Anti-freezing agent for concrete

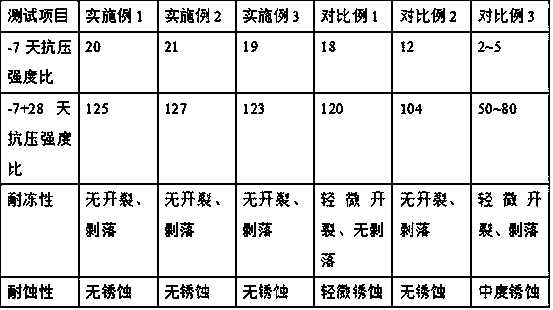

A technology of antifreeze and concrete, which is applied in the field of concrete antifreeze, which can solve the problems of antifreeze corrosion, low compressive strength, poor freeze-thaw resistance, etc., and achieve the effect of slowing down corrosion damage, less surface defects, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of anti-cracking resist comprises the steps:

[0025] (1) Take lanthanum oxide and add hydrochloric acid with a mass fraction of 20% according to the mass ratio of 1:8, stir and mix for 20~30min, filter, take the filter residue and dry to obtain the dried product, take β-cyclodextrin and maleic anhydride according to the mass ratio 1:8~10:80~90, add tetrahydrofuran, stir and mix at 70~75°C for 7~8h, cool to room temperature, and get the cooling product, take the cooling product and add chloroform according to the mass ratio of 3:5, and let it stand for 1~2h , take the precipitate, wash it with acetone, suction filter, take the suction filter residue, grind and pulverize, pass through a 100-mesh sieve, and collect the sieved particles;

[0026] (2) Take the sieved particles and add dry matter and distilled water according to the mass ratio of 1:7~11:100~120, stir and mix at 30~50°C for 1~2h, then add triethylamine which is 3~5 times the amount of d...

Embodiment 1

[0034] Compatibilizer: maleic anhydride grafted ethylene-1-octene copolymer, purchased from Shanghai Rizhisheng New Technology Development Co., Ltd., with a grafting rate of 0.8%.

[0035] Boron mud: taken from Liaoyang City, Liaoning Province, mainly containing phosphorus magnesium ore, forsterite ore, hematite, dolomite, magnesium sulfate, magnesium borate, and lizardite.

[0036] Steel fiber: purchased from Laiwu Antai Engineering Materials Co., Ltd., tensile strength ≥ 800MPa, elastic modulus > 190GPa.

[0037] Corrosion inhibitor: mix sodium gluconate, zinc dihydrogen phosphate and thiourea in a mass ratio of 4:1:4.

[0038] The preparation method of anti-cracking resist comprises the steps:

[0039] (1) Take lanthanum oxide and add hydrochloric acid with a mass fraction of 20% according to the mass ratio of 1:8, stir and mix for 20 minutes, filter, take the filter residue and dry to obtain a dry product, take β-cyclodextrin and maleic anhydride according to the mass rat...

Embodiment 2

[0048] Compatibilizer: maleic anhydride grafted ethylene-1-octene copolymer, purchased from Shanghai Rizhisheng New Technology Development Co., Ltd., with a grafting rate of 0.8%.

[0049] Boron mud: taken from Liaoyang City, Liaoning Province, mainly containing phosphorus magnesium ore, forsterite ore, hematite, dolomite, magnesium sulfate, magnesium borate, and lizardite.

[0050] Steel fiber: purchased from Laiwu Antai Engineering Materials Co., Ltd., tensile strength ≥ 800MPa, elastic modulus > 190GPa.

[0051] Corrosion inhibitor: mix sodium gluconate, zinc dihydrogen phosphate and thiourea in a mass ratio of 4:1:4.

[0052] The preparation method of anti-cracking resist comprises the steps:

[0053] (1) Take lanthanum oxide and add hydrochloric acid with a mass fraction of 20% according to the mass ratio of 1:8, stir and mix for 30 minutes, filter, and take the filter residue to dry to obtain a dried product. Take β-cyclodextrin and maleic anhydride according to the mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com