD sensors collect and record information of light spot position changes, and the computer analyzes collected data, the straightness error of the cement concrete pipes can be evaluated. Through manual adjusting of a jack, the jacking direction of the cement concrete pipes can be adjusted; in the manual jacking pipe construction process, the extension deviation of a pipeline underground can be corrected, the jacking direction is effectively controlled, a deviation correcting control system and a jacking device are integrated, safety is improved, thedifficulty of pipeline deviation correcting in the pipeline jacking process can be effectively reduced, and the comprehensive cost is reduced.

Owner:CHINA MCC5 GROUP CORP

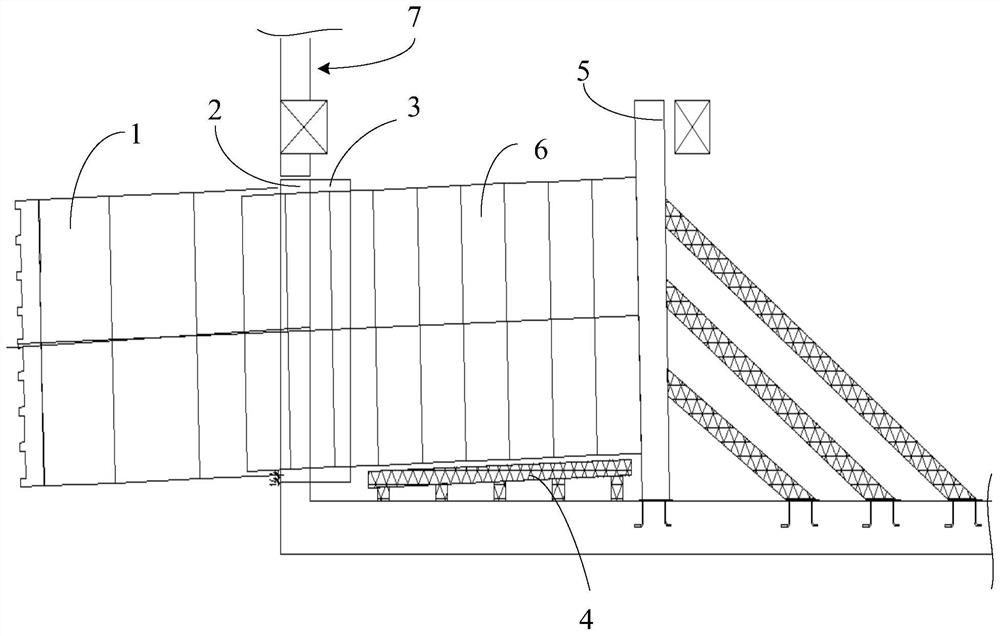

Shield large-gradient launching construction method

ActiveCN112324444AReduce the difficulty of correctionAvoid the problem of adjusting the design lineHydro energy generationTunnelsStructural engineeringShield tunneling

The invention relates to a shield large-gradient launching construction method. The shield large-gradient launching construction method comprises the following steps that a portal steel ring is provided, and the portal steel ring is pre-buried in the side wall of a working well according to the design axis of a shield tunnel; a launching frame is provided, the provided launching frame is providedwith an inclined receiving plate, and the launching frame is annularly arranged above the bottom of the working well corresponding to the portal steel ring; a reaction frame is provided, the side, close to the launching frame and away from the portal steel ring, of the reaction frame is arranged above the bottom of the working well, and the reaction frame is perpendicular to the launching frame; and a shield tunneling machine is provided, the shield tunneling machine is hoisted to the receiving plate, and the shield tunneling machine is moved into the portal steel ring and tunneled into the soil body. When the shield tunneling machine enters the soil body, the center line of the shield tunneling machine can be closer to the inclined design axis, so that the center line of the shield tunneling machine is close to the design axis of a shield tunnel, and the deviation rectifying difficulty of the shield tunneling machine is greatly reduced.

Owner:中建八局轨道交通建设有限公司

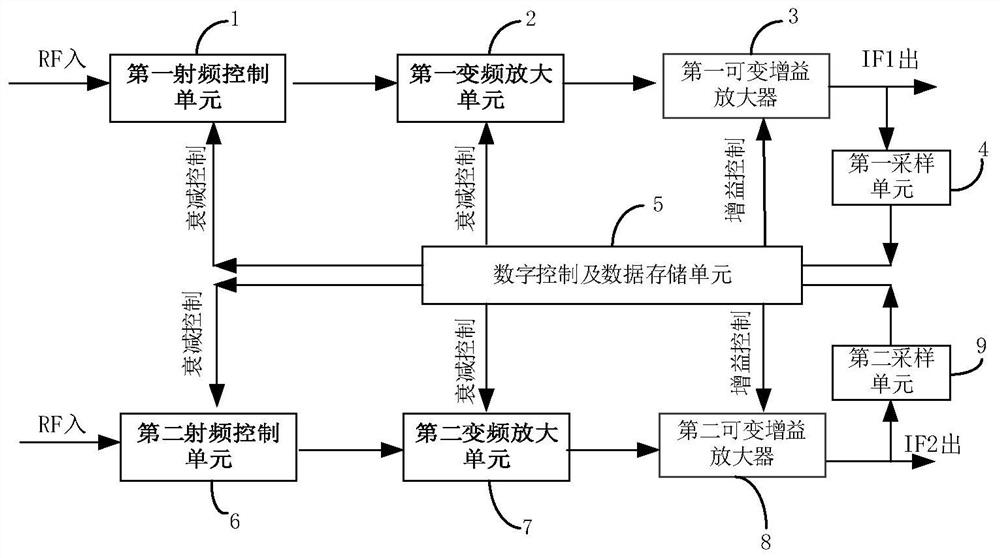

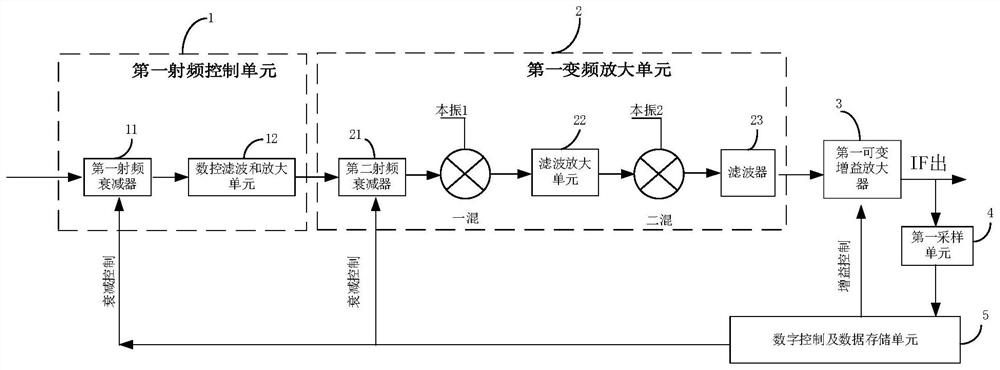

Phase-controllable dual-channel direction finding device and method

PendingCN112731276AReduce the difficulty of correctionImprove direction finding accuracyRadio wave direction/deviation determination systemsHigh level techniquesVariable-gain amplifierControl cell

The invention provides a phase-controllable double-channel direction finding device. The device comprises a first radio frequency control unit, a first variable-frequency amplification unit, a first variable gain amplifier, a first sampling unit, a digital control and data storage unit, a second radio frequency control unit, a second variable-frequency amplification unit, a second variable gain amplifier and a second sampling unit. According to the method for eliminating the channel phase error through the phase-controllable dual-channel direction finding device, the phase change between channels can be corrected in dual-channel direction finding, and extra errors brought to a direction finding system due to the difference of channel responses are eliminated. The invention also provides a phase-controllable dual-channel direction finding method. Compared with the prior art, the phase-controllable dual-channel direction finding device and the phase-controllable dual-channel direction finding method are high in direction finding accuracy.

Owner:SHAANXI FENGHUO ELECTRONICS

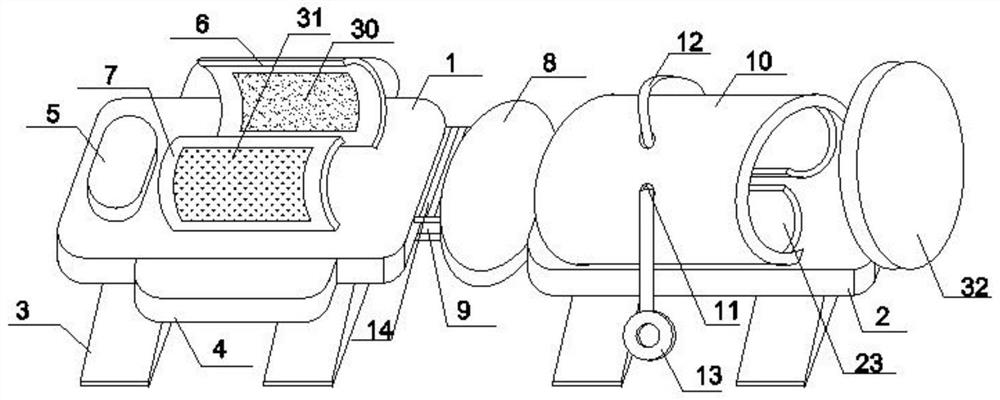

A gynecological nursing device with pelvic floor correction function

ActiveCN112773587BWith pelvic floor correction functionReduce the difficulty of correctionMedical sciencePelvic diaphragm muscleTraction cord

The invention discloses a gynecological nursing device with a pelvic floor correction function, comprising a trunk board and a lower limb board, wherein a bracket is connected to the bottom of the trunk board and the lower limb board, and the trunk board and the lower limb board can be connected between them. Hip pads are connected to move, armrests are respectively connected to the left and right sides of the trunk board, a headrest is connected to the surface of the trunk board, a protective cover is connected to the surface of the lower limb board, and a lower limb support is elastically connected to the inside of the protective cover. Two traction rope passage grooves are arranged on the surface of the protective cover, a traction rope is connected to the lower limb support, and a pull ring is connected to the bottom of the traction rope. The invention adds a lower limb support that can be controlled by a traction rope, which can assist the user to roll over the body and reduce the difficulty of correction.

