Compact-type mixing device capable of meeting Euro-VI emission standard

An emission standard, mixing device technology, applied in exhaust devices, mufflers, engine components, etc., to achieve better uniformity, reduced risk of urea crystallization, and outstanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

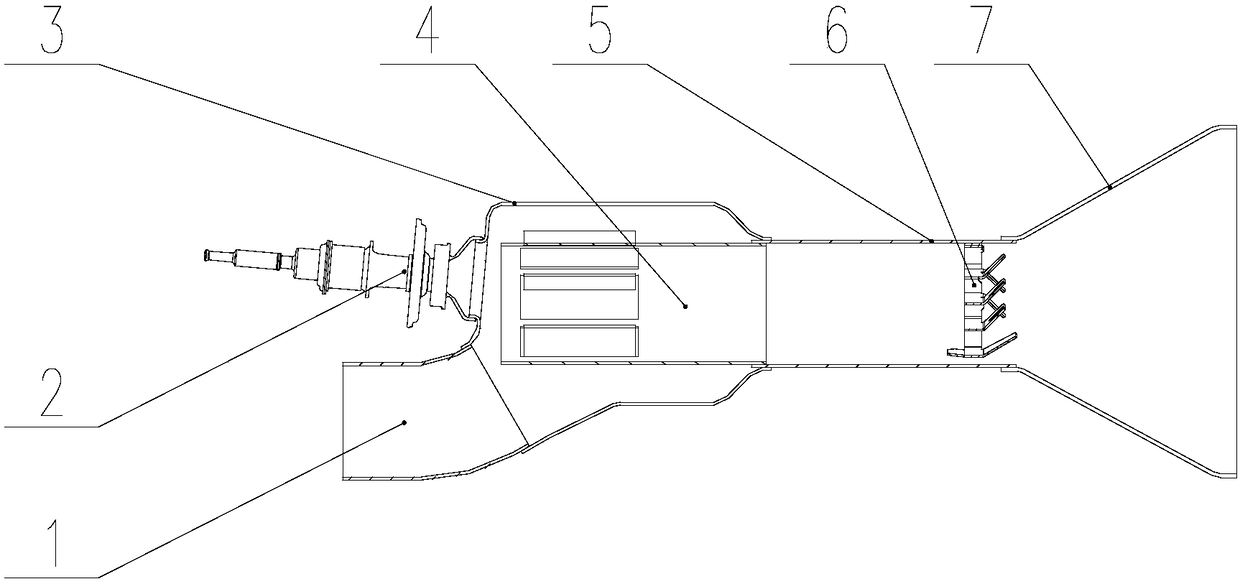

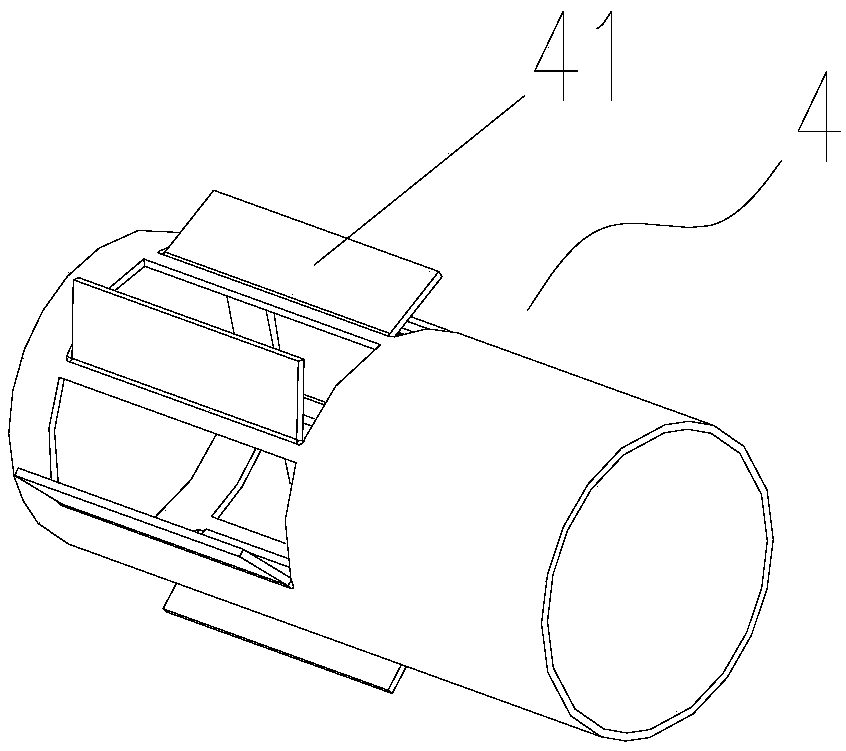

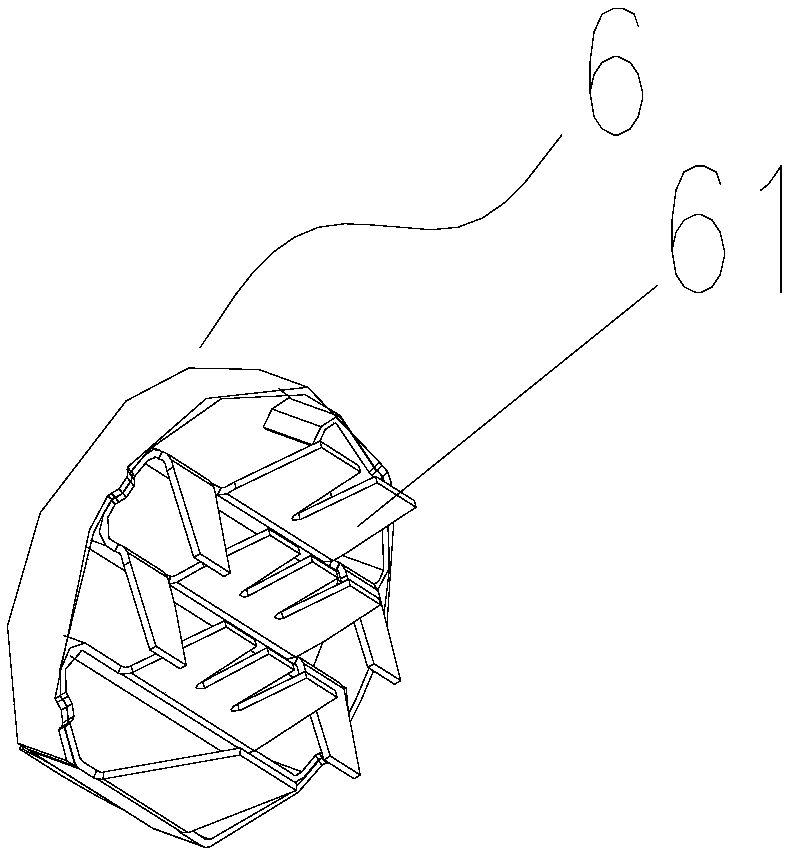

[0020] According to attached Figure 1~3 As shown, a compact mixing device that meets the Euro VI emission standard includes an air intake pipe 1, a urea nozzle 2, a housing 3, a transition pipe 5, and a cone 7. It is characterized in that the air inlet pipe 1 and the urea nozzle 2 They are all connected to one side of the housing 3, and there is a certain angle between the air intake pipe 1 and the urea nozzle 2, the angle between the injection direction of the urea nozzle 2 and the horizontal direction of the airflow is 10°~15°, and the airflow of the air inlet pipe 1 The angle between the direction and the horizontal direction of the airflow is 40°-50°, the other side of the housing 3 is connected to the transition pipe 5, and the transition pipe 5 is connected to the vertebral body 7; a swirl pipe is installed in the housing 3 4. There is a gap of 3-5 mm b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com