Patents

Literature

202results about How to "Increases hydration activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light high-strength concrete and preparation method thereof

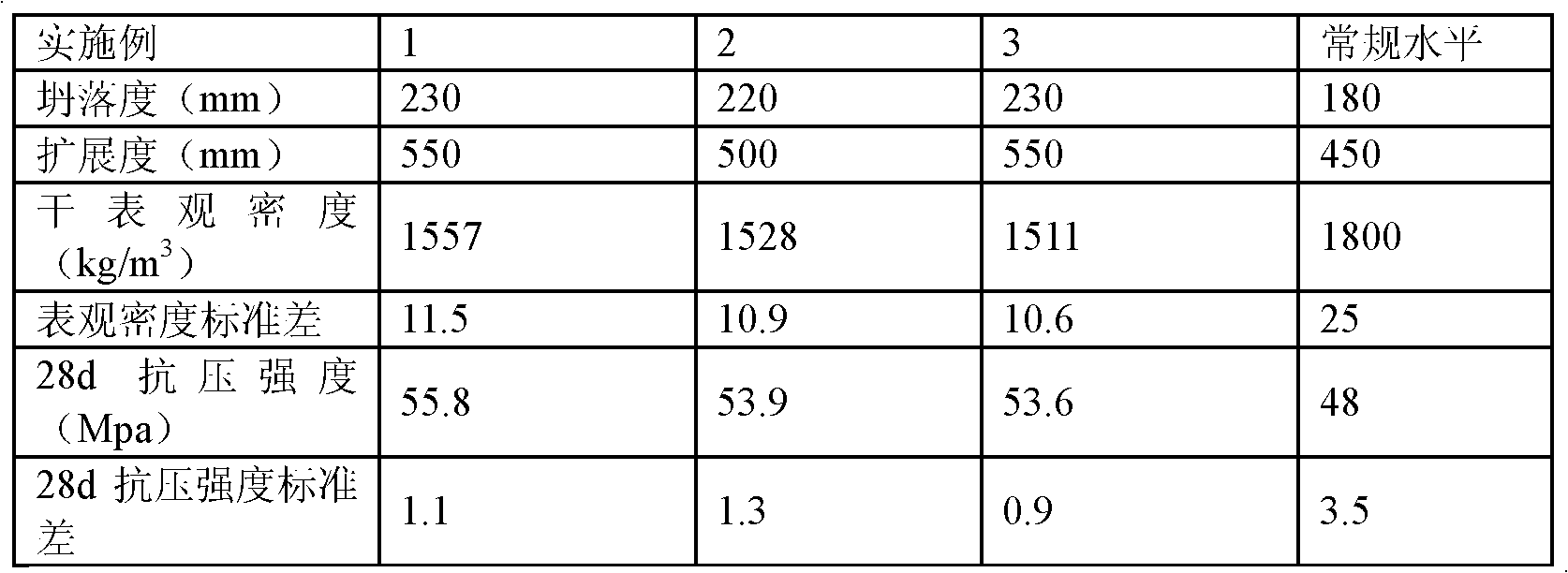

The invention discloses light high-strength concrete, which is prepared from the following raw materials in percentage by weight: 10 to 15 percent of silicate cement, 8 to 12 percent of mineral powder, 6 to 10 percent of coal ash, 2 to 6 percent of wollastonite, 20 to 30 percent of ceramsite,25 to 35 percent of ceramic sand, 0.2 to 0.8 percent of high-performance water reducing agent, 0.05 to 0.3 percent of exciting agent, 0.05 to 0.8 percent of tackifier and 8 to 12 percent of water. The light high-strength concrete has the advantages that compact accumulation is realized by optimizing the grain composition of cementing materials; the mineral powder is subjected to ultrafine grinding, so that the hydrated activity of the mineral powder is improved substantially; and the using quantity of the low-density cementing materials can be increased, and the cohesiveness of slurry is improved by combining the high-performance water reducing agent, the exciting agent and the tackifier, so that the concrete slurry is high in working performance and is not segregable, and the aim of reducing the volume weight of the hardened slurry substantially is fulfilled on the basis of ensuring the mechanical property of the hardened slurry.

Owner:JIANGSU MINGHE GRP

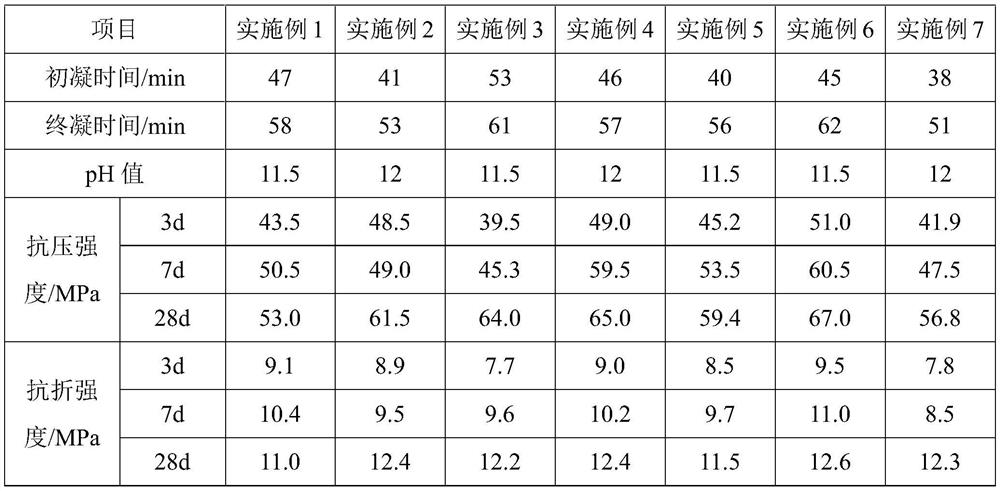

High fluidization micro expansive high-strength grouting material

ActiveCN104402345AReduce physical water consumptionImprove early strengthSolid waste managementChemical admixtureSlag

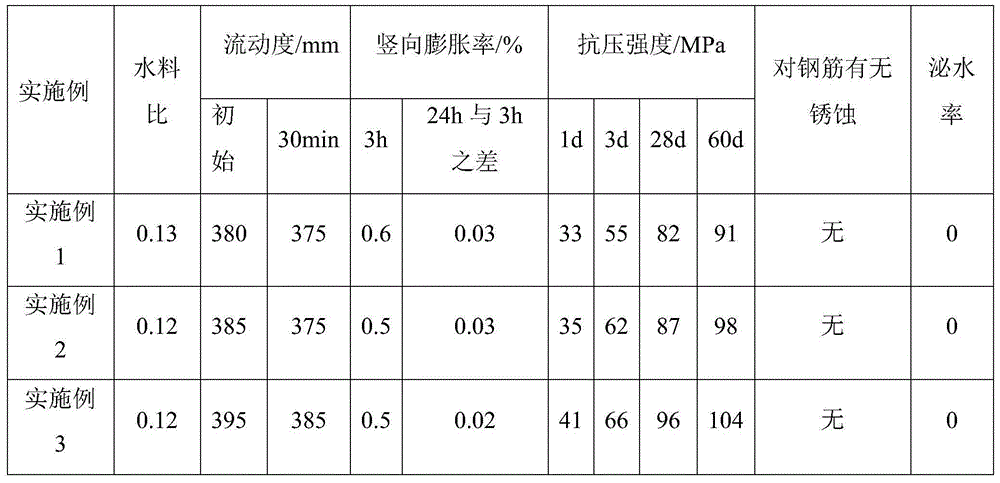

The invention discloses a high fluidization micro expansive high-strength grouting material which comprises the following raw materials by mass percentage: 23-34% of cement, 3-5% of microbead, 5-7.5% of phosphorus slag composite powder, 2.5-3.5% of silica fume, 2.5-3.5% of quartz powder, 46-55% of fine aggregate, 0.7-1% of water reducer, 0.01-0.03% of defoaming agent, 2.5-3.5% of expanding agent and 0.5-1% of early strength agent. The grouting material has the advantages of high strength in the early stage and later stage, good flowing property and adjustable expansiveness by taking the cement as a major binding material and employing the silica fume, the microbead and the phosphorus slag composite powder with different hydration activities together with a chemical additive matched with a binding material system and an aggregate system with reasonable gradation, and is particularly applicable to high precision equipment mounting, secondary grouting of an equipment foundation, bolt anchoring, crack repairing, duct grouting and the like.

Owner:中建西部建设西南有限公司

Steel slag treating method

ActiveCN102559960AEliminate hazardsSafe useRecycling and recovery technologiesThermal energyCalcium silicate

The invention provides a steel slag treating method comprising the following steps of: directly mixing thermal-state revolving furnace steel slag with blast furnace slag in an arc furnace in proportion, adjusting the molten slag in the furnace into a proper temperature by virtue of the arcing of the arc furnace, and stirring the molten slag by virtue of arc disturbance, so that acidic oxide and basic oxide in the molten slag are sufficiently reacted with each other; reacting free calcium oxide and free magnesium oxide in the raw steel slag with silicon dioxide component and low-calcium calcium silicate in the blast furnace slag to generate safe calcium silicate and magnesium silicate, quenching the molten slag to form glass-state solid slag which is higher in hydration reactivity and free of short-term or long-term inflation harm, and further finely grinding the solid slag into slag powder which can be safely used for related building material as the blast furnace slag. According to the method, the damage caused by the free calcium oxide and free magnesium oxide in the steel slag can be removed, and a basis is provided for the whole use of the steel slag. The heat energy of the thermal-state molten slag can be sufficiently used, so that the energy source can be saved, the energy consumption can be reduced, the cost can be reduced, and the discharge of CO2 can be reduced, and the method is extremely high in social meaning and economic meaning.

Owner:北京联合荣大工程材料股份有限公司

Soft soil curing agent prepared by means of industrial residues

InactiveCN105236908AReduce pressure on environmental protectionSolve the shortage of resourcesSolid waste managementPortland cementSlag

The invention discloses a soft soil curing agent prepared by means of industrial residues. The curing agent is prepared from, by weight, 35-65% of steel slag, 30-50% of mineral waste residues, 10-30% of desulfurization gypsum, 2-6% of sulphoaluminate cement clinker, 2-4% of ordinary portland cement clinker, 2-5% of aluminum dregs and 0-5% of cement. The sum of the weight percentages of all the components is 100%. The soft soil curing agent is prepared by fully utilizing industrial residues of heat-engine plants, steel works and aluminum electrolysis enterprises, unconfined compression strength is high during soft soil foundation reinforcement, waste is recycled, and economic benefits and environmental protection benefits are high.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

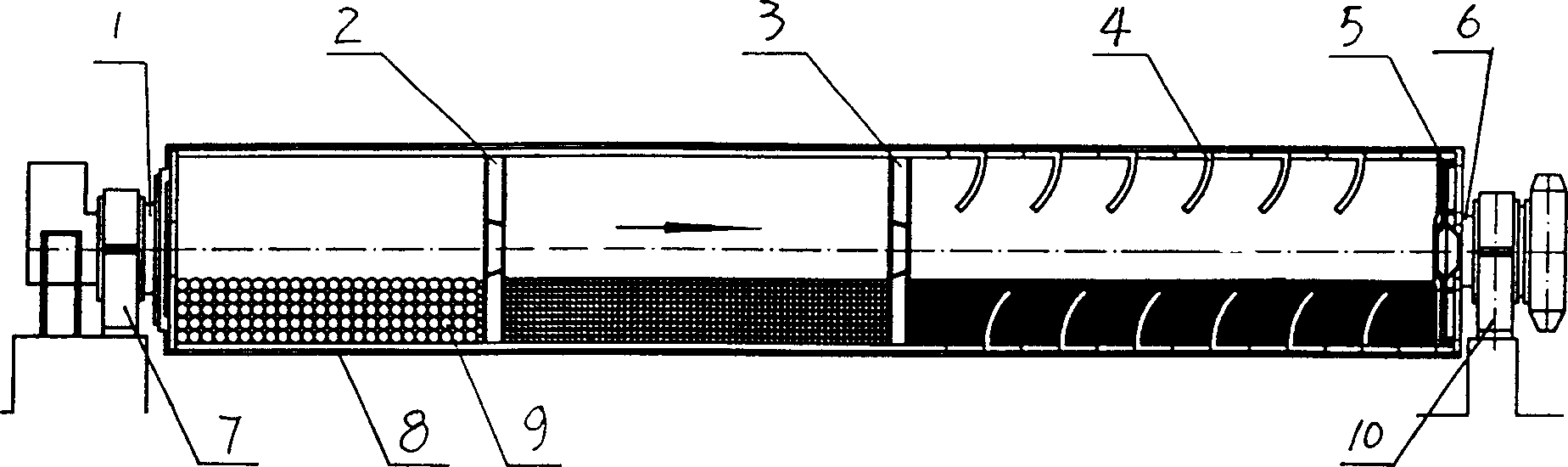

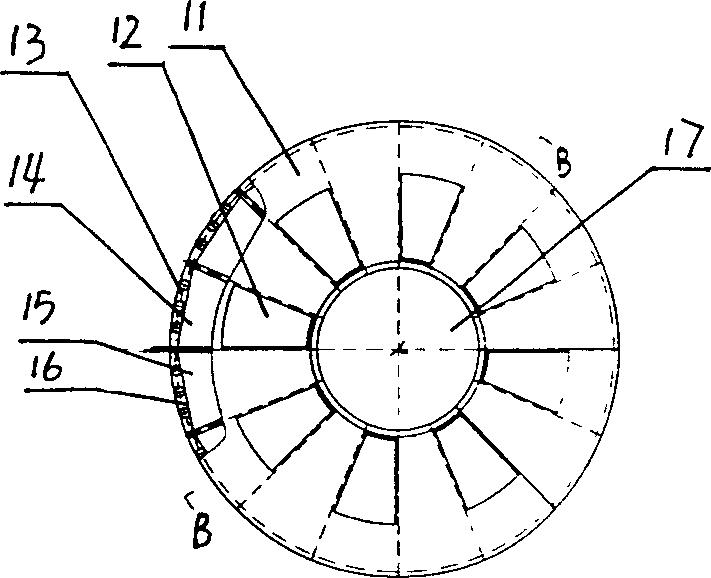

Device and method for dry-method treatment for and sensible heat recovery of high-temperature molten slag

