Patents

Literature

32results about How to "Reduce internal cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-compacting concrete and preparation method thereof

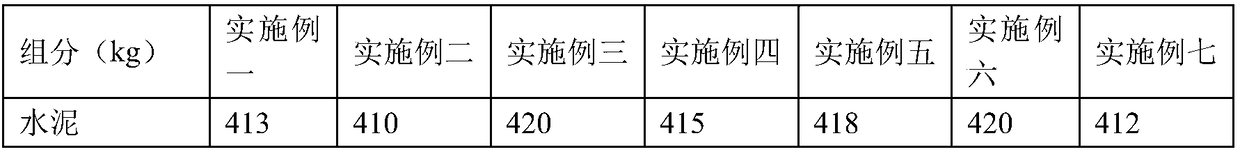

The invention relates to a self-compacting concrete. The self-compacting concrete comprises, by weight, 410 to 420 parts of cement, 50 to 60 parts of fly ash, 30 to 35 parts of slag powder, 750 to 760parts of sand, 970 to 980 parts of coarse aggregate, 10 to 15 parts of an additive, 28 to 35 parts of an expanding agent and 150 to 160 parts of water, wherein the coarse aggregate comprises cobblestone and phase-change ceramsite in a weight ratio 5: 1, and the additive comprises a polycarboxylate superplasticizer and a binder in a mass ratio of 2: 1. According to the invention, the expanding agent and a composite phase-change material are added into the concrete, so gaps in the self-compacting concrete are filled, and internal cracks in the concrete are reduced.

Owner:北京中实上庄混凝土有限责任公司

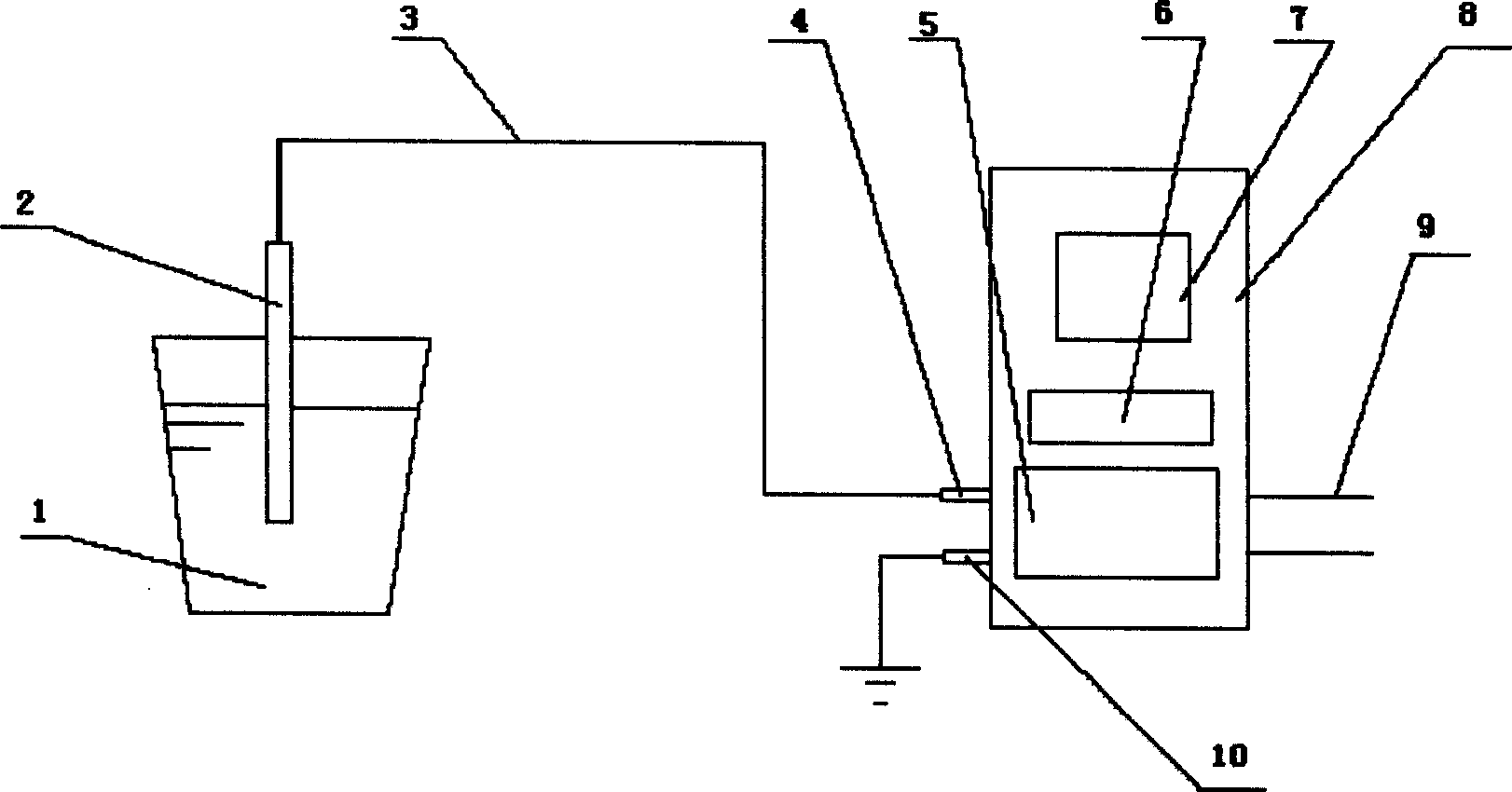

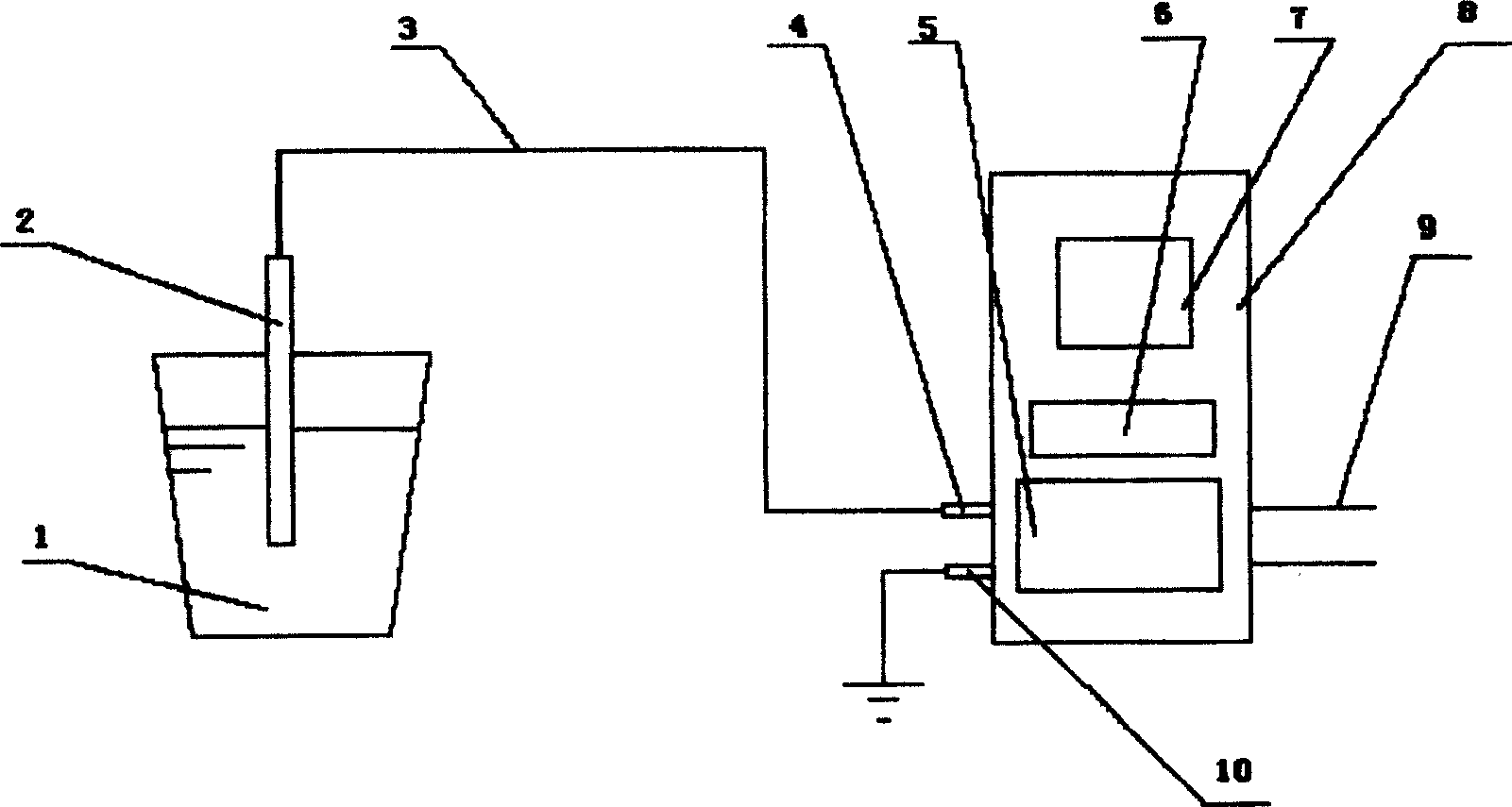

Method in use for conticaster for controlling solidification structure of casting block

A method for the conticaster to control the solidified structure of cast blank includes providing a HF pulse power supply with positive and negative electrodes, inserting its negative electrode into the molten steel in the crystallizer or tundish of conticaster, electrically connecting its positive eletrode with the steel base of conticaster, and conticasting while regulating the voltages, current and frequency to improve the performance of cast blank.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Killed steel casting method

A periodic tube rolling machine with slant rolling drill rig is used to generate big caliber thick wall steel blocks, to satisfy the inside and surface quality requirements. Inner cavity working section of the mold is wave shape multilateral cross section shape wave ingot mold, with sulfur content controlled under 0.025% of the steel liquid, casting temperature within 40 to 80DEG C, linear speed 80 to 230mm / min, cracking ratio lower than 5%, pass rate 98.81%, with low consumption of metal, low cost, especially suitable for rolling into seamless steel tubes with multi types and specification and phi> / =426mm.

Owner:攀钢集团成都钢铁有限责任公司

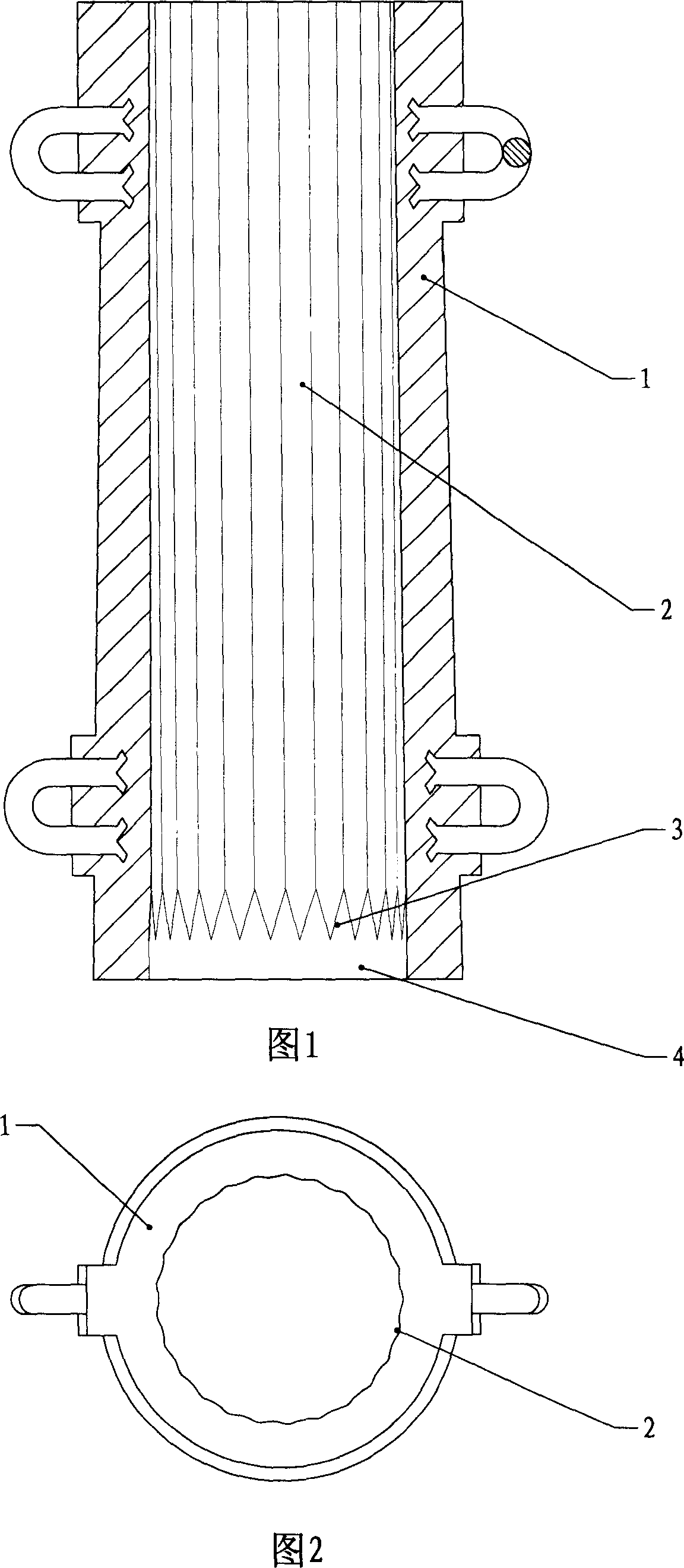

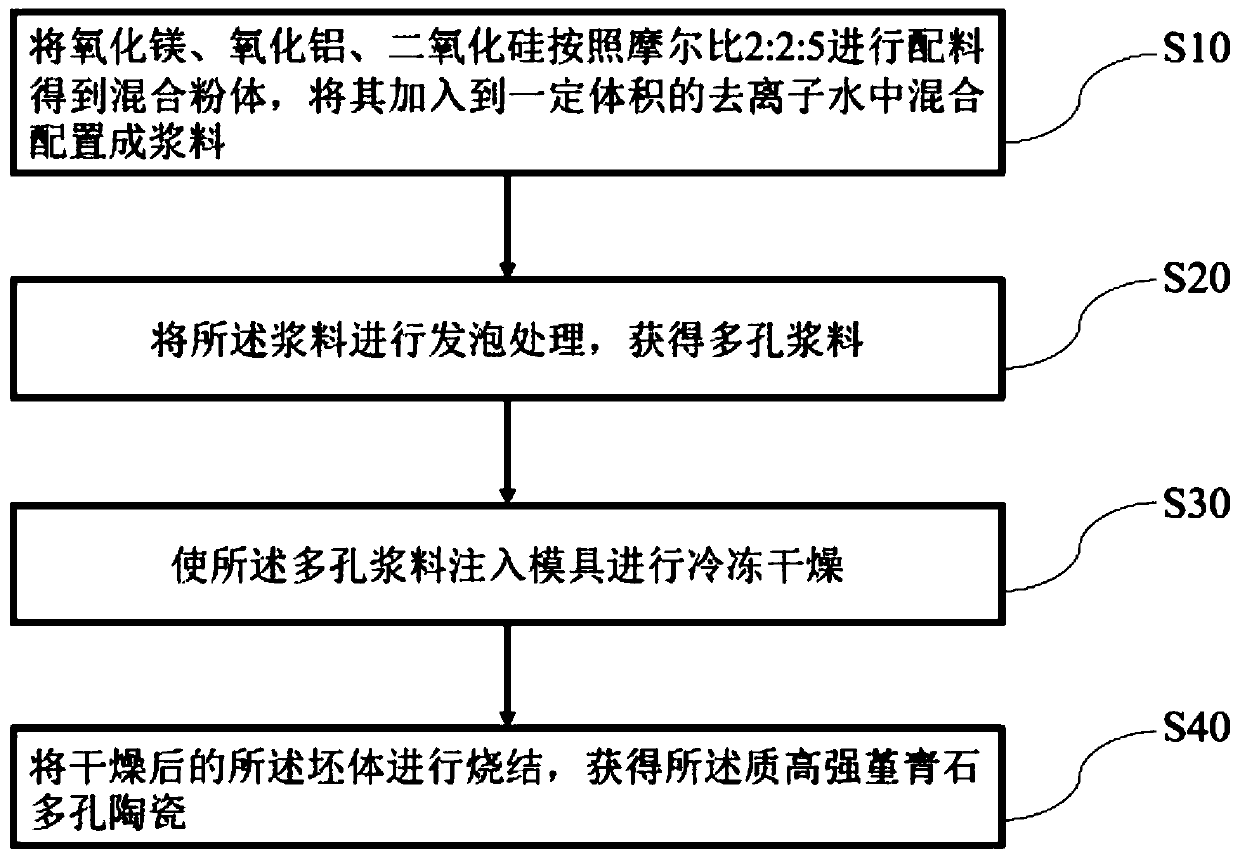

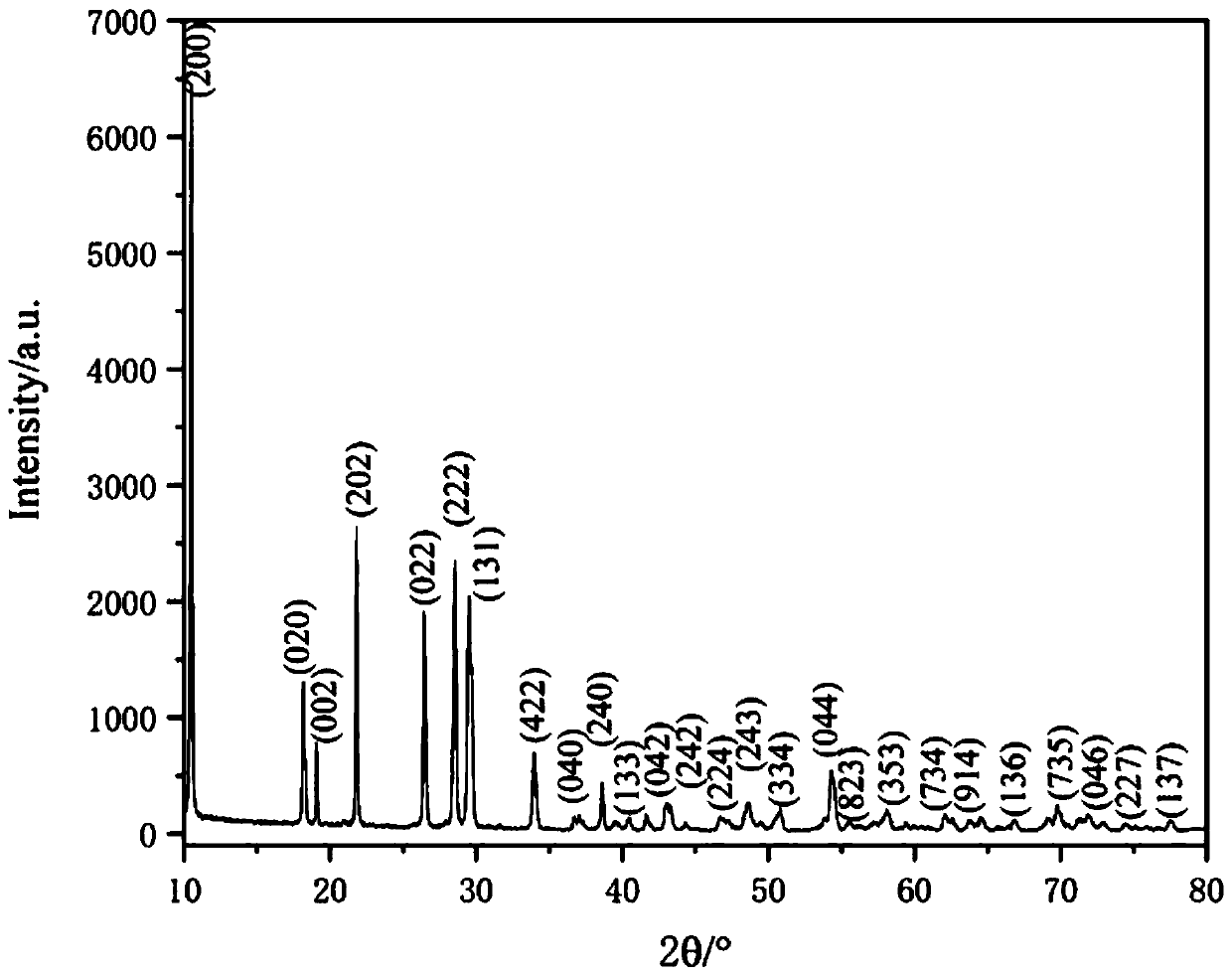

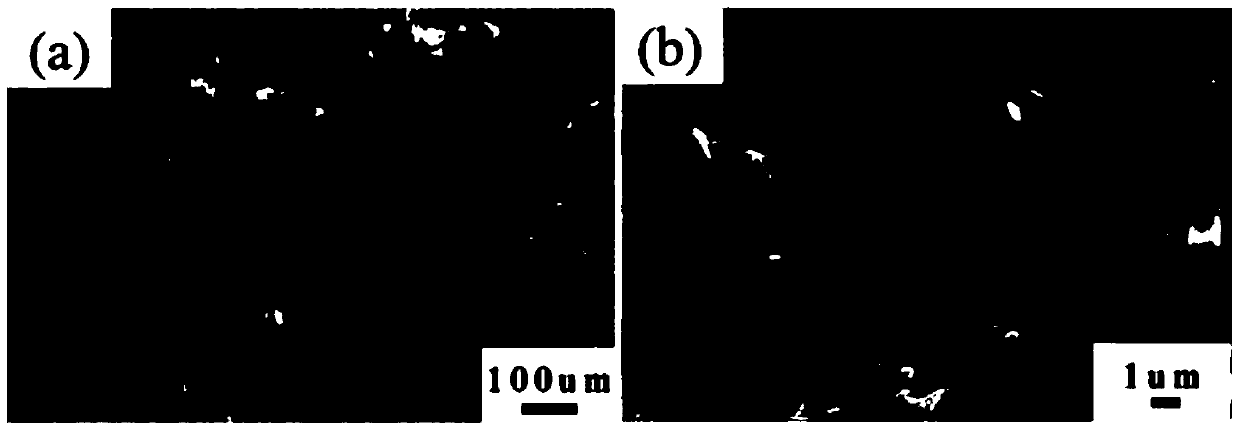

Green preparation method of light high-strength cordierite porous ceramic and filter

InactiveCN110668802AImprove permeabilityHigh strengthCeramic shaping apparatusFiltration separationFreeze-dryingCordierite

The invention provides a green preparation method and a filter for a lightweight high-strength cordierite porous ceramic. The preparation method comprises the following steps: step S10, mixing magnesium oxide, aluminum oxide and silicon dioxide according to a cordierite stoichiometric ratio to obtain mixed powder, adding the mixed powder into deionized water with a certain volume, ball milling andmixing to prepare slurry; step S20, foaming the slurry to obtain foam slurry; step S30, injecting the foam slurry into a mold for freeze drying; step S40, sintering the dried green body to obtain thelightweight high-strength cordierite porous ceramic. According to the invention, the green preparation method is small in additive dosage used and environment-friendly, the size change from injectionmolding to sintering is less than 2% (the bus shrinkage range is-1.87% to 0.45%), and the method accords with the technical characteristic of green preparation.

