Preparation method and application of irregular gear with annular groove

A kind of annular groove, irregular technology, applied in the application, fishing reel, fishing and other directions, can solve the problem that the sawtooth part is prone to warping or inward tilt, and the sawtooth part is offset, so as to reduce the difficulty of correction. , Solve the effect of inward tilt and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

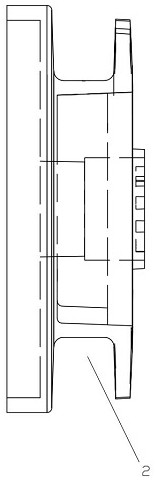

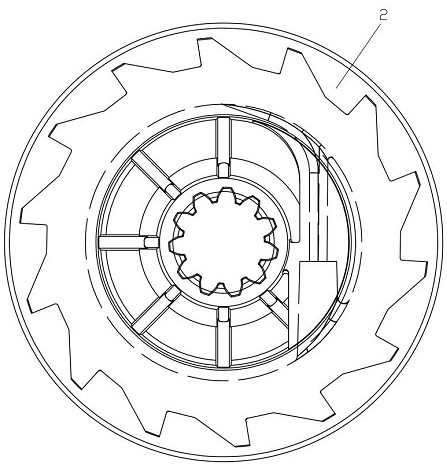

[0032] see Figure 1-7 Shown, a kind of preparation method of the irregular gear with annular groove, comprises the steps:

[0033] S1. Powder filling: put a certain amount of powder metallurgy raw materials (related metal powder) for preparing gears into the mold (referring to the mold for manufacturing gears);

[0034] S2. Compression molding: Press the powder metallurgy raw materials in the mold into the required shape and density, and then demould to obtain the green body;

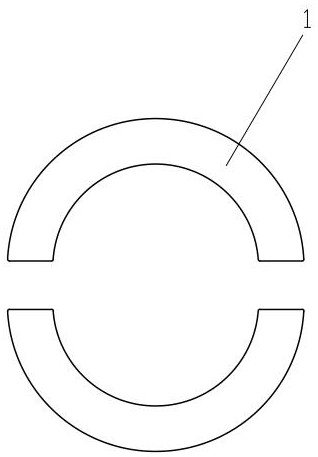

[0035] S3, sintering: clamp the annular gasket 1 in the annular groove 2 of the green body, then send the green body and the gasket 1 into the sintering furnace for the sintering pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com