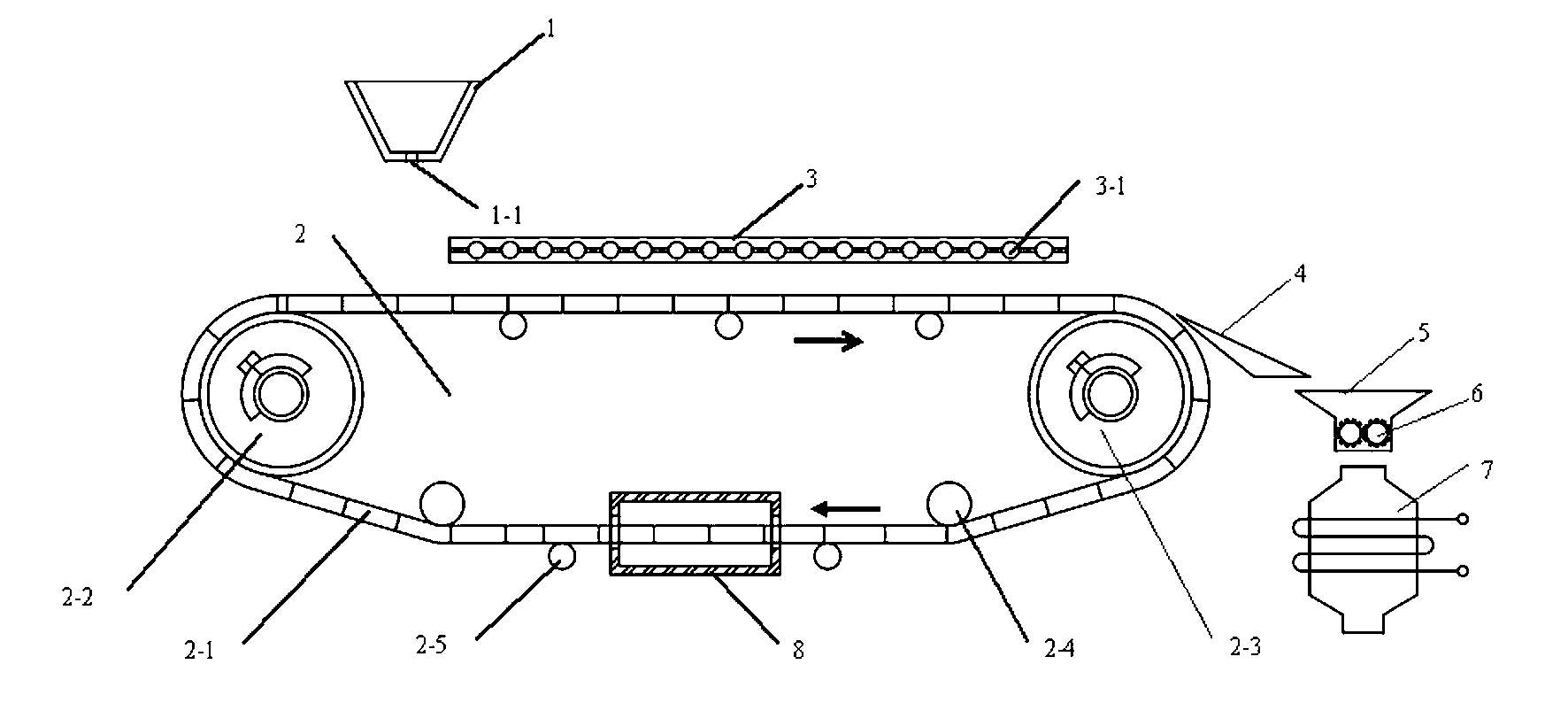

ActiveCN103320554ALight in massReduce pollutionIncreasing energy efficiencyWaste heat treatmentCrusherMolten slag

The invention discloses a device and a method for dry-method treatment and sensible heat recovery of high-temperature molten slag. The device comprises a chain grate, a water-cooling wall, a slag-scraping plate, a slag particle collector and a waste heat recovery device, wherein a first drive chain wheel of the chain grate is located below a tundish; the water-cooling wall is located above a grate plate; a gap is reserved between one end of the slag-scraping plate and the grate plate, and the slag particle collector is arranged below the other end of the slag-scraping plate; a crusher and the waste heat recovery device are arranged at the bottom of the slag particle collector. The method comprises the following steps of: starting the chain grate, and placing the high-temperature molten slag on the grate plate on the upper part of the chain grate via the tundish; separating the high-temperature molten slag from the grate plate by the slag-scraping plate after cooling and solidifying; conveying the high-temperature molten slag into the slag particle collector; and then conveying the high-temperature molten slag into the crusher, and conveying the high-temperature molten slag into the waste heat recovery device after crushing. The method disclosed by the invention has the characteristics of being simple to operate, few in environment pollution, low in process cost, and the like, as well as has a good application prospect.

Owner:NORTHEASTERN UNIV

Portland cement of industrial tailing

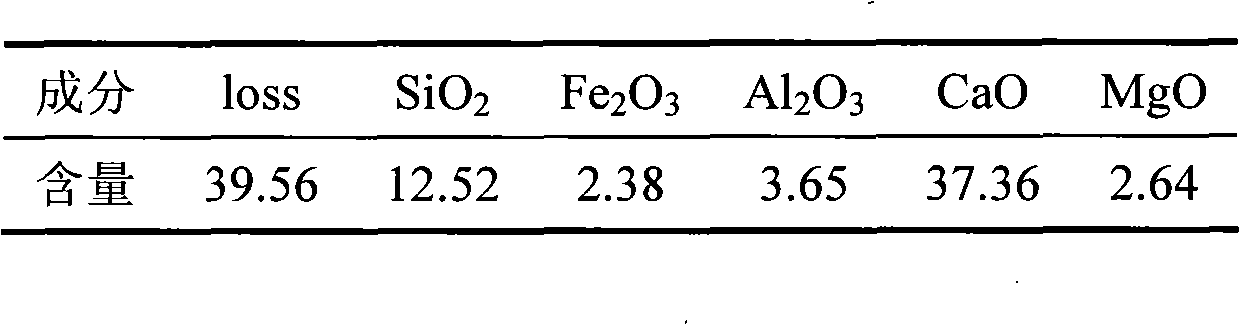

InactiveCN1616372AIncreases hydration activityExcellent hydration activityCement productionSlagPortland cement

The industrial tailing cement is prepared with cement clinker, gypsum and treated Ca-Mg tailing in certain proportion, and through mixing, and grinding to 80 micron size. The tailing content is 6-15 wt% in portland cement, 15-50 wt% in composite portland cement, 20-50 wt% in gaize cement, 20-50 wt% in portland blast furnace slag cement, and 20-50 wt% in type-II portland cement. The cement with industrial tailing is easy to produce hydrated silicate, has high technological indexes, especially cement stability.

Owner:夏根华

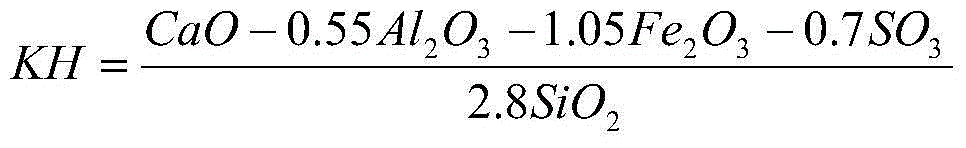

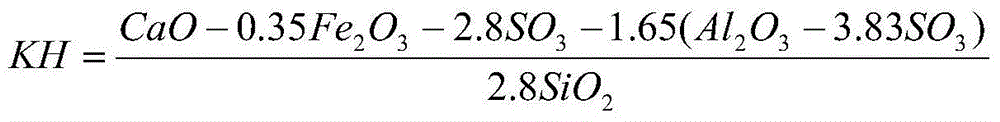

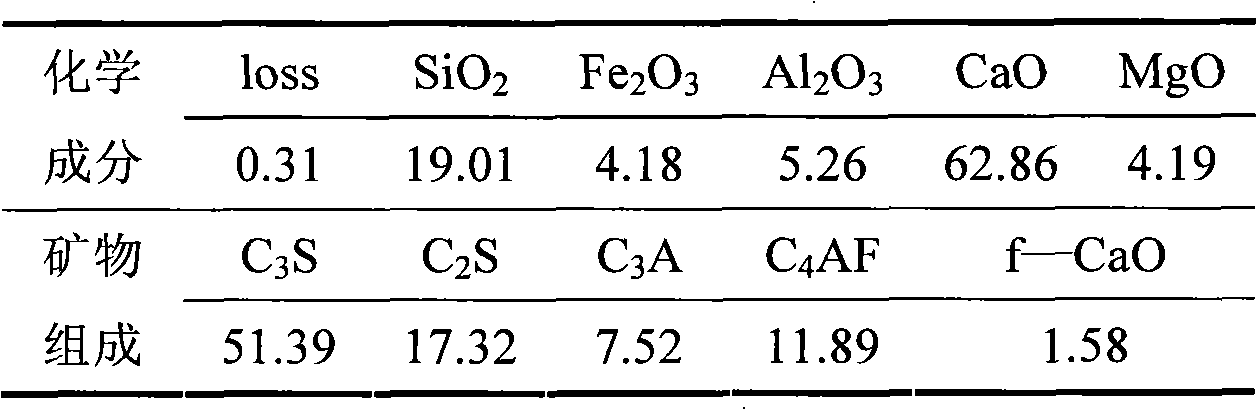

Belite cement and preparation method thereof

ActiveCN104788032AIncreases hydration activityImprove early strengthCement productionTricalcium silicateCalcium aluminoferrite

The invention discloses belite cement and a preparation method thereof. Belite cement clinker comprises mineral components in percentage by weight as follows: 40%-70% of dicalcium silicate, 10%-40% of tricalcium silicate, 6%-15% of tetra calcium aluminoferrite, 1%-10% of anhydrous calcium sulphoaluminate, 0%-8% of tricalcium aluminate and 0%-2% of calcium sulfate. A small number of anhydrous calcium sulphoaluminate minerals are introduced into the belite cement clinker, and on the basis that advantages of low calcium, low energy consumption, low requirements for raw material taste and the like of belite cement are not changed, the early strength of the belite cement is substantially improved and approaches that of ordinary cement; and the belite cement has a remarkable effect of resource and energy saving with utilization of low-grade limestone and industrial residue resources.

Owner:CHINA BUILDING MATERIALS ACAD

Method for activating waste concrete micro powder

InactiveCN102992669AFast curing reactionFull curing reactionSolid waste managementRoom temperatureSodium silicate

The invention relates to a method for activating waste concrete micro powder, comprising the following steps of: (1) mixing waste concrete micro powder and powdered sodium silicate, heating to 250-350 DEG C, preserving heat for 1-2 hours, and decreasing the temperature to room temperature, wherein the weight of the added powdered sodium silicate is 1-3% of that of the added waste concrete micro powder; and (2) mixing the mixture of the waste concrete micro powder and the powdered sodium silicate with desulfurization gypsum and an admixture, grinding for 15-60 minutes to obtain the powder with the fineness and the specific surface area of more than 450m<2> / kg, wherein the weight of the desulfurization gypsum is 1-5% of that of the mixture of the waste concrete micro powder and the powdered sodium silicate, and the weight of the admixture is 1-3% of that of the mixture of the waste concrete micro powder and the powdered sodium silicate. The method can improve the activity of the waste concrete micro powder so that the waste concrete micro powder is fully utilized.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

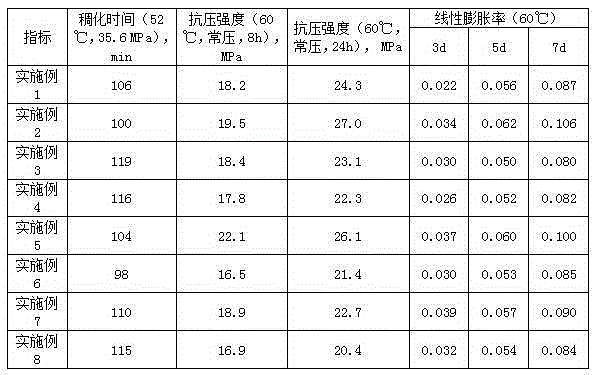

Slightly-expanded oil well cement

ActiveCN105295876AOvercome the defect of slow expansionPromote expansionDrilling compositionWell cementingUltimate tensile strength

The invention discloses slightly-expanded oil well cement, belonging to the technical field of well cementing and cementing for oil and gas wells. The well cementing cement comprises the following raw materials in parts by weight: 50 to 80 parts of gel material, 20 to 40 parts of active materials, 0.5 to 3 parts of magnesia expanding agent, 0.1 to 8 parts of alkaline activator, and 2 to 5 parts of stabilizing material; the magnesia expanding agent is light calcined magnesia powder. The slightly-expanded oil well cement disclosed by the invention is mainly used for solving the problem that the expansion effect of expanding cement is poor to influence the early strength in the prior art and has the advantages of good expansion properties in the early, medium and later stages of cement hydration.

