Weight removing machine based on dynamic balance mechanism of rotor shaft of turbocharger

A technology of turbocharger and turbine rotor, which is applied in the direction of grinding machine parts, grinding frames, grinding drives, etc. Fracture and other problems to achieve the effect of reducing the difficulty of correction, reducing the vibration value and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

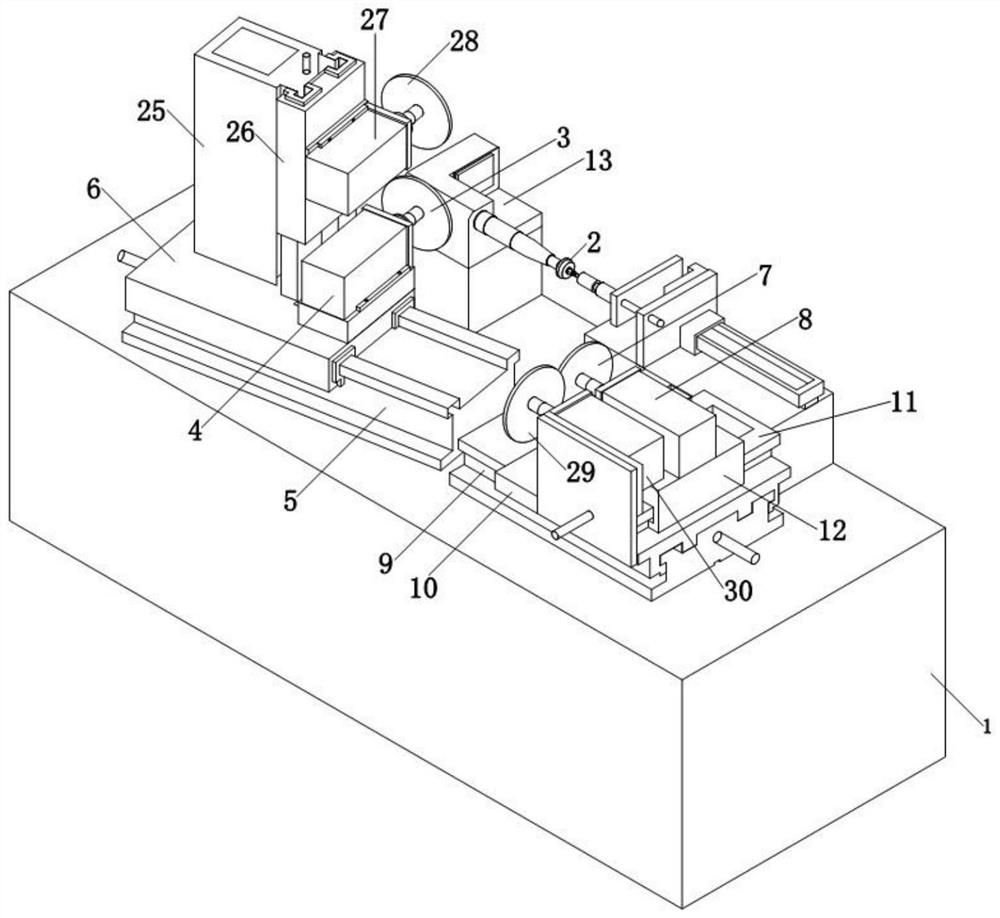

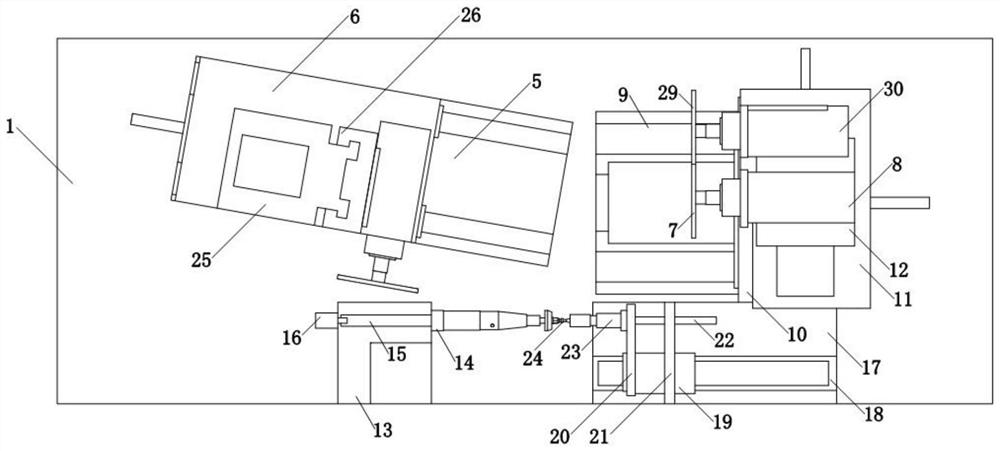

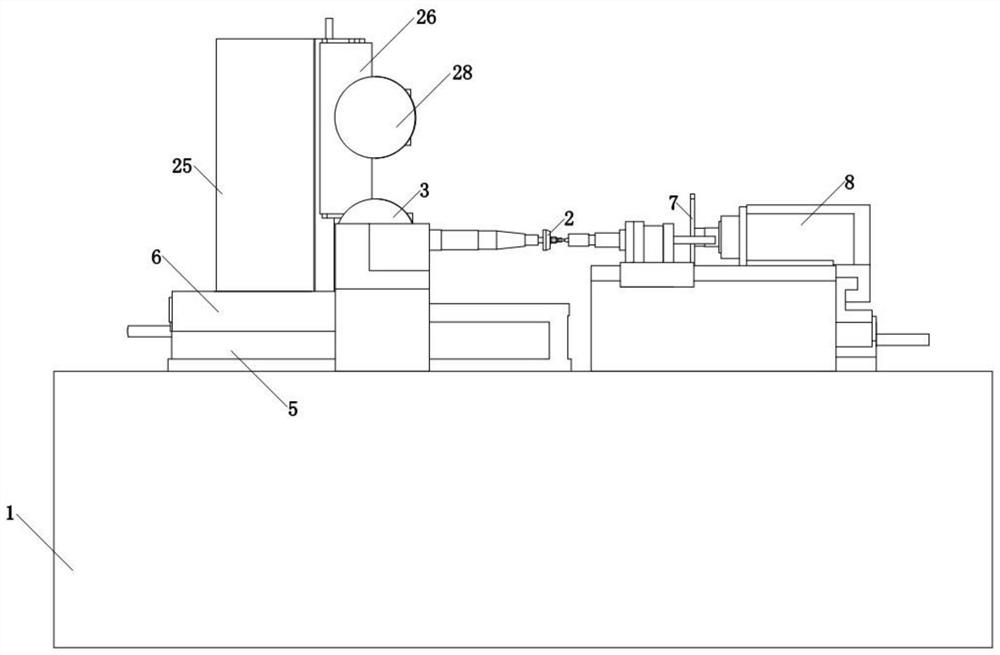

[0064] Such as Figure 1-Figure 3 As shown, a de-weighting machine based on the dynamic balancing mechanism of the turbocharger rotor shaft proposed by the embodiment of the present invention includes a base 1, the upper surface of which is fixed to hold one end of the turbine rotor shaft 2 and drive the turbine rotor The clamping mechanism for the rotation of the shaft 2, the upper surface of the base 1 is fixed with a positioning mechanism for tightening the other end of the turbine rotor shaft 2; The first moving unit on the upper surface of the base 1, the moving direction of the first moving unit is inclined at an angle relative to the axis of the turbine rotor shaft, the moving part of the first moving unit is connected with the first grinding unit, and the first moving unit The first grinding unit is driven to reciprocate between the grinding position for grinding the turbine rotor shaft impeller and the retracted position retreating from the grinding position; the turb...

Embodiment 2

[0067] This embodiment is based on Embodiment 1, the first grinding unit includes a first grinding wheel 3, the center of the first grinding wheel 3 is connected to the output shaft of the first motor 4, and the first motor 4 is used to drive the first grinding wheel 3 to rotate and grind at a high speed Turbine rotor shaft impeller.

