Patents

Literature

78results about How to "Reduce the vibration value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for self-lubricating steel balls for precision bearing by ion-plating GLC (graphite-like carbon) coating

InactiveCN102230153AIncrease rotation speedVibration increases slowlyVacuum evaporation coatingSputtering coatingVibration amplitudeCold air

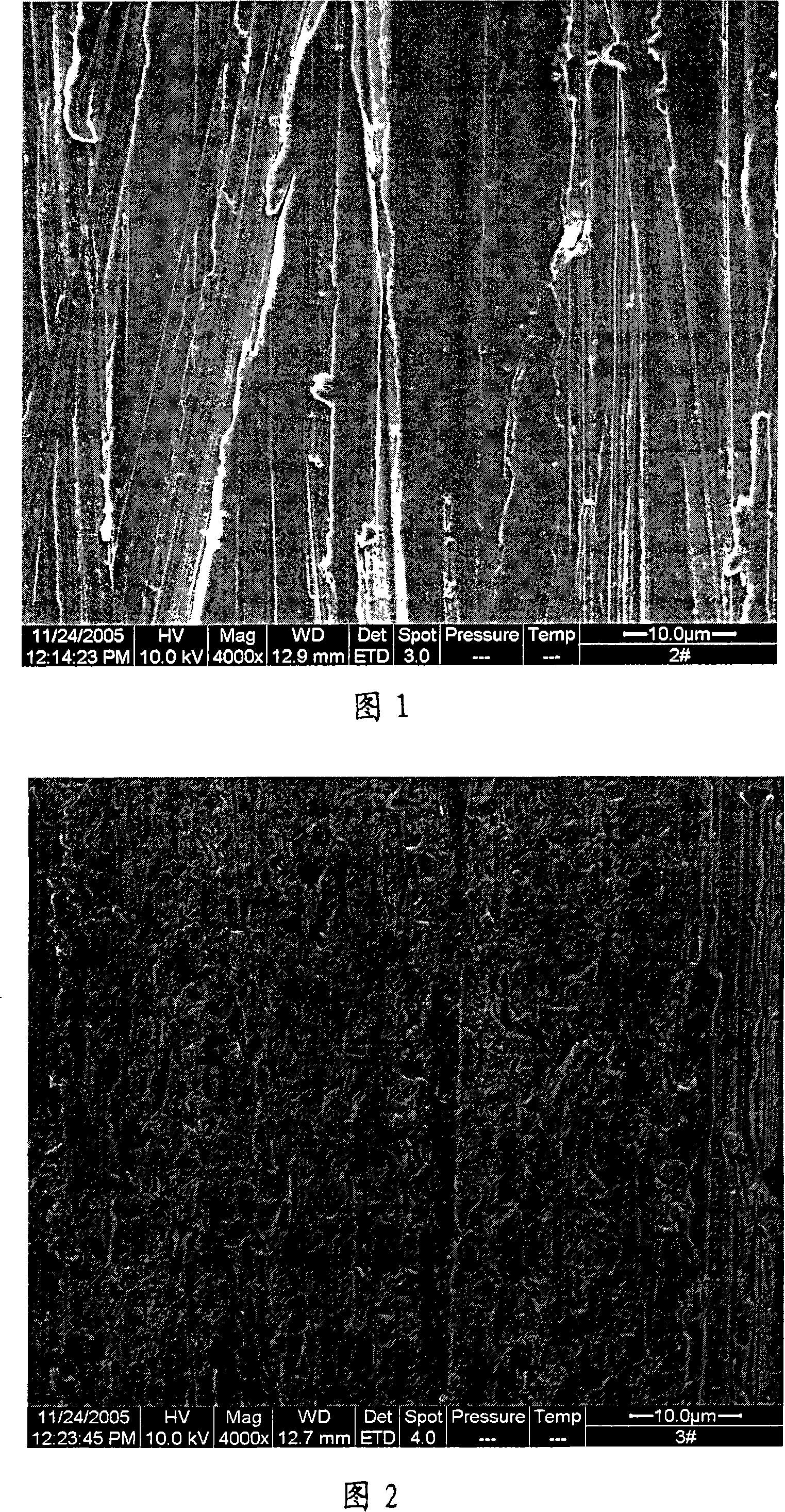

The invention provides a method for self-lubricating steel balls for a precision bearing by ion-plating a GLC (graphite-like carbon) coating. The method comprises the following steps: ultrasonically cleaning the steel balls to be treated, then washing with deionized water and drying with cold air; placing the dried steel balls in a workpiece disk in a vacuum chamber of magnetron sputtering ion-plating equipment for sputter cleaning; depositing a pure chromium base layer; depositing a transition layer; and depositing a graphitelike working layer. The steel balls treated by the method has the characteristics of strong bearing capacity, high revolving speed, small vibration amplitude and low friction coefficient, thus being applicable to the fields such as aerospace and the like.

Owner:XIAN UNIV OF TECH

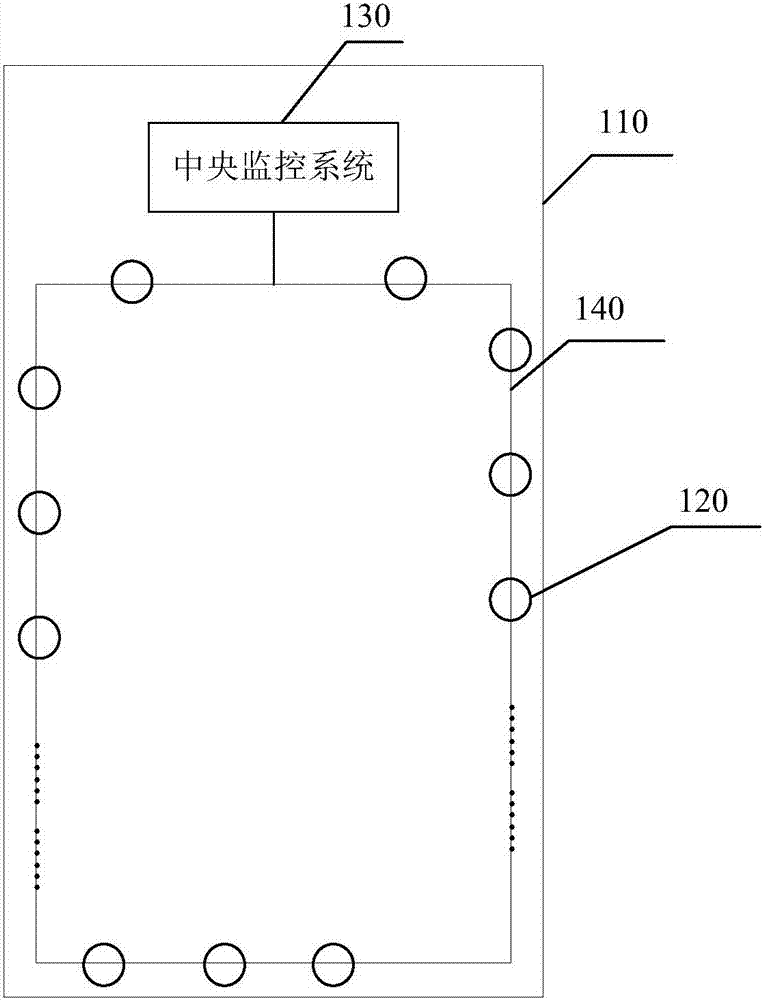

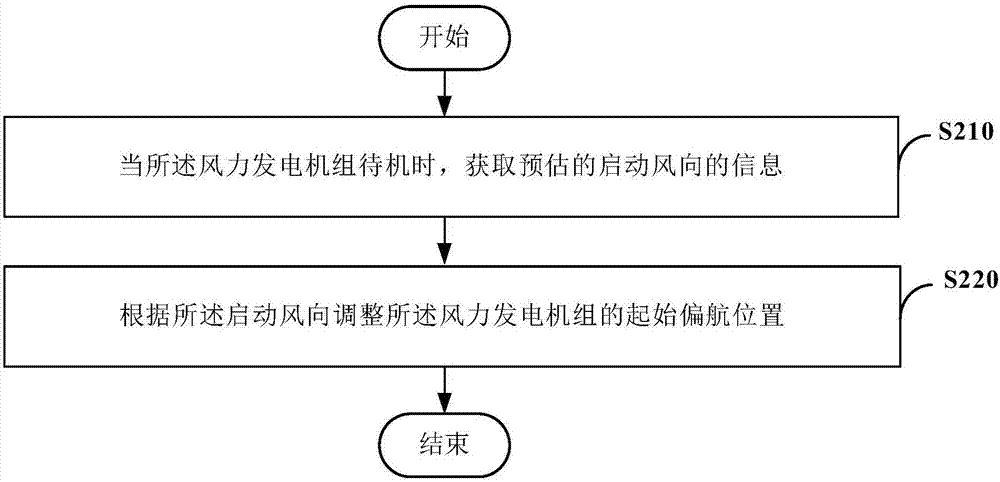

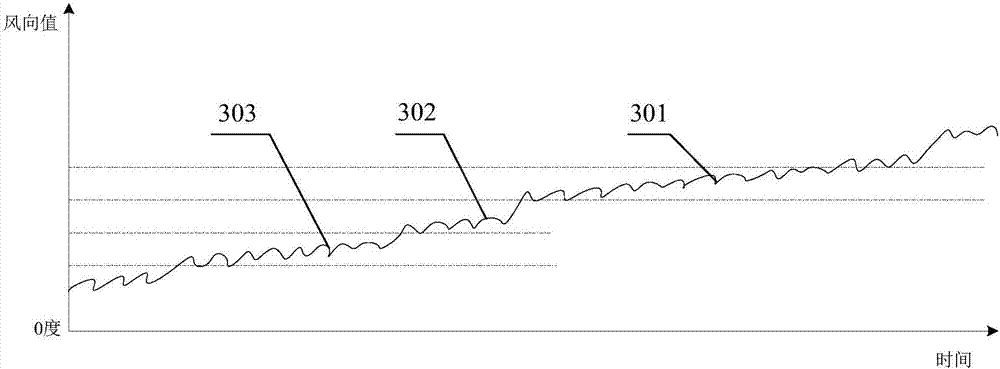

Control method and device of wind generating set and wind power plant group control system

ActiveCN107514337AShorten the timeIncrease power generationWind motor controlMachines/enginesAutomotive engineeringElectric generator

The embodiment of the invention provides a control method and device of a wind generating set and a wind power plant group control system. The control method comprises the steps that when the wind generating set is in the standby state, information of the forecast starting wind direction is obtained, and the initial yawing position of the wind generating set is adjusted according to the starting wind direction; and / or, the power generator rotation speed of the wind generating set is obtained, and if the power generator rotation speed is in the resonance rotation speed range, the set value of the power generator rotation speed is set as the lower limiting value of the resonance rotation speed range. By the adoption of the technical scheme, the yawing time during starting of the wind generating set is shortened, and / or, the power generator rotation speed of the wind generating set avoids the resonance rotation speed set value, and the vibration value and the fatigue load of the wind generating set are decreased.

Owner:BEIJING ETECHWIN ELECTRIC

Method for carrying out dynamic balance on aeroplane propeller by dynamic mass center correction method

ActiveCN104019943AThe trimming effect is accurate and reliableReduce the vibration valueStatic/dynamic balance measurementDynamic balancePropeller

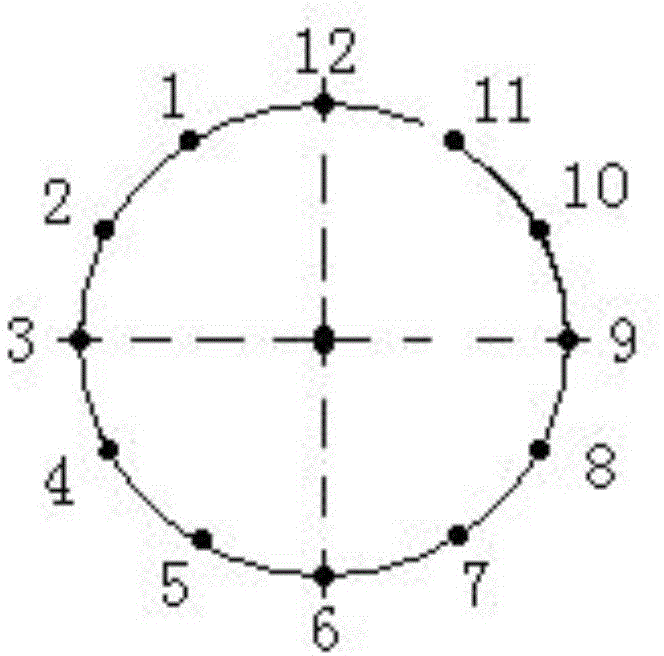

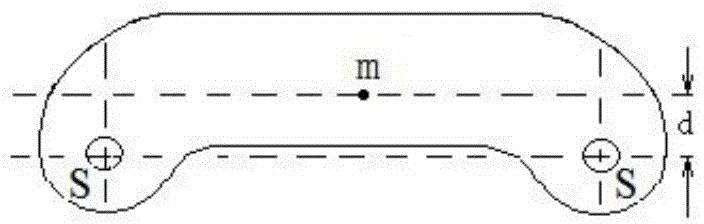

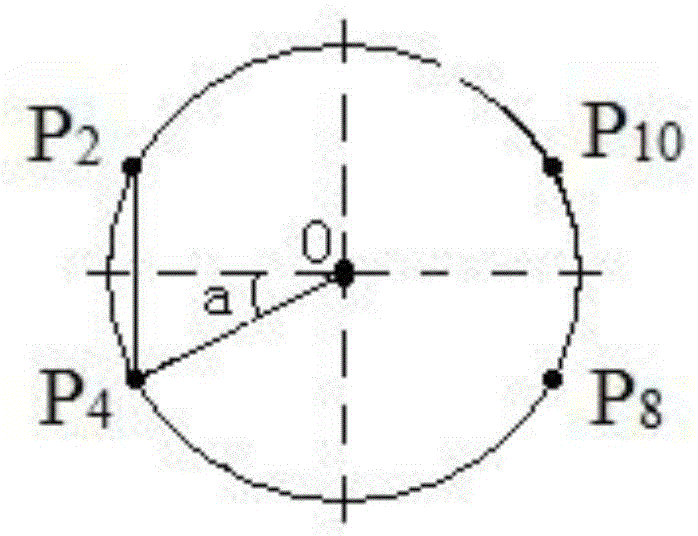

The invention relates to a method for carrying out dynamic balance on an aeroplane propeller by a dynamic mass center correction method. The method comprises the steps of dividing a counter weight planned to be arranged at a light point position into two sub-counter weights according to a vector synthesis and decomposition principle, and installing the two sub-counter weights at two adjacent standard installation positions to ensure that the synthesis effect of the two sub-counter weights is equivalent to the balancing effect of the original counter weight planned to be arranged at the appointed light point position; accurately calculating the mass of the sub-counter weights planned to be arranged at the two standard positions by a method of dynamically correcting the mass center positions of the counter weights to improve the calculation accuracy; and accurately calculating a balancing coefficient K of the propeller to be balanced to enable a later balancing process to be rapid. According to the method, the mass of a needed counter weight can be directly calculated by the balancing coefficient according to the measured vibration value, accurate factorization and calculation are carried out, and the counter weight is installed at an appointed standard clock position according to the calculation result, so that balancing is successfully carried out once; the method is simple and convenient, and is independent of work experience of an operator; the balancing effect is exact and reliable.

Owner:宇翔盛泰(北京)航空科技有限公司

Ureido lubricating grease and its preparation method

An carbamide-base lubricating grease contains hydrogenated mineral oil, plant oil and carbamide-base thickening agent. Its advantages are high thickening power and dripping point, and low vibration and noise of bearing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bearing vibration-reducing chemical milling agent and method for using same

InactiveCN101139517AImprove surface topographyReduce the vibration valueOther chemical processesLapping machinesMineral oilSurface-active agents

A vibration-reducing chemical lapping agent for bearings essentially comprises abrasive, surface active agent, anti-rust additive and substrate medium, wherein, the abrasive is 30-60%, the surface active agent is 2-5%, the anti-rust additive is 3-5%, and the substrate medium is mineral oil and accounts for 30-65%. The materials in above proportions are mixed fully, injected evenly on a frictional surface of a bearing to be processed, lapped at 900-1500 r / min for 2-5 minutes, ultrasonically washed by detergent, or washed by cleaning gasoline when the lapping agent is of low amount. The chemical lapping agent is to carry out chemical erosion and mechanical grinding by using the physical and chemical properties of the material, and join in an organic way the specialty of nanometer material, so as to improve the surface shape, and reduce vibration and noise on the frictional surfaces of bearings. The invention can effectively reduce vibration 2-8 dB in bearings.

Owner:DATANG LUOYANG CO GENERATION POWER

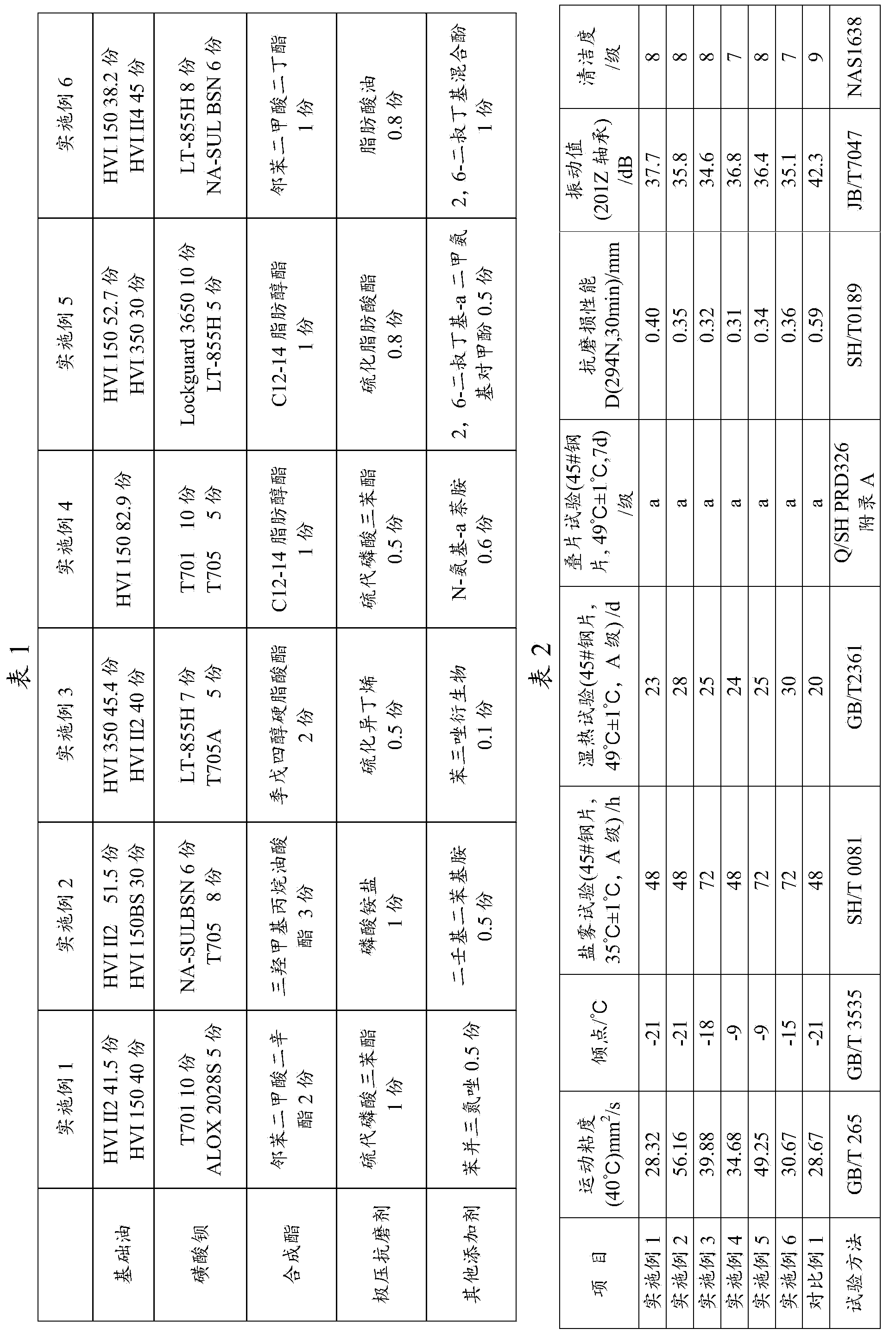

Antirust oil composition, and preparation method and application thereof

ActiveCN104342252AHigh degree of refinementImprove cleanlinessLubricant compositionRust converterOil soluble

The invention relates to an antirust oil composition, and a preparation method and application thereof, and mainly solves the problem of incapability of simultaneously implementing rust prevention and high cleanliness in the prior art. The composition comprises the following components in parts by weight: a) 75-90 parts of base oil, b) 5-15 parts of oil-soluble barium sulfonate rust inhibitor, c) 1-3 parts of synthetic ester, d) 0.5-1 part of extreme-pressure antiwear additive and e) 0.1-1 part of other additives. The technical scheme well solves the problem, and can be used in industrial production of the high-cleanliness antirust oil composition.