Owner:GENERAL HOSPITAL OF THE NORTHERN WAR ZONE OF THE CHINESE PEOPLES LIBERATION ARMY

Flow Compensation Method and Flow Compensation Device of Proportional Control Pump

ActiveCN106438527BImproved output scaling characteristicsReduce the difficulty of correctionServomotor componentsServomotorsProportional controlControl theory

The invention discloses a flow compensation method of a proportional control pump. When outlet pressure of the proportional control pump changes, by carrying out pressure compensation on the valve element end of a proportional control valve, compensation acting force generates a tilting tray angle increment value, and a proportional control pump output flow increment value generated by the tilting tray angle increment value compensates for a flow value lost due to the outlet pressure; a flow compensation device comprises an electric proportional control valve and a main pump provided with an oil absorbing opening and a working oil opening, the variable cylinder small end and the variable cylinder large end of the main pump are connected with the electric proportional control valve, and a pressure compensation valve is arranged at the tail end of the electric proportional control valve. By means of compensation, the influence on flow output by the main pump from pressure change is avoided, the load speed can be controlled stably, and accuracy is ensured.

Owner:AVIC LIYUAN HYDRAULIC

A barcode tilt correction method based on multi-task target detection

ActiveCN110046530BReduce the difficulty of correctionImprove accuracySensing by electromagnetic radiationFeature extractionBarcode

The invention discloses a barcode tilt correction method based on multi-task target detection, comprising: constructing a single-stage target detector, the single-stage target detector includes a sequentially connected feature extraction basic network and a detection head network; Inputting the feature extraction basic network to extract a feature map; inputting the feature map into the detection head network, performing classification and position regression on the feature map, and obtaining a correction result. The present invention firstly classifies the degree of inclination of the barcode, and then performs angle regression, which effectively reduces the difficulty of barcode correction, and forms a multi-task target detection model by merging with a single-stage target detector, thereby improving the efficiency of detection and correction in parallel, and improving the translation efficiency. Code accuracy and speed play a better role in promoting.

Owner:WAYZIM TECH CO LTD

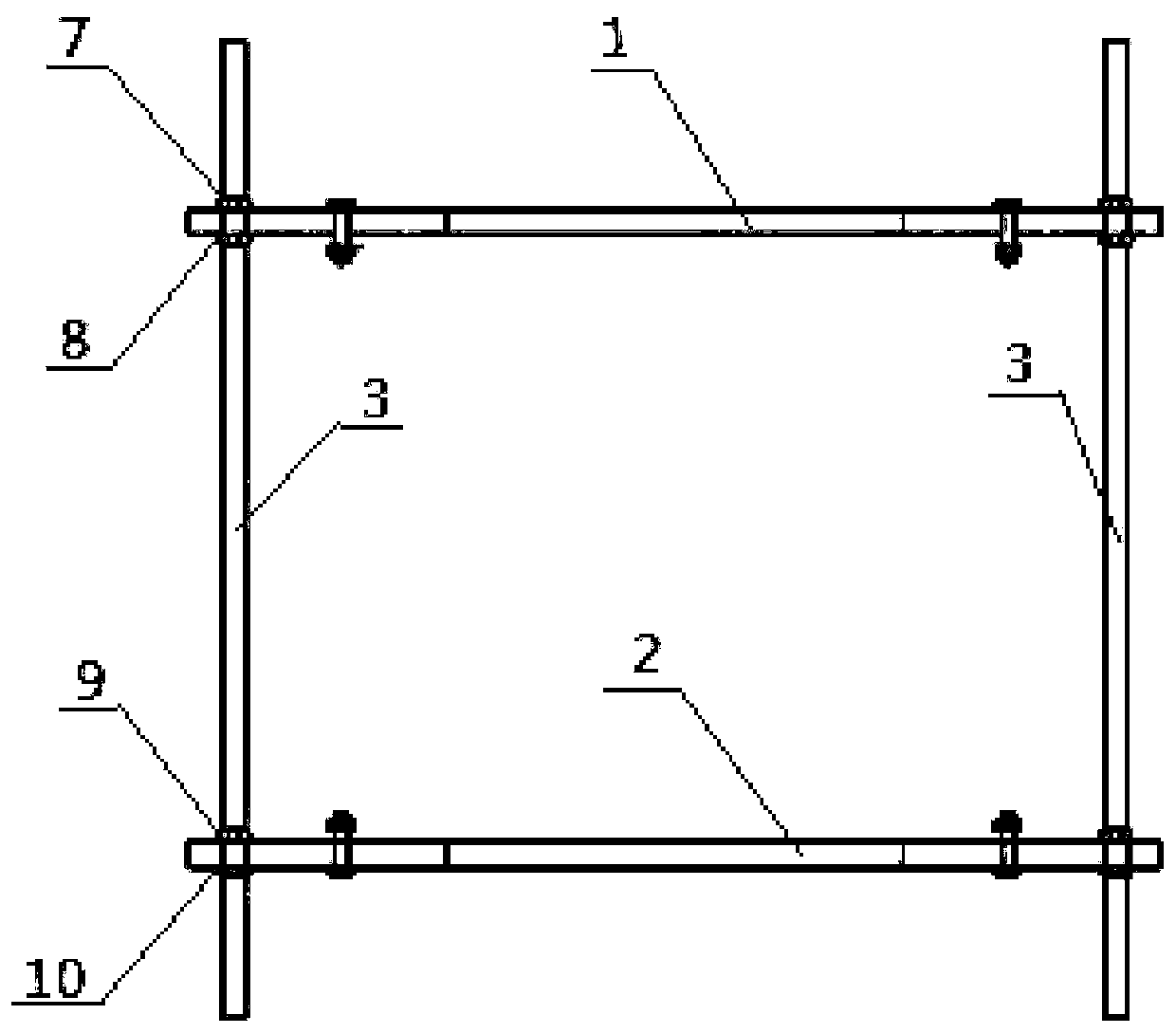

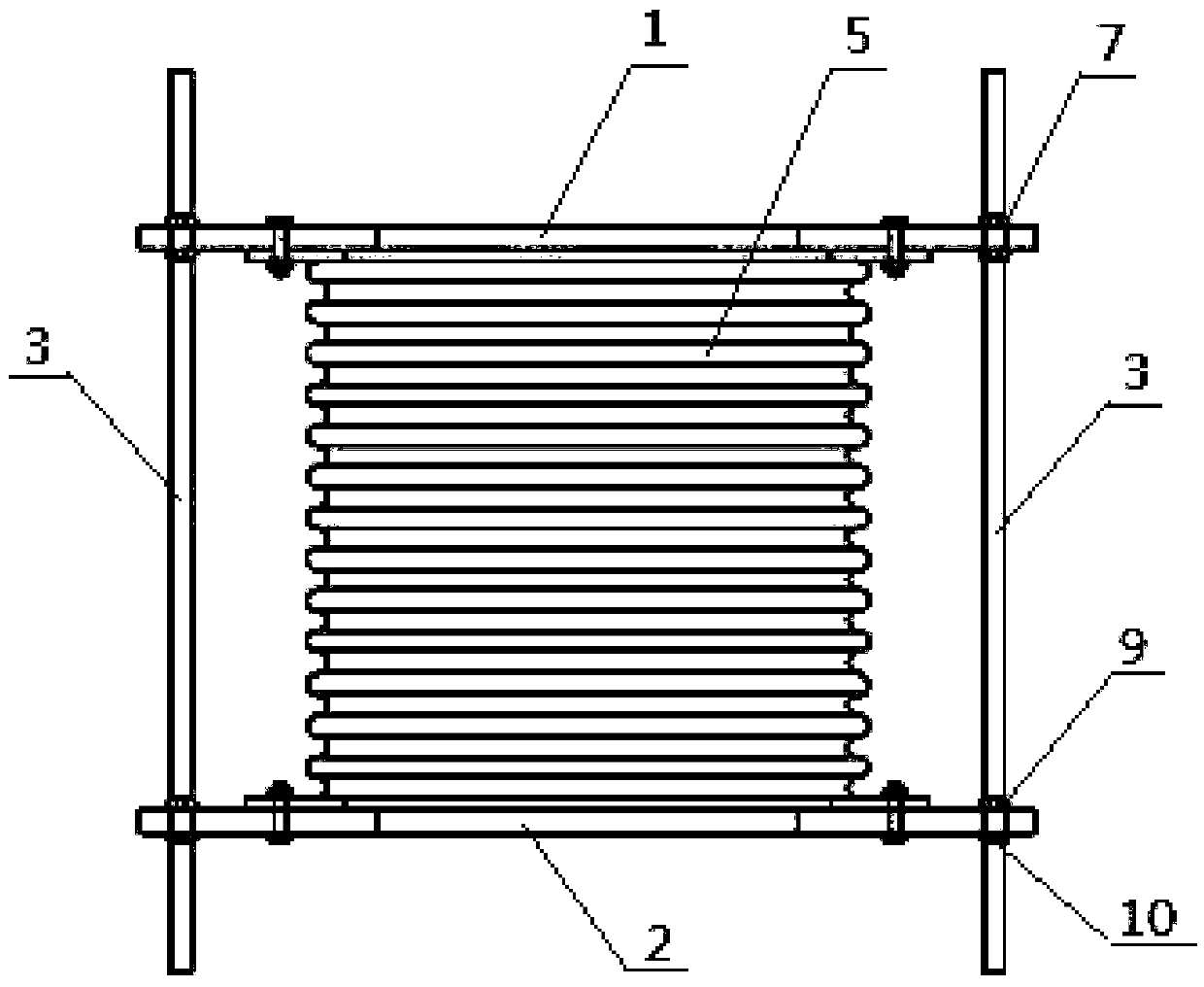

Device and method for correcting deformed expansion joint

ActiveCN109551166AAvoid scratchesConducive to shape deformationVessel designingEngineeringExpansion joint

