Miniature bearing plastic retainer

A technology of miniature bearings and cages, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as difficult access to pockets, poor lubrication effect, difficulty in holding grease, etc., to ensure normal guidance and improve use service life and the effect of enhancing the lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

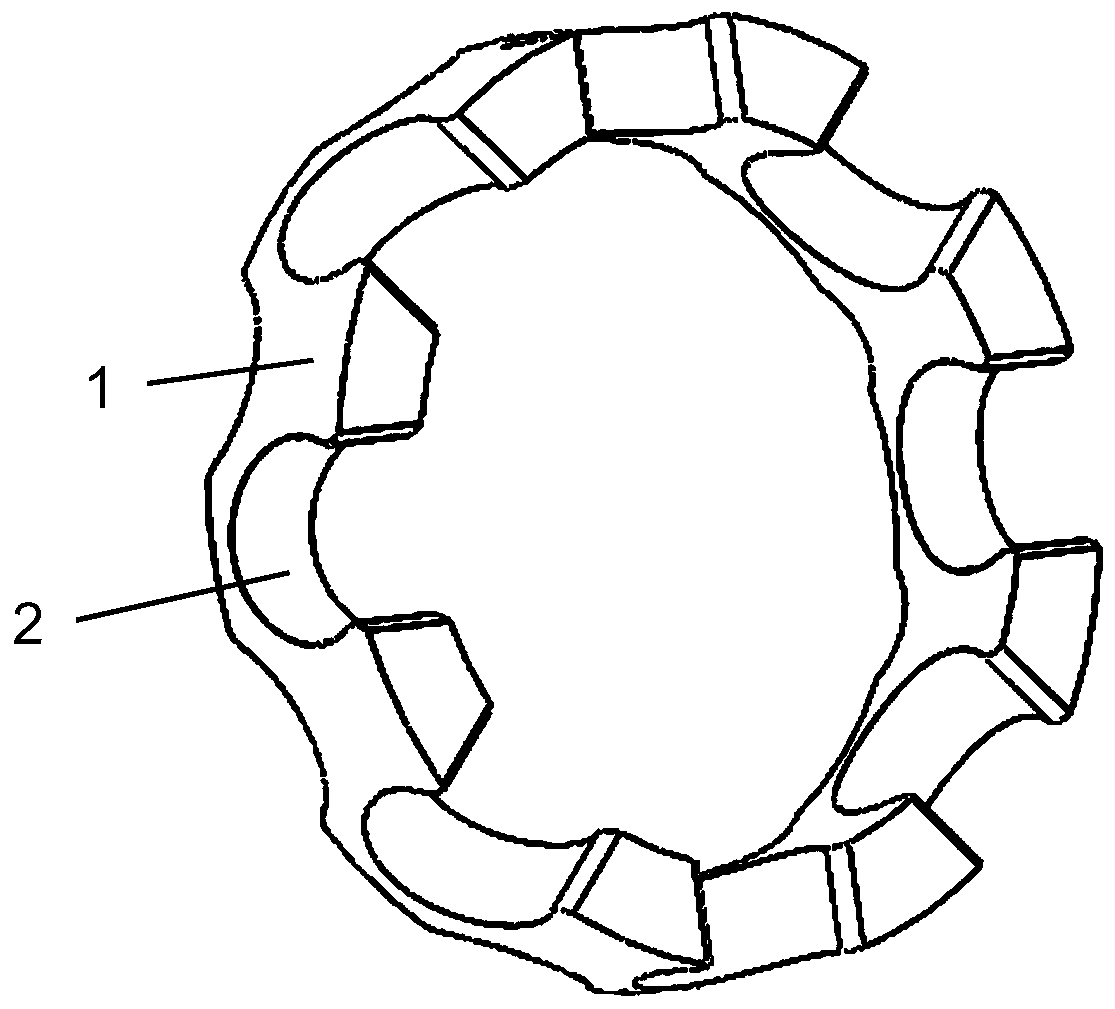

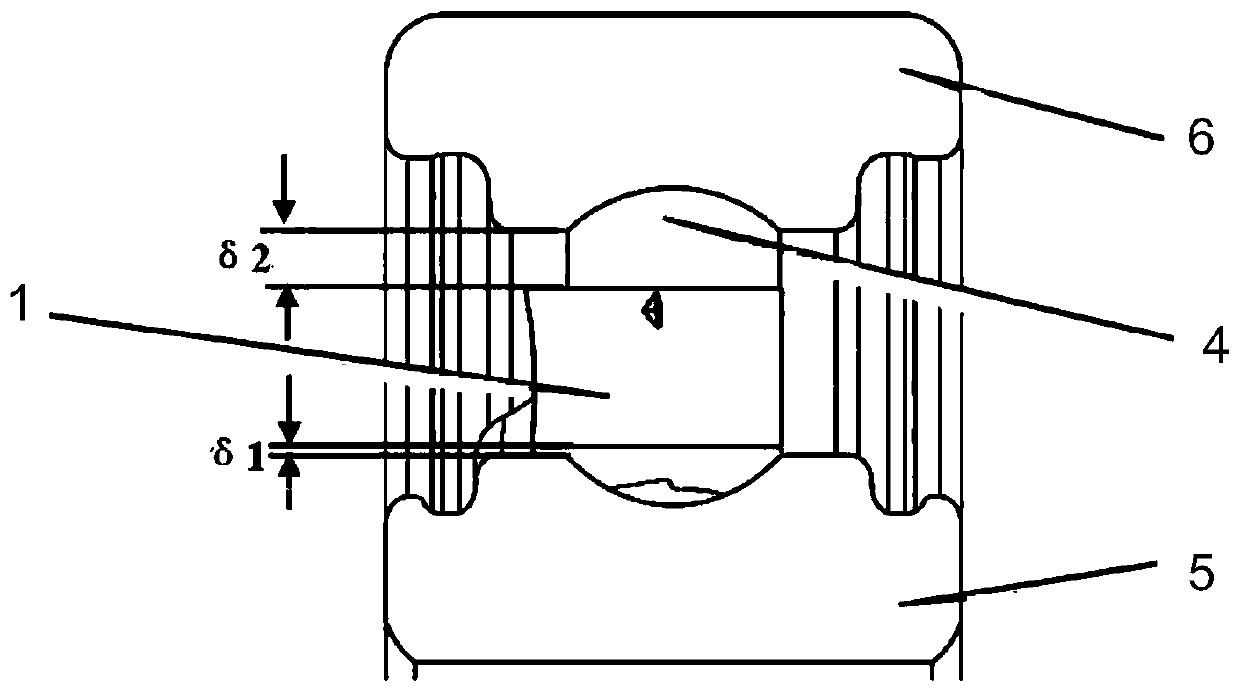

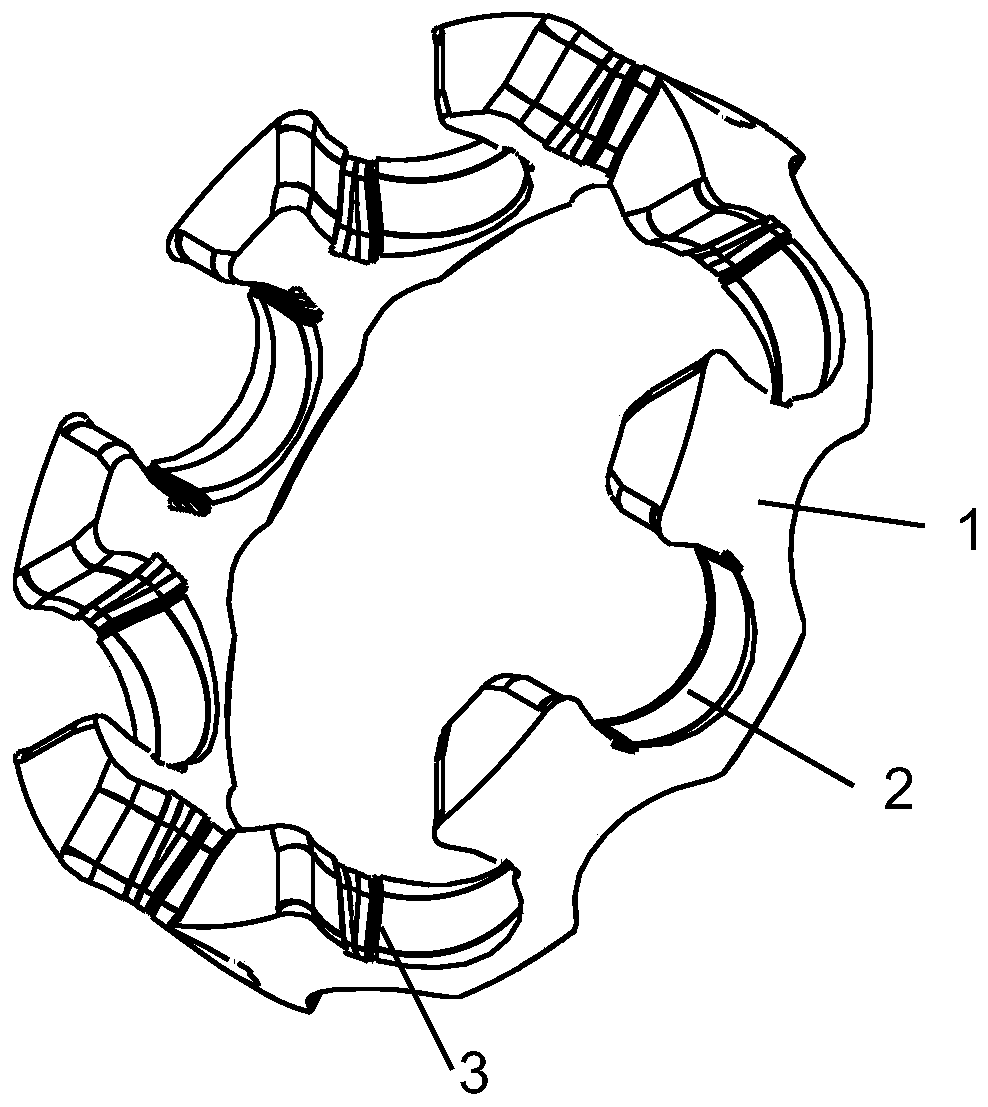

[0021] Miniature bearing plastic cage of the present invention such as Figure 3-6 As shown, it is the same as the prior art in that it also includes a circular frame body 1 and a plurality of pockets 2 radially opened on the ring wall of the frame body 1, and the upper ends of the pocket holes 2 are open. The difference is that Each pocket hole 2 is designed in three sections along the radial direction of the frame body 1, wherein the middle section 21 is a cylindrical hole, and the inner and outer sections 22, 23 are conical with a large inside and a small outside along the radial direction of the frame body 1. shape, and the cone angle β1 of the inner section 22 is greater than the cone angle β2 of the outer section. Because the outer section port (exit) of pocket hole 2 is smaller, the inner section 22 port (inlet) of pocket hole 2 is larger, when it can be ensured that the bearing rotates at high speed, the grease is easy to flow near the bottom of pocket hole 2 inner sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com