Owner:CHINA PETROLEUM & CHEM CORP

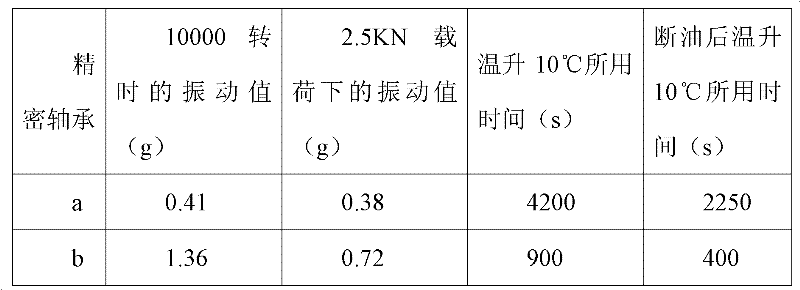

Method for manufacturing novel super-high speed precision ball bearing

InactiveCN104674177AImprove performanceImprove temperature rise performanceVacuum evaporation coatingSputtering coatingBall bearingSteel ball

The invention discloses a method for manufacturing a novel super-high speed precision ball bearing. The method comprises the following steps: (a) preparing a Cr-N-C gradient compound coating; (b) washing a steel ball sample and drying with cold air; (c) highly vacuumizing by putting the steel ball in a cavity; (d) introducing Ar2, exerting a negative bias after rising of the air pressure, opening a Cr target to promote the current, washing the matrix, and opening a rotary workpiece clamp to rotate the steel ball in a constant speed; (e) reducing the negative bias and the chromium target current; (f) depositing the Cr-N-C gradient compound coating by exerting a negative bias on the matrix, wherein the Cr-N-C gradient compound coating is composed of a Cr bottom layer, a Cr-N transition layer and a Cr-N-C work layer; and (9) closing the Cr target, the C target and the nitrogen, and continuously introducing an argon. By adopting the technical solution provided by the invention, the temperature rise of the precision ball bearing can be greatly reduced, the vibration of the bearing can be reduced and the vibration stationarity can be increased, and then the high speed performance of the precision ball bearing and the reliability of the performance life can be increased and simultaneously the loading ability can be increased.

Owner:LUOYANG INST OF SCI & TECH

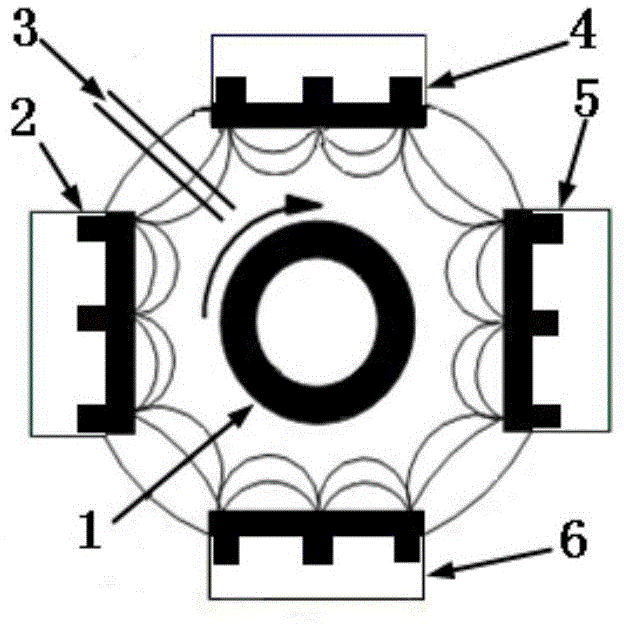

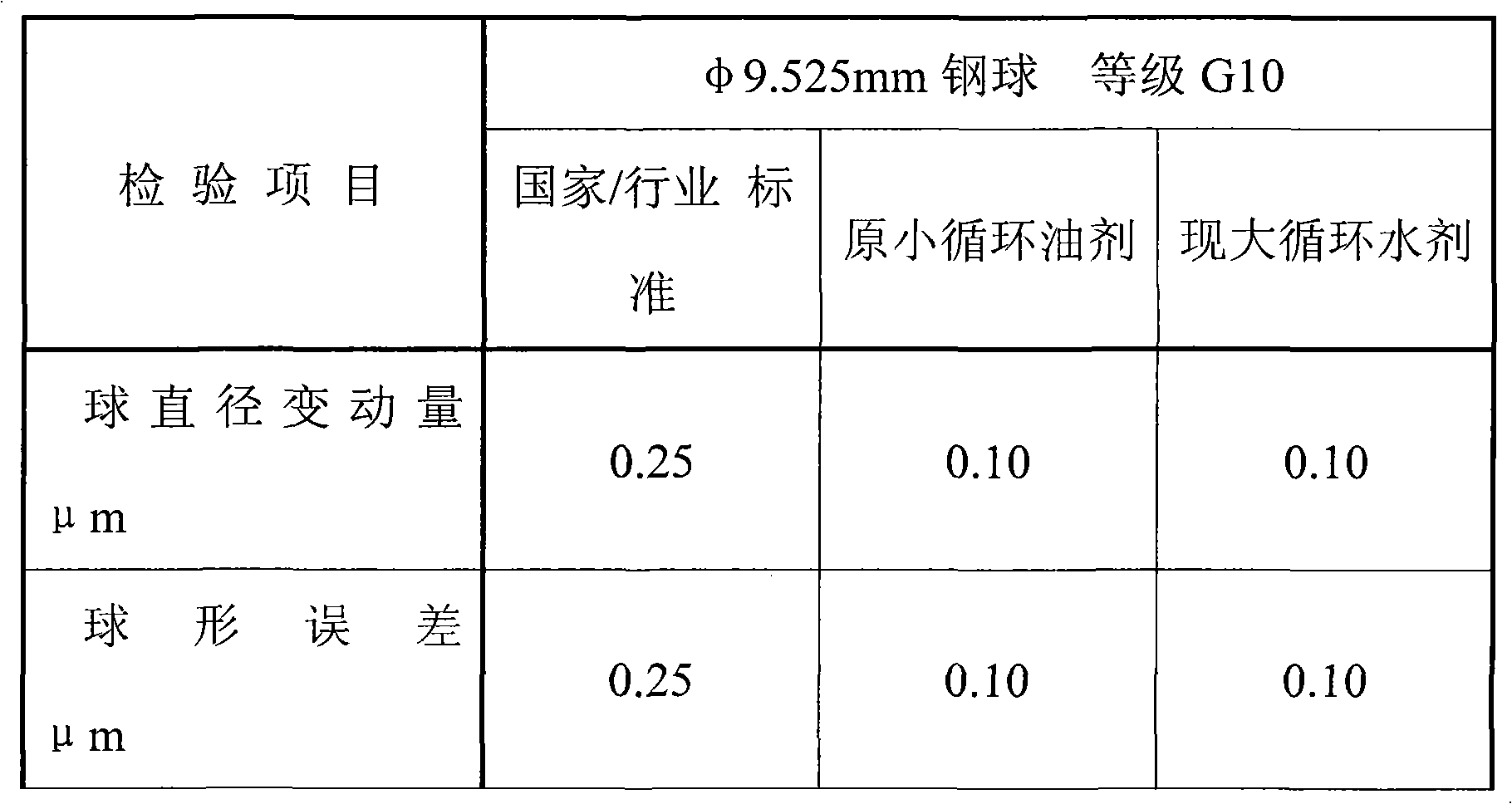

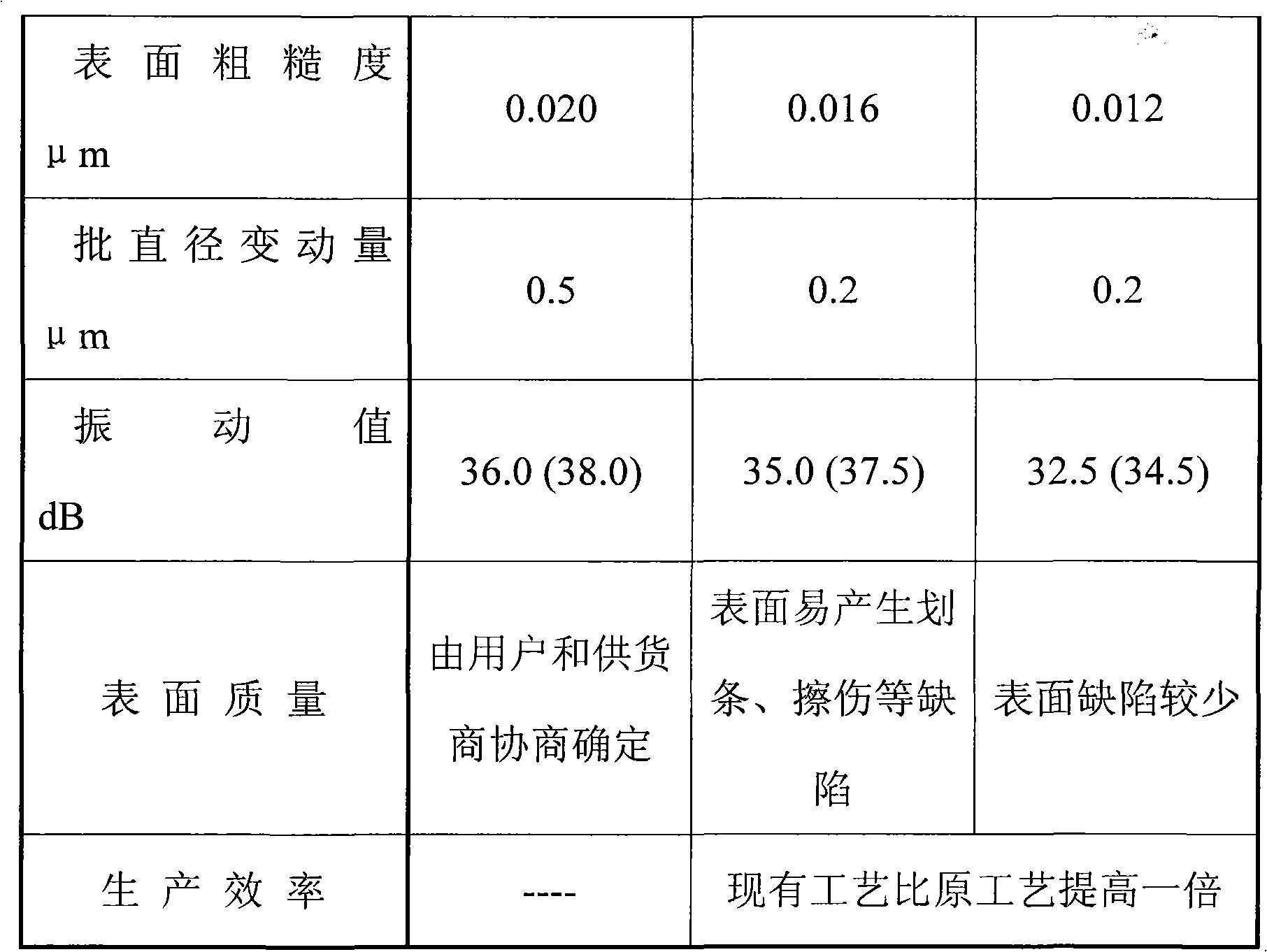

Large-cycle water-aqua grinding process for precision steel ball

ActiveCN102211312AReduce pollutionImprove production conditionsLapping machinesChromium sesquioxideChromium(III) oxide

Owner:力星钢球(南阳)有限责任公司

Method for preparing and using emulsion type lapping liquid for steel ball grinding

ActiveCN101747864AImprove surface quality and precisionImprove overall craftsmanshipOther chemical processesEmulsionWater tanks

The invention discloses a method for preparing emulsion type lapping liquid for steel ball grinding, comprising a suspension and a circulating liquid, wherein the suspension is prepared from 70-75 percent of 46# machine oil and 25-30 percent of refined oleic acid; the circulating liquid is prepared from 34-40 percent of 46# machine oil, surplus coal oil, 6-10 percent of oleic acid, 4-6 percent of sodium petroleum sulfonate, 1-3 percent of sorbitan monooleate, 5-8 percent of polyoxyethylene castor oil, 2-4 percent of triethanolamine oleate, 1.5-3 percent of diethanolamine borate and 0.5-1 percent of potassium hydroxide. One part of chromium oxide is added to two parts of suspensions for mixing in a thin paste state, and 20-30ml chromium oxide suspension is needed by each 200-250kg steel ball and is brushed on the steel ball in one step; nine parts of tap water are added to one part of the circulating liquid for stirring and uniformly forming an emulsion type circulating liquid, and then the emulsion type circulating liquid is disposed in a water tank of a refining mill for circularly flushing the steel ball, and the grinding is finished by 20-24 hours. The autorotation of the steelball is fine in the refine grinding process, so the steel ball and plate grooves can be prevented from being corroded.