The invention discloses a device and a method for correcting a deformed expansion joint, and belongs to the technical field of ship construction. The device comprises a first adjustment plate, a second adjustment plate and more than two adjustment screw rods, wherein the first adjustment plate is used for being fixed to an upper flange disc of the expansion joint to be corrected; the second adjustment plate is used for being fixed to a lower flange disc of the expansion joint to be corrected; the two ends of each adjustment screw rod are connected with the first adjustment plate and the secondadjustment plate separately; the distance between the first adjustment plate and the second adjustment plate can be adjusted by rotating nuts on the adjustment screw rods, and the expansion joint tobe corrected is compressed or stretched, so that the expansion joint to be corrected is corrected. During the correction, a protective cable is embedded into a deformed thread, so that the uniformityof the gap of the thread after the correction can be effectively ensured; and during the correction, the deformed thread is heated, so that the deformation of the expansion joint to be corrected is promoted, and the correction difficulty of the expansion joint to be corrected is lowered. The correction method is high in operability, and is an indispensable emergency handling means.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Gynecological nursing device with pelvic floor correction function

ActiveCN112773587AReduce the difficulty of correctionPrevent rotationMedical sciencePelvic diaphragm muscleTraction cord

The invention discloses a gynecological nursing device with a pelvic floor correction function. The device comprises a trunk plate and a lower limb plate, wherein supports are connected to the bottom of the trunk plate and the bottom of the lower limb plate; a hip pad is movably connected between the trunk plate and the lower limb plate; armrests are connected to the left side and the right side of the trunk plate; a headrest is connected to the upper surface of the trunk plate; a protective cover is connected to the surface of the lower limb plate; a lower limb support is elastically connected inside the protective cover; two traction rope through grooves are formed in the surface of the protective cover; a traction rope is connected to the lower limb support; and a pull ring is connected to the bottom of the traction rope. The lower limb support which can be controlled by the traction rope is additionally arranged, so that the body of a user can be assisted to turn on one side, and the correction difficulty is reduced.

Owner:GENERAL HOSPITAL OF THE NORTHERN WAR ZONE OF THE CHINESE PEOPLES LIBERATION ARMY

A Deviation Correction Method for Immersed Tube Tunnel

ActiveCN103912017BReduce the difficulty of correctionSimplify the construction processArtificial islandsUnderwater structuresEngineeringImmersed tube

The invention provides a rectification method for an immersed tube tunnel. The rectification method comprises a step of mounting a jack group in a joint chamber, a step of controlling the jack group to jack up a tube section to be adjusted until completion, a step of backfilling at the two sides of the immersed tube, a step of removing the jacking force of the jack group, and a step of detaching the jack group. Due to the adopted steps, the jack group is mounted in the jointed chamber to perform fine adjustment rectification on the immersed tube in the chamber, and therefore, the rectification difficulty of the immersed tube under water can be reduced, the construction cost can be reduced and the rectification precision can be improved; air can be charged into the jointed chamber so that the total pressure in the joint chamber is basically equal to the sum of water pressure outside the tube section to be adjusted and the frictional force of a foundation bed, and therefore, the tube section to be adjusted is located in a dynamic-static critical state; rectification can be realized by just applying relatively low jacking force to the immersed tube by using the jack group of a relatively small size, and therefore, the size of the jack group is effectively reduced and then the jack group can be matched with the relatively small space of the joint chamber.

Owner:CCCC FIRST HARBOR ENG +1

Imaging Method of Rotary Optical Tomography System Based on Linear Array Detector

ActiveCN107091810BReduce the difficulty of correctionImaging RealizationMaterial analysis by optical meansConical scanningOptical tomography

The invention belongs to the field of optical imaging, and particularly relates to a rotating type optical tomography system based on a linear array detector. The system comprises a reflector set, a cylindrical mirror and a linear array detector which are sequentially arranged in the front-face direction of the to-be-tested face of a to-be-tested object. The linear array detector is connected with a computer. The invention correspondingly provides a method utilizing the rotating type optical tomography system for imaging. By means of the rotating type optical tomography technology based on the linear array detector, meanwhile, the rotating type optical system is adopted, the single rotating device is arranged, the structure is simple, the rotating eccentric effect and the optical system off-focus effect during conical scanning are overcome, the algorithm correction difficulty during later period algorithm reconstruction is lowered, and the system stability is improved.

