Iron-manganese heat resistant cooker and production technology thereof

A production process and cooker technology, applied in the field of ceramic materials, can solve the problems of increased production cost, low heat utilization rate, small firing temperature range, etc., to improve the ability to resist cold and heat exchange, the production process is simple, and the firing temperature is small. into a wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

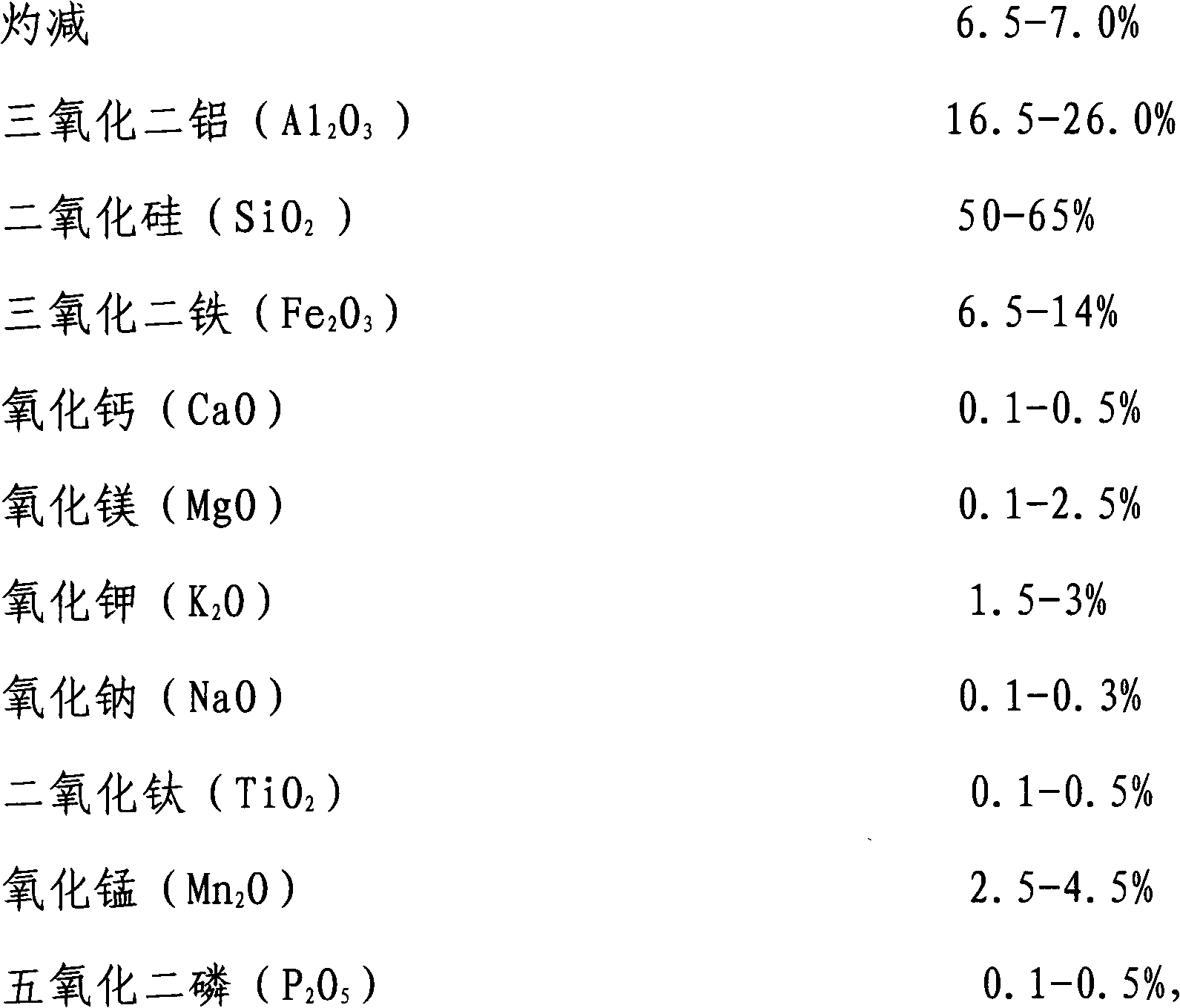

[0017] Use the following formula

[0018]