Owner:上海德润宝特种润滑剂有限公司

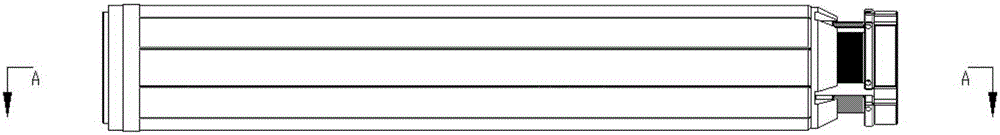

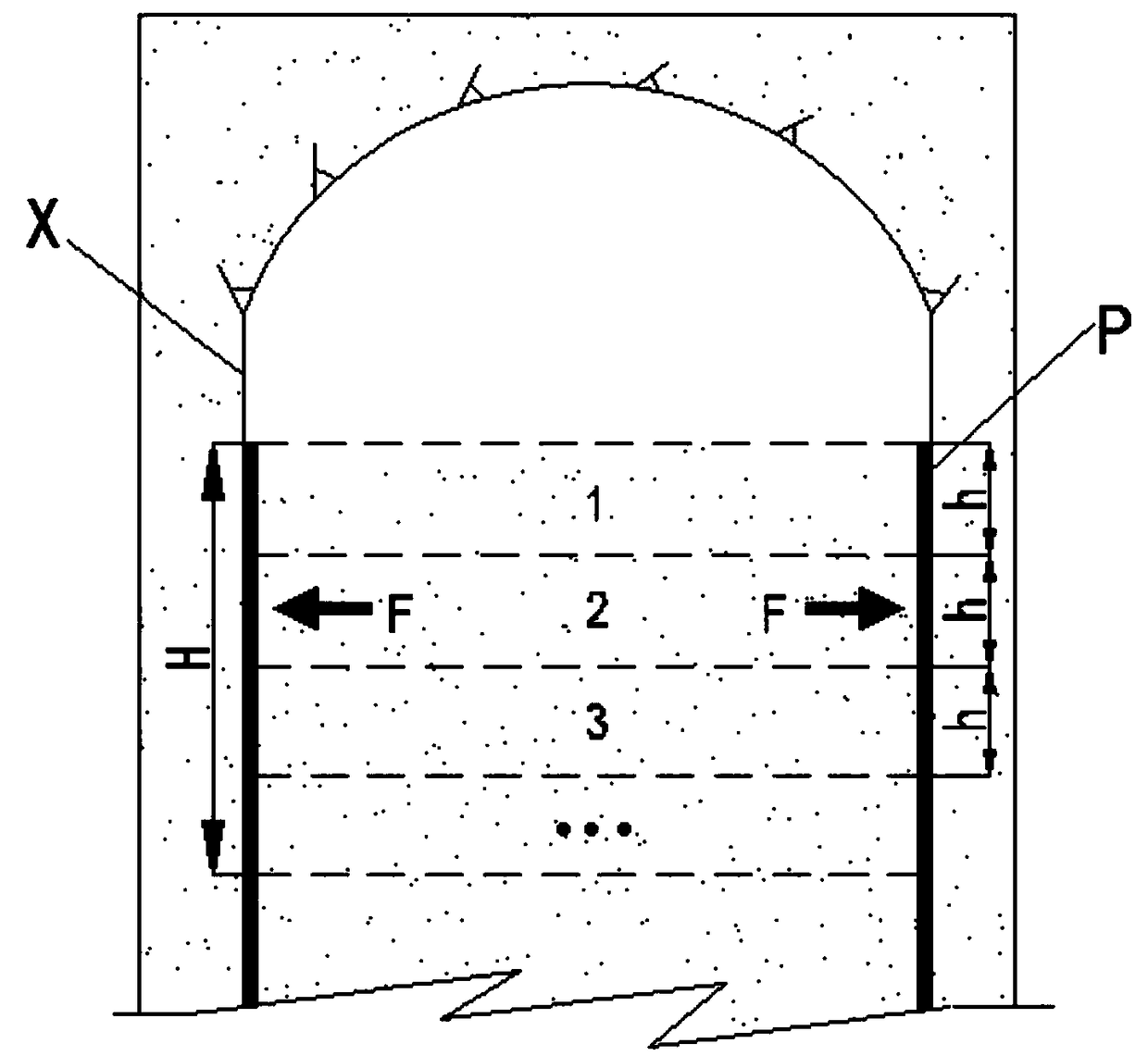

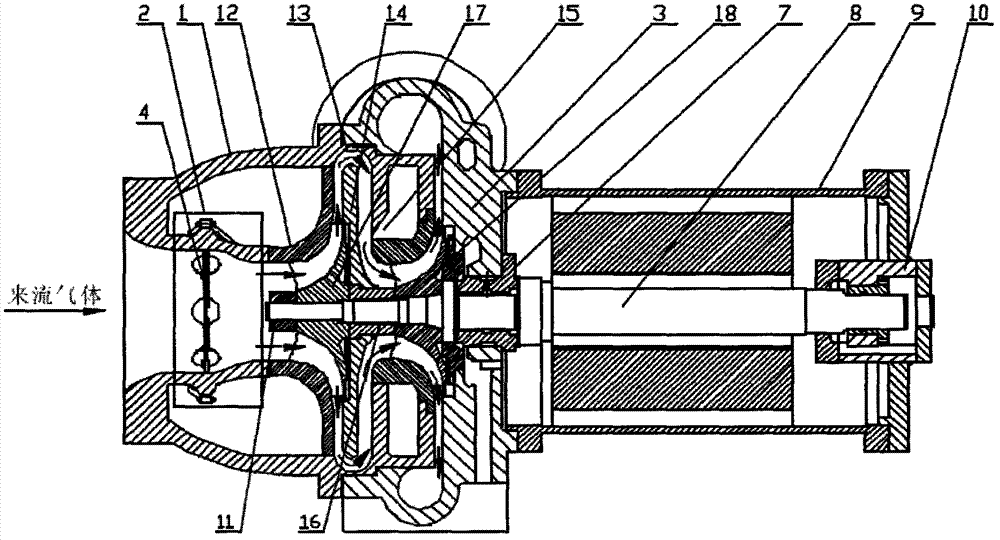

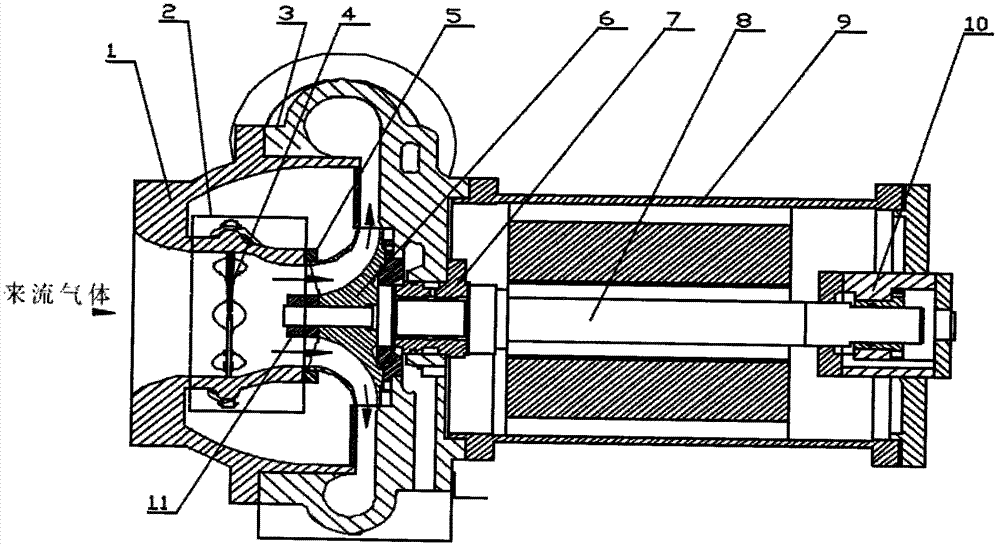

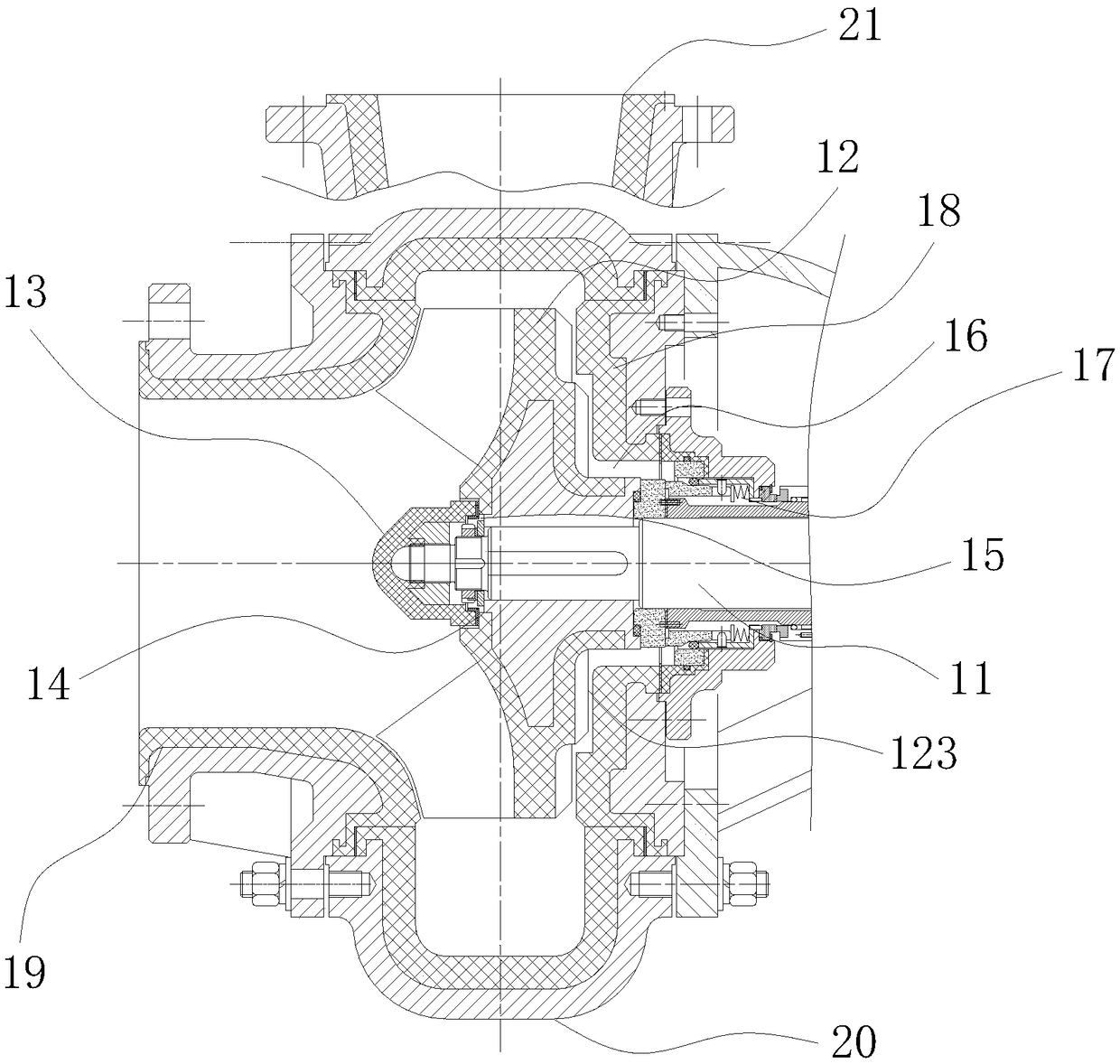

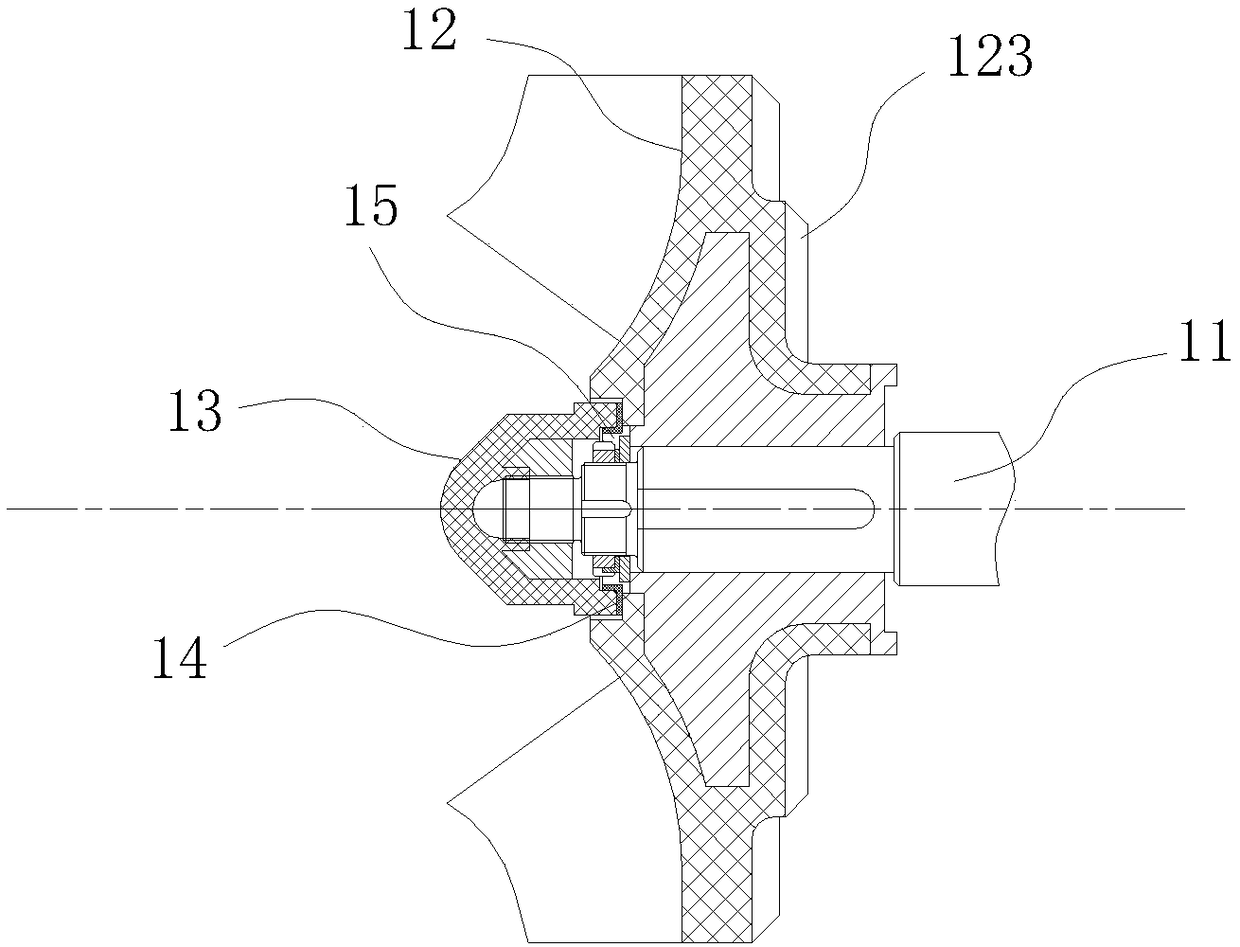

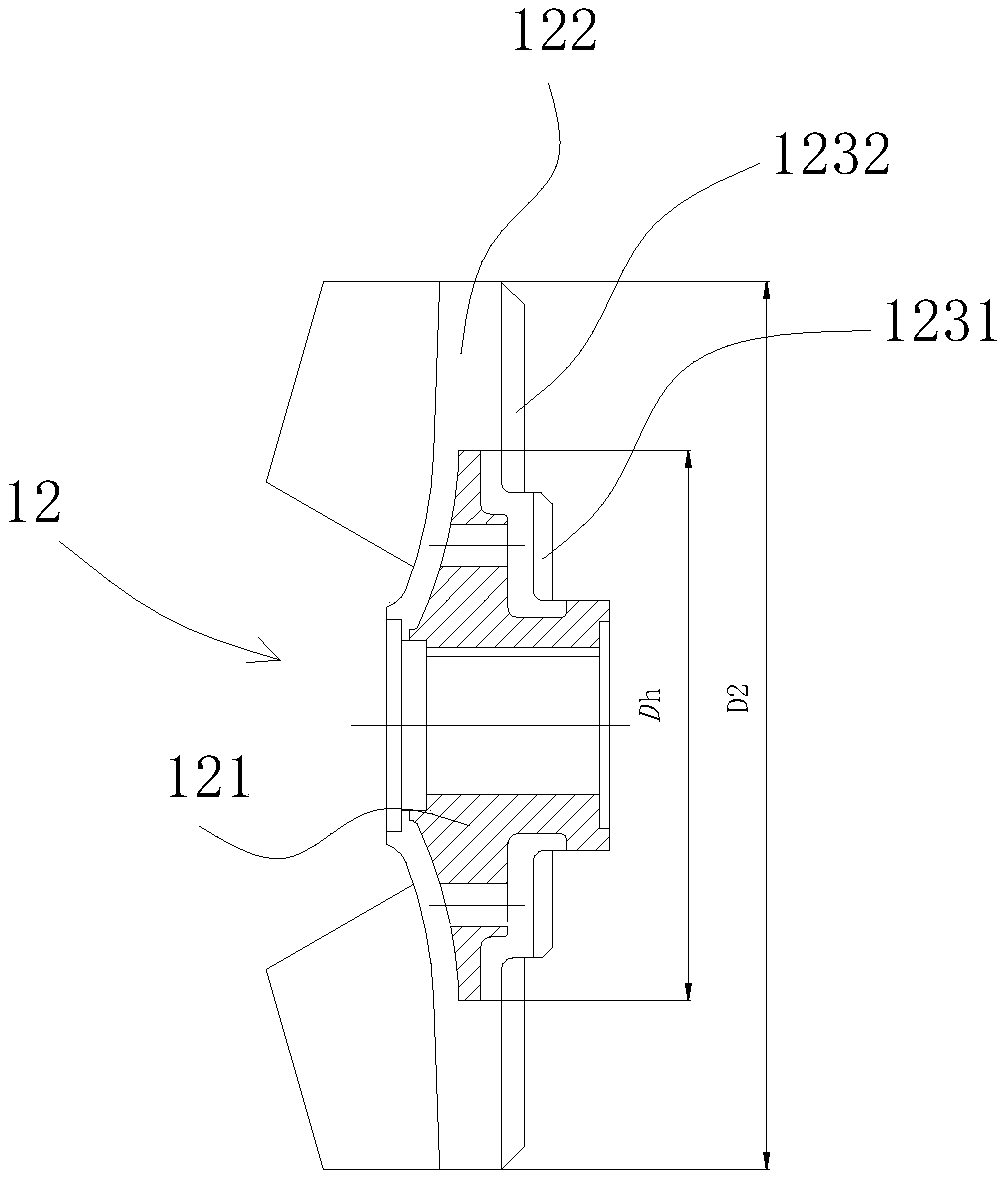

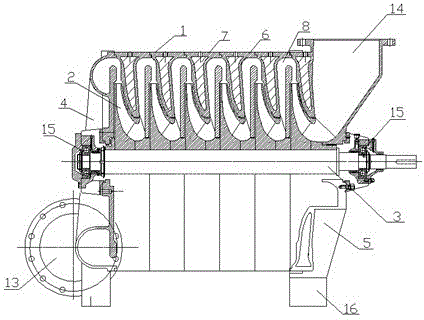

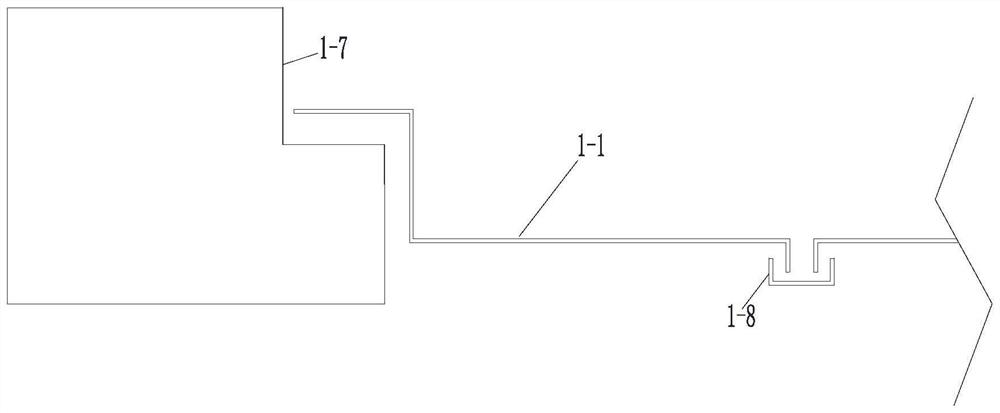

Direct-connection power generation equipment for natural gas radial turbine expansion machine

ActiveCN110439634AHigh degree of integrationReduce the vibration valueLeakage preventionStatorsImpellerNuclear engineering

The invention provides direct-connection power generation equipment for a natural gas radial turbine expansion machine, and belongs to the technical field of power generation of the radial turbine expansion machine. The natural gas radial turbine expansion machine comprises a shape ring, an impeller, a nozzle ring, a volute and a power generator main shaft. The power generator main shaft penetrates through the volute and is rotationally connected with the volute, and a gas inlet and a gas outlet which are in dry gas seal are formed in the side wall of the volute, the shape ring is installed onthe inner wall of the volute, the nozzle ring is arranged on the inner wall of the volute, and the impeller is fixedly installed at the input end of the power generator main shaft through a stay bolt. A high-speed permanent magnet synchronous generator comprises a power generator stator assembly, the power generator main shaft and a power generator shell, the power generator stator assembly is fixedly installed on the power generator shell, and the power generator main shaft is rotationally connected with the power generator shell through a first magnetic suspension bearing and a second magnetic suspension bearing. The volute is fixedly connected with the power generator shell. A speed reduction box device is omitted, the occupied area is small, and the equipment is good in performance, high in unit efficiency and small in loss.

Owner:HARBIN ELECTRIC CO LTD

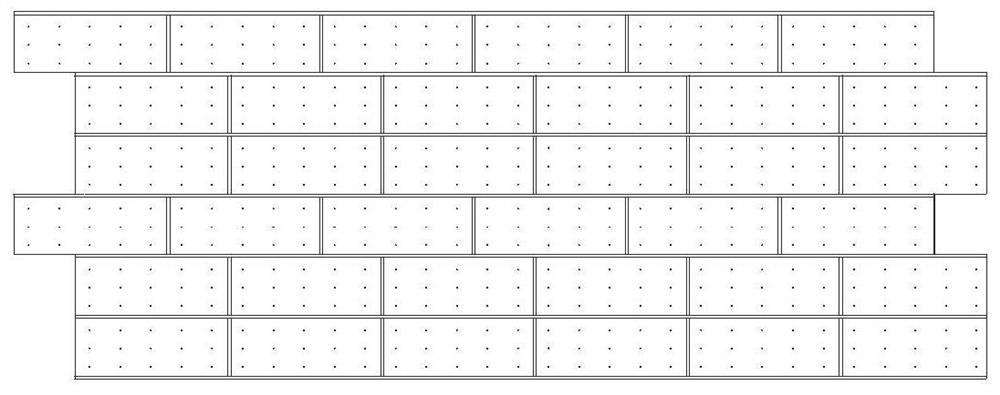

Novel tripartite direct yarn drawing machine for glass fiber

The invention relates to a novel tripartite direct yarn drawing machine for glass fiber. The novel tripartite direct yarn drawing machine comprises a machine body, two machine heads mounted on the machine body are different in mass, and the mass difference mainly concentrates on the front end of each machine head, and the difference of mass values of the two machine heads ranges from 8 kg-15 kg; the two machine heads are a first machine head and a second machine head respectively. The novel tripartite direct yarn drawing machine has the advantages as follows: during high-speed rotation of the machine heads, the resonant frequencies of the two machine heads are not consistent due to mass difference, the two machine heads don't influence each other, and resonance cannot be caused, so that the vibration value is reduced; a balancing weight and end covers are convenient to mount and dismount, the vibration value of the machine heads can be effectively reduced, and the forming quality of a yarn ball is guaranteed.

Owner:泰安佳成机电科技有限公司

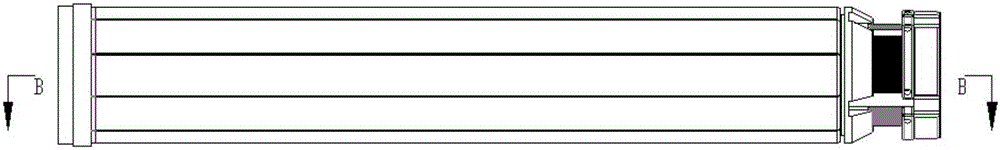

Excavation method for middle and lower portion of underground cavern in high-crustal-stress area

InactiveCN108999613AAvoid harmReduce local stress concentrationBlastingTunnelsStress concentrationShotcrete

The invention discloses an excavation method for the middle and lower portion of an underground cavern in a high-crustal-stress area. After excavation of the top of the cavern, excavation is carried out in a layered way from top to bottom; deep-hole pre-crack explosion is carried out along the sidewall structure line of the cavern, a pre-crack is formed, the depth of the crack is 3 to 5 times of the thickness of a layered bench explosion layer, after that a cycle of crack is formed, and thin-layer bench explosion excavation is carried out on a rock within the crack depth range in 3 to 5 layersand shotcrete bolting is completed timely till excavation construction of the rock within the pre-crack depth range is completed; next deep-hole pre-crack explosion is carried out, and excavation iscarried out layer by layer till the design elevation of the bottom of the underground cavern is reached; and the depth and pitch of the pre-crack explosion hole are 12-20m and 0.8m respectively. Thus,construction of a relatively deep pre-crack can be implemented in advance, part of stress force can be released in advance, so that surrounding rocks can make stage and limited stress adjustment, andthe stress change rate of the surrounding rack is controlled by reserving the rock to be excavated of the cavern, and the local stress is less concentrated.

Owner:SINOHYDRO BUREAU 7 CO LTD

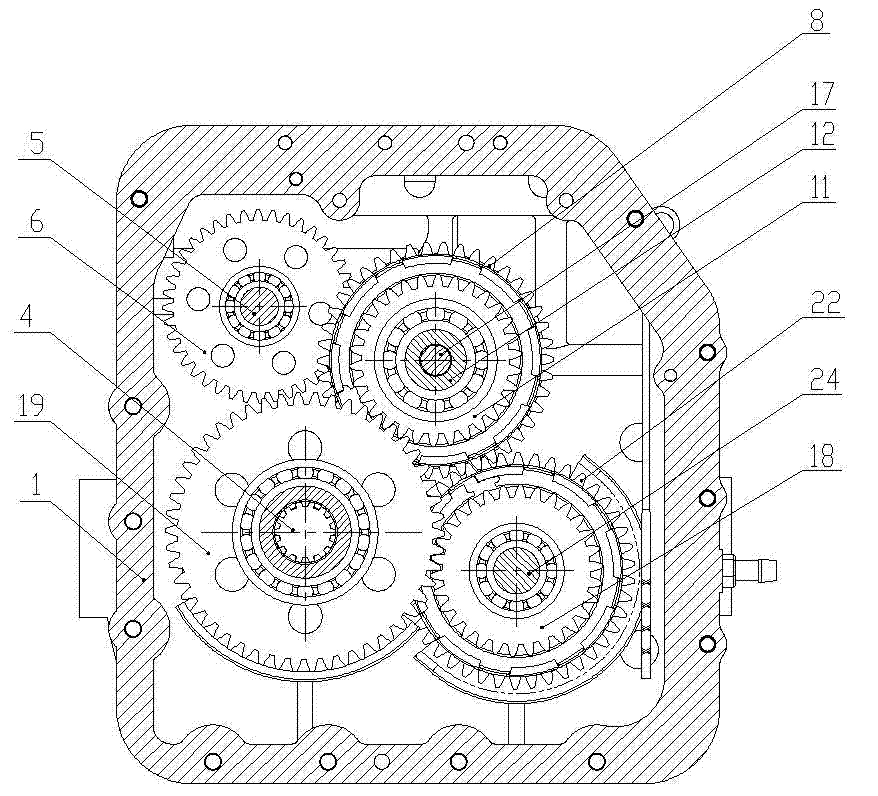

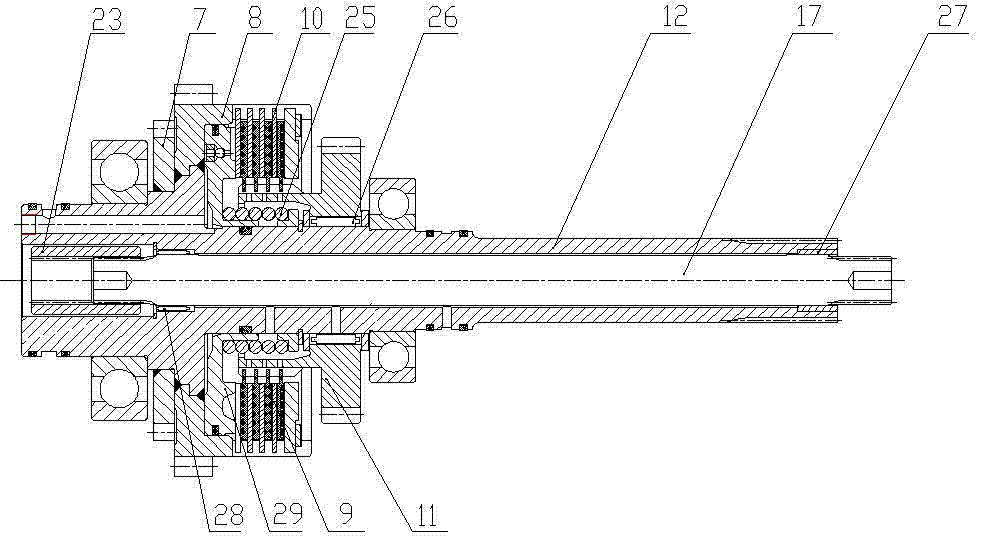

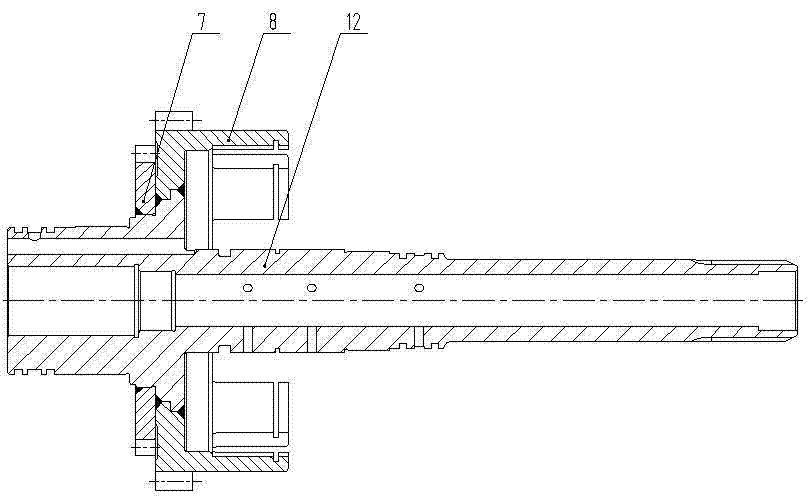

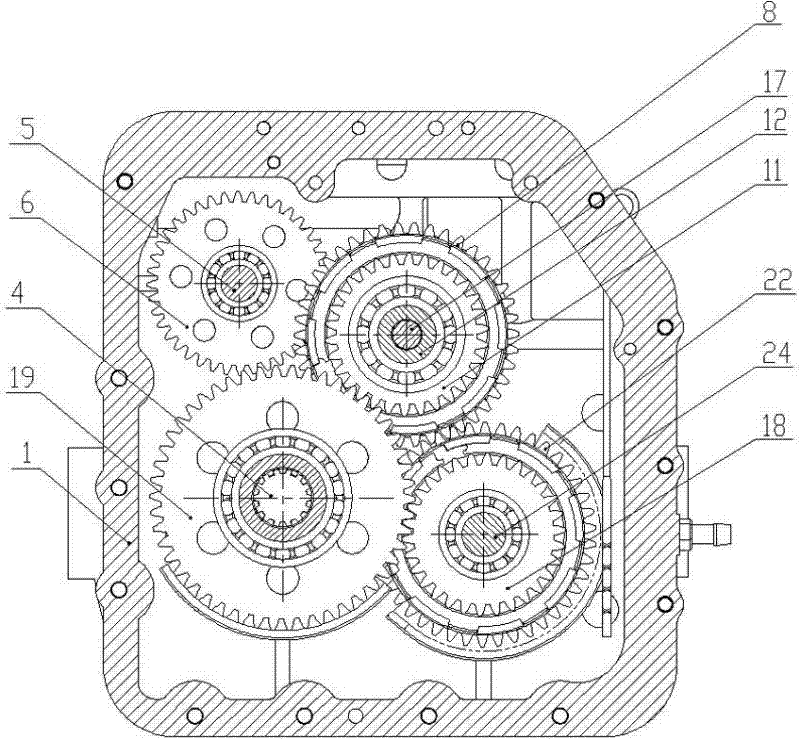

Hydrodynamic transmission used for hydrodynamic forklift and provided with pump mechanism

InactiveCN102758900AReduce vibrationImprove handling comfortGear lubrication/coolingFluid gearingsGear wheelDrive shaft

The invention relates to a hydrodynamic transmission used for a hydrodynamic forklift and provided with a pump mechanism. A lubrication pump transmission shaft is arranged on one side of the upper part of a transmission body, a lubrication pump is arranged at an outward extending end of the lubrication pump transmission shaft, and a first lubrication pump transmission gear is arranged on the lubrication pump transmission shaft; a hollow working pump transmission shaft tube is arranged on the other side of the upper part, a forward gear clutch and a forward gear of a second lubrication pump transmission gear are sequentially fixed on one side of the working pump transmission shaft tube, the forward gear clutch includes a forward gear clutch gear, and an oil supply pump and a hydrodynamic torque converter are arranged on the other side; a working pump transmission shaft is arranged in the working pump transmission shaft tube, and the outer end part of the working pump transmission shaft is connected with a working pump; a backward gear clutch shaft is arranged below the working pump transmission shaft tube, a backward gear clutch and a backward gear are sequentially arranged on the backward gear clutch shaft, and a clutch gear is arranged on a casing of the backward gear clutch; and a transmission shaft is arranged below the lubrication pump transmission shaft, and an output gear is arranged on the transmission shaft. The hydrodynamic transmission has two power output ports, and is provided with the working pump and the lubrication pump at the same time, thereby facilitating an entire vehicle matched wet-type brake drive axle.