Owner:JIAHUA SPECIAL CEMENT

Construction waste regenerated high-activity mineral admixture and preparation thereof

ActiveCN103979807AReduced water needs for hydrationF-CaO content decreasedClinker productionSlagMaceral

The invention discloses a regenerated high-activity mineral admixture prepared through resourceful utilization of construction waste and metallurgical waste residue, and a preparation method thereof. The method comprises the following steps: crushing waste concrete so as to obtain cement stone flour; mixing 70 to 98 wt% of cement stone flour, 0 to 25 wt% of metallurgical waste residue and 1 to 5 wt% of floating beads, adding water accounting for 10 to 15% of the total mass of cement stone flour, siliceous metallurgical waste residue and floating beads into the obtained mixture and carrying out drying so as to obtain slag stone flour; calcining the obtained slag stone flour at a temperature of 800 to 1000 DEG C for 15 to 20 min so as to obtain calcined slag stone flour; and mixing 50 to 70 wt% of calcined slag stone flour and 30 to 50 wt% of blast furnace slag powder so as to obtain the regenerated high-activity mineral admixture. According to the invention, solid waste like construction waste, metallurgical waste residue, floating beads and the like is used, so components of the mineral admixture are simple and manufacturing cost is low; and the mineral admixture has high activity and can effectively reduce the amount of cement in preparation of high performance concrete.

Owner:WUHAN TIANYICHENG RENEWABLE RESOURCES CO LTD

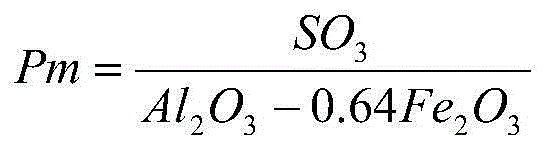

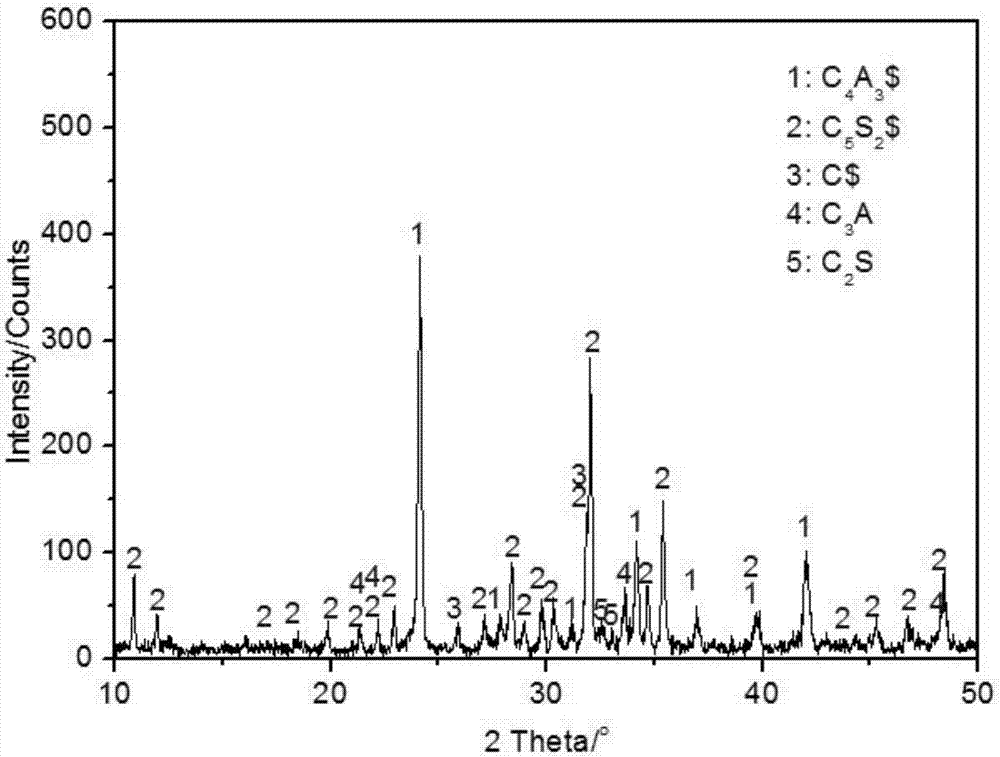

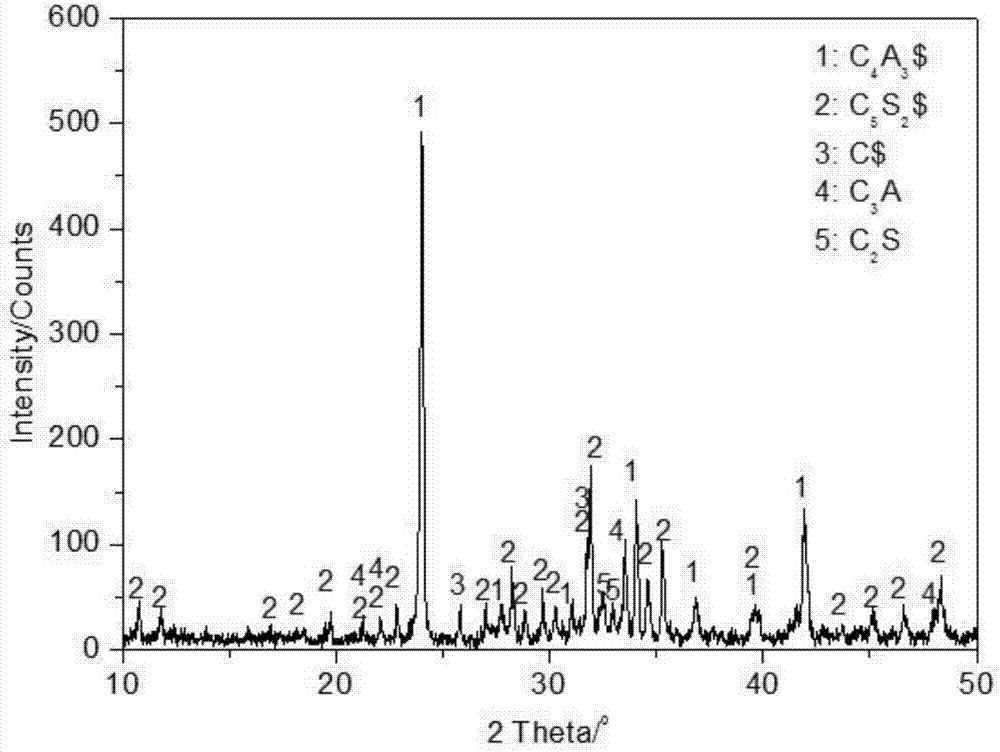

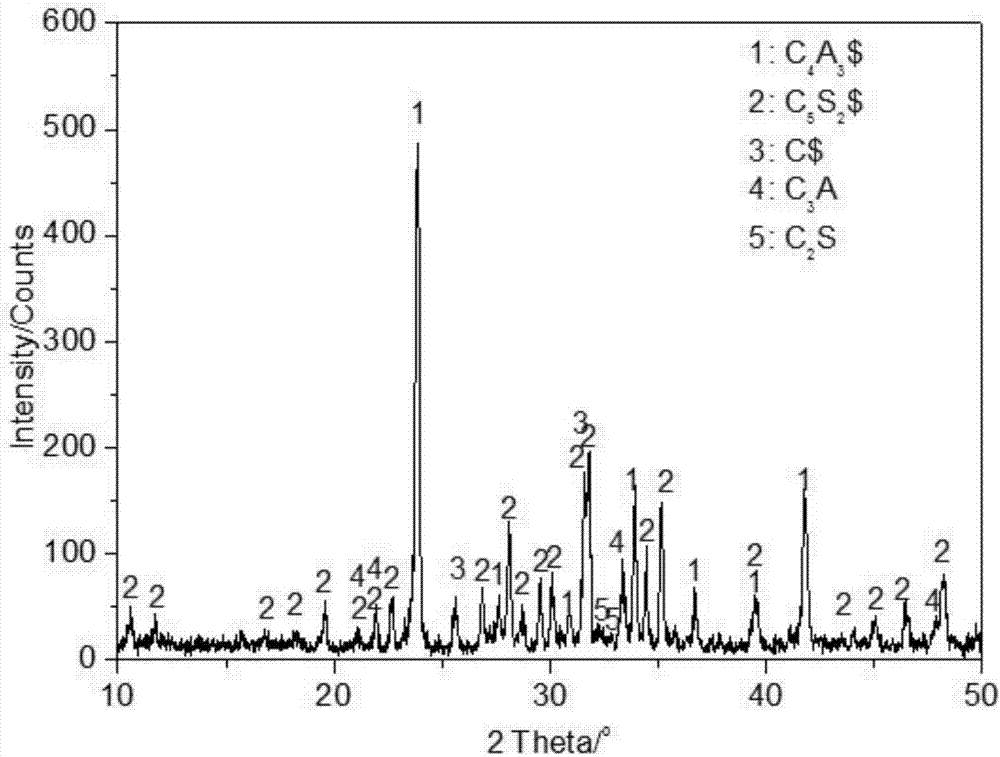

Calcium sulfo-silicate sulfo-aluminate cement and preparation method thereof

ActiveCN107021654ACalcination temperature is lowReduce CO2 emissionsClinker productionGypsumAluminate

The invention discloses calcium sulfo-silicate sulfo-aluminate cement and a preparation method thereof. A main mineral phase of clinker of the cement comprises the following ingredients in parts by mass: 5-40 parts of C4(AxF1-x)3$, 20-65 parts of C5S2$, 5-15 parts of C$ and 5-20 parts of C3A. The preparation method comprises the steps of calcining crude materials of the cement once at the temperature of 1,050 DEG C to 1,200 DEG C, and carrying out heat preservation for 1 hour or less, thereby preparing the cement. According to the calcium sulfo-silicate sulfo-aluminate cement and the preparation method thereof, the energy consumption and CO2 discharge of preparation of the cement clinker are lowered to a large extent, and the calcined clinker has good grindability. The calcium sulfo-silicate sulfo-aluminate cement presents good early mechanical properties, calcium sulfoaluminate minerals are basically hydrated completely at a seventh day, and calcium sulfo-silicate minerals already start to hydrate at a seventh day, so that the problem of sulfo-aluminate cement that later strength is lowered is solved; dihydrate gypsum generated from the hydration of calcium sulfo-silicate can be converted into mono-sulfur calcium sulfo-aluminate hydrate from tri-sulfur calcium sulfo-aluminate hydrate.

Owner:CHONGQING UNIV

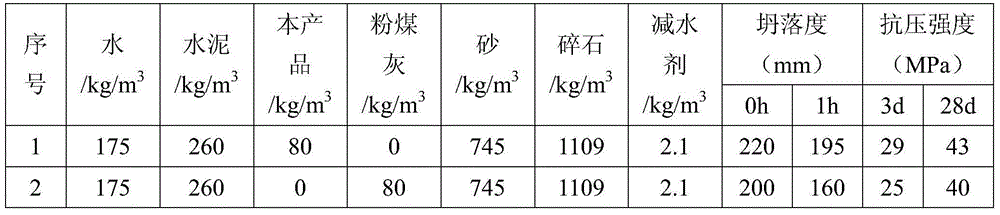

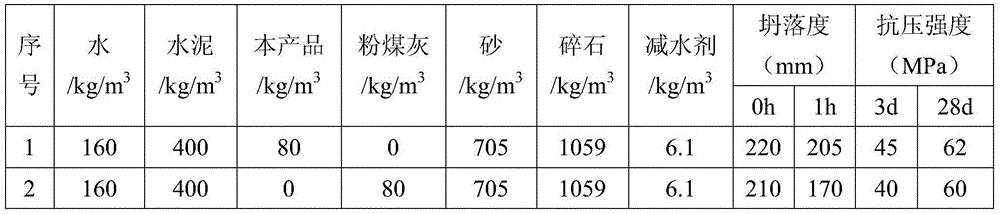

Modified active iron tailing admixture for concrete and preparation method thereof

