Formula and preparation method for renewable concrete

A technology of recycled concrete and water-reducing agent, applied in the field of concrete, can solve the problems of cracking of recycled concrete, high water absorption rate of recycled concrete, and poor bonding between aggregate and cement, and achieve the effect of promoting strength, increasing strength and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

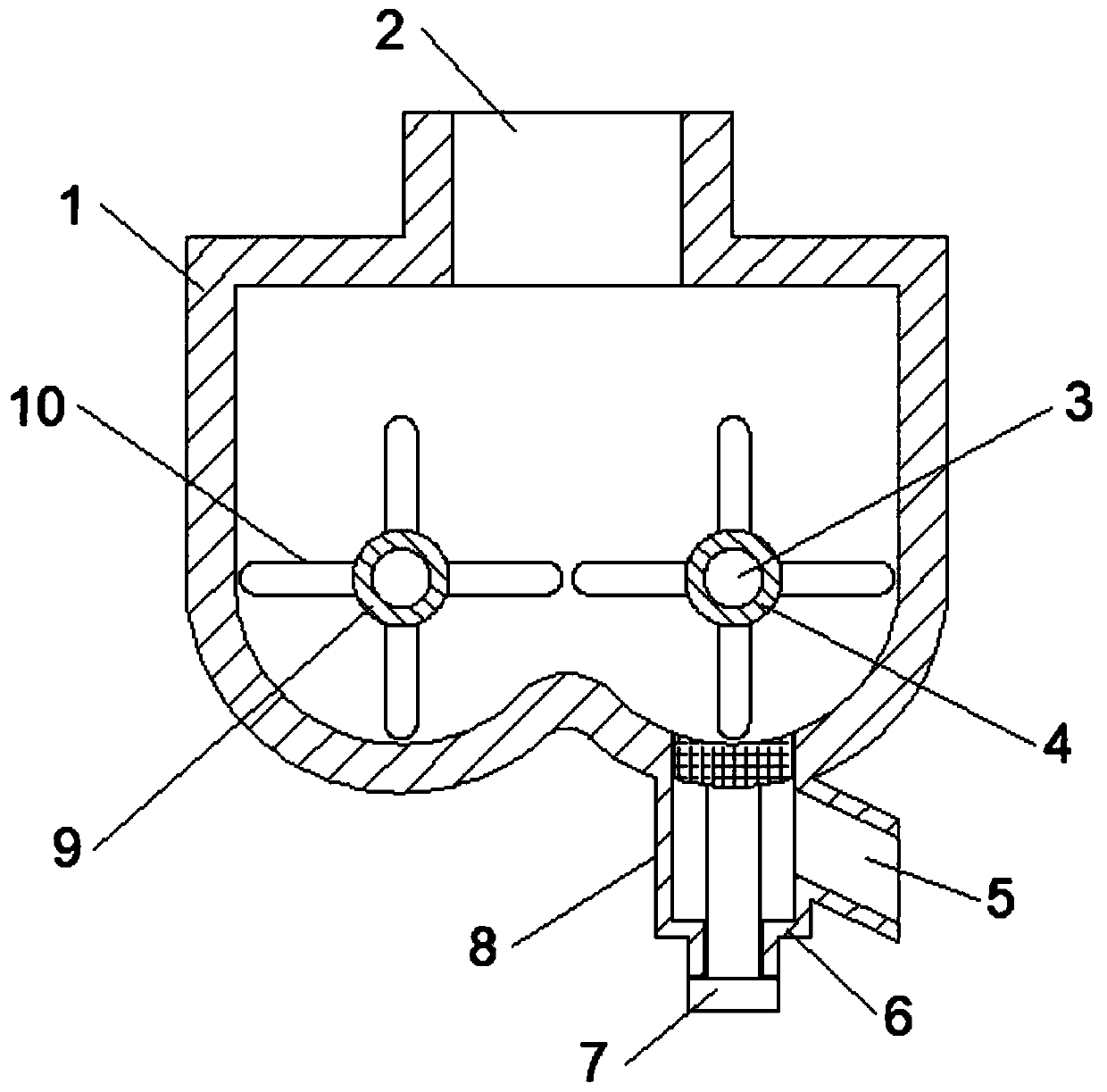

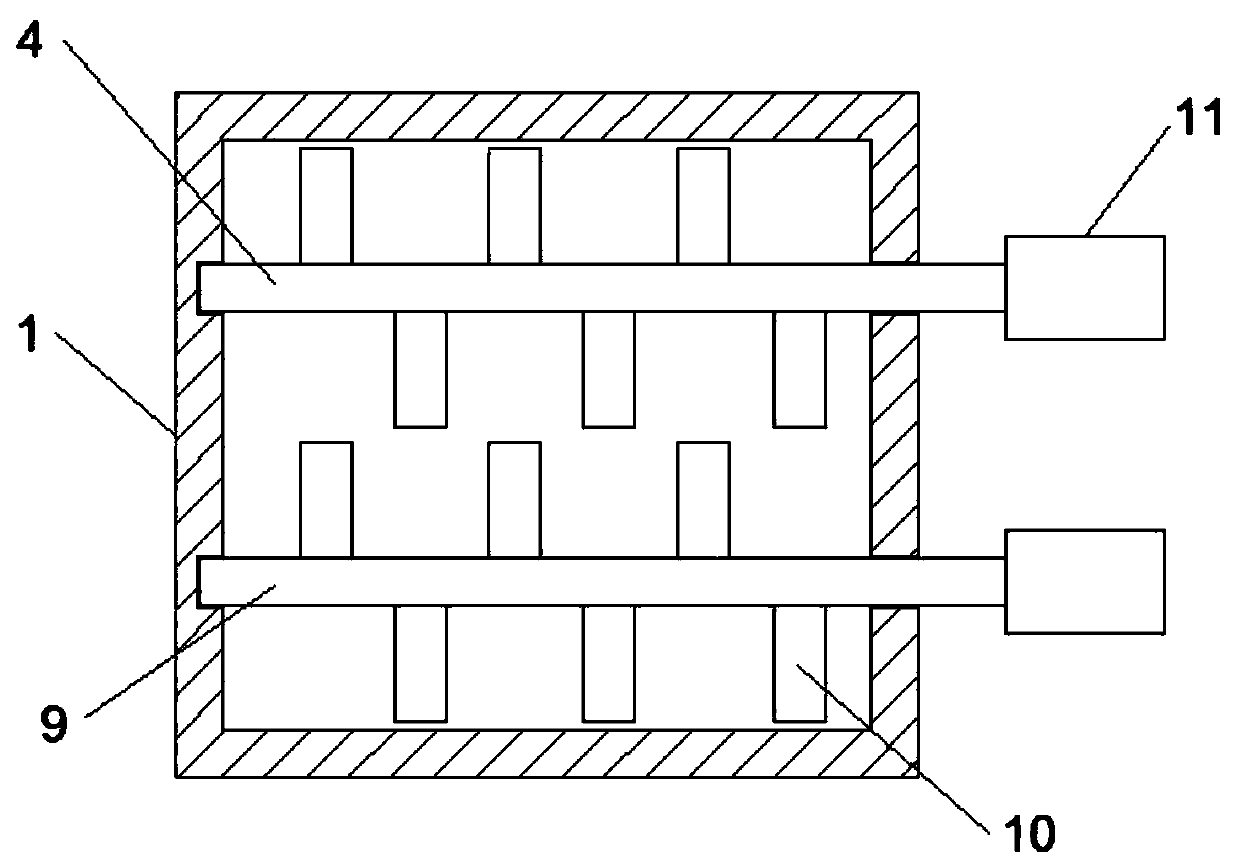

Method used

Image

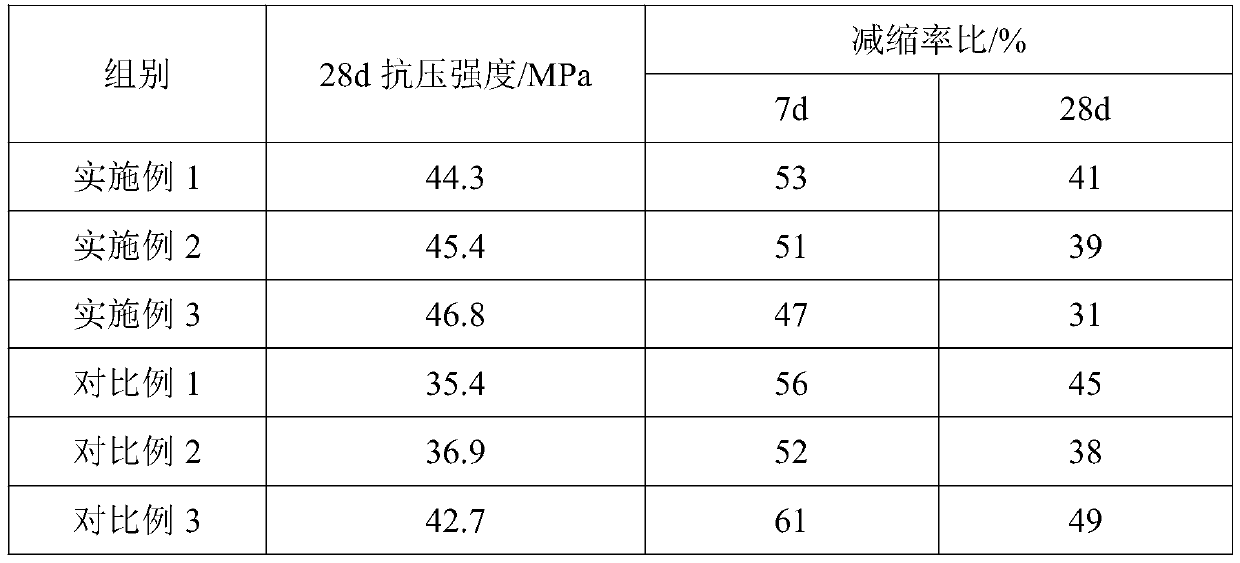

Examples

Embodiment 1

[0038] The renewable concrete proposed by the present invention comprises the following raw materials in parts by weight:

[0039] 100 parts of Portland cement, 15 parts of fly ash, 100 parts of river sand, 4 parts of polycarboxylate superplasticizer, 5 parts of shrinkage reducing agent, 200 parts of coarse aggregate, 100 parts of fine aggregate, 5 parts of polyester fiber, 5 parts of steel fiber, 5 parts of straw ash, 50 parts of water;

[0040] Both the coarse aggregate and the fine aggregate are obtained from waste concrete after crushing and grinding, and the particle diameter of the coarse aggregate is 20mm, and the particle diameter of the fine aggregate is 8mm.