Owner:ANHUI HELI CO LTD

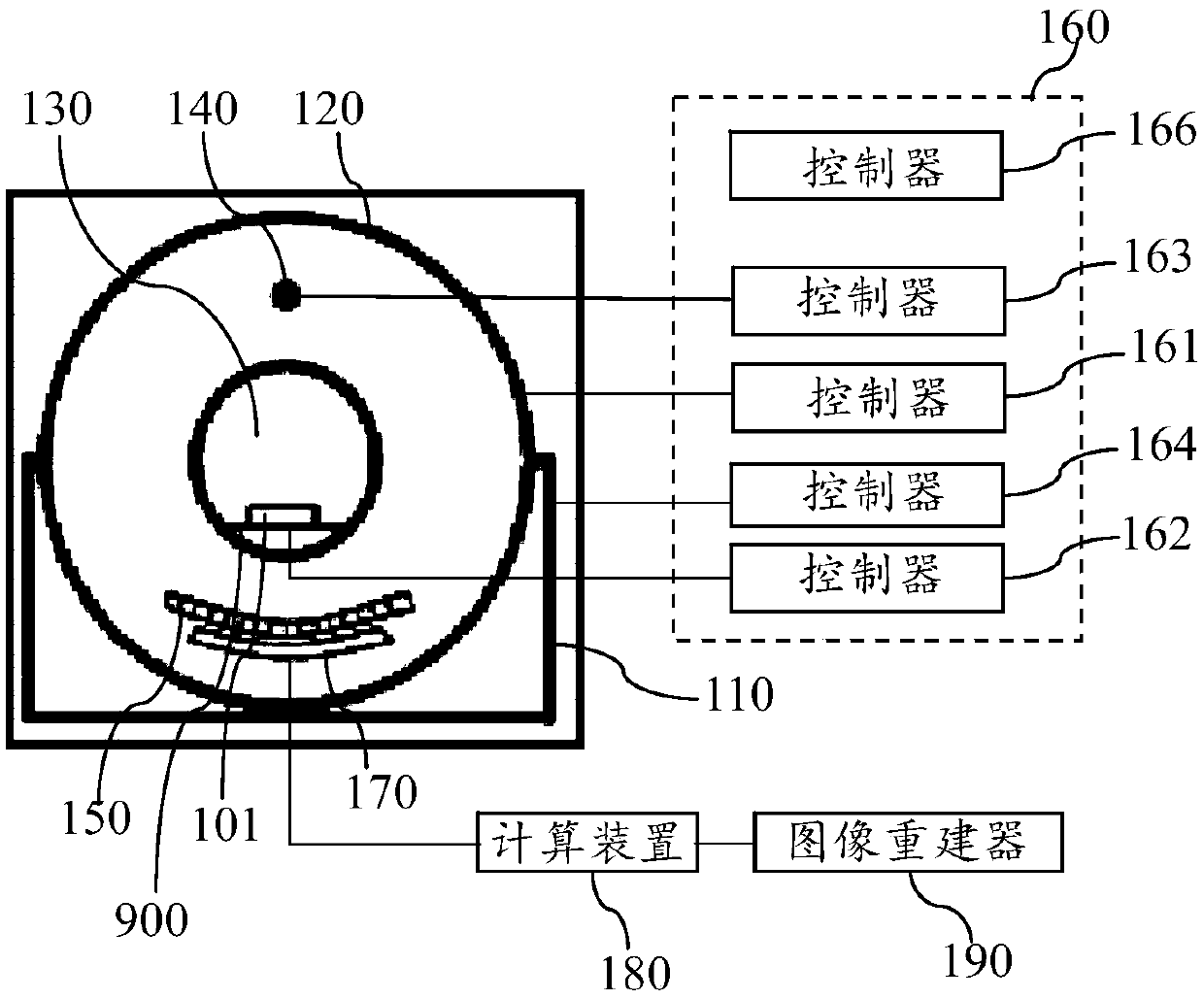

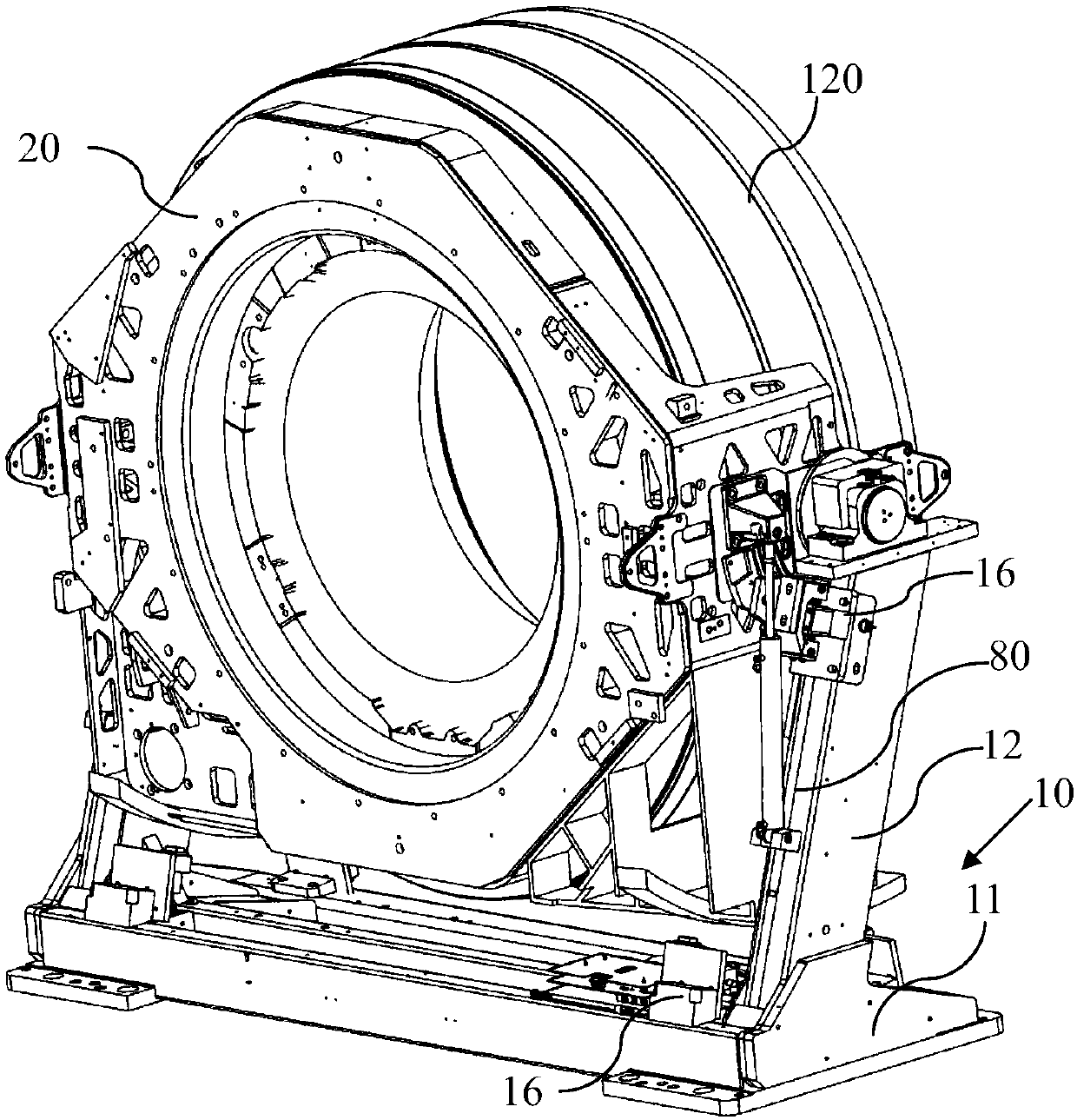

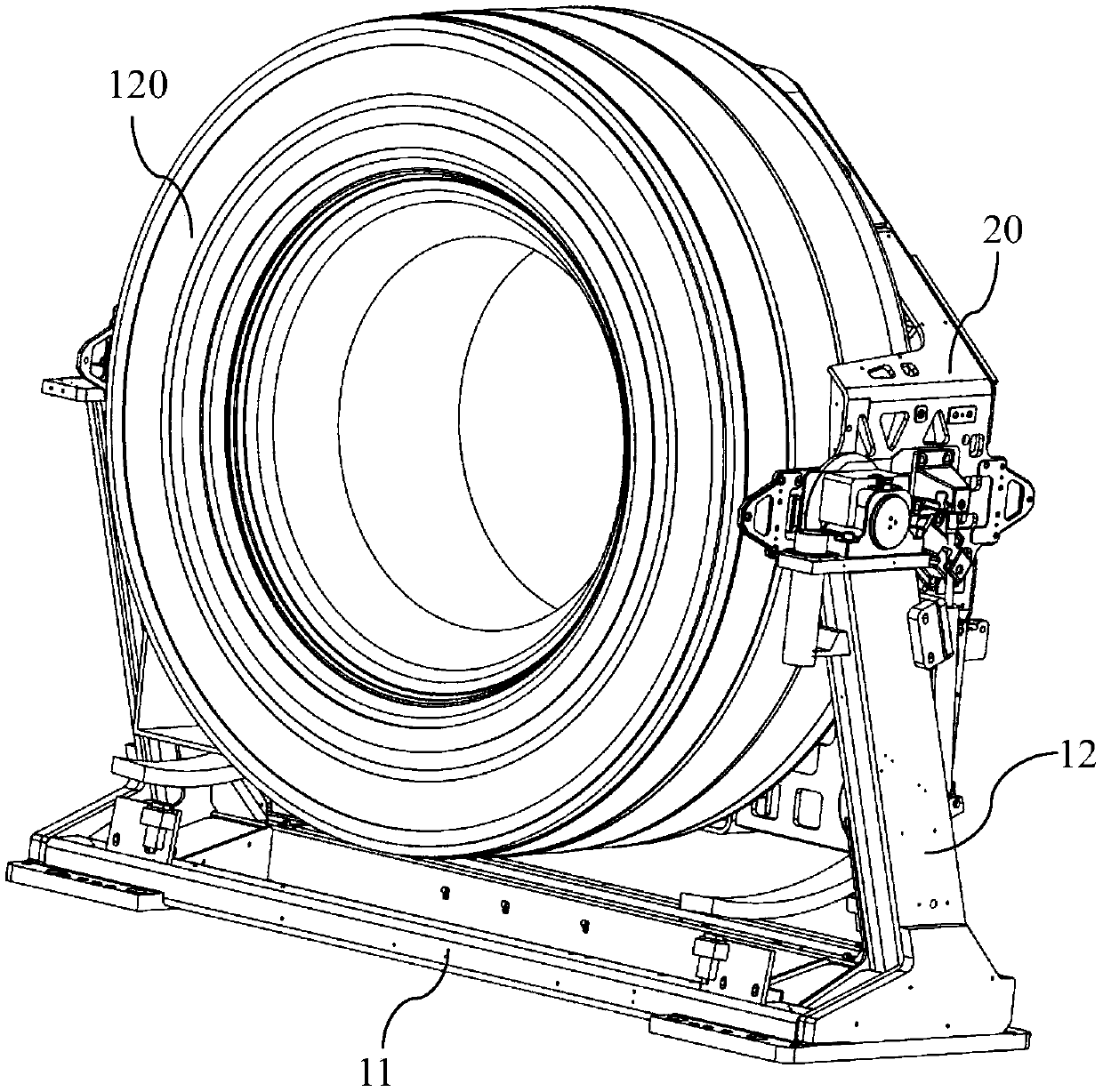

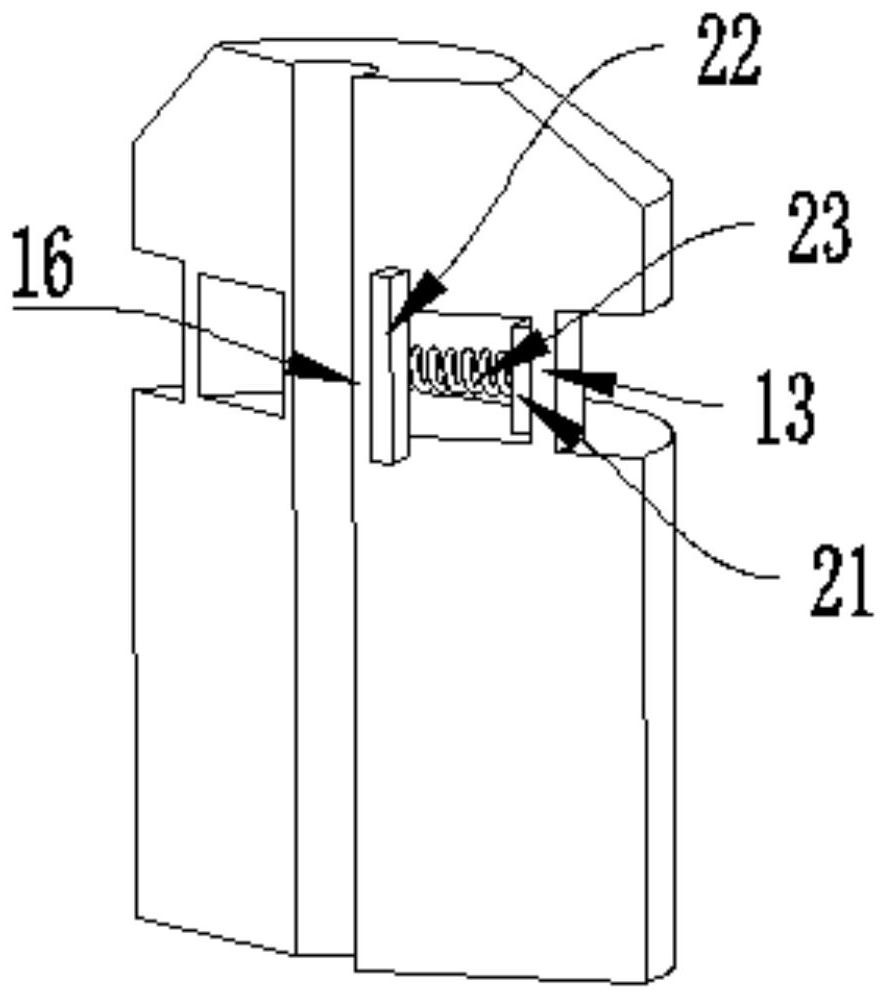

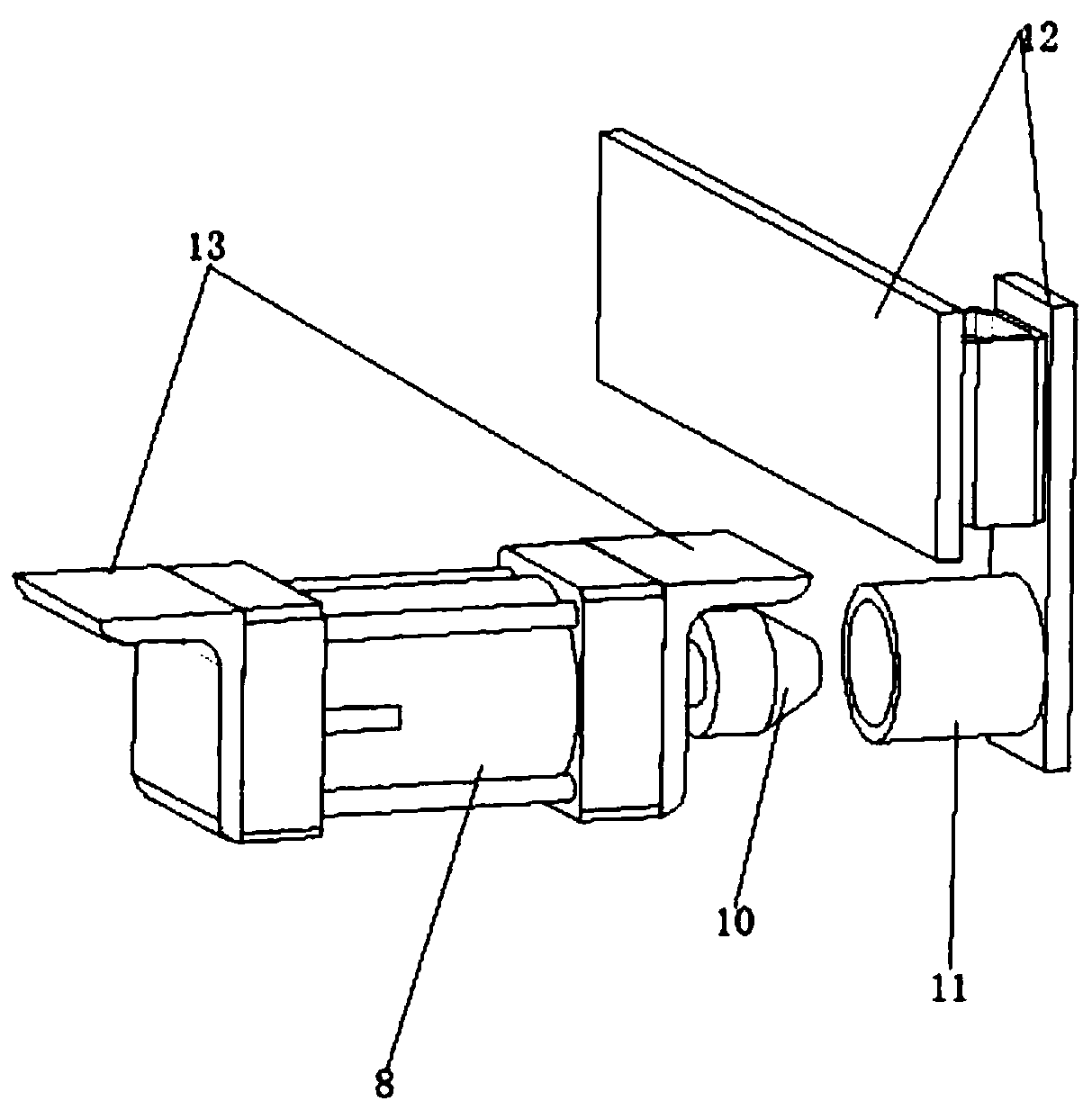

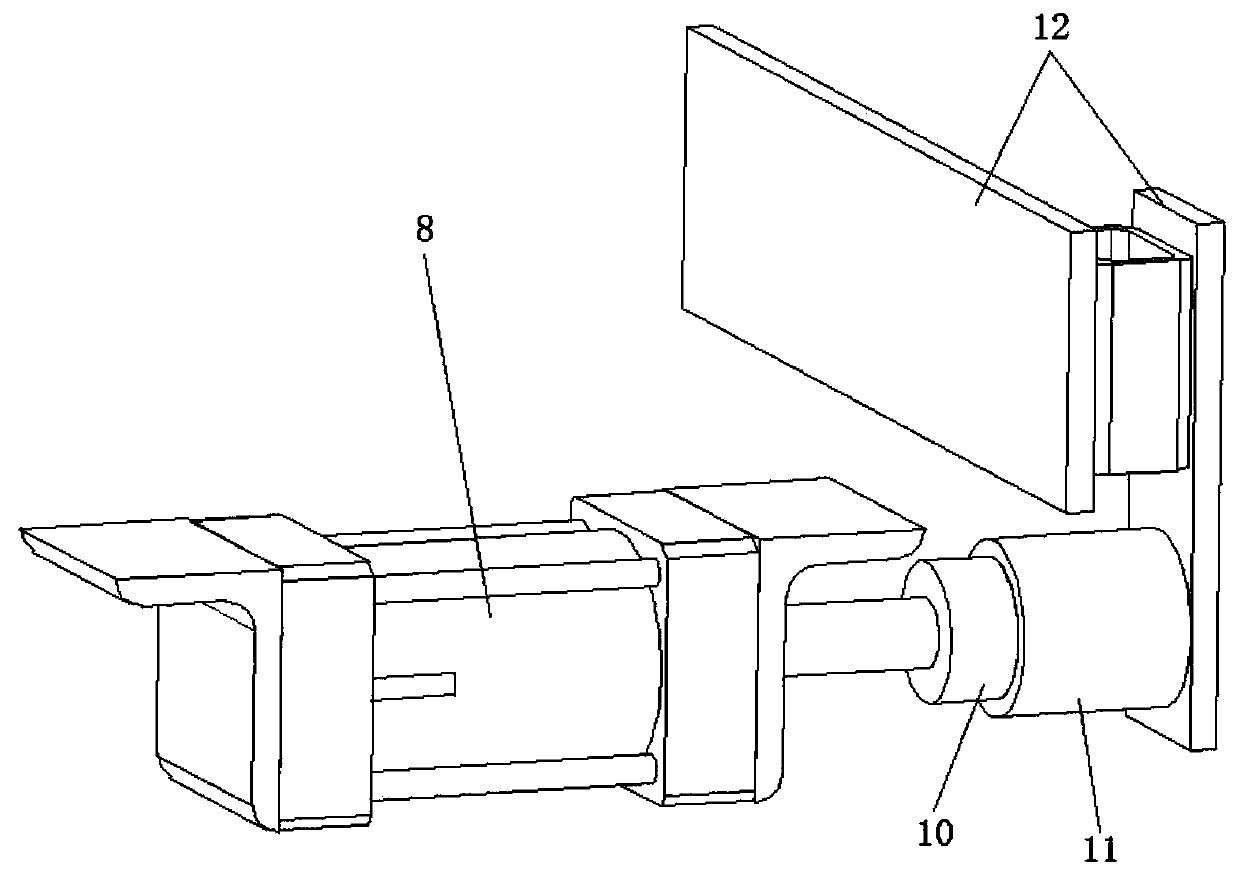

Scanning bracket of medical imaging system

PendingCN111374691AFast spinReduce the vibration valueComputerised tomographsTomographyClassical mechanicsEngineering

The invention provides a scanning bracket for a medical imaging system. The scanning bracket comprises a bottom support frame and a tilt support frame connected to each other, and the tilt support frame can be tilted relative to the bottom support frame. The scanning bracket also comprises a locking mechanism connected between the bottom support frame and the tilt support frame, and the locking mechanism is in an unlocked state during the tilting of the tilt support frame relative to the bottom support frame; and the locking mechanism is in a locked state when the tilt support frame is stationary relative to the bottom support frame, so as to prevent the tilt support frame from moving relative to the bottom support frame.