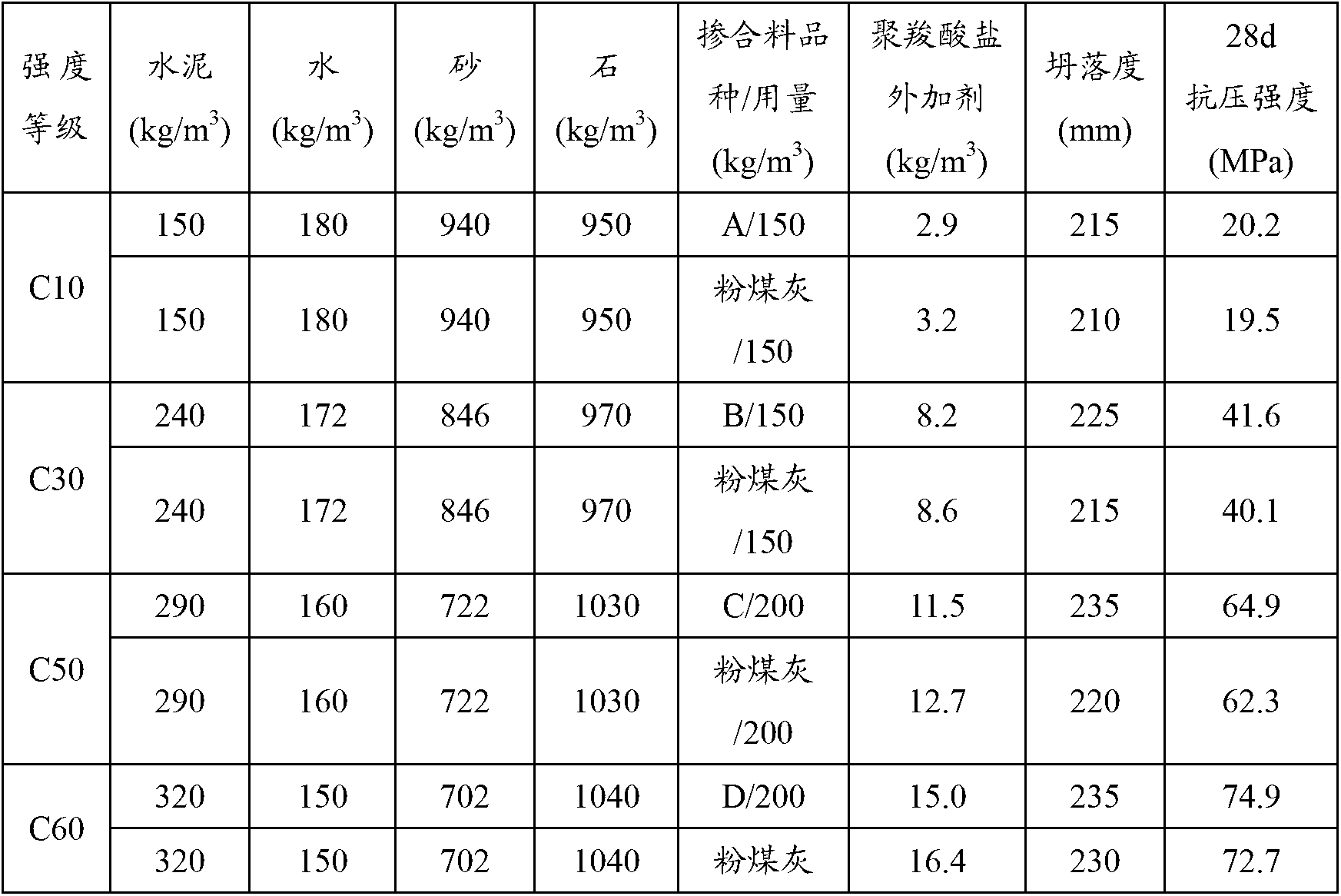

The invention provides a modified active iron tailing admixture for concrete, which comprises the following elements: iron tailings and polycarboxylate, wherein the dosage of the polycarboxylate is 0.2-0.6wt% based on the mass of the iron tailings, and both the specific surface of the iron tailings and that of the polycarboxylate are 400-600m<2> / kg. Replacing slag powder and pulverized coal ash, the active iron tailing admixture provided by the invention is applied to the concrete and can prepare C10-C100 pump concrete, and the active iron tailing admixture can meet each performance index of build concrete and has a brilliant application prospect in the construction engineering.

Owner:北京东方建宇混凝土科学技术研究院有限公司

Compound gel material special for marine concrete, production method and application thereof

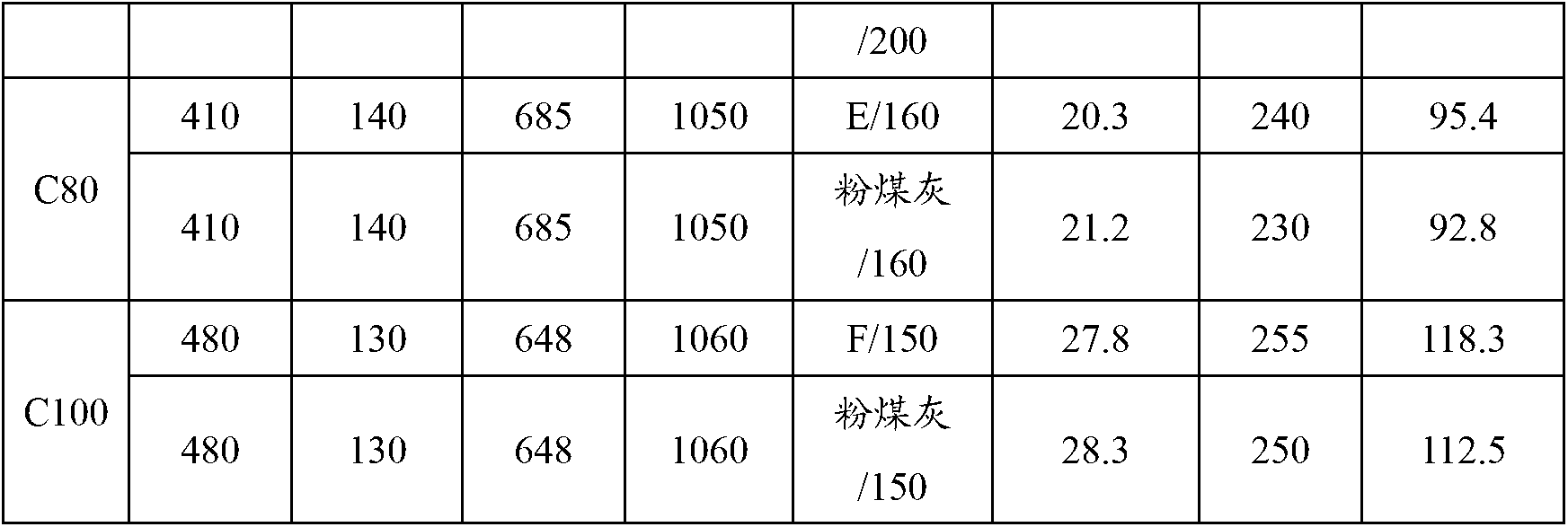

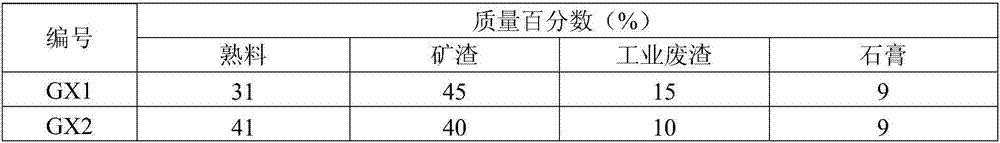

InactiveCN106927701AHigh initial bulk densityReasonable distributionCement productionWork performanceSlag

The invention discloses a compound gel material special for marine concrete, a production method and an application thereof. The compound gel material is prepared from 20-60% of clinker, 30-70% of granulated blast-furnace slag, 5-15% of gypsum and 5-30% of industrial residue. The method comprises the following steps: while producing, milling clinker, gypsum and industrial residue till the specific surface area is 320-380m2 / kg; milling the granulated blast-furnace slag into mineral powder with the specific surface area of not less than 420m2 / kg; uniformly mixing all the powder, thereby acquiring the compound gel material. Compared with the marine concrete prepared according to the traditional method, the high corrosion resistance marine concrete adopting the compound gel material provided by the invention has better working performance, mechanical property and chloride ion erosion resistance.

Owner:CHINA RESOURCES CEMENT TECH RES DEV

Magnesium phosphate cement

The invention discloses a magnesium phosphate cement, which is prepared from the following ingredients in parts by mass: 45-75 parts of magnesium oxide mixture, 15-50 parts of dihydric phosphate and 2-10 parts of retarder, wherein the magnesium oxide mixture comprises calcined dolomite dust. A preparation method of the calcined dolomite dust comprises the following steps: after smashed dolomite and silicon-containing ingredients are evenly mixed, calcining at the temperature of 1100-1800DEG C; and then, grinding a calcined product to obtain the calcined dolomite dust. Compared with traditionalmagnesium phosphate cement, the magnesium phosphate cement prepared by the method has the advantages that performance is similar and color is white, meanwhile, the selection range of a magnesium oxide raw material in the magnesium phosphate cement is enlarged, the cost of the magnesium phosphate cement is obviously lowered, and therefore, the magnesium phosphate cement has a good market prospect.

Owner:CHONGQING UNIV

Large-dosage fly ash concrete and preparation method thereof

ActiveCN107602023AOvercome the defect of low early strengthHigh strengthCalcium hydroxideSodium Bentonite

The invention provides large-dosage fly ash concrete and a preparation method thereof. The large-dosage fly ash concrete is prepared from the following raw materials: cement, fly ash, mineral powder,gravel, river sand, water, a modified reinforcing agent and a polycarboxylate superplasticizer, wherein the modified reinforcing agent is prepared from bentonite, attapulgite, lignosulfonate, sodium sulfate, calcium hydroxide, triethanolamine maleate and water. The preparation method comprises the following steps: adding the cement, the mineral powder, the fly ash, the modified reinforcing agent,the gravel and the river sand into a mixer; performing dry mixing for 30-40min; adding the water and the superplasticizer into the mixer; mixing for 10-15min to obtain the large-dosage fly ash concrete. According to the large-dosage fly ash concrete and the preparation method thereof provided by the invention, a multifunctional modified synergistic for large-dosage fly ash concrete is prepared from the roasted bentonite together with attapulgite, organic and inorganic activators and a surfactant; by combining the multifunctional modified synergistic with an early-strength polycarboxylate superplasticizer, the aim of improving the strength, compactness and durability of the large-dosage fly ash concrete can be achieved.

Owner:南京平达绿色建材科技有限公司

Method using titanium gypsum and acetylene sludge to prepare high-calcium sulphoaluminate or high-sulfur clinkers

A method using titanium gypsum and acetylene sludge to prepare high-calcium sulphoaluminate or high-sulfur clinkers includes the steps: (1) compounding; (2) homogenizing; and (3) calcining. According to the method using the titanium gypsum and the acetylene sludge to prepare the high-calcium sulphoaluminate or the high-sulfur clinkers, drying and grinding of wet sludge titanium gypsum and the acetylene sludge are omitted, energy consumption in drying and grinding is reduced, the firing temperature is low, firing energy consumption is low, production cost of the clinkers is low, and waste recycling benefits are good.

Owner:长沙紫宸科技开发有限公司

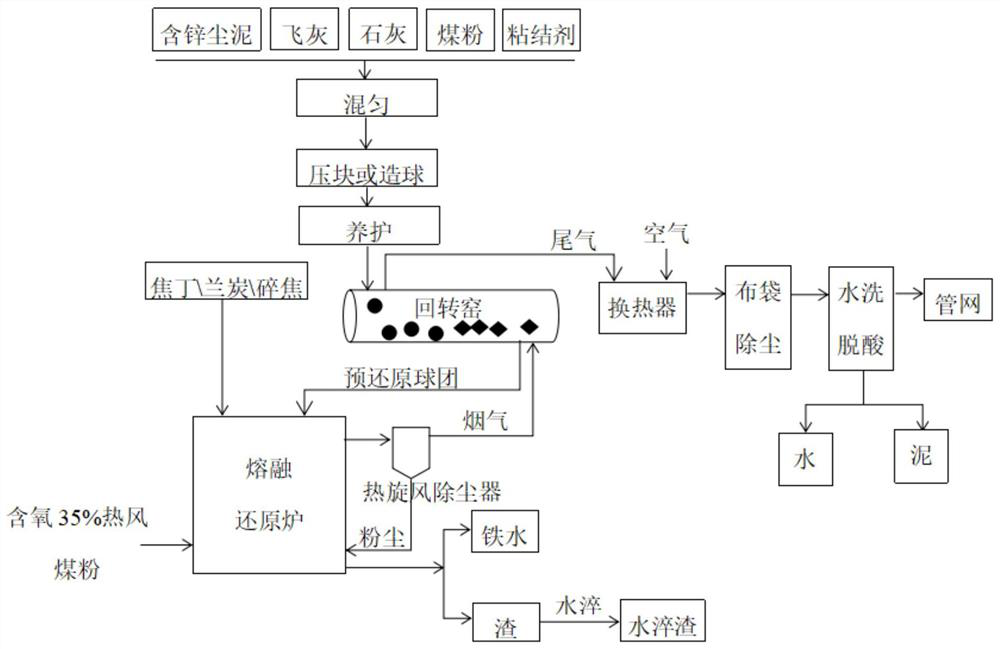

Method and system for co-processing waste incineration fly ash and zinc-containing dust mud of steel plant

ActiveCN112442589APromote resource utilizationQualified Chemical CompositionRotary drum furnacesSlagCo-processing

