Brake pad friction block pressing device and method

A technology of friction blocks and brake pads, which is applied in the field of brake pad pressing, can solve problems such as the friction block of brake pads falling off, and achieve the effects of avoiding fracture and falling off, weakening the arch bridge effect, and working stably and effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

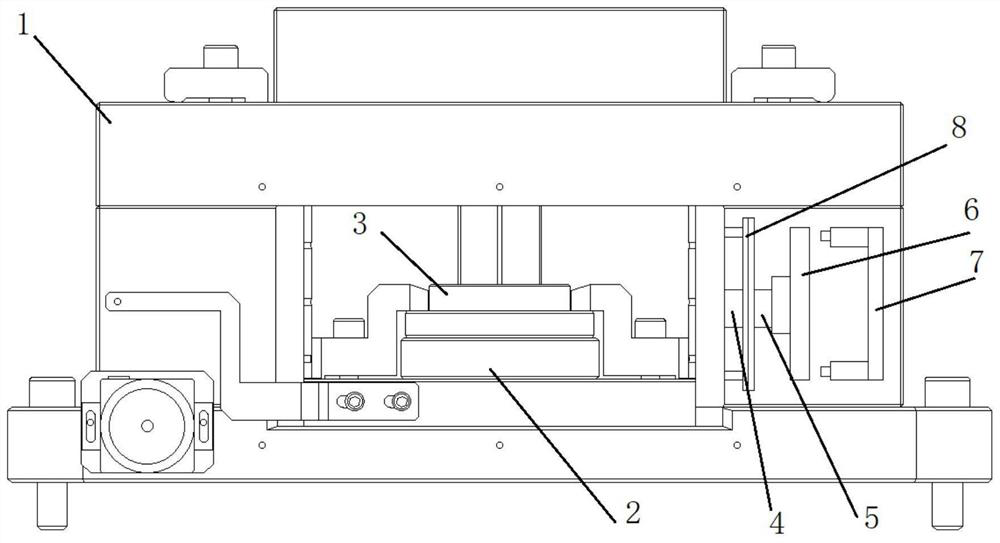

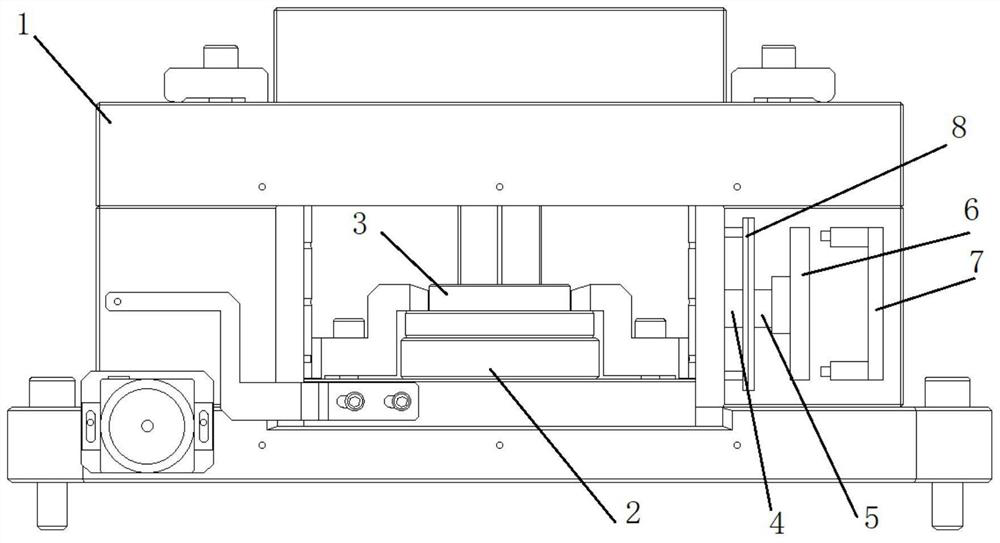

[0035] Such as figure 1 Shown is a brake pad friction block pressing device provided by this embodiment, including: a supporting cavity structure as the installation assembly 1, a stamping mechanism for pressing and forming, and a vibration mechanism for driving the stamping mechanism to vibrate. A pressing chamber is arranged in the mounting assembly 1, the stamping mechanism is installed in the pressing chamber, and the vibration mechanism is installed on the outer wall of the pressing chamber.

[0036] The stamping mechanism is installed on the mounting assembly 1. The stamping mechanism includes a stamping die 2 and a stamping head 3 arranged coaxially. The stamping die 2 is fixedly installed on the bottom of the pressing chamber, and the stamping head 3 is installed on the top of the pressing chamber through a cylinder. The cylinder drives the stamping The head 3 moves up and down to press or demould the materials in the stamping die 2 .

[0037] The vibrating mechanism ...

Embodiment 2

[0041] This embodiment provides a brake friction block pressing method, using the brake friction block pressing device provided in Example 1, including the following steps:

[0042] First, inject the powder material into the stamping die of the stamping mechanism, use the vibration mechanism to drive the stamping die to vibrate for 30s, the amplitude range is 1-2mm, and the vibration frequency is 40-60Hz; the vibration time, amplitude range and vibration frequency can be determined according to the metal in the powder The ratio of copper powder and graphite powder is adjusted. In this embodiment, the vibration frequency is 50 Hz, and the amplitude is 2 mm.

[0043] After the vibration is completed, the mold is closed to press the powder material. The cylinder drives the punching head down and extends into the punching die. When the punching head touches the material in a single step, it continues to descend for 5mm, and then maintains the pressing state for 3s. The rear cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com