Owner:GENERAL ELECTRIC CO

Hydraulic transmission for 2-3.5t hydraulic forklift with pump mechanism

ActiveCN102261451AReduce vibrationImprove handling comfortGear lubrication/coolingFluid gearingsDrive shaftGear wheel

The invention relates to a hydrodynamic transmission for a 2-3.5t hydraulic fork truck with a pump mechanism. A lubricating pump transmission shaft is arranged at one side of the upper part of a transmission box, a lubricating pump is arranged at the extended end of the lubricating pump transmission shaft, and a lubricating pump transmission gear A is arranged on the lubricating pump transmissionshaft; a hollow working pump transmission shaft tube is arranged at the other side of the upper part of the transmission box, a forward clutch of a lubricating pump transmission gear B and a forward gear are sequentially and fixedly arranged at one side of the working pump transmission shaft tube, the forward clutch comprises a forward clutch shell gear, and an oil supply pump and a hydraulic torque converter are arranged at the other side of the working pump transmission shaft tube; a working pump transmission shaft is positioned in the working pump transmission shaft tube, and the external end of the working pump transmission shaft is connected with a working pump; a backward clutch shaft is arranged below the working pump transmission shaft tube, a backward clutch and a backward gear are sequentially arranged on the backward clutch shaft, and a clutch shell gear is arranged on a backward clutch shell; and a transmission shaft is arranged below the lubricating pump transmission shaft, and an output gear is arranged on the transmission shaft. The hydrodynamic transmission is provided with two power output ports, and the working pump and the lubricating pump are simultaneously driven, so that a wet braking drive axle can be conveniently selected for a whole vehicle.

Owner:ANHUI HELI CO LTD

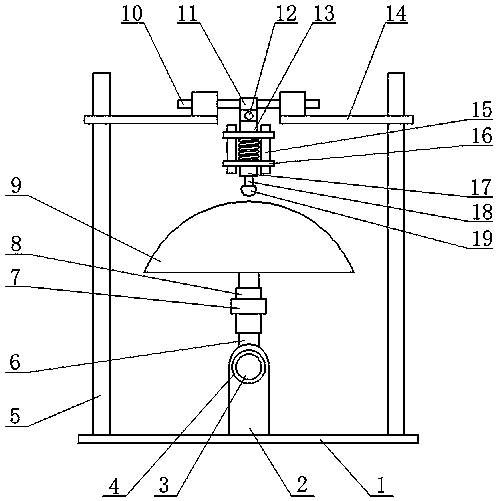

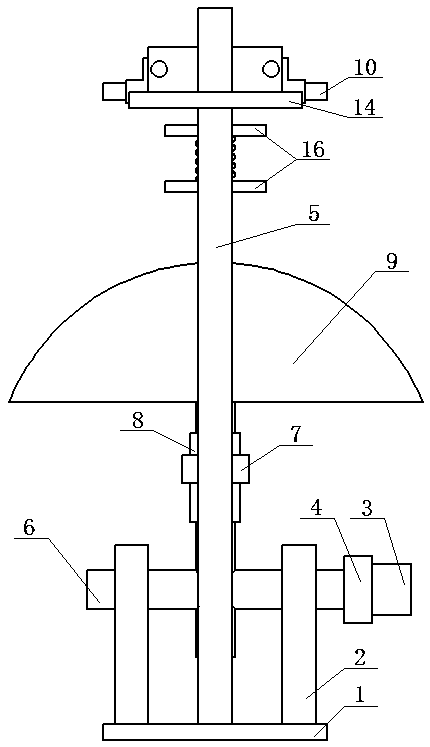

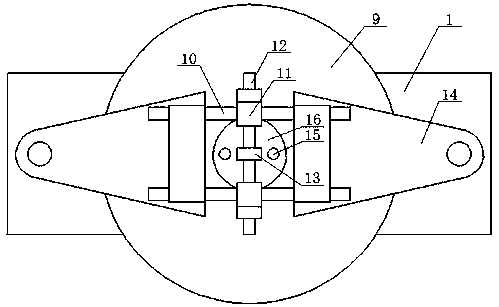

Cambered surface part polishing device

InactiveCN111558874ACompact structureReduce the vibration valueGrinding carriagesGrinding drivesPolishingElectric machine

The invention discloses a cambered surface part polishing device. The cambered surface part polishing device comprises a base, wherein the middle part of the base is provided with a cambered surface supporting plate for placing a cambered surface part, the polishing head for polishing the cambered surface part is arranged above the cambered surface supporting plate, the polishing head moves on anaxis Z, an axis X and an axis Y through a first sliding mechanism, a second sliding mechanism and a third sliding mechanism correspondingly, the cambered surface supporting plate rotates around the axis Y and the axis Z correspondingly through a first driving mechanism and a second driving mechanism to determine the position, and the polishing head is used for polishing the cambered surface part through a third driving mechanism. According to the cambered surface part polishing device, the position of the cambered surface supporting plate is adjusted by driving of a motor, the structure is compact, and the vibration value is small; and the position of the polishing head is adjusted by a mechanical structure, the structure is simple, the reliability is high, and the control precision is high.

Owner:YANSHAN UNIV

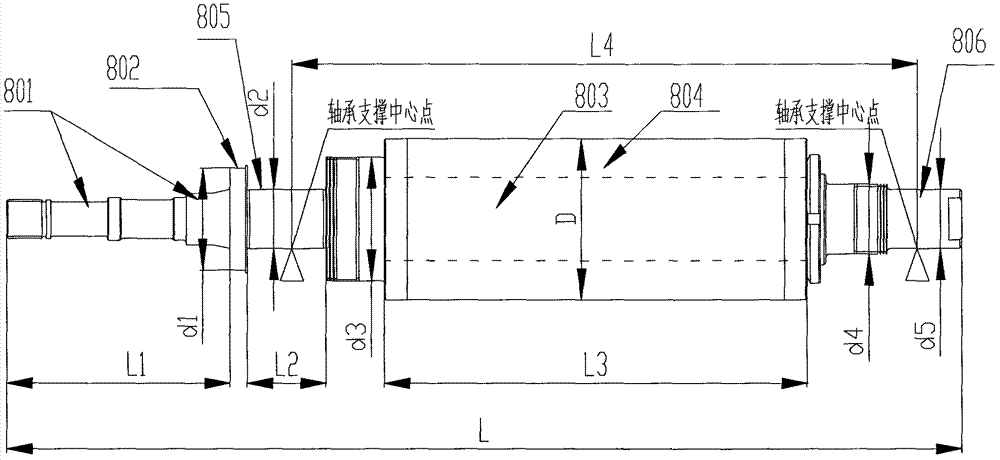

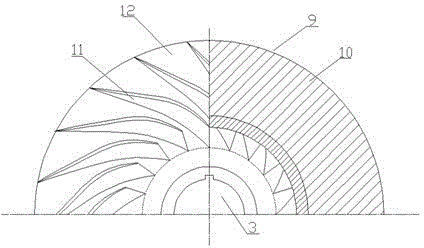

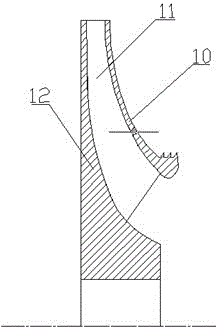

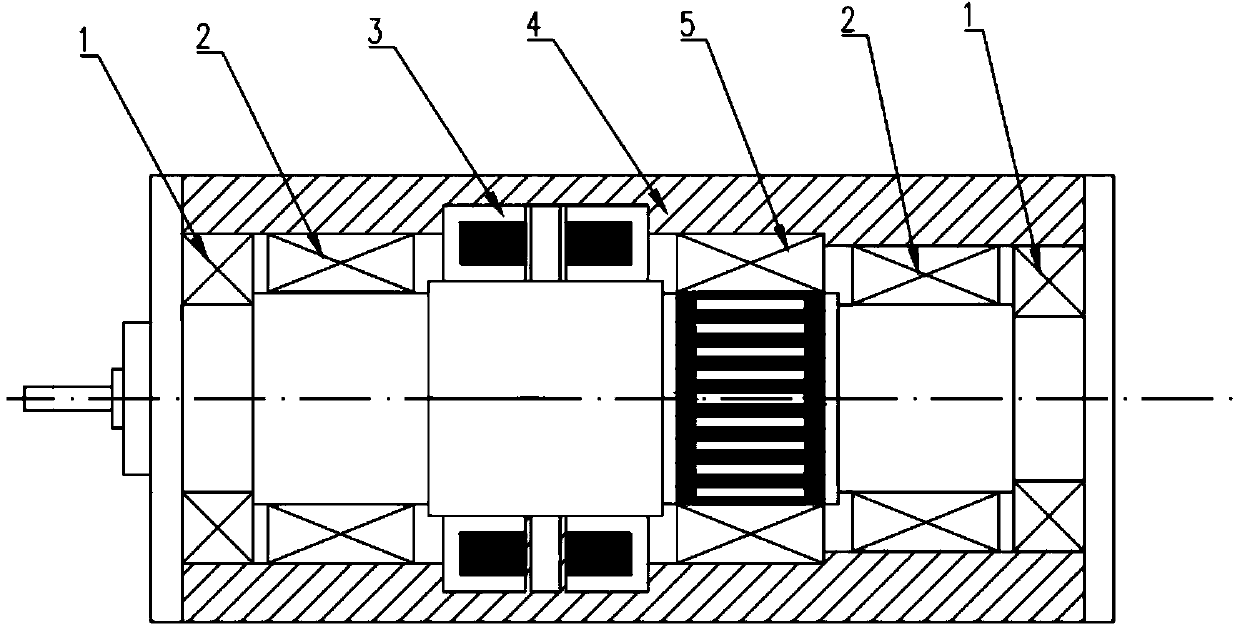

Cantilever type motor rotor for direct connection centrifugal compressor and direct connection centrifugal compressor

ActiveCN103362833ASimple structureEliminate transmission mechanical lossesPump componentsPump installationsHigh rateHigh energy

The invention discloses a cantilever type motor rotor for a direct connection centrifugal compressor. An impeller mounting part, a front bearing mounting part, a rotor iron core mounting part and a rear bearing mounting part are formed on the rotor sequentially in an axial direction, wherein a rotor iron core is mounted on the rotor iron core mounting part; the external diameter of the rotor iron core is D, and the length of the rotor iron core is L3; and a range of a ratio D / L3 of the external diameter of the rotor iron core to the axial length of the rotor iron core is 0.25-0.35. The invention further discloses the direct connection centrifugal compressor provided with the motor rotor structure. According to the centrifugal compressor, a motor is adopted to drive an impeller to rotate directly; a speed-increasing gearbox is removed; the centrifugal compressor has the advantages of high rated efficiency, small size, light weight and high energy efficiency; a rotating shaft structure is optimized; and the compressor can keep lower vibration at a high rotating speed.