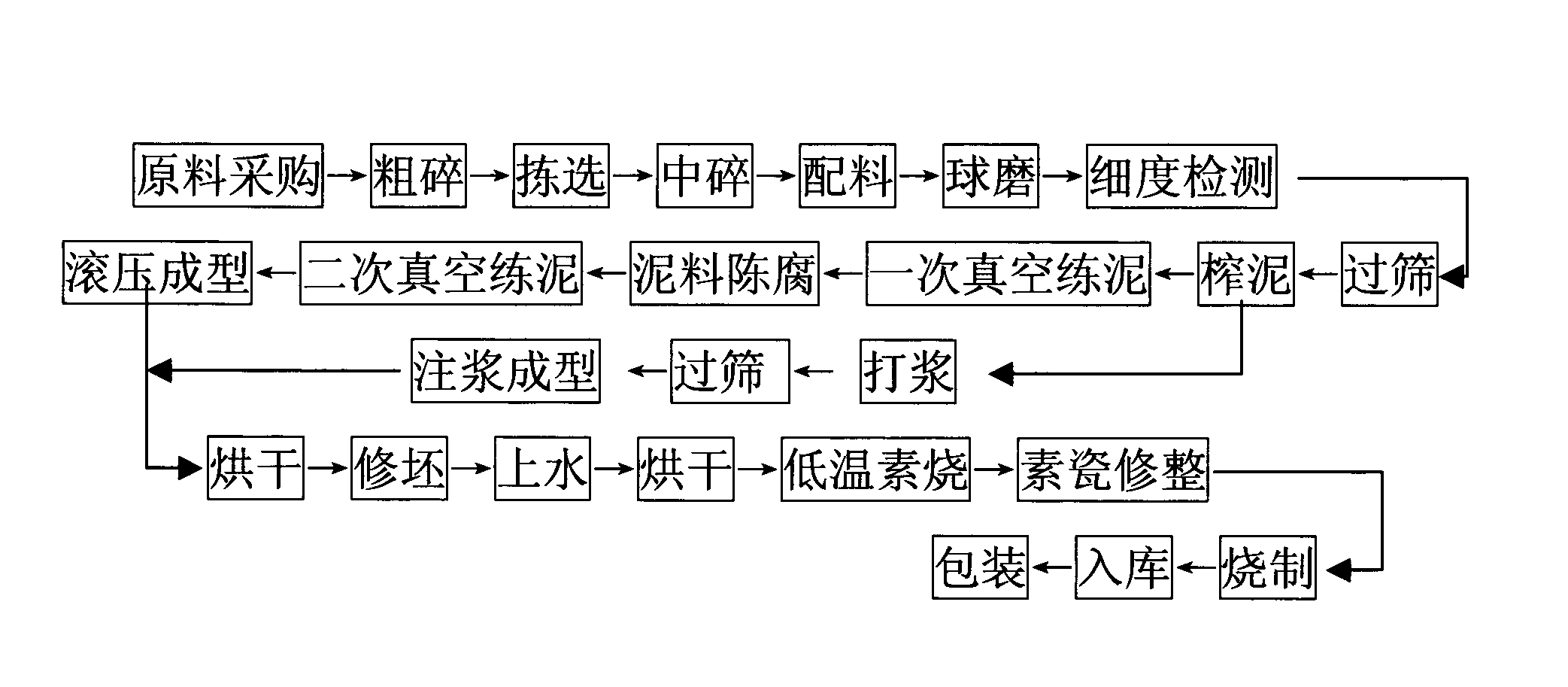

[0019] According to the process flow shown in the attached figure, the firing temperature can be controlled between 1160°C and 1230°C. The experience of the finished product shows that (1) heat resistance: heat exchange once at 500°C-20°C without cracking. (2) Volume specific gravity: 2.4*10 3 kg / m 3 about. (3) Water absorption: ≤2%.

