A speed-limiting tooling for forming cone parts for a plate rolling machine and a cone forming method

A plate rolling machine and tooling technology, applied in the field of mechanical processing, can solve problems such as increased labor intensity, low production efficiency, and poor stability of workpiece dimensional accuracy, and achieve the effects of reducing safety hazards, improving production efficiency, and reducing the difficulty of correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

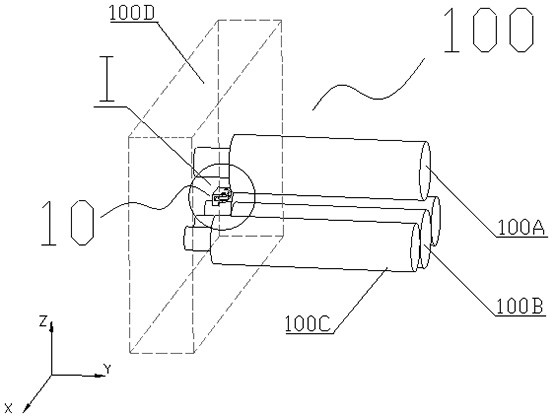

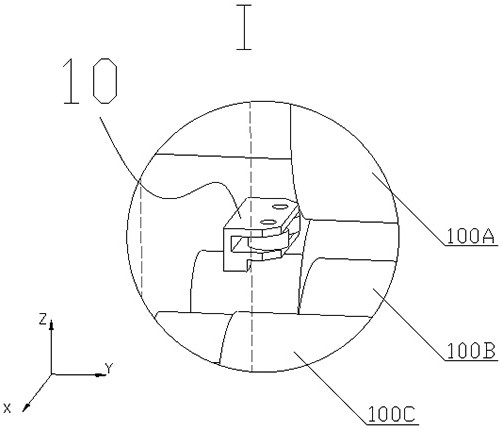

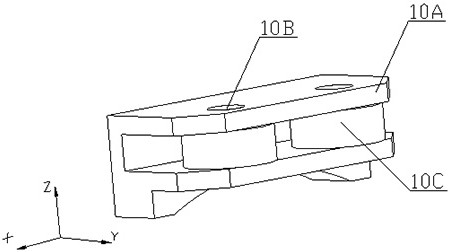

[0034] In some embodiments, a speed-limiting tool for forming cone parts for a plate rolling machine is installed on figure 1 On the plate bending machine 100 shown, the plate rolling machine 100 is used to process Figure 5 and Figure 6 The plate 200 to be rolled is shown. The plate rolling machine 100 may be a commonly used three-axis plate rolling machine or a four-axis plate rolling machine, and a four-axis plate rolling machine is used as an example below.

[0035] Such as figure 1 As shown, for the convenience of expression, it is assumed that the space has an XYZ coordinate system including the X axis, the Y axis and the Z axis, and the X axis, the Y axis and the Z axis are perpendicular to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com