Owner:GREE ELECTRIC APPLIANCES INC +1

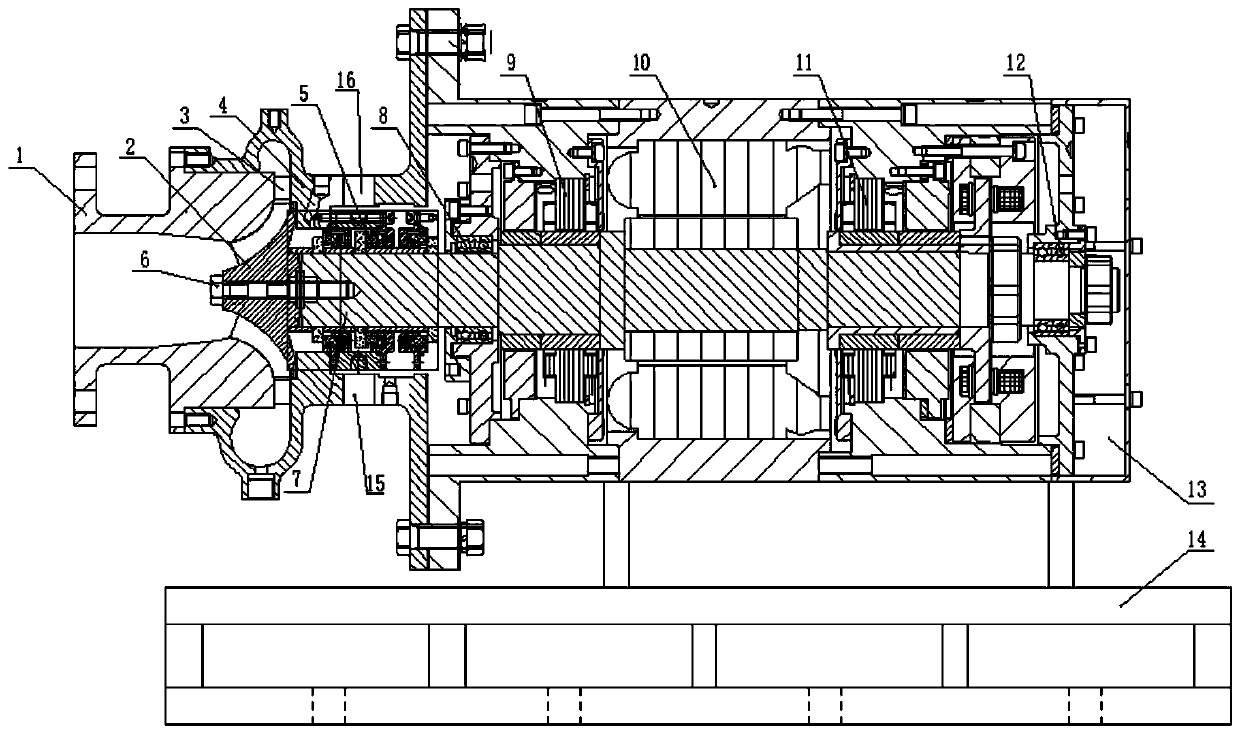

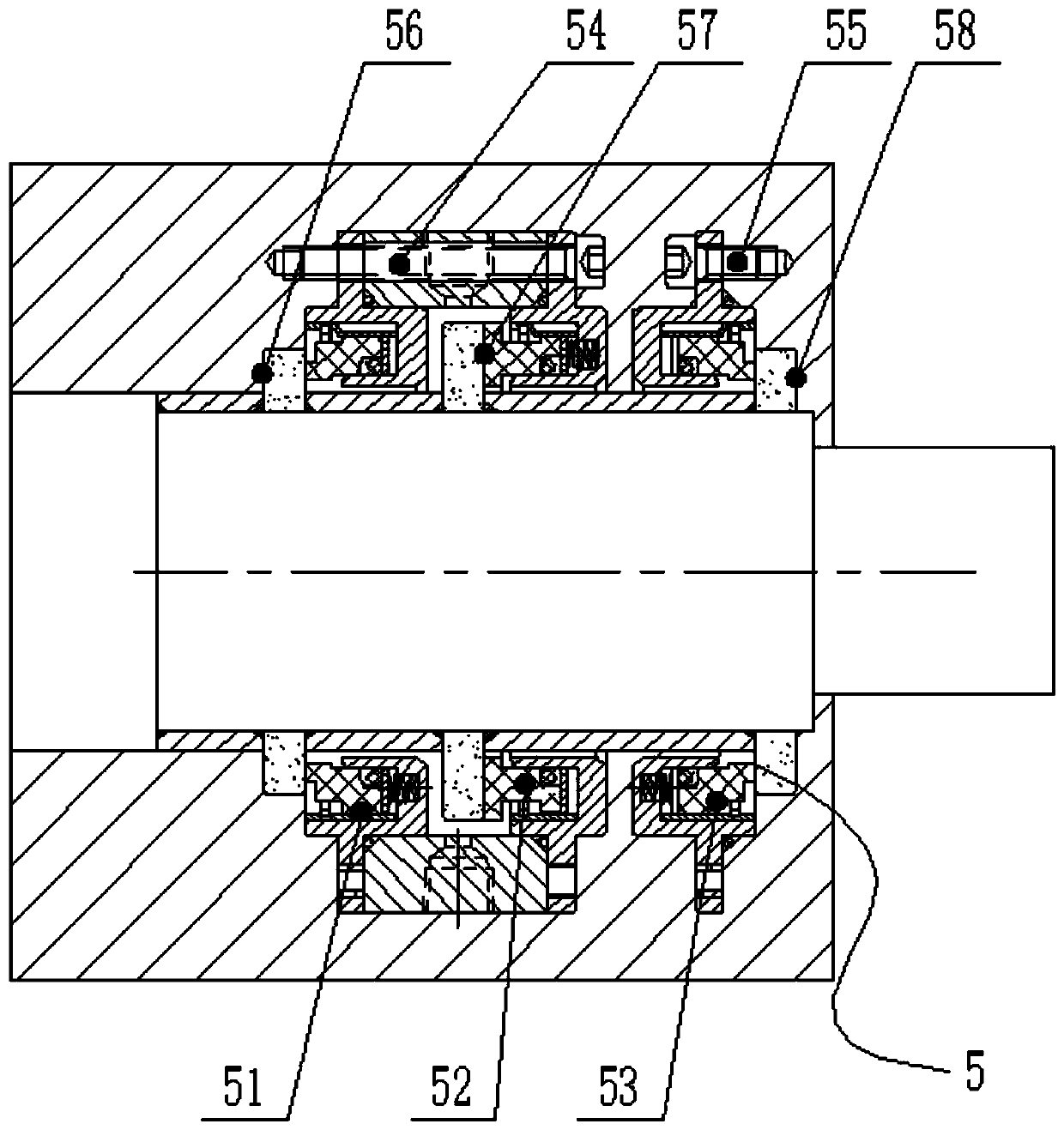

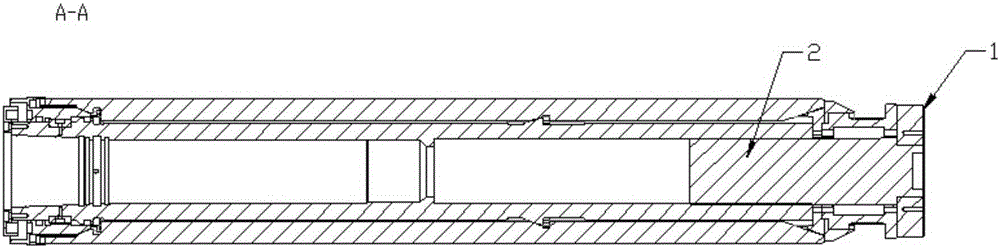

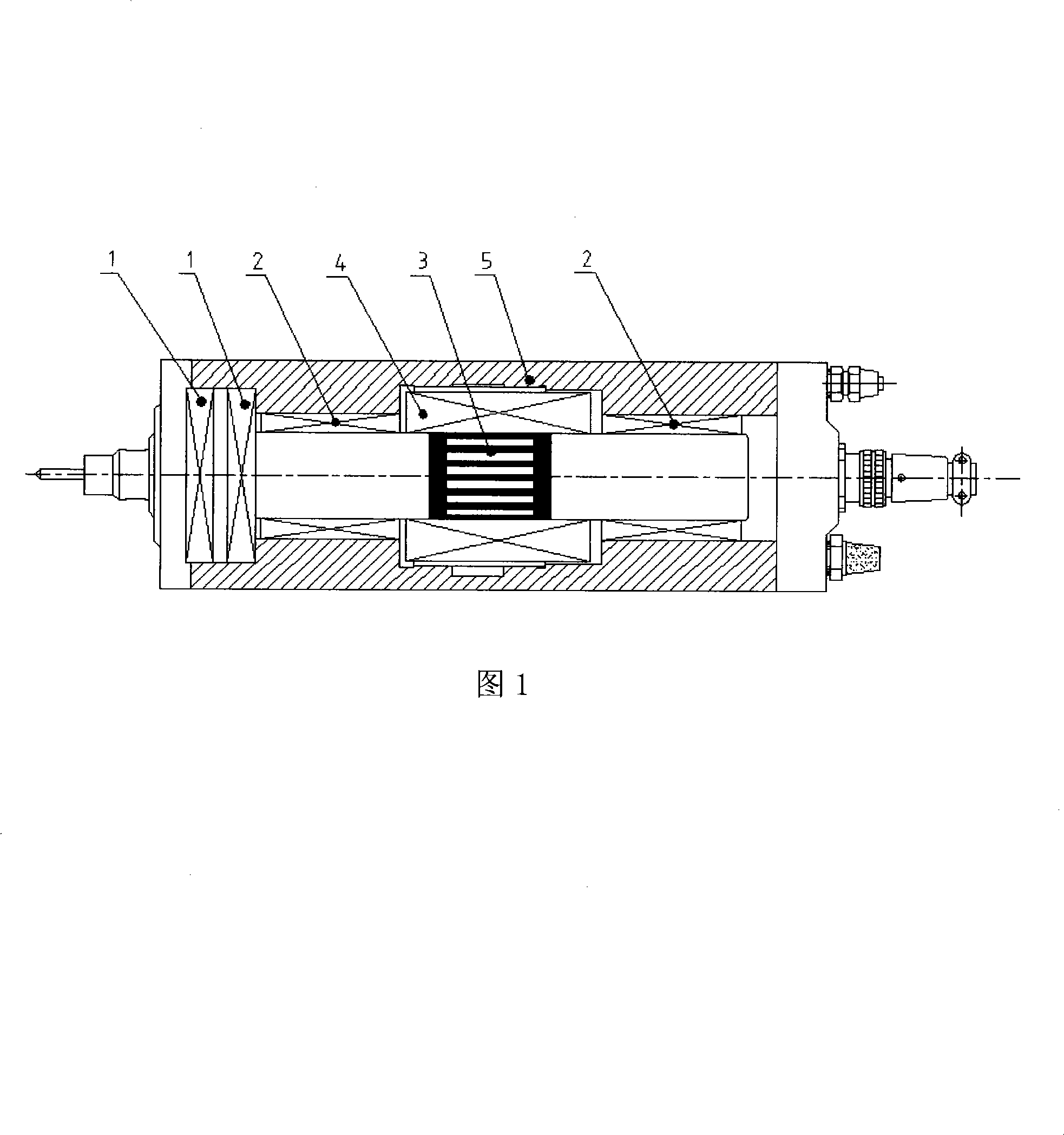

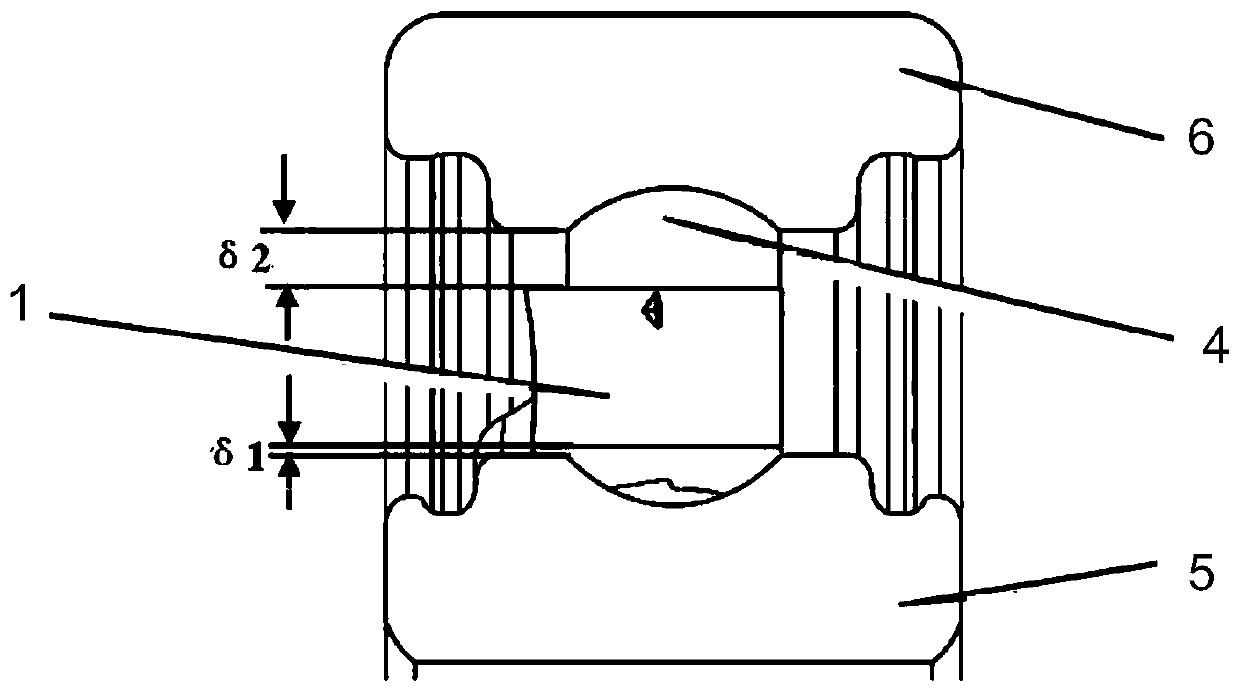

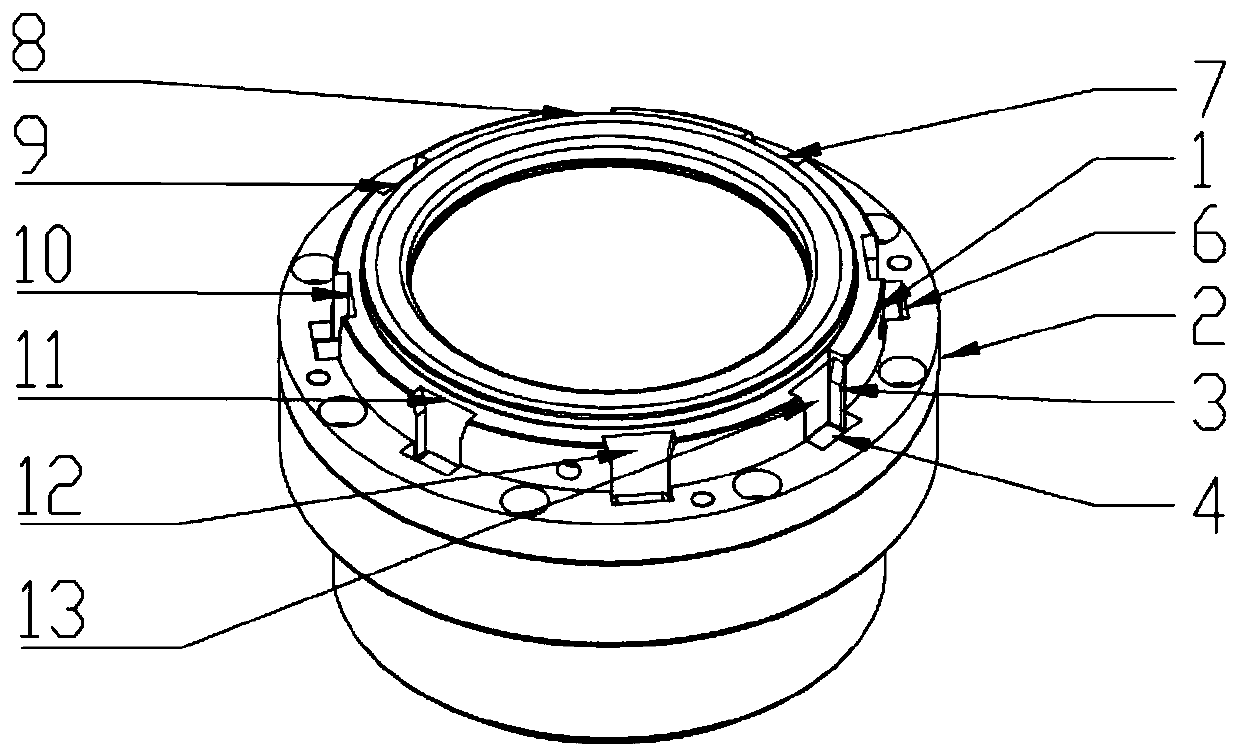

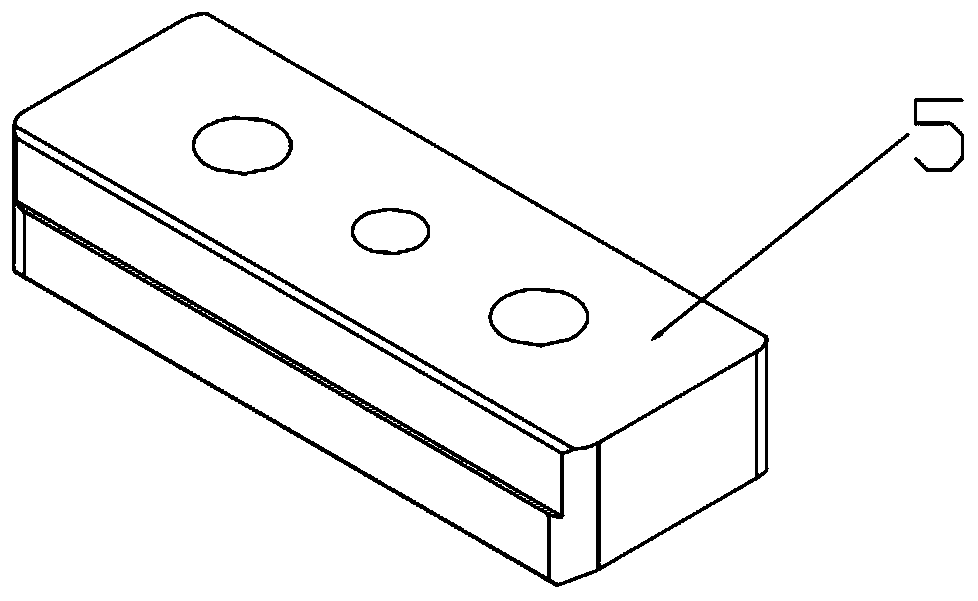

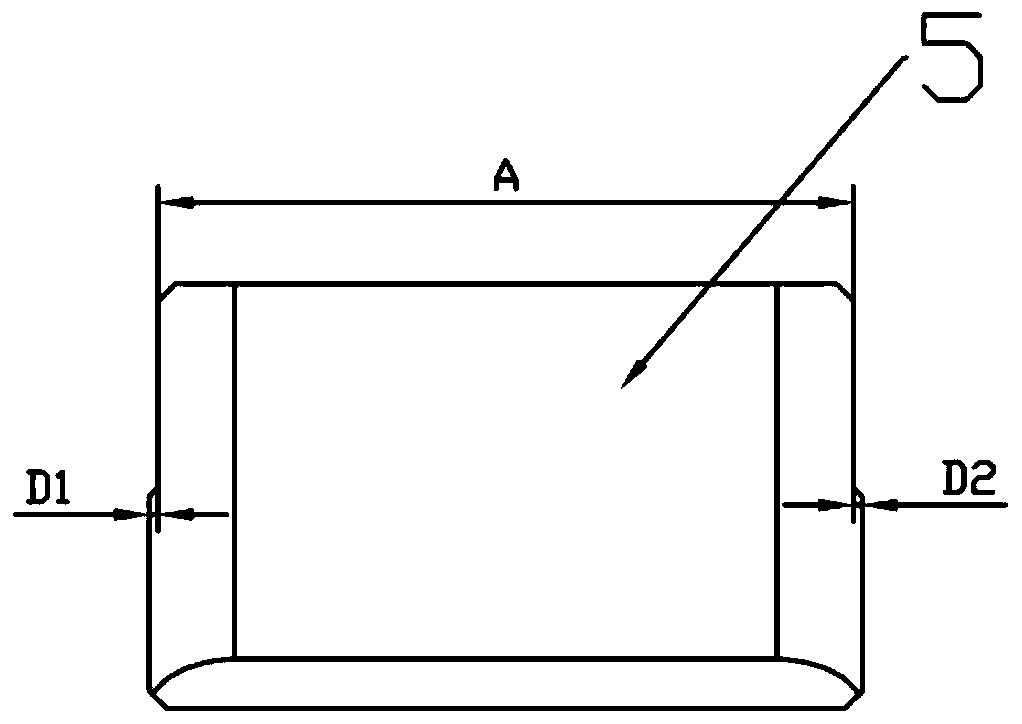

An electric spindle design adopting air static pressure anti-thrusting and air static pressure radial bearing support

InactiveCN101217241ACompact structureEasy to installAsynchronous induction motorsMechanical energy handlingThrust bearingEngineering

The invention relates to an electric spindle design adopting an aerostatic pressure anti-thrust and an aerostatic pressure radial bearing support. According to the outline dimension limit and the stiffness requirement of the electric spindle, the front end inside a shell (5) of the electric spindle is centrally provided with two aerostatic pressure anti-thrust bearings (1), thus leading the space utilization to be optimized and the structure to be compact, and at the same time the two aerostatic pressure anti-thrust bearings lead a supply air line convenient to centralize and install and provides the needed radial stiffness for a rotor-rotating shaft integrated shaft system (3). The two sides of a stator (4) are symmetrically provided with an aerostatic pressure radial bearing (2) so as to support the rotor-rotating shaft integrated shaft system, reduce the vibration of the shaft system (3) and ensure the radial stiffness. The rotor-rotating shaft integrated shaft system makes the squirrel-cage bar of the rotor of the electric motor and the rotating shaft into the integrated structure and the corresponding position of the stator arranged in the middle section and the shell of the electric spindle, that is the position of the squirrel-cage bar, adopts copper alloys directly welded in a groove of the integrated shaft system so as to reduce the creep deformation of the squirrel-cage bar, reduce the vibration value of the integrated shaft system and improve the power rate and the structural strength.

Owner:LUOYANG BEARING SCI & TECH CO LTD

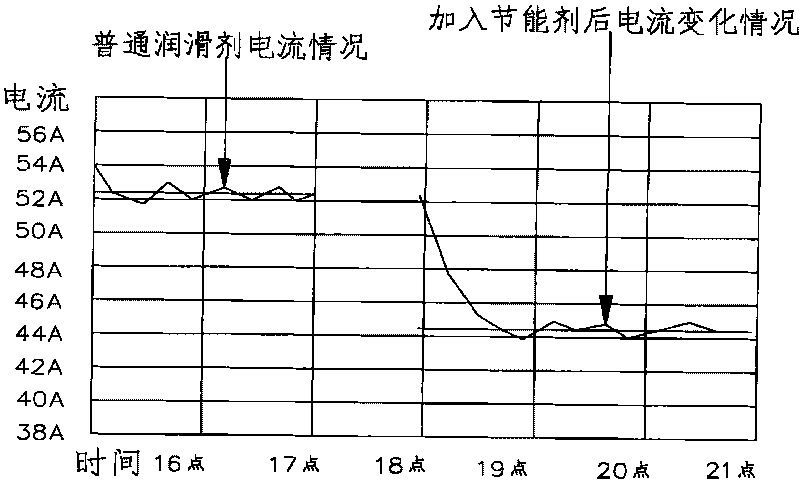

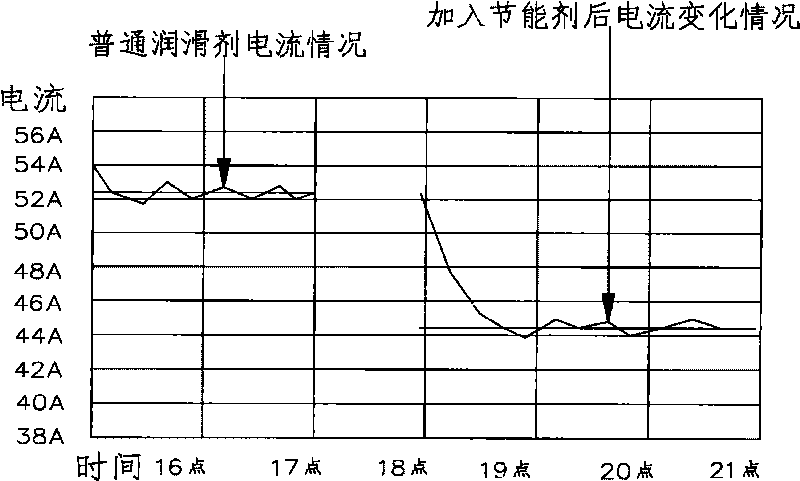

Energy-saving agent special for spindle motor of textile machine and preparation method thereof

InactiveCN101760289AImprove temperature resistanceGood mechanical stabilityAdditivesVibration amplitudePolyvinyl alcohol

The invention relates to an energy-saving agent special for a spindle motor of a textile machine and a preparation method thereof. The energy-saving agent comprise manometer diamond powder, base oil, diamond powder pulvis, copper anti-blushing agent, cleaning dispersing agent and polyving akohol solution, etc. The preparation method comprises the steps of: mixing the manometer diamond powder, thediamond powder pulvis with the polyving akohol solution; evenly dispersing in a stirring way with a certain rotation speed at the temperature of 45-60 DEG C for later use; raising the temperature of the base oil to the temperature of 80 DEG C and adjusting into solution; putting in to a regulating container; adding the copper anti-blushing agent and the cleaning dispersing agent; evenly stirring;and adding the mixture, and stirring for 1-2h. The product has good mechanical stability, chemical stability and colloform stability; has good thermal endurance and high dropping point; has good wear-resistance, extreme pressure performance, oxidation resistance and anti-rusting performance; has long service life under high temperature and good low-temperature starting performance; has obvious effects for saving oil and energy; can further repair the friction surface to a certain degree; and reduces the noise and the vibration amplitude caused by the rolling of a bearing.

Owner:郑州宏大纺纱新技术咨询有限公司

Compound impeller rotor

The invention relates to a compound impeller rotor. The compound impeller rotor comprises an impeller body installed on a pump shaft, the impeller body comprises a metal hub lining and a non-metal blade lining body wrapped and machined on the peripheral surface of the lining of the metal hub in a compression molding mode, and the non-metal blade lining body is composed of an ultrahigh molecular weight polyethylene material. The impeller body is compounded by two materials of metal and plastic. Excellent abrasive resistance of ultrahigh molecular weight polyethylene and high strength of metal are combined, the weight of the impeller body is reduced, and the material cost is reduced; in addition, the phenomenon of high thickness of the impeller body is avoided, and the strength of the impeller body is ensured. The impeller body is wear-proof and corrosion-proof, in addition, the unbalanced eccentric torque and starting inertia of the impeller body are reduced, and the balance degree of the impeller body is ensured; the dynamic balance degree of the impeller body is ensured, the vibration valve of a pump can be conveniently reduced, the rotor is easy to machine and low in cost, and the running efficiency of the pump is greatly improved.