Embodiment 2

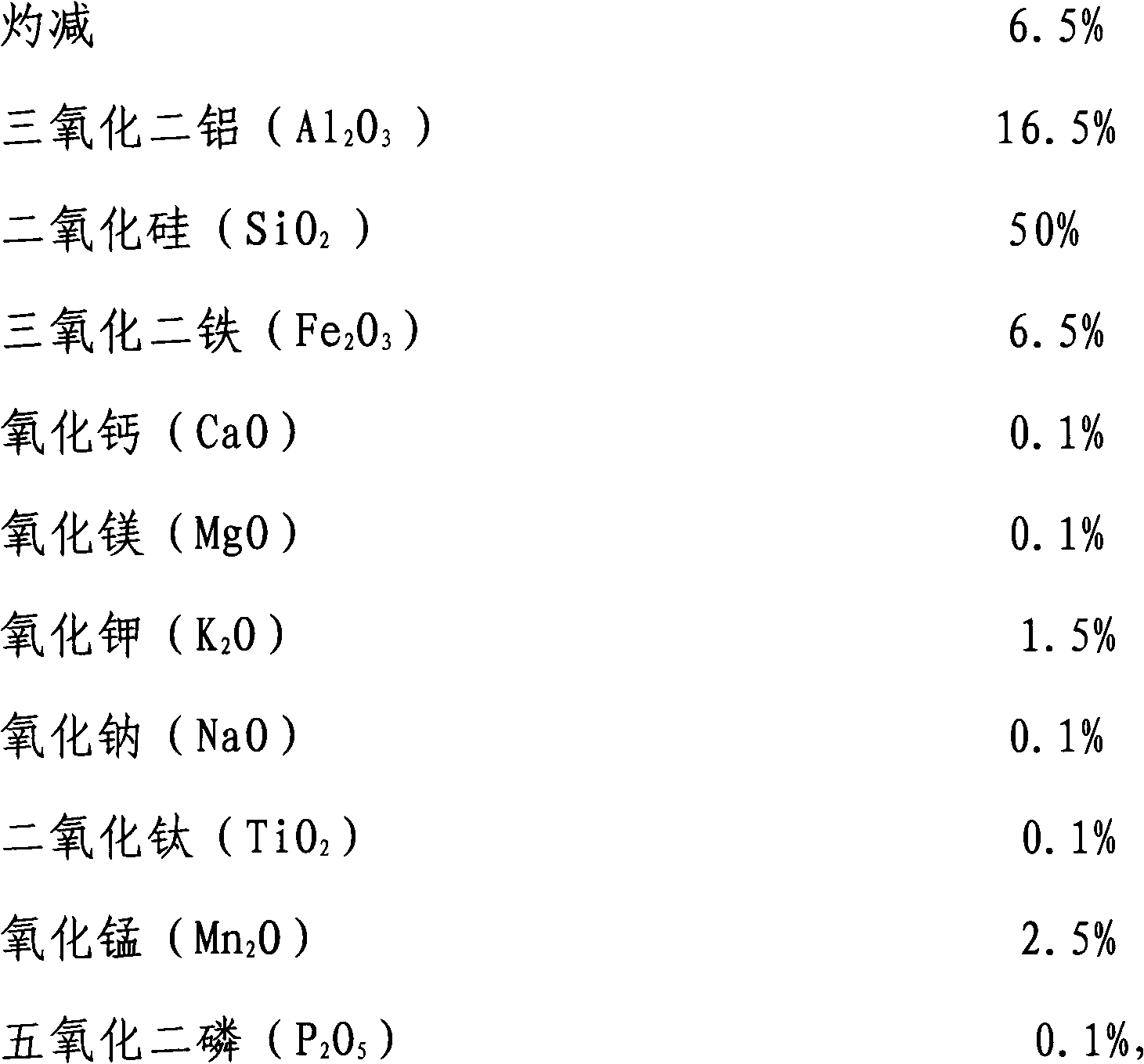

[0021]

[0022]

[0023] According to the process flow shown in the attached figure, the firing temperature can be controlled between 1160°C and 1230°C. The experience of the finished product shows that (1) heat resistance: heat exchange once at 500°C-20°C without cracking. (2) Volume specific gravity: 2.4*10 3 kg / m 3 about. (3) Water absorption: ≤2%.

Embodiment 3

[0025]

[0026] According to the process flow shown in the attached figure, the firing temperature can be controlled between 1160°C and 1230°C. The experience of the finished product shows that (1) heat resistance: heat exchange once at 500°C-20°C, no cracking phenomenon (2) volume specific gravity: 2.4*10 3 kg / m 3 about. (3) Water absorption: ≤2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com