[0041] The shrinkage reducing agent comprises the following raw materials in parts by weight: 10 parts of water glass, 15 parts of oxyalkylene compound, 1 part of comb polymer, and 5 parts of polyethylene glycol.

[0042] The method steps for the preparation of renewable concrete proposed by the present invent...

Embodiment 2

[0049] The renewable concrete proposed by the present invention comprises the following raw materials in parts by weight:

[0050] 150 parts of Portland cement, 35 parts of fly ash, 200 parts of river sand, 8 parts of polycarboxylate superplasticizer, 15 parts of shrinkage reducing agent, 400 parts of coarse aggregate, 200 parts of fine aggregate, 10 parts of polyester fiber, 15 parts of steel fiber, 15 parts of straw ash, 80 parts of water;

[0051] Both the coarse aggregate and the fine aggregate are obtained from waste concrete after crushing and grinding, and the particle diameter of the coarse aggregate is 20mm, and the particle diameter of the fine aggregate is 8mm.

[0052] The shrinkage reducing agent comprises the following raw materials in parts by weight: 20 parts of water glass, 20 parts of oxyalkylene compound, 5 parts of comb polymer, and 15 parts of polyethylene glycol.

[0053] The method steps for the preparation of renewable concrete proposed by the present ...

Embodiment 3

[0060] The renewable concrete proposed by the present invention comprises the following raw materials in parts by weight:

[0061] 120 parts of Portland cement, 25 parts of fly ash, 150 parts of river sand, 6 parts of polycarboxylate superplasticizer, 10 parts of shrinkage reducing agent, 300 parts of coarse aggregate, 150 parts of fine aggregate, 8 parts of polyester fiber, 10 parts of steel fiber, 10 parts of straw ash, 65 parts of water;

[0062] Both the coarse aggregate and the fine aggregate are obtained from waste concrete after crushing and grinding, and the particle diameter of the coarse aggregate is 20mm, and the particle diameter of the fine aggregate is 8mm.

[0063] The shrinkage reducing agent comprises the following raw materials in parts by weight: 15 parts of water glass, 18 parts of oxyalkylene compound, 3 parts of comb polymer, and 10 parts of polyethylene glycol.

[0064] The method steps for the preparation of renewable concrete proposed by the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com