Patents

Literature

64results about How to "Play the role of "internal maintenance"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh strength high-performance fiber concrete at C160 strength grade and preparation method thereof

ActiveCN107382205APrevent pulling outImprove energy consumptionSolid waste managementModified carbonCarbon nanotube

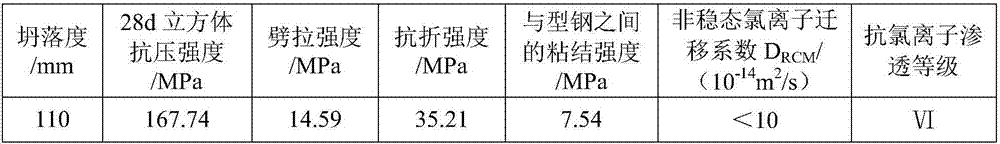

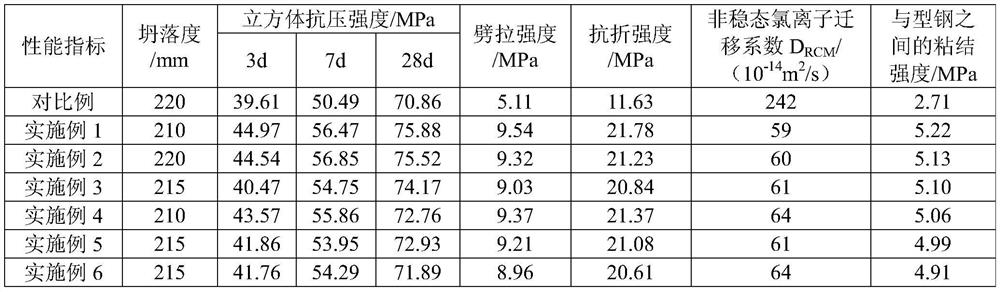

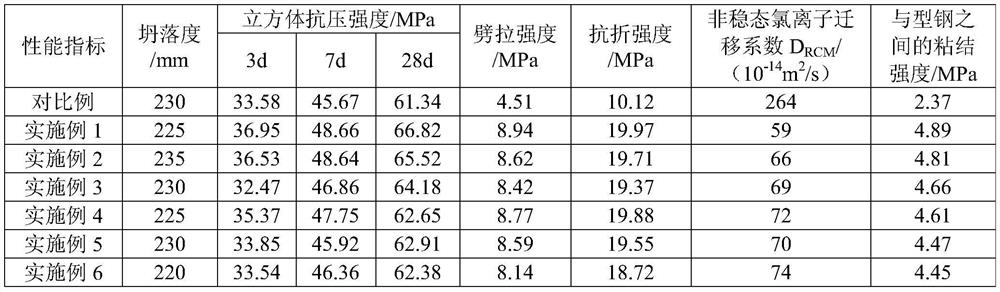

The invention discloses an ultrahigh strength high-performance fiber concrete at C160 strength grade and a preparation method thereof. The concrete comprises the following components in parts by weight: 485 parts of cement, 82 parts of water, 1000 parts of macadam, 750 parts of fine aggregate, 70 parts of coal ash, 73 parts of rice hull ash, 102 parts of silica fume, 14.0 parts of water reducer, 9.5 parts of excitant, 1.6 parts of cellulosic fiber, 40 parts of hydroxy modified carbon nano tube dispersion liquid, 37 parts of graphene oxide dispersion liquid and 2.6 parts of de-foaming agent. The prepared concrete has higher toughness, durability, higher bonding strength with profile steel, compressive strength reaching up to 167.74MPa, breaking strength reaching up to 35.21MPa, splitting strength reaching up to 14.59MPa, bonding strength with profile steel reaching up to 7.54MPa and chloride penetration resistance grade at VI-grade. When the ultrahigh strength high-performance fiber concrete is applied to a profile steel concrete combined structure, the cooperative working property between the profile steel and the concrete is effectively exerted and the defects of poor bonding property of the profile steel and the concrete and incapability of fully utilizing the respective mechanical properties of the profile steel and the concrete can be overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

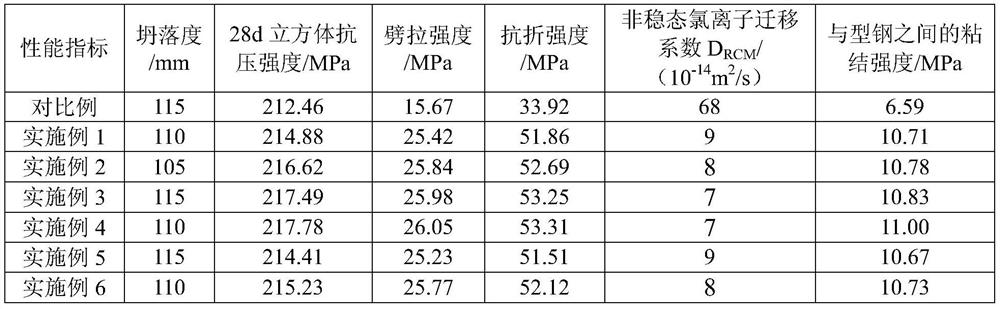

Coarse-aggregate-containing C240-strength-grade ultrahigh-performance fiber concrete and preparation method

ActiveCN107285708AImprove toughnessImprove deformation abilitySolid waste managementModified carbonCellulose fiber

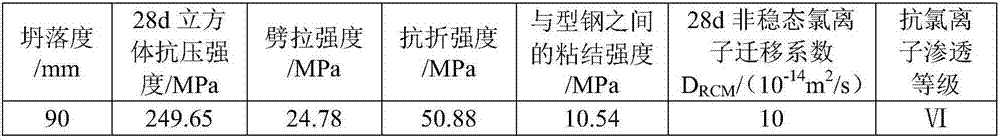

The invention discloses coarse-aggregate-containing C240-strength-grade ultrahigh-performance fiber concrete and a preparation method. The concrete is composed of, by mass, 578 parts of cement, 62 parts of water, 880 parts of rubble, 800 parts of fine aggregate, 70 parts of coal ash, 60 parts of rice husk ash, 154 parts of silicon ash, 16.5 parts of water reducer, 11.5 parts of excitant, 1.7 parts of cellulosic fiber, 90 parts of steel fiber, 51 parts of hydroxyl modified carbon nanotube dispersion, 54 parts of oxidized graphene dispersion and 2.9 parts of defoamer. The concrete prepared by the method has high toughness and durability and has high binding strength with section steel, compressive strength reaches 249.65MPa, bending strength reaches 50.88MPa, splitting tensile strength reaches 24.78MPa, the binding strength with the section steel reaches 10.54MPa, and chlorion anti-permeation grade reaches VI grade. When the concrete is used in a section steel and concrete combined structure, cooperative working performance between the section steel and the concrete can be brought into play effectively, and the defects that the section steel and the concrete are poor in binding performance and respective mechanical performance of the section steel and the concrete cannot be brought into full play are made up.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