Owner:BEIJING JIAOTONG UNIV

Method for producing 75Cr1 hot-rolled sheet steel

InactiveCN101745535AEnsure fatigueImprove uniformityTemperature control deviceMetal rolling arrangementsPorosityChemical composition

The invention provides a method for producing high-quality 75Cr1 hot-rolled sheet steel based on the continuous thin slab casting and rolling process, which mainly adopts the following process flow: smelting, refining, continuous thin slab casting, soaking, hot continuous rolling, cooling and coiling. The superheat T of molten steel is larger than 30 DEG C and less than or equal to 45 DEG C, the charging temperature T of the cast slab is larger than or equal to 900 DEG C and less than or equal to 1050 DEG C, the finish rolling temperature T is larger than or equal to 850 DEG C and less than or equal to 950 DEG C, the coiling temperature T is larger than or equal to 550 DEG C and less than or equal to 630 DEG C, and the drawing speed S of continuous casting is larger than or equal to 3.5m / min and less than or equal to 5.5m / min; mold flux casting is adopted; and the chemical composition of molten steel is as follows: 0.70 percent to 0.80 percent by weight of C, 0.20 percent to 0.45 percent by weight of Si, 0.60 percent to 0.90 percent by weight of Mn, 0.025 percent by weight or less of P, 0.025 percent by weight or less of S, 0.30 percent to 0.60 percent by weight of Cr and 0.02 percent to 0.08 percent by weight of V. When the method is adopted to produce the 75Cr1 hot-rolled sheet steel, the segregation, porosity and cracks of the cast slab are reduced, and the 75Cr1 hot-rolled sheet steel is characterized by uniform microstructure and properties and high fatigue resistance.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

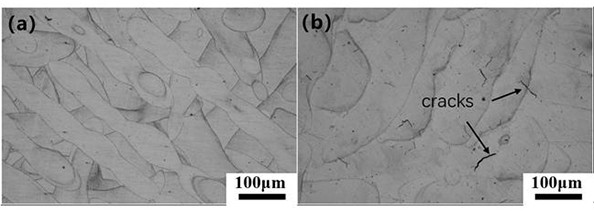

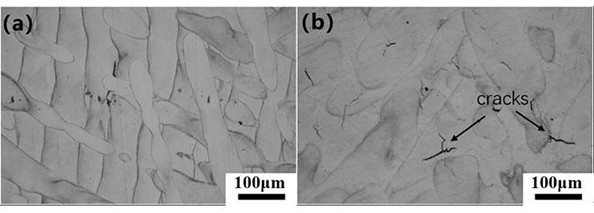

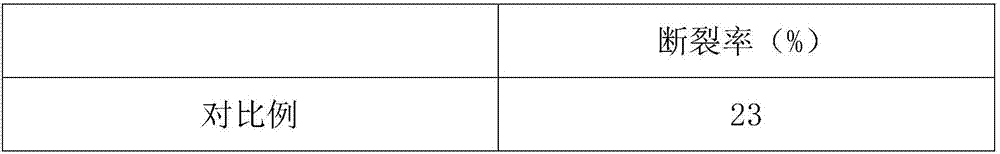

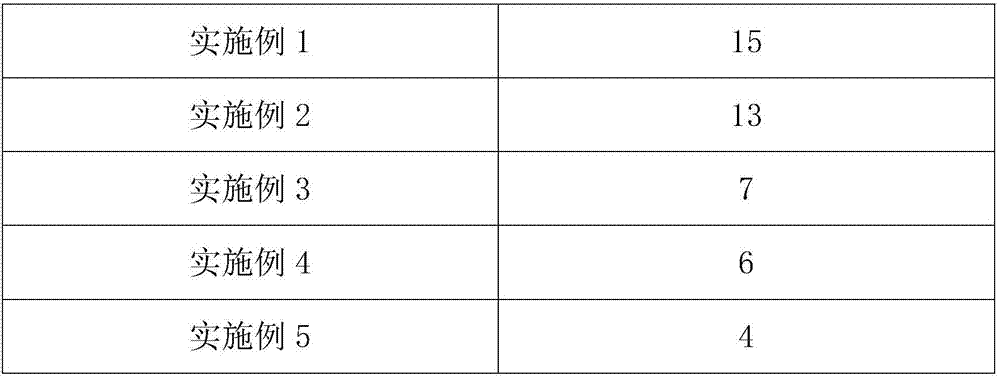

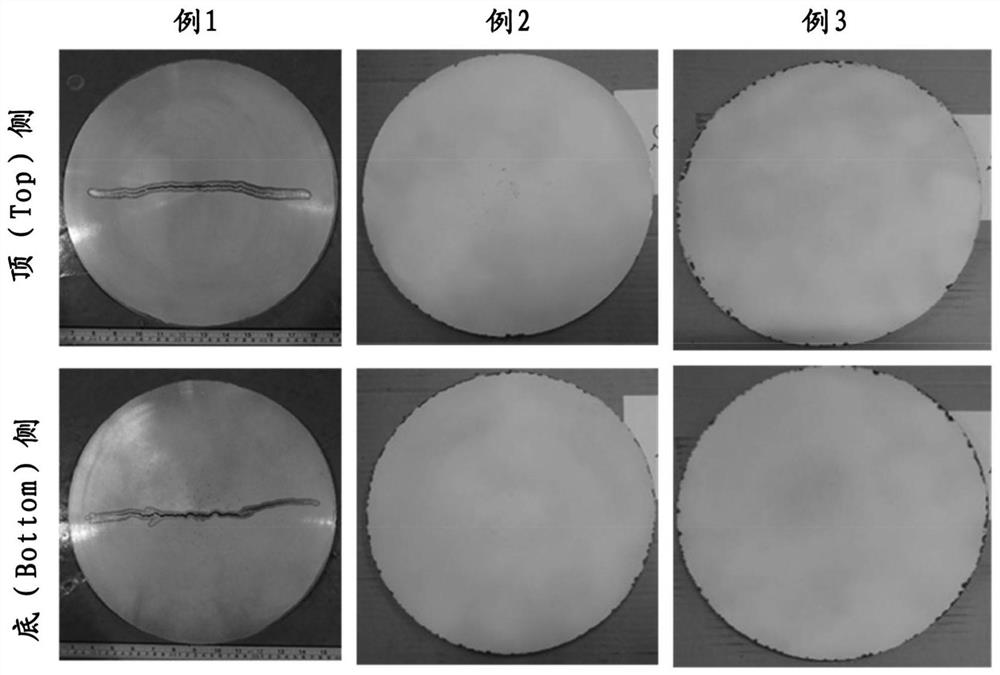

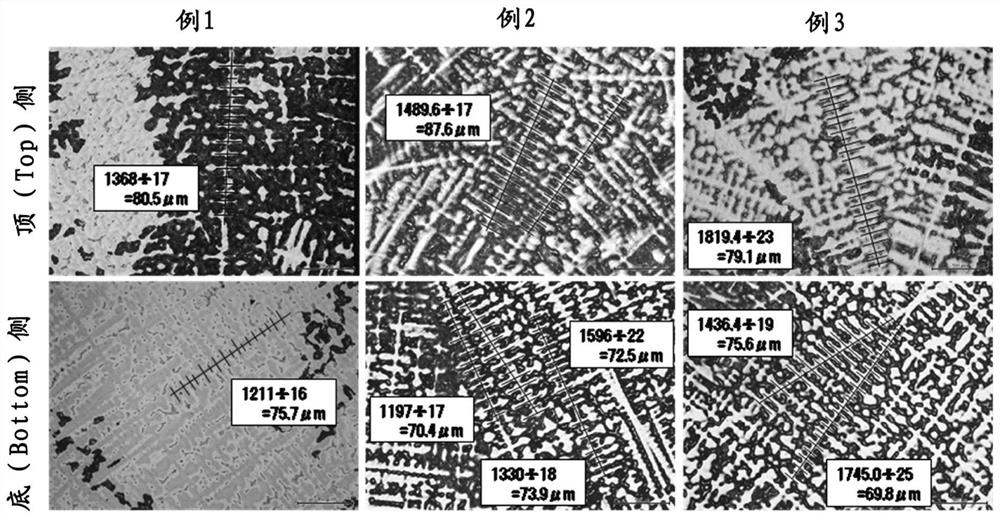

Method for reducing cracks of nickel-based superalloy formed by SLM (selective laser melting) and improving mechanical property

ActiveCN113042753AInhibition of large size cracksImprove mechanical propertiesAdditive manufacturing apparatusTransportation and packagingSelective laser meltingTube furnace

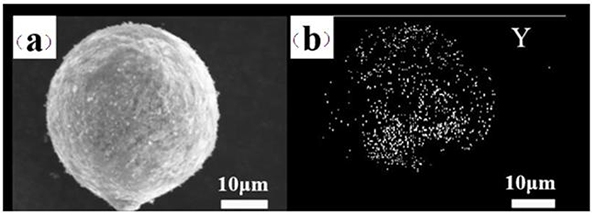

The invention provides a method for reducing cracks of nickel-based superalloy formed by SLM (selective laser melting) and improving mechanical property. The method comprises the following steps: pouring yttrium nitrate powder into absolute ethyl alcohol, and carrying out ultrasonic vibration stirring until the yttrium nitrate powder is completely dissolved; pouring GH3536 nickel-based high-temperature powder into a yttrium nitrate absolute ethyl alcohol solution, and carrying out ultrasonic vibration stirring, enabling metal powder and the solution to be fully contacted and wetted; drying the obtained solid-liquid mixture, then putting the solid-liquid mixture into a tubular furnace for calcining, and then cooling along with the furnace; grinding and screening the obtained calcined powder to obtain GH3536 powder uniformly coated with yttrium oxide; and preparing a GH3536 nickel-based high-temperature alloy block sample from the yttrium oxide uniformly coated GH3536 nickel-based high-temperature powder through a selective laser melting method. According to the method, the number of cracks in the SLM printed GH3536 nickel-based high-temperature alloy is effectively reduced, the microstructure state is improved, and the mechanical property of the GH3536 nickel-based high-temperature alloy is greatly improved.

Owner:TIANJIN UNIV

Improved production technology for fine dried noodles

InactiveCN107279719AImprove flexural performanceReduce the probability of breakageFood dryingWheat flourHumidity

The invention discloses an improved production technology for fine dried noodles. The improved production technology comprises the following steps: A, kneading a dough, namely selecting wheat flour with the gluten content of 32-34% and the protein content of 18-19%, and kneading the dough, wherein a mixing ratio of the wheat flour to water is 2:1; B, curing, namely carrying out standing on the dough in an environment at the temperature of 40 DEG C and the humidity of 70%, and curing for 3 hours; C, pressing into sheets, namely putting the cured dough into a noodle press, and pressing into the sheets with the thickness of 1mm; D, preliminary drying, namely putting the sheets into a drying room, and drying for 10 minutes while a drying temperature is controlled to be 45-55 DEG C; E, slitting, namely slitting the preliminarily dried sheets; F, drying, namely drying the noodles; G, cutting, namely cutting the dried noodles according to set length; and H, packaging, namely weighing the cut fine dried noodles, and packaging. The improved production technology for the fine dried noodles has the advantages that defects of the prior art can be solved, and fracture rate of the fine dried noodles is reduced.