[0068] Further, the first mobile unit includes a first workbench 5 fixed on the upper surface of the base 1, on the first workbench 5 is provided a first sliding platform 6 slidingly connected to it through a sliding mechanism, the first sliding The upper surface of table 6 is fixedly connected with the first motor 4 of the first grinding unit, the outer casing of the first motor 4 of the first grinding unit is fixed on the upper surface of the first sliding table 6, the first motor 4 is a high-speed motor, and the high-speed motor drives The first grinding wheel 3 rotates at high speed; the first ball screw mechanism is provided in the groove p...

Embodiment 3

[0071] This embodiment is based on Embodiment 1, the second grinding unit includes a second grinding wheel 7, the center of the second grinding wheel 7 is connected to the output shaft of the second motor 8, and the second motor 8 is used to drive the second grinding wheel 7 to rotate and grind at a high speed Turbine rotor shaft port.

[0072] Further, the second mobile unit includes a second workbench 9 fixed on the upper surface of the machine base 1, the second workbench 9 is slidably connected with the second slide table 10 through a sliding mechanism, and a recess is opened inside the second workbench 9. Groove, the second ball screw mechanism used to drive the second sliding table 10 to reciprocate along the second worktable 9 is provided in the groove provided by the second worktable 9, and the second ball screw mechanism is selected from the prior art The ball screw mechanism that machine tool feed adopts; The upper surface of described second slide table 10 is also f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com