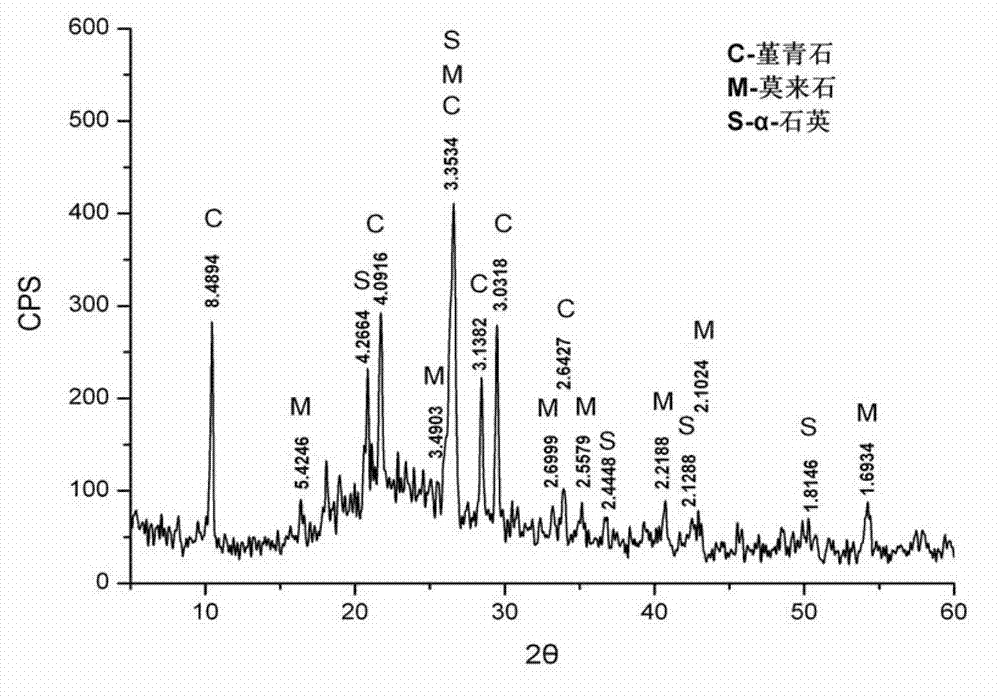

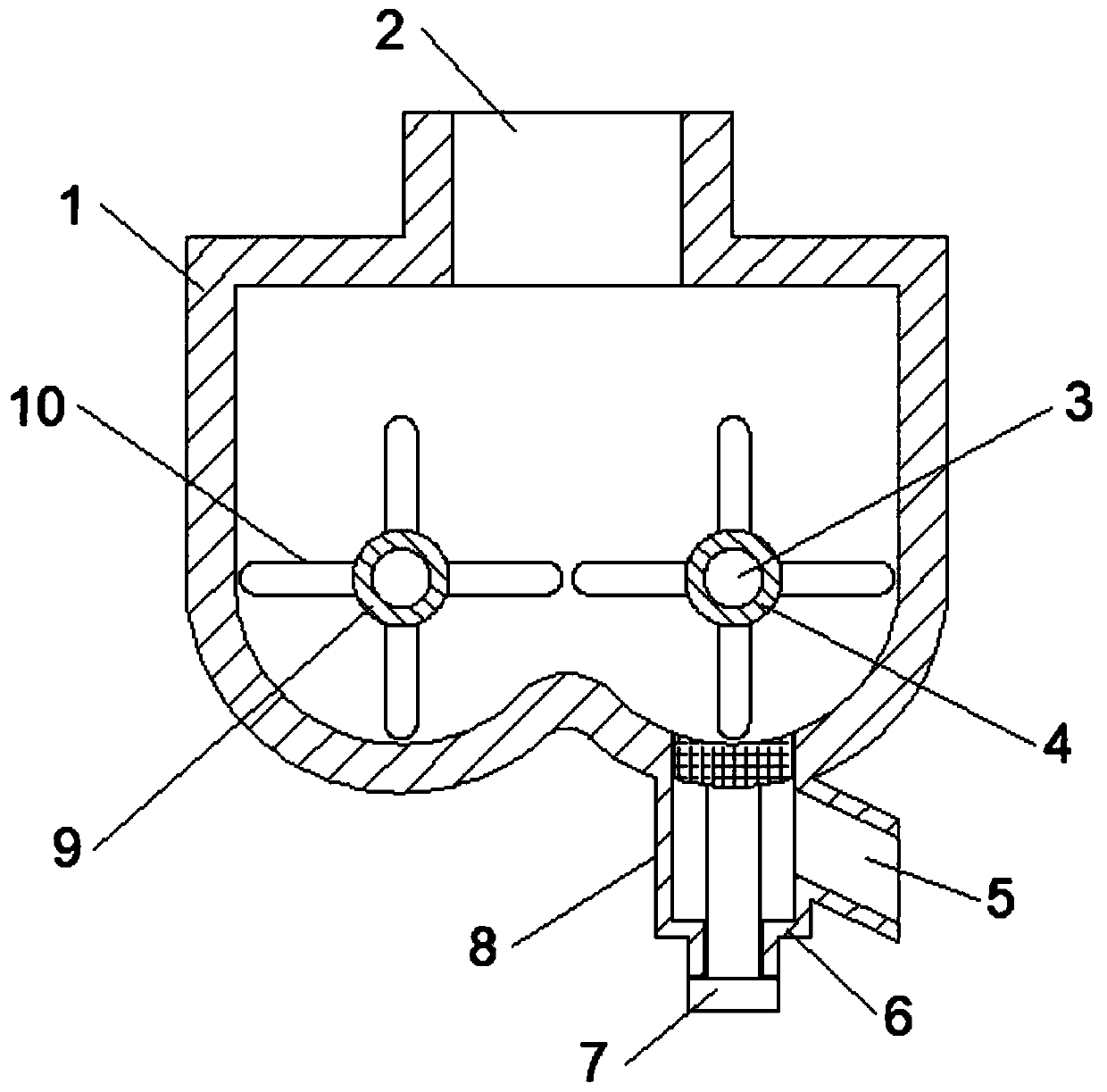

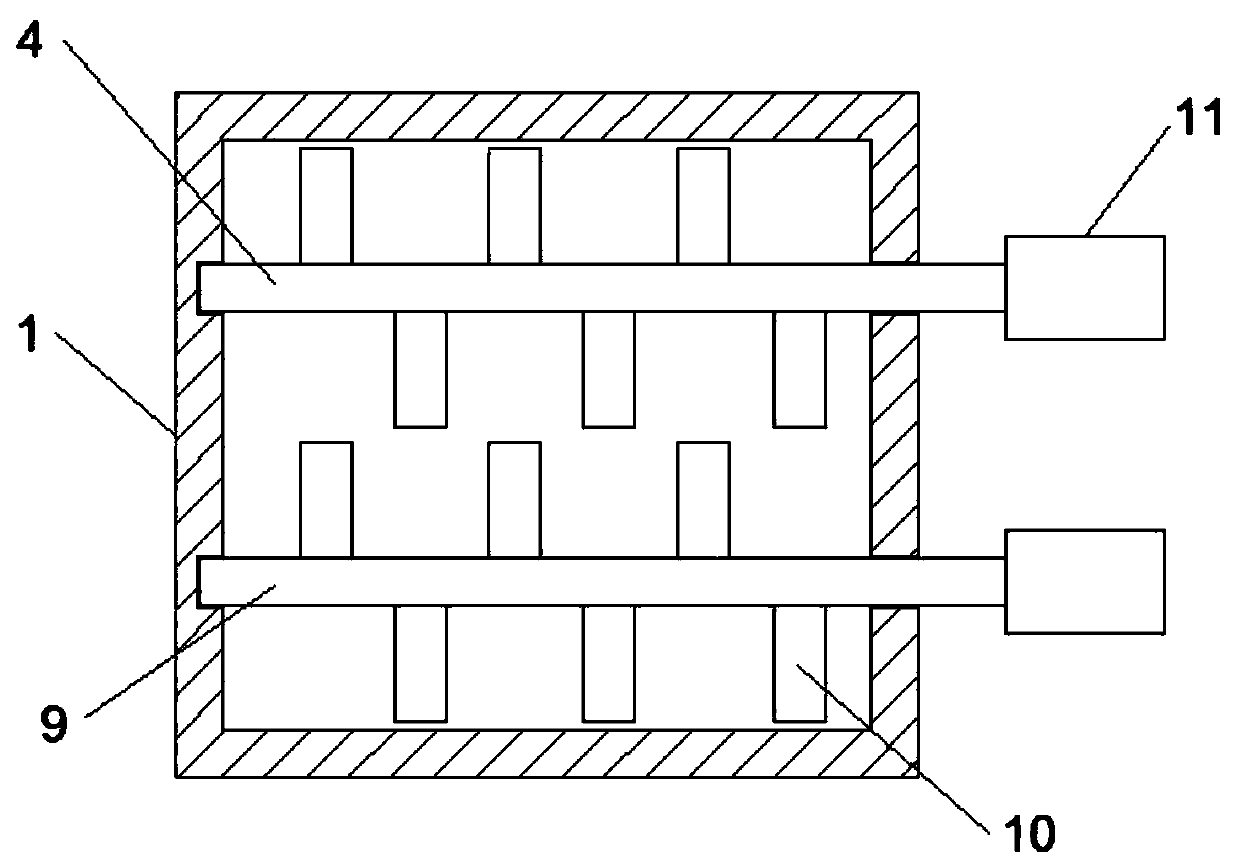

Functional aggregate and preparation method thereof

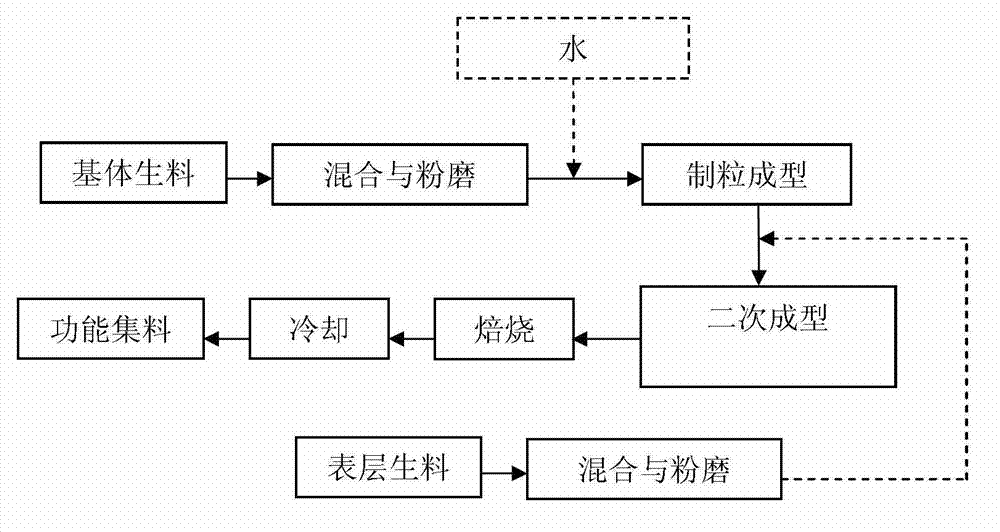

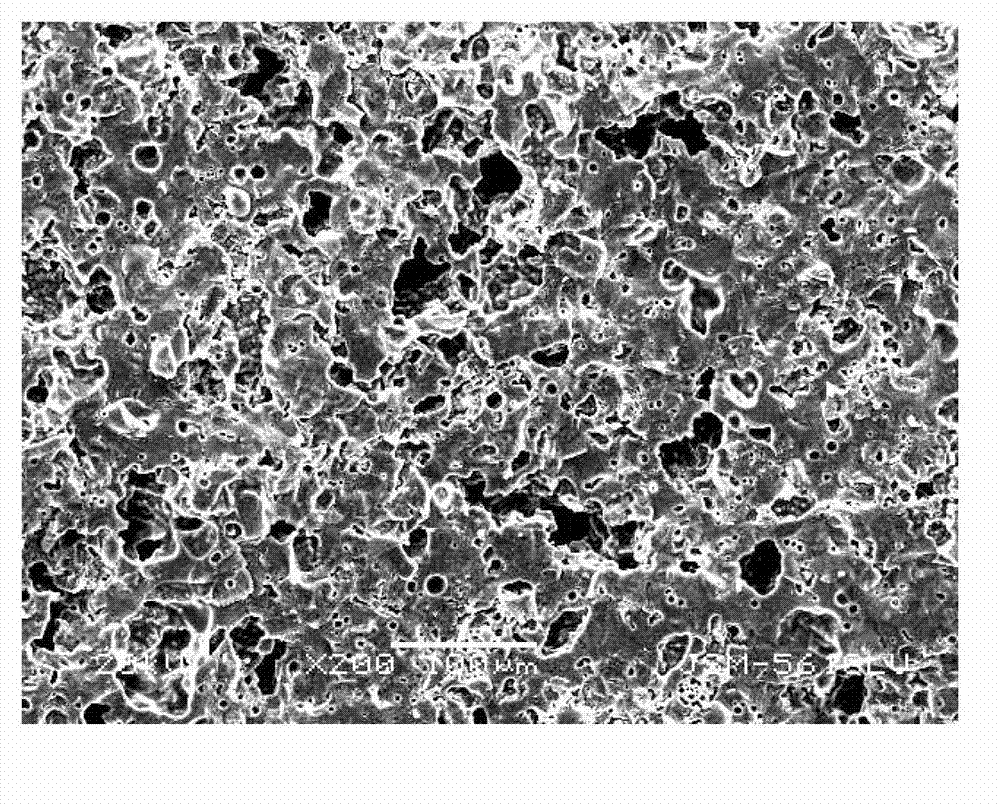

The invention belongs to the field of concrete materials, and specifically relates to a functional aggregate and a preparation method thereof. The functional aggregate is characterized in that: the functional aggregate has a core-shell structure, and is composed of a porous core substrate and an alkaline surface active shell. Mullite is a main mineral phase of the porous core substrate, and a continuous phase is formed. Pores are distributed in the continuous phase. The pore sizes of the pores are distributed in a multilevel form. The pores are mainly micron-leveled pores. The mineral phase of the alkaline surface active shell is mainly composed of dicalcium silicate, tricalcium silicate, tricalcium aluminate, and tetracalcium iron aluminate. The functional aggregate provided by the invention has light weight and high strength. The functional aggregate can be internally cured, and has a surface active layer. When the functional aggregate is used in concrete, an interfacial transition zone (ITZ) can be completely enhanced and improved, cement stone structure formation can be regulated, and concrete overall performance can be improved. The preparation process is simple and controllable, and is easy to operate.

