Belite-calcium barium sulphoaluminate cement

A technology of barium calcium sulfoaluminate and calcium aluminum ferrite, which is applied in the field of cement materials, can solve the problems of reducing the corrosion resistance and durability of cement, high energy consumption, and increasing the amount, so as to reduce the amount of consumption, improve the quality of construction, and later The effect of increased intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] See Table 1, Table 2 and Table 3 for specific examples of Belite-barium calcium sulfoaluminate cement of the present invention.

[0039] serial number

[0040] Prepare the raw meal according to the above six ingredients, and add a small amount of fluorite at the same time, according to CaF 2 Calculated as 0.5 to 1.2%. The chemical composition of the raw meal is shown in Table 2

[0041] serial number

[0042] In the laboratory, the above clinker is fired in a silicon-molybdenum rod electric furnace, and the firing temperature is 1320°C-1360°C. The physical properties of cement are listed in Table 3.

[0043] serial number

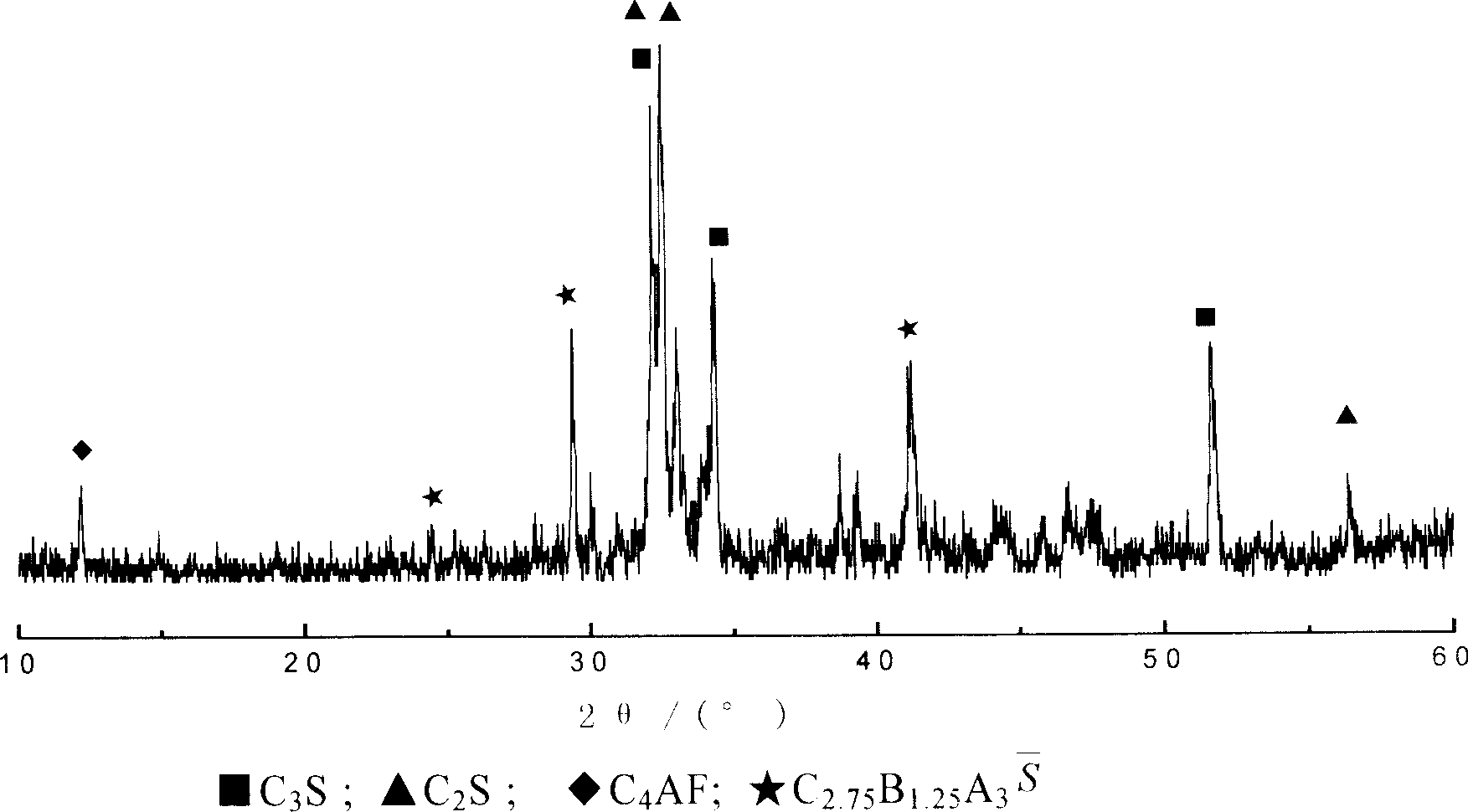

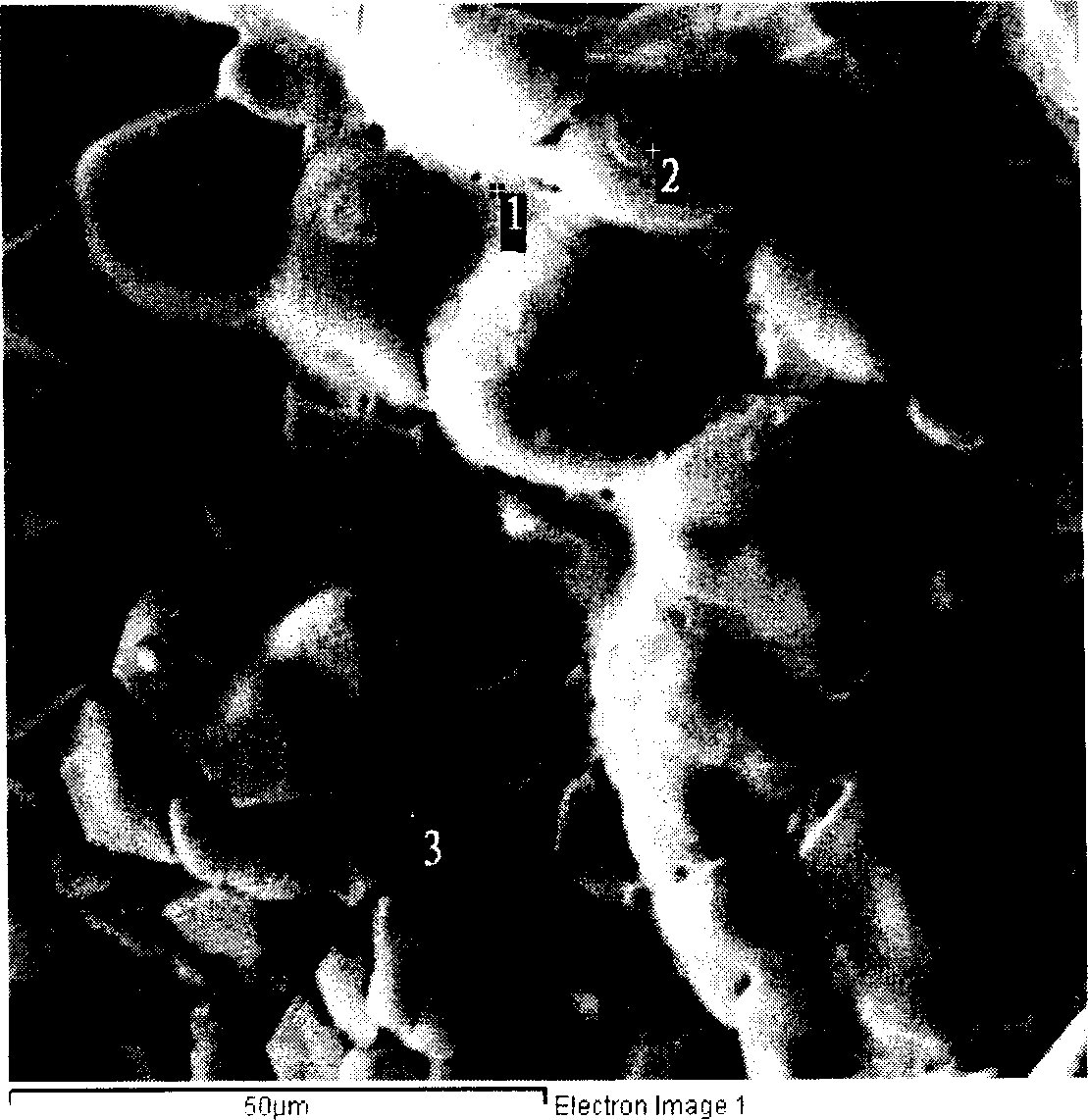

[0044] Carried out XRD analysis and SEM analysis to 4# clinker wherein, see respectively figure 1 with figure 2 . It can be seen that in the belite-barium calcium sulfoaluminate cement clinker mineral system, a new type of cement with belite-barium calcium sulfoaluminate as the dominant mineral phase system has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com