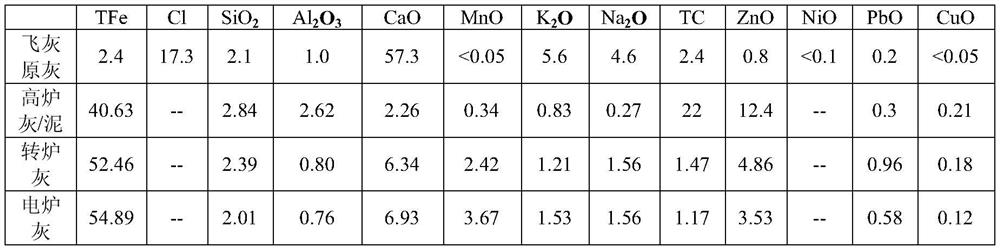

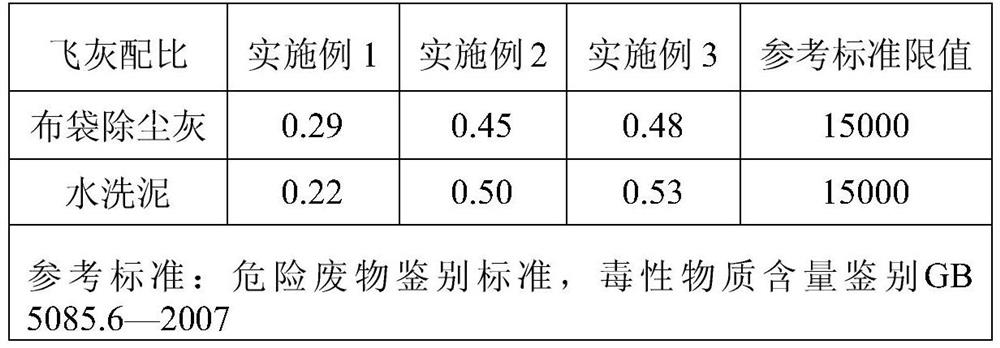

The invention discloses a method and a system for co-processing waste incineration fly ash and zinc-containing dust mud of a steel mill. The method comprises the following steps: 1, adding 1.5% of lime and pulverized coal into the fly ash and the dust mud according to the slagging alkalinity of 1.1-1.3, the total carbon content of 2-8% and the binder ratio of 2-5% for proportioning, wherein the fly ash accounts for 5-20% of the dust mud; 2, adding water into the mixture, extruding into blocks or pelletizing, and curing until the strength meets the requirement; 3, adding the agglomerates or pellets into a rotary kiln, and introducing high-temperature coal gas to pre-reduce the agglomerates or pellets in the kiln; 4, continuously adding the pre-reduced agglomerates or pellets into a smeltingreduction furnace, and meanwhile distributing main fuel such as nut coke within the range of the material surface radius of the smelting reduction furnace; blowing hot air with the oxygen concentration of 35% from a tuyere of a reduction furnace, and spraying pulverized coal through the tuyere; and carrying out further indirect reduction, softening melting and FeO-C final reduction on the pre-reduced pellets in a coke bed in the reduction furnace to generate molten iron and furnace slag. According to the main purpose, the fly ash is cooperatively treated and utilized by combining the advantages of a metallurgical furnace for treating zinc-containing dust according to the chemical components of the fly ash.

Owner:BAOSHAN IRON & STEEL CO LTD

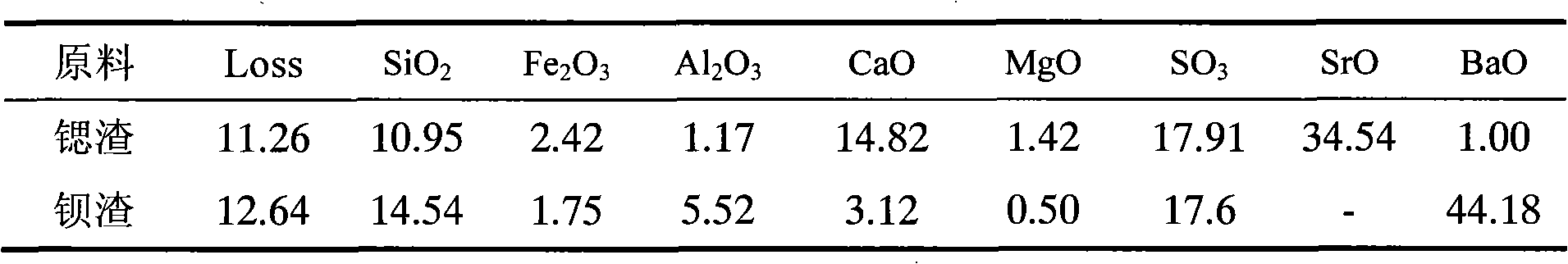

Strontium-barium cement calcination composite mineralizer

The invention relates to a strontium-barium cement calcination composite mineralizer, which is mainly made of strontium slag and barium slag, wherein both the weight percentage of the strontium slag and the weight percentage of the barium slag are 15 to 85 percent; the strontium slag is waste residue for producing strontium carbonate, and the weight percentage of SrO is required to be 25 to 40 percent; and the barium slag is waste residue for producing barium carbonate, and the weight percentage of BaO is required to be 20 to 50 percent. The invention utilizes the strontium slag and the barium slag as raw materials to synthesize the composite mineralizer, and achieves the aims of improving the cement strength, accelerating the hydrating and hardening of cement, improving the yield of kilns, reducing the cement cost, saving energy and resources, and reducing environmental pollution through the activation and mineralization of the composite mineralizer during the calcination of cement clinker.

Owner:UNIV OF JINAN

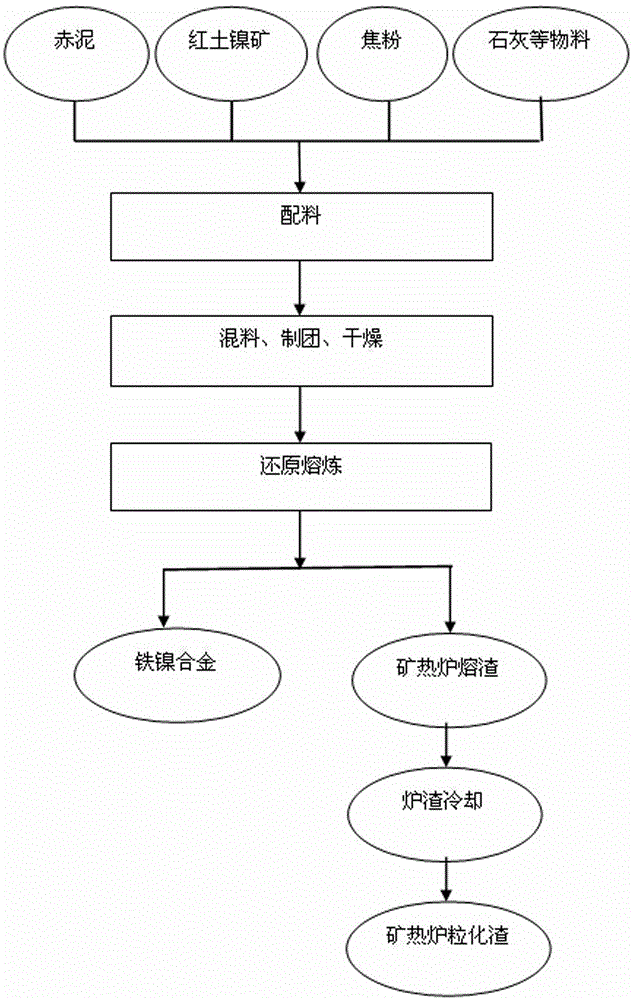

Method for preparing ferronickel byproduct active smelting electric furnace grain slag through red mud and nickel laterite ore

ActiveCN106148699AHighlight substantive featuresSignificant progressProcess efficiency improvementRed mudResource utilization

The invention provides a method for preparing ferronickel byproduct active smelting electric furnace grain slag through red mud and nickel laterite ore. The method is characterized by comprising the following steps that 1, proportioning is carried out, specifically, raw materials include the red mud, the nickel laterite ore, coke powder and lime; and 2, reduction smelting of a smelting electric furnace is carried out, specifically, clusters formed through the raw materials prepared in the step 1 are conveyed into the smelting electric furnace for reduction smelting, slag and iron separation is completed through slag pre-making, melting and reduction, a furnace slag layer is formed, the furnace slag is discharged out of a slag opening regularly and subjected to water quenching or air-cooling pelletization, and the active smelting electric furnace grain slag is obtained. The smelting electric furnace grain slag prepared through the method can serve as a mixed material applied in the cement production process, the cement performance is improved, the variety and labels of cement products are adjusted, and the production cost is reduced; and meanwhile, the slag can be used for producing a concrete admixture independently or by being combined with other raw concrete admixture materials, and the resource utilization of the ferronickel byproduct active smelting electric furnace grain slag prepared through the red mud and the nickel laterite ore is effectively achieved.

Owner:GUANGXI UNIV

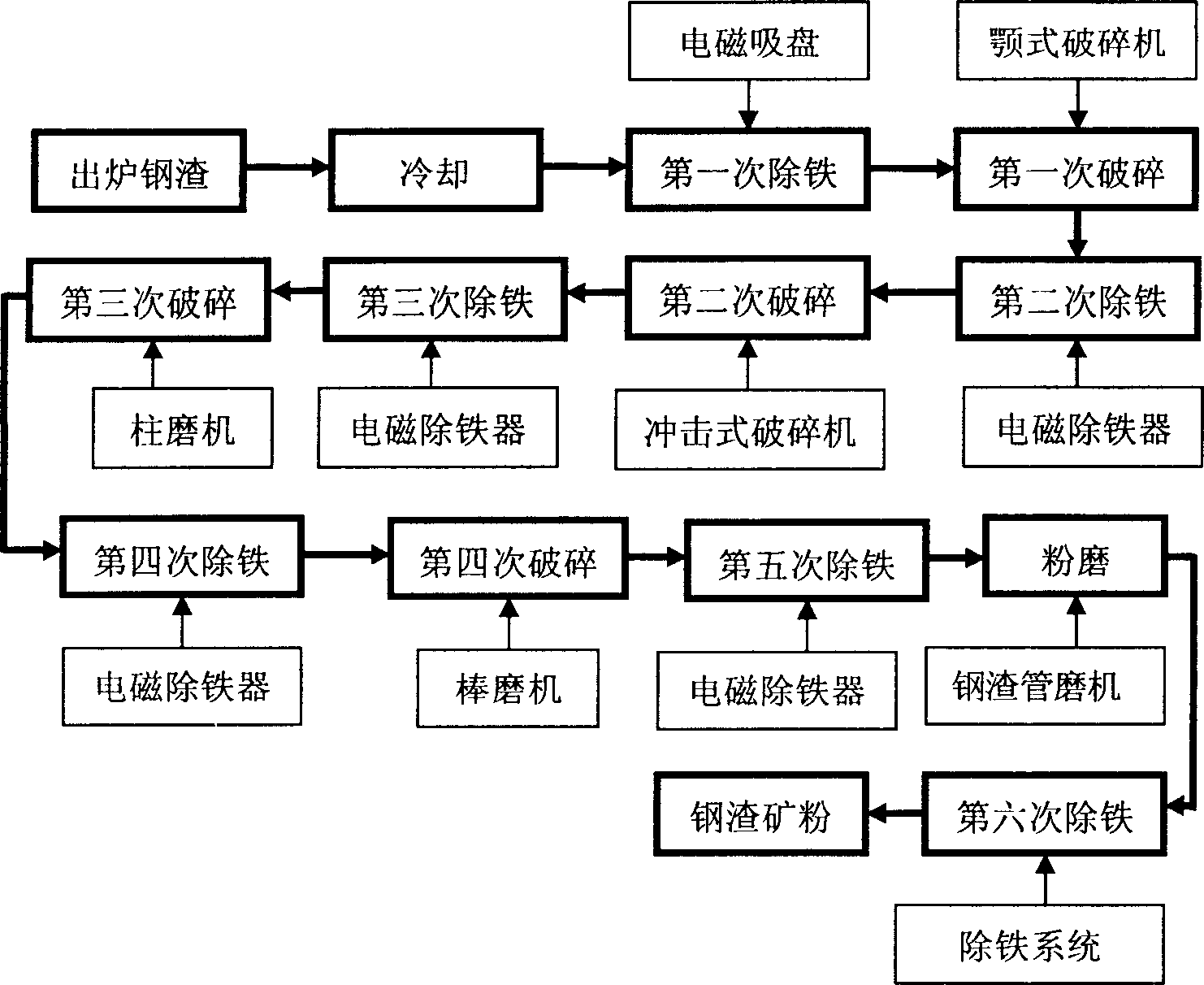

Production technology of high quality steel slag breeze

InactiveCN1718746AReduce energy consumptionReduce manufacturing costRecycling and recovery technologiesMagnetic separationSlagCrusher

A technology for preparing the breeze from steel slag includes such steps as cooling, removing iron by electromagnetic sucking disc, breaking by alligator, removing iron by ferroelectric magnetic iron remover, breaking by impact crusher, removing iron by ferroelectric magnetic iron remover, pulverizing by post grinder, removing iron by ferroelectric magnetic iron remover, pulverizing by rod grinder, removing iron by ferroelectric magnetic iron remover, pulverizing by tube grinder, and removing iron by iron removing system. The product has low content of Fe and large specific surface area.

