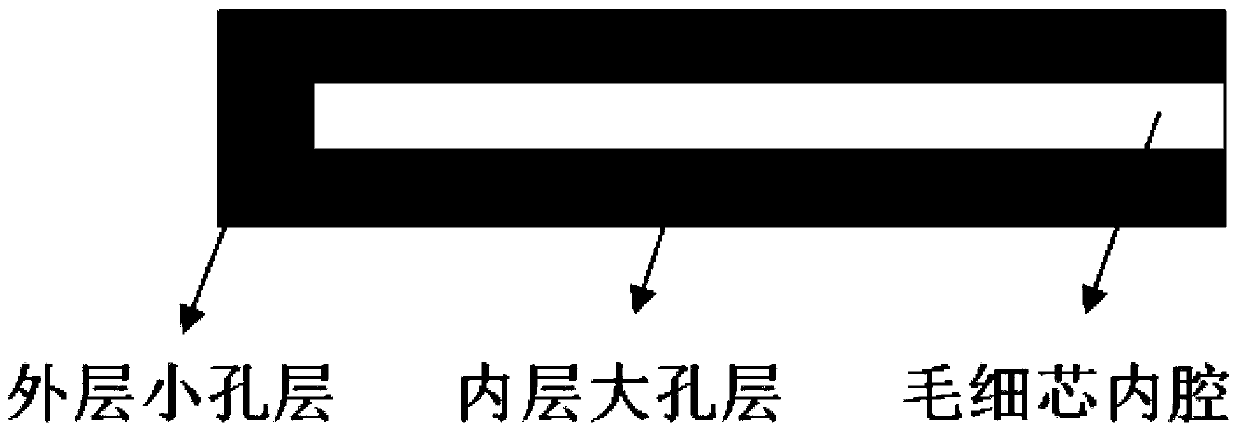

Silicon nitride gradient porous capillary core for loop heat pipe and preparation method of silicon nitride gradient porous capillary core by combining coating method

A loop heat pipe and gradient porous technology, applied in the field of gradient porous capillary cores for loop heat pipes and its preparation, can solve problems such as singleness and complex processing, and achieve improved stability and reliability, large capillary suction, and realization The effect of efficient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Using the foaming method, the Si 3 N 4 Powder: Yttrium Oxide: Water: Polyvinyl Alcohol: n-Propyl Gallate The weight ratio is 100:5:72:1:5 After mixing evenly, stir vigorously at a speed of 2000rpm to obtain a foamy slurry and keep it at room temperature for 24 hours Cured, then placed in a 60°C oven to dry for 12 hours, and then sintered at 1800°C for 2 hours. A primary capillary wick with a larger pore size is prepared and subjected to preliminary processing. The pore diameter of the primary silicon nitride capillary core is 10-200 microns, and the porosity is 82%;

[0044] (2) Slurry configuration Add silicon nitride powder, sintering aid yttrium oxide, gelling agent isobutylene-maleic anhydride copolymer, and pore-forming agent PMMA into water, and after ball milling and mixing, the slurry is obtained. The nitriding The mass ratio of silicon powder, sintering aid, gelling agent, pore forming agent and water is 100:4:0.3:10:80;

[0045] (3) Coating a layer of ...

Embodiment 2

[0049] (1) The Si 3 N 4 : yttrium oxide: water: isobutylene-maleic anhydride copolymer uniformly mixed at a weight ratio of 100:6:120:0.5 to obtain a slurry, injected into a mold, cured at room temperature for 48 hours, and then dried in an oven at 80°C for 24 hours , sintered at 1750°C for 2 hours. A primary capillary wick with a larger pore size is prepared and subjected to preliminary processing. The pore diameter of the primary silicon nitride capillary core is 10-20 microns, and the porosity is 68%;

[0050] (2) Slurry configuration Add silicon nitride powder, sintering aid lutetium oxide, gelling agent isobutylene-maleic anhydride copolymer, and pore-forming agent starch into water, and after ball milling and mixing, the slurry is obtained. The nitriding The mass ratio of silicon powder, sintering aid, gelling agent, pore forming agent and water is 100:5:0.2:5:72;

[0051] (3) Coat a layer of silicon nitride slurry on the outside of the primary capillary pump, and co...

Embodiment 3

[0055] (1) adopt freeze-drying method, with Si 3 N 4 The weight ratio of powder: water: polyvinyl alcohol: polyethylene glycol can be 100:100:5:5. Mix evenly by mechanical wet ball milling to make a slurry. The resulting slurry was defoamed and vacuum degassed, poured into a mold, and then frozen at -50°C for 6 hours. After debonding, the green body was sintered at 1700° C. for 2 hours to prepare a primary capillary core with a relatively large pore size and perform preliminary processing. The pore diameter of the primary silicon nitride capillary core is 20-100 microns, and the porosity is 78%;

[0056] (2) Slurry configuration Add silicon nitride powder, sintering aid ytterbium oxide, gelling agent isobutylene-maleic anhydride copolymer, and pore-forming agent liquid paraffin into water, and after ball milling and mixing, the slurry is obtained. The mass ratio of silica powder, sintering aid, gelling agent, pore forming agent and water is 100:6:0.4:8:72;

[0057] (3) Sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com