Owner:WUHAN UNIV OF TECH

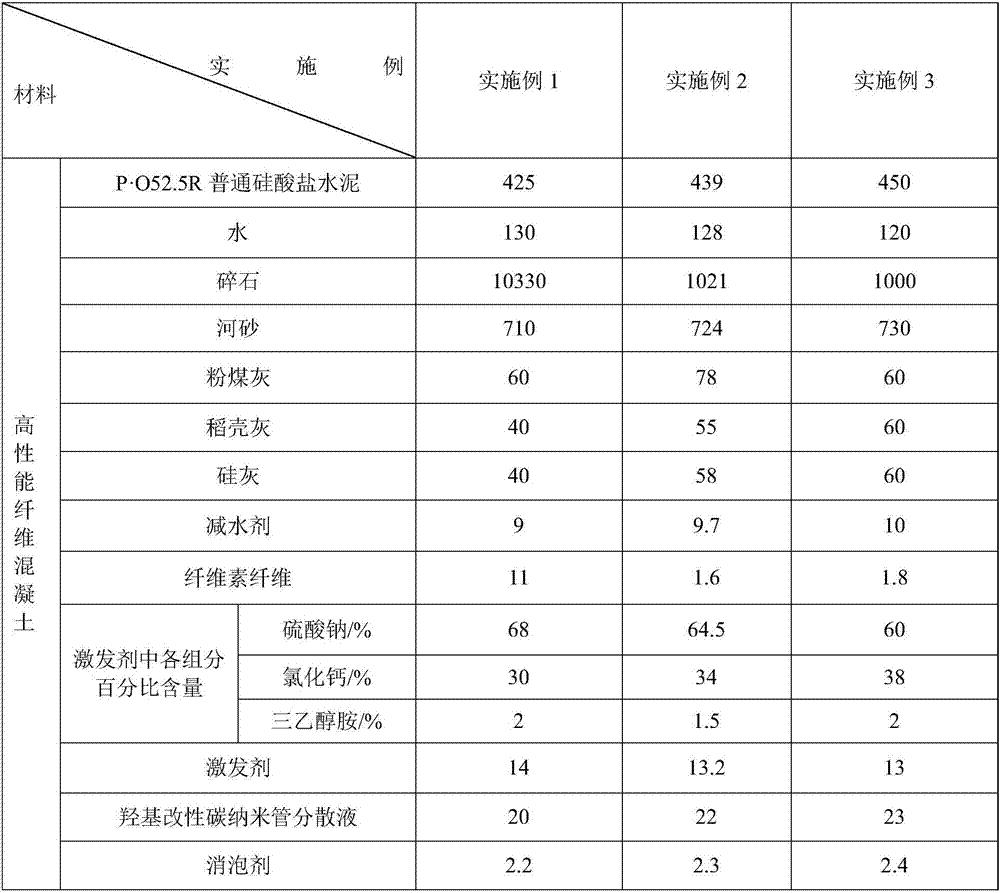

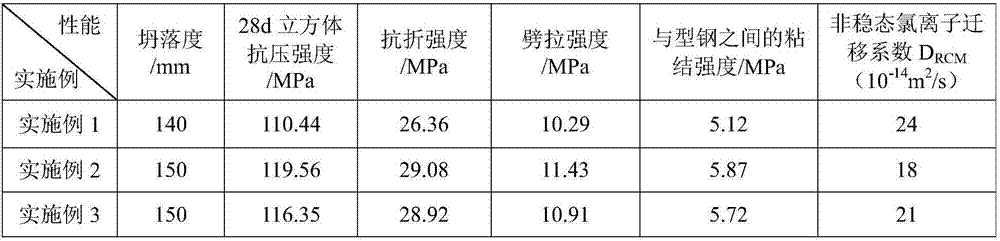

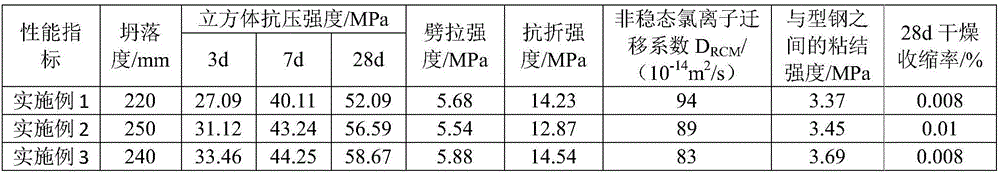

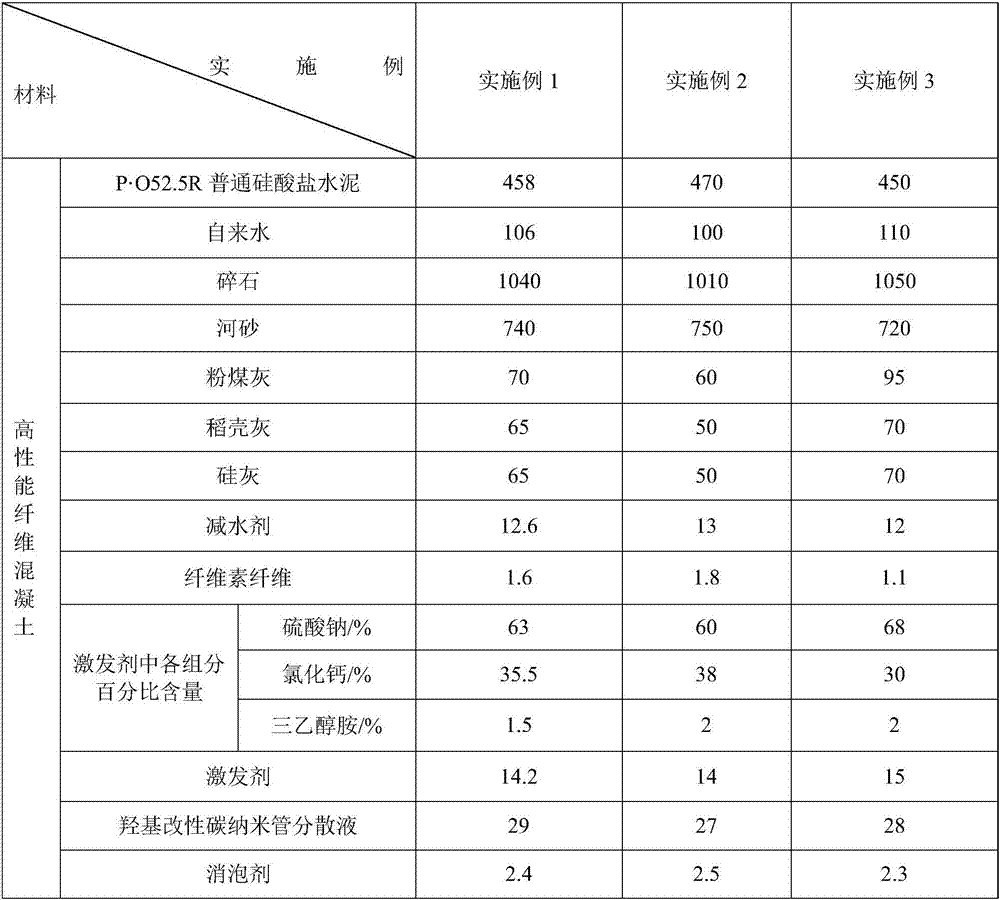

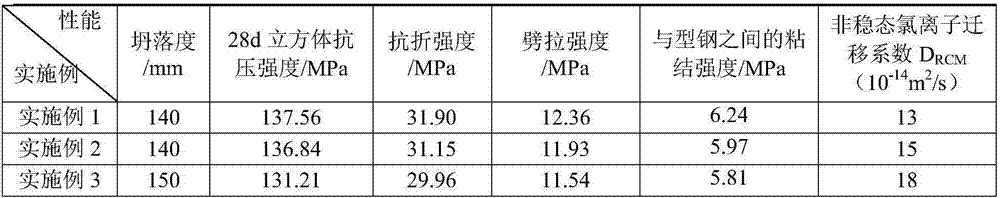

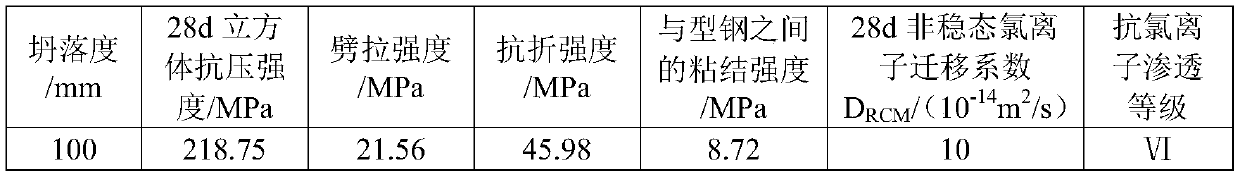

High-performance fiber concrete with C110 strength grade and preparation method thereof

The invention discloses high-performance fiber concrete with a C110 strength grade and a preparation method thereof. The concrete is prepared from the following components in parts by mass: 425 to 450 parts of cement, 120 to 130 parts of water, 710 to 730 parts of river sand, 1000 to 1030 parts of crushed stones, 60 to 90 parts of fly ash, 40 to 60 parts of rich husk ash, 40 to 60 parts of silicon ash, 9 to 10 parts of a water reducing agent, 13 to 14 parts of an exciting agent, 1.1 to 1.8 parts of cellulose fibers, 20 to 23 parts of a hydroxyl-modified carbon nanotube dispersion solution and 2.2 to 2.4 parts of a de-foaming agent. The concrete prepared by the preparation method has relatively high toughness and excellent durability and has relatively high bonding strength with section steel. The high-performance fiber concrete is used in a section steel concrete composite structure and can effectively express cooperative work performance between the section steel and the concrete; the disadvantages that the bonding performance of the section steel and the concrete is poor and respective mechanical properties of the section steel and the concrete cannot be sufficiently expressed are overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

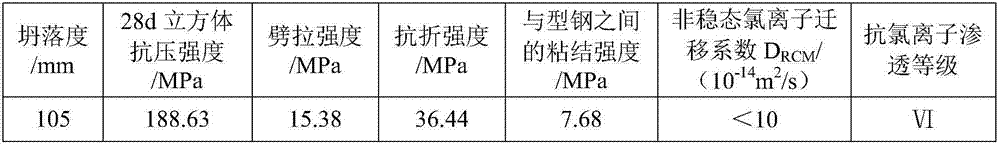

Ultrahigh-strength and high-performance fiber concrete with C180 strength grade and preparation method thereof

ActiveCN107352913AImprove volume stabilityInhibit plastic shrinkageSolid waste managementIonFlexural strength

The invention discloses ultrahigh-strength and high-performance fiber concrete with a C180 strength grade and a preparation method thereof. The concrete is prepared from the following components in parts by mass: 505 parts of cement, 70 parts of water, 1000 parts of crushed stones, 770 parts of fine aggregate, 70 parts of fly ash, 78 parts of rich husk ash, 118 parts of silicon ash, 15 parts of a water reducing agent, 10 parts of an exciting agent, 1.7 parts of cellulose fibers, 43 parts of a hydroxyl-modified carbon nanotube dispersion solution, 45 parts of a graphene oxide dispersion solution and 2.7 parts of a de-foaming agent. The concrete prepared by the preparation method has relatively high toughness and excellent durability and has relatively high bonding strength with section steel; the compression strength reaches 188.63MPa, the flexural strength reaches 36.44MPa, the splitting tensile strength reaches 15.38MPa, the bonding strength with the section steel reaches 7.68MPa and a chloride ion anti-leakage grade reaches a grade VI. The ultrahigh-strength and high-performance fiber concrete is used in a section steel concrete composite structure and can effectively express cooperative work performance between the section steel and the concrete; the disadvantages that the bonding performance of the section steel and the concrete is poor and respective mechanical properties of the section steel and the concrete cannot be sufficiently expressed are overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Ultrahigh-strength and high-performance fiber concrete with C170 strength grade and preparation method thereof