Owner:HEFEI UNIV OF TECH +1

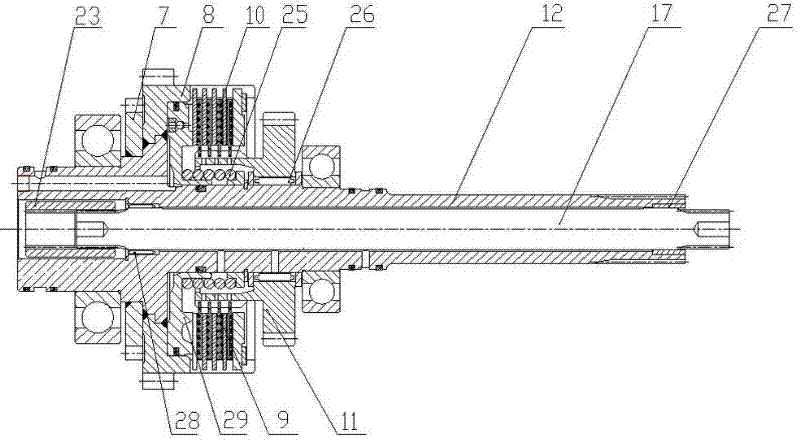

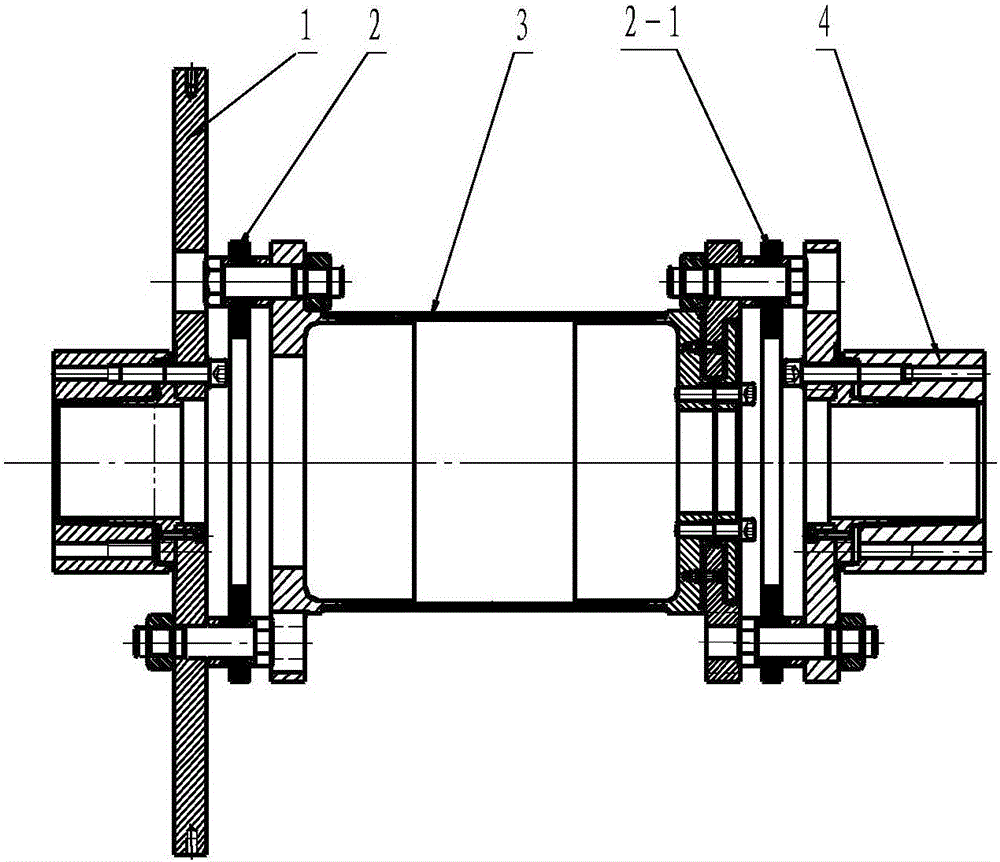

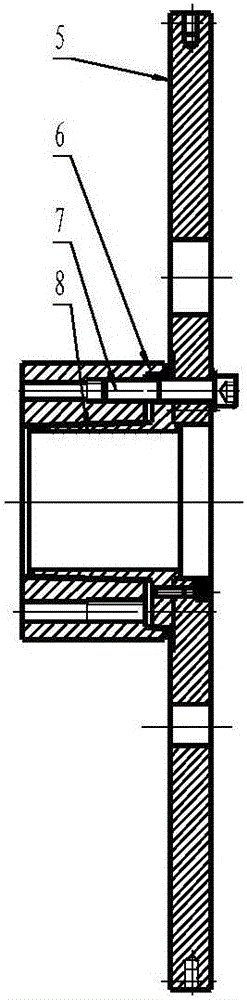

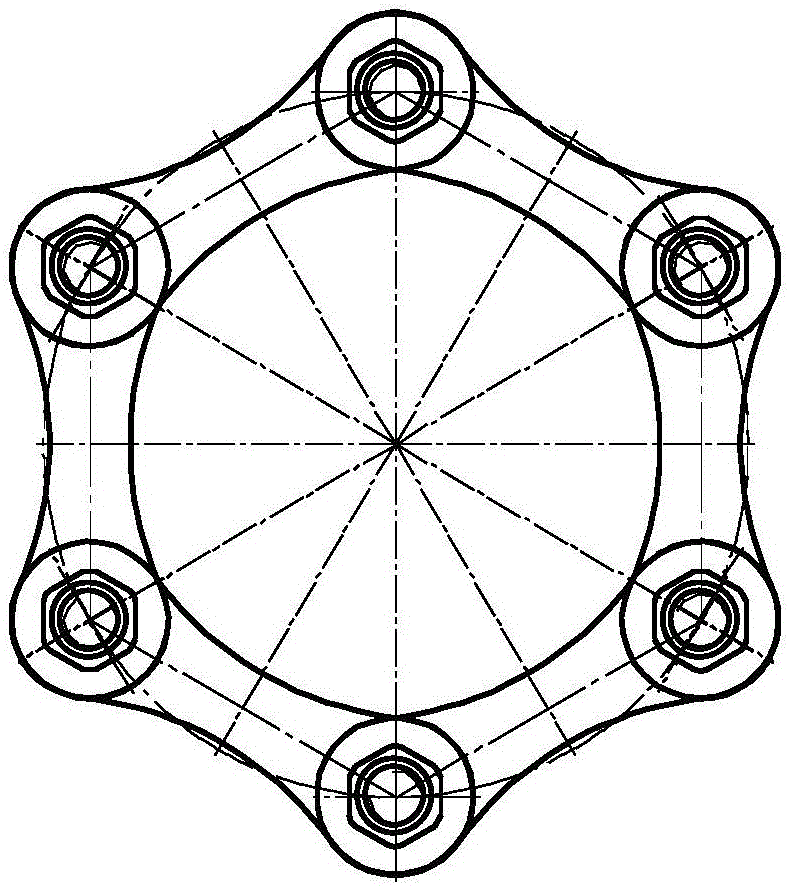

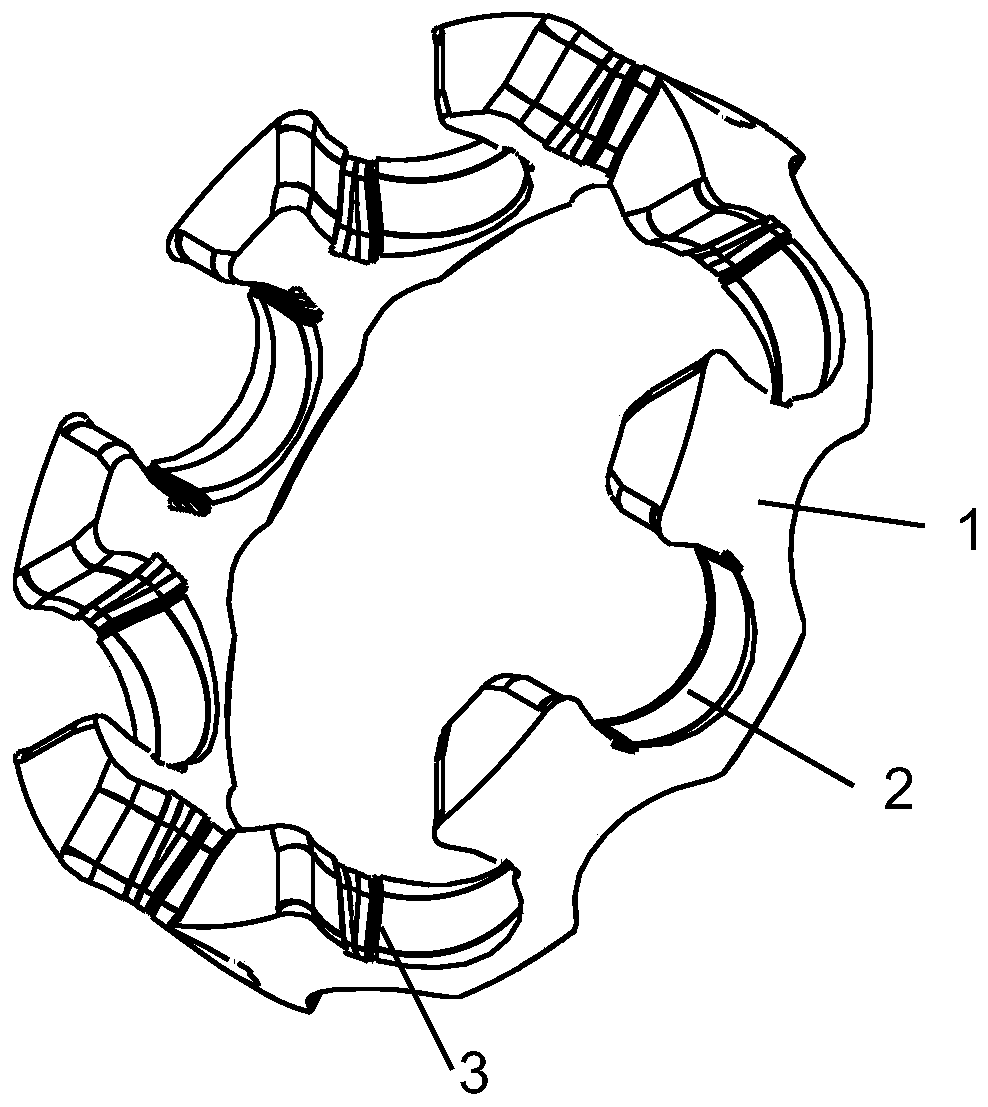

Flexible coupling of wind generator set and assembling or replacing method of flexible coupling

ActiveCN106050959AAvoid leasingShorten maintenance timeClutchesYielding couplingDynamic balanceCoupling

The invention discloses a flexible coupling of a wind generator set and an assembling or replacing method of the flexible coupling. The assembling or replacing method is characterized by comprising the following steps: designing and manufacturing parts by unit, assembling the parts to form five unit components, namely a brake disc component, a left flexible connecting sheet component, a middle connector component, a right flexible connecting sheet component and a generator side coupling component; carrying out dynamic balance tests and adjustments of the unit components separately so that the unit components have symmetric structures and dynamically balanced configuration; assembling the unit components to form the flexible coupling; and carrying out a dynamic balance test and an adjustment of the whole flexible coupling so that the whole flexible coupling has dynamically balanced configuration. According to the invention, the parts of the flexible coupling, which are designed and manufactured by unit, can be reliably assembled and conveniently and separately disassembled and replaced, so that the problem of inconvenience caused by breakdown maintenance of the conventional flexible coupling is effectively solved, the maintenance time is greatly shortened, a great amount of maintenance cost is saved, and the flexible coupling has high practicability.

Owner:绵阳国顺电气有限公司

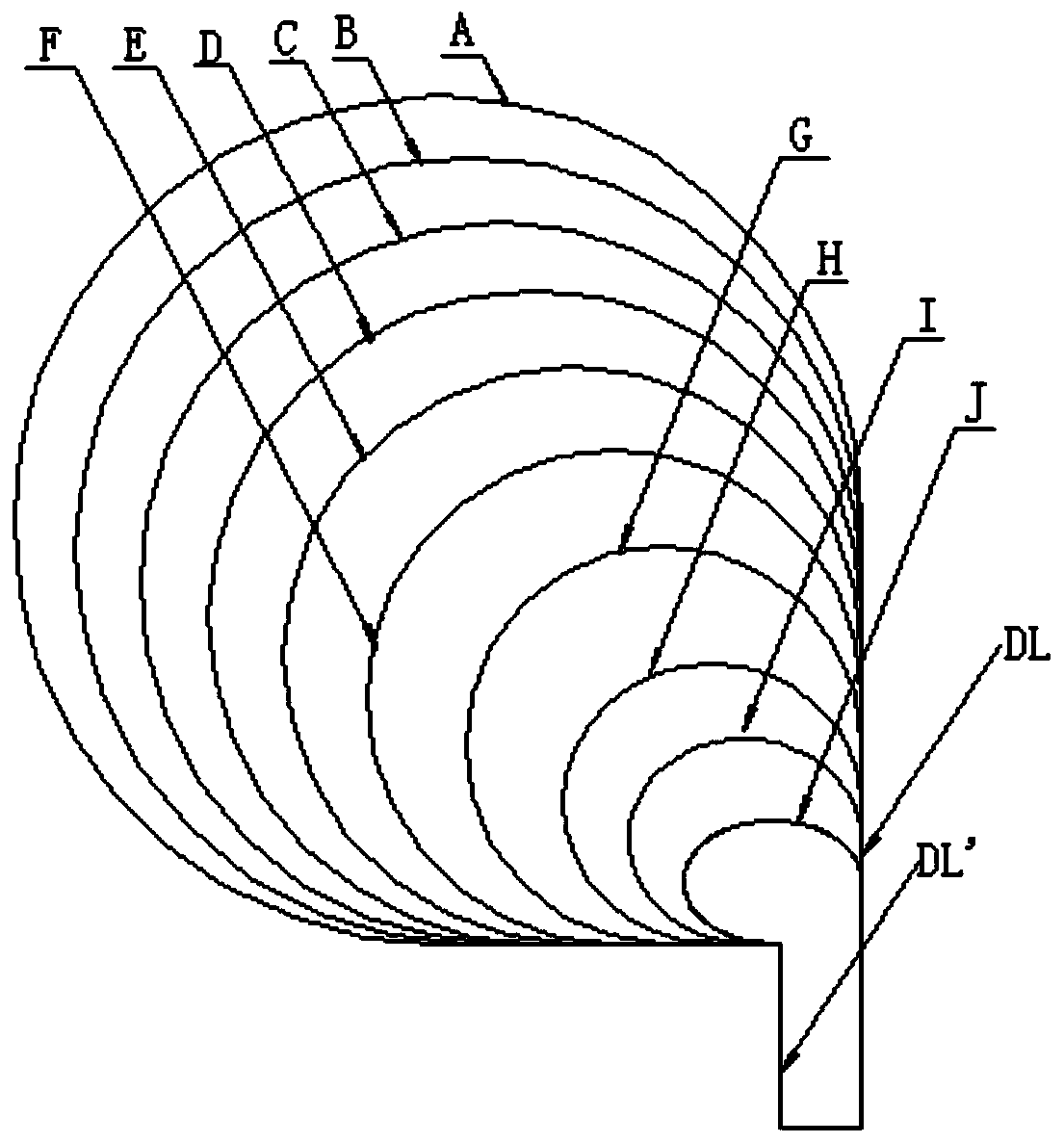

Efficient and energy-saving three-dimensional-flow multi-stage centrifugal blower

InactiveCN104963876AEasy to operateImprove efficiencyPump componentsRadial flow pumpsImpellerEngineering

The invention relates to an efficient and energy-saving three-dimensional-flow multi-stage centrifugal blower which comprises a blower shell, an impeller set and a main shaft. A vertically-sealed face is adopted by the blower shell. The blower shell comprises a front baffle, a rear baffle and an integrated partition disc. The front baffle and the rear baffle are arranged at the two ends of the integrated partition disc. A cooling water cavity is formed in the integrated partition disc. A partition disc chamber is formed in the middle of the integrated partition disc. The impeller set is arranged in the partition disc chamber. The main shaft penetrates through the two ends of the blower shell and is arranged in the middle of the blower shell. The impeller set is arranged on the main shaft and comprises a plurality of impellers. Each impeller comprises a front wheel disc, a blade and a rear wheel disc. The blades are arranged on the rear wheel discs respectively. The front wheel discs are arranged on the front sides of the blades respectively. Each blade is a three-dimensional blade. According to the efficient and energy-saving three-dimensional-flow multi-stage centrifugal blower, because the three-dimensional-flow impellers, the blower shell with the vertically-sealed face and the integrated partition disc are adopted, the blower can operate more stably, efficiency is improved, energy consumption is lowered, and the service life is prolonged.

Owner:JIANGSU LAISEN ENVIRONMENTAL PROTECTION EQUIP CO LTD

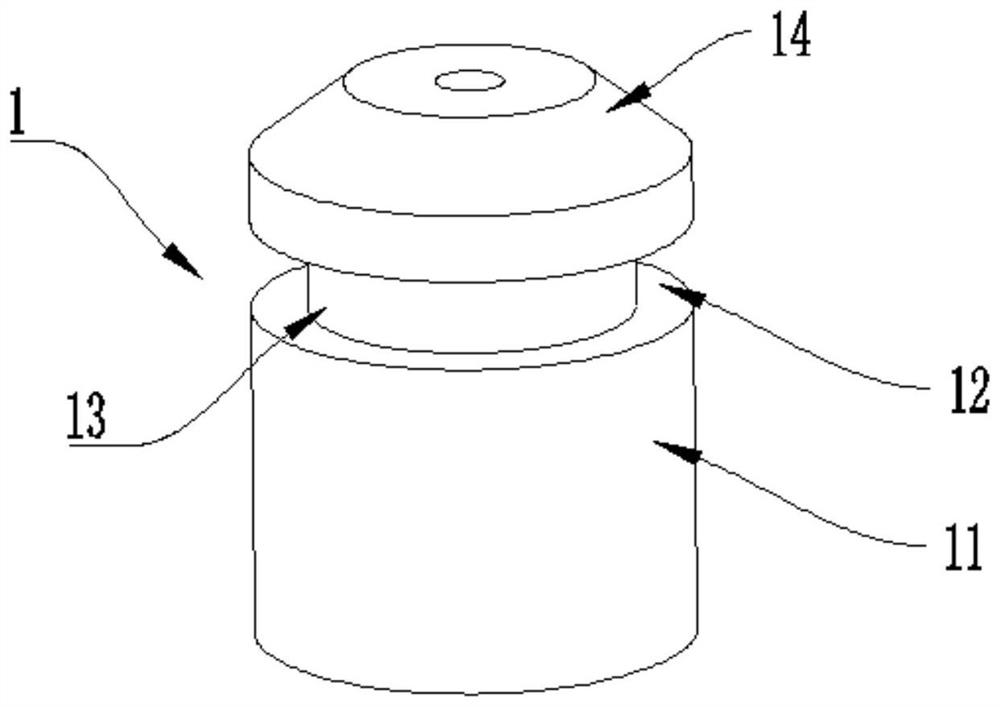

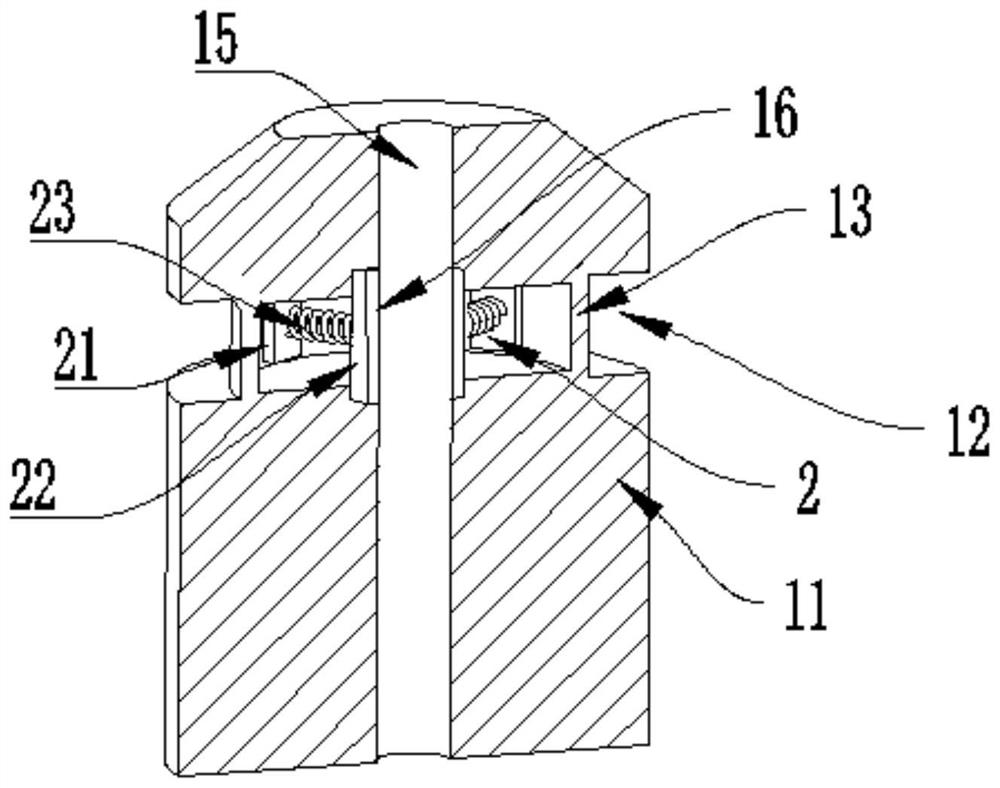

Rigidity-adjustable compressor damping foot pad, compressor and control method

PendingCN113719915ASolve the lack of vibration control in the horizontal directionReduce the vibration valuePositive displacement pump componentsLighting and heating apparatusVibration controlFoot cushion

The invention provides a rigidity-adjustable compressor damping foot pad, a compressor and a control method. The rigidity-adjustable compressor damping foot pad comprises a compressor damping foot pad body, wherein a mounting cavity is formed in the compressor damping foot pad body, a mounting groove is formed in the peripheral wall of the compressor damping foot pad body, and a first supporting wall is formed in the position, between the mounting groove and the mounting cavity, of the compressor damping foot pad body; and a rigidity adjusting device which comprises a first supporting plate, wherein the first supporting plate is arranged in the mounting cavity of the compressor damping foot pad body and abuts against the supporting wall so as to provide supporting force for the first supporting wall. The rigidity adjusting device can adjust the supporting force provided by the first supporting plate to the first supporting wall. The rigidity of the compressor damping foot pad can be adjusted according to the vibration characteristics of a compressor, a good damping effect can be achieved in the full frequency band of the compressor, the problem that a common compressor damping foot pad lacks horizontal vibration control is solved, and then abnormal sound of an outdoor unit and the vibration value of a pipeline are reduced.