Owner:HEFEI UNIV OF TECH

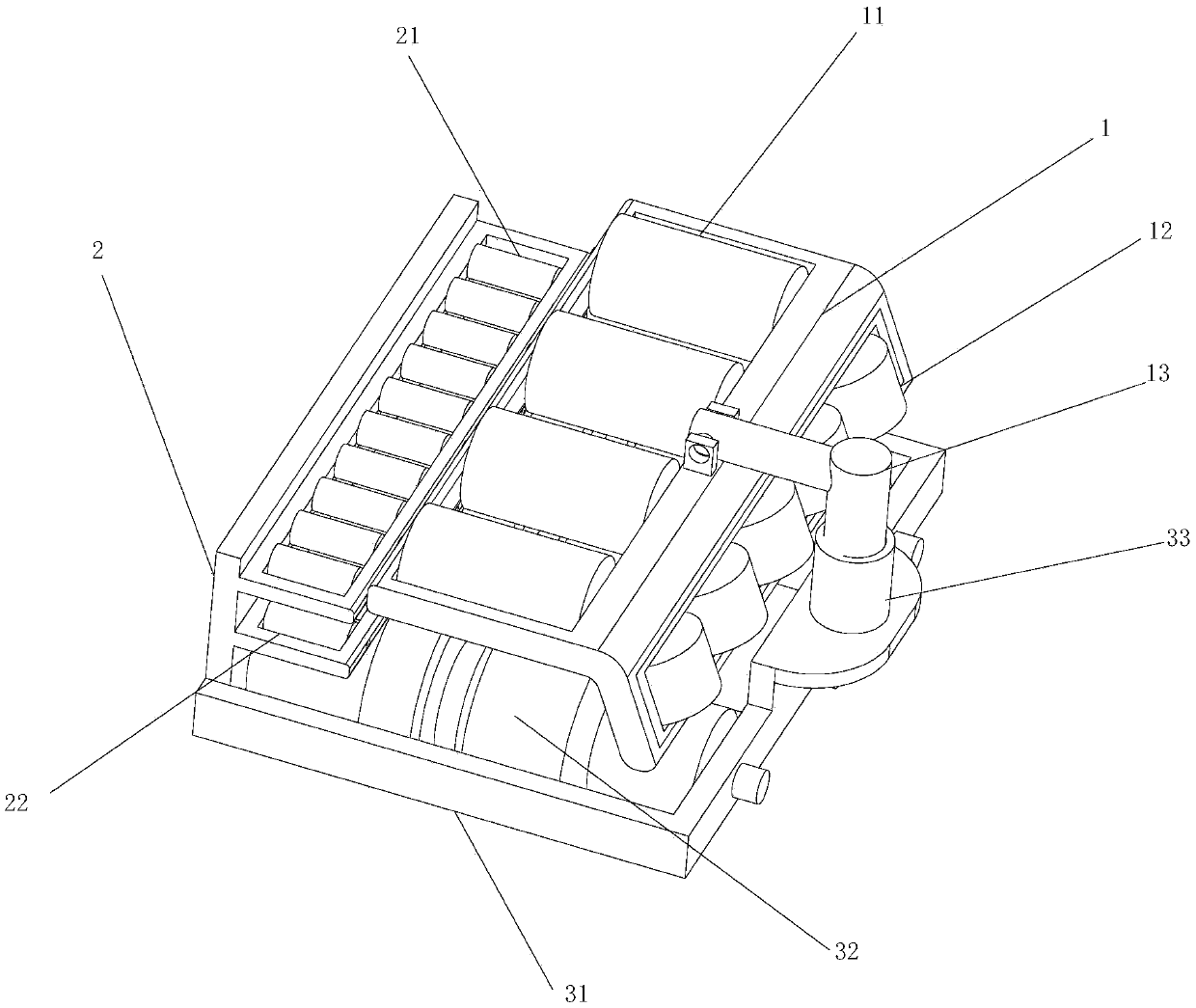

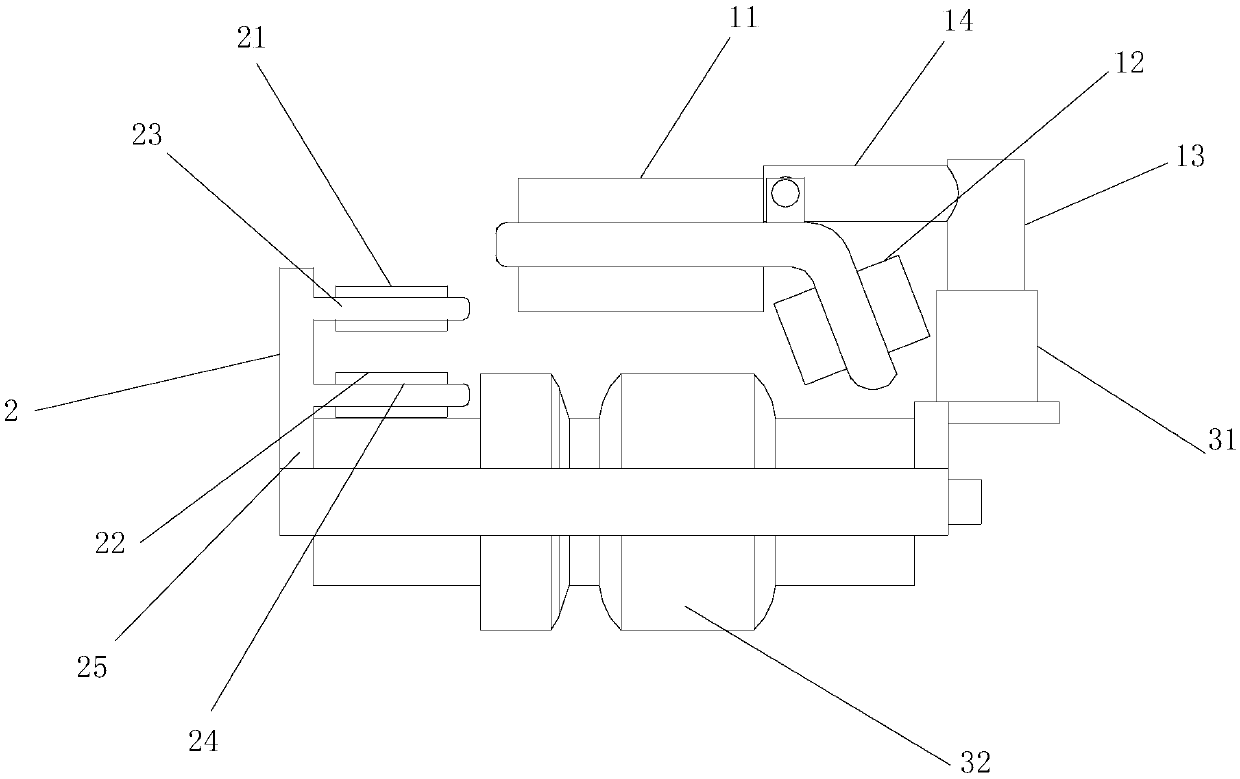

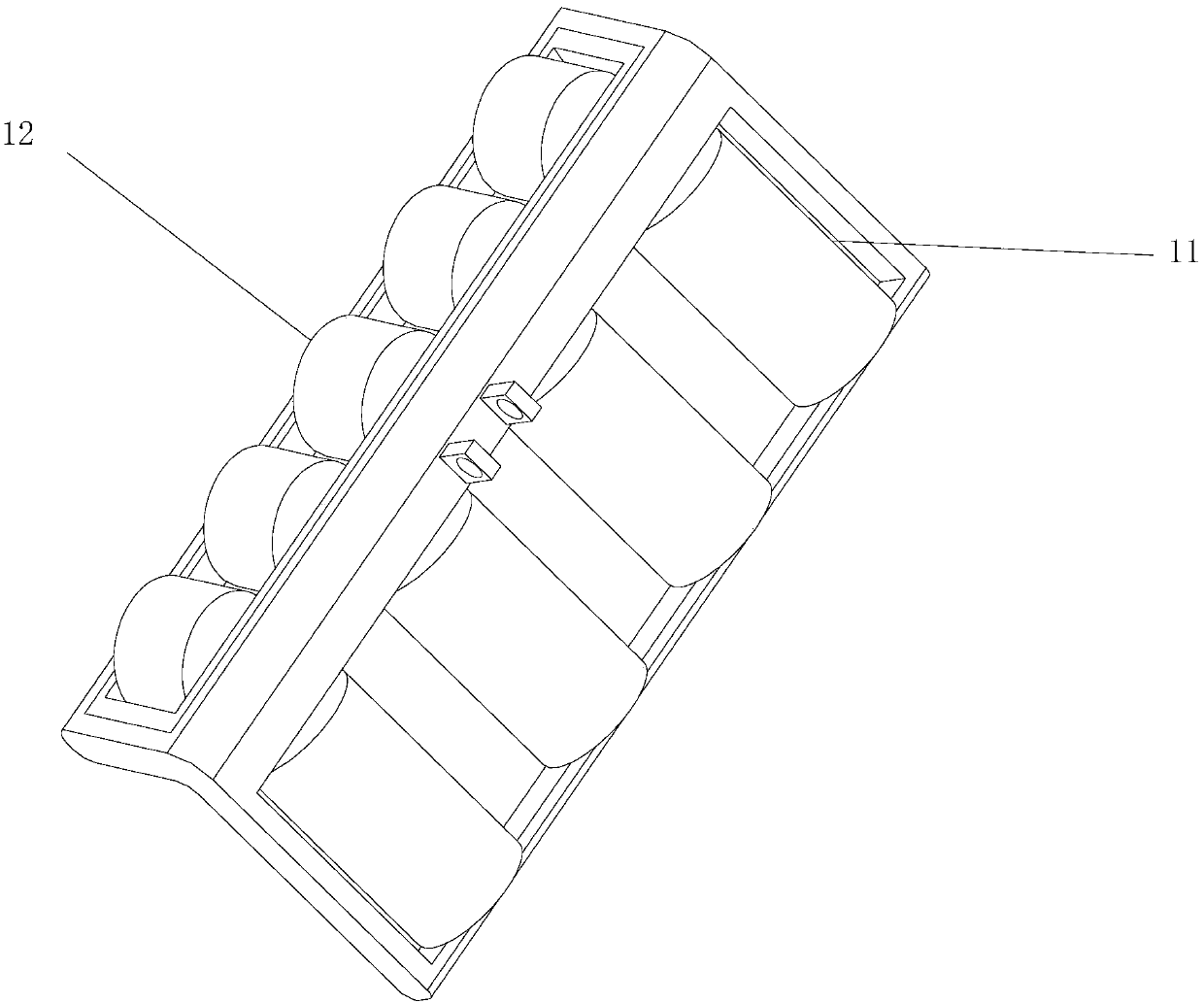

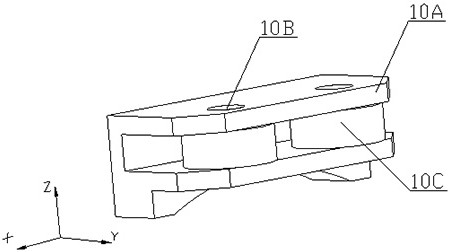

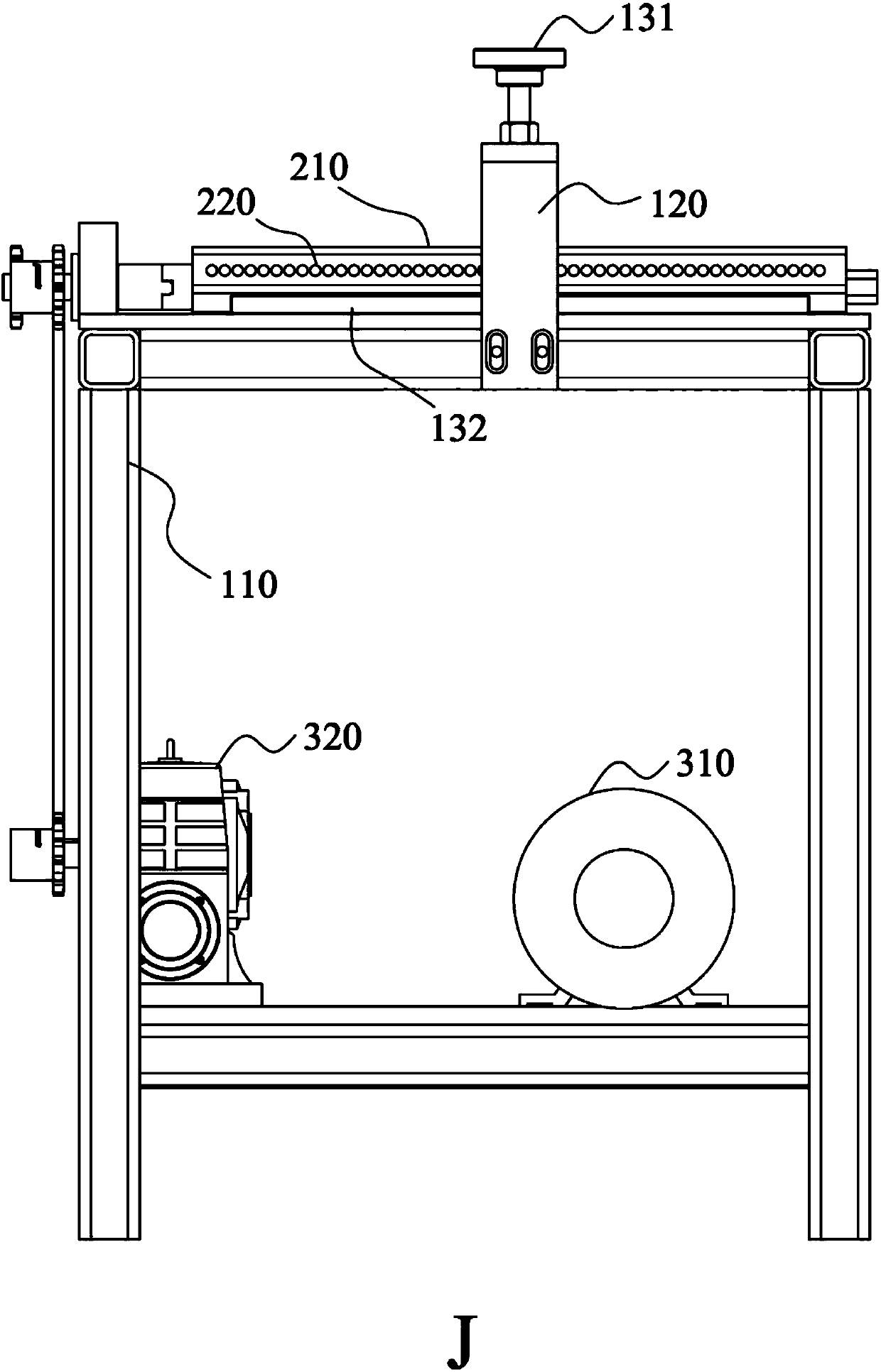

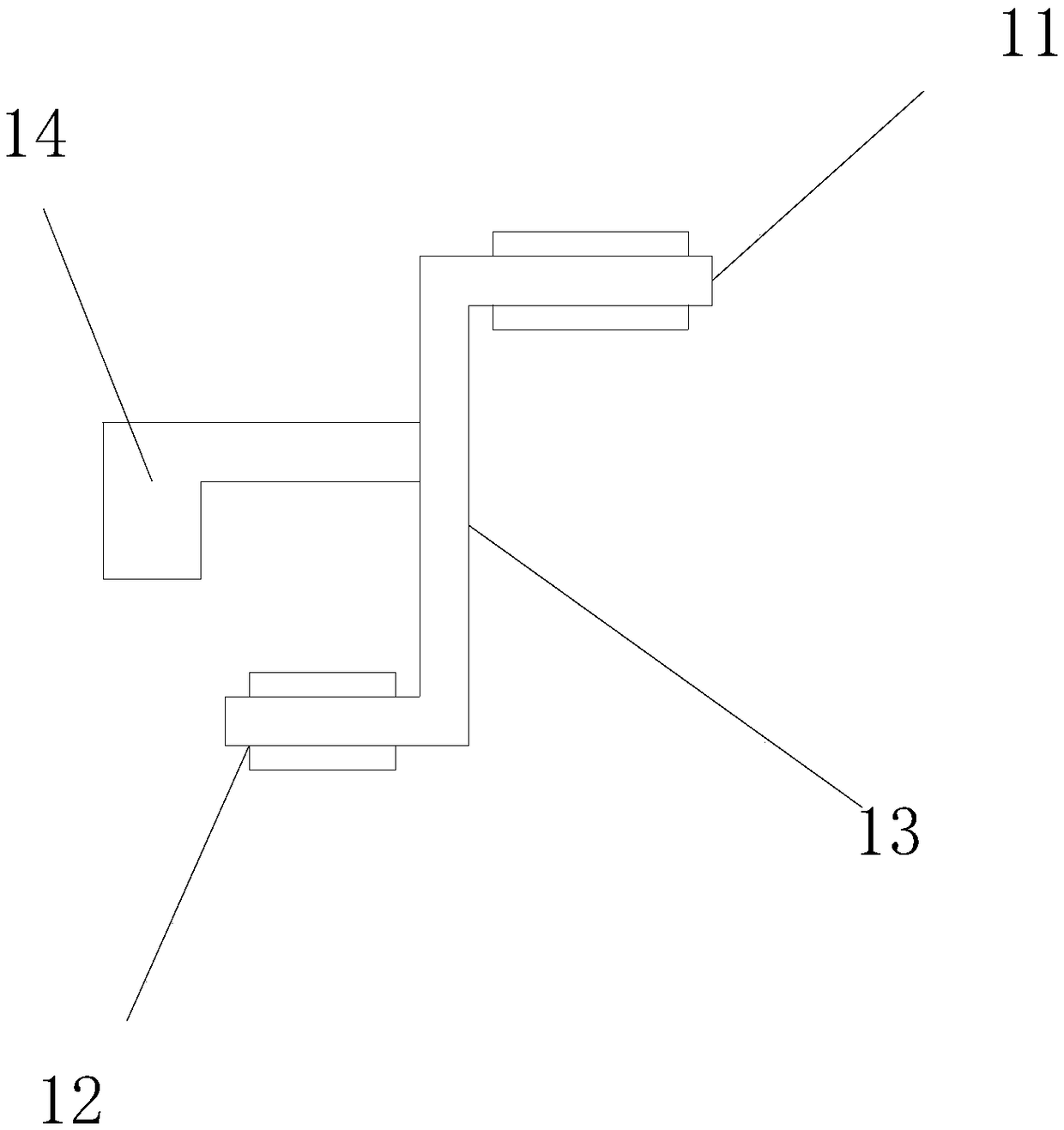

Rolling type low-temperature correction device of F-shaped steel

The invention provides a rolling type low-temperature correction device of F-shaped steel. The correction device comprises an upper correction portion, a lower correction portion and a tail flange correction portion. The upper correction portion is used for correcting a web and a second leg flange of the F-shaped door frame channel steel. The lower correction portion is located below the upper correction portion and is used for correcting the web and a first leg flange of the F-shaped door frame channel steel. The lower correction portion