ActiveCN107352912AOvercoming brittlenessOvercome crackingSolid waste managementModified carbonFlexural strength

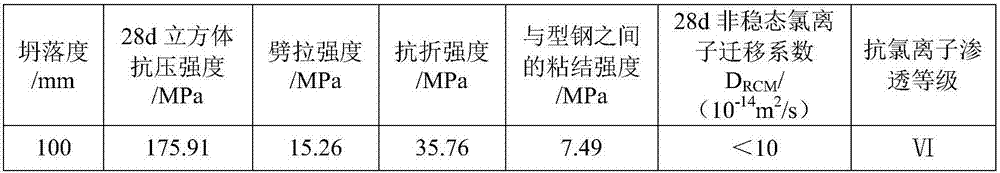

The invention discloses ultrahigh-strength and high-performance fiber concrete with a C170 strength grade and a preparation method thereof. The concrete is prepared from the following components in parts by mass: 497 parts of cement, 74 parts of water, 1000 parts of crushed stones, 760 parts of fine aggregate, 80 parts of fly ash, 75 parts of rich husk ash, 111 parts of silicon ash, 14.4 parts of a water reducing agent, 10 parts of an exciting agent, 1.6 parts of cellulose fibers, 41 parts of a hydroxyl-modified carbon nanotube dispersion solution, 42 parts of a graphene oxide dispersion solution and 2.6 parts of a de-foaming agent. The concrete prepared by the preparation method has relatively high toughness and excellent durability and has relatively high bonding strength with section steel; the compression strength reaches 175.91MPa, the flexural strength reaches 35.76MPa, the splitting tensile strength reaches 15.26MPa, the bonding strength with the section steel reaches 7.49MPa and a chloride ion anti-leakage grade reaches a grade VI. The ultrahigh-strength and high-performance fiber concrete is used in a section steel concrete composite structure and can effectively express cooperative work performance between the section steel and the concrete; the disadvantages that the bonding performance of the section steel and the concrete is poor and respective mechanical properties of the section steel and the concrete cannot be sufficiently expressed are overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C250 ultrahigh-strength hybrid fiber concrete and preparation method thereof

ActiveCN113024189AHigh tensile strengthHigh elastic modulusSolid waste managementPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C250 ultrahigh-strength hybrid fiber concrete and a preparation method thereof. The ultrahigh-strength hybrid fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, CaCO3 whiskers, a carboxyl modified polyvinyl alcohol polymer and nano titanium / graphene oxide dispersion liquid according to the mixing ratio of (550-560): (760-770): (830-840): (65-70): (103- 108): (125-135): (5.4-5.6): (70-75): (20-21): (16-17): (3-3.3): (14.5-15): (7.5-8): (13.3-13.6): (21-21.5): (22-23.5): (42-46). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The mechanical property and durability of the concrete and the bonding property between the concrete and the profile steel are obviously improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