Owner:吴忠市嘉禾粮油食品有限公司

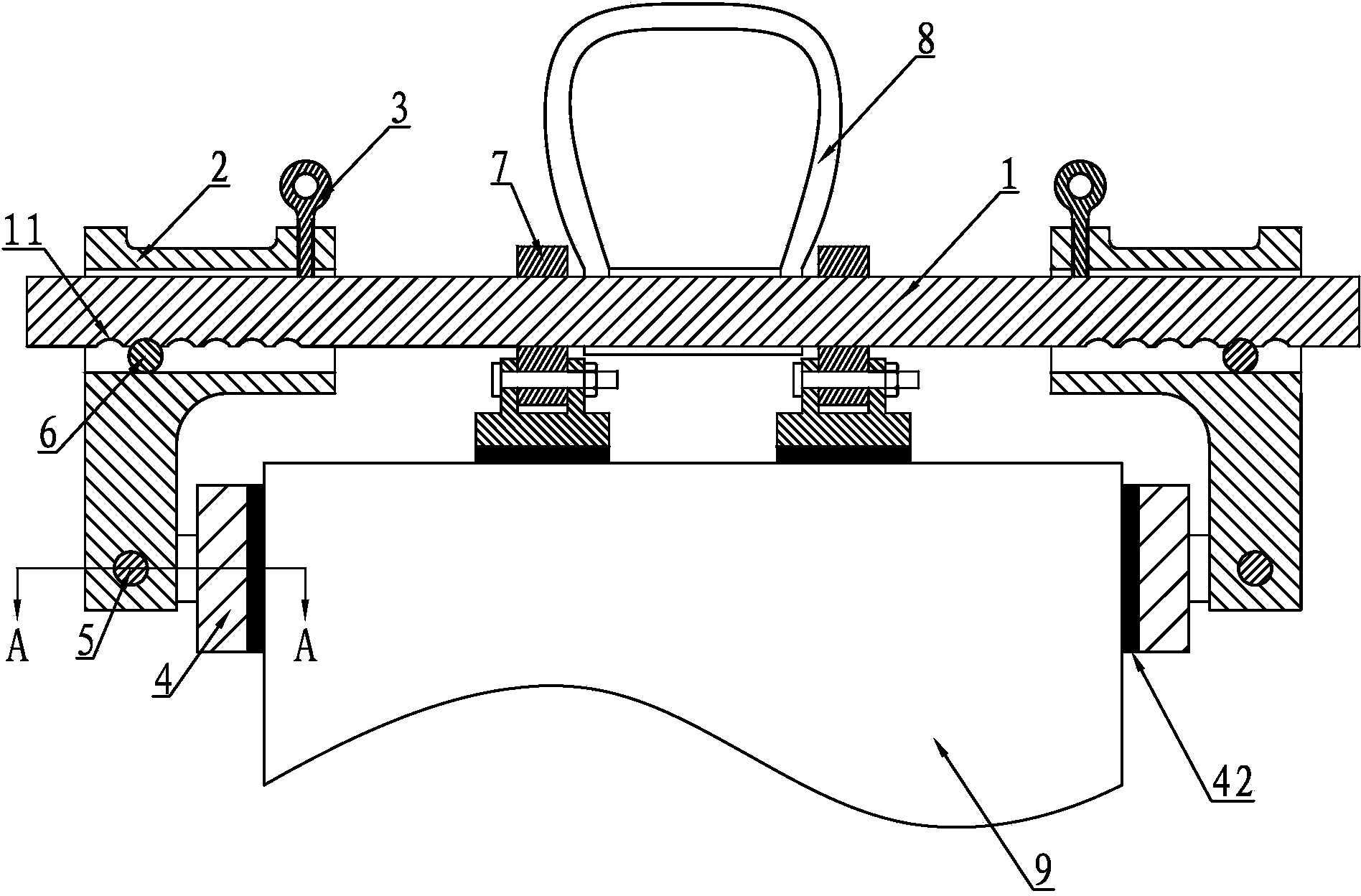

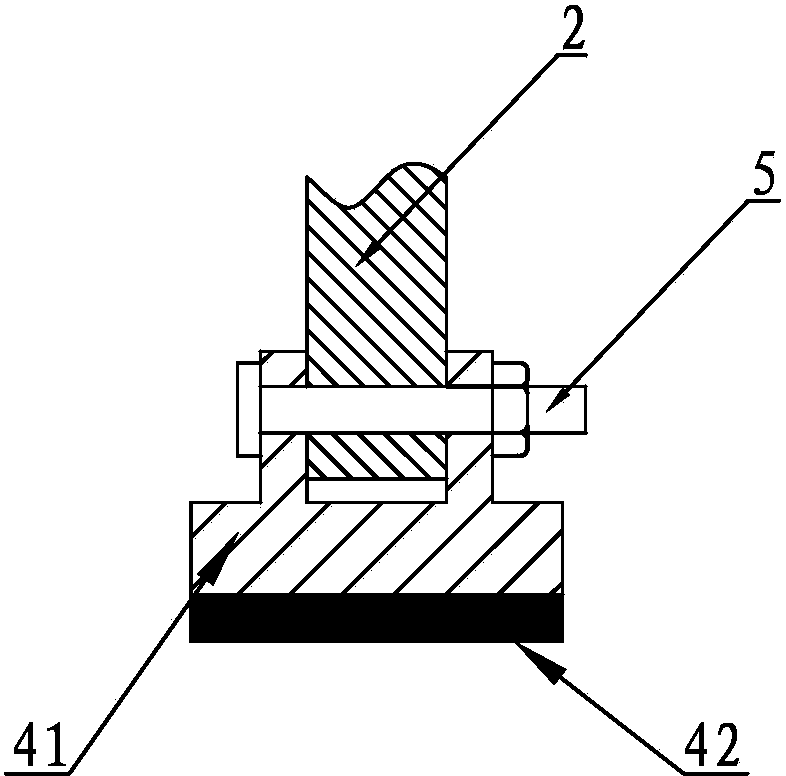

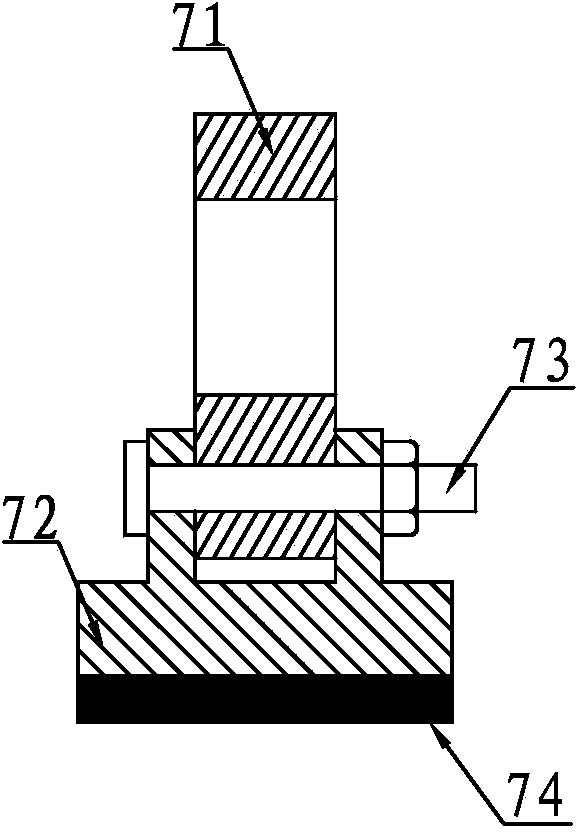

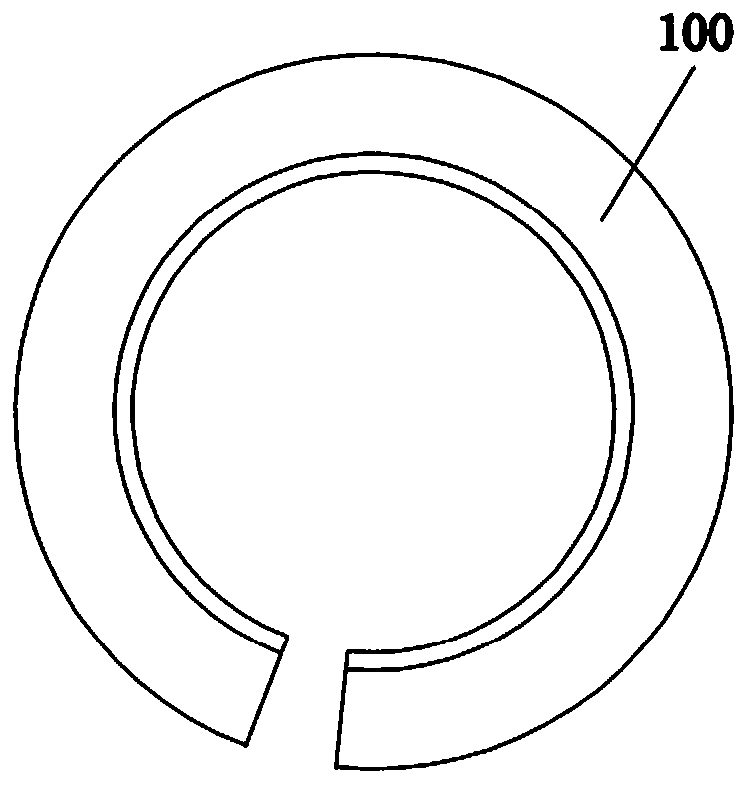

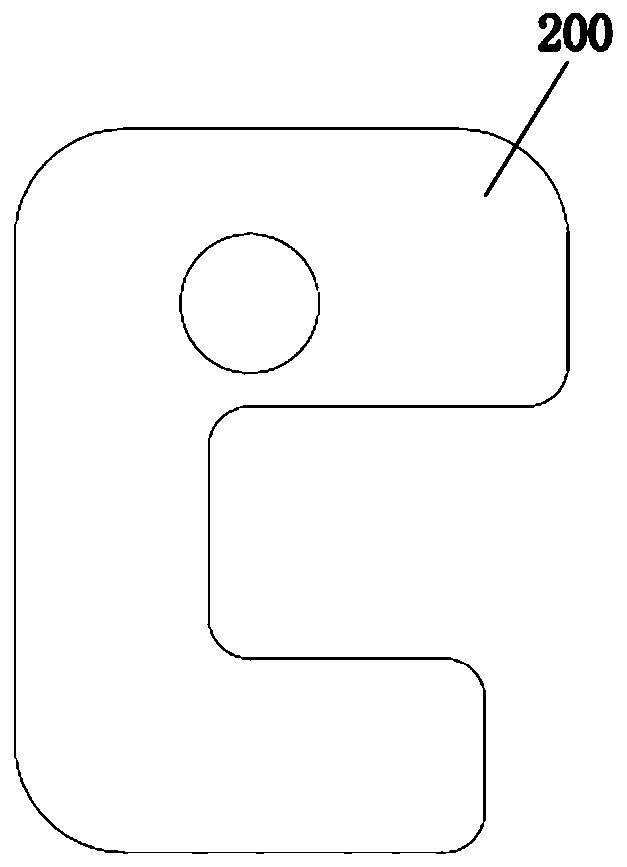

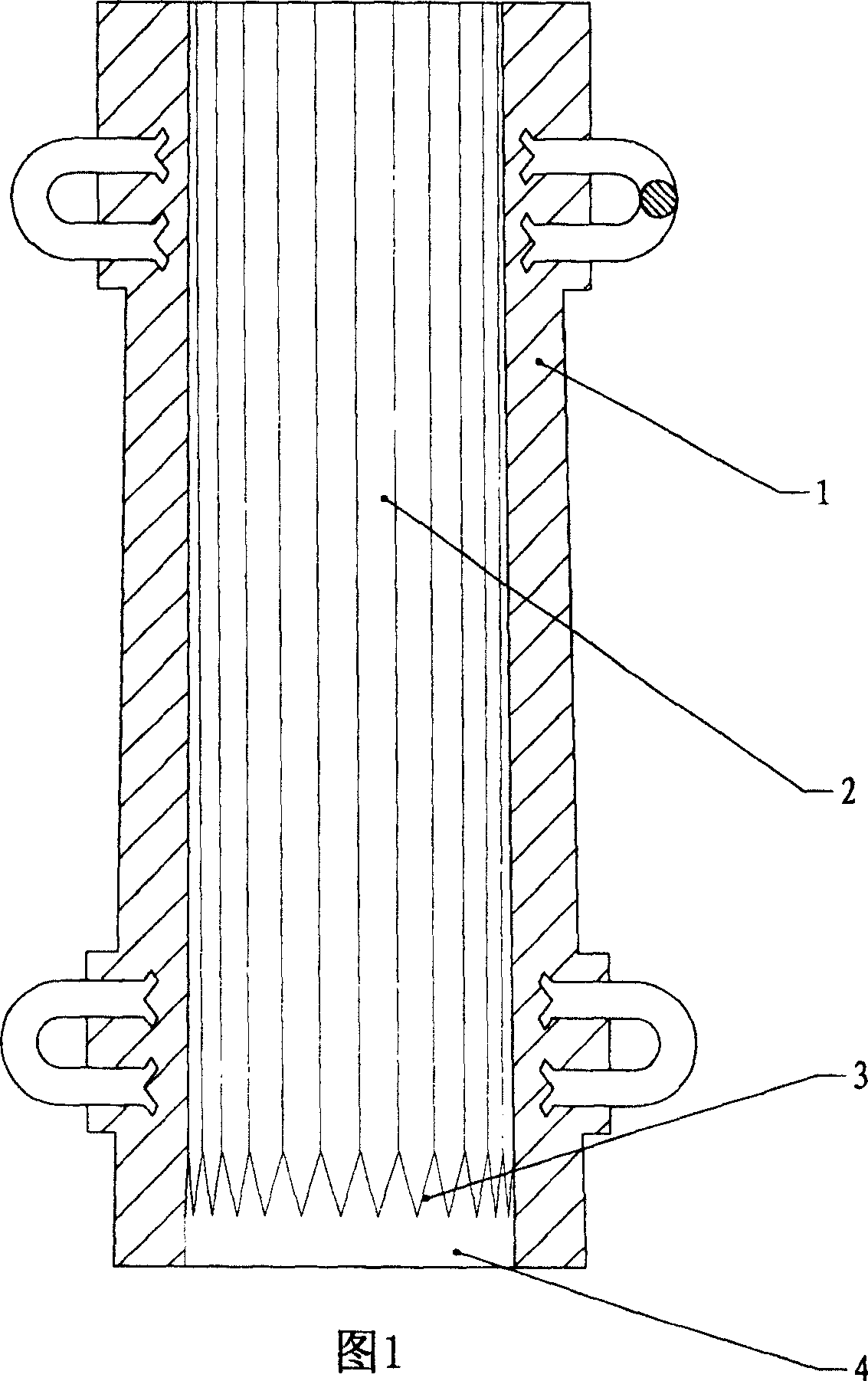

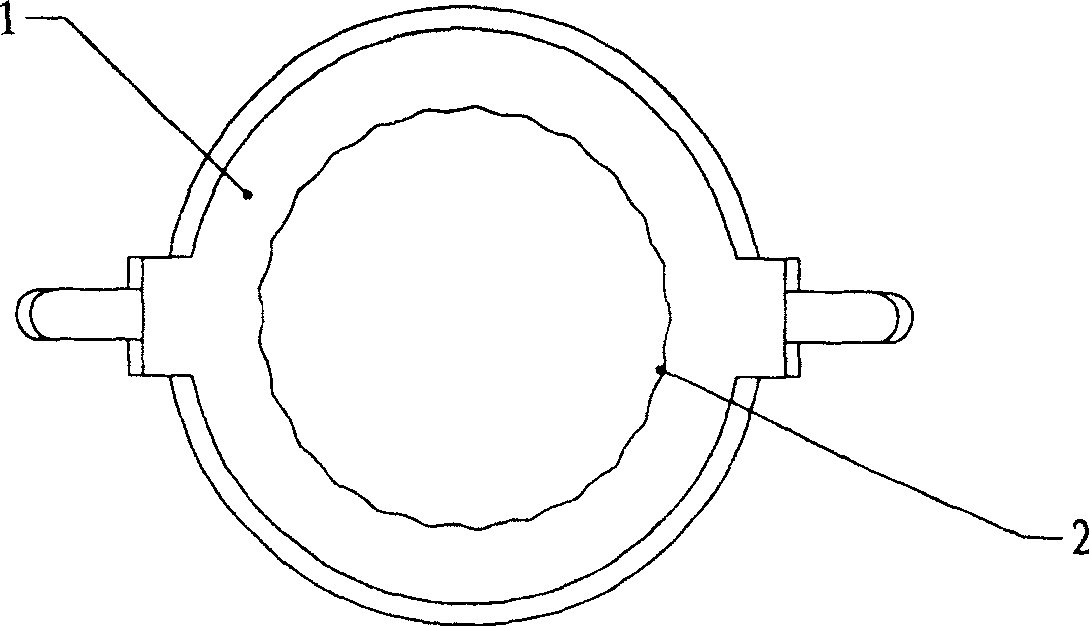

Ingot tilting fixture for turning over polycrystalline silicon ingot

An ingot tilting fixture for turning over a polycrystalline silicon ingot comprises a balance hanger rod, side clamping arms, side pressure adjusting screws, side clamping blocks, clamping block rotating pins, arm rotating pins, top loss prevention blocks and a strap. Rotating notches matched with the arm rotating pins are formed in the lower end faces of two ends of the balance hanger rod, the side clamping arms are sleeved at the two ends of the balance hanger rod, the arm rotating pins are mounted on the side clamping arms and correspond to the rotating notches of the balance hanger rod, the side pressure adjusting screws are screwed on the upper end faces of the side clamping arms, the lower ends of the side pressure adjusting screws correspond to the upper end of the balance hanger rod, the side clamping blocks are mounted on the side clamping arms through the clamping block rotating pins and can freely rotate relative to the side clamping arms, the top loss prevention blocks are mounted on the balance hanger rod and correspond to the top of the polycrystalline silicon ingot, and the strap is fixed onto the balance hanger rod. An advanced silicon ingot square-cutting process can be smoothly implemented, internal hidden cracks caused by internal stress imbalance of tilting and square-cutting of the polycrystalline silicon ingot are reduced, cracking of the ingot is avoided, and the yield of polycrystalline silicon rods is improved.

Owner:JIANGSU ZHAOJING PHOTOELECTRIC TECH DEV

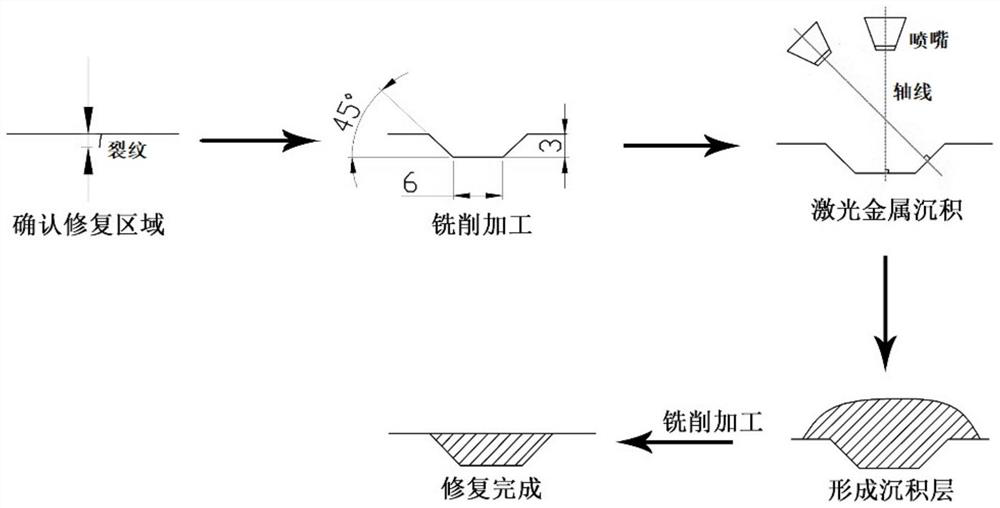

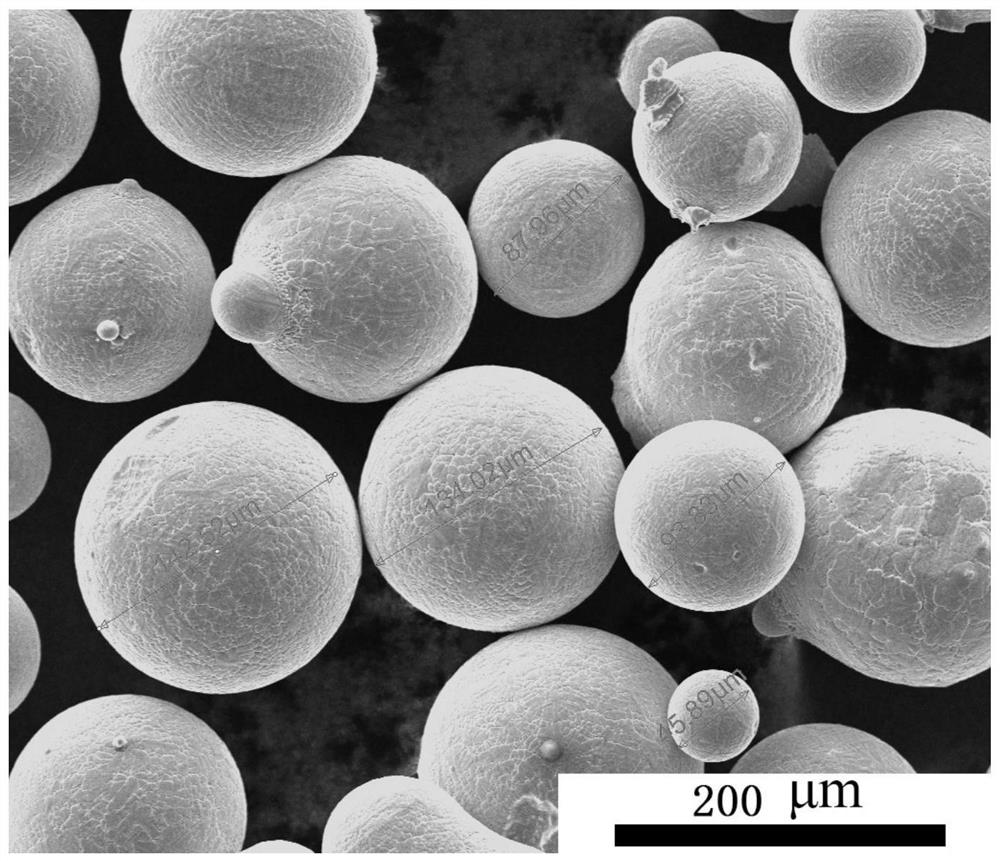

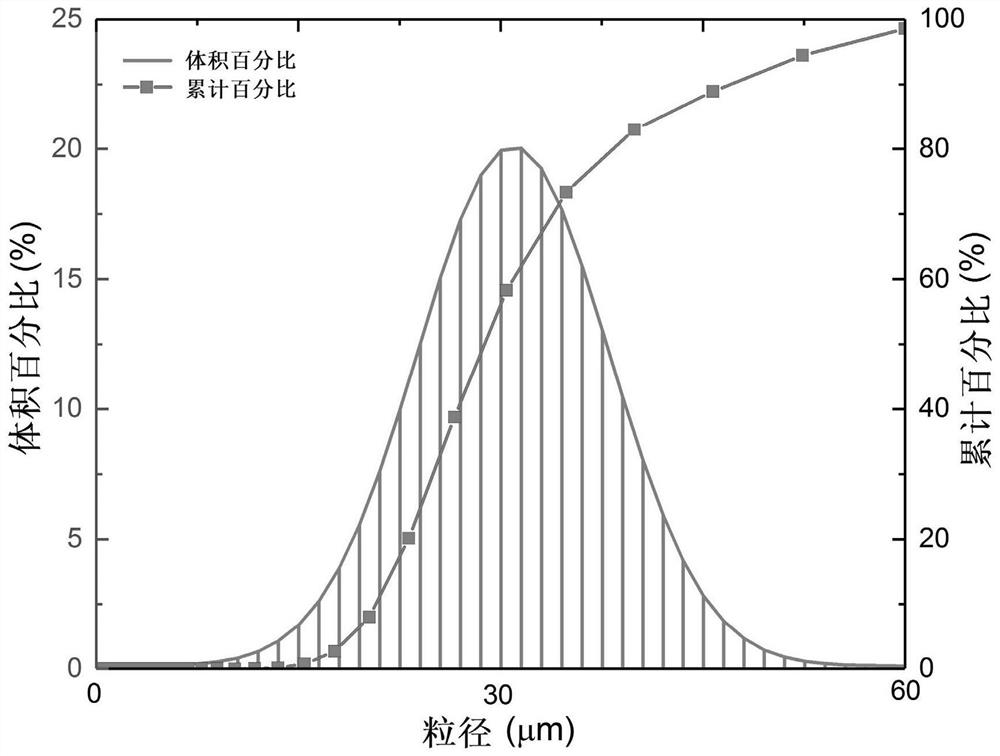

Laser additive repairing method for H13 steel mold

ActiveCN114226751AHigh strengthHigh hardnessAdditive manufacturing apparatusIncreasing energy efficiencyHardnessLaser additive manufacturing

The invention discloses a laser additive repairing method for an H13 steel mold. The laser additive repairing method comprises the following steps that (1) a to-be-repaired area of the H13 steel mold is pretreated; (2) spherical H13 steel mixed powder with different particle size distribution is adopted for conducting laser metal deposition on the to-be-repaired area through laser additive manufacturing, the position and angle of a nozzle are dynamically adjusted according to the characteristics of the to-be-repaired area, and laser power is dynamically adjusted according to the number of deposition layers; and (3) milling a deposition layer formed by laser metal deposition. By means of the method, laser additive repairing can be conducted on various surfaces such as the plane, the inclined face and the arc face of the H13 steel mold, the strength, hardness and impact toughness of a repairing area are large, and good metallurgical bonding is formed between the repairing area and an H13 steel mold base body.