comprises a lower frame, a sleeve and lower correctionrollers. The tail flange correction portion is connected to the lower correction portion and is used for correcting a tail flange of the F-shaped door frame channel steel. According to the rolling type low-temperature correction device of the F-shaped steel, space matched with the F-shaped door frame channel steel is formed by upper correction rollers, upper flange rollers, lower flange rollers, side correction rollers and the lower correction rollers, the F-shaped channel steel is driven by the lower correction roller to smoothly slide forwards, and meanwhile the web, the tail flange, the first leg flange and the second leg flange are corrected.

Owner:SHANDONG IRON & STEEL CO LTD

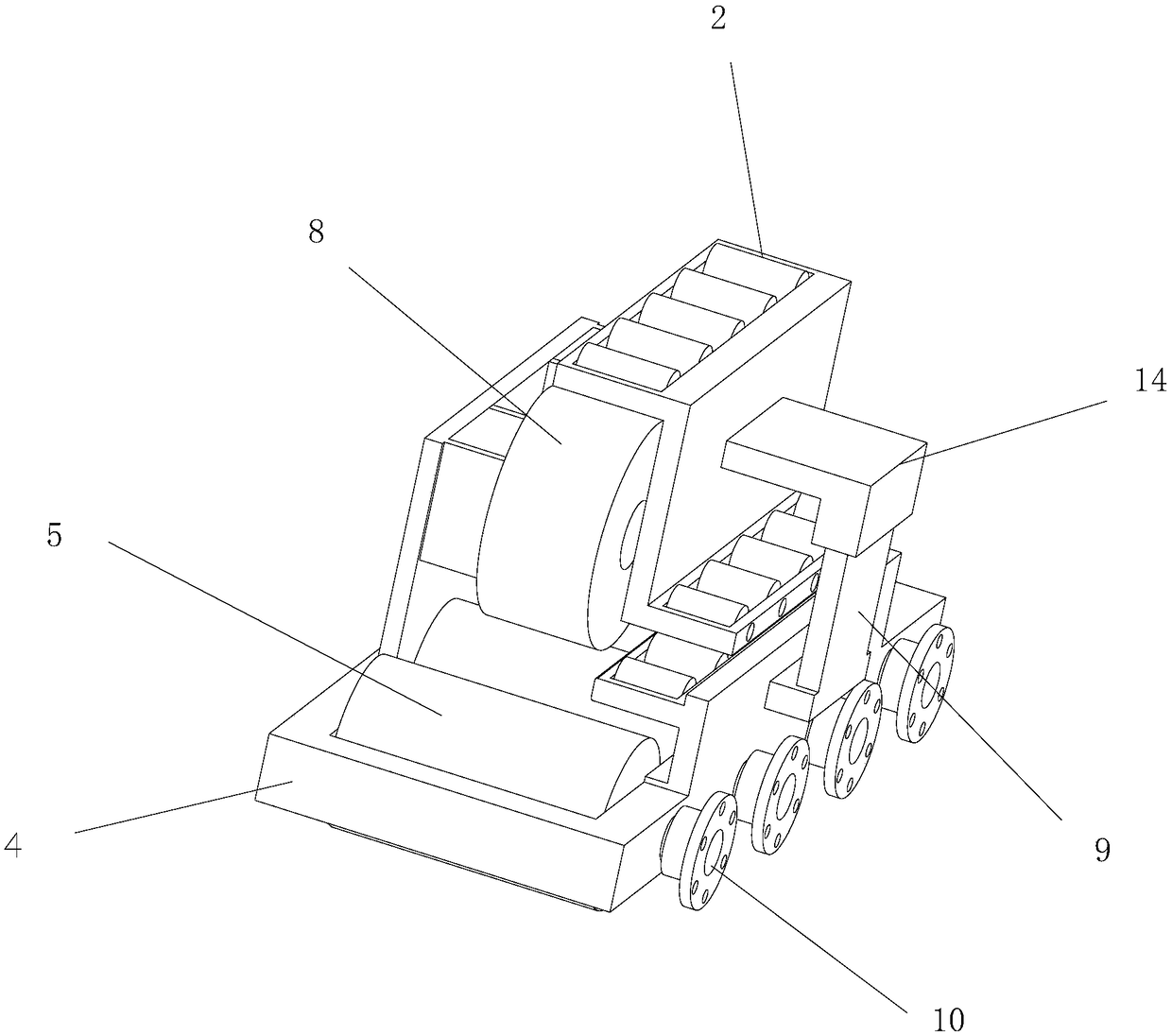

A speed-limiting tooling for forming cone parts for a plate rolling machine and a cone forming method