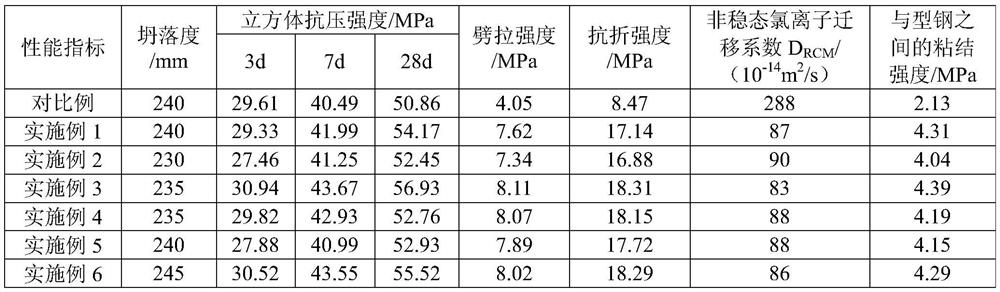

High-performance fiber concrete at C60 strength grade and preparation method thereof

ActiveCN107445548APrevent pulling outImprove energy consumptionSolid waste managementFiberUltimate tensile strength

The invention discloses high-performance fiber concrete at a C60 strength grade and a preparation method thereof. The concrete comprises the following components in parts by mass: 360-380 parts of cement, 145-160 parts of water, 700-720 parts of river sand, 1020-1040 parts of gravel, 80-125 parts of fly ash, 40-60 parts of rice hull ash, 6-7.5 parts of a water reducing agent, 9-10 parts of a shrinkage reducing agent, 12.5-14 parts of an excitant, 1.1-1.8 parts of cellulosic fibers, 16-20 parts of a carboxyl butadiene styrene polymer an 1.7-1.8 parts of an antifoaming agent. The prepared concrete has high toughness and excellent durability, has high bonding strength with section steel, can effectively achieve the cooperative working performance between the section steel and the concrete when applied to a section steel and concrete combined structure, and overcomes the defects that the adhesive property between the section steel and the concrete is poor and respective mechanical properties of the two cannot be fully achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-damping concrete and preparation method thereof

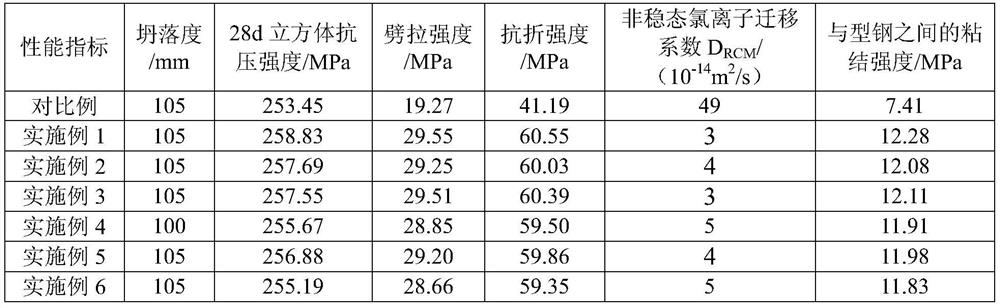

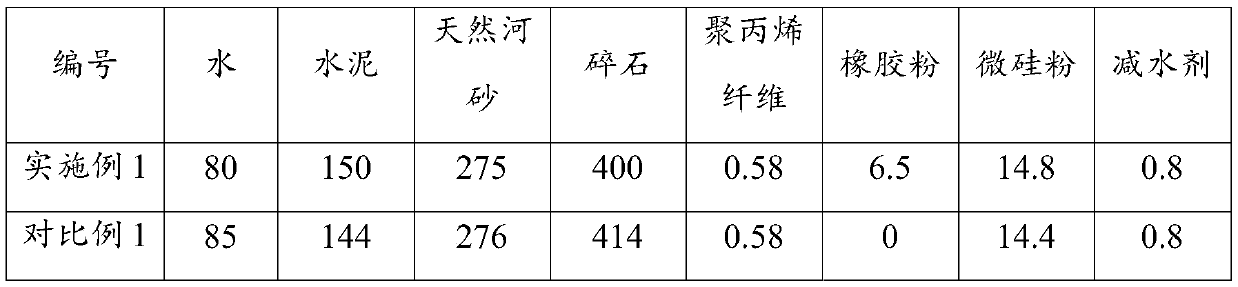

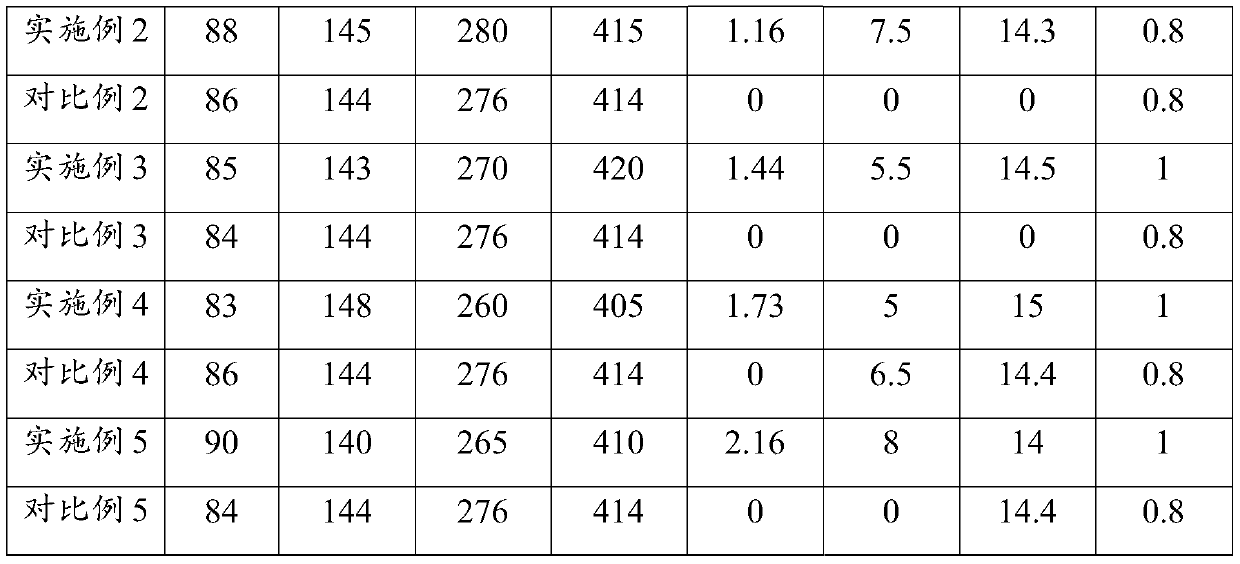

The invention relates to high-damping concrete. The high-damping concrete comprises the following components in parts by mass: 140-150 parts of cement, 260-280 parts of natural river sand, 5-8 parts of rubber powder, 12-15 parts of silica fume, 400-420 parts of gravels, 0.58-2.16 parts of polypropylene fibers, 0.8-1 parts of a water reducing agent and 80-90 parts of water, wherein the granularityof the gravels is less than 40mm; the high-damping concrete is formed by fully mixing and curing the components. The invention further provides a technical scheme of the preparation method of the high-damping concrete. According to the invention, the polypropylene fiber with toughening and internal curing effects, the rubber powder with viscoelasticity, the silica fume with physical filling effectand the like are added, and the components cooperate with one another to improve the performance of the concrete, so that the concrete has high damping ratio.

Owner:YANGTZE UNIVERSITY

High-performance fiber concrete with a C50 strength grade and preparation method of high-performance fiber concrete

ActiveCN107434384APrevent pulling outImprove energy consumptionSolid waste managementCellulose fiberMechanical property

The invention discloses high-performance fiber concrete with a C50 strength grade and a preparation method of the high-performance fiber concrete. The concrete comprises the following components in parts by mass: 330-350 parts of cement, 160-175 parts of water, 710-730 parts of river sand, 1010-1030 parts of gravels, 90-130 parts of coal ash, 20-50 parts of rice hull ash, 5-7 parts of water reducing agent, 8-9 parts of shrinkage reducing agent, 12-14 parts of exciting agent, 1.1-1.7 parts of cellulose fiber, 12-15 parts of carboxyl styrene butadiene polymers and 1.7-1.8 parts of defoaming agent. The prepared concrete has relatively high toughness and excellent durability and has relatively high bonding strength with profile steel; and when the high-performance fiber concrete is used in a profile steel and concrete combined structure, the coordinated working performance between the profile steel and the concrete can be effectively exerted, and the defects that the bonding performance of the profile steel and the concrete is poor and the mechanical properties of the profile steel and the concrete cannot be sufficiently exerted are made up.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