Owner:SOUTH CHINA UNIV OF TECH +1

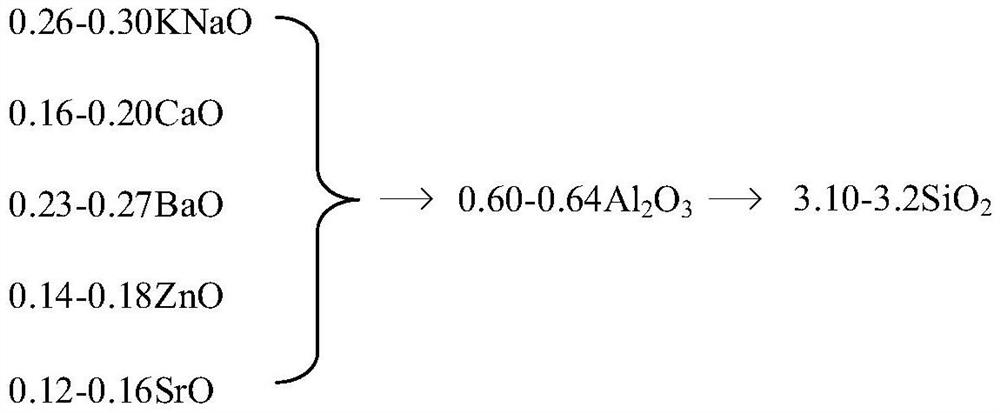

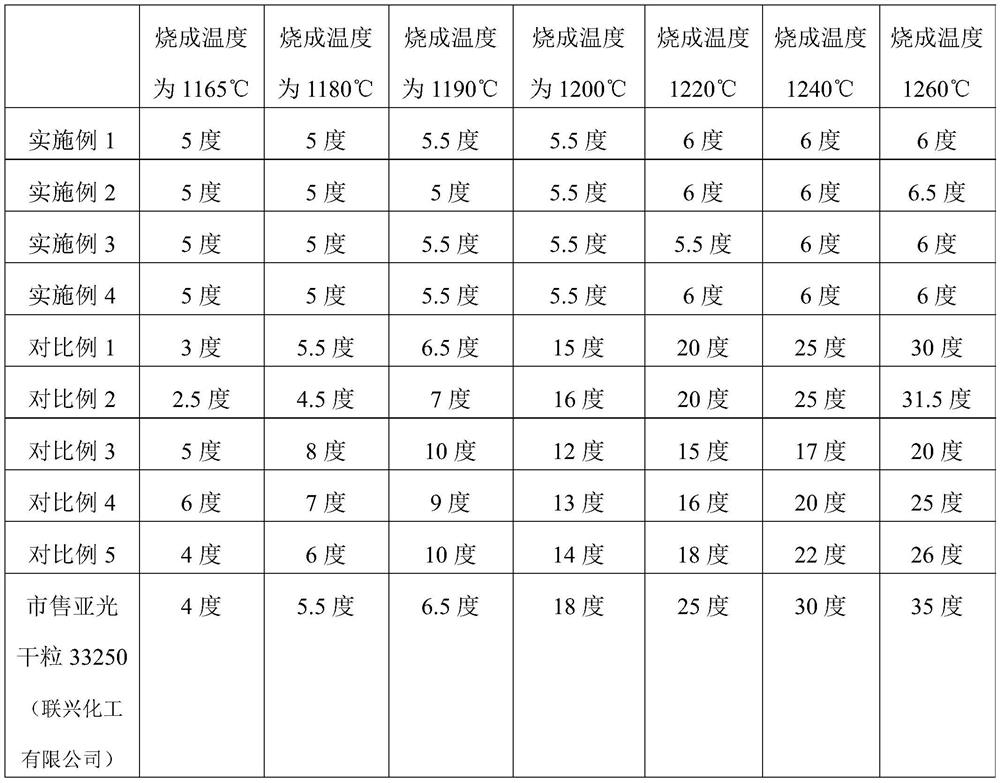

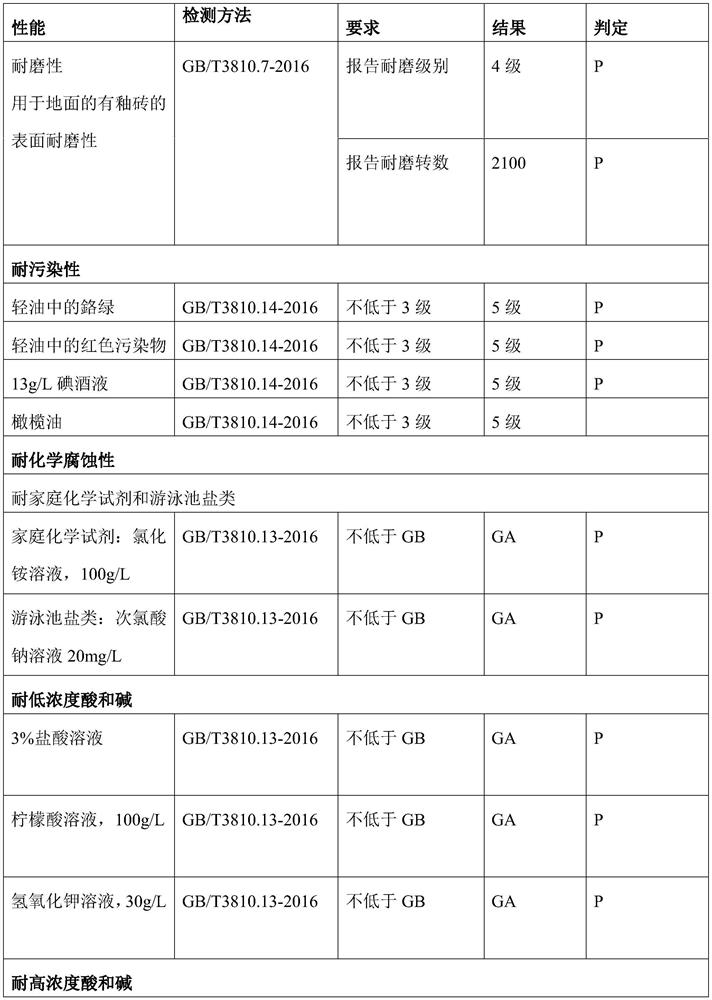

Matte dry granular material and preparation method thereof

ActiveCN113860737AWide firing temperature rangeHigh densityCeramic materials productionStrontium carbonateKaolin clay

The invention relates to a matte dry granular material and a preparation method thereof. The matte dry granular material is mainly prepared from the following raw materials in parts by weight: 30-45 parts of potassium feldspar, 5-15 parts of albite, 6-10 parts of kaolin, 10-20 parts of barium carbonate, 3-8 parts of wollastonite, 3-10 parts of zinc oxide, 4-10 parts of strontium carbonate, 7-13 parts of calcite, 1-4 parts of quartz and 1-5 parts of aluminum oxide. The matte dry granular material shows stable matte gloss at different specifications of firing temperatures, and has excellent physical properties such as wear resistance and pollutant resistance.