Owner:WUHAN UNIV OF TECH

Method for producing high-iron sulphoaluminate cement by using red mud and aluminum ash

The invention relates to the technical field of special cement, in particular to a method for producing high-iron sulphoaluminate cement by utilizing red mud and aluminum ash. The method for producingthe high-iron sulphoaluminate cement by utilizing the red mud and the aluminum ash comprises the following steps: mixing carbide slag and waste sulfuric acid, reacting, and drying to obtain calcium sulfate-containing waste residues; mixing red mud, secondary aluminum ash, waste cathode carbon blocks, calcium sulfate-containing waste residues and / or waste gypsum, adopting limestone as a correctionmaterial, grinding and drying to obtain a cement raw material, and calcining the cement raw material to obtain cement clinker; mixing the modified red mud and the waste gypsum to obtain a mixture A;mixing the modified red mud, waste gypsum and limestone to obtain a mixture B; and mixing the cement clinker with the mixture A or the mixture B, and grinding to obtain the high-iron sulphoaluminate cement. Waste sulfuric acid is treated and utilized while industrial solid waste is utilized, and the produced high-iron sulphoaluminate cement is high in strength, free of heavy metal dissolution andlow in cost.

Owner:淄博海慧工程设计咨询有限公司

Collaborative process for carbonizing and hydrating steel slag

The invention belongs to the technical field of building materials, and particularly relates to a collaborative process for carbonizing and hydrating steel slag. The process comprises the following steps: (1) pre-wetting lightweight ceramic sand; (2) uniformly mixing the pre-wetted lightweight ceramic sand, the steel slag and quartz sand in parts by weight: 50 to 70 parts of the steel slags, 18 to30 parts of the quartz sand and 5 to 20 parts of the pre-wetted lightweight ceramic sand; and (3) pressing and forming, namely, immediately placing the mixture into a carbonizing box for carbonizing,and then performing standard curing. According to the collaborative process for carbonizing and hydrating the steel slag, a carbonizing curing and pre-wetted ceramic sand internal curing collaborative mechanism is introduced by utilizing the chemical characteristics of carbonizing activity and hydrating activity of the steel slag; the overall reaction degree of the steel slag is improved; the mechanical properties and the durability of a steel slag product are further improved; the prepared steel slag product has the characteristics that the homogeneousness of a carbonized matrix is high, themechanical properties and the durability are excellent, the cost is low, and the environment friendliness is high.

Owner:WUHAN UNIV OF TECH

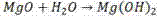

Magnesian concrete damage self-repairing additive and preparation method thereof

The invention relates to the field of building material additives. A magnesian concrete damage self-repairing additive comprises the following components in parts by weight: 30 to 60 parts of magnesium oxide, 15 to 40 parts of quartz powder, 10 to 20 parts of kaoline, 2 to 6 parts of sodium silicate, 2 to 10 parts of sodium hexametaphosphate and 5 to 10 parts of gypsum. The concrete damage self-repairing additive based on a light calcinesia magnesia expanding agent has rapid and excellent self-repairing effect on cracks and internal damage caused by various reasons while improving the mechanical property and the crack resistance of the concrete.

Owner:GUANGDONG YUESHENG SPECIAL BUILDING MATERIALS

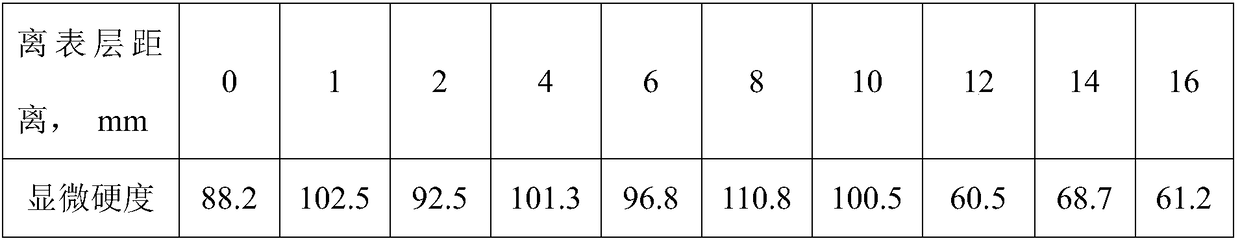

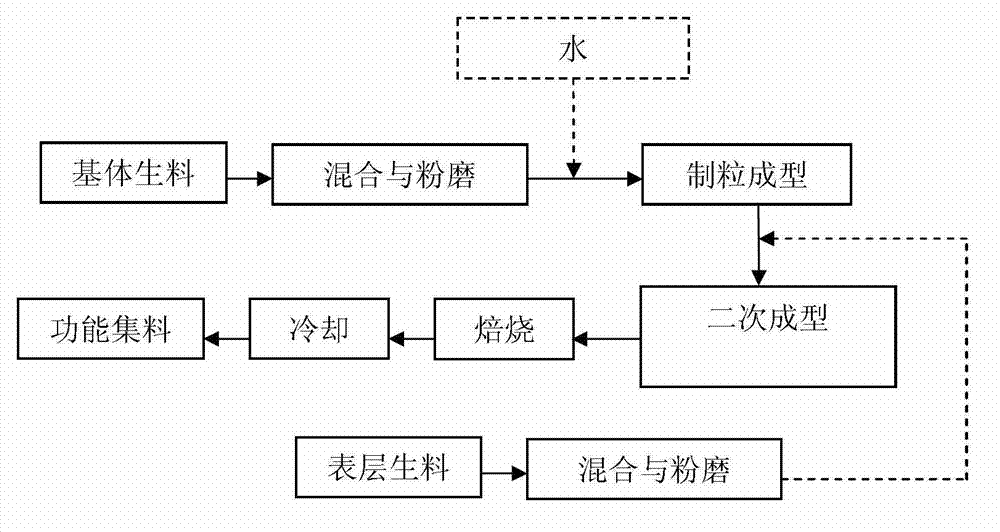

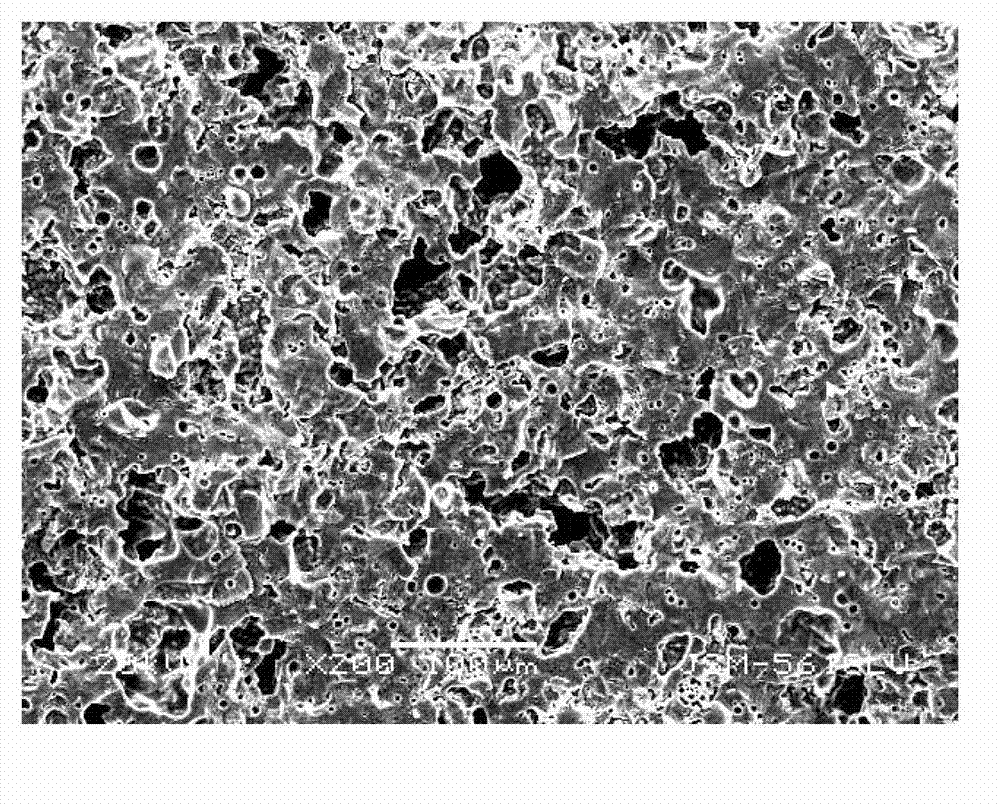

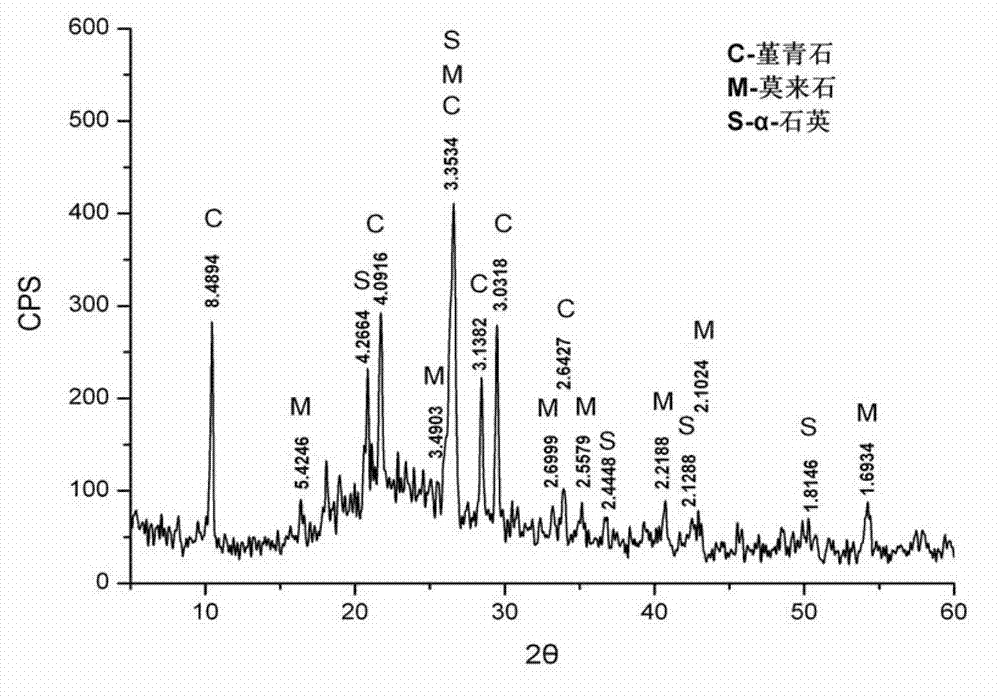

Functional aggregate and preparation method thereof

The invention belongs to the field of concrete materials, and specifically relates to a functional aggregate and a preparation method thereof. The functional aggregate is characterized in that: the functional aggregate has a core-shell structure, and is composed of a porous core substrate and an alkaline surface active shell. Mullite is a main mineral phase of the porous core substrate, and a continuous phase is formed. Pores are distributed in the continuous phase. The pore sizes of the pores are distributed in a multilevel form. The pores are mainly micron-leveled pores. The mineral phase of the alkaline surface active shell is mainly composed of dicalcium silicate, tricalcium silicate, tricalcium aluminate, and tetracalcium iron aluminate. The functional aggregate provided by the invention has light weight and high strength. The functional aggregate can be internally cured, and has a surface active layer. When the functional aggregate is used in concrete, an interfacial transition zone (ITZ) can be completely enhanced and improved, cement stone structure formation can be regulated, and concrete overall performance can be improved. The preparation process is simple and controllable, and is easy to operate.

Owner:WUHAN UNIV OF TECH

Full steel slag roller compacted concrete and preparation method thereof

The invention discloses a full steel slag roller compacted concrete and a preparation method thereof. The full steel slag roller compacted concrete comprises the following raw materials by weight: 24-37 portions of a steel slag composite powder, 45-65 portions of a steel slag aggregate, 11-18 portions of steel slag water washing mud and 3-5 portions of water. The method is as below: weighing the steel slag composite powder, steel slag aggregate, steel slag water washing mud and water according to the weight ratio; and uniformly mixing to obtain the full steel slag roller compacted concrete. The invention can play the recycling value of metallurgical wastes, reduce the cost of roller compacted concrete, and obtain great economic benefits. More important, application of the invention can economize natural gravel and cement, thereby saving natural resources and energy and protecting the ecological environment.

Owner:宝武环科武汉金属资源有限责任公司

Energy-saving cement clinker quick sintering intensifier

InactiveCN101723611ALower firing temperatureReduce heat consumptionTrace element compositionMetallic materials

The invention discloses an energy-saving cement clinker quick sintering intensifier, which is prepared into a finished product through the steps of crushing, screening, metering, uniformly mixing, metering and packing rear earth ores, fluorite mines, barium slag, copper slag, lead-zinc slag and steel slag which are in certain weight percentages. The energy-saving cement clinker quick sintering intensifier is a granular and powdery, nontoxic, harmless and radiation-free inorganic nonmetallic material which consists of a plurality of catalytic components and trace elements. When the product is used for a dry-process rotary kiln, the product can greatly improve the rate of dissolution of calcium carbonate, reduce the content of f-CaO, improve the yield per hour of the kiln by 10 to 30 percent, improve the early strength of clinkers by 3 to 7 MPa, keep the later strength of the clinkers about 60 MPa, reduce the sintering temperature of the clinkers by 50 to 100 DEG C, reduce coal consumption by 5 to 15 percent and reduce power consumption by 10 to 20 percent.