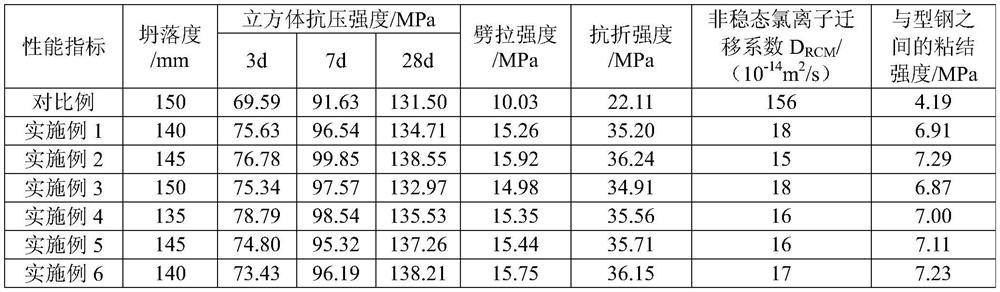

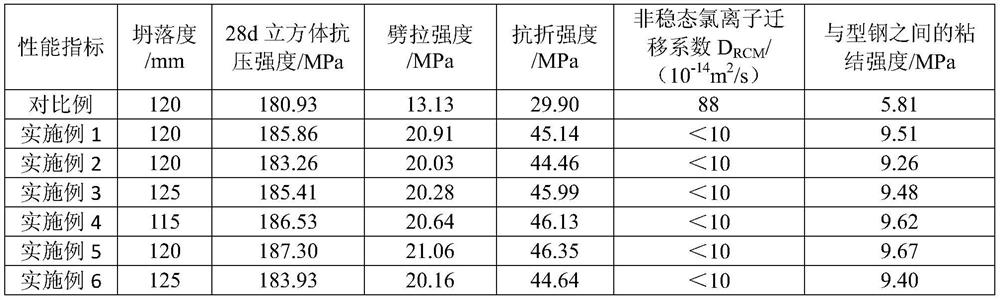

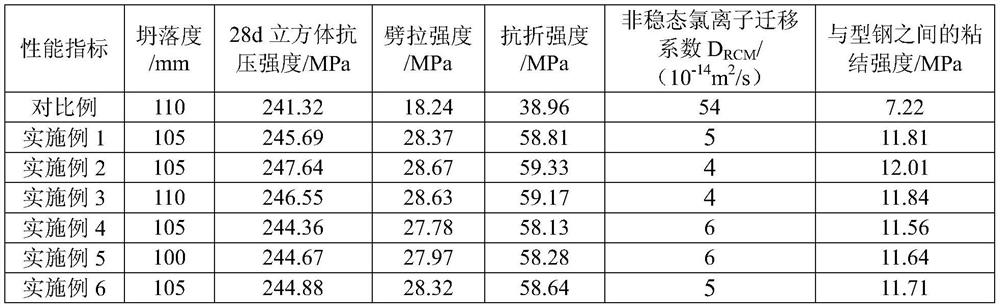

High-toughness and high-cohesiveness C130-strength high-strength fiber concrete and preparation method thereof

ActiveCN113024213AImprove adhesionImprove flexural strengthSolid waste managementCement mixing apparatusPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C130-strength high-strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, CaCO3 whiskers and a carboxyl modified polyvinyl alcohol polymer according to the mixing ratio of (425-430): 718: 985: (80-85): (60-65): (30-35): (3.5-4.2): (120- 125): (12-13): (13-14): (1.9-2.3): (10-11): (5.4-5.6): (9-9.4): (17.8- 18.1): (20-22). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The fracture resistance, the compression resistance, the bonding strength with the profile steel and the impermeability of the concrete are remarkably enhanced, and the cooperative work capacity with the profile steel is further improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

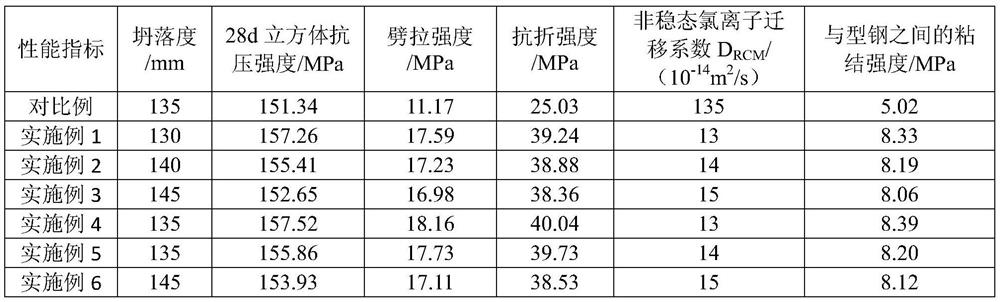

High-toughness and high-cohesiveness C150-strength ultrahigh-strength fiber concrete and preparation method thereof

PendingCN113024211AImprove adhesionImprove flexural strengthSolid waste managementCement mixing apparatusPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C150-strength ultrahigh-strength fiber concrete and a preparation method thereof. The ultrahigh-strength fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, hydroxyl modified single-walled carbon nanotube dispersion liquid and a carboxyl modified polyvinyl alcohol polymer according to the mixing ratio of (460-470): (710-720): 985: (75-85): (65-70): (40-45): (3.8-4.4): (105-110): (14-16): (12-13): (2.2-2.6): (11-12): (5.5-5.7): (9.8-10.2): (25-30): (16.5-18). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The concrete mechanics including the profile steel bonding performance and the durability are remarkably improved, and the cooperative work capacity with the profile steel is enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

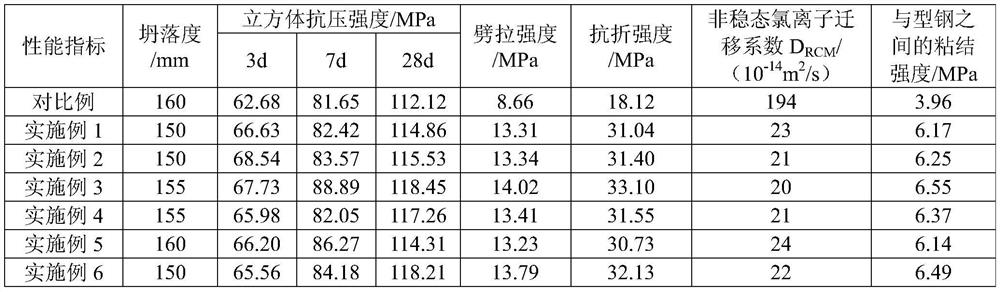

High-toughness and high-cohesiveness C80-strength fiber concrete and preparation method thereof

The invention discloses high-toughness and high-cohesiveness C80-strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, river sand, broken stone, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers and CaCO3 crystal whiskers according to the mixing ratio of (360-370): 725: 1007: (100-110): (55-65): (17-19): (2.5-4): (150-155): (8.5-9.5): (12.5-13.5): (1.8-2.1): (7.8-8.2): (4.9-5.2): (8.1-8.3): (17.4-17.6). Through a layered stirring method, all the materials are uniformly mixed at intervals, and discharging, forming and curing are performed. The compression resistance, the fracture resistance, the splitting tensile strength, the toughness, the durability and the like of the concrete can be effectively improved, and the bonding strength and the cooperative deformation capacity between the concrete and the profile steel are enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Formula and preparation method for renewable concrete

InactiveCN111574142AHigh strengthNo problem of crackingSolid waste managementCement mixing apparatusPolyesterPortland cement

The invention discloses a formula and preparation method for renewable concrete. The formula comprises the following raw materials in parts by weight: 100-150 parts of Portland cement, 15-35 parts offly ash, 100-200 parts of river sand, 4-8 parts of a water reducing agent, 5-15 parts of a shrinkage reducing agent, 200-400 parts of coarse aggregate, 100-200 parts of fine aggregate, 5-10 parts of polyester fibers, 5-15 parts of steel fibers, 5-15 parts of straw ash and 50-80 parts of water, wherein the coarse aggregate and the fine aggregate are both prepared by crushing and grinding waste concrete, the particle size of the coarse aggregate is 18-22 mm, and the particle size of the fine aggregate is 5-10 mm. According to the invention, the formula and the preparation process of the renewable concrete are adjusted, so the strength of the prepared concrete can reach C60 or above, the problem of cracking is avoided, and problems in recycling of waste concrete are well solved.

