Rectification method for immersed tube tunnel

An immersed tube tunnel and deviation correction technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of high requirements for deviation correction equipment, difficult underwater operation, and large immersed tube volume, so as to reduce construction costs, Cost saving and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

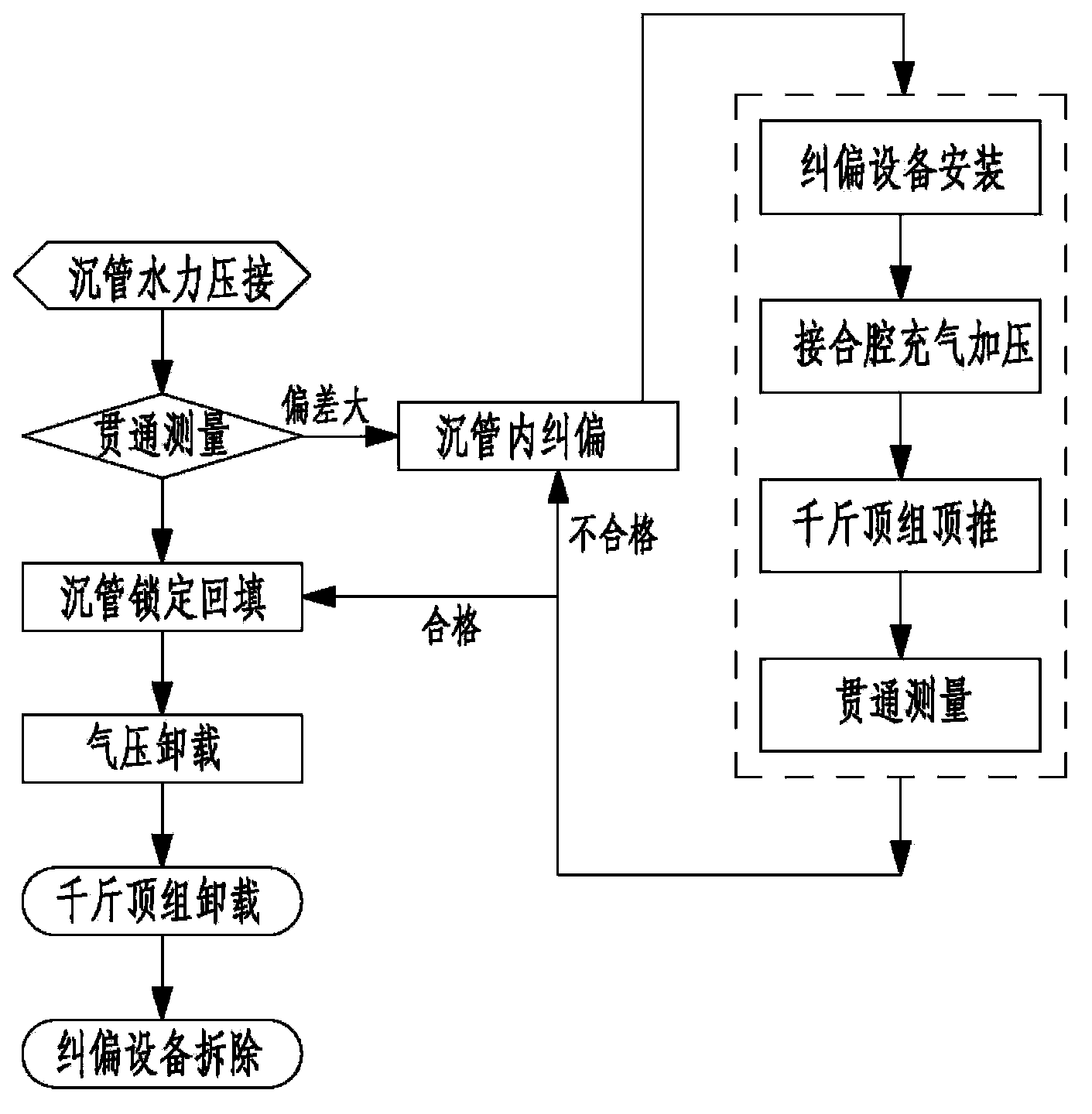

[0040] see figure 1 As shown, a deviation correction method for an immersed tube tunnel of the present invention, the deviation correction method includes the following steps:

[0041] 1. The following commissioning preparations need to be done before the deviation correction operation:

[0042] 1. The surveyor conducts penetration measurement in the immersed tube, and records the deviation value at the end of the immersed tube, and compares the deviation value at the end of the immersed tube with the allowable deviation value to judge whether it is necessary to correct the deviation;

[0043] 2. When the deviation value exceeds the allowable deviation range, deviation correction is required;

[0044] 3. Report the deviation value, and calculate the required pushing stroke of the jack group according to the deviation value;

[0045] 4. Prepare the required deviation correction equipment;

[0046] 5. Steps to make the deviation correction operation meet the constraints of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com