The invention discloses a speed-limiting tool for forming cone parts for a plate rolling machine and a method for forming the cone. The speed-limiting tool is processed on one side of the frame body of the plate rolling machine, and the speed-limiting tool is provided, including a tool body, a pin Shafts, speed limiting and bearings. During processing, place the plate to be rolled between the upper roller and the lower roller, and keep the side of the small head of the plate to be rolled in contact with the speed-limiting peripheral surface. When the plate rolling machine is started, when the plate to be rolled moves continuously along the speed-limiting axis , the frictional force will be generated between the plate to be coiled and the speed limit, so that the speed of the side of the plate to be coiled contacting the speed limit will be slower than the speed of the plate to be rolled away from the side away from the speed limit, so that the two opposite sides of the plate to be coiled will form a stable The speed difference ensures that the axis of the rolled cone is always centripetal and parallel to the roller axis, so as to achieve the purpose of forming the cone.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Rock mass pile foundation pore-forming preboring construction method

ActiveCN101570971BReduce the difficulty of correctionImprove pore forming efficiencyReciprocating drilling machinesFoundation engineeringPunchingDrill bit

The invention relates to a rock mass pile foundation pore-forming preboring construction method, including: five hole sites are arranged at a drilled pile site, a center hole sit is arranged in the center of the drilled pile site, four surrounding hole sites are evenly distributed outside the center hole site, the distance between the center of each surrounding hole and the margin of the drilled hole site is equal, and an in-the-hole drill with a drill model number of Phi 140mm is used for drilling on the center hole site and the surrounding hole site. Another hole distribution mode includes:three hole sites are arranged at the drilled pile site, the distance between the center of each hole site and the center of the drilled hole pile site is equal and the connection lines of two adjacenthole site and the center form a 120 degrees angle, the distance between the center of the hole site and the margin of the drilled hole pile site is equal, and an in-the-hole drill with the model number of Phi 220mm is used for punching on the hole site. The method of the invention realizes that pore-forming efficiency of a punching drill is high, slant rock correction difficulty is reduced, construction quality is high, construction period is short and construction cost is low when rock bearing capacity at the foundation pile site of a bridge pile is more than 1000kPa or a slant rock is existed.

Owner:SINOHYDRO ENG BUREAU 4 +1

A method and system for manual pipe jacking control

ActiveCN108458164BReduce the difficulty of correctionRealize integrationPipe laying and repairUsing optical meansLaser transmitterControl system

The invention discloses a manual l jacking pipe control method and control system. Two laser detection pipes are symmetrically arranged in the wall of each cement concrete pipe, a PSD sensor is arranged at the position, on the front end of a jacking pipe, in each laser detection pipe of each cement concrete pipe, a computer connected with the PSD sensors are arranged outside each cement concrete pipe, and laser emitters are arranged at the position, on the outer end of the jacking pipe, in the laser detection pipes of one cement concrete pipe, laser emitted by the laser emitters is irradiatedon the PSD sensors to form light spots, the PSD sensors collect and record information of light spot position changes, and the computer analyzes collected data, the straightness error of the cement concrete pipes can be evaluated. Through manual adjusting of a jack, the jacking direction of the cement concrete pipes can be adjusted; in the manual jacking pipe construction process, the extension deviation of a pipeline underground can be corrected, the jacking direction is effectively controlled, a deviation correcting control system and a jacking device are integrated, safety is improved, thedifficulty of pipeline deviation correcting in the pipeline jacking process can be effectively reduced, and the comprehensive cost is reduced.

