Microcrystalline glass ceramic binding agent, preparing method thereof, SG grinding wheel and preparing method thereof

A ceramic bond, glass-ceramic technology, applied in the field of abrasives, can solve the problems of low working efficiency of grinding wheels, insufficient machining accuracy, long firing time, etc., to improve work efficiency and machining accuracy, equipment and operators. The effect of low requirements and reduced firing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

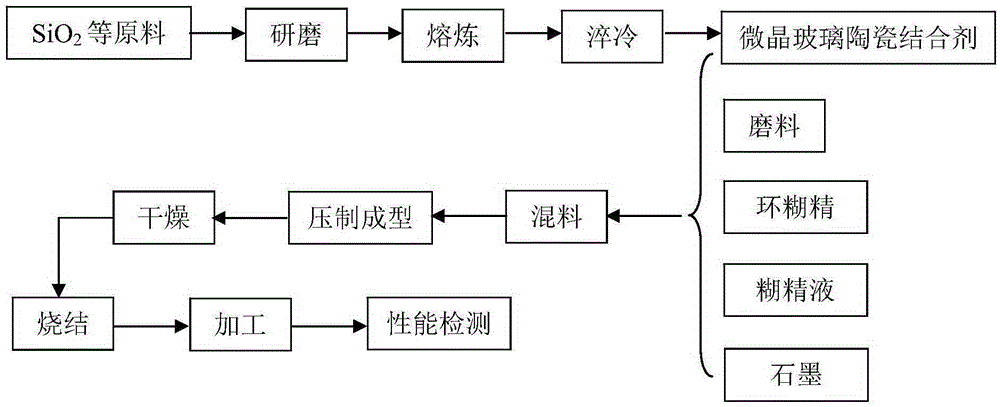

Method used

Image

Examples

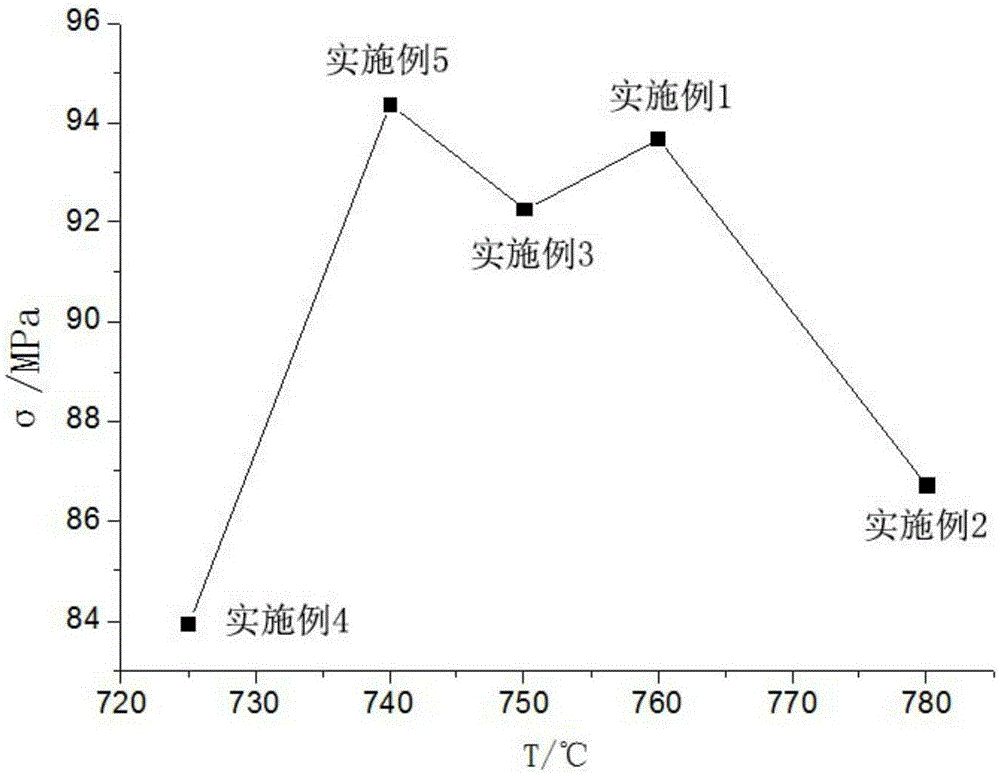

Embodiment 1

[0030] The glass-ceramic bonding agent of the present embodiment is made up of the following components by weight percentage: SiO 2 54%, Al 2 o 3 17%, Na 2 O7.5%, CaO0.5%, K 2 O7.5%, B 2 o 3 11%, MgO0.5%, TiO 2 2%.

[0031] The preparation method of the glass-ceramic bond of this embodiment includes: grinding and mixing the raw material powders, melting at 1350° C. for 2 hours, and quenching with water to obtain the glass-ceramic bond.

[0032] The SG grinding wheel of the present embodiment is made of the following raw materials in weight percentage: 27% of SG abrasive, 56% of white corundum abrasive, 11% of glass-ceramic ceramic bond, 2% of cyclodextrin, 3% of dextrin, and 1% of graphite ; The dextrin solution is prepared from cyclodextrin and water, and its mass concentration is 30%. SG abrasive is made by mixing 30# and 46# grain sizes, and the mixing mass ratio is 1:1; the grain size type and mixing ratio of white corundum abrasive (WA abrasive) and SG abrasive ar...

Embodiment 2

[0035] The glass-ceramic bond of the present embodiment consists of the following components by weight percentage SiO 2 40%, Al 2 o 3 9%, Na 2 O5.5%, CaO0.5%, K 2 O10%, B 2 o 3 30%, MgO0.5%, TiO 2 4.5%.

[0036] The preparation method of the glass-ceramic binder of this embodiment includes: grinding and mixing the raw material powders, melting at 1300° C. for 1.5 h, and quenching with water to obtain the glass-ceramic binder.

[0037]The SG grinding wheel of the present embodiment is made of the following raw materials in weight percentage: 30% of SG abrasive, 55% of white corundum abrasive, 8% of glass-ceramic ceramic bond, 1% of cyclodextrin, 4% of dextrin, and 2% of graphite ; The dextrin liquid is prepared from cyclodextrin and water, and its mass concentration is 35%. SG abrasive is made by mixing 80# and 100# grain sizes, and the mixing mass ratio is 2:1; the grain size type and mixing ratio of white corundum abrasive (WA abrasive) and SG abrasive are consistent....

Embodiment 3

[0040] The glass-ceramic bond of the present embodiment consists of the following components by weight percentage SiO 2 46%, Al 2 o 3 6%, Na 2 O11.5%, CaO0.5%, K 2 O5%, B 2 o 3 27%, MgO0.5%, TiO 2 3.5%.

[0041] The preparation method of the glass-ceramic bond of this embodiment includes: grinding and mixing the raw material powders, melting at 1400° C. for 2.5 hours, and quenching with water to obtain the glass-ceramic bond.

[0042] The SG grinding wheel of the present embodiment is made of the following raw materials in weight percentage: 40% of SG abrasive, 40% of white corundum abrasive, 14% of glass-ceramic ceramic bond, 1.5% of cyclodextrin, 3% of dextrin, and 1.5% of graphite ; The dextrin solution is prepared from cyclodextrin and water, and its mass concentration is 40%. SG abrasive is made by mixing two grain sizes of 120# and 150#, and the mixing mass ratio is 3:1; the grain size type and mixing ratio of white corundum abrasive (WA abrasive) and SG abrasive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com