Matte dry granular material and preparation method thereof

A technology of dry particles and raw materials, applied in the field of ceramics, can solve problems such as the influence of firing temperature in the application range, high formula temperature, easy to store dirt, etc., and achieve the effect of stabilizing matt gloss, reducing internal cracks, and wide application scenarios.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

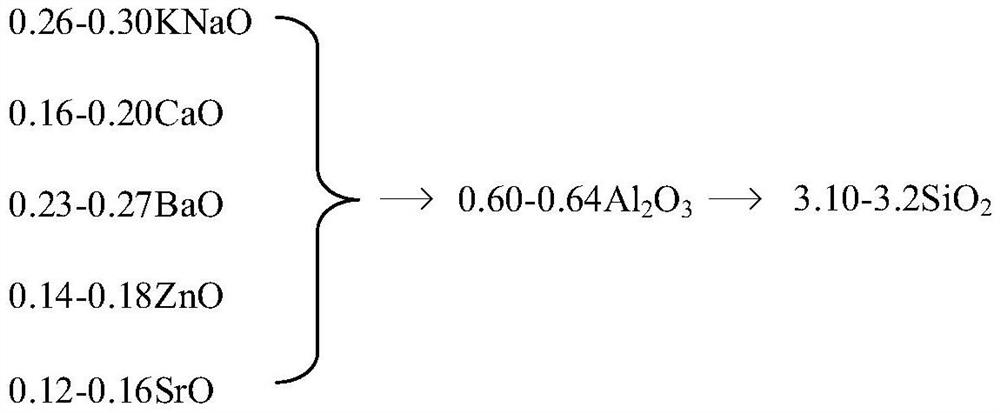

Method used

Image

Examples

preparation example Construction

[0052] One embodiment of the present invention provides a kind of preparation method of matte dry granular material, comprises the following steps:

[0053] S101: Weigh each raw material according to the formula, mix each raw material to obtain a mixture; wherein, in parts by weight, each raw material includes: 30-45 parts of potassium feldspar, 5-15 parts of albite, 6-10 parts of kaolin, 10-20 parts of barium carbonate, 3-8 parts of wollastonite, 3-10 parts of zinc oxide, 4-10 parts of strontium carbonate, 7-13 parts of calcite, 1-4 parts of quartz and 1-5 parts of alumina;

[0054] S102: Calcining the mixtures in step S101 to obtain a calcined product, the calcining includes the following temperature control procedures:

[0055] at the first time t 1 Internally heated to 295°C ~ 305°C, and then at the second time t 2 Internally heated to 1050°C ~ 1150°C, and then at the third time t 3 Internally heated to 1300°C ~ 1500°C, and then kept in the range of 1300°C ~ 1500°C for ...