Owner:CHINA MCC5 GROUP CORP

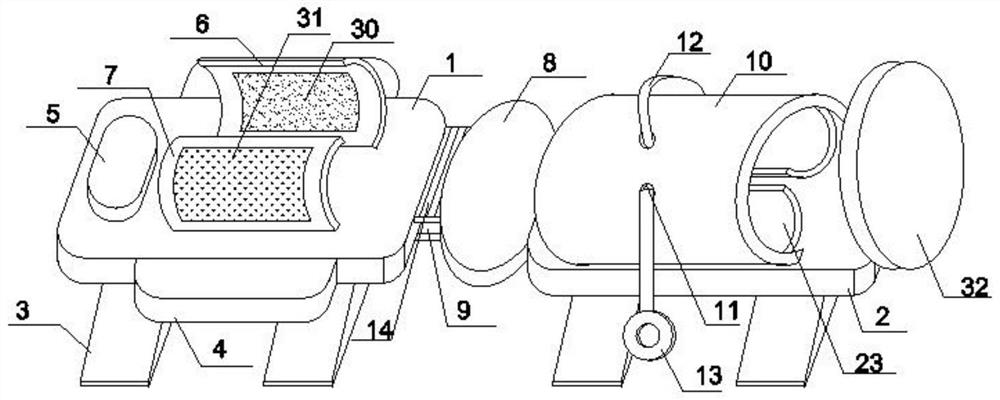

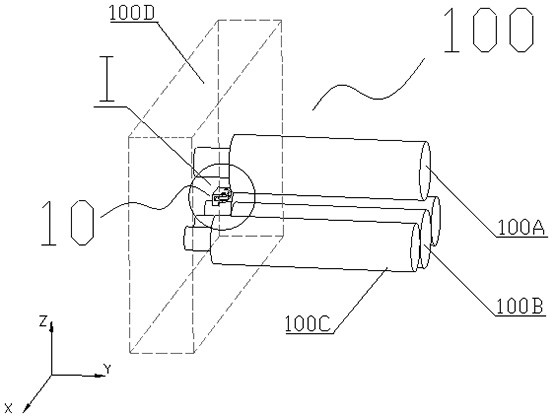

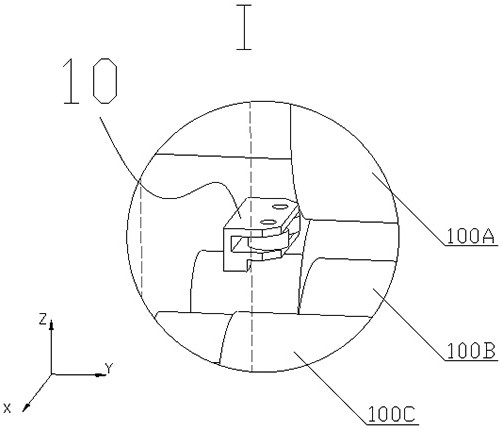

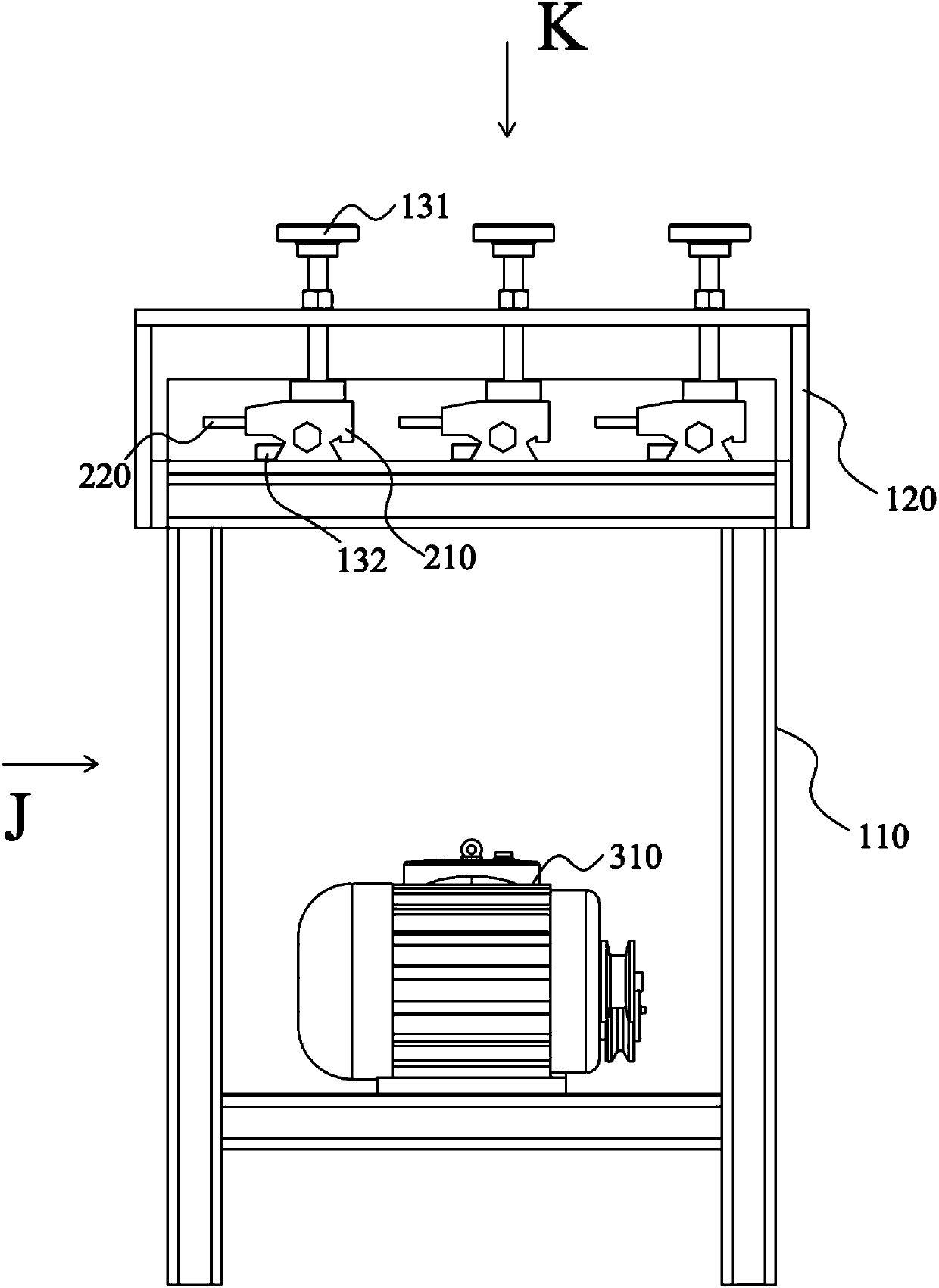

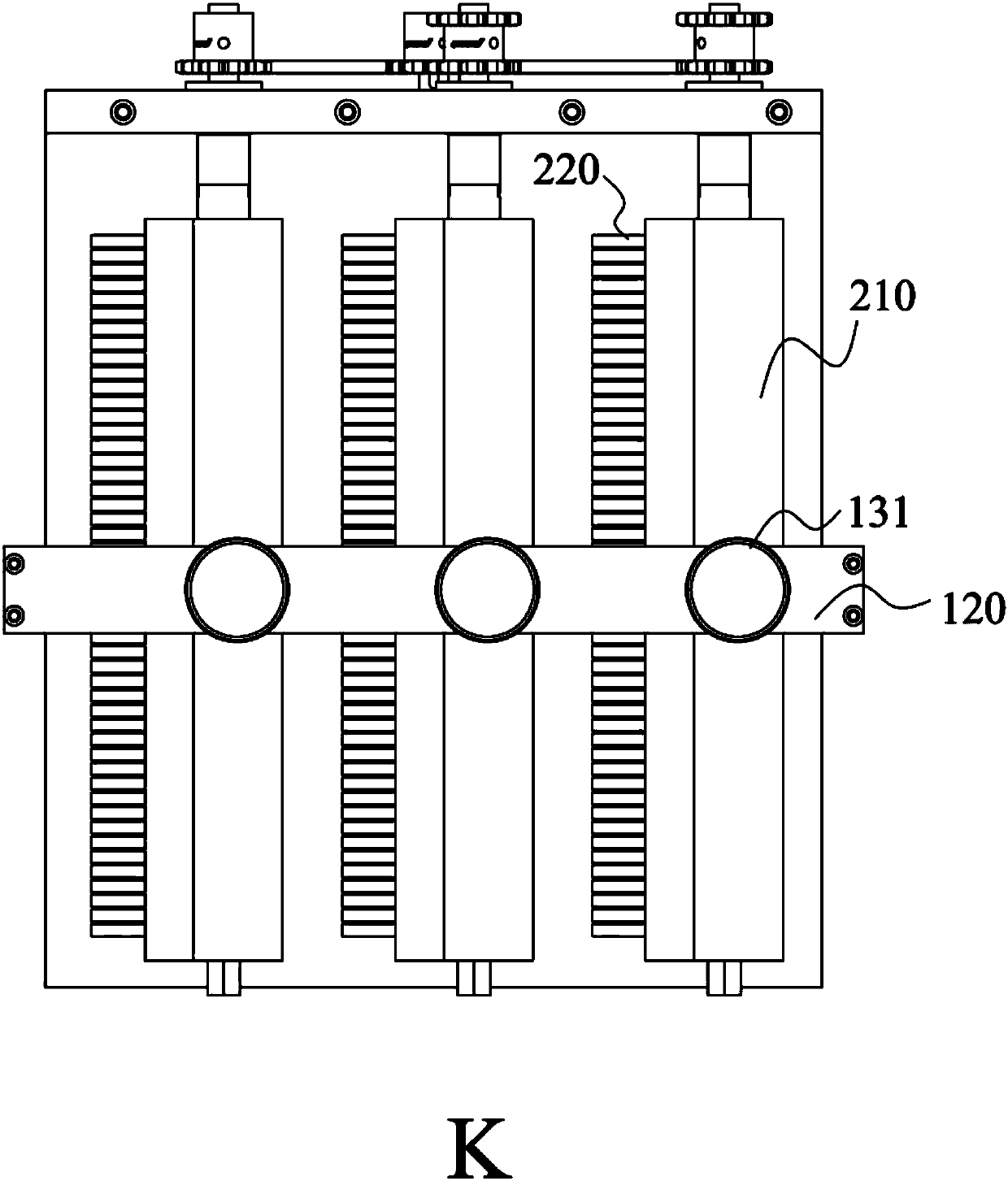

Rotary correcting device for gem machining row body

InactiveCN108044817AReduce the difficulty of correctionEasy to unloadWorking accessoriesFine working devicesEngineeringMechanical engineering

The invention discloses a rotary correcting device for a gem machining row body. The rotary correcting device comprises a frame body capable of installing the multiple sets of row bodies at the same time, and a transmission mechanism capable of driving threaded rods in the multiple sets of row bodies at the same time. The rotary correcting device has the advantages that the multiple sets of row bodies can be rotated at one time through the transmission mechanism so that the rotating conditions of gem clamps of the multiple sets of row bodies can be observed by technical personnel through auxiliary lines at one time.

Owner:WUZHOU UNIV

B-type gantry steel channel rolling type low-temperature correcting device

PendingCN109500149AReduce the difficulty of correctionImprove correction efficiency and correction accuracyEngineeringFlange

The invention provides a B-type gantry steel channel rolling type low-temperature correcting device. The correcting device comprises an upper correcting portion for correcting a flange and a supporting flange of a B-type gantry steel channel, a lower correcting portion located below the upper correcting portion and used for correcting the flange and the supporting flange of the B-type gantry steelchannel and a side correcting portion connected to the lower correcting portion and used for correcting a web plate and the supporting flange of the B-type gantry steel channel. The upper correctingportion includes an upper frame, an upper correcting roller and a flange upper roller; the upper correcting roller and the flange upper roller are both disposed on the upper frame; the flange upper roller is located on the lower side of the upper correcting roller; and the side correction portion includes a base and a side correcting roller, the base is disposed on a lower frame, and the side correcting roller is disposed on the base. The B-type gantry steel channel rolling type low-temperature correcting device can correct the web plate, the flange and the supporting flange of the B-type steel channel while the B-type steel channel is driven by a lower correcting roller to slide smoothly forward.

Owner:SHANDONG IRON & STEEL CO LTD

Lenses, cameras and electronics

ActiveCN110072045BLow costReduce the difficulty of correctionTelevision system detailsColor television detailsCorrection algorithmOphthalmology

The embodiment of the application discloses a lens, a camera and electronic equipment. Wherein, the lens is arranged on the camera head, and the optical distortion of the lens is a negative value, wherein the optical distortion of the lens satisfies a preset curve, and in the preset curve, the absolute value of the optical distortion of the lens and the field of view The angle is positively related. The embodiment of the present application adopts the above-mentioned technical solution to provide a negative distortion lens that satisfies the preset curve, and compensates the 3D distortion formed by shooting in a physical way, which replaces the way of compensation through the correction algorithm in the later stage, and reduces the loss of 3D distortion. The correction is difficult, and at the same time, it breaks the thinking of reducing the optical distortion of the lens in the prior art, and reduces the cost of optical distortion design in the lens production process.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

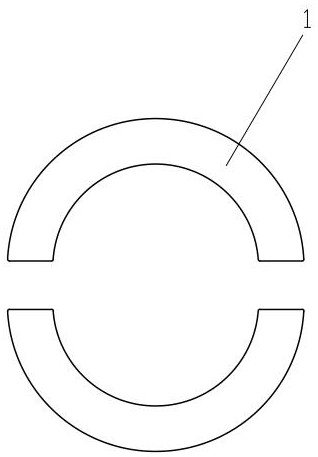

Preparation method and application of irregular gear with annular groove

PendingCN114273661AGood flatnessReduce the difficulty of correctionReelsPowder metallurgyEngineering

A preparation method of an irregular gear with an annular groove comprises the following steps that S1, a certain amount of powder metallurgy raw materials for preparing the gear are loaded into a mold; s2, after the powder metallurgy raw materials in the mold are pressed into the needed shape and compactness, demolding is conducted, and a green body is obtained; s3, the annular gasket is clamped in the annular groove of the green body, then the green body and the gasket are sent into a sintering furnace together to be sintered, and after the sintering process is finished, the gear with the gasket is taken out; and S4, the gasket is taken out of the annular groove, whether the sawtooth part, close to the annular groove, of the gear is warped or not is observed, if the sawtooth part, close to the annular groove, of the gear is warped, a correction mold is used for correction till the warped part disappears, the gear is taken out of the correction mold, and a final product is obtained. The problem that the sawtooth part close to the annular groove inclines inwards in the preparation process of the gear can be effectively solved, and the method is simple, convenient to operate and low in cost.

