Process method for nuclear power station four-bearing shaft-sealing main pump centering block dimension configuration

A centering block and nuclear power plant technology, applied in the direction of manufacturing tools, grinding workpiece brackets, workpiece clamping devices, etc., can solve the problems of excessive vibration of the main pump, inaccurate centering block size, and uncertain centering block, etc. Achieve the effect of reducing assembly time, increasing precision and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention provides a process method with high reliability, high precision and high efficiency, which can meet the design requirements of the size preparation of the centering block of the four-bearing shaft seal main pump of the nuclear power plant. In order to achieve the above purpose, the scheme is as follows: the process method for preparing the size of the centering block of the four-bearing shaft seal main pump of the power station,

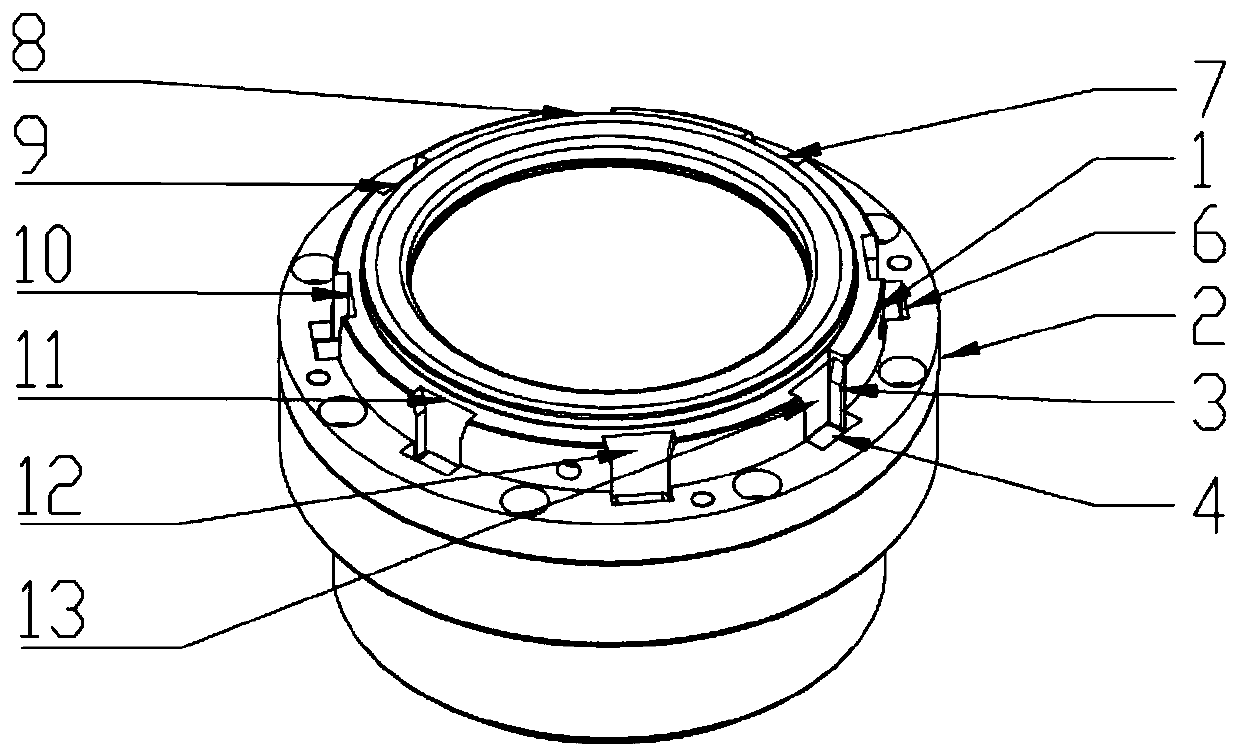

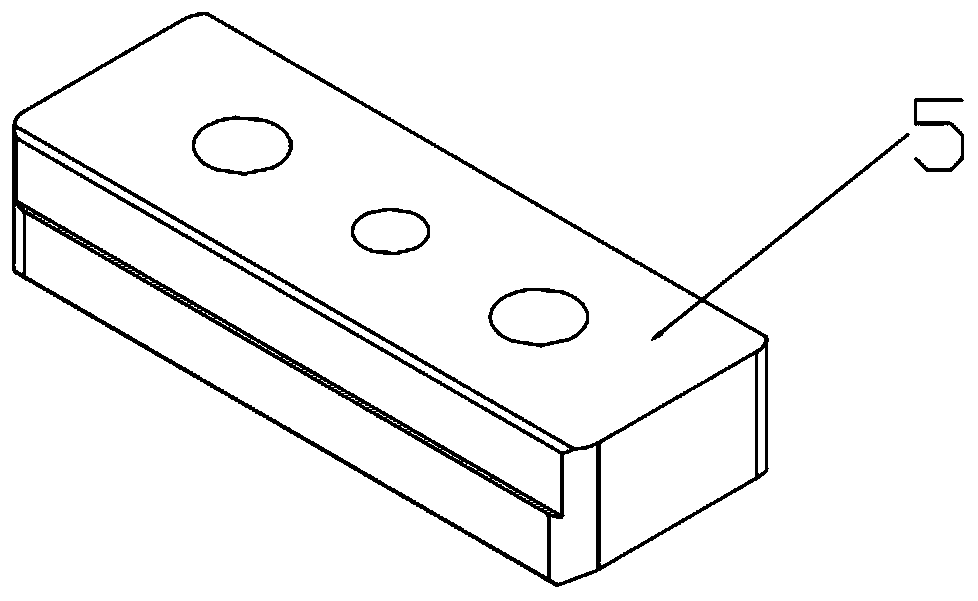

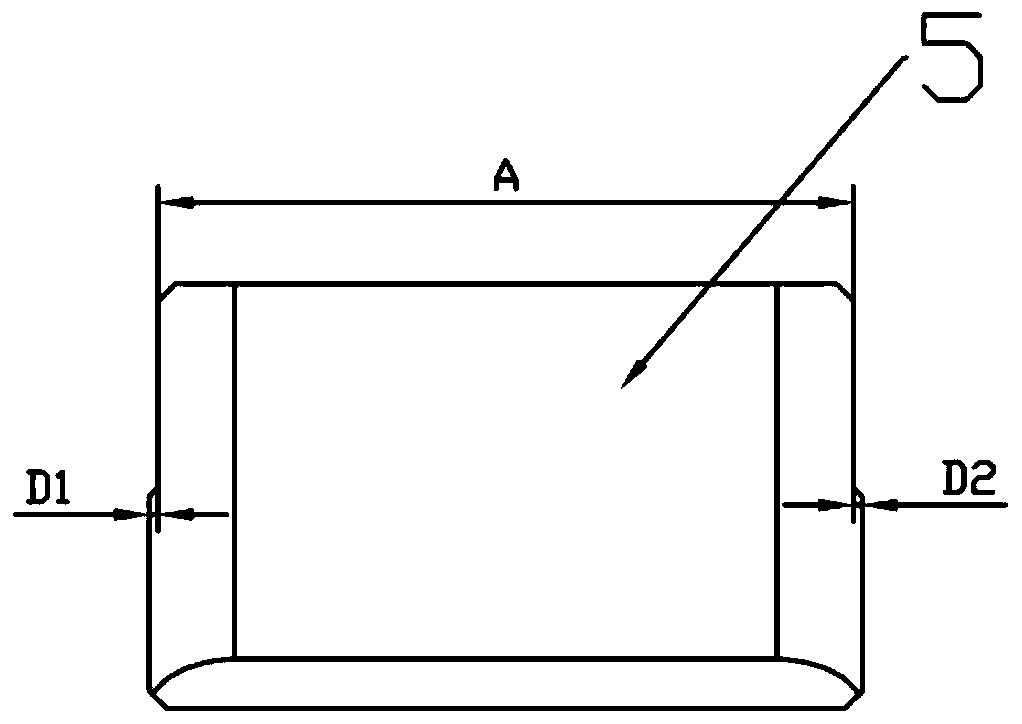

[0033] like figure 2 As shown, 8 tool keys are used to cooperate with the feeler gauge to measure the gap, so as to determine the preparation size of the centering block. The above method includes the following steps: figure 1 as shown,

[0034] 1) Arrange the first keyway 6, the second keyway 7, the third keyway 8, the fourth keyway 9, the fifth keyway 10, the sixth keyway 11, the seventh keyway 12, and the eighth keyway of the guide bearing 1 counterclockwise 13. Numbering, respectively measure the 8 keyway width dimensions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com