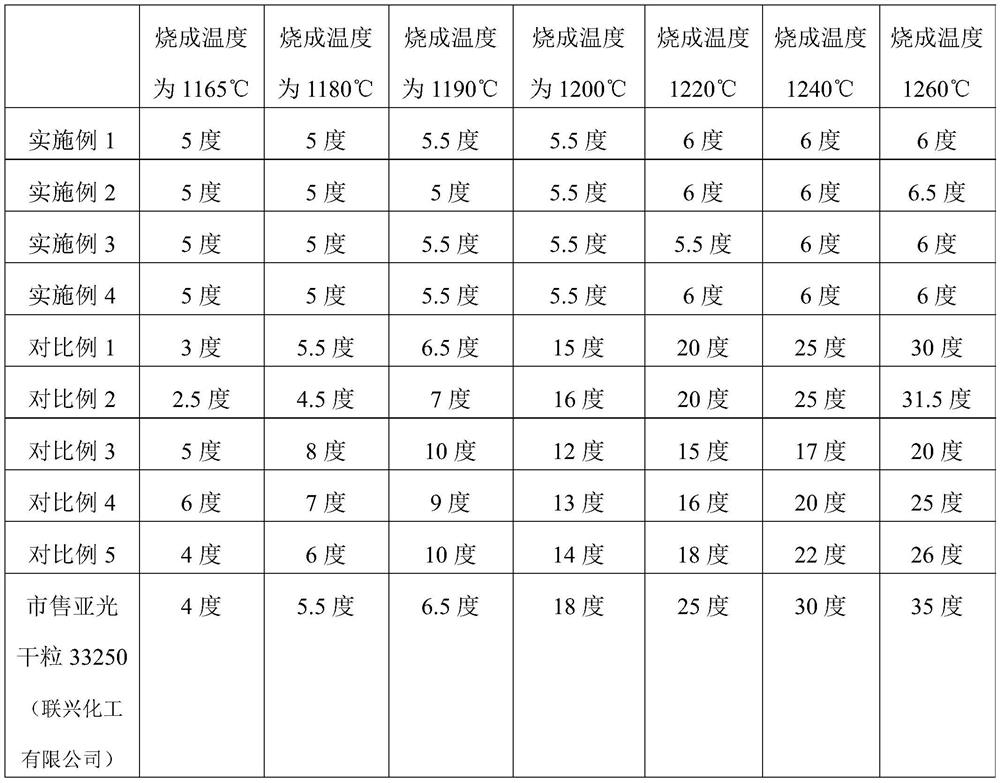

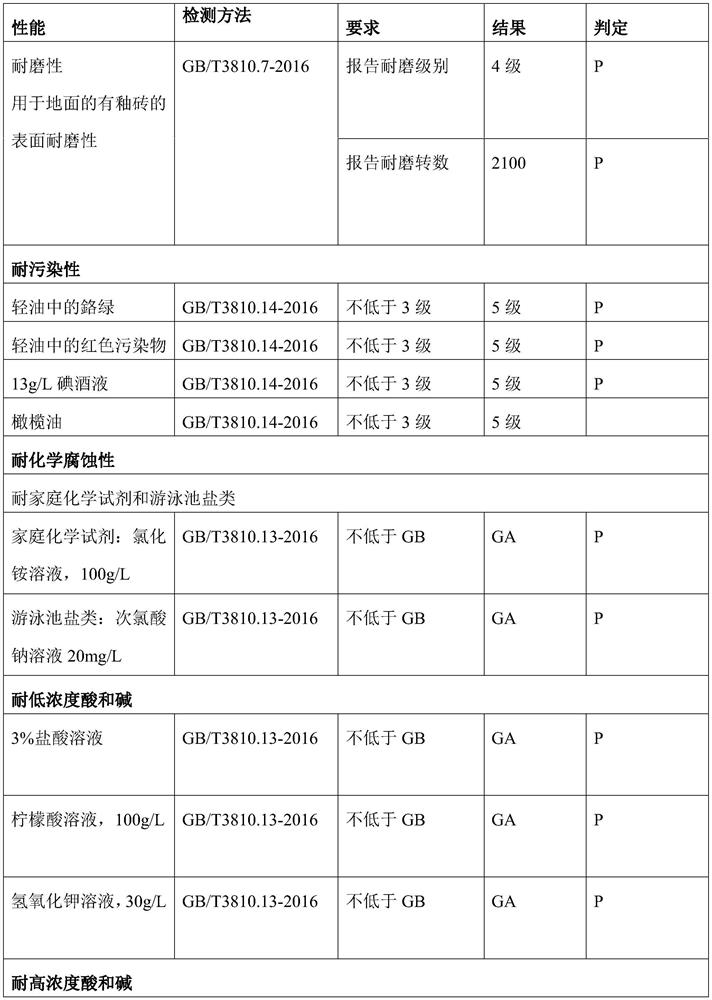

Embodiment 1

[0069] Each raw material in the present embodiment: 35 parts of potassium feldspar, 8 parts of albite, 8 parts of kaolin, 15 parts of barium carbonate, 6 parts of wollastonite, 5 parts of zinc oxide, 6 parts of strontium carbonate, 11 parts of calcite, 2 parts of quartz 4 parts of alumina; the particle size of potassium feldspar, albite, kaolin, wollastonite, calcite, and quartz is controlled between 150 and 200 mesh; the particle size of barium carbonate, strontium carbonate, zinc oxide, and alumina Control at 200-250 mesh.

[0070] The ratio of silicon to aluminum is 4.9;

[0071] Preparation:

[0072] (1) mix each raw material, stir evenly, obtain compound;

[0073] (2) Transport the above-mentioned mixture into the frit firing furnace, and carry out firing according to the following temperature control procedure, heat to 300°C for 10 minutes, then heat to 1100°C for 30 minutes, then heat to 1450°C for 20 minutes, and then In the range of 1450 ° C for 10 minutes, then co...

Embodiment 2

[0077] Each raw material in the present embodiment: 40 parts of potassium feldspar, 6 parts of albite, 8 parts of kaolin, 18 parts of barium carbonate, 3 parts of wollastonite, 4 parts of zinc oxide, 8 parts of strontium carbonate, 7 parts of calcite, 2 parts of quartz Parts, 4 parts of alumina; Among them, the particle size of potassium feldspar, albite, kaolin, wollastonite, calcite, and quartz materials is controlled between 150 and 200 meshes, and barium carbonate, strontium carbonate, zinc oxide, and alumina materials are The particle size is controlled at 200-250 mesh, and the silicon-aluminum ratio is 5.1;

[0078] Preparation:

[0079] (1) mix each raw material, stir evenly, obtain compound;

[0080] (2) Transport the above-mentioned mixture into the frit firing furnace, and carry out firing according to the following temperature control procedure, heat to 300°C for 10 minutes, then heat to 1100°C for 30 minutes, then heat to 1450°C for 20 minutes, and then In the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com