Organic nucleating agent for rapidly crystallizing polylactic acid and rapidly-crystallized polylactic acid resin of organic nucleating agent

An organic nucleating agent, polylactic acid technology, applied in the field of polylactic acid functional additives, can solve problems such as poor compatibility and easy agglomeration of inorganic particles, and achieve the effects of strong processing performance, accelerated crystallization rate, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment one: the preparation of pure polylactic acid

[0040] 100 parts of vacuum-dried semi-crystalline poly-L-lactic acid (weight average molecular weight 19.5W) is extruded and granulated in a twin-screw extruder at an extrusion temperature of 160-185°C, and then the polylactic acid particles are injection-molded into impact, tensile Stretch spline, to be tested. Its crystallization rate and mechanical properties are listed in Table 1.

Embodiment 2

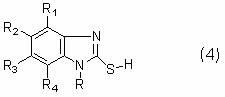

[0041] Example 2: Preparation of benzotriazole-modified polylactic acid

[0042] The benzotriazole with a mass purity of 98% and a mass water content of 45 ppm is ultrafinely pulverized to obtain an average particle size of 30 μm.

[0043] Vacuum-dried semi-crystalline poly-L-lactic acid (weight average molecular weight 19.5W) 98 parts, benzotriazole 0.5 part, heat stabilizer maleic anhydride 0.7 part, antioxidant tetraerythritol ester 0.3 part, lubricated 0.5 part of aluminum stearate is uniformly mixed in a high-speed mixer, extruded and granulated in a twin-screw extruder at an extrusion temperature of 160-185°C, and then the modified polylactic acid particles are injected into impact, tensile Spline, to be tested. Its crystallization rate and mechanical properties are listed in Table 1.

Embodiment 3

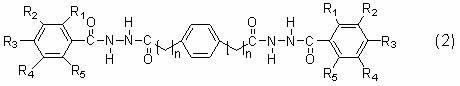

[0044] Example 3: Preparation of terephthalic acid dibenzohydrazide modified polylactic acid

[0045] The preparation method of terephthalic acid dibenzohydrazide: terephthalic acid and excess sulfur oxychloride were refluxed for 6 hours under the catalysis of dimethylformamide, and then rotary steamed to obtain terephthaloyl chloride; 2 Under protection, add terephthaloyl chloride dropwise to the dimethylformamide solution dissolved in benzoylhydrazine, react at 60 degrees for 2 hours, pour into water, filter with suction, and wash with deionized water and methanol respectively 3 times, and finally vacuum-dried at 65°C to obtain dibenzohydrazide terephthalate, melting point: 334°C, mass purity 97.5%, mass water content 40ppm, average particle size 25μm.

[0046] Vacuum-dried semi-crystalline poly L-lactic acid (weight average molecular weight 19.5W) 94 parts, terephthalic acid dibenzohydrazide 4.5 parts, thermal stabilizer maleic anhydride 0.4 parts, antioxidant tetraerythrit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com