Owner:GREE ELECTRIC APPLIANCES INC

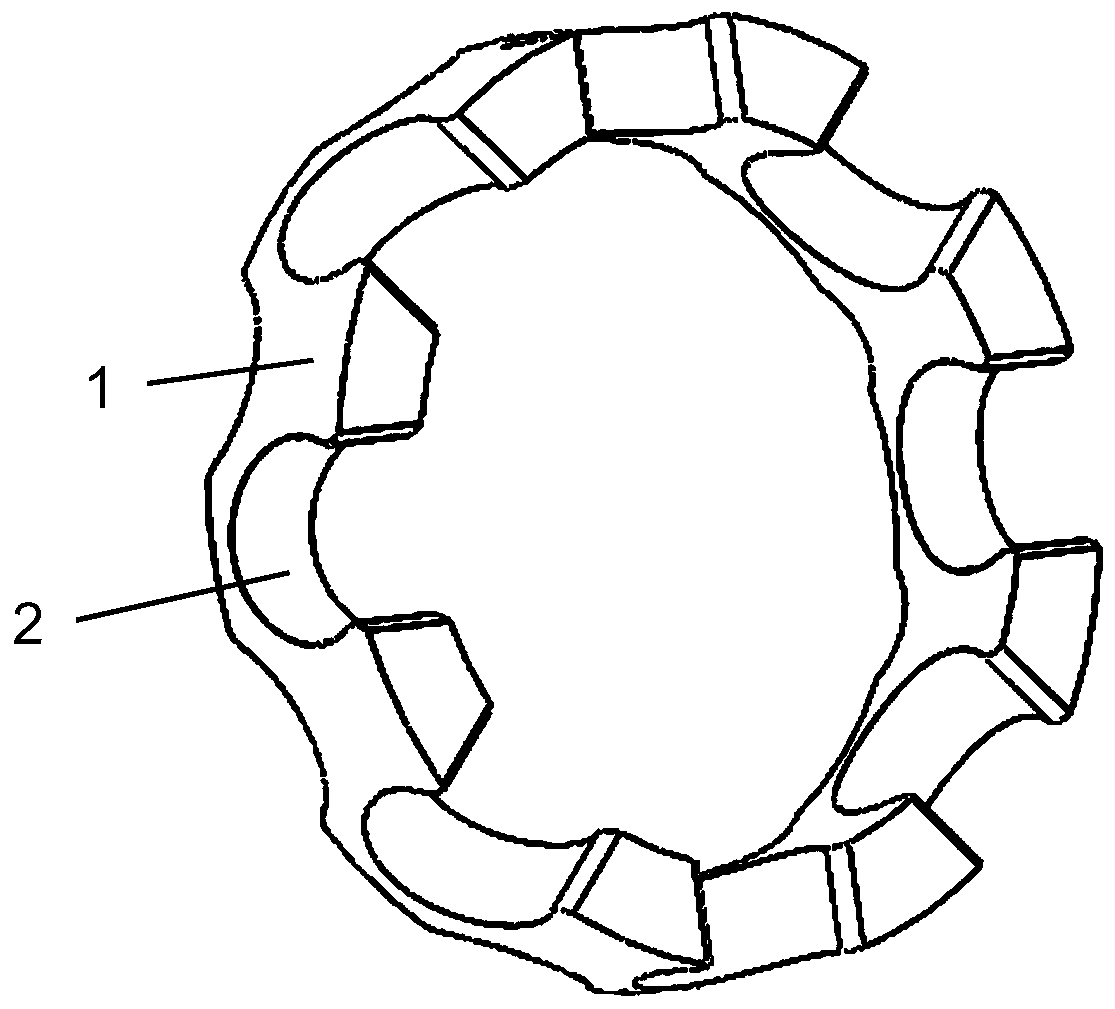

Miniature bearing plastic retainer

PendingCN111188839AReduce the vibration valueExtended service lifeBearing componentsEngineeringSteel ball

The invention discloses a miniature bearing plastic retainer. The miniature bearing plastic retainer is characterized in that each pocket of the miniature bearing plastic retainer is designed in a three-section mode in the radial direction of a retainer body, the middle section of the miniature bearing plastic retainer is a cylindrical hole, the inner section and the outer section of the miniaturebearing plastic retainer are each in a cone shape with a large outside and small inside in the radial direction of the retainer body, and the cone angle of the inner section is larger than that of the outer section. Due to the fact that the inlet and the outlet of each pocket are conical, when the bearing rotates at a high speed, lubricating grease can be easily contained at the bottom close to the inner diameter end of each pocket and can easily enter the pocket, and the lubricating effect between steel balls and the pockets of the retainer is enhanced; the cone angle of the inner section isgreater than that of the outer section so that lubricating grease can be easily retained at the port of the outer section when flowing out of the pocket, and can be quickly sprayed to an outer raceway under the action of quick rotation of the steel balls and centrifugal force, thereby the contact lubricating effect between the outer raceway and the steel balls can be improved; and the designed oil groove is beneficial to oil storage and lubrication between the steel balls and the retainer when the bearing rotates at a high speed, friction and temperature rise are reduced, deformation of a locking jaw is reduced, normal guiding of the steel balls is guaranteed, and the service life of the bearing is prolonged.

Owner:邓四二 +1

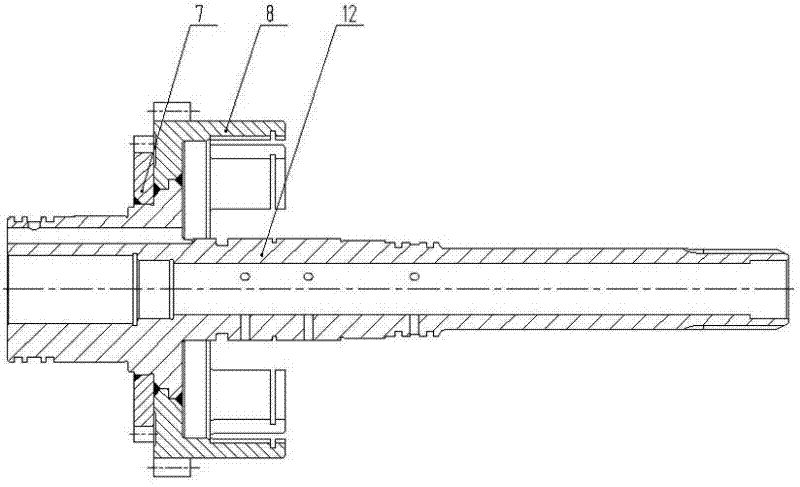

Electric spindle adopting double supports of electromagnetic bearing and angular contact ball bearing

InactiveCN111431337AIncrease limit speedExtended service lifeMechanical energy handlingSupports/enclosures/casingsMagnetic bearingBall bearing

The invention relates to an electric spindle adopting double supports of an electromagnetic bearing and an angular contact ball bearing. An axial magnetic bearing (3) is arranged on the spindle in anelectric spindle shell (4), and radial magnetic bearings (2) are symmetrically arranged on the two sides of the axial magnetic bearing (3). The rigidity of the magnetic suspension bearing at a balanceposition is improved by using the electric spindle structure supported by the electromagnetic bearing and the angular contact ceramic ball bearing so that the magnetic suspension bearing is no longerlimited by the current rigidity.

Owner:SHENYANG POLYTECHNIC UNIV

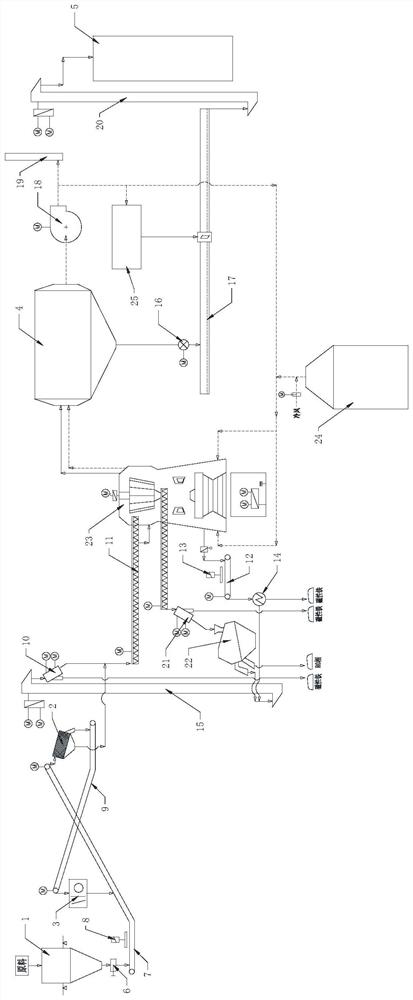

High-activity steel slag micro-powder preparation system

ActiveCN112624637AReduce labor quotaImprove labor efficiencyDrying gas arrangementsAir heatersSlagReamer

The invention belongs to the technical field of steel slag micro-powder preparation, and particularly relates to a high-activity steel slag micro-powder preparation system which comprises a raw material bin, an advancing type biomass combustion furnace, a screening device, a crushing device, a vertical mill grinding device, a dust collecting device, an excitant preparation device and a finished product bin. Materials in the raw material bin are conveyed to the screening device through a conveying device A, unqualified materials of the screening device are conveyed to the crushing device through a conveying device B, a discharging port of the crushing device is connected with the conveying device A, and qualified materials of the screening device are conveyed into the vertical mill grinding device through a mill feeding conveying reamer. The high-activity steel slag micro-powder preparation system solves the problems that existing steel slag micro-powder is poor in grindability, low in activity and limited in drying heat source, and is used for reducing steel slag grinding energy consumption, improving the activity of the steel slag micro-powder, ensuring the drying effect of the system and promoting steel slag solid waste recycling.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

Process method for nuclear power station four-bearing shaft-sealing main pump centering block dimension configuration

ActiveCN109968239AHigh precisionSave assembly timeWork holdersGrinding work supportsEngineeringNuclear power

The invention relates to a process method for nuclear power station four-bearing shaft-sealing main pump centering block dimension configuration. Eight tool keys and filler gauges are matched to carryout clearance measurement, so that the configured dimensions of centering blocks are determined. The dimensions of the eight centering blocks configured by the process method provided by the invention are accurate, and the positioned tool keys and the filler gauges at the corresponding positions have the same thickness and dimension requirements, so that the coaxiality of a bearing guide ring anda lower guiding bearing can be ensured, the problem that the lower guiding bearing and the bearing guide ring are not coaxial due to nonuniformity of the configured dimensions of the centering blocksis solved, the problem that the lower guiding bearing and the bearing guide ring cannot be assembled due to inaccurate configured dimensions of the centering blocks is solved, the production capacityand the production capacity of enterprises are greatly improved, and a domestic technical capacity of a nuclear main pump is increased.

Owner:HARBIN ELECTRIC POWER EQUIP

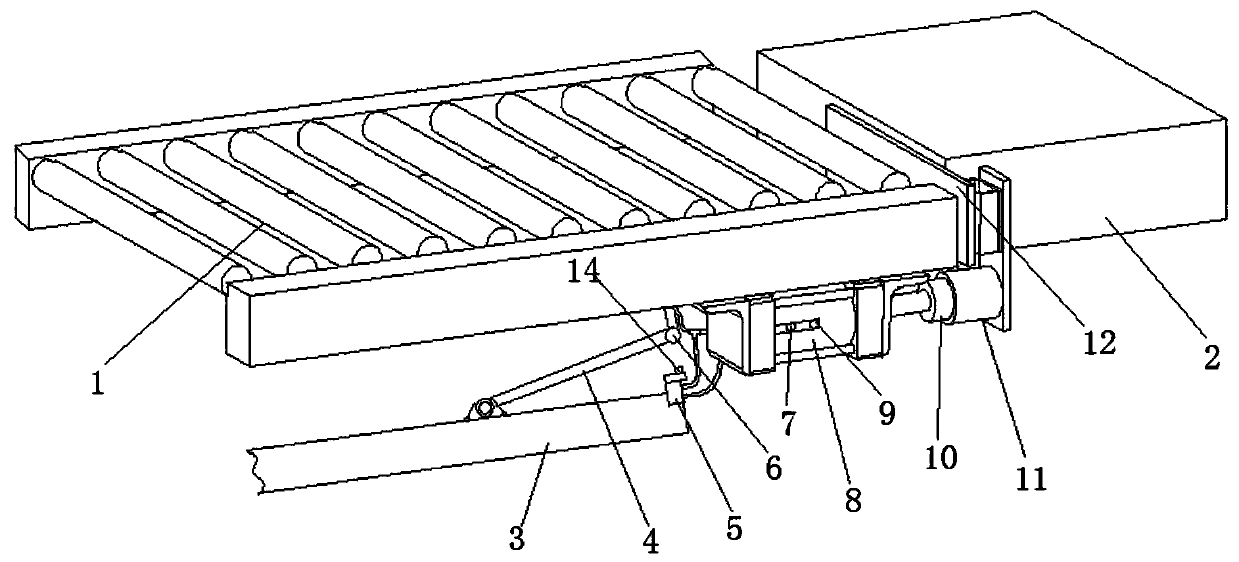

Stable ceramic press green body receiving platform

PendingCN110000898AReduce internal cracksReduce the vibration valueDischarging arrangementMaterials scienceGreen body

The invention belongs to the technical field of ceramic manufacturing equipment, and particularly relates to a stable ceramic press green body receiving platform. The stable ceramic press green body receiving platform comprises a green body receiving roller platform and a press which are connected. The ends, close to the press, of the left side and the right side of the green body receiving rollerplatform are provided with automatic extensible and retractable positioners. Each automatic extensible and retractable positioner is composed of a fixed device, a movable extensible and retractable device and a control device, wherein the fixed device comprises a fixed part and an abutting part, the fixed part is arranged on a middle frame of a press mold, the abutting part is arranged on the green body receiving roller platform, the abutting part can be driven by the movable extensible and retractable device to be completely embedded into the fixed part, and therefore stable positioning of the green body receiving roller platform and the press is guaranteed; and the control device is used for judging the positioning state of the green body receiving roller platform and the press and controlling work of the movable extensible and retractable device according to the positioning state. According to the stable ceramic press green body receiving platform, a vibration value of the roller platform is reduced, green body receiving is stable, and probability of internal hidden fractures and cracks in green bodies is greatly reduced.

Owner:JIANGXI HEMEI CERAMICS +1

Spinning tube bending nitrogen cooling process

InactiveCN101157974AUniform wearReduce the vibration valueFurnace typesHeat treatment process controlSiphonNitrogen

The invention provides the cooling technics of nitrogen gas produced by bending spin pipe, the step is as follows: (1) both ends of a straight pipe used for spin pipe are welded, drilled, and tapped, and then are heated for five minutes through seven minutes in a heating furnace with the temperature between 980 DEG C and 1050 DEG C; (2) the siphon machine is sent to a tube bender to mold within 30 seconds after drawing from the furnace, and then is provided with a case-hardened clip; (3) the head of pipe is jointed, by wafting the nitrogen gas of lower temperature into the pipe, the cooling is accelerated with the rate of reducing temperature between 65 DEG C and 80 DEG C per second, and the reduced temperature reaches between 30 DEG C and 60 DEG C; (4) the pipe is taken from the siphon machine after being naturally cooled to room temperature. The nitrogen gas of lower temperature is wafted into the pipe, and the lower temperature of the nitrogen gas is between minus 300 DEG C and minus 280 DEG C.

Owner:武钢集团有限公司

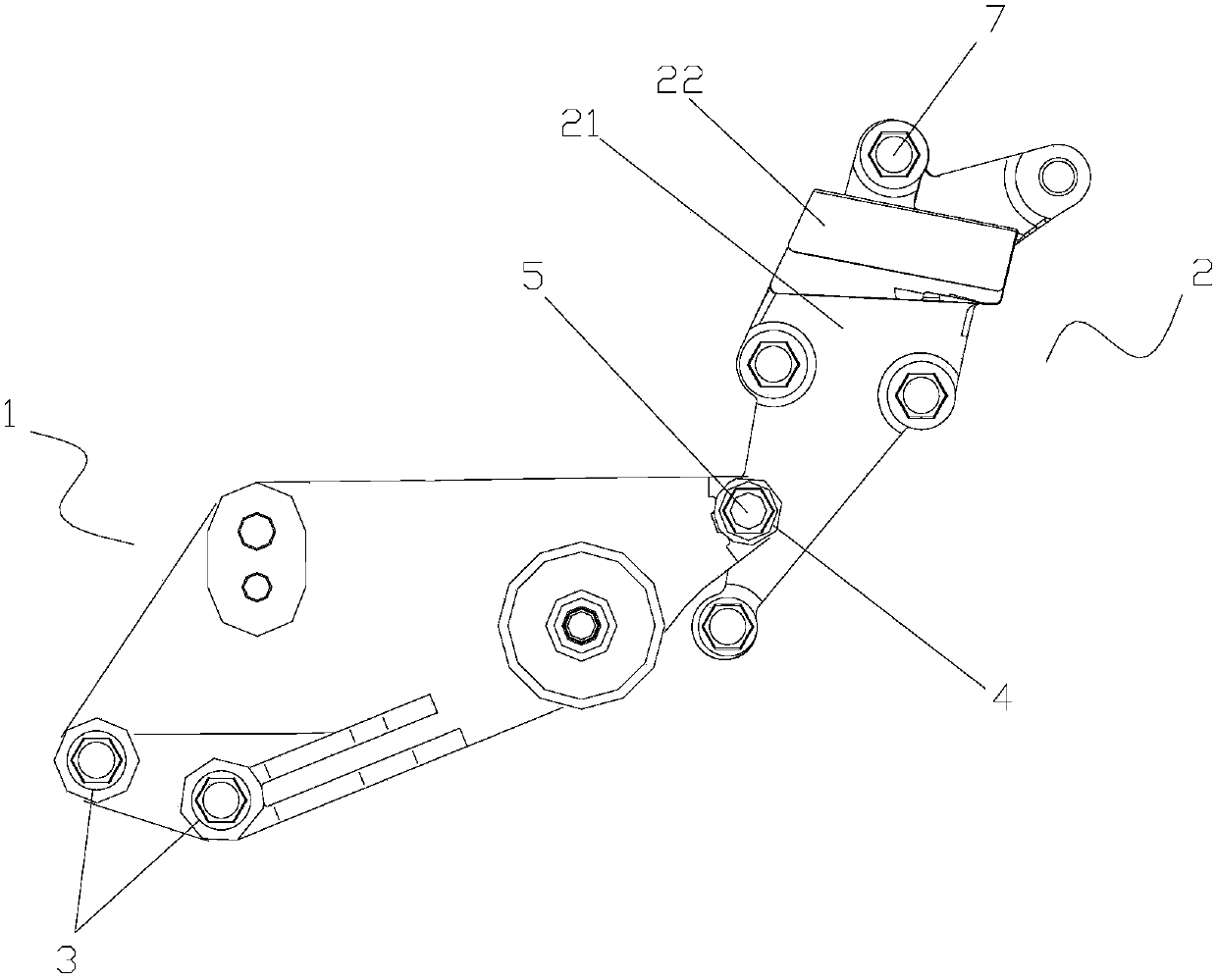

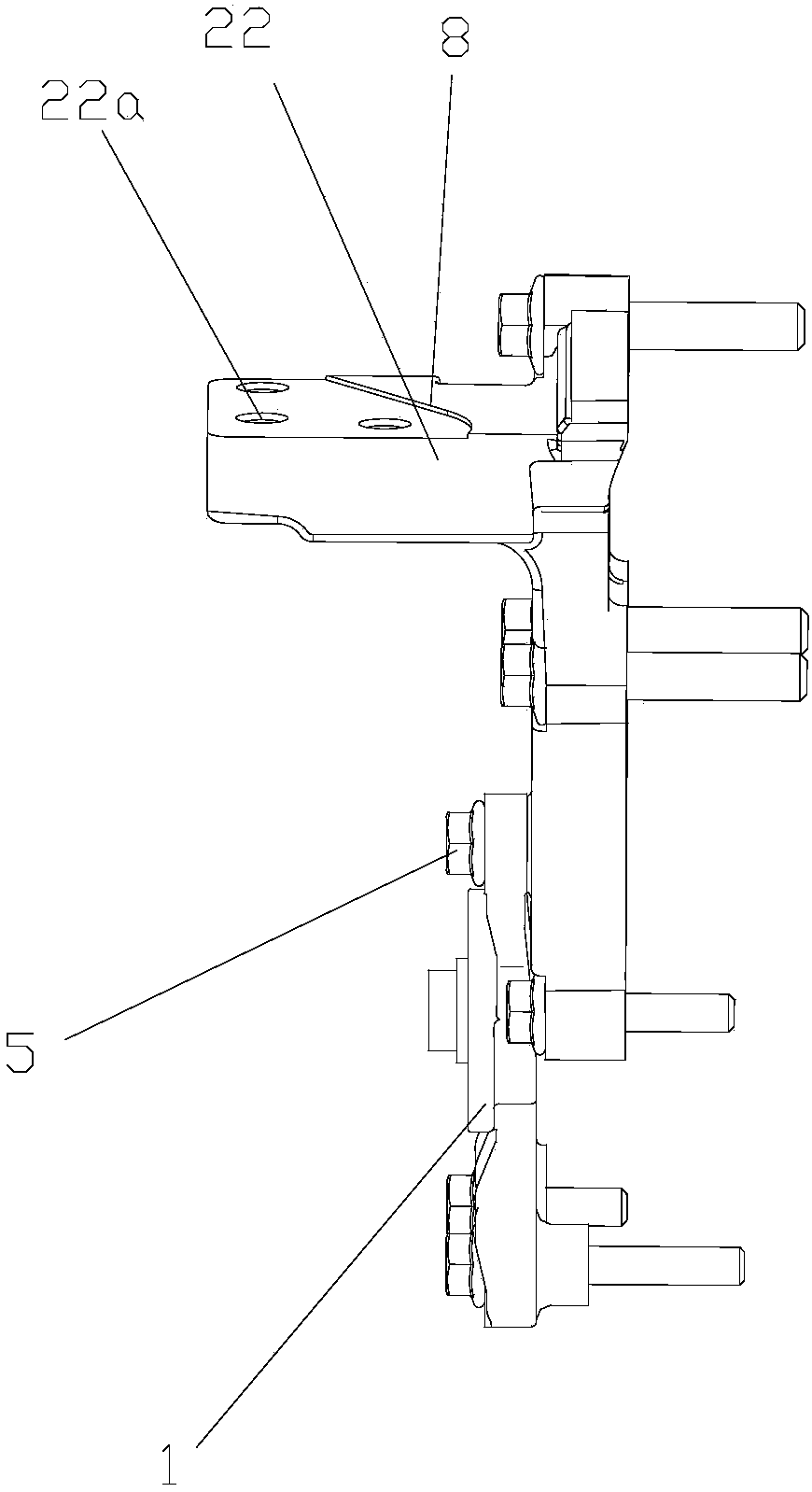

Idle wheel mounting component

The invention discloses an idle wheel mounting component. The idle wheel mounting component comprises an idle wheel support used for mounting an idle wheel and a suspension carrier used for mounting of an engine suspension. The left end of the idle wheel support is provided with an engine fixing position I fixed to an engine cylinder body, and the right end of the idle wheel support is provided with a carrier fixing position fixed to the suspension carrier. The idle wheel mounting component has advantages that one end of the idle wheel support can be fixed to the engine cylinder body while theother end of the idle wheel support is fixed to the suspension carrier through the carrier fixing position, two ends of the idle wheel support both have supporting points, and accordingly a cantilever structure of an existing idle wheel support is changed, the idle wheel support is supported stably, a shaking force value is decreased, breakage of the idle wheel support is effectively prevented, and operating reliability of an engine is improved.

Owner:CHONGQING SOKON IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com