Owner:XIAN DELAIKE CONCRETE ADDITIVE

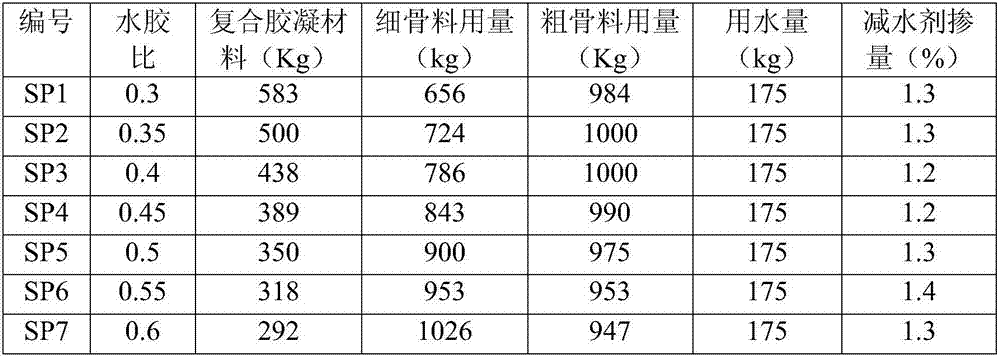

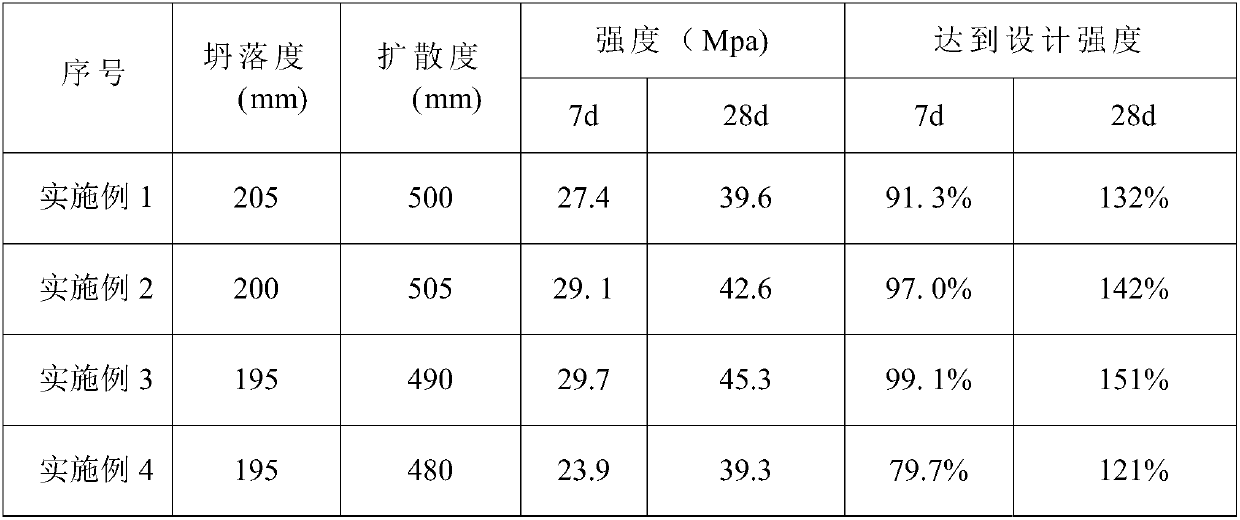

Self-compacting non-contract concrete used in large-span CFST (Concrete Filled Steel Tube) arch bridge tube

ActiveCN108395174AImprove workabilityLow viscosityArch-type bridgeBridge materialsMechanical propertyMix proportion

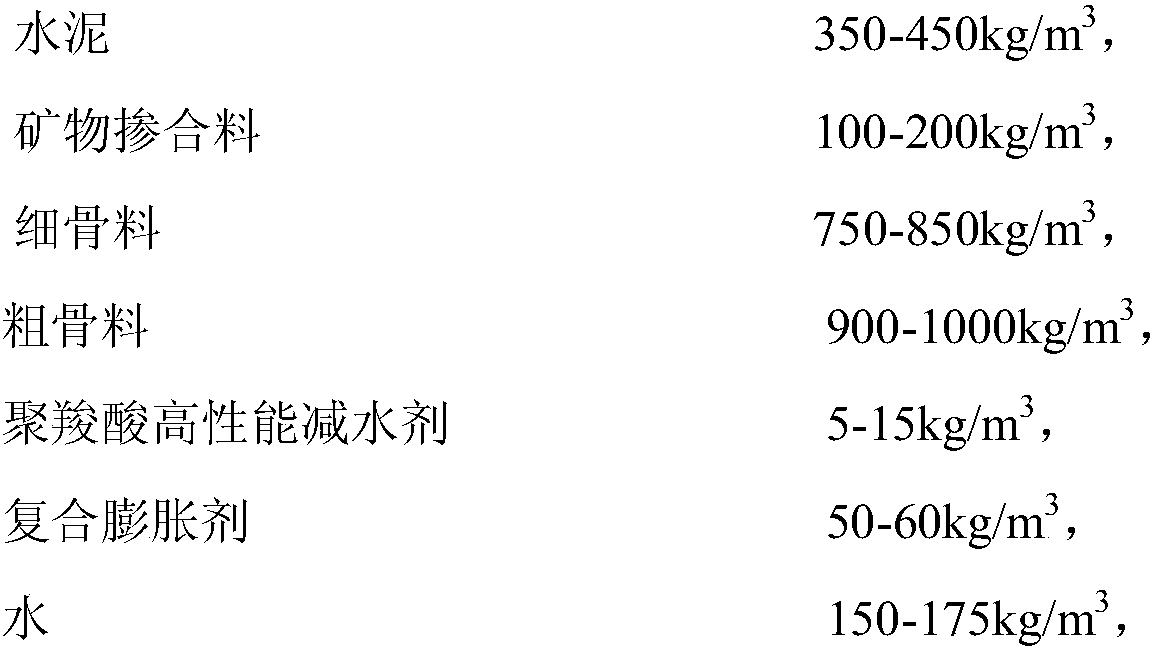

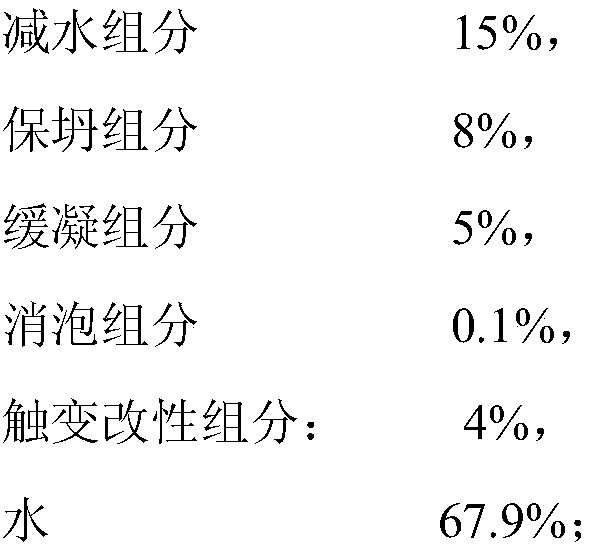

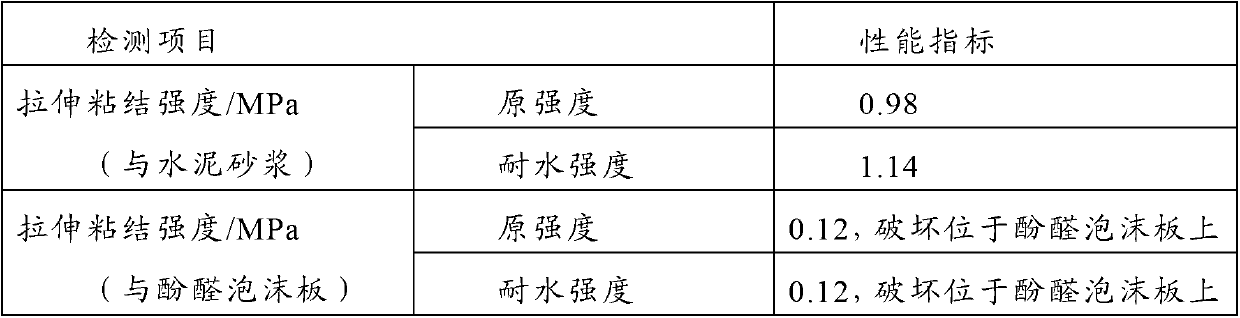

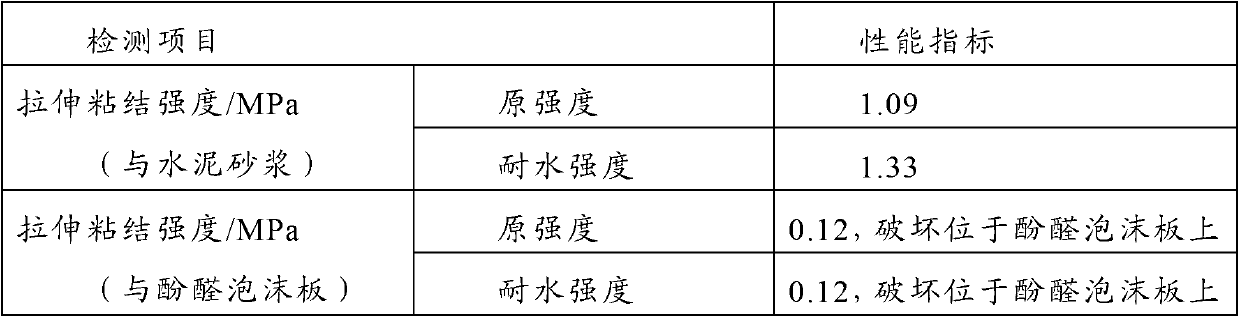

The invention discloses self-compacting non-contract concrete used in a large-span CFST (Concrete Filled Steel Tube) arch bridge tube. The self-compacting non-contract concrete used in the large-spanCFST arch bridge tube disclosed by the invention is prepared from the following components by weight: 350 to 450 kg / m<3> of cement, 100 to 200 kg / m<3> of mineral admixture, 750 to 850 kg / m<3> of fineaggregate, 900 to 1,000 kg / m<3> of coarse aggregate, 5 to 15 kg / m<3> of high-performance polycarboxylate water-reducing agent, 50 to 60 kg / m<3> of compound expanding agent, and 150 to 175 kg / m<3> of water. According to the self-compacting non-contract concrete used in the large-span CFST arch bridge tube, mechanical properties of the concrete are ensured through an optimal design of the mixing proportion of the concrete; the high-performance water-reducing agent which is compounded with the components with the functions of reducing water, retaining slump, delaying coagulation, defoaming, thixotropic modifying and the like is doped, so that the flowability of fresh concrete is improved; dense filling of the admixture in a steel tube is guaranteed; meanwhile, the thixotropy of the fresh concrete is enhanced, and a disengaging phenomenon at the upper part of the steel tube of a horizontal section of an arch crown is remarkably improved; the compound expanding agent is doped, so that the contraction deformation of the steel tube concrete is compensated in stages in the whole process; therefore, the concrete is closely adhered to the wall of the steel tube; the concrete and the steel tube are stressed cooperatively; a hoop effect is enhanced; the structural bearing capacity is guaranteed.