Owner:江苏鹿晶新材料科技有限公司

High-toughness high-cohesiveness C70 strength fiber concrete and preparation method thereof

PendingCN113185212AHigh tensile strengthHigh elastic modulusCeramic shaping apparatusCement mixing apparatusBasalt fiberUltimate tensile strength

The invention discloses high-toughness and high-cohesiveness C70 strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, river sand, broken stone, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fiber, basalt fiber and CaCO3 whisker according to the mixing ratios of (350 to 360): (723): (1010): (105 to 112): (45 to 55): (14 to 17): (2 to 3.5): (155 to 160): (7.5 to 8.5): (12 to 13): (1.8 to 2.1): (6.8 to 7.8): (4.7 to 4.9): (7.9 to 8.1): (17.3 to 17.5). Through a layered stirring method, all the materials are uniformly mixed at intervals, and discharging, forming and curing are performed. The compression resistance, the fracture resistance, the splitting tensile strength, the toughness, the durability and the like of the concrete can be effectively improved, and the bonding strength and the cooperative deformation capacity between the concrete and profile steel are enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-performance fibrous concrete of C130 strength level and preparation method thereof

ActiveCN107512889AInhibit plastic shrinkageStrong bonding abilitySolid waste managementSilica fumeReinforced concrete

The invention discloses high-performance fibrous concrete of a C130 strength level and a preparation method thereof. The concrete comprises the following components in parts by mass: 450-470 parts of cement, 100-110 parts of water, 720-750 parts of river sand, 1010-1050 parts of gravel, 60-95 parts of fly ash, 50-70 parts of rice hull ash, 50-70 parts of silica fume, 12-13 parts of water reducing agent, 14-15 parts of activator, 1.1-1.8 parts of cellulose fiber, 27-29 parts of hydroxyl modified carbon nanotube dispersion liquid and 2.3-2.5 parts of defoamer. The prepared concrete has high toughness and excellent durability, and has high binding strength with section steel. When the concrete is used in a steel reinforced concrete composite structure, the cooperative work performance between the section steel and the concrete can be effectively achieved, thereby compensating for defects that the binding performance between the section steel and the concrete is poor and the mechanical properties of each of the both can not be fully displayed.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Seawater coral sand ultra-high performance concrete and preparation method thereof

InactiveCN112551974AImprove water absorptionWith water absorption and water return characteristicsKaolin clayMetakaolin

The invention discloses seawater coral sand ultra-high performance concrete, and belongs to the technical field of building materials. The seawater coral sand ultra-high performance concrete comprisesthe following components in parts by weight: 900-1100 parts of coral sand, 700-900 parts of cement, 100-270 parts of silica fume, 75-120 parts of modified metakaolin, 78-312 parts of steel fibers, 200-300 parts of water, 5-20 parts of a water reducing agent, and 1-2 parts of an defoaming agent. According to the concrete, coral sand is adopted to replace quartz sand to serve as an aggregate, by means of the water absorption and water return characteristics of the coral sand, the internal curing effect can be achieved in the concrete, self-shrinkage of seawater coral sand ultra-high performanceconcrete can be improved, corrosion of chloride ions in the ocean to concrete steel can be prevented by adopting modified metakaolin, and the durability of the concrete is further improved; stainlesssteel fibers are adopted to replace common steel fibers, the compressive strength and breaking strength of the concrete are improved, and the water reducing agent and the defoaming agent are adopted,so that the concrete has good workability and compactness. The proportion is reasonable and scientific, and the prepared seawater coral sand ultra-high performance concrete has the characteristics ofgood workability, high strength, low shrinkage and high durability.

Owner:CCCC THIRD HIGHWAY ENG +1

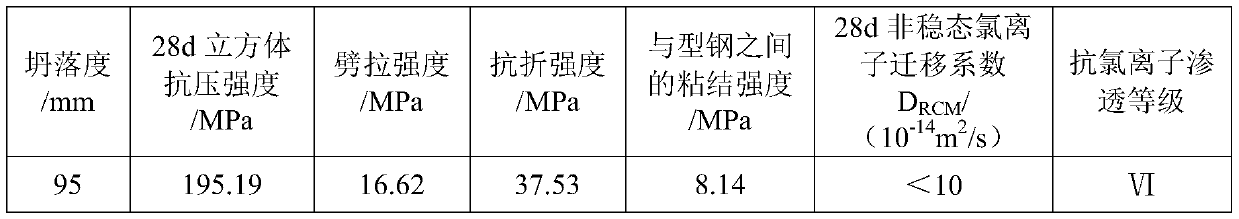

A kind of ultra-high-strength high-performance fiber concrete of c190 strength grade and preparation method thereof

ActiveCN107512890BPrevent pulling outImprove energy consumptionSolid waste managementAggregate (composite)Modified carbon

The invention discloses an ultra-high-strength high-performance fiber concrete of C190 strength grade and a preparation method thereof. The mass parts of the concrete are as follows: 514 parts of cement, 68 parts of water, 990 parts of gravel, 780 parts of fine aggregate, powder 68 parts of coal ash, 75 parts of rice husk ash, 120 parts of silica fume, 15.4 parts of water reducer, 10 parts of activator, 1.7 parts of cellulose fiber, 45 parts of hydroxyl modified carbon nanotube dispersion, 46 parts of graphene oxide dispersion part, 2.7 parts of defoamer. The prepared concrete has high toughness and excellent durability, and has a high bond strength with the steel. The compressive strength reaches 195.19MPa, the flexural strength reaches 37.53MPa, and the splitting tensile strength reaches 16.62MPa. The bonding strength between them reaches 8.14MPa, and the chloride ion impermeability level reaches level VI. Used in steel-concrete composite structures, it can effectively exert the synergistic performance between steel and concrete, make up for the poor bonding performance of steel and concrete, and the inability to give full play to their respective mechanical properties.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

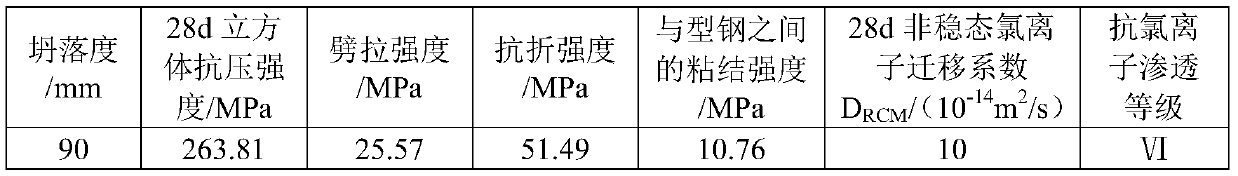

A kind of C250 strength grade ultra-high performance fiber concrete containing coarse aggregate and its preparation method

ActiveCN107285711BImprove toughnessImprove deformation abilitySolid waste managementAggregate (composite)Modified carbon

The invention discloses a C250 strength grade ultra-high performance fiber concrete containing coarse aggregate and a preparation method thereof. The mass parts of the concrete are as follows: 596 parts of cement, 60 parts of water, 870 parts of gravel, and 810 parts of fine aggregate 70 parts of fly ash, 65 parts of rice husk ash, 168 parts of silica fume, 17 parts of water reducer, 12 parts of activator, 1.6 parts of cellulose fiber, 85 parts of steel fiber, 55 parts of hydroxyl modified carbon nanotube dispersion Parts, 58 parts of graphene oxide dispersion liquid, 3.0 parts of defoamer. The prepared concrete has high toughness and durability, and has a high bond strength with the steel, with a compressive strength of 263.81MPa, a flexural strength of 51.49MPa, and a splitting tensile strength of 25.57MPa. The bonding strength reaches 10.76MPa, and the chloride ion impermeability level reaches level VI. Used in steel-concrete composite structures, it can effectively exert the synergistic performance between steel and concrete, make up for the poor bonding performance of steel and concrete, and the inability to give full play to their respective mechanical properties.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C60 strength fiber concrete and preparation method thereof

The invention discloses high-toughness and high-cohesiveness C60 strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, river sand, broken stone, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers and CaCO3 whiskers according to the mixing ratio of (340-350): 719: 1015: (108-115): (40-50): (13-16): (1.5-3): (160-165): (6.5-7.5): (11.5-12.5): (1.6-2): (5.8-6.8): (4.5-4.7): (7.8-8): (17.1-17.4). Through a layered stirring method, all the materials are uniformly mixed at intervals, and discharging, forming and curing are performed. The compression resistance, the fracture resistance, the splitting tensile strength, the toughness, the durability and the like of the concrete can be effectively improved, and the bonding strength and the cooperative deformation capacity between the concrete and the profile steel are enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

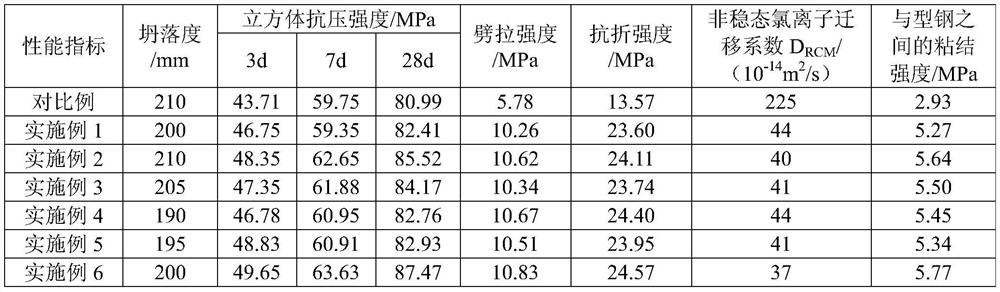

High-toughness and high-cohesiveness C210 ultrahigh-strength hybrid fiber concrete and preparation method thereof

ActiveCN113024142AImprove adhesionImprove flexural strengthSolid waste managementCement mixing apparatusPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C210 ultrahigh-strength hybrid fiber concrete and a preparation method thereof. The ultrahigh-strength hybrid fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, CaCO3 whiskers, a carboxyl modified polyvinyl alcohol polymer andnanometer titanium / graphene oxide dispersion liquid according to the mixing ratio of (525-535):(735-740):(890-900): (70-80): (85-95:(95-100):(4.7-5):(90-95):(17-18):(14.5-15):(2.5-2.9) :(12-13):(6.5-6.7):(12.2-12.5):(19-19.3):(20.5-22):(33-36). The materials are uniformly mixed by a layered stirring method, and are prepared and maintained. The mechanical property of the concrete and the bonding property and durability between the concrete and the profile steel are obviously improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C180 ultrahigh-strength fiber concrete and preparation method thereof

