Functional aggregate and preparation method thereof

A technology with a set of functions and functions, applied in the field of concrete materials, can solve the problems of reducing the combination of aggregates and cement stones, and achieve the effects of adjusting and controlling the formation of cement stones, reducing self-shrinkage, and promoting hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

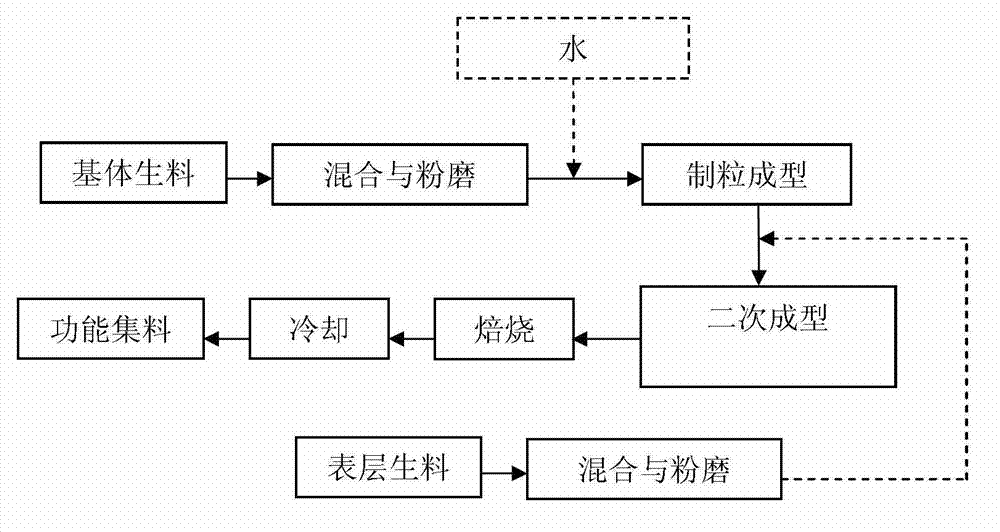

[0032] (1) Ingredients: According to Table 2, Table 3 and Table 5, the corresponding ingredients are carried out, and the chemical composition and loss on ignition LOI of the matrix raw meal thus prepared are shown in Table 4. Wherein the chemical composition content and loss on ignition LOI of each raw material in this embodiment are shown in Table 1.

[0033] (2) Grinding: Put the prepared matrix raw material into a ball mill for grinding for 4 hours, control the particle size of the raw material at 325 mesh, add 22% water of the matrix raw material, mix well, seal with a plastic film, and stale for 3 hours; The raw material of the permanent surface activation layer, that is, Portland cement clinker, was ground by a ball mill for 4 hours, and the particle size was controlled at 325 mesh, and it was set aside.

[0034] (3) Molding: the stale matrix is manually molded (extrusion molding is also possible) to make a small ball with a diameter of 10 mm. Then the powder of the ...

Embodiment 2

[0045] (1) Ingredients: According to Table 2, Table 3 and Table 5, the corresponding ingredients are carried out, and the chemical composition and loss on ignition LOI of the matrix raw meal thus prepared are shown in Table 4.

[0046] (2) Grinding: Put the prepared matrix raw material into a ball mill for grinding for 4 hours, control the particle size of the raw material at 325 mesh, add 30% water of the matrix raw material, mix well, seal with a plastic film, and stale for 2 hours; The raw materials of the surface active layer were pulverized by a ball mill for 4 hours, and the particle size was controlled at 325 meshes, and they were set aside.

[0047] (3) Molding: the stale substrate is manually molded (extrusion molding is also possible) to make a ball with a diameter of 15mm. Then the alkaline surface active layer powder is wrapped as evenly as possible on the surface of the matrix pellet (rotary molding method can be used), and the secondary molding is carried out. Th...

Embodiment 3

[0054] (1) Ingredients: According to Table 2, Table 3 and Table 5, the corresponding ingredients are carried out, and the chemical composition and loss on ignition LOI of the matrix raw meal thus prepared are shown in Table 4.

[0055] (2) Grinding: Put the prepared matrix raw material into a ball mill for grinding for 4 hours, control the particle size of the raw material at 325 mesh, add water and mix evenly, seal it with a plastic film, and put it stale; grind the raw material of the alkaline surface active layer with a ball mill 4 hours, control the particle size at 325 mesh, and set aside.

[0056] (3) Molding: the stale matrix is manually molded (extrusion molding is also possible) to make small balls. Then wrap the alkaline surface active layer powder on the surface of the matrix pellet as evenly as possible (rotational molding can be used), and perform secondary molding. The overmolded samples were dried to constant weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com