Owner:KINGSON POWDER METALLURGY STAINLESS STEEL

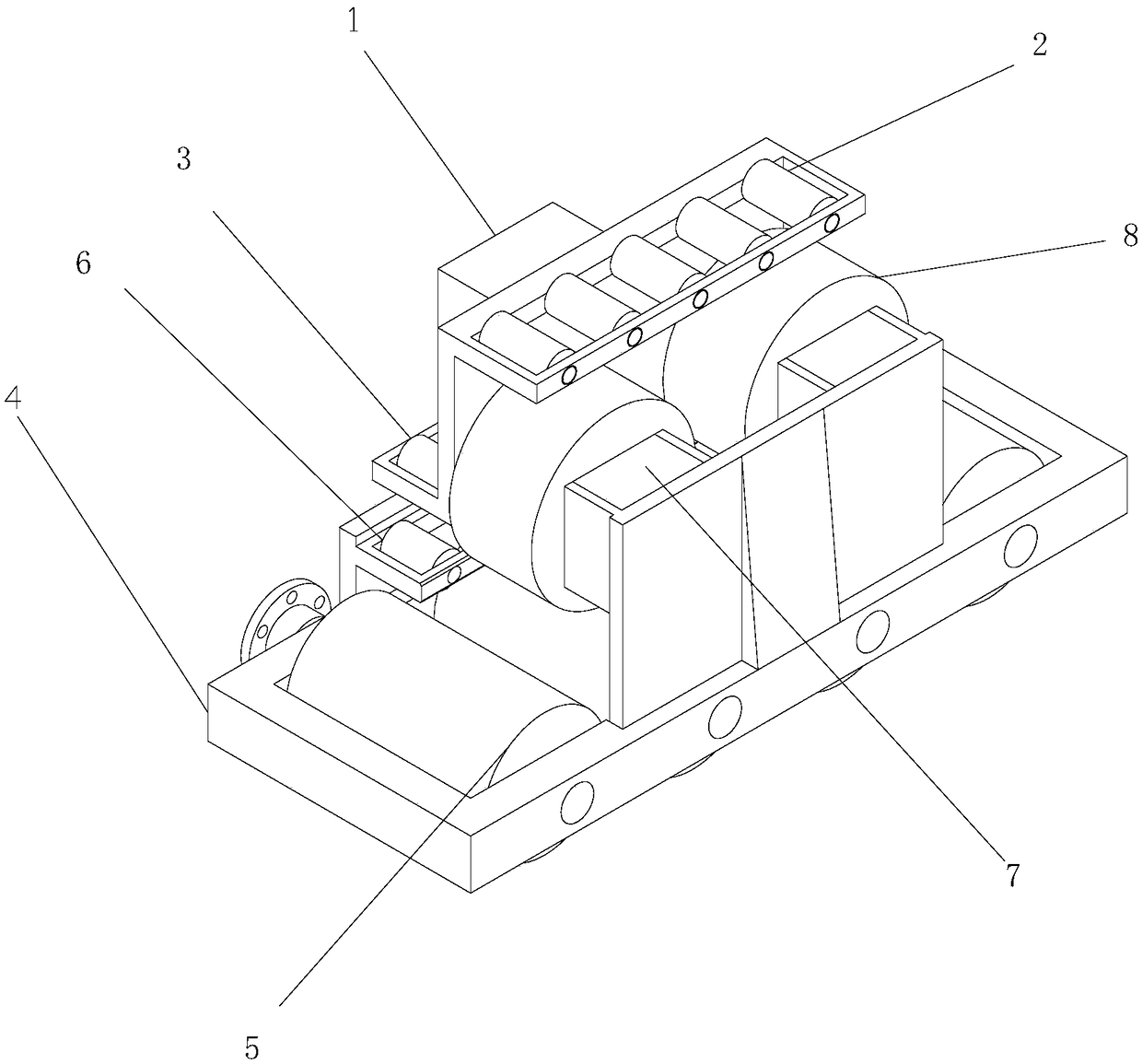

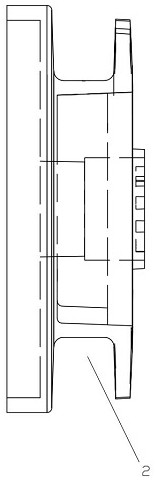

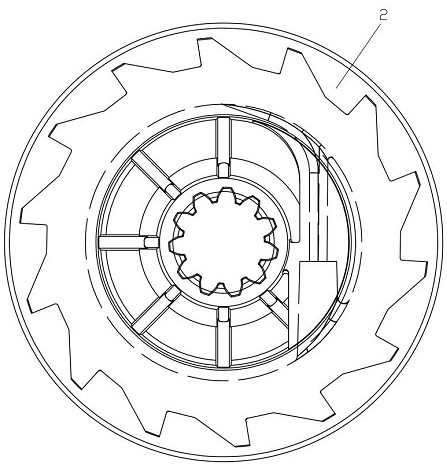

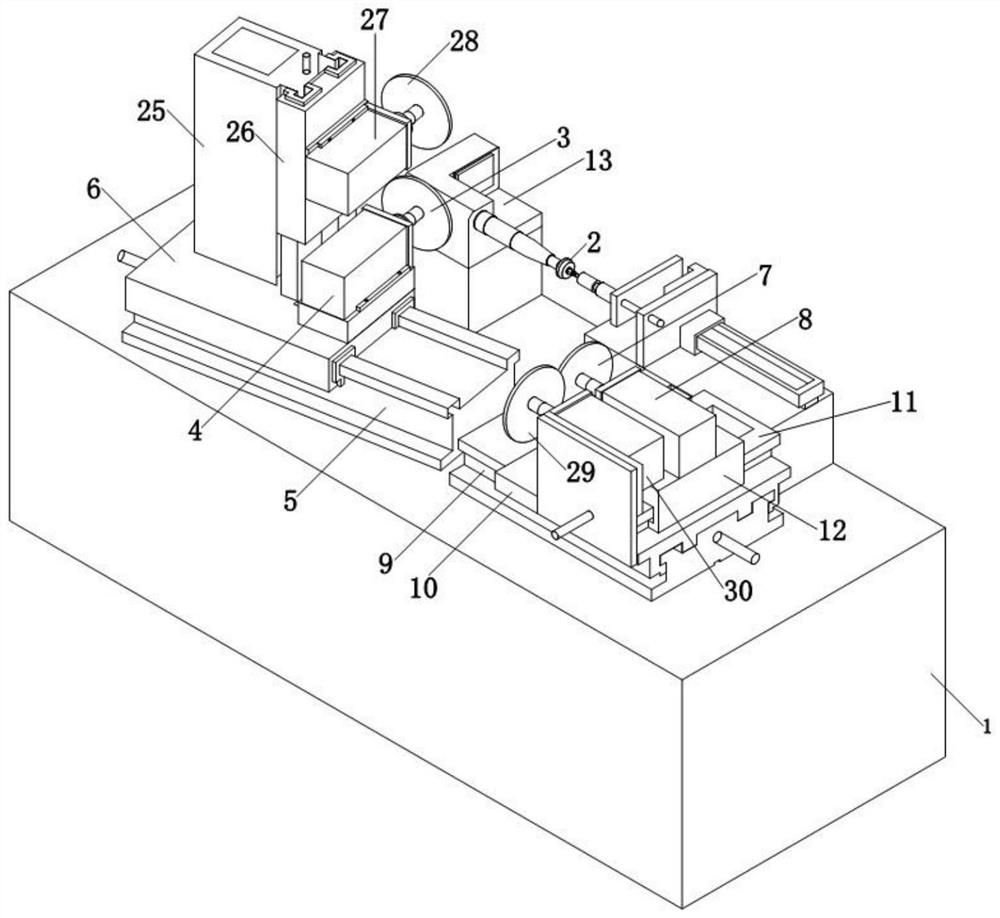

Weight removing machine based on dynamic balance mechanism of rotor shaft of turbocharger

PendingCN114074278AImprove stabilityReduce the difficulty of correctionGrinding carriagesGrinding drivesImpellerBalancing machine

The invention discloses a weight removing machine based on a dynamic balance mechanism of a rotor shaft of a turbocharger. The weight removing machine comprises a machine base, and a clamping mechanism, a positioning mechanism, a turbine rotor shaft impeller grinding mechanism and a turbine rotor shaft port grinding mechanism are fixed to the upper surface of the machine base. The turbine rotor shaft impeller grinding mechanism comprises a first moving unit fixed to the upper surface of the machine base, and the first moving unit is used for driving a first grinding unit to move back and forth to grind a turbine rotor shaft impeller. The turbine rotor shaft port grinding mechanism comprises a second moving unit fixed to the upper surface of the machine base, and the second moving unit is used for driving a second grinding unit to move back and forth to grind a turbine rotor shaft port. According to the weight removing machine based on the dynamic balance mechanism of the rotor shaft of the turbocharger, the unbalance amount on a turbine rotor shaft port and an impeller of the turbocharger is reduced in a weight removing mode, then the vibration value during high-speed rotation is reduced, and the stability of the turbine rotor shaft is improved.

Owner:LIAONING JIDIAN POLYTECHNIC

Path planning method for automatic parallel parking based on two second-order Bezier curves

ActiveCN110949374BReduced starting pose requirementsReduce the difficulty of correctionControl devicesSimulationObstacle avoidance

The invention discloses an automatic parallel parking path planning method based on two second-order Bezier curves. The method determines the parking target position by obtaining the target parking space information, and establishes a global coordinate system with it as the origin to construct a parking space. The trajectory segmentation judgment model is used to determine the number of planned trajectory segments, plan the end position range of the first segment of the trajectory, determine the start and end points of each segment of the planned trajectory and the position of the control point, use the second-order Bezier curve for path planning, and monitor at regular intervals And use the method of dynamically adjusting the planned trajectory to adjust the planned trajectory. The present invention reduces the requirements for the initial pose of the vehicle to be parked, and improves the environmental adaptability of the path planning method; the vehicle can be artificially driven into the planned area through simple adjustments to reduce costs, and can be applied to middle and low-end vehicles; The control points of the vehicle trajectory planning are easy to determine, the trajectory generation algorithm is simple, and the path curvature is continuous; the difficulty of correcting the trajectory error is reduced, and the vehicle obstacle avoidance and parking efficiency are improved.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com