Owner:GUANGDONG NEWPEARL CERAMIC GRP CO LTD +4

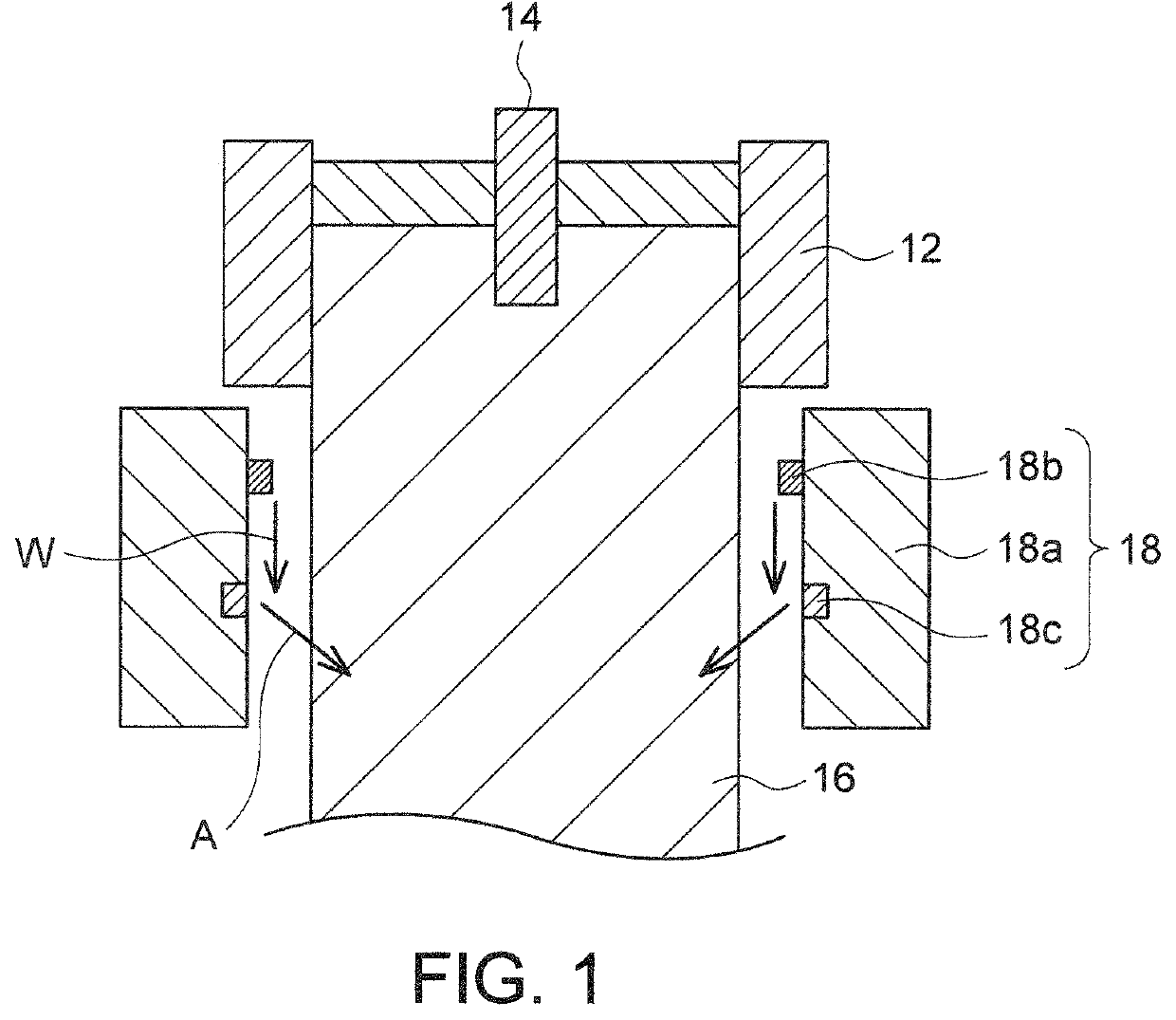

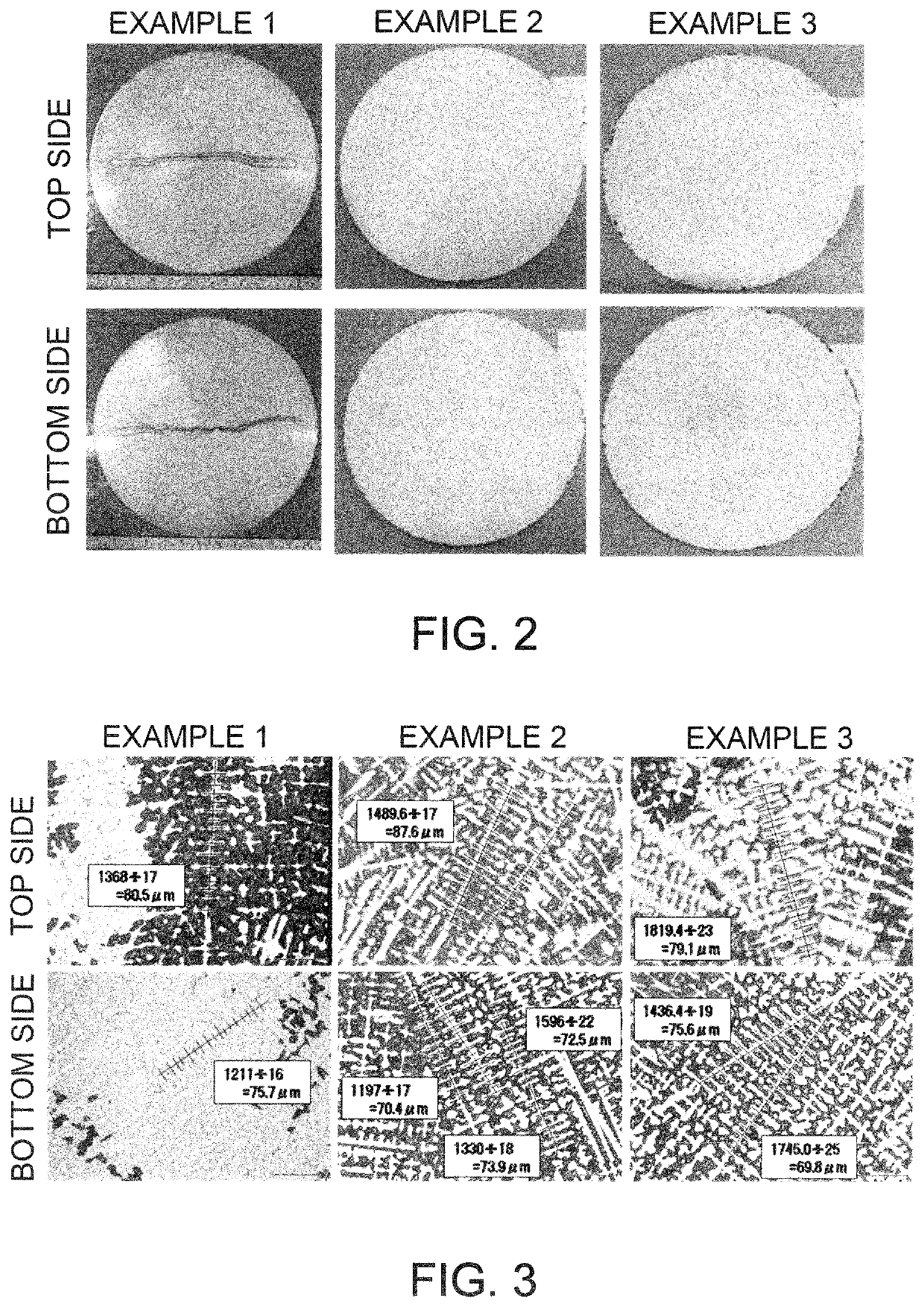

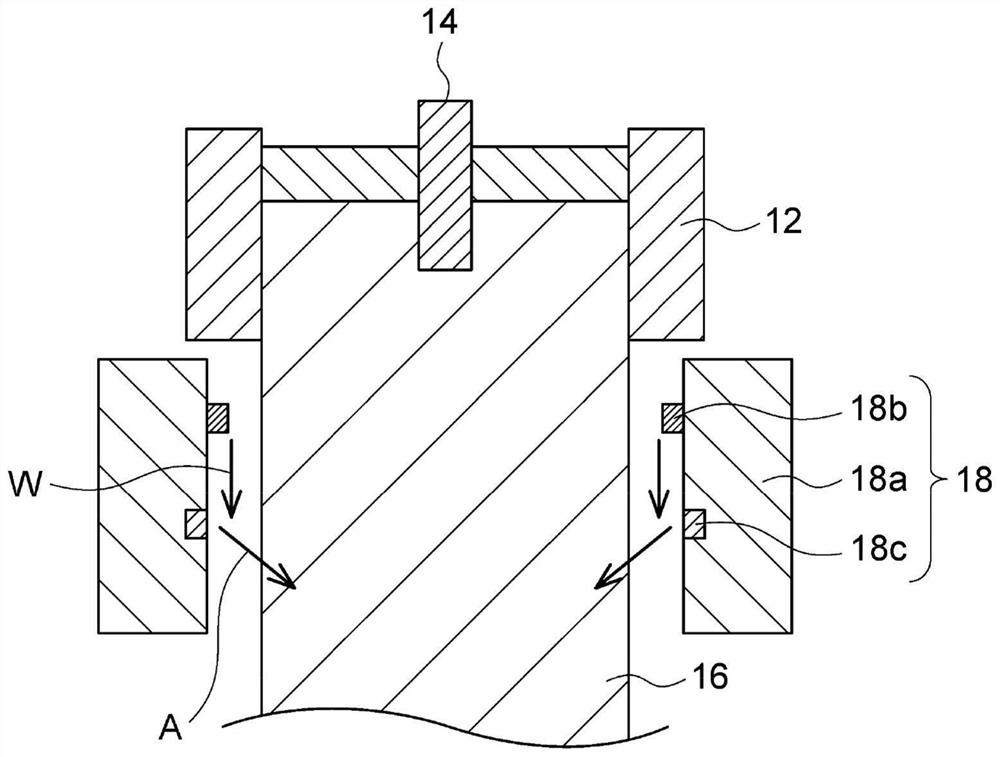

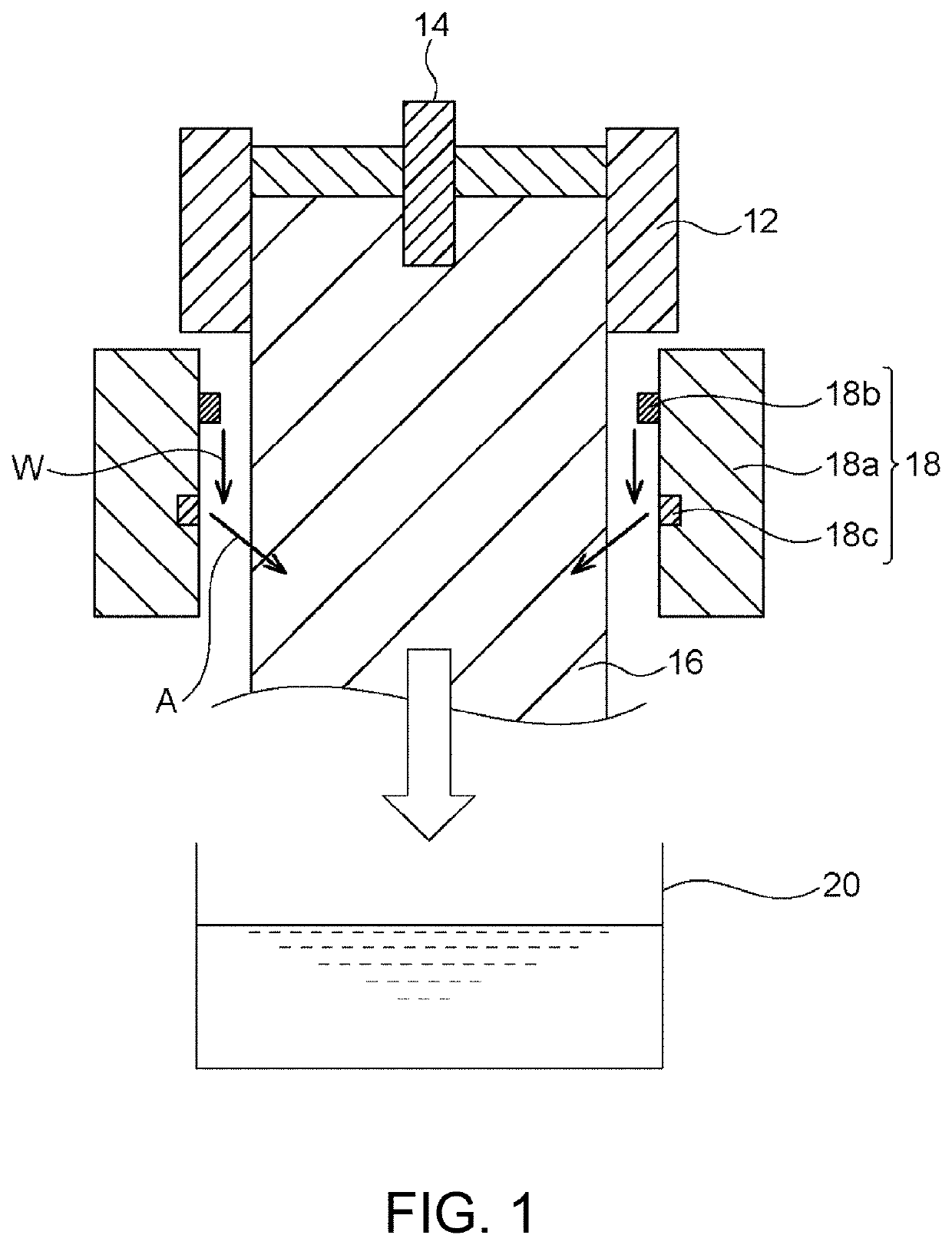

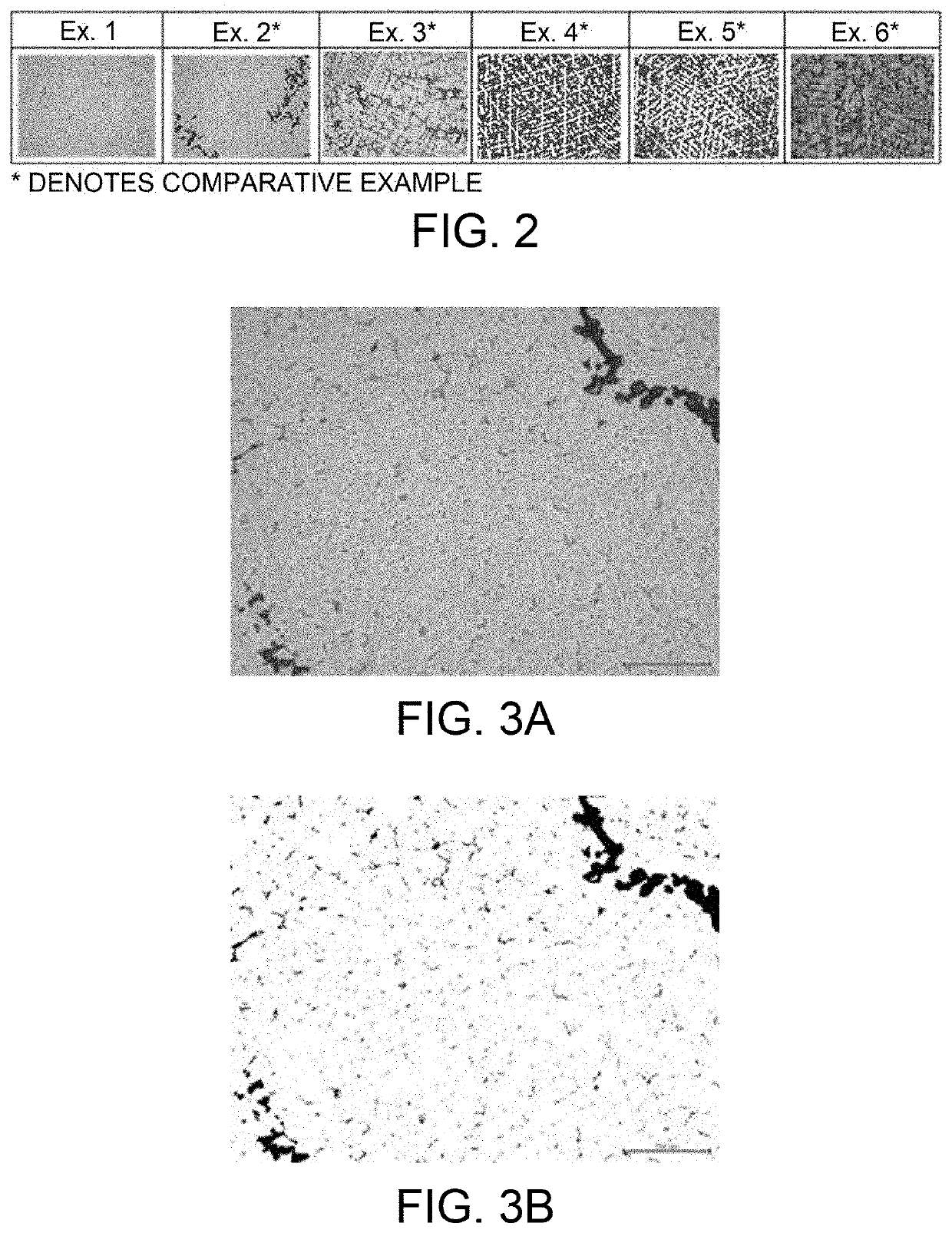

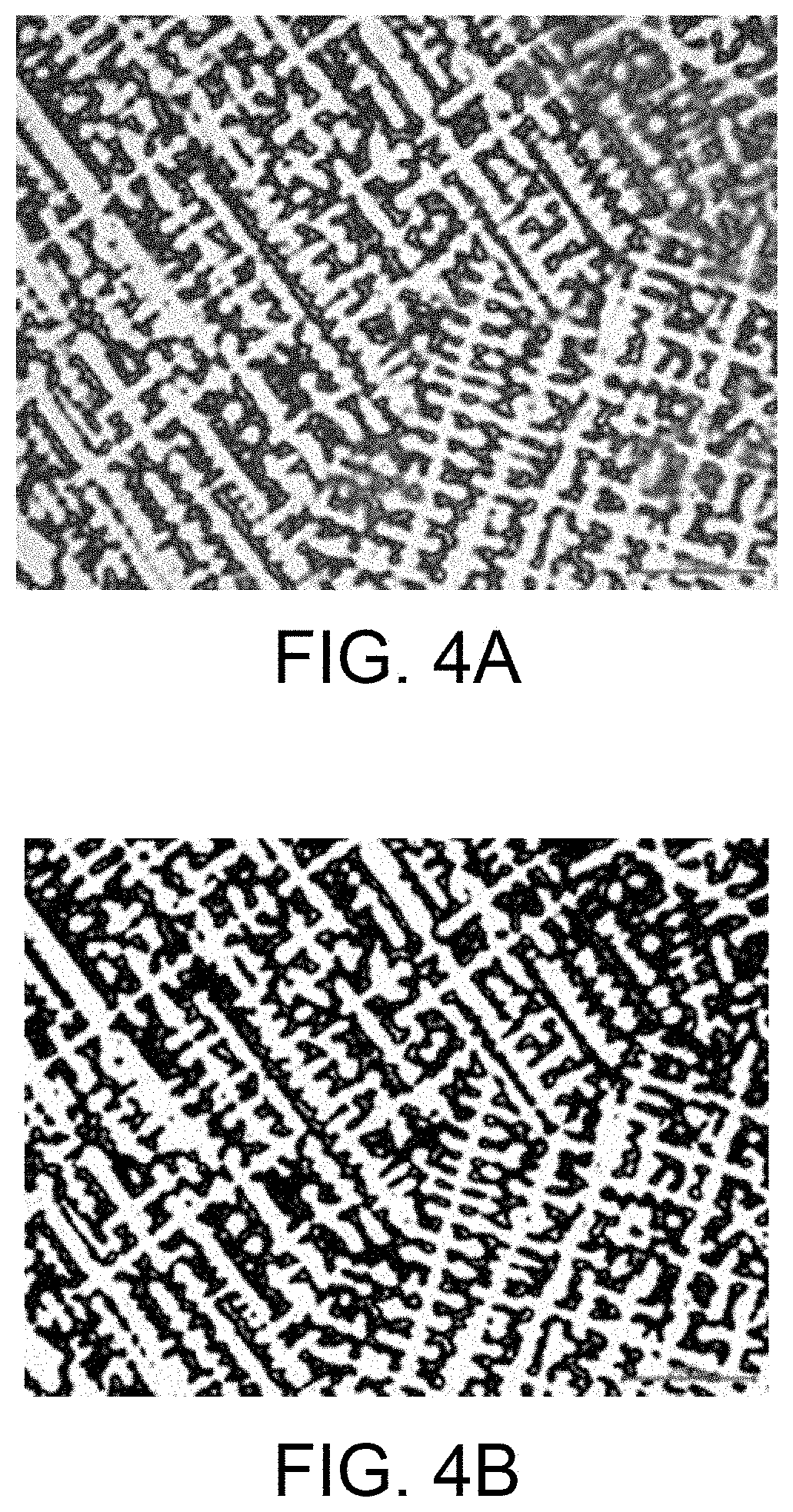

Method for producing Cu—Ni—Sn alloy and cooler to be used for same

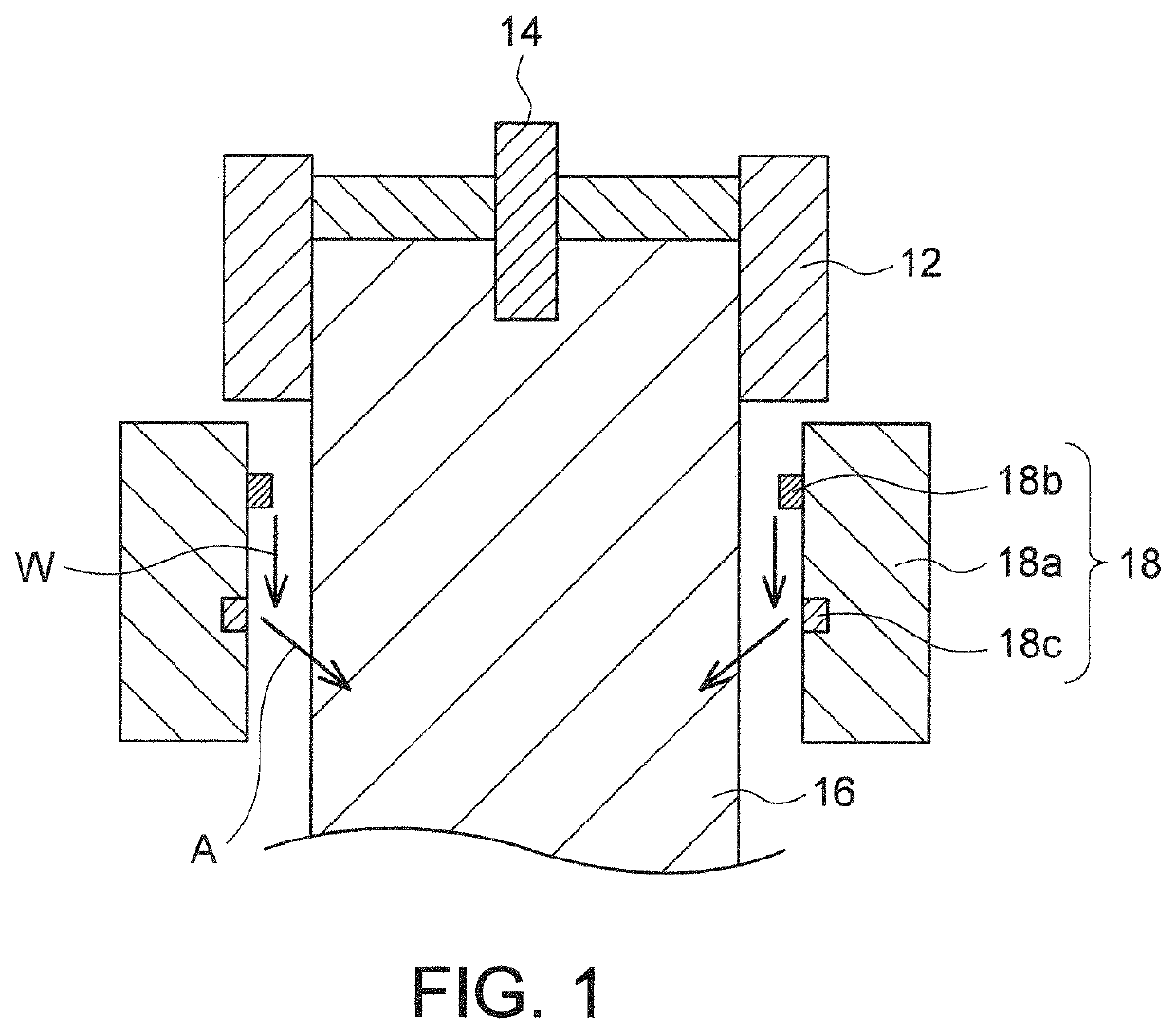

ActiveUS11440086B2Reduce internal cracksShortening the time for cooling an ingotIngotContinuous casting

There is provided a method for producing a Cu—Ni—Sn alloy by a continuous casting method or a semi-continuous casting method, the method including pouring a molten Cu—Ni—Sn alloy from one end of a mold, both ends of which are open, and continuously drawing out the alloy as an ingot from the other end of the mold while solidifying a part of the alloy, the part being near the mold; and spraying mist-like liquid on the drawn-out ingot to cool the ingot, thereby making a cast product of the Cu—Ni—Sn alloy.

Owner:NGK INSULATORS LTD

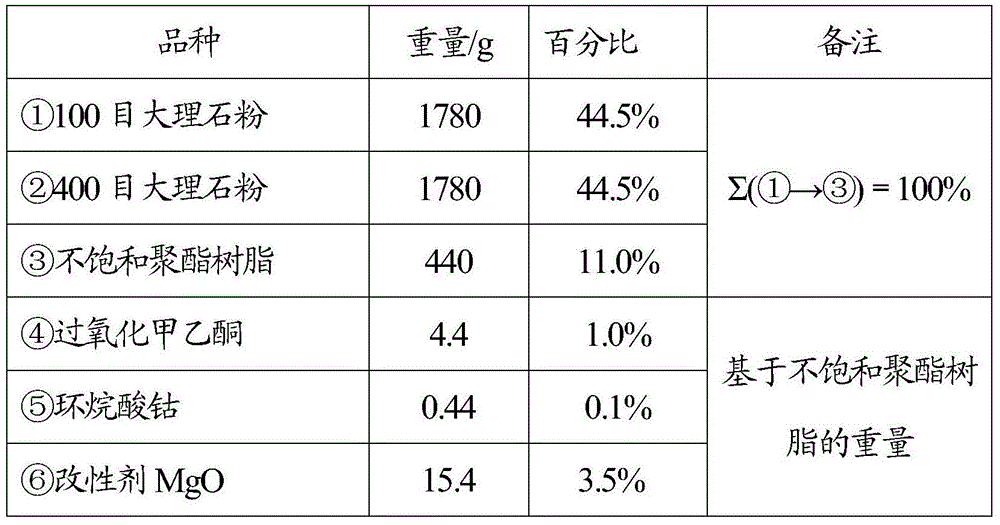

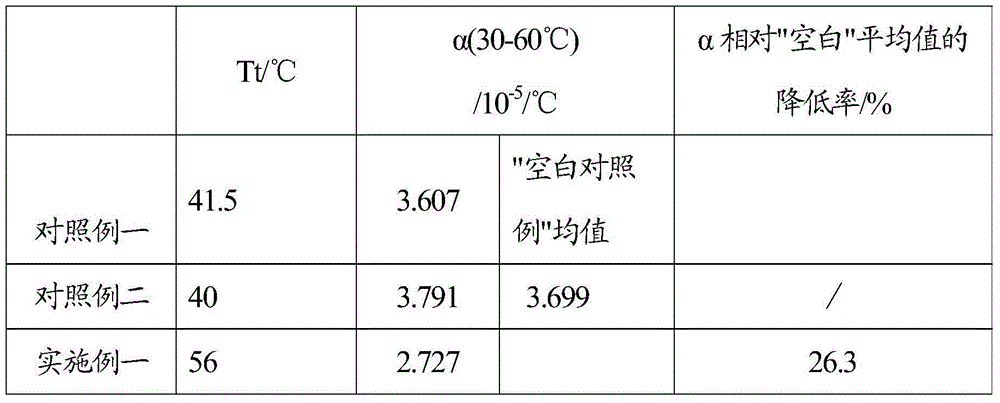

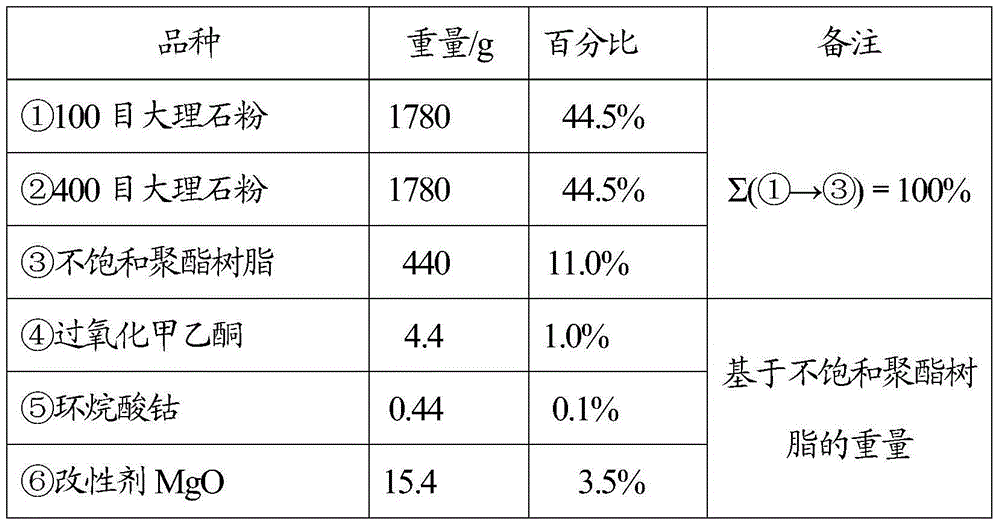

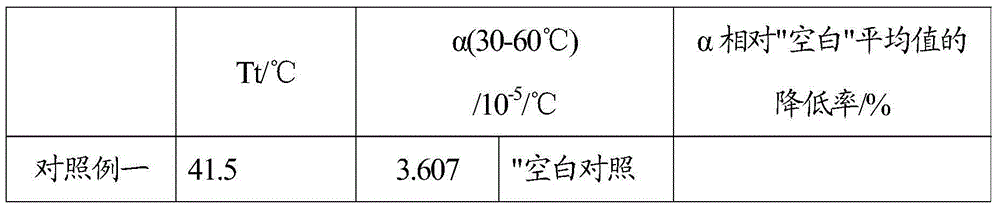

Post treatment process of man-made stone raw materials

InactiveCN105563628AReduce internal cracksNot easy to deformCeramic shaping apparatusLiquid mediumRoom temperature

The invention discloses a post treatment process of man-made stone raw materials. After pressing and before cutting, the man-made stone raw materials are subjected to soaking and curing treatment by liquid media with the temperature higher than the normal temperature; and then, normal-temperature maintenance is performed. The post treatment process has the advantages that the pressed man-made stone raw materials are subjected to maintenance post treatment, so that the traditional normal-temperature maintenance node is changed; the mode of firstly performing soaking, heating and curing treatment by liquid media with the temperature higher than the normal temperature and then performing normal-temperature maintenance is used; by using the post treatment process of soaking, heating and curing, unsaturated polyester resin reaction can be sufficient; and the stable product performance is achieved on the original basis, so that the quality problems of internal cracking, easy product deformation, warping and the like of the man-made stone raw materials are reduced.

Owner:WANFENG COMPOUND STONE TECH

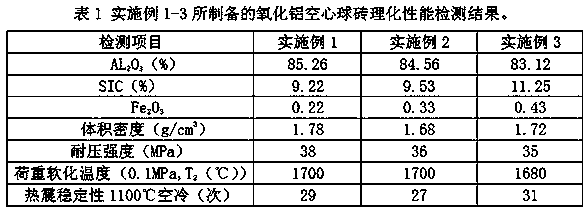

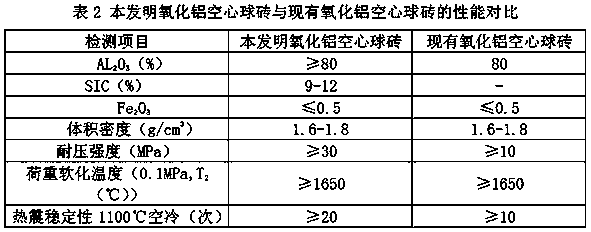

Alumina hollow ball brick and preparation method thereof

InactiveCN110423104ASmall expansion coefficientImprove thermal shock performancePolymer scienceBrick

The invention provides an alumina hollow ball brick and a preparation method thereof. The alumina hollow ball brick is prepared from the following raw materials by weight: 30-50 parts of alumina hollow balls with particle sizes of no less than 4 mm, 8-20 parts of fine white corundum powder with a particle size of no less than 150 meshes, 5-10 parts of silicon carbide with particle size of no lessthan 200 meshes, 8-16 parts of alumina micropowder with a particle size of no less than 500 meshes, 2-4 parts of kyanite micropowder with a particle size of no less than 500 meshes, 2-4 parts of sillimanite micropowder with a particle size of no less than 500 meshes, 4-7 parts of clay micropowder with a particle size of no less than 200 meshes and 8-12 parts of a binder. The alumina hollow ball brick of the invention has the characteristics of high temperature resistance, high strength, good thermal shock resistance, fuel economy and the like, and is particularly applicable to high-temperatureroller bar sintering kilns and kilns with similar working conditions; and the preparation method is simple in process and easy to implement, and has wide application and promotion value.

Owner:郑州明珠实业有限公司

Composite forming method for thick spiral blade

ActiveCN110814144AGuaranteed inside and outside diameterImprove molding qualityShaping toolsGas flame welding apparatusSpiral bladeEngineering

The invention relates to the technical field of spiral blade forming machining, and particularly relates to a composite forming method for a thick spiral blade. The method comprises the following steps that a, blanking is carried out, and a plane body spiral blade blank blanking graph is calculated according to a spiral blade expansion calculation formula; b, a plane body spiral blade blank is heated, and the plane body spiral blade blank is converted into austenite at the high temperature; c, the plane body spiral blade blank is drawn, the first end of the edge of an inner hole notch of the high-temperature plane body spiral blade blank is fixed, the second end of the edge of the inner hole notch of the high-temperature plane body spiral blade blank is drawn through hoisting equipment, the inner spiral line of the spiral blade is stretched to the required size, and the plane body spiral blade blank is initially formed into a spiral blade; and d, the initially-formed spiral blade is placed on a prefabricated spiral mold, and pressure is applied to the prefabricated spiral mold through a press machine to press the prefabricated spiral mold into a standard thick spiral blade. According to the method, the inner diameter and the outer diameter of the formed spiral blade can be guaranteed, the method is suitable for mass production of thick spiral blades, the efficiency is high, andthe forming quality of the spiral blade is stable.