Owner:CHINA RAILWAYS CORPORATION +4

Castable cordierite-mullite refractory material and production technique thereof

The invention relates to a castable cordierite-mullite refractory material which is prepared from 20-40% of 1.2-0.5mm molochite, 10-25% of 0.5-0.088mm molochite, 0-15% of 0.5-0.088mm synthetic cordierite, 10-35% of <0.088mm synthetic cordierite, 0-20% of <0.088mm synthetic mullite, 1-3% of magnesia micropowder, 2-8% of alumina micropowder, 3-10% of silica fume, 0-15% of calcined kaolin micropowder, 0.01-0.1% of additional third-generation water reducing agent and 4-8% of additional water. The production technique comprises the following steps: proportionally weighing the raw materials, mixing, and forming to obtain a green body; and standing for 12-24 hours to demold, curing at normal temperature for 1-3 days, drying at 40-60 DEG C for 1-2 days, and firing at 1150-1350 DEG C. The invention uses <10 mu m magnesia micropowder instead of common magnesia fine powder, adopts high-purity raw materials to improve the high-temperature properties, adopts abundant synthetic raw materials to reduce the firing shrinkage, and adds proper micropowder to widen the sintering temperature range, thereby solving the contradictions between low magnesia amount and high setting rate, between special shapes and dimensions and low manufacturing cost and between the difficulty in sintering and high performance. The invention develops a novel easy-forming easy-sintering technique, and prepares a refractory material product which has the advantages of special shapes and dimensions, high purity, high strength, high temperature resistance and good thermal shock resistance.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Low-temperature-resistant early-strength dry powder adhesive and bonding slurry

The invention provides a low-temperature-resistant early-strength dry powder adhesive comprising the components of, by weight, 30-40 parts of SAC cement, 50-65 parts of sand, 2-15 parts of heavy calcium, 0.5-3 parts of re-dispersible latex powder, 0.1-0.3 parts of a water retention thickening agent, and 0.1-0.3 parts of a water repellent. The invention also provides a bonding slurry obtained by mixing the dry powder adhesive and water, wherein a mass ratio of the dry powder adhesive to water is 100:(20-25). Under a low-temperature construction environment with a temperature of 0-5 DEG C, the dry powder adhesive has the advantages of fast strength increasing and high early strength. The dry powder adhesive is suitable for various exterior wall insulation systems, and provides excellent bonding force for base wall surfaces of cement concrete and the other, and insulation materials such as polystyrene, plastic extruded sheet, polyurethane, phenolic foam, and the like.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

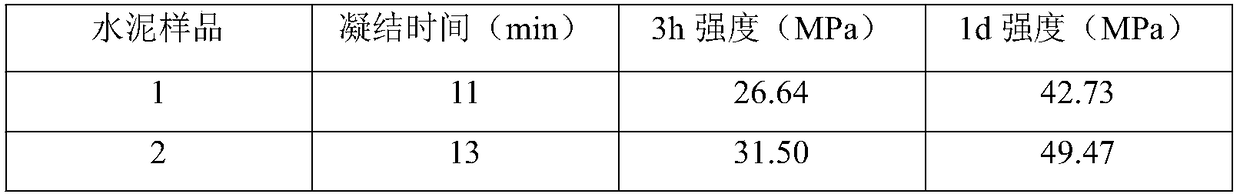

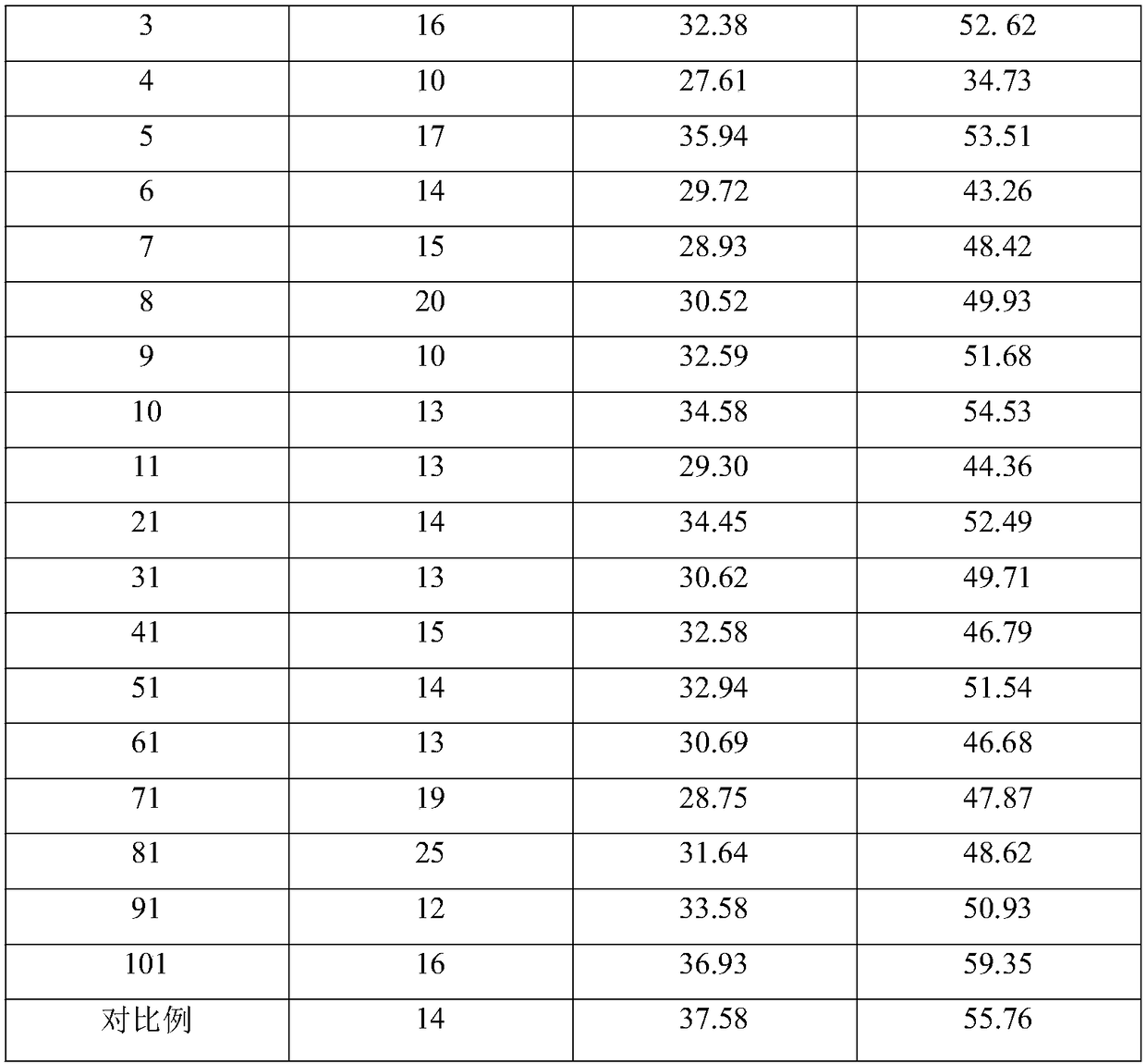

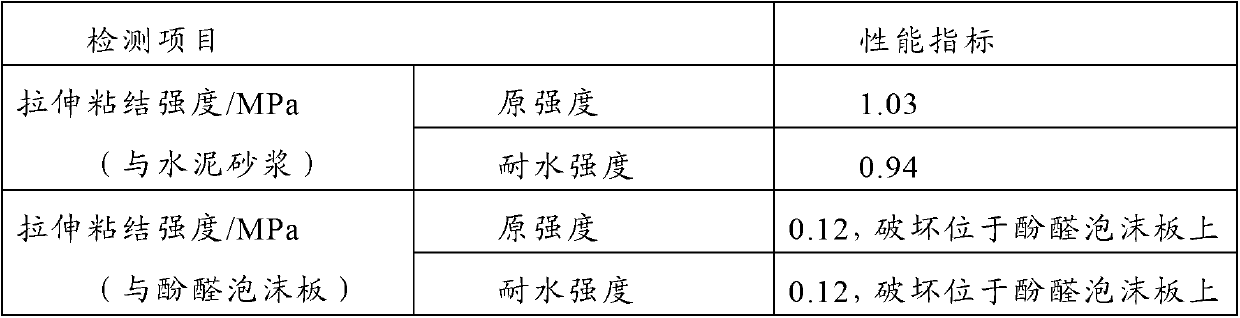

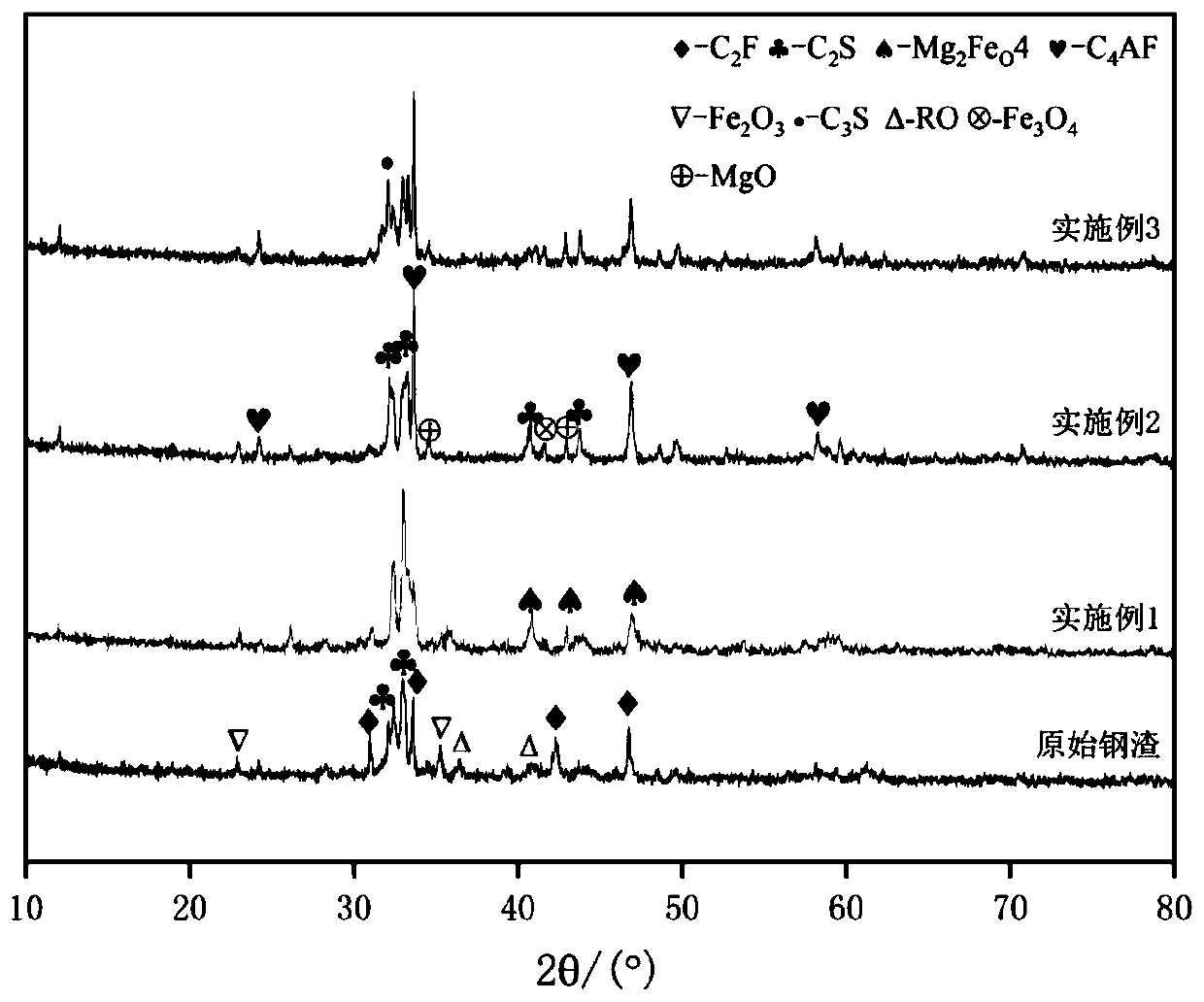

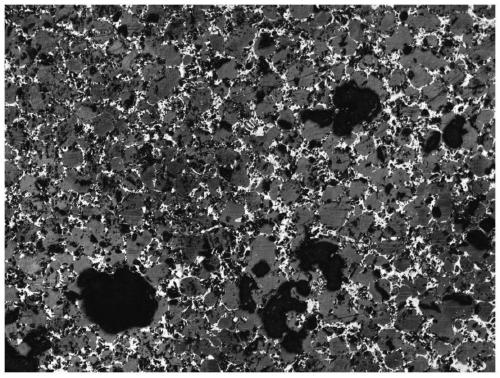

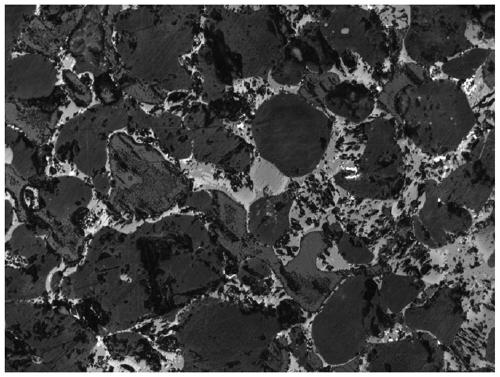

Method for preparing high-gelling-activity steel slag through high-temperature reconstruction of calcium-aluminum components and application thereof

InactiveCN111320400AMaximize value utilizationMeet environmental protection requirementsCement productionSlagAluminate

The invention discloses steel slag reconstructed at a high temperature by utilizing calcium-aluminum components as well as a preparation method and an application thereof. The preparation method comprises the following steps: drying 74%-83% of steel slag, 11%-24% of a calcium hardening and tempering material (lime) and 2%-6% of an aluminum hardening and tempering material (bauxite), crushing, grinding, mixing, preparing a sample, calcining to obtain a calcined material, and grinding the calcined material to obtain the high-gelling-property steel slag clinker. The steel slag mineral compositionis reconstructed through calcium-aluminum components, so that low-activity minerals such as steel slag Fe2O3 and RO are converted into a high-gelling-activity mineral phase with dicalcium silicate (C2S) and aluminoferrite (C4AF) as main components. The change of the mineral phase enables the hydration activity of the steel slag to be improved, and research results show that the 28-day compressivestrength of the calcium-aluminum component reconstructed steel slag obtained by using the preparation method provided by the invention reaches 42.9 MPa, and the activity index reaches 91.3%. The obtained high-activity steel slag can be directly used as a cement admixture or a high-performance concrete admixture as a finished product, the comprehensive utilization rate of the steel slag is increased, and the method has practical significance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com