ActiveCN113233832AImprove adhesionImprove flexural strengthSolid waste managementPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C180 ultrahigh-strength fiber concrete and a preparation method thereof. The high-toughness and high-cohesiveness C180 ultrahigh-strength fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, hydroxyl modified single-walled carbon nanotube dispersion liquid and a carboxyl modified polyvinyl alcohol polymer according to the mixing ratio of (490-496): (710-725): 970: (68-72): (75-77): (60-67): (4.3-4.5): (92-97): (16-17): (13.5-14): (2.4-2.8): (13.5-14.5): (5.9-6.2): (10.7-11): (29.5-32): (19-21). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The mechanical property of the concrete and the bonding property and durability of the concrete and the profile steel are remarkably improved, and the cooperative working capacity of the concrete and the profile steel is enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C50-strength fiber concrete and preparation method thereof

PendingCN113024187AInhibition formationHigh strengthSolid waste managementBasalt fiberUltimate tensile strength

The invention discloses high-toughness and high-cohesiveness C50-strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, river sand, broken stone, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers and CaCO3 whiskers according to the mixing ratio of (330-340): 715: 1020: (110-125): (30-40): (10-14): (1-3): (170-180): (5.5-6.5): (11-12): (1.5-1.8): (5.5-6): (4.5-4.6): (7.8-7.9): (17-17.3). Through a layered stirring method, all the materials are uniformly mixed at intervals, and discharging, forming and curing are performed. The compression resistance, the fracture resistance, the splitting tensile strength, the toughness, the durability and the like of the concrete can be effectively improved, and the bonding strength and the cooperative deformation capacity between the concrete and the profile steel are enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

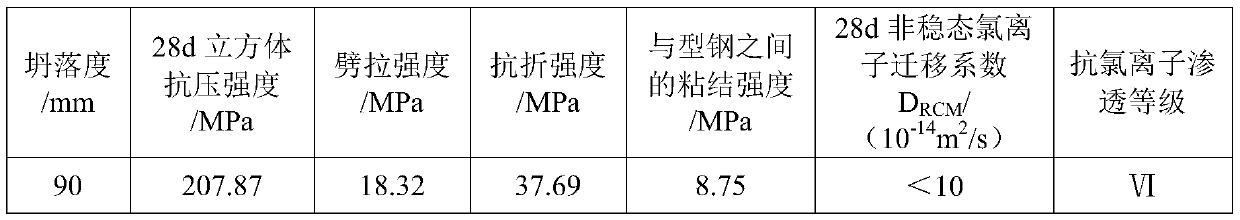

A kind of ultra-high-strength high-performance fiber concrete of C200 strength grade and preparation method thereof

ActiveCN107512886BPrevent pulling outImprove energy consumptionSolid waste managementModified carbonCellulose fiber

The invention discloses an ultra-high strength high-performance fiber concrete with a strength grade of C200 and a preparation method thereof. The concrete comprises the following components in parts by mass: 520 parts of cement, 66 parts of water, 990 parts of gravel, 760 parts of fine aggregates, 65 parts of fly ash, 72 parts of rice husk ash, 126 parts of silica fume, 15.6 parts of a water reducer and 10.2 parts of an activator, 1.7 parts of cellulose fibers, 46 parts of a hydroxyl modified carbon nanotube dispersion liquid, 47 parts of a graphene oxide dispersion liquid and 2.8 parts of a defoaming agent. The prepared concrete has high toughness and excellent durability and has high bonding strength with section steel. The compressive strength reaches 207.87 MPa, the breaking strength reaches 37.69 MPa, the splitting tensile strength reaches 18.32 MPa, the bonding strength with section steel reaches 8.75 MPa, and the impermeability grade of chloride ions reaches a VI grade. The concrete provided by the invention is used in a section steel concrete composite structure, the cooperative working performance between the section steel and the concrete can be effectively exerted, and the defects that the bonding property between section steel and concrete is poor and respective mechanical properties of the steel sections and the concrete can not be fully exerted are made up.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C240 ultrahigh-strength hybrid fiber concrete and preparation method thereof

PendingCN113024184AWell gradedImprove adhesionSolid waste managementCeramic shaping apparatusSilica fumeDefoaming Agents

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of ultra-high performance fiber concrete of c210 strength grade containing coarse aggregate and its preparation method

ActiveCN107352916BImprove toughnessImprove deformation abilitySolid waste managementAggregate (composite)Modified carbon

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-strength fiber concrete with high toughness and high cohesion c110 strength and its preparation method

ActiveCN113024183BHigh tensile strengthHigh elastic modulusSolid waste managementCement mixing apparatusPolyvinyl alcoholCrushed stone

The invention discloses a high-strength fiber concrete with high toughness and high cohesiveness C110 strength and a preparation method thereof. The mixing ratio includes: cement: sand: crushed stone: fly ash: straw ash: silica fume: nano-silicon: water: water-reducing Agent: activator: defoamer: shrinkage reducer: ramie fiber: basalt fiber: CaCO 3 Whiskers: carboxyl-modified polyvinyl alcohol polymer = 405‑415: 713: 995: 85‑90: 45‑55: 20‑25: 3‑4: 125‑130: 11‑12: 12‑13: 1.8‑ 2.1: 9‑9.5: 5.2‑5.4: 8.7‑8.9: 17.6‑17.8: 18‑20. The material is mixed evenly at intervals by the layered stirring method, and the material is discharged, formed and maintained. The bending resistance, compression resistance, bonding strength and impermeability of the concrete in the invention are significantly enhanced, and the cooperative work ability with the steel is further improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Anti-freezing agent for concrete

InactiveCN108706903AIncrease the rate of crystallizationReduce surface defectsCorrosionNegative temperature

The invention discloses an anti-freezing agent for concrete and belongs to the field of chemical engineering. The anti-freezing agent for the concrete is prepared by mixing 40-60 parts of anti-fracture corrosion resisting agent, 70-90 parts of anti-freezing activator, 50-60 parts of porous doped materials, 20-30 parts of corrosion-inhibition protective agent and 20-30 parts of steel fibers by mass. The anti-freezing agent solves the problems that current traditional anti-freezing agents are likely to cause corrosion, the resistance to freezing and thawing is poor, and particularly under negative-temperature maintenance, the compressive strength is too low.

Owner:王敏

A kind of high-performance fiber concrete of C50 intensity level and preparation method thereof

ActiveCN107434384BPrevent pulling outImprove energy consumptionSolid waste managementCellulose fiberUltimate tensile strength

The invention discloses a high-performance fiber concrete of C50 strength grade and a preparation method thereof. The mass parts of the concrete are as follows: 330-350 parts of cement, 160-175 parts of water, 710-730 parts of river sand, and 1010 parts of gravel ‑1030 parts, 90‑130 parts of fly ash, 20‑50 parts of rice husk ash, 5‑7 parts of water reducing agent, 8‑9 parts of shrinkage reducing agent, 12‑14 parts of activator, 1.1‑1.7 parts of cellulose fiber, 12-15 parts of carboxylated styrene-butadiene polymer, 1.7-1.8 parts of defoamer. The prepared concrete has high toughness and excellent durability, and has a high bond strength with the section steel. When used in the steel-concrete composite structure, it can effectively exert the synergistic performance between the section steel and the concrete, and make up for the relationship between the section steel and the concrete. Concrete has poor bonding performance and cannot give full play to the respective mechanical properties of the two.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Fiber-reinforced recycled aggregate pervious concrete

PendingCN114804763ABalanced road mechanical propertiesBalanced with long-term performanceSlurryRoad surface

The invention discloses fiber-reinforced recycled aggregate pervious concrete, which is prepared by adopting the following formula: 270-350 kg / m < 3 > of cement, 355-450 kg / m < 3 > of water, 1360-1950 kg / m < 3 > of coarse aggregate, 35-100% of recycled aggregate, 0-30 kg / m < 3 > of polymer emulsion, 0-9.6 kg / m < 3 > of water reducing agent, 0-5 kg / m < 3 > of high-performance admixture, a water-binder ratio of 0.24-0.42, a slurry-bone ratio of 1: 3.8-1: 4.7, the maximum nominal particle size of the coarse aggregate is 5-20 mm, the maximum nominal particle size of the recycled aggregate is 5-20 mm, and the maximum nominal particle size of the recycled aggregate is 5-20 mm. The pervious concrete is prepared from the recycled aggregate, carbon emission in the whole life cycle of ground and pavement paving materials is further reduced, meanwhile, construction waste and solid waste are effectively utilized, the breaking strength and toughness of a pervious paving layer are greatly improved through the fiber reinforcement technology, a premixing mode is adopted for production in a breakthrough mode, the production efficiency is greatly improved, and the production cost is reduced. And the quality stability of a pervious concrete product is ensured to a greater extent.

Owner:CHENGBANG ECO ENVIRONMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com