Owner:中铁工程装备集团盾构制造有限公司

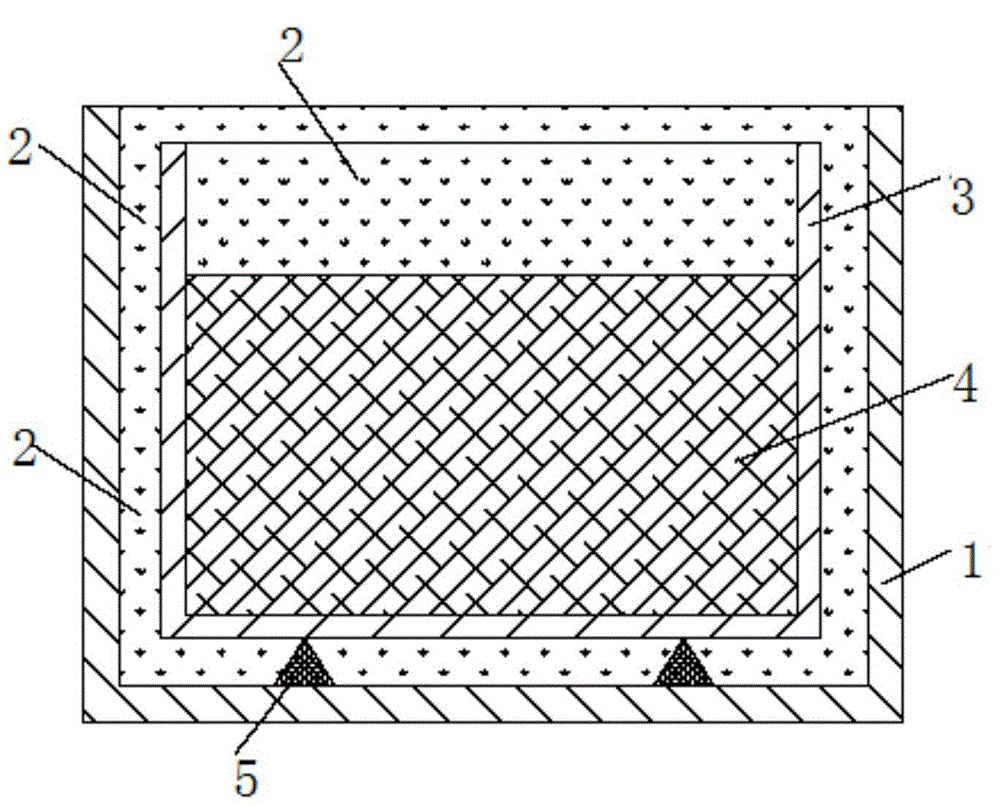

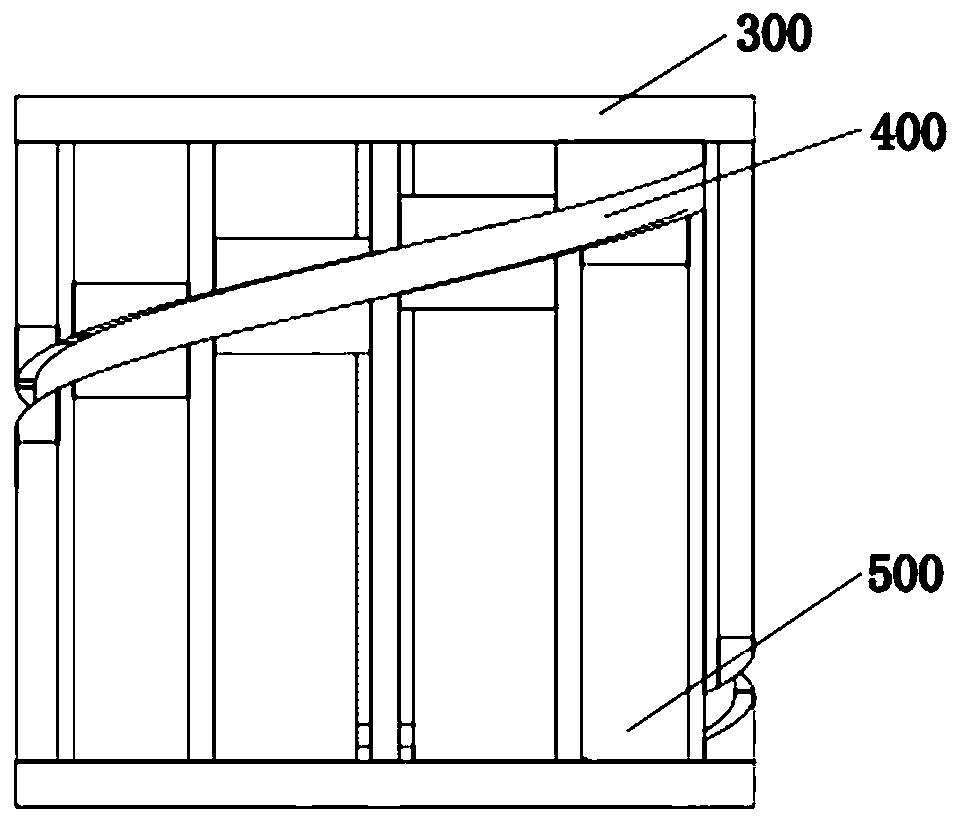

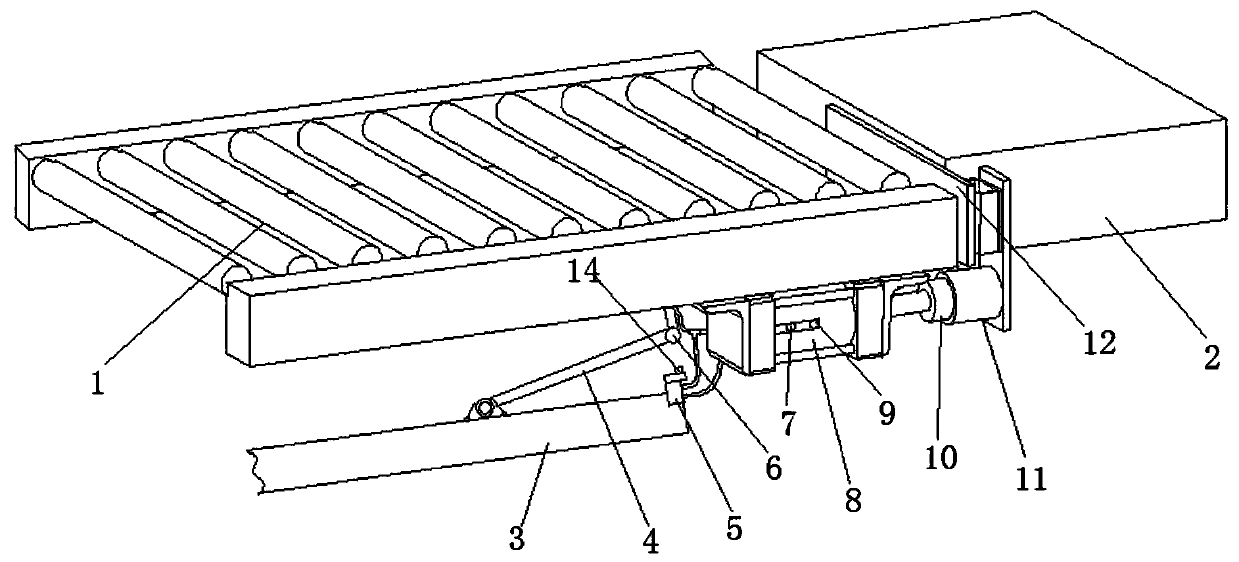

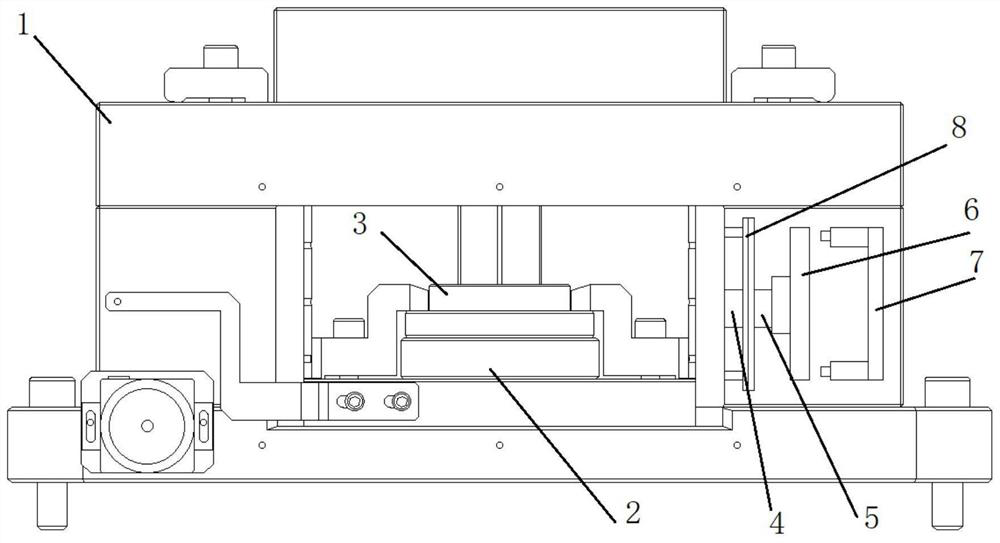

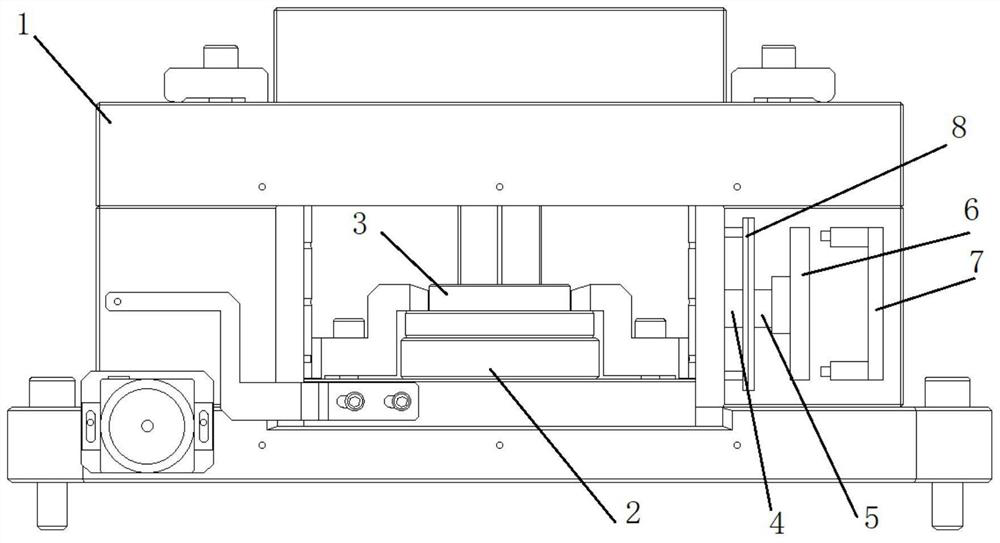

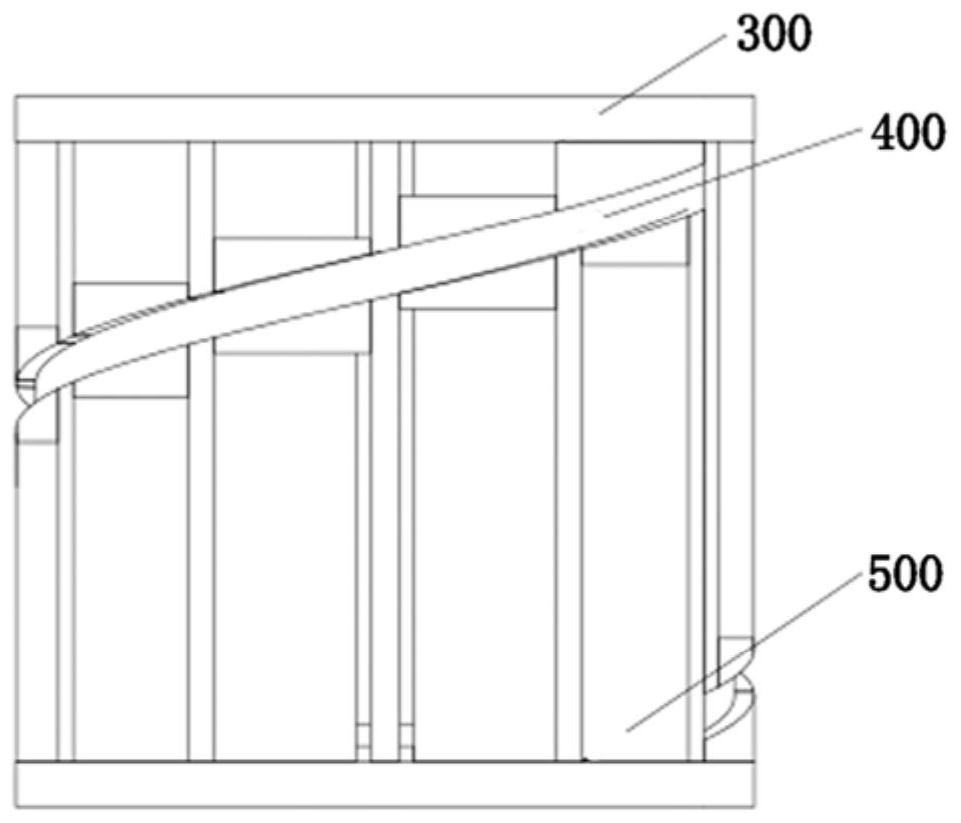

Stable ceramic press green body receiving platform

PendingCN110000898AReduce internal cracksReduce the vibration valueDischarging arrangementMaterials scienceGreen body

The invention belongs to the technical field of ceramic manufacturing equipment, and particularly relates to a stable ceramic press green body receiving platform. The stable ceramic press green body receiving platform comprises a green body receiving roller platform and a press which are connected. The ends, close to the press, of the left side and the right side of the green body receiving rollerplatform are provided with automatic extensible and retractable positioners. Each automatic extensible and retractable positioner is composed of a fixed device, a movable extensible and retractable device and a control device, wherein the fixed device comprises a fixed part and an abutting part, the fixed part is arranged on a middle frame of a press mold, the abutting part is arranged on the green body receiving roller platform, the abutting part can be driven by the movable extensible and retractable device to be completely embedded into the fixed part, and therefore stable positioning of the green body receiving roller platform and the press is guaranteed; and the control device is used for judging the positioning state of the green body receiving roller platform and the press and controlling work of the movable extensible and retractable device according to the positioning state. According to the stable ceramic press green body receiving platform, a vibration value of the roller platform is reduced, green body receiving is stable, and probability of internal hidden fractures and cracks in green bodies is greatly reduced.

Owner:JIANGXI HEMEI CERAMICS +1

Method for manufacturing water permeable brick with dredged sediment firing-free aggregate

InactiveCN109648685AImprove resource utilizationStructural scienceClimate change adaptationCeramic shaping plantsEcological environmentBrick

The invention relates to a method for manufacturing a water permeable brick with dredged sediment firing-free aggregate. The method comprises the following steps of (1) screening the dredged sedimentfiring-free aggregate is screened; (2) preparing pretreated firing-free aggregate; (3) manufacturing base layer ingredients; (4) adding water to the base layer ingredients and stirring the mixture; (5) manufacturing face layer ingredients; (6) adding water to the face layer ingredients and stirring the mixture; (7) conducting compression formation with a brick machine; (8) maintaining the manufactured product. The method for manufacturing the water permeable brick with the dredged sediment firing-free aggregate can consume a large amount of dredged sediment, reduces exploitation of natural aggregate, achieves the purposes of recycling and ecological environment protection and meets the demands of the dredging industry; the firing-free method is low in production energy consumption and lessin emission, the produced water permeable brick is low in cost and excellent in performance, the dredged sediment recycling approaches can be widened, the demand of a building material market can bemet, and the urban heat island effect can be well relieved.

Owner:TIANJIN UNIV OF SCI & TECH

Killed steel casting method

A periodic tube rolling machine with slant rolling drill rig is used to generate big caliber thick wall steel blocks, to satisfy the inside and surface quality requirements. Inner cavity working section of the mold is wave shape multilateral cross section shape wave ingot mold, with sulfur content controlled under 0.025% of the steel liquid, casting temperature within 40 to 80DEG C, linear speed 80 to 230mm / min, cracking ratio lower than 5%, pass rate 98.81%, with low consumption of metal, low cost, especially suitable for rolling into seamless steel tubes with multi types and specification and phi> / =426mm.

Owner:攀钢集团成都钢铁有限责任公司

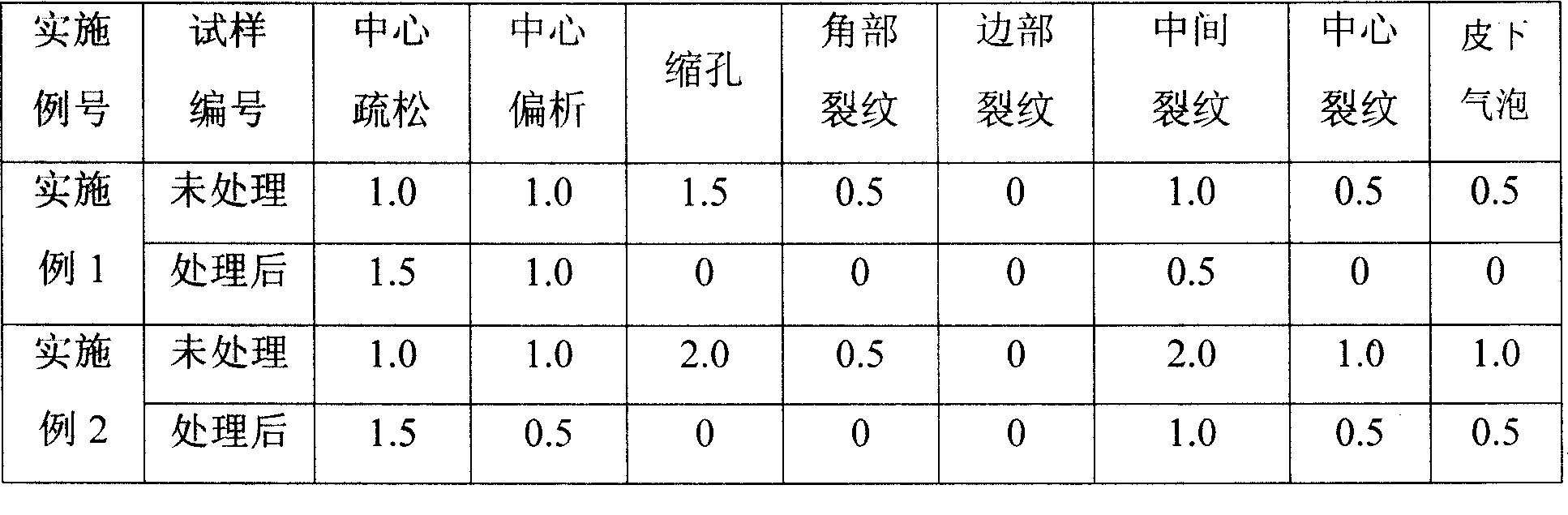

method for manufacturing Cu-Ni-Sn-Sn alloy and cooler for Cu-Ni-Sn alloy

The present invention provides a method for manufacturing a Cu-Ni-Sn-Sn alloy and a cooler for the Cu-Ni-Sn alloy by reducing internal cracks while shortening the cooling time of the casting block, thereby giving consideration to productivity and quality. A method for manufacturing a Cu-Ni-Sn-Sn alloy is a method for manufacturing a Cu-Ni-Sn alloy using a continuous casting method or a semi-continuous casting method, comprising: flowing a molten Cu-Ni-Sn alloy into one end of a casting mold open at two ends, solidifying a portion near the mold of the alloy, and continuously extracting as a casting block from the other end of the mold.; and a step of cooling the drawn liquid by blowing the mist-like liquid to the extracted casting block to produce a cast product of the Cu-Ni-Sn alloy.

Owner:NGK INSULATORS LTD

φ500~650mm Cr6 Type Forged Electroslag Steel Cold Rolled Work Roll Blank Forging Deformation Process

The invention discloses a Phi 500-650mm Cr6 type forged-electroslag-steel cold-rolled work roll blank forging and deforming technology. The technology includes the steps of converter producing plus LF refining plus VD vacuuming, continuous casting of round blank, hot annealing of electronic blank, clearing, electroslag remelting, annealing of electroslag ingot, forging and annealing after forging, wherein four-fire mode production is adopted in forging, upsetting and drawing out deformation methods are adopted in the first fire time, forging under great pressure is adopted in the second fire time, and forging to forming in the third and fourth fire time. Temperature and heat preservation time in high-temperature diffusion are key to control in forging, furnace return temperature and time in each fire time of forging and deformation and final forging temperature of each fire time are controlled. The spheroidized structure of the produced Cr6 type forged-electroslag-steel cold-rolled work roll blank is 2-3 in grade, carbide mesh is less than or equal to 2.0 in grade, carbide strap and liquation are below 1.0 in grade, total non-metallic inclusions is less than or equal to 2.0 in grade, flaw detection eligibility rate is increased from original 75% to 95%, carbide distribution is small and diffused, and long service life is achieved.

Owner:建龙北满特殊钢有限责任公司

Machining method of iron-chromium-aluminum high-resistance electrothermal alloy

The invention relates to the technical field of electrothermal alloy materials, in particular to a machining method of an iron-chromium-aluminum high-resistance electrothermal alloy. According to the technical scheme, the method comprises the following step of 1) weighing corresponding parts of chromium, aluminum, iron, yttrium, titanium, rhenium, cobalt and rare earth elements of lanthanum and yttrium by weight, fully mixing, and fully stirring for 10 minutes at the temperature of 80-90 DEG C, wherein the components specifically comprise 26.5 parts of chromium, 17.2 parts of aluminum, 33.5 parts of iron, 28.1 parts of yttrium, 1.44 parts of titanium, 8.25 parts of rhenium, 0.6 to 1.3 parts of cobalt, 1.5 parts of silicon, 6.8 parts of manganese, and 0.3-0.4 part of rare earth elements of lanthanum and yttrium. The machining method has the advantages that the oxidation resistance, the heat resistance, the corrosion resistance and the like of the produced iron-chromium-aluminum high-resistance electrothermal alloy can be ensured to be more reliable, the use requirements in a wider use environment can be met, and the overall cost in the production process is ensured to be lower.

Owner:JIANGSU MINGLUSINLESS STEEL

Preparation method of epoxy resin profile

The invention relates to a preparation method of an epoxy resin profile. The preparation method comprises the following steps that raw materials are uniformly mixed to obtain a mixture, and the mixture is preheated; the mixture is distributed, so that the mixture is uniformly distributed on a transmission device; the mixture on the transmission device is subjected to gradient heating, and then themixture is segmented to obtain a semi-finished product; the semi-finished product is subjected to heat preservation; the semi-finished product after heat preservation is pressed into a mold to be molded to obtain the epoxy resin profile, and the semi-finished product is subjected to gradient cooling in the forming process; and after the epoxy resin profile and the mold are cooled, demolding and blanking and forming are carried out, and then a film pasting is carried out to obtain an epoxy resin profile finished product. The epoxy resin mixture is subjected to gradient heating during gelationand curing to form an epoxy resin cured product, and the epoxy resin cured product adopts gradient cooling in the forming process of the epoxy resin cured product, so that internal stress generated inthe preparation process of the epoxy resin profile is reduced, cracks generated in the preparation process are reduced, and the problem that the finished product is prone to cracking after a period of time is used is reduced.

Owner:上海伟贞实业有限公司

METHOD FOR PRODUCING Cu-Ni-Sn ALLOY

The present invention provides a method for producing a Cu—Ni—Sn alloy, which achieves both productivity and product quality by reducing internal cracks and dispersing Sn uniformly while shortening the time for cooling an ingot. The method for producing a Cu—Ni—Sn alloy is a method for producing a Cu—Ni—Sn alloy by a continuous casting method or a semi-continuous casting method, the method including: pouring a molten Cu—Ni—Sn alloy from one end of a mold, both ends of which are open, and continuously drawing out the alloy as an ingot from the other end of the mold while solidifying a part of the alloy, the part being near the mold; performing primary cooling by spraying a liquid mist on the drawn-out ingot; and performing secondary cooling by immersing the ingot having been subjected to the primary cooling in a liquid, thereby making a cast product of the Cu—Ni—Sn alloy.

Owner:NGK INSULATORS LTD

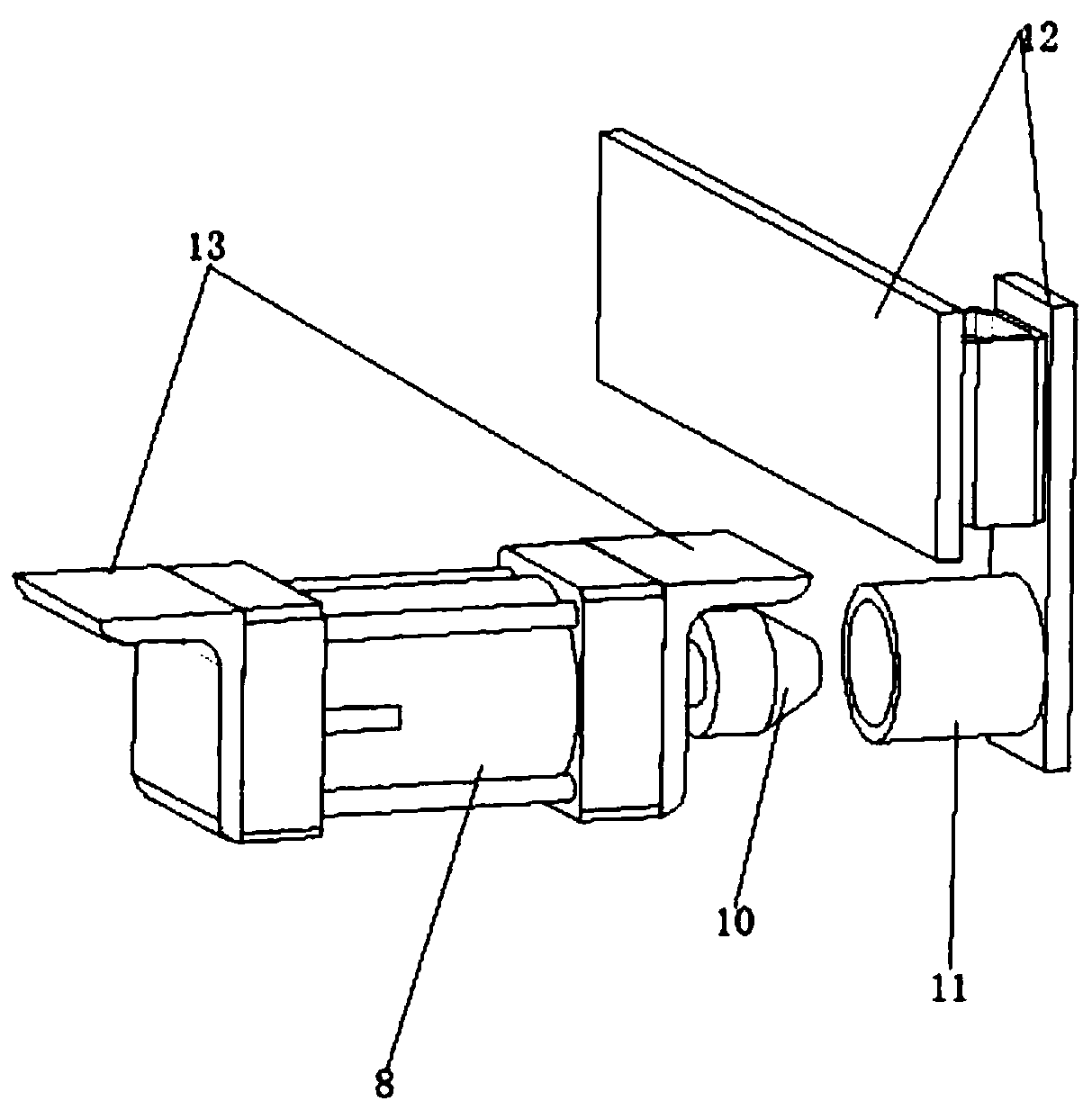

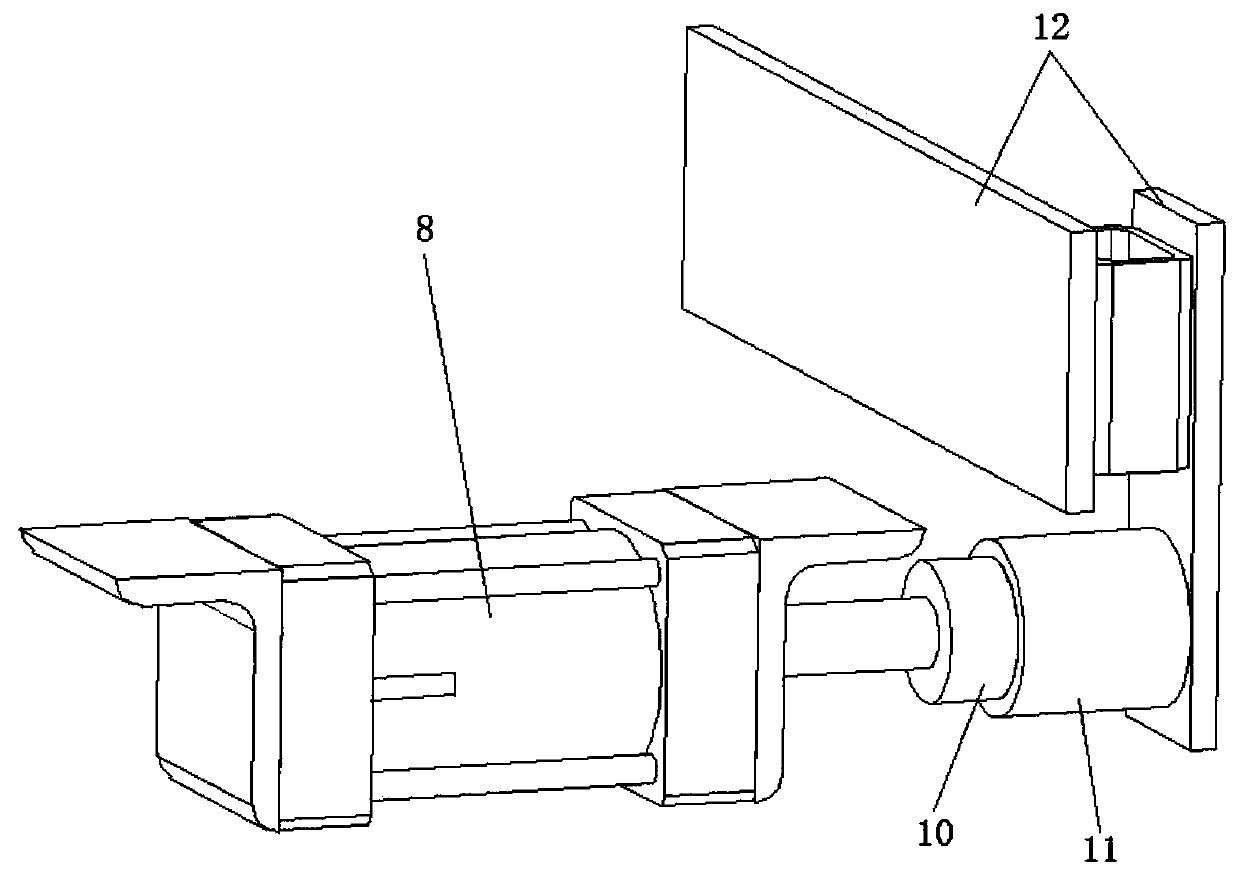

Brake pad friction block pressing device and method

PendingCN113953508AStable and efficient workAvoid the risk of breaking and falling offStructural engineeringMechanical engineering

The invention relates to the technical field of brake pad pressing, in particular to a brake pad friction block pressing device and method. The brake pad friction block pressing device comprises a mounting assembly, a stamping mechanism and a vibration mechanism. The stamping mechanism is mounted on the mounting assembly, and the stamping mechanism comprises a stamping die and a stamping head which are coaxially arranged. The vibration mechanism is provided with a first sliding part and a second sliding part which are in sliding connection, the first sliding part is fixedly installed on the mounting assembly, a first vibration part is installed at the end, away from the first sliding part, of the second sliding part in the sliding direction, a second vibration part is installed on the mounting assembly, and the first vibration part moves towards or away from the second vibration part under the action of the second vibration part. According to the brake pad friction block pressing device and method, internal cracks of a brake pad friction block obtained after vibrating pressing can be greatly reduced, in the long-term running process of a train, a brake pad can stably and effectively work, the risk that the brake pad friction block breaks and falls off is avoided, and the manpower maintenance and overhaul cost during the running period of the train can be greatly reduced.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

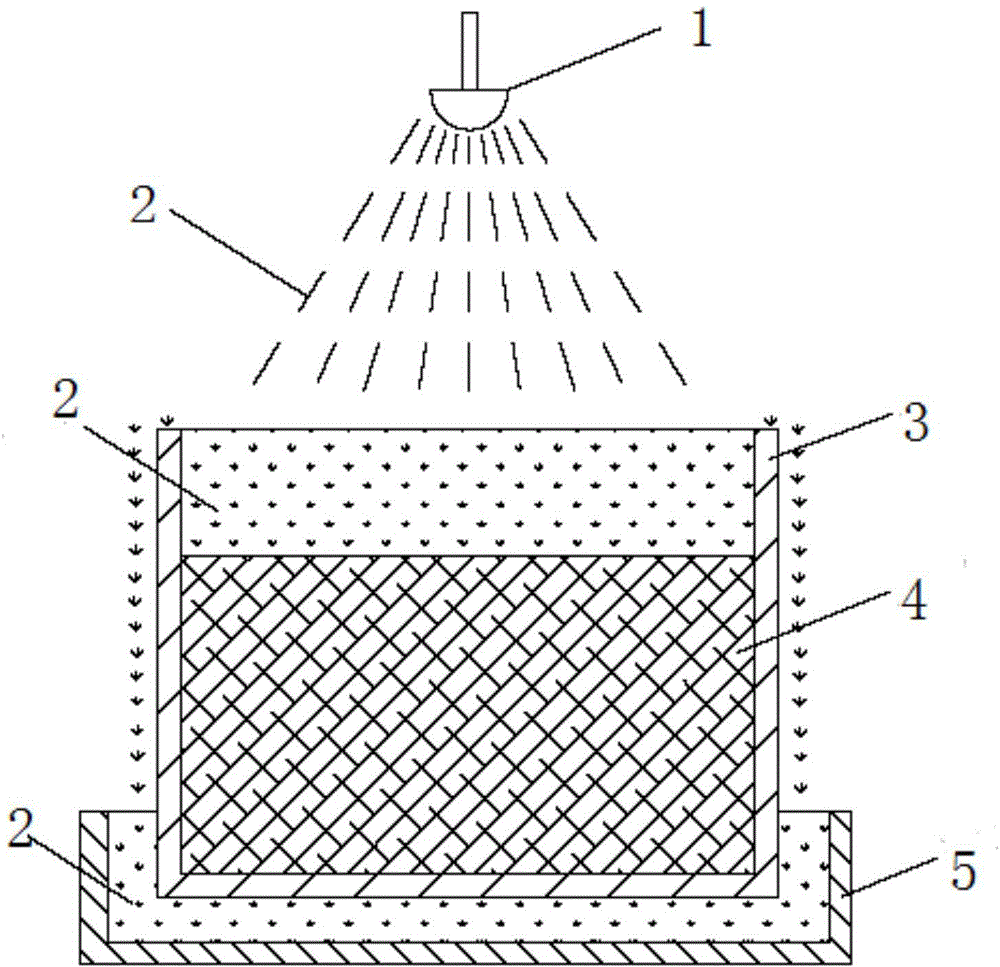

Artificial stone rough block curing process

InactiveCN105622165AProduct performance is stableReduce internal crackingArtificial stoneRoom temperature

The present invention discloses an artificial stone rough block curing process, which artificial stone rough block is subjected to spraying curing treatment by using a liquid medium with a temperature of higher than a normal temperature after pressing and before cutting, and then normal temperature curing is performed. According to the present invention, the pressed artificial stone rough block is cured, the traditional normal temperature curing way is changed, the way sequentially comprising heating curing through the spraying of the liquid medium with the temperature of higher than the normal temperature and the normal temperature curing is used, and through the spraying heating curing process, the reaction of the unsaturated polyester resin can be complete, the relatively stable product performance can be achieved on the original basis, and the quality problems of internal cracking, easy product deformation generation, easy product warping generation and the like of the artificial stone rough block can be reduced.

Owner:WANFENG COMPOUND STONE TECH

METHOD FOR PRODUCING Cu-Ni-Sn ALLOY AND COOLER TO BE USED FOR SAME

ActiveUS20210299744A1Reduce internal cracksShortening the time for cooling an ingotIngotContinuous casting

There is provided a method for producing a Cu—Ni—Sn alloy by a continuous casting method or a semi-continuous casting method, the method including pouring a molten Cu—Ni—Sn alloy from one end of a mold, both ends of which are open, and continuously drawing out the alloy as an ingot from the other end of the mold while solidifying a part of the alloy, the part being near the mold; and spraying mist-like liquid on the drawn-out ingot to cool the ingot, thereby making a cast product of the Cu—Ni—Sn alloy.

Owner:NGK INSULATORS LTD

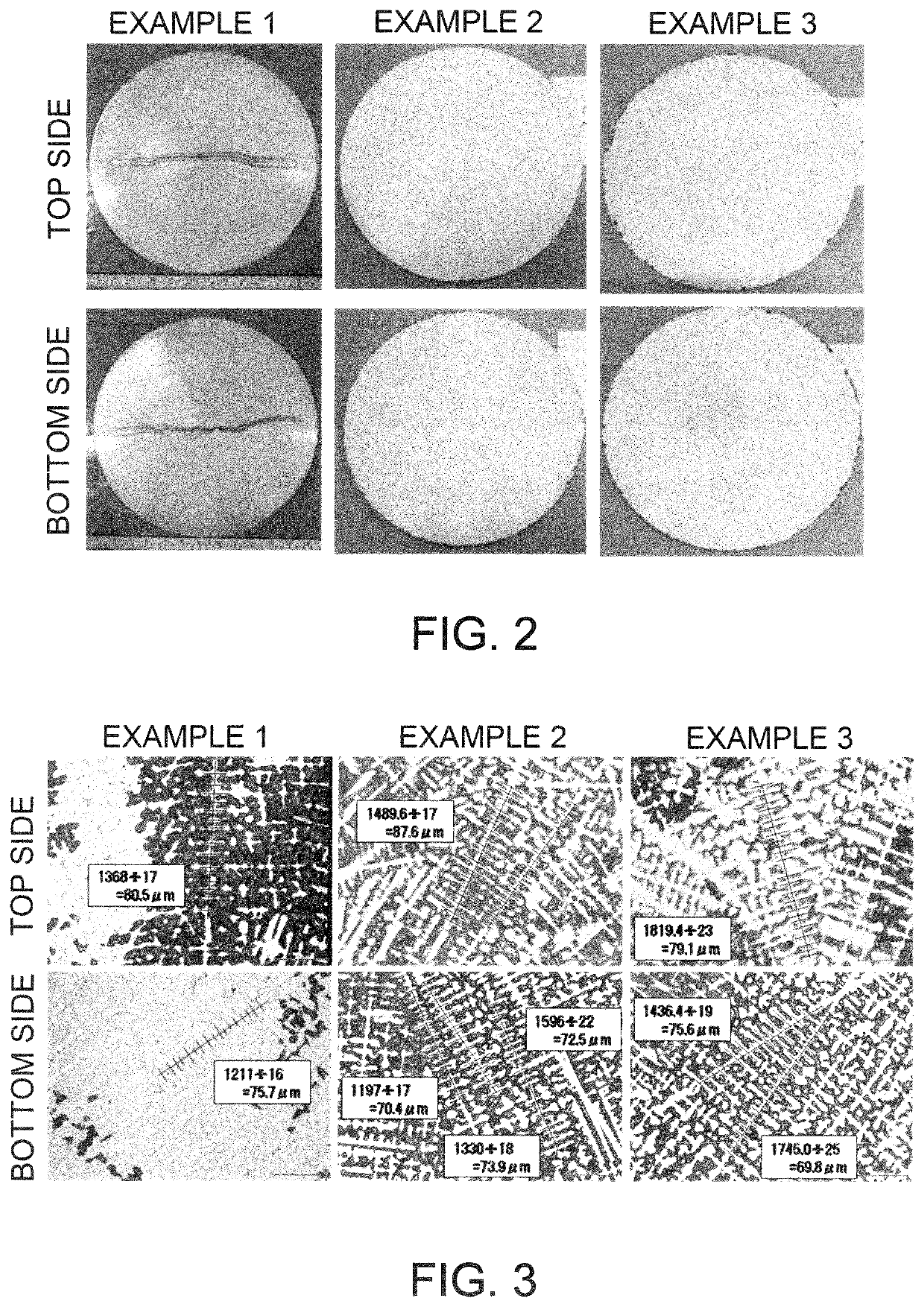

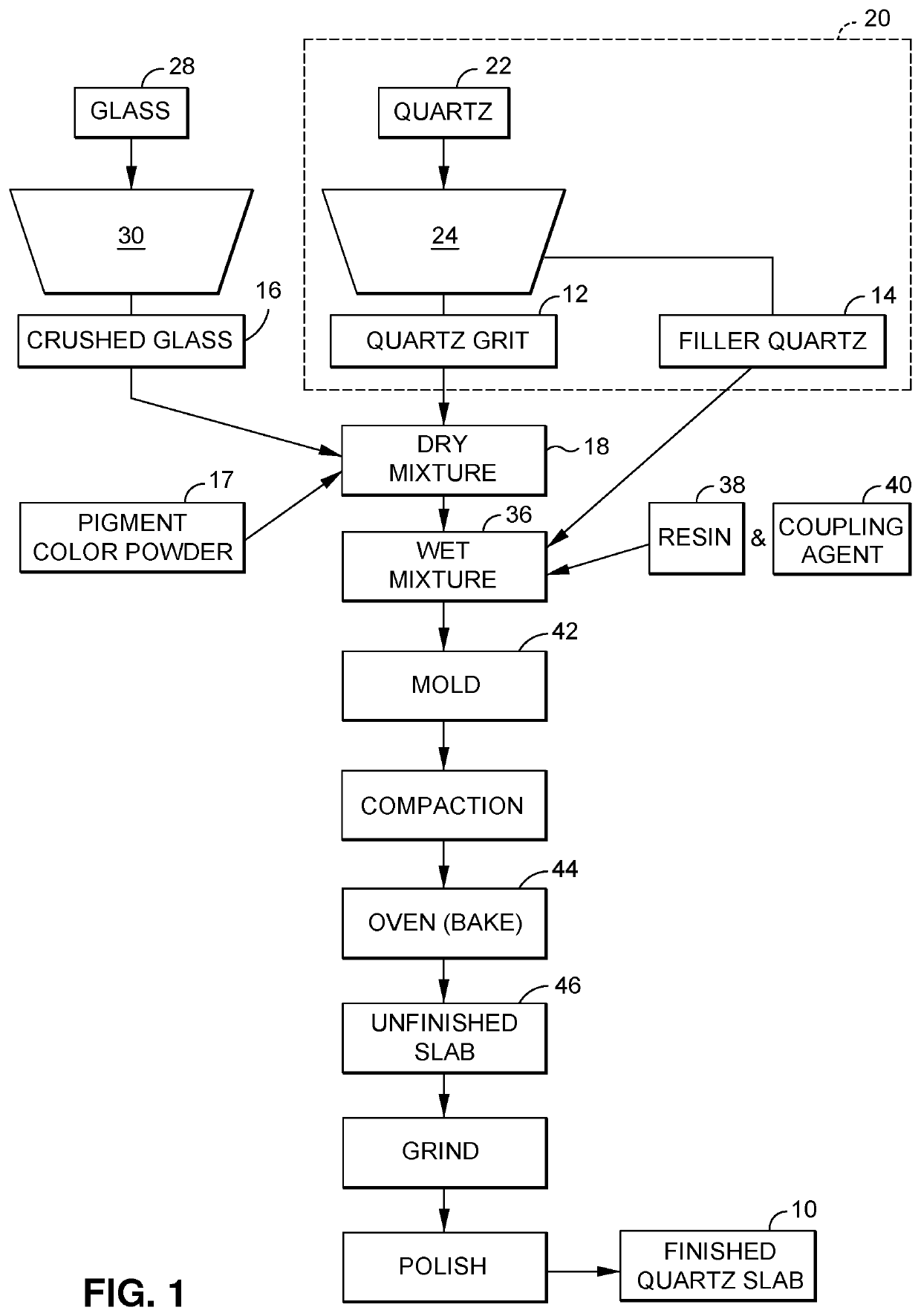

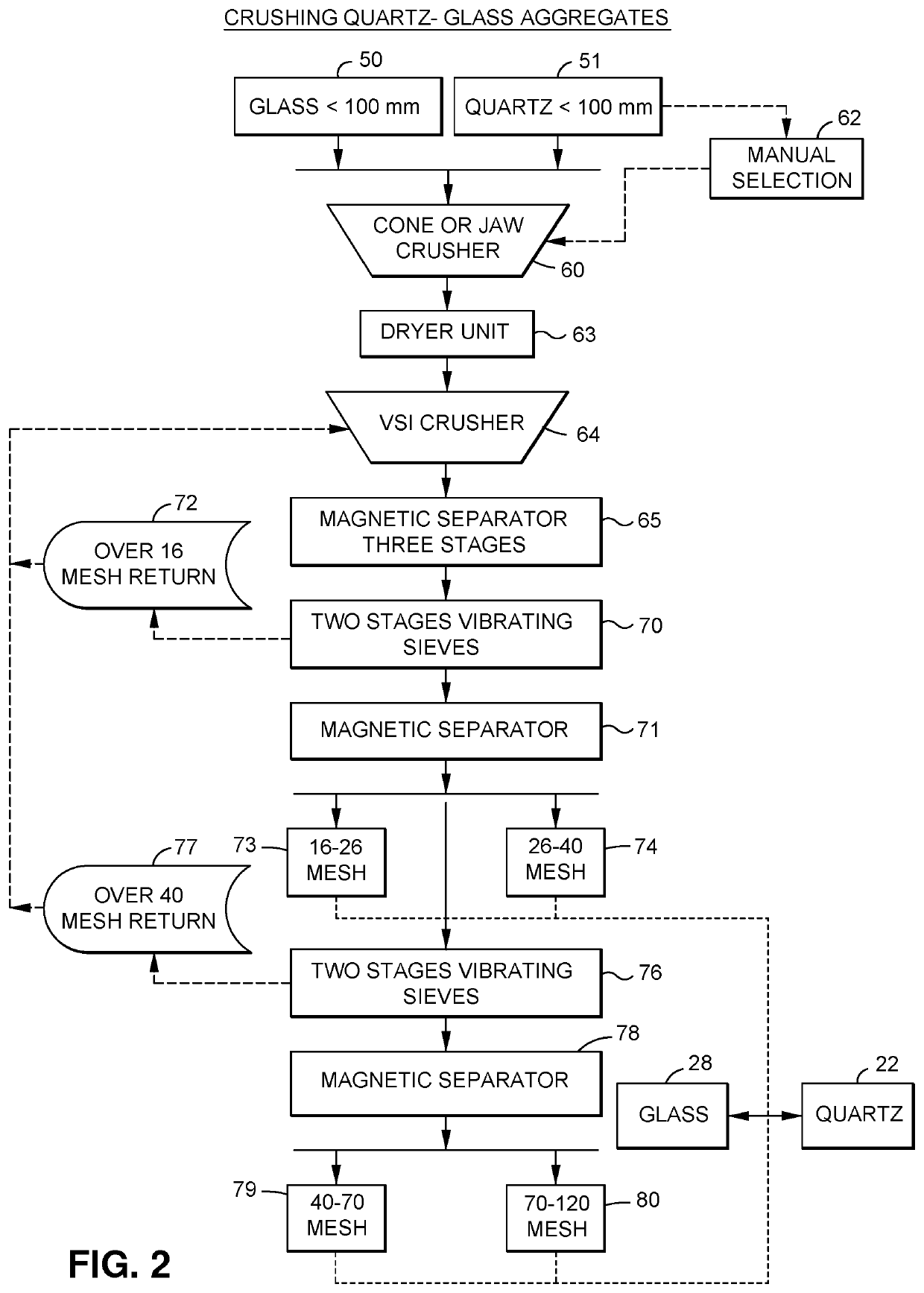

Glass/quartz composite surface

InactiveUS20200002214A1Small sizeReduce internal cracksDomestic articlesGrain treatmentsPhysical chemistryNatural mineral

A glass / quartz composite structure comprises quartz grit, quartz powder and glass grit wherein the glass grit is in an amount greater than 50% by weight of the composite structure, and a binding resin. The glass / quartz composite structure may be formed into a 1.2-1.5 cm thick slab for countertops using standard cabinet perimeter support. The slab may be made by mixing the quartz grit, the quartz powder, the glass grit, and the binding resin, pouring the mixture in a mold, and compacting the mixture in the mold. Specific natural mineral components may be added to the glass / quartz / resin composite structure to provide aesthetics of specific natural stones.

Owner:MQ US INC

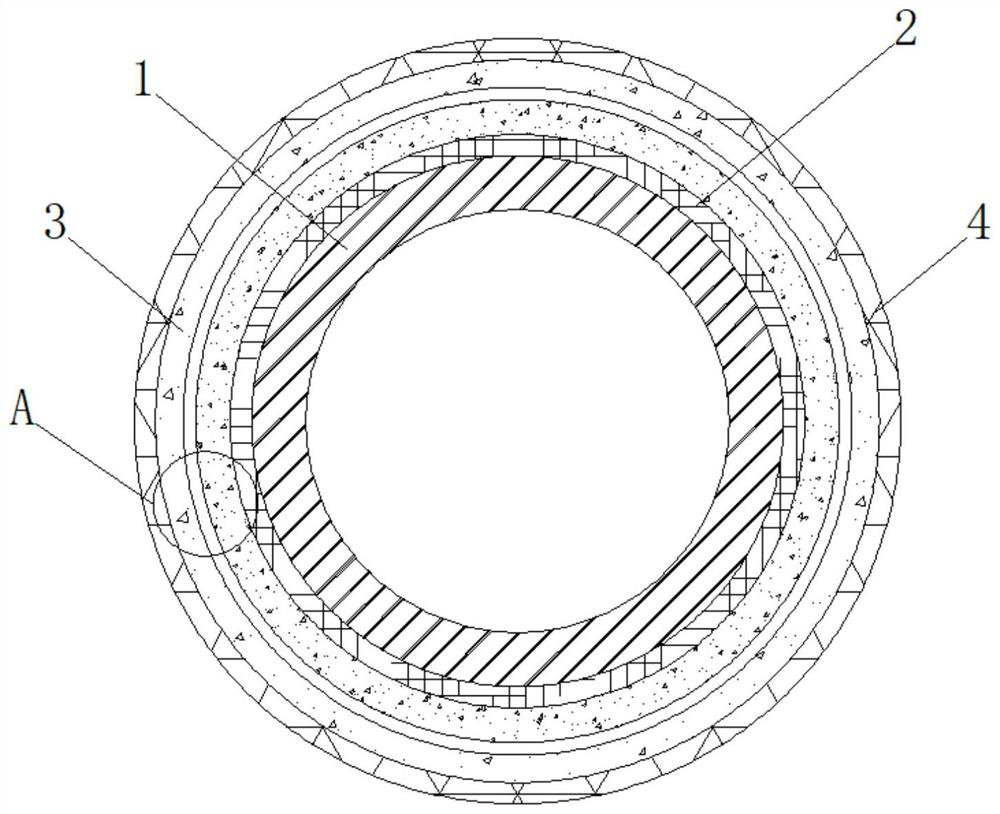

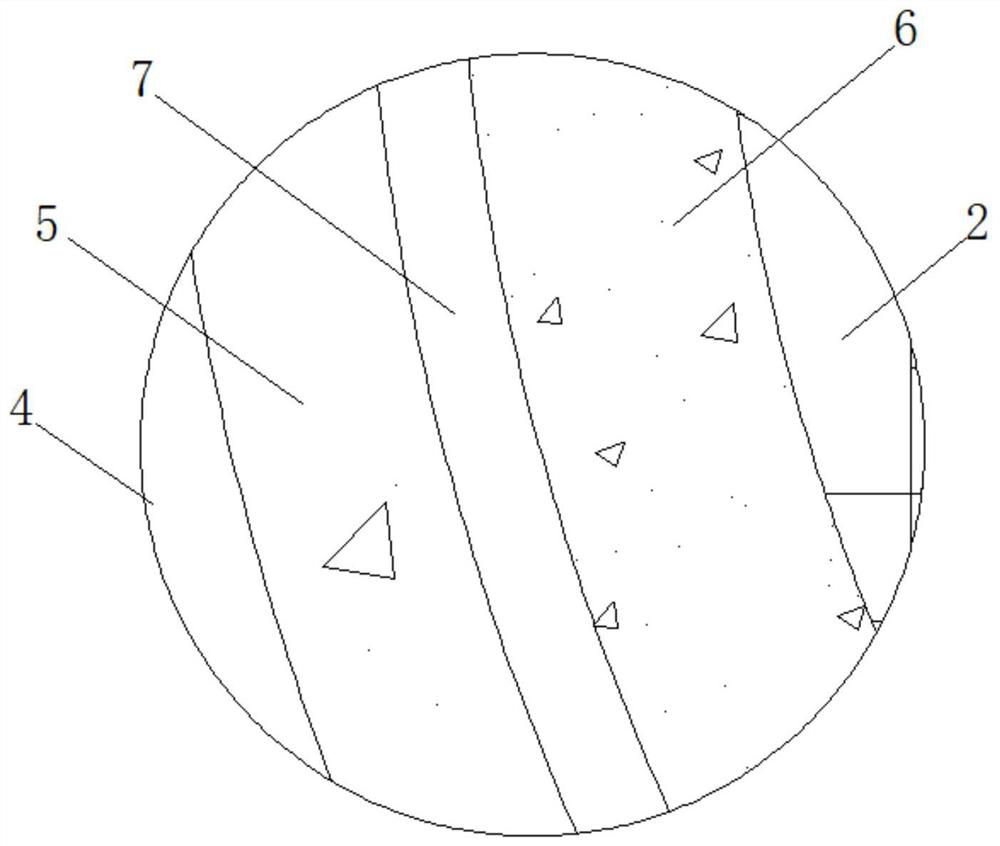

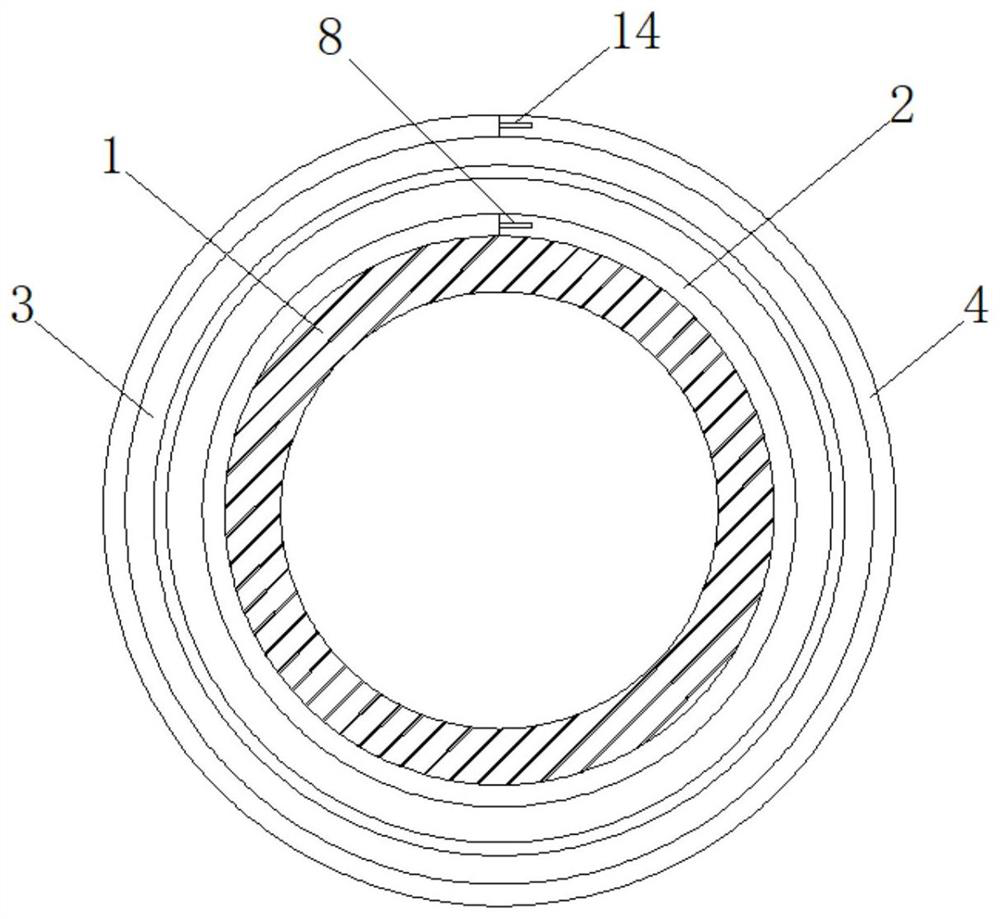

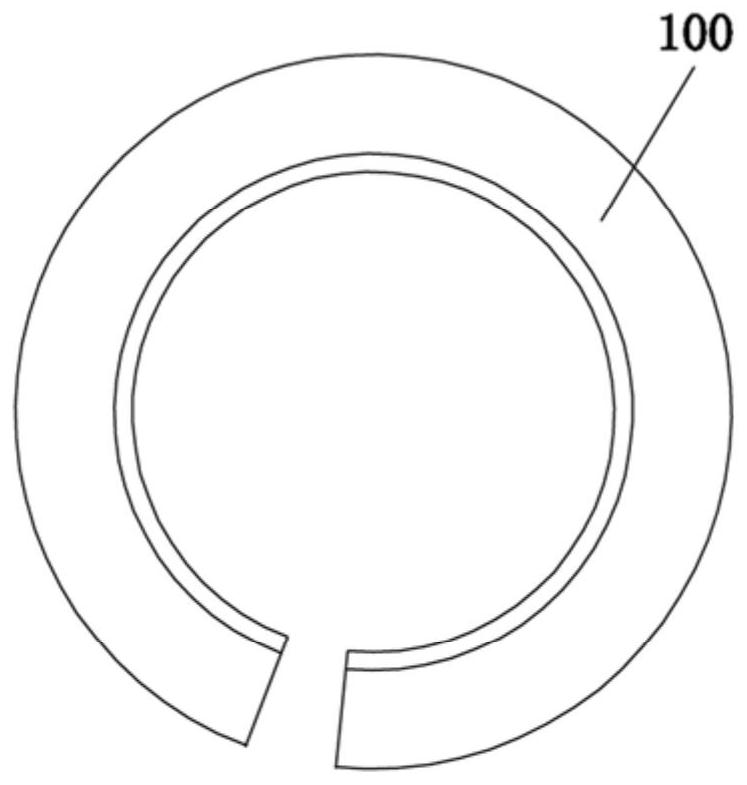

Insulation layer structure for disposable anti-demolition chemical equipment

ActiveCN110375153BGood insulation performanceReduce internal stress deformationThermal insulationPipe protection by thermal insulationInsulation layerThermal insulation

The invention discloses a heat preservation layer structure for disposable anti-dismantling chemical equipment, and belongs to the field of chemical equipment. The heat preservation layer structure for the disposable anti-dismantling chemical equipment comprises a chemical transmission pipe, wherein an inner limiting thermal insulation layer is arranged on the outer side of the chemical transmission pipe, the inner side of the inner limiting thermal insulation layer is attached to the outer end of the chemical transmission pipe, an outer limiting thermal insulation layer is arranged on the outer side of the inner limiting thermal insulation layer, a heat preservation center core layer is arranged between the inner limiting thermal insulation layer and the outer limiting thermal insulationlayer, and the right end of the outer limiting thermal insulation layer is fixedly connected with a photothermal fastener. Compared with common chemical equipment heat preservation layers, deformationcan be generated according to difference changes between internal and external temperatures of the chemical equipment, the internal stress of the heat preservation layer structure can be balanced, internal stress deformation caused by temperature changes of the heat preservation layer structure is reduced, the situation that a heat preservation layer cannot be attached to a surface layer of the chemical equipment in the case of large internal and external temperature differences is reduced, the thermal insulation effect of the heat preservation layer structure on the chemical equipment is enhanced, and meanwhile internal cracks caused by stress are reduced.

Owner:山东金岭新材料有限公司

Composite molding method for thick helical blades

ActiveCN110814144BGuaranteed inside and outside diameterImprove molding qualityShaping toolsGas flame welding apparatusSpiral bladeEngineering

The invention relates to the technical field of spiral blade forming machining, and particularly relates to a composite forming method for a thick spiral blade. The method comprises the following steps that a, blanking is carried out, and a plane body spiral blade blank blanking graph is calculated according to a spiral blade expansion calculation formula; b, a plane body spiral blade blank is heated, and the plane body spiral blade blank is converted into austenite at the high temperature; c, the plane body spiral blade blank is drawn, the first end of the edge of an inner hole notch of the high-temperature plane body spiral blade blank is fixed, the second end of the edge of the inner hole notch of the high-temperature plane body spiral blade blank is drawn through hoisting equipment, the inner spiral line of the spiral blade is stretched to the required size, and the plane body spiral blade blank is initially formed into a spiral blade; and d, the initially-formed spiral blade is placed on a prefabricated spiral mold, and pressure is applied to the prefabricated spiral mold through a press machine to press the prefabricated spiral mold into a standard thick spiral blade. According to the method, the inner diameter and the outer diameter of the formed spiral blade can be guaranteed, the method is suitable for mass production of thick spiral blades, the efficiency is high, andthe forming quality of the spiral blade is stable.

Owner:中铁工程装备集团盾构制造有限公司

Processing method of nitrogen-containing austenitic stainless steel

InactiveCN113042531AReduce brittle inclusionsReduce off-party problemsWork cooling devicesMetal rolling arrangementsSS - Stainless steelHeat conservation

The invention relates to the technical field of stainless steel material processing, in particular to a processing method of nitrogen-containing austenitic stainless steel. According to the technical scheme adopted by the invention, the processing method comprises the following steps of: (1) heating a steel billet of the nitrogen-containing austenitic stainless steel to 1100 to 1250 DEG C by a walking beam furnace, preserving heat for 1 to 1.5 hours, and then performing heat-insulating treatment on the steel billet of the nitrogen-containing austenitic stainless steel subjected to heat preservation; and (2) performing rolling by a hole-free flat roll roughing mill unit, wherein in the rolling process, the elongation coefficient of each pass is controlled to be 1.25 to 1.35, the broadening coefficient is controlled to be 0.10 to 0.42, and the operating speed of the steel billet in the rolling process is 0.60 m / s to 1.12 m / s. The processing method has the advantages that by the processing method, the properties such as strength, toughness and corrosion resistance of the produced economical medium-nitrogen austenitic stainless steel can be guaranteed to be more reliable; the use requirements in the wider use environments can be met; and the lower overall cost in the production process is guaranteed.

Owner:JIANGSU MINGLUSINLESS STEEL

Method for conticaster controlling solidification structure of casting block

A method for the conticaster to control the solidified structure of cast blank includes providing a HF pulse power supply with positive and negative electrodes, inserting its negative electrode into the molten steel in the crystallizer or tundish of conticaster, electrically connecting its positive eletrode with the steel base of conticaster, and conticasting while regulating the voltages, current and